Franke Foodservice F3Dn 18001165 Service Manual

*** Sensor bracket bar 19002065

F3Dn “Twin” Frozen French Fries Dispenser

Service Manual [P/N 1900xxxx]

For Technical Support, Call 800-537-2653. Page 1 of 1 Copyright 2006 Franke, Inc. All rights reserved.

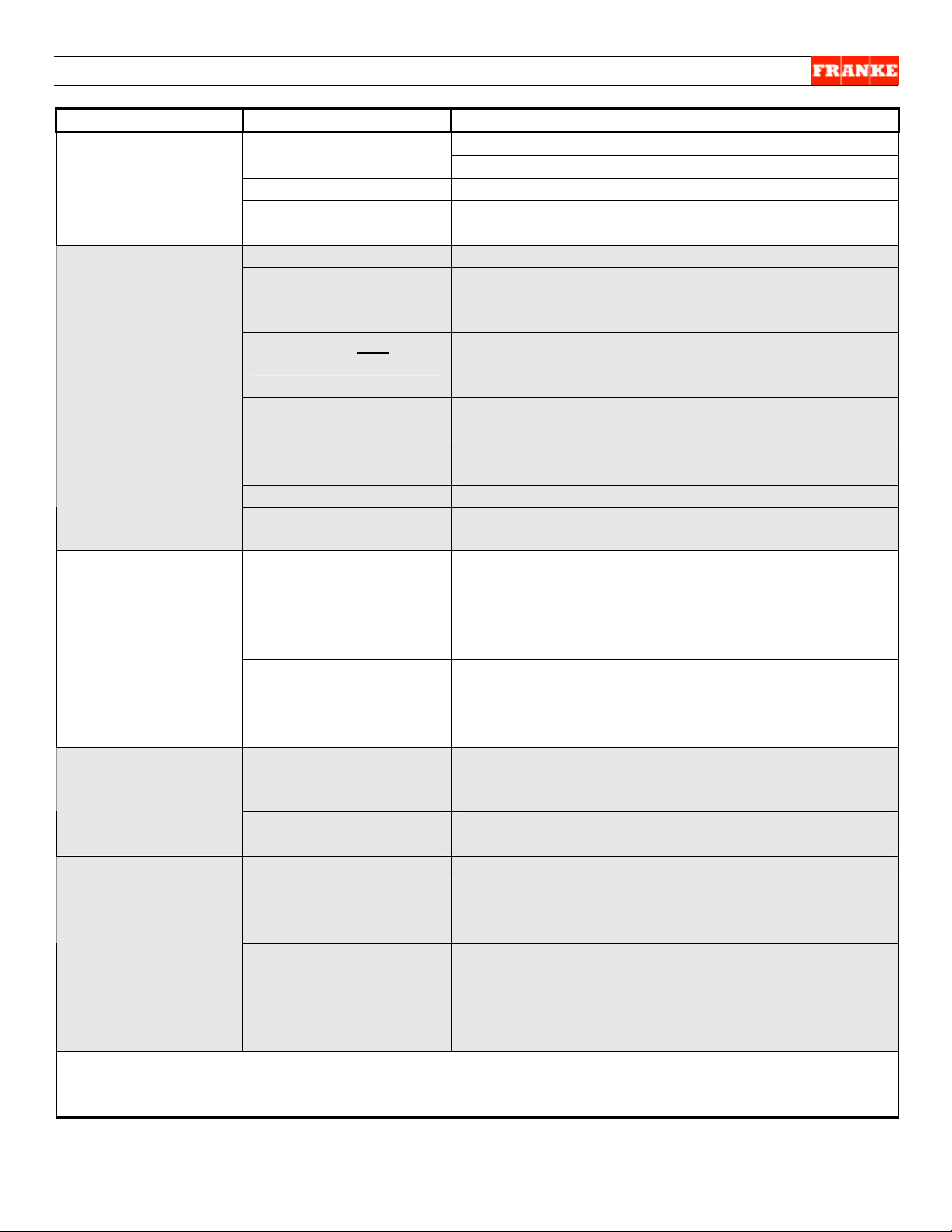

F3Dn Service Manual Table of Contents/Section 1.1

Section No. Content/Service Operation Create/Update

1.1 Table of Contents 12/1/06

1.2A Franke Warranty Coverage 6/29/06

1.2B Franke Service Commitment 6/29/06

1.3 F3Dn Trouble Shooting Tables 12/13/06

1.4 F3Dn Parts List & Component Diagrams 6/13/06

1.5 F3Dn Electric Schematics 11/30/06

1.6 Control Panel Function Guide 6/13/06

[Part Replacement]

2.1 General Service Instructions, Warnings & Tools 12/13/06

2.2 Freezer Door Gasket Replacement 6/13/06

2.3 Automation Assemble [Complete] Replacement 9/8/06

2.4 Door Lift Slide Replacement 9/7/06

2.5 Motors Test Procedure [Check Before Replacing] 10/17/06

2.6 Drum Rotor Motor Replacement 9/7/06

2.7 Door Lift Motor Replacement 9/7/06

2.8 Door [Open] Motor Replacement 9/7/06

2.9 Load Cell Replacement 9/7/06

2.10 Door-Closing Spring Replacement 9/8/06

2.11 Low Product Sensor Replacement 9/8/06

2.12 Basket-Present [Load] Sensor Replacement 12/13/06

2.13 Door-Open Sensor Replacement 11/20/06

2.14 Touch Pad Controls Assembly Replacement 12/13/06

2.15 Main Power ON/OFF Switch Replacement 12/13/06

2.16 LED Unit Temperature Display Replacement 11/20/06

2.16A Temperature Controller Sensor Cable Replacement 11/21/06

2.17 24-Volt Power Supply Replacement 11/20/06

2.18 Main PC Control Board Replacement 11/20/06

2.19 Main Control Board Chip Replacement 10/26/06

2.20 Hopper Rotor Replacement 6/13/06

[Part or Component Adjustments]

3.1 Low Product Sensor Sensitivity Adjustment 11/20/06

3.2 Reverse Door Hinges/Door Swing 11/21/06

3.3 Adjusting Automation Assembly Alignment 6/13/06

3.4 Adjustment of Standard Load Size: Large/Med/Small 11/30/06

3.5 Drum Rotor Motor Adjustment [When making noises] 11/21/06

3.6 Fry Hopper Hanger Alignment 11/21/06

3.7 Load Cell Calibration 11/6/06

3.8 Freezer Thermostat Adjustment 11/21/06

[Refrigeration System Repair & Replacement]

4.1 Basic [Operator] Refrigerator Maintenance 11/21/06

4.2 Freezer Thermostat Replacement 11/21/06

4.3 Replace Condenser Fan Motor 12/1/06

4.4 Replace Start Relay & Replace Start Capacitor 12/13/06

For Technical Support, Call 800-537-2653. Copyright 2006 Franke, Inc. All rights reserved.

F3Dn Service Manual Table of Contents/Section 1.1

Section No. Content/Service Operation Create/Update

4.5 Check System Pressure & Electronic Leak Detection 12/1/06

4.6 Repair System [Refrigerant] Leak 11/30/06

4.7 Replace Thermostatic Expansion Valve & Filter 12/1/06

4.8 Condenser Unit Replacement 12/1/06

Rev 3 [12/13/06]

For Technical Support, Call 800-537-2653. Copyright 2006 Franke, Inc. All rights reserved.

F3Dn Service Manual Warranty/Section 1.2A

Franke New Equipment Limited Warranty

Franke Foodservice Systems (“Franke”) warrants new equipment manufactured in Franke’s own facilities to be

free of defects due to poor materials or workmanship for the period of time listed below (following the date of

original installation):

Franke-Manufactured Equipment

• Stainless Steel Surfaces – Life of the equipment

• Compressor -- 5 Year Extended Warranty, as detailed below

• All Other Components – 1 Years Parts and Labor

• Replacement (Authorized Service) parts – 90 Days Parts and Labor

5-Year Extended Compressor Warranty

• One Year from Date of Installation – Parts & Labor

• 2nd through 5th Year from Date of Installation – Parts only

In accordance with the compressor manufacturer’s policy, the serial number plate affixed to the

compressor must be returned with the service invoice before reimbursement will be made.

Exclusions. Certain Franke parts that are expendable by nature and that need to be replaced frequently may

not be covered. Franke is not liable under these warranties for repairs or damages due to improper operation,

attempted repairs or installation by unauthorized persons, alterations, water quality, abuse, fire, flood, or acts

of God. Additionally, this warranty may be voided in the case of:

• Failure to follow Franke instructions for use, care or maintenance

• Removal, alteration or defacing of the Franke-affixed serial number

• Service by a non-authorized service company

This warranty is conditional upon Franke receiving notice of any defect subject to this warranty within thirty (30)

days of its original discovery by the Buyer.

Other Equipment (Not Manufactured by Franke)

Equipment not manufactured by Franke (commonly known as “buyouts” or purchased goods) and

manufactured by other entities is covered by the warranties, if any, of such third-party manufacturers. Where

such third party manufacturers provide warranties on any or all portions of said “buyouts,” Franke agrees to

transfer all such warranties to the Buyer.

Rev. 1. 6/06

For Technical Support, Call 800-537-2653. Copyright 2006 Franke, Inc. All rights reserved.

F3Dn Service Manual Service Commitment/Section 1.2B

The Franke Service Commitment

Franke Foodservice Systems’ Technical Support Department and its third-party Service Network are

committed to meeting the unique service needs of restaurant operators worldwide. Accordingly, we strive to

provide the following response times to service requests for Franke-manufactured equipment:

1. Provide contact with the customer:

– Within 30 minutes of request for service during normal business hours

– Within 90 minutes after normal business hours (including weekends)

2. Perform service visit:

– The same day for emergency service*

– Within 24 hours for standard service

3. Target a 90% “first call” fix rate

4. Provide 90-day warranty on the service performed

*An “emergency” is defined as an equipment operating condition that poses an immediate risk to the

safety of restaurant workers or customers.

This response time breakdown applies throughout the week and weekend. Due to varying customer locations,

and varying service agent locations and schedules, response rates may occasionally be extended. In these

situations, Franke Technical Support will work directly with the customer to find mutually acceptable options.

Franke reserves the right to use service agents outside of the stated Service Network.

Service Network - United States & Canada

Franke fully supports and is a member of the National Service

Cooperative (“NSC”), the leading independent provider of factoryauthorized service in North America. Franke provides 24-hour, 7-days-aweek response to customer service requests, through its own Call

Center and that of the NSC.

Whenever possible, Franke selects service agents who belong to the Commercial Food Equipment Service

Association (CFESA). This trade association currently has more than 450 members in the United States,

Canada, Mexico and Puerto Rico.

When Franke cannot select a CFESA member, it nonetheless adheres to the CFESA standards for qualified

service agents in North America. Among them are:

• 24 Hour emergency service

• Factory authorized warranty service

• Factory trained and certified technicians

• OEM parts availability

• System for communication with field technicians

Performance of service agents, including their parts stocking abilities, call response time, service rates and

customer satisfaction are monitored by the Franke Field Service Department via online, written and phone

surveys. Franke Technical Support updates this Service Network list annually.

Contact Information:

Franke Technical Services

1-800-5FRANKE (1-800-537-2653); select option 5 or visit: FS-TS@Franke.com

For Technical Support, Call 800-537-2653. Copyright 2006 Franke, Inc. All rights reserved.

F3Dn Service Manual Service Commitment/Section 1.2B

Service Network - Australia

Franke fully supports Comcater, the leading independent provider

of factory-authorized service in Australia. Comcater provides 24hour, 7-days-a-week response to customer service requests

through its own Call Center.

Comcater adheres to the Franke standard for qualified service agents in Australia. Among them are:

• 24 Hour emergency service

• Factory authorized warranty service

• Factory trained and certified technicians

• OEM parts availability

• System for communication with field technicians

Performance of service agents, including their parts stocking abilities, call response time, service rates and

customer satisfaction are monitored by Comcater. This Service Network list is updated annually by Comcater.

Contact Information:

Comcater Foodservice Equipment

Phone: 1800 810 161

Email: controller@comcater.com.au

Service Network - Europe

In Europe, Franke provides service through our own service subsidiary: Franke Foodservice Systems GmbH

based in Bad Saeckingen, Germany. They provide 24-hour, 7-days-a-week response to customer service

requests through their Call Center.

Our European Service Group adheres to the Franke standard for service support, providing:

• 24 Hour emergency service

• Factory authorized warranty service

• Factory trained and certified technicians

• OEM parts availability

• A system for communication with field technicians

Contact Information:

Franke Technical Services

Franke Foodservice Systems GmbH

Jurastrasse 3

79713 Bad Saeckingen

Germany

Switchboard: +49 7761 52 400

Fax: +49 7761 52 408

Rev. 1. 6/06

For Technical Support, Call 800-537-2653. Copyright 2006 Franke, Inc. All rights reserved.

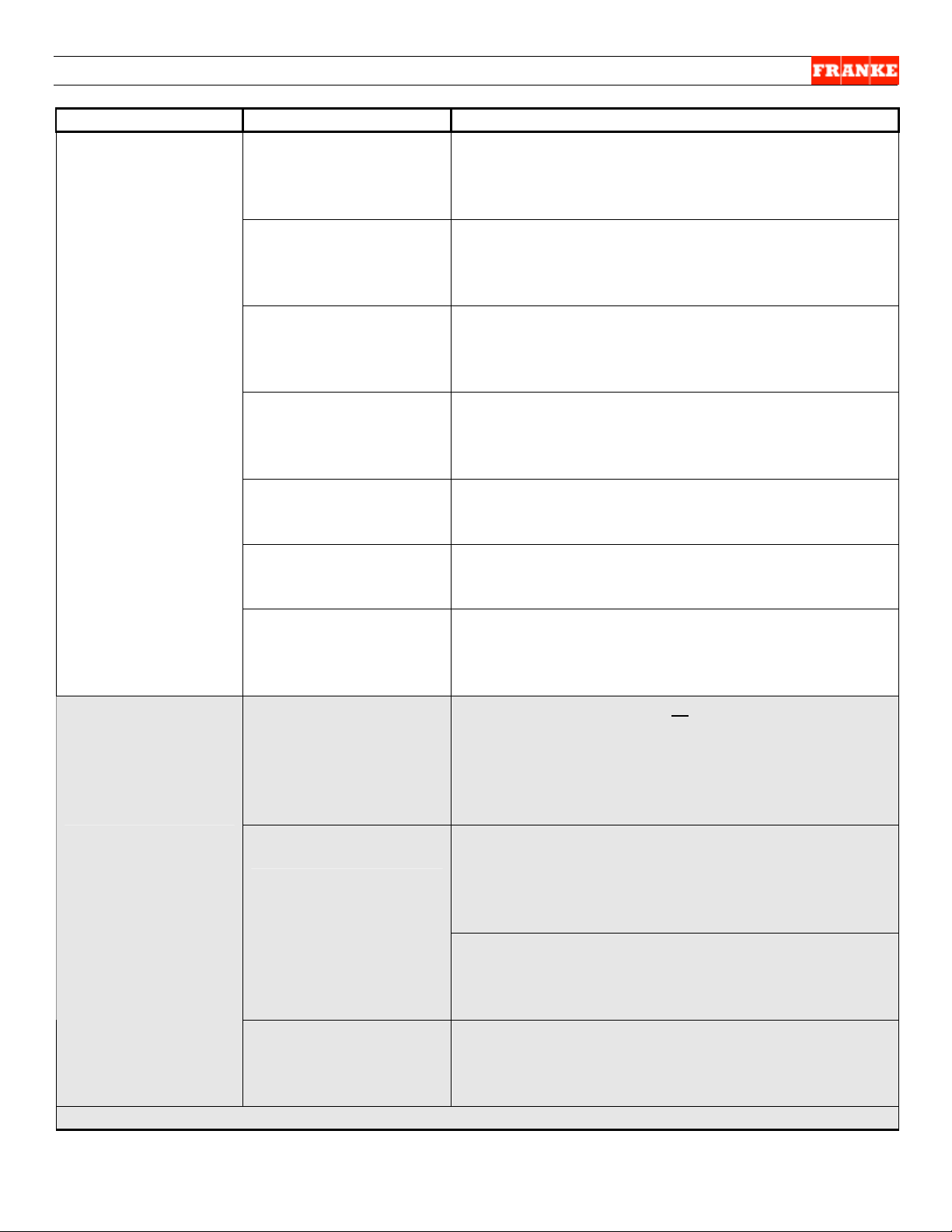

F3Dn Service Manual Advanced Troubleshooting Guide / Section 1.3

The Problem Possible Cause What To Check & Do

Main Power Not

“ON”

No Display On

Control Panel

Low Product Light Is

Flashing

“Reset Lane”

Light s are ON

[Failure to tare

error]

“Reset Lane”

Lights are Flashing

Steadily [Time out

error]

Power not available to

unit:

Power cord OK? Yes = Continue; No = Replace power cord

Main power switch? Yes = Check for loose wires on back of switch;

No power to machine? See Main Power Not “ON” instructions above.

Temperature Indicator

displaying

temperature?

No power to one lane

only:

24-Volt DC Power

Supply OK?

PC Control Board OK? Yes = continue…; No = replace Control Board per

Ribbon Cable OK? Yes = continue…; No = replace Ribbon Cable

Operator’s Panel OK? Yes = Return unit to service; No = replace Operator

French fries in

Hopper?

Low product sensor

out of calibration?

Low Product Sensor

defective?

PC Control Board

failed?

Is Hopper, Drum &

Baffle assembled

correctly?

Is Product Chute

assembled correctly?

French fries in hopper? Yes = continue…; No = Fill with fries & continue…

Reset Lane Button? Press “Reset Lane” button; after 20 seconds, did

Fries bridge In

Hopper?

Breaker OK? Yes = Continue; No = Call electrician

Receptacle OK? Yes = Continue; No = Call electrician

No = Replace switch, [See Sect. 2.15]

Yes = continue; No = check 24-Volt AC transformer;

[See Sect. 2.16 for temperature indicator

replacement]

“Push & Hold” touch pad for 2 seconds (required) to

turn each lane on: AUTO or MANUAL light ON?

Yes = Test & return unit to service; No = continue…

Yes = continue…; No = replace Power Supply per

Section 2.17

Section 2.18

Control Panel per Section 2.14

Yes = continue; No = fill with fries to sensor level or

simulate fries present to test.

Calibrate low product sensor per Section 3.1; Is

light still flashing? Yes = continue…; No = Return

unit to service.

Yes = replace Low Product Sensor per Section

2.11; No = continue…

Yes = replace PC Board per Section 2.18; No = call

Franke Technical Support.

Yes = continue…; No = reassemble correctly &

press RESET LANE touch pad

Yes = continue…; No = reassemble correctly &

press RESET LANE touch pad

“Load Ready” light illuminate? Yes = Return unit to

service; No = continue…

Open door and press “Reset Lane” button again.

Did drum rotate? Yes = look for fries bridged inside

hopper due to thawing and refreezing. Disrupt

bridge by hand. Press Reset Button. No = Go to

“No Fries Dispensed” section which follows.

[NEXT PAGE]

For Technical Support, Call 800-537-2653. Copyright 2006 Franke, Inc. All rights reserved.

F3Dn Service Manual Advanced Troubleshooting Guide / Section 1.3

The Problem Possible Cause What To Check & Do

NO Fries Dispensed

NO Fries

Dispensed:

[Dispense Doors Do

Not Open]

Not allowing enough

cycle time?

Fries bridge forming

inside Hopper?

Drum Is binding inside

Hopper?

Drum Rotor Motor

failure?

PC Control Board? No = check 24-Volt DC power to PC Control Board?

24-Volt DC Power

Supply?

Main Power

Switch/Main Power

Supply?

First things to check: Is LANE POWER: AUTO or MANUAL illuminated?

Basket Present

Sensor?

Control Wiring

Harness?

[Continue…NEXT PAGE]

Wait 8 seconds after dispensing fries; did “Load

Ready” light illuminate? Yes = withdraw basket and

reinsert. If no fries dispensed, go to Basket Present

sensor item below.

Open freezer door and press “Reset Lane” button;

did drum rotate? Yes = look for fries bridged inside

hopper due to thawing and refreezing; disrupt

bridge by hand...

No = Remove hopper/drum assembly & repeat;

does drum rotor drive rotate? Yes = drum is binding

inside hopper; clear obstacle [i.e. ice] then replace

hopper/drum and retry this step. No = continue…

Check power from PC Board to drum rotor motor. Is

it getting 24-Volt DC? Yes = remove drum rotor

motor and check for free rotation of drive rotor shaft.

If free, replace drum motor per Section 2.6

Yes [has power] = replace PC Control Board per

Section 2.18

No = Check for 120-Volt AC input to power supply?

Yes [OK] = replace 24-Volt DC power supply per

Section 2.17

No = Check 120-Volt AC input from Main Power

Switch & power supply to unit. If Yes/Main Power is

OK = replace Power Switch per Section 2.15; if No

= see section: Main Power Not “ON”.

Yes = Continue… No = Press and hold LANE

OFF/ON button for 1.5 seconds. Did LANE

AUTO/MANUAL button light turn on within 20

seconds? Yes = Continue…No = Go to “Reset

Lane” Indicator Flashing section above.

Remove basket from dispenser area and identify

Basket Present Sensor for lane not working. Is “Low

Product LED on the Main Board illuminated? Yes =

Install fry basket; does LED on backside of sensor

change its brightness? Yes = basket sensor is OK.

Check DOOR OPEN motor assembly (see below)

No = Replace Basket Present Sensor per Section

2.12

.

No = Is wiring harness from basket present sensor

connected to PC Control Board? Yes = Continue…

No = Connect (or replace if damaged) cable

assembly & return to LED check described above.

For Technical Support, Call 800-537-2653. Copyright 2006 Franke, Inc. All rights reserved.

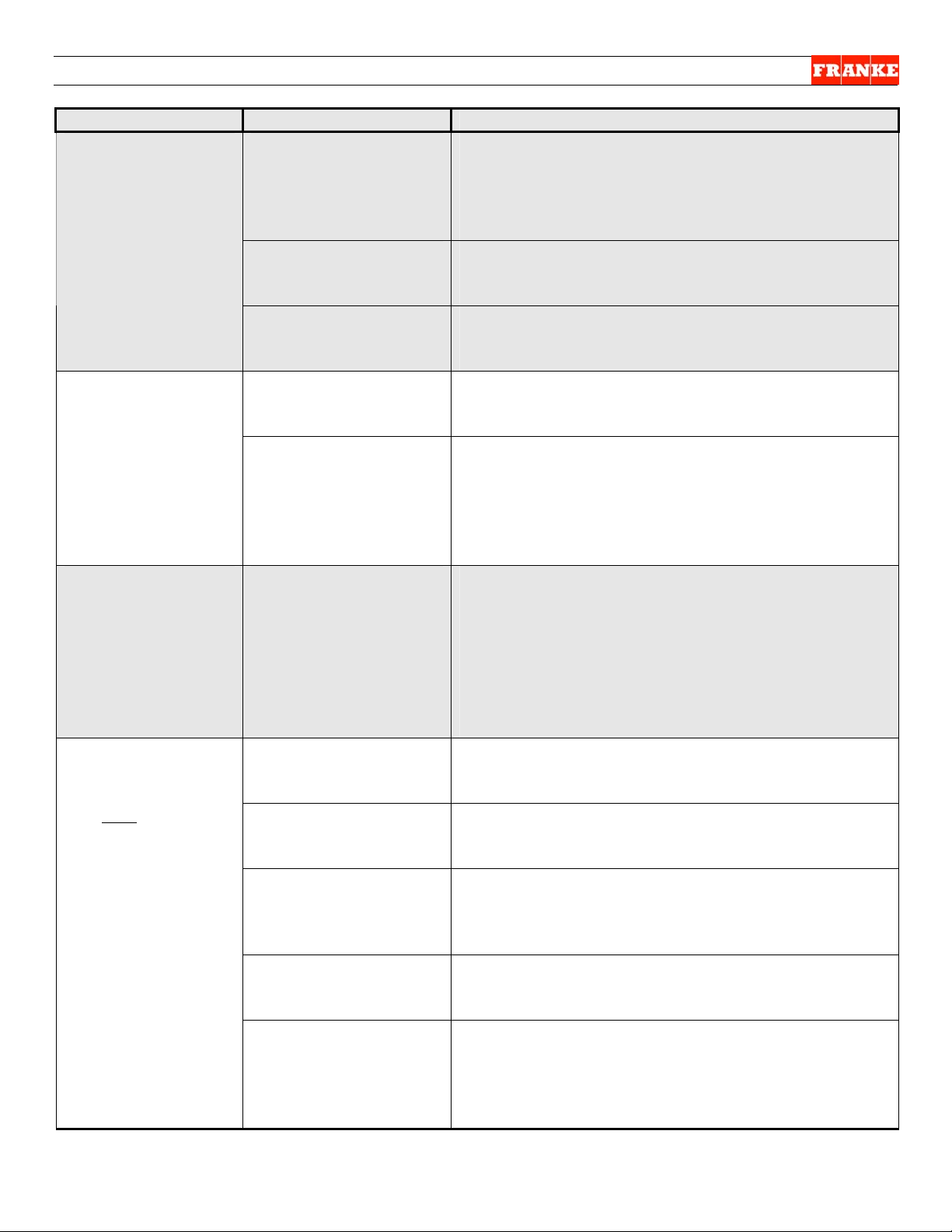

F3Dn Service Manual Advanced Troubleshooting Guide / Section 1.3

The Problem Possible Cause What To Check & Do

NO Fries

Dispensed:

[Dispense Doors Do

Not Open]

Continued…

Product Dispensing

Doors Remain

OPEN

LOAD READY

Indicator LED On,

Doors Open…But

No Product

Dispensed

Wrong Load Size:

Too Few Fries

Does PC Control

Board have 24-Volt DC

power input from

supply?

Door Open Motor/Slide

Assembly?

PC Control Board? If 24-Volt DC Power, Door-Open Motor & Slide

Door Closing Spring? Are doors partially open and easily moved by hand?

Broken Link? Door

Open Sensor?

Load Cell Calibration? Remove upper back panel. Press Load Size button

Hopper Low On Fries? Is LOW PRODUCT light on Operators Panel

Load Size Setting? Is LOAD SIZE selected correctly (Small, Medium or

Frozen Fries Bridge? Have French Fries formed a bridge inside hopper

Product Chute

Alignment?

Load Cell Calibration? Recalibrate Load Cell per Section. 3.7. Did

No = replace Power Supply per Section 2.17; Yes

= check momentary +24-VDC and –24-VDC input to

Door Open Motor by removing basket and

reinserting it into dispense position. Did 24-Volt DC

signal occur?

Check Slide Assembly for binding components. If

OK = replace 24-Volt DC Door Open Motor per

Section 2.8

Assembly are OK, replace PC Control Board per

Section 2.18

Yes = Replace Door Closing [Extension] Spring per

Section 2.10

Check for broken link between door shaft blocks on

rear of unit. Yes = Replace using Spring & Link

Repair Kit P/N 18000798. No = Locate Door Open

Sensor and actuate flag on rear of unit. Is sensor

functioning? No = Replace Door Open Sensor per

Section 2.13

and record “T=” numbers (5 digits) on LED display

on upper right of PC Control Board. Numbers

should vary by 50 – 100 counts when load size is

changed between: Small-Medium-Large. If not,

Load Cell Calibration may be incorrect (calibrated

for 0 weight); See Section 3.7 for Load Cell

Calibration procedure.

flashing? Yes = Refill hopper with fries; No =

Continue…

Large)? Yes = Continue… No = Select correct load

size and restart this Lane.

(thawed and re-frozen)? Yes = Break bridge inside

hopper by gentle hand agitation of product. No =

Continue…

Is metal Product Chute assembled correctly inside

freezer? Yes = Continue… No = Reassemble F3Dn

parts correctly, per Operating Manual.

recalibration procedure correct “too few fries”

problem? Yes = Return unit to service; No = See

Load Size Adjustment procedure in Section 3.4

[Note: Usually required at installation only.]

For Technical Support, Call 800-537-2653. Copyright © 2006 Franke, Inc. All rights reserved.

F3Dn Service Manual Advanced Troubleshooting Guide / Section 1.3

The Problem Possible Cause What To Check & Do

Wrong Load Size:

Too Many Fries

Load Size Setting? Is Load Size selection on Operator’s Panel as

desired? Yes = Continue… No = Change Load Size

selection to desired basket fill level.

Rubber Product

Baffle?

Is rubber baffle assembled inside hopper? If YES =

continue… No = find and insert it. [Note: See

Operating Manual for assembly directions.]

Product Chute

Alignment?

Is metal Product Chute (funnel shape) assembled

below hopper and positioned above dispense doors

correctly? Yes = Continue… No = Reassemble

Product Chute per Operating Manual instructions.

Freezer Bottom

improperly installed?

Is Freezer Bottom assembled inside freezer upside

down or backwards? Yes = Remove freezer bottom

and install per Operating Manual instructions. No =

Continue…

Loose fries buildup? Is small gap between outside of Product Chute and

plastic Freezer Bottom clear of loose fries and other

debris? Yes = Continue; No = Clean out loose fries

and reassemble Freezer Bottom and Product Chute

per Operating Manual instructions.

Load Cell Calibration? Follow Load Cell Calibration Procedure per Section

3.7. Did this procedure correct problem of “Too

Many Fries”? Yes = Return unit to service. No =

Continue…

Dispense Door

up/down movement?

Check Dispense Door Slide Assembly for free

up/down motion; if any signs of component

corrosion are evident, replace slide assembly per

Section 2.4 or replace complete Automation

Assembly per Section 2.3. Did this procedure

correct problem of “Too Many Fries”? Yes = Return

unit to service. No = Contact Franke Service

Department for more troubleshooting options at:

1-800-537-2653, option 5.

Rev. 1 12/06

For Technical Support, Call 800-537-2653. Copyright 2006 Franke, Inc. All rights reserved.

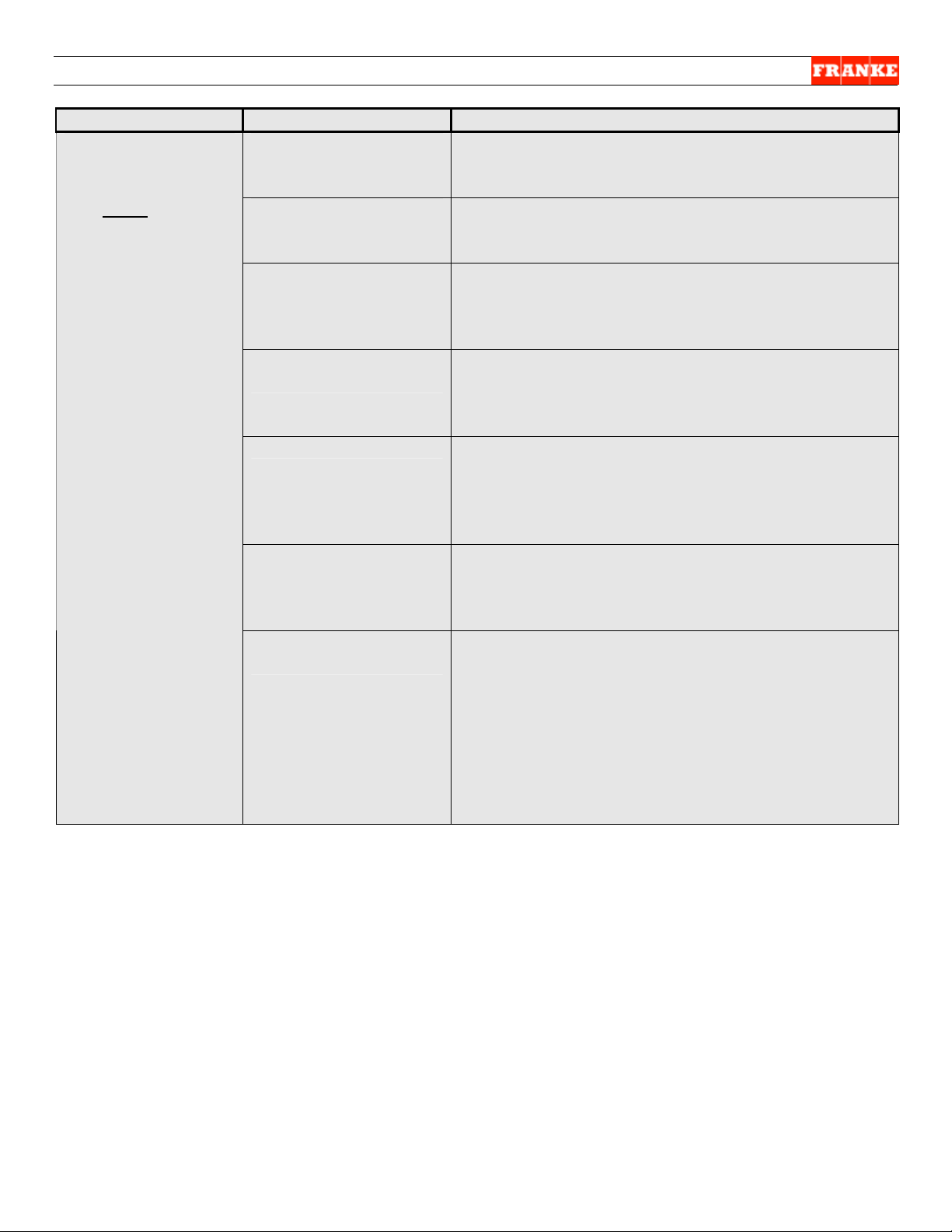

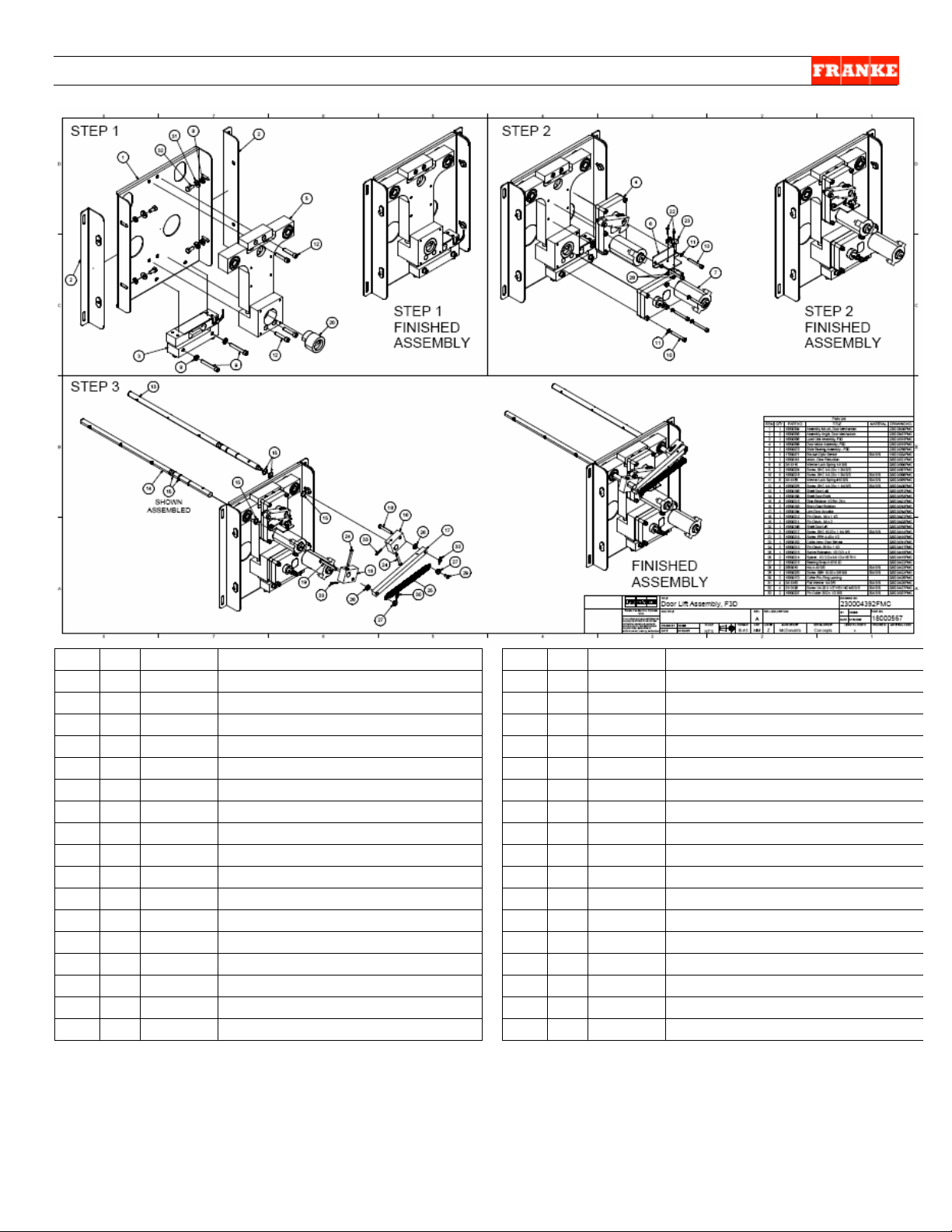

F3Dn Service Manual Parts List & Component Diagrams / Section 1.4

20 X 1/2" HEX HD MS S/S

ITEM QTY PART NO TITLE

1 1 18000334 Assembly Mount, Door Mechanism

2 2 18000335 Assembly Angle, Door Mechanism

3 1 18000555 Load Cell Assembly, F3D

4 1 18000558 Door Motor Assembly, F3D

5 1 18000673 Slide Bearing Assembly - F3D

6 1 17000471 Bracket Optic Sensor

7 1 19000161 Motor, Gear Reduction

8 6 3416116 Washer Lock Spring 1/4 S/S

9 2 19000224 Screw, SHC 1/4-20 x 1 3/4 S/S

10 6 19000218 Screw, SHC 1/4-20 x 1 3/4 S/S

11 8 3416138 Washer Lock Spring #10 S/S

12 4 19000225 Screw, SHC 1/4-20 x 1 1/4 S/S

13 1 19000195 Shaft Door Left

14 1 19000196 Shaft Door Right

15 6 19000215 Ring Retainer 1/2 Ext. Zink

16 2 19000193 Block Door Rotation

ITEM QTY PART NO TITLE

17 1 19000194 Link Door Actuator

18 1 19000212 Pin Clevis, 1/4 x 1 1/2

19 1 19000211 Pin Clevis, 1/4 x 2

20 1 19000198 Shaft Door Lift

21 2 19000217 Screw, SHC 10-32 x 1 1/4 S/S

22 2 19000216 Screw, PPH 4-40 x 1/2

23 1 19000192 Cable Assy. Door Sensor

24 2 19000210 Pin Clevis, 3/16 x 1 1/2

25 1 19000213 Spring Extension, 1/2 O.D. x 5

26 2 19000214 Spacer, 1/2 O.D.x1/4 I.D.x1/8 THK

27 2 19000219 Bearing Snap-In 5/16 ID

28 2 3589010 Nut 4-40 S/S

29 1 19000220 Screw, SBH 10-32 x 3/8 S/S

30 2 19000170 Cotter Pin, Ring Locking

31 4 3416160 Flat Washer 1/4 S/S

32 4 3113128 Screw 1/433 2 19000207 Pin Cotter 3/32 x 1/2 S/S

Rev. 1 6/06

For Technical Support, Call 800-537-2653. Copyright 2006 Franke, Inc. All rights reserved.

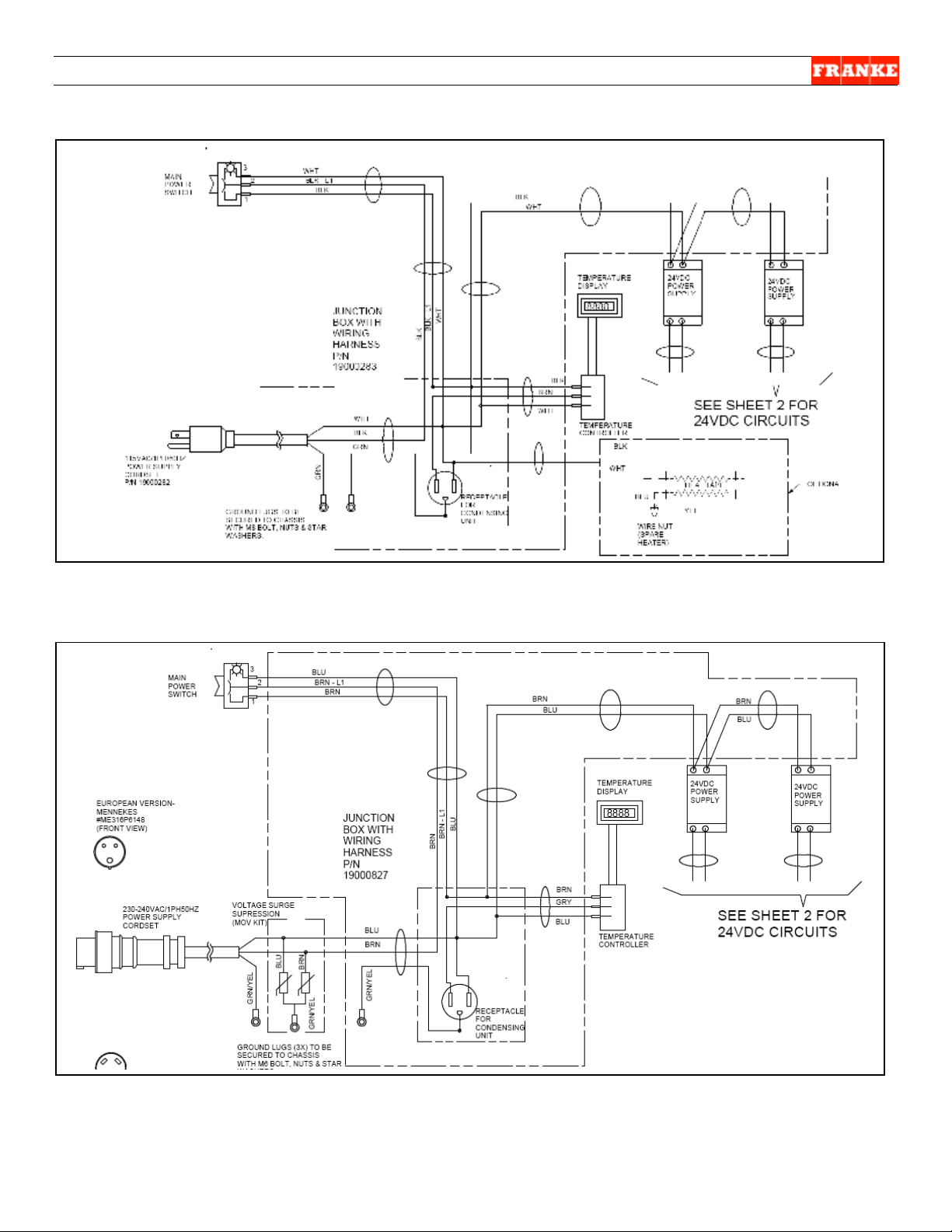

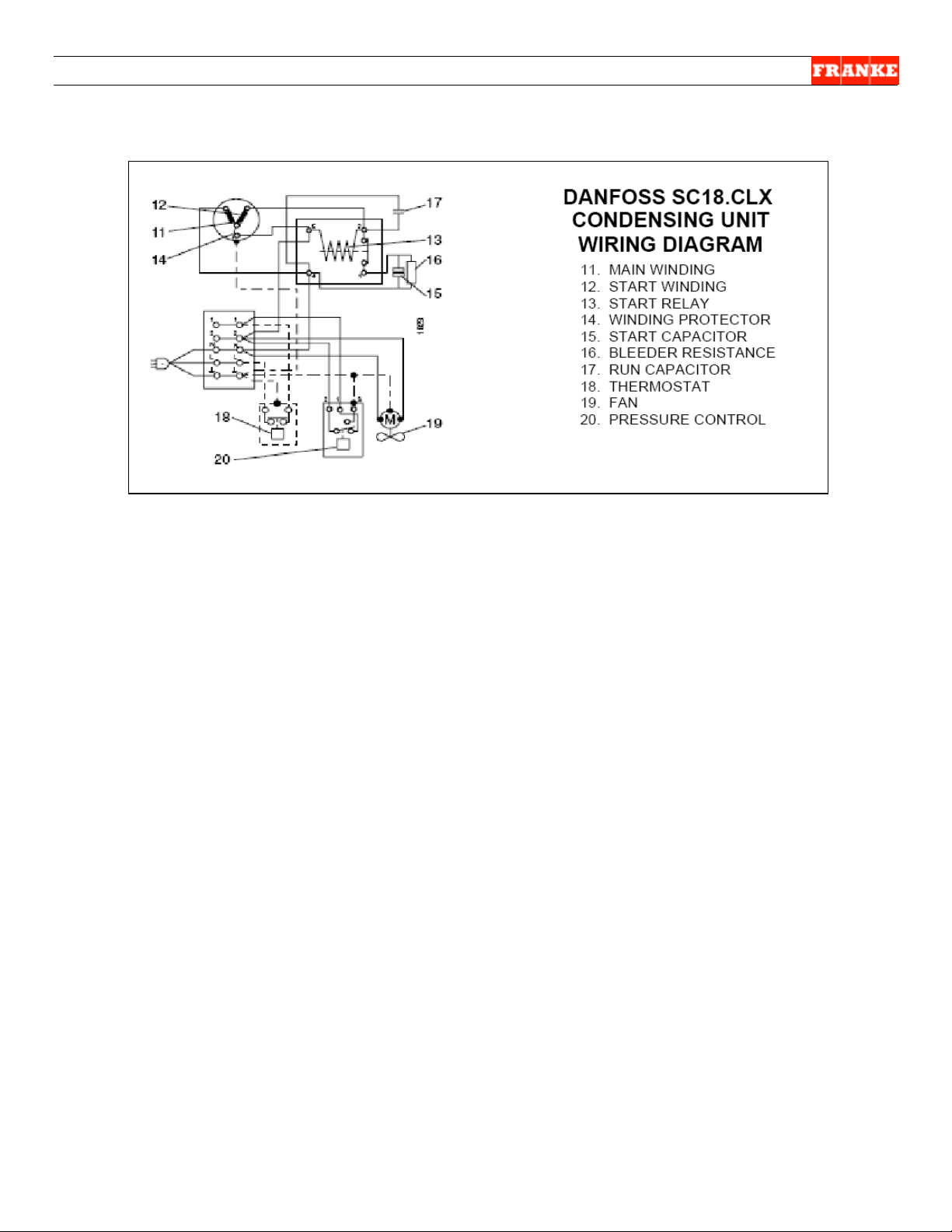

F3Dn Service Manual Electric Schematics / Section 1.5

120-Volt, 1-Phase, 60 Hz Model

230-Volt, 1-Phase, 50 Hz Model

For Technical Support, Call 800-537-2653. Copyright 2006 Franke, Inc. All rights reserved.

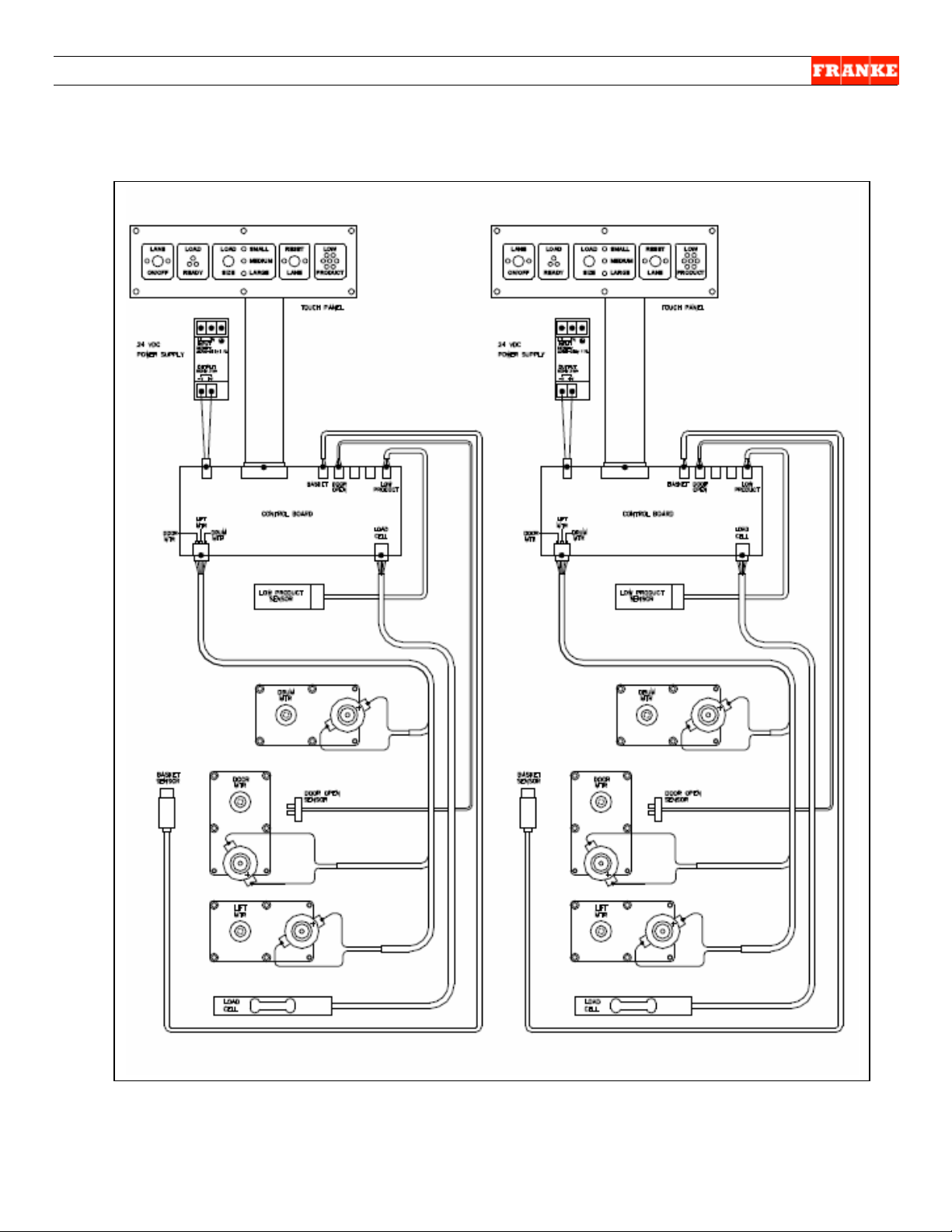

F3Dn Service Manual Electric Schematics / Section 1.5

120-Volt, 1-Phase, 60 Hz Model

[Sheet 2] 24-Volt Wiring Diagram

For Technical Support, Call 800-537-2653. Copyright 2006 Franke, Inc. All rights reserved.

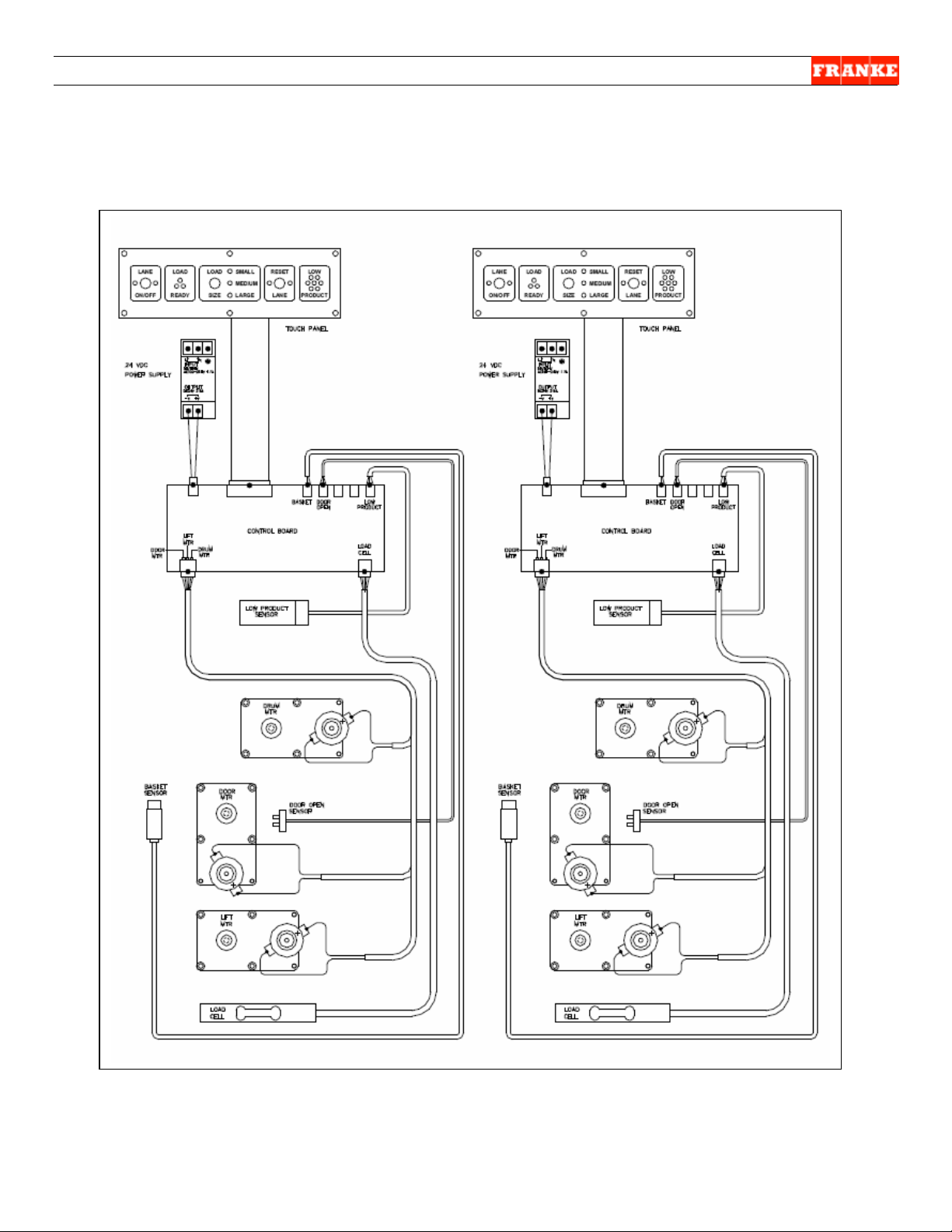

F3Dn Service Manual Electric Schematics / Section 1.5

230Volt 1-Phase 50 Hz Model

[Sheet 2 ] 24-Volt Wiring Diagram

For Technical Support, Call 800-537-2653. Copyright 2006 Franke, Inc. All rights reserved.

F3Dn Service Manual Electric Schematics / Section 1.5

230Volt 1-Phase 50 Hz Model

Rev. 2 11/06

For Technical Support, Call 800-537-2653. Copyright 2006 Franke, Inc. All rights reserved.

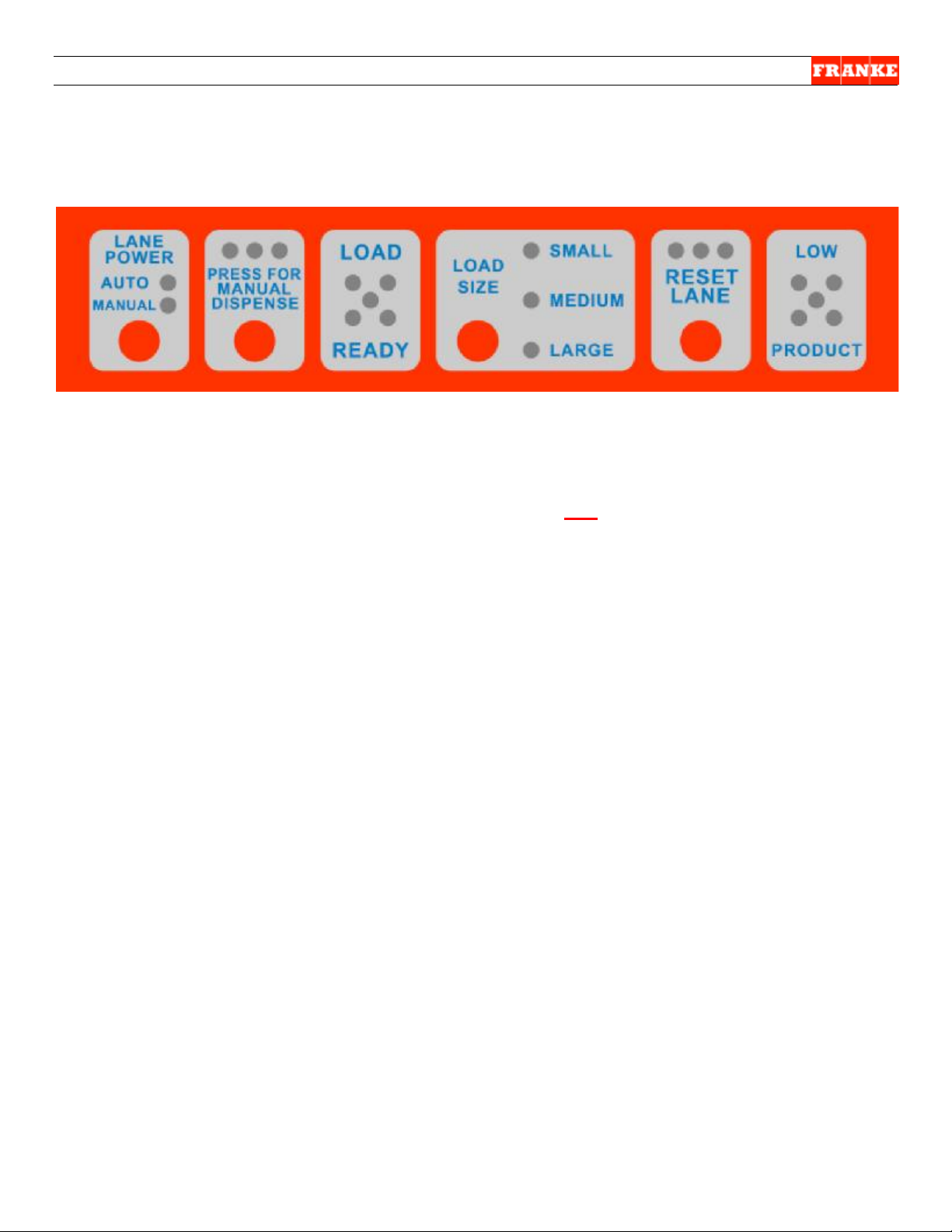

F3Dn Service Manual Control Panel Guide / Section 1.6

Control Panel Function Guide:

-1- -2- -3- -4- -5- -6-

Each lane overlay has the following touch-pad controls and LED displays:

1. LANE POWER – Turns individual lane on and off. Press and Hold to activate. Press again to

change to AUTO or MANUAL. Do NOT turn lane ON until after hopper is filled with fries.

2. PRESS FOR MANUAL DISPENSE – Press touch pad to dispense a single load of fries. LANE

POWER must be in MANUAL mode, the lights above MANUAL DISPENSE button illuminated and

an empty fries basket in load position. (Note: In AUTO Mode, a load of fries is dispensed

automatically, if basket is present and activates basket-present sensor.)

3. LOAD READY – Indicates that lane is ready to dispense a load of fries.

4. LOAD SIZE – Indicates size of load of fries to be dispensed. Can only be changed when LOAD

READY lights are illuminated. The default is LARGE (Load Size). Pressing LOAD SIZE touch-pad

cycles from: LARGE to SMALL, to MEDIUM, then back to LARGE.

5. RESET LANE – A fault condition has occurred.

• Flashing Lights – Time out error. Hopper is either out of fries or a bridge has formed

preventing fries from feeding. Correct condition and press RESET LANE button to resume

normal operation.

• Lights ON – Failure to tare error. Most likely an assembly issue. Disassemble and

reassemble lane per Operating Manual or Quick Reference Card instructions. Make sure all

stray fries are cleaned out. Then press RESET LANE button to resume normal operation.

6. LOW PRODUCT – Fry level in hopper is low and hopper should be refilled. Approximately 1 bag

of fries remains. Unit will continue to dispense fries.

Rev.1 6/06

For Technical Support, Call 800-537-2653. Copyright 2006 Franke, Inc. All rights reserved.

F3Dn Service Manual General Service Instructions / Section 2.1

WARNING:

or death.

2.1 An Introduction To F3Dn Service Manual

The Basics:

1) Technicians should be authorized to work on Franke

Equipment and be qualified to diagnose and repair

refrigeration equipment.

2) The F3Dn operates on 120VAC/60Hz or 230VAC/50Hz

power and is provide with a grounded plug and 10’ [3meter] power cord.

Unplug unit from power source whenever servicing electrical

components or removing the rear service access panel.

Failure to unplug this unit may result in electric shock, burns

3) The F3Dn refrigeration system is charged with ozonesafe R404A refrigerant. Only use R404A refrigerant

when recharging this unit.

4) Always verify proper unit loose component assembly,

proper unit cleaning and correct use of controls by unit

operators, before replacing or repairing components.

5) The F3Dn Compressor Package is top mounted and may

require use of a sturdy ladder to access components,

check for leaks or to replace the compressor.

Suggested [On-Truck] Repair Parts:

We suggest the following to ensure first-trip fix of the F3Dn:

120V/60Hz 230V/50Hz Description Quantity

19000388 19000388 Freezer Door Gasket 1

19000161 19000161 Drum/Door Lift Rotor Motor 2

19000165 19000165 Load Cell 1

18000558 18000558 Door [Open] Motor 1

19000192 19000192 Door-Open Sensor 1

19000798 19000798 Operator Touch Pad Control Panel 1

3126151 19000978 Main Power Switch 1

19000514* 19000515** Temperature Controller Kit 1

3156 3156 Siemens 24-Volt Power Supply 1

19000800 19000800 Main Control Board 2

18000795 18000795 Kit, Low Product Sensor 2

18000796 18000795 Kit, Basket Present Sensor 2

18000797 18000797 Kit, Drive Shaft Rotor Repair 2

18000798 18000798 Kit, Spring & Link Repair 2

18000799 18000799 Kit, Product Door (1-Side) 2

18000800 18000800 Kit, Product Baffle (6 Baffles) 2

3589847 19001086 Condenser Fan Motor 1

19001082 19001080*** Start Relay 1

[Continued on page 2]

For Technical Support, Call 800-537-2653. Copyright 2006 Franke, Inc. All rights reserved.

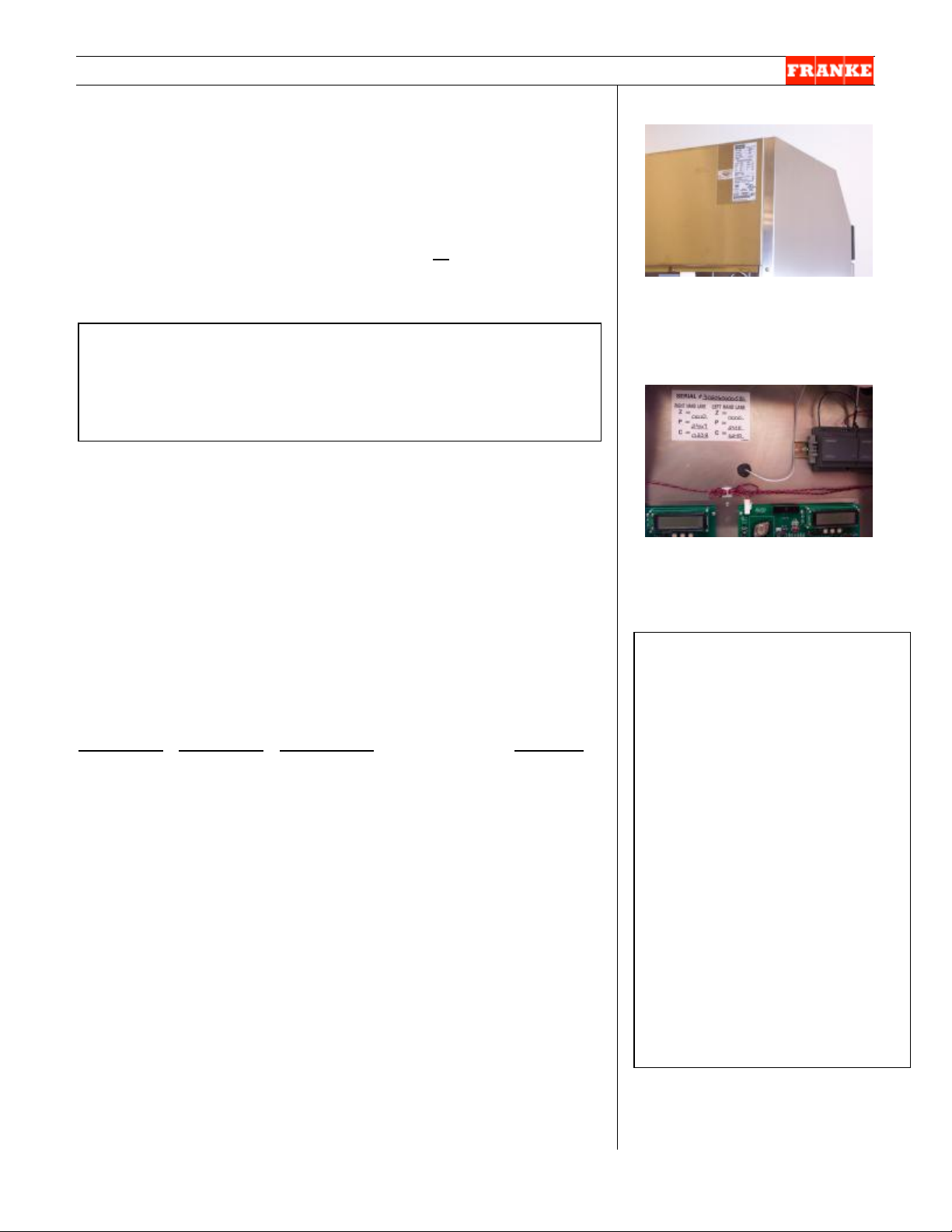

[Photo 1]

The F3Dn Unit Serial Number is

located at the top of the Model

Number & Data sticker, which is

on the back of the unit.

[Photo 2]

Load cell weight values are

checked and recorded on sticker

above main control boards,

before unit ships from Franke.

@Tools Required:

[For Mechanical Systems Repair]

Ø 3/8” [10 mm] flat screw driver

Ø ¼” [6-7 mm] flat screw driver

Ø 1/16” [2 mm] flat screw driver

Ø 1/8” [3 mm] Allen/hex wrench

Ø 3/16” [5 mm] Allen/hex

wrench

Ø 5/32” [4 mm] Allen/hex

wrench

Ø 5 mm Allen/hex wrench

Ø 13 mm Allen/hex wrench

Ø 7/16” [11 mm] box/socket

wrench

Ø Razor knife

19000282 Cordset [8-

Ø Needle nose pliers

feet] 1

Ø ‘C’ ring pliers

Ø Small wire cutters

Ø Rubber mallet

Ø Feeler or Gap Gauge

Ø Plastic Wire Ties

Rev. 1 12/06

F3Dn Service Manual General Service Instructions / Section 2.1

Suggested [On-Truck] Repair Parts Contined:

120V/60Hz 230V/50Hz Description Quantity

19001085 19001080*** Motor Start Capacitor 1

19000496 19000496 Thermostatic Expansion Valve 1

19000362 19000453 Condenser/Compressor 1

19000801 19000826 Cord Set [10-feet] 1

19000452 19000452 Air Filter 1

* NOTE: Temperature Controller Kit P/N 19000514

[120V/60Hz] consists of the following parts:

Ø ETC1H Controller, 1-Relay programmed for FRANKE

F3Dn product (Franke P/N 19000652);

Ø Remote Display (Franke P/N 19000437);

Ø 10’ long Remote Display Cable (Franke P/N

19000649);

Ø Cabinet Temp Sensor (Franke P/N 19000648);

Ø Black Knob (Franke P/N 19000650); and

Ø Knob number ring (Franke PN 19000651)

** NOTE: Temperature Controller Kit P/N 19000515

[230V/50Hz] consists of the following parts:

Ø ETC1H Controller, 1-Relay programmed for FRANKE

F3Dn product (Franke P/N 19000435);

Ø Remote Display (Franke P/N 19000437);

Ø 3-meter long Remote Display Cable (Franke P/N

19000649);

Ø Cabinet Temp Sensor (Franke P/N 19000648);

Ø Black Knob (Franke P/N 19000650); and

Ø Knob number ring (Franke P/N 19000651)

*** NOTE: 230V/50Hz P/N 19001080 is a kit containing both

the Start Relay and Motor Start Capacitor.

When In Doubt:

Call Franke Technical Support at: 800 537-2653

For Technical Support, Call 800-537-2653. Copyright 2006 Franke, Inc. All rights reserved.

F3Dn Service Manual Parts Replacement / Section 2.2

2.2 Freezer Door Gasket Replacement

[Photo 1]

[Part No. 19000685]

1) F3Dn Dispenser should be OFF and the freezer

compartment fully defrosted before proceeding.

2) Open freezer door and inspect the one-piece magnetic

door gasket. If the gasket is torn or crushed so that it

doesn’t completely seal around the door perimeter, it

should be replaced.

3) Remove top door hinge using a 7/16” box wrench or

socket, being careful not to drop the door. Place door on

a non-mar surface with the gasket side facing up.

4) Carefully remove the one-piece gasket from the slotted

plastic extrusion built into the back of the freezer door.

[Note: Plastic extrusion can be easily damaged. Using a

razor knife to separate the old gasket from its retaining

tailpiece may facilitate this procedure. Carefully remove

the separated tailpiece from the slot by pulling toward

each corner using small needle nose pliers. See Photos

2 and 3]

5) Take the new gasket [P/N 19000685] and insert the

tailpiece into the gasket-mounting slot. Align the corners

and start at the top of the door. Continue around the door

perimeter until completely seated. [Tip: Place the door

on a cushioned surface and carefully hammer the new

gasket tailpiece into slot around the door perimeter.]

6) Re-install freezer door on bottom hinge with bushing,

then mount the upper hinge. Be careful to align the door

before tightening the hinge mounting bolts.

7) Test the replacement of the Freezer Door Gasket by:

8) Close the door and visually check the door seal and fit.

9) Turn on main power switch. Allow compressor to draw

down Freezer Compartment temperature. Check with

your hand around the full door perimeter for any leaks of

cold air.

Ø 7/16” [11 mm] socket wrench

Ø Razor knife

Ø Needle nose pliers

Ø Rubber mallet

For Technical Support, Call 800-537-2653. Copyright 2006 Franke, Inc. All rights reserved.

@Tools Required:

The F3Dn freezer door is

equipped with a one-piece

magnetic door seal.

[Photo 2]

To speed replacement, just cut

away the old door gasket from

its tail piece.

[Photo 3]

Use a needle nose pliers to pull

gasket tailpiece from slot.

[Photo 4]

Align gasket tailpiece with door

slot and hammer carefully into

place around door perimeter.

Rev. 1 6/06

Loading...

Loading...