Page 1

2

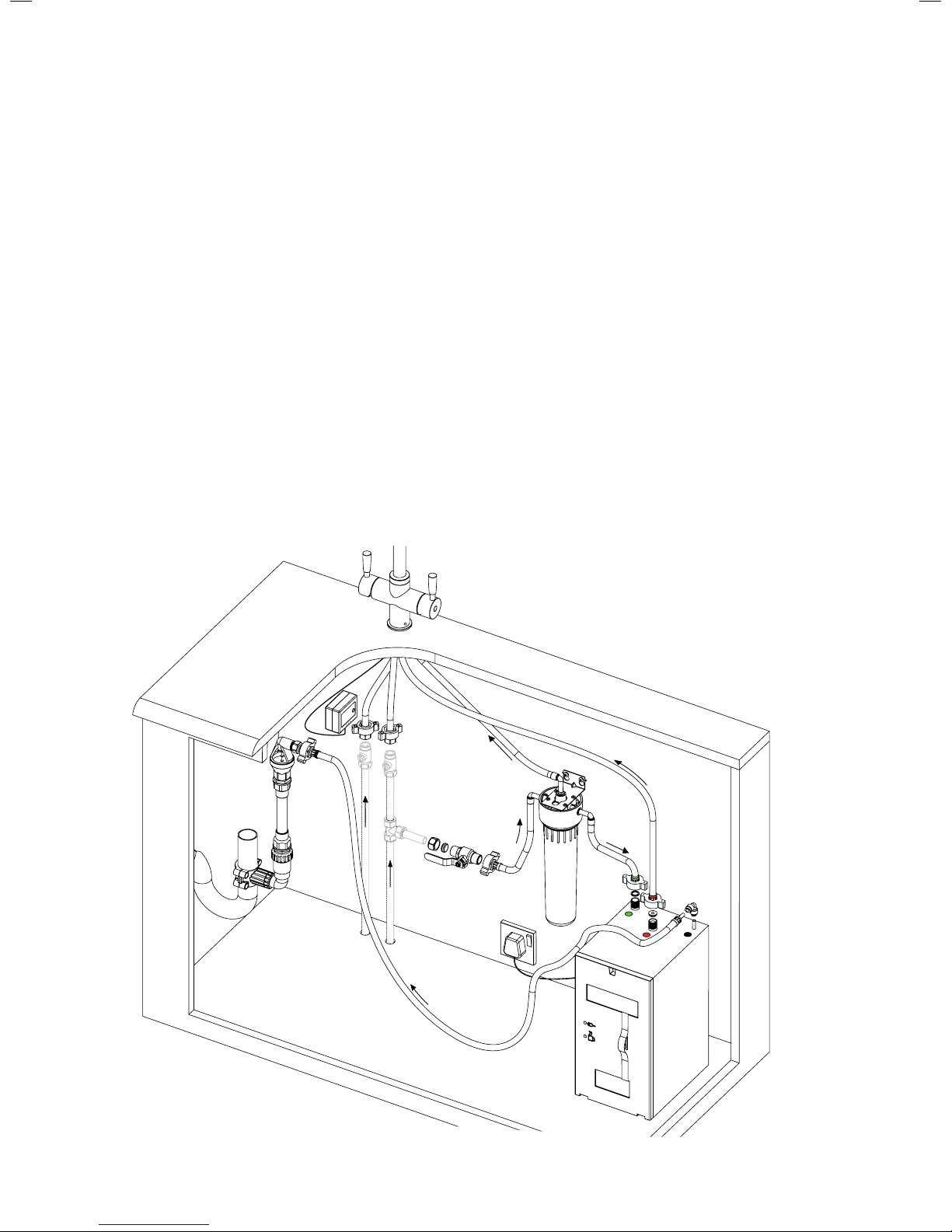

FRANKE OMNI 4in1

BOILING WATER SYSTEM

Installation instructions

Page 2

2

ON

OFF

HOT

COLD

The Franke Omni System must be installed using only the

genuine Franke items listed below. Substituting any of the

above 3 items for non-Franke manufactured alternatives, or

failing to install and maintain the unit in strict accordance with

these instructions, will invalidate your product warranty.

Franke will not accept liability for damage or accidents

resulting from the use of non-genuine Franke components,

incorrect installation or operation.

Application

This product is a boiling water device intended for domestic

use only. The water supply pressure must be between

minimum 1.5 BAR (22 psi) maximum 5 BAR (73psi)

Introduction

This guide explains how to install a new Franke Omni 4in1®

Boiling Water System.

Thank you for purchasing a Franke Omni Tap System. In

keeping with Franke’s worldwide reputation this product has

been designed and manufactured to the very highest quality

standards. Correctly installed and properly maintained in

accordance with the following instructions, it will provide you

with reliable service for many years.

The Franke Omni System comprises 3 separately packaged

assemblies:

1. Franke 4in1 Omni tap (Part Number: 119.0380.520)

2. Franke boiler - Model QHT-1 (Part Number: 119.0380.581)

3. Franke water filter complete with a Franke 08 filter

cartridge. (Part Number: 119.0380.582)

Please Note: This diagram is for guidance only

Page 3

3

Boiler technical data

Description Value Unit

Dimensions 230 x 182 x 354 mm

Load 10 Amps

Voltage 230 Volts

Power 1500 Watts

Stored Temperature 105 °C

Min Water Pressure 1.5 Bar

Max Water Pressure 5 Bar

Heating Up Time 20 Mins

Recovery Time 10 Mins

Boiler Capacity 4 Litres

Pressure Release Valve Rating 8 Bar

Before you begin

1. Check the mains water pressure. The pressure must not

be below 1.5 BAR (22 psi) or above 5 BAR (73psi),

measured during a low demand period – (mid-morning or

mid-afternoon). If the pressure exceeds 5 BAR a pressure

reducing valve must be installed in the cold mains supply

to protect both the boiler and the water filter housing. A

suitable pressure reducing valve can be purchased at

www.frankefilterflow.co.uk.

2. The unit must be installed in a frost free environment.

3. Ensure that the cabinet is well ventilated. If in doubt it is

advisable to improve the circulation of air by drilling some

holes in the top and bottom of the rear panel.

4. Be careful when making the various connections to the

mains water stop valve and the boiler. Do not be tempted

to over-tighten the connections. It is only necessary to

firmly hand tighten the nuts using the patented

NutRunna

®

plastic tightening devices provided to make a

secure watertight seal.

5. Locate the existing hot and cold water supply pipes.

6. Shut off the mains water supply.

7. Switch off the mains electricity supply at the socket.

Safety

Remember: Boiling water is potentially dangerous and great

care should be exercised when using the Franke Omni tap.

The installation must be carried out by a suitably qualified

professional in strict accordance with the instructions

provided and comply with the UK Water Supply (Water

Fittings) Regulations 1999 and safety standards.

• If a new electrical power supply is required you must

seek the ser vices of a qualified electrician.

• The boiler must only be connected to the 230V mains

electricity supply through either an earthed independent

wall socket or a fused spur.

• The boiler is fitted with an electrical lead terminating in

a UK 3 pin fused plug for connection to the 230 volt 13

amp domestic electricity supply. It is impor tant to use a

socket with a built in switch and position it to provide

convenient access to switch off the boiler.

• Turn off the mains water supply before commencing

installation.

• Never lift the boiler by the flexible connector hoses.

• The power to the boiler must only be switched on once

the installation is complete and the tank is full of water.

• Always turn off the electricity supply to the boiler before

you close the mains stop valve. Restore power to the

boiler after the mains stop valve has been opened.

• Young people and potentially vulnerable users must

be instructed how to operate the boiling water function

safely by a responsible adult.

• This is a domestic appliance and must not be installed in

a commercial environment.

• If the supply cord is damaged it must be replaced by

the manufacturer, an official ser vice agent or similarly

qualified persons in order to avoid a hazard.

Page 4

4

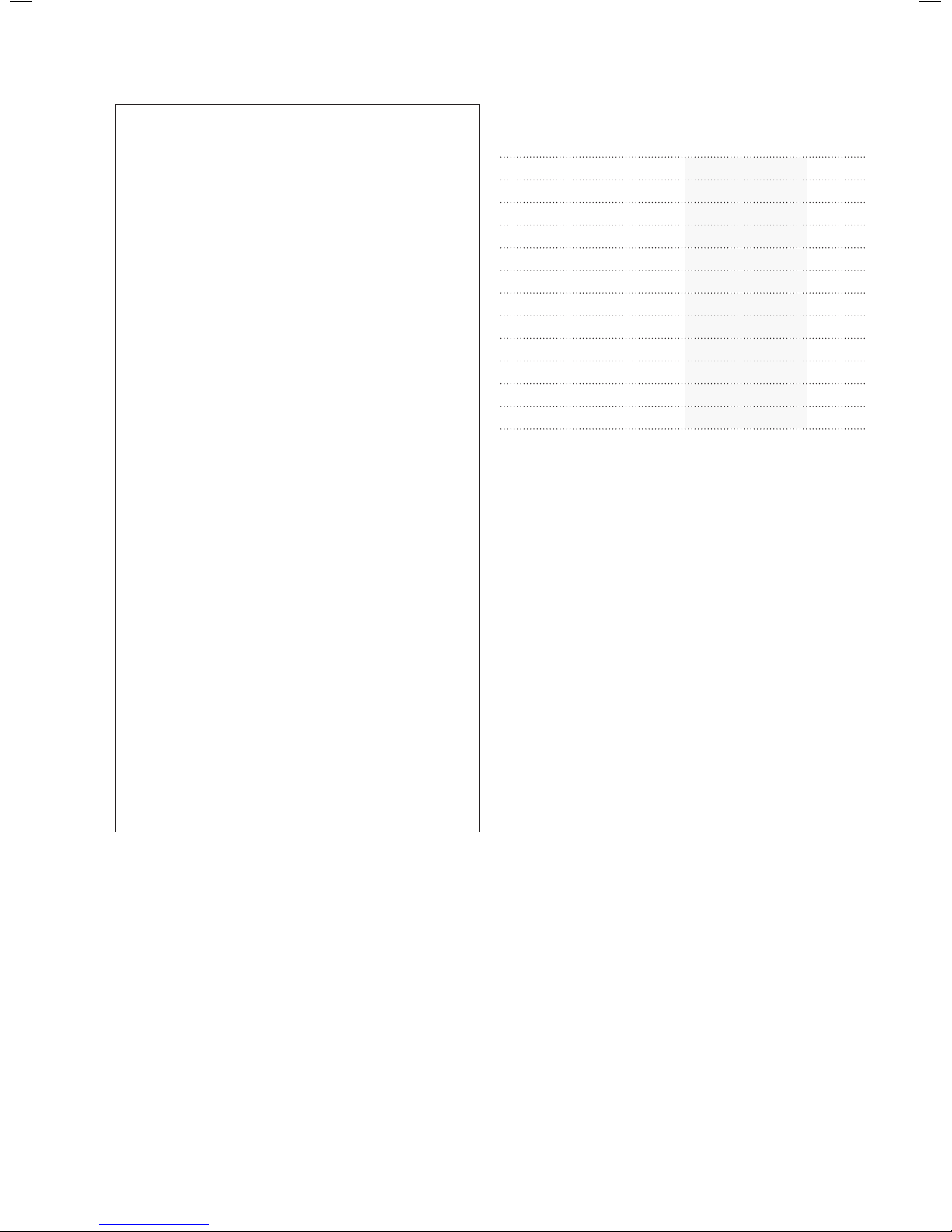

Component list

1. Franke Omni 4in1 tap

2. Filter Cartridge change indicator module

3. Safety clip for boiling water handle

4. AA Batteries for filter cartridge change

indicator module x2

5. Tap clamp

6. Tap clamping nut x2

7. Box spanner for tap clamp nuts

8. Compression washer for underside of tap

9. Cable ties x4

10. NutRunna

®

hand-tightening device for

G¼” nuts x2

11. NutRunna

®

hand-tightening device for

G½” nuts x4

12. Franke QHT-1 boiler

13. Push-fit elbow

14. Tapered silicone washer for boiling water

outlet. (red sticker)

15. Flat silicone sasher for boiler water inlet.

(green sticker)

16. Vent assembly

17. Saddle clamp

18. Vent hose

19. Vent assembly elbow

20. Pipe cutter

21. Water filter housing assembly

22. Franke 08 water filter cartridge

23. Stop valve

24. Water filter retaining screws

Supplied in box with tap

Supplied in box with boiler

Supplied in box with filter system

A

B

C

D

A

G1/2" x2

B

Stem Elbow

C

G1/4"

D

LED Plug

AA

x2

x4

x2

x4

x2

1 2 3

4 5

6 7 8

119 10

233mm

182mm

352mm

80mm Min clearance

A

B

A

Straight Stem

B

G1/2"

12 13 14

15

17

16

18

19 20

A

B

A

G1/2"

B

G1/4"

x3

Flow

21 22

23 24

Page 5

5

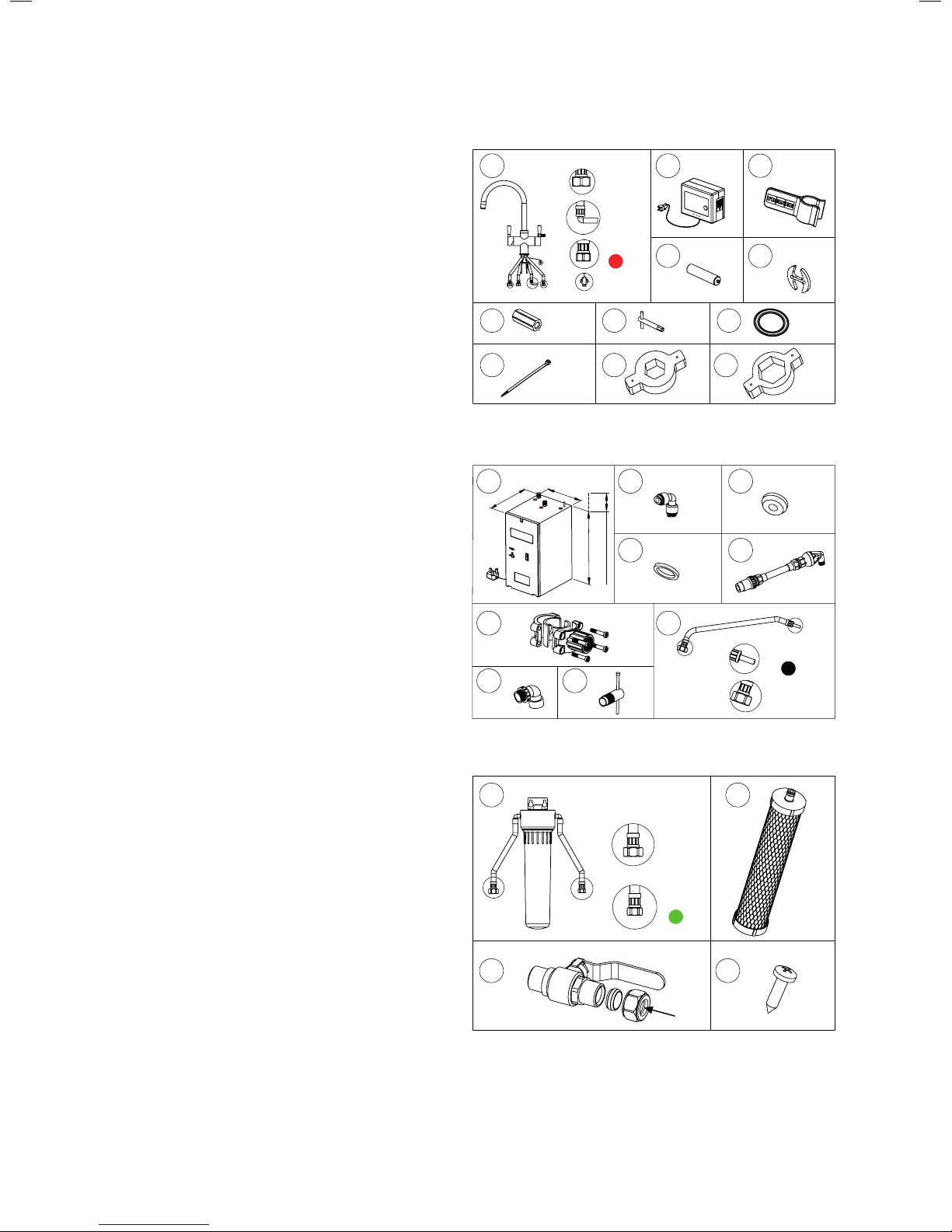

THE INSTALLATION PROCEDURE

Install the Franke Omni 4in1 kitchen tap

Carrying out this operation first will make it easier to plan

the layout inside the cabinet. For safety, it is advisable to

locate the tap at, or towards, the back of the sink out of

reach of smaller children.

1. The tap will require a standard 35mm diameter hole

drilled in the kitchen work surface. Important note:

before drilling the hole make sure that there is enough

clearance between the tap handles and the back splash

when the handles are in the fully open position.

2. Insert the flexible hoses and the wire lead through the

35mm hole.

Position the tap for the owners convenience. (The tap

can be rotated 180° for left handed operation of the

boiling water function).

3. Working inside the cabinet, slide the gasket (8) and the

clamp plate (5) over the hoses and the two studs at the

base of the tap. Screw the two clamp nuts (6) on to the

studs using the box spanner (7).

4. Check the alignment of the tap then tighten the two

clamp nuts using the box spanner to firmly secure it on

the work surface.

Plan the layout inside the cabinet

• Determine the best positions for the hot and cold mains

water supply.

• Determine the best positions for the boiler and the filter

unit, making sure that the boiler power cable, the flexible

hoses, and the filter cartridge change indicator cable, are

all within comfortable reach of their respective

connection points without them being compressed,

stretched or kinked.

• The boiler must be installed upright with the hose

connections at the top, never on its side.

• Allow a minimum clearance of 80mm at the top of the

boiler for the connecting hoses.

• Choose a location for the filter unit (21) and the stop

valve (23) to allow convenient access for future filter

cartridge changes.

240mm

Min

100mm

235mm

385mm

35mm

60mm Max

Page 6

6

The plumbing

Provide a hot and cold water supply for the tap. (We

recommend that service stop-valves are fitted in both the hot

and cold water supplies to the tap).

1. Tee off the cold mains water supply to provide an

independent feed to the water filter.

2. Install the stop-valve (23) inline on the independent feed

to the filter. Important note: the ends of the stop valve

are different. One end has an internal chamfer to connect

to compression pipework; the opposite end has a flat

washer face to suit the G½” (½” BSP) nut and washer of a

flexible hose (refer to diagram (23) in component list).

3. Connect the hot and cold G½” flexible hoses to the

respective hot and cold supplies and tighten them firmly

to make a watertight seal — two G½” NutRunna

®

hand

tightening devices (11) are supplied loose with the tap for

this purpose. The tap hose with the blue indicator should

be connected to the cold supply and the hose with the

orange indicator to the hot supply.

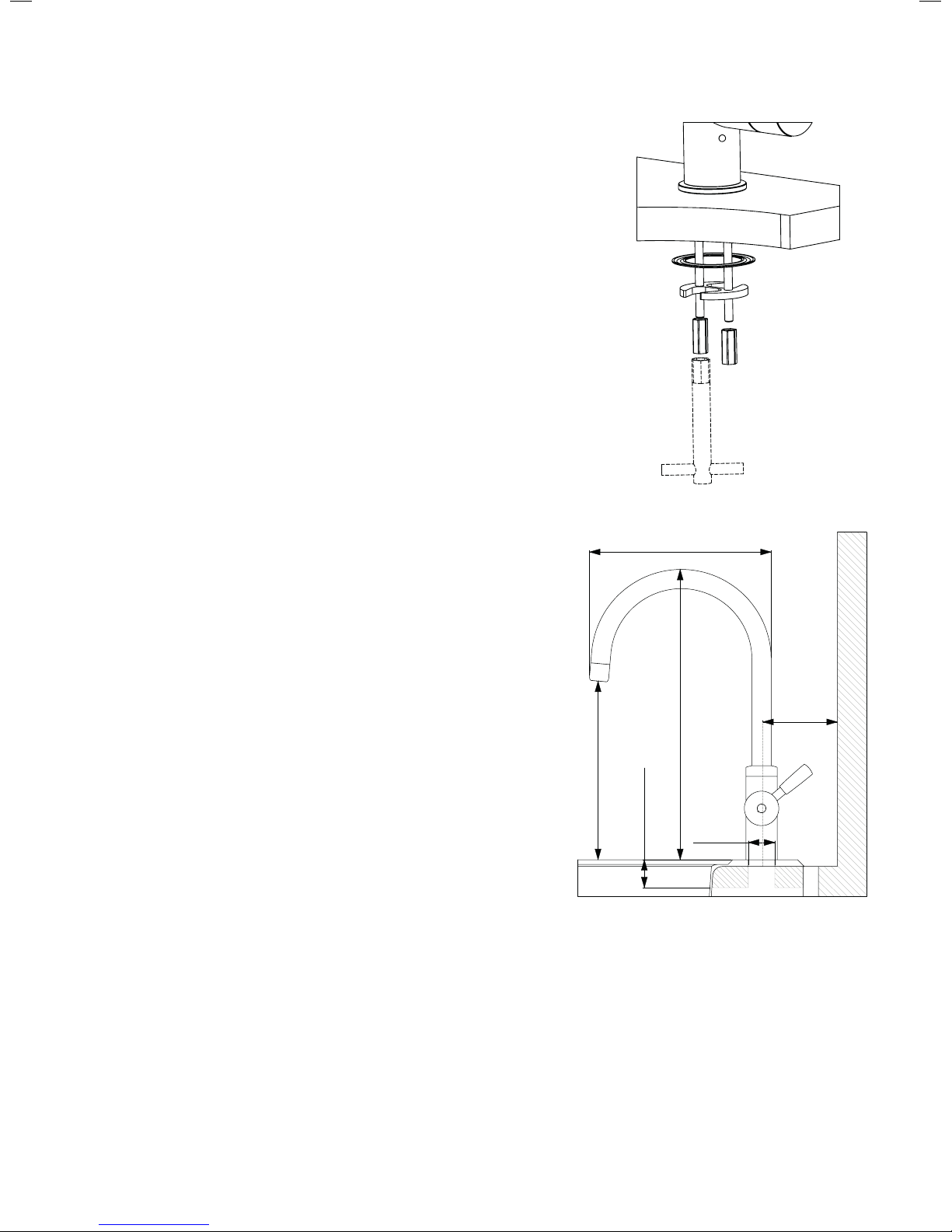

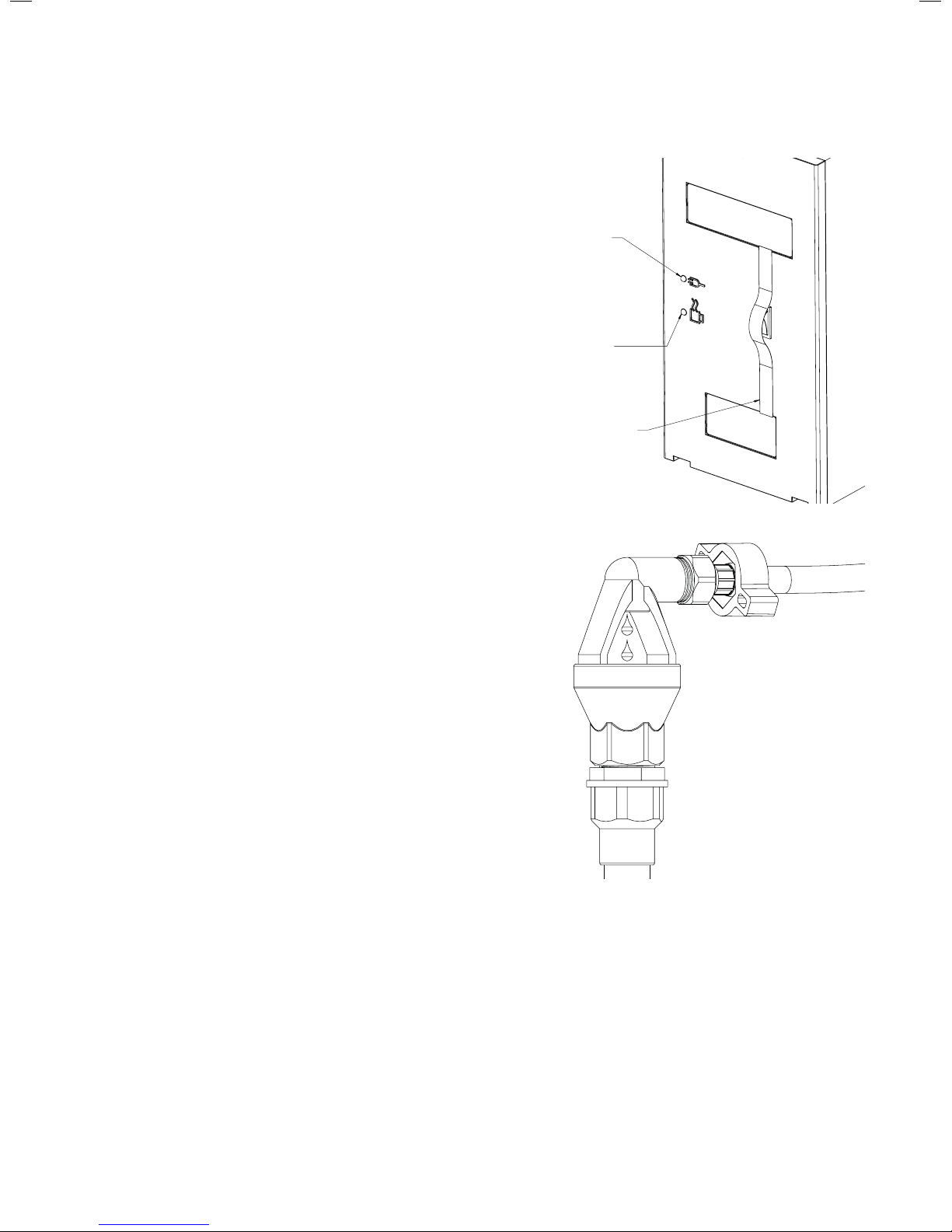

Install the filter unit

Important note: The filter unit must be installed inside a

cupboard. Long term exposure to direct light can degrade the

plastic sump leading to eventual failure.

1. Position the filter unit (21) vertically with the hoses at the

top, in its previously determined location.

2. Mark the positions for the two filter unit support screws

(24) using the holes in the filter bracket as a guide.

3. Set the filter unit aside and screw in the two screws

leaving the heads slightly proud (approximately 4mm).

4. Take the G½”nut (21.A) at the free end of the filter inlet

hose (blue indicator) and screw it on the G½” male outlet

thread of the stop valve (23). Hand tighten the nut firmly

using the attached NutRunna® (11) sufficient to make a

watertight seal. Do not overtighten.

5. Take the grey push fit stem elbow at the free end of the

cold filtered water hose attached to the tap, wet the stem

before pushing it firmly into the female outlet at the top

of the filter. Important note: ensure that the stem

connector is pushed fully home — 10mm of the stem

should enter the female connector.

6. Hang the filter unit on the two screws. If the panel is too

thin to mount the filter securely strengthen the panel with

a wooden batten.

Cold water

inlet from

filter stop valve

Filtered water

outlet to tap

Filtered

water

outlet

to boiler

Pressure relief

button

Filtered water

outlet to tap

Filtered water

outlet to boiler

Pressure relief

button

Cold water

inlet from

filter stop valve

Page 7

7

Install the plastic vent assembly

Important note: The vent pipe must be installed vertically

with the air-gap at the top. The vent pipe conforms to the

building regulations and on no account should be shortened

or modified in any way.

1. Choose a convenient position to fit the saddle clamp (17)

preferably on a vertical section (Option 1) of the waste

pipe, or alternatively on a horizontal section (Option 2).

When installing the saddle clamp horizontally the elbow

(19) is not required. Be careful to allow sufficient

clearance for the height of the vent assembly and enough

room to operate the pipe cutter (20).

2. Separate the two halves of the saddle clamp by

unscrewing and removing the four nuts and bolts. Discard

the two black rubber inserts for 41mm waste pipe. Leave

them in place for 32mm pipe.

3. Place the saddle clamp in position on the chosen section

of waste pipe and re-assemble the clamp. Tighten the

nuts and bolts securely to make a watertight seal.

4. Insert the pipe cutter (20) into the saddle clamp and cut

a hole in the waste pipe by rotating it to the right until it

breaks through. (see diagram.)

5. Screw the vent assembly (16) into the saddle clamp. When

the saddle clamp is installed on a vertical section of the

waste pipe screw the elbow in first and use the lock nut to

secure the air gap assembly in the vertical position.

6. Take the vent hose (18) (black indicator) and connect

the G½” nut end onto the corresponding G½” male

thread at the top of the vent assembly. Use the attached

NutRunna® (11) to tighten the nut firmly, sufficient to

make a water- tight seal. Do not overtighten.

365mm

Lock Nut

Option 1 Option 2

Lock Nut

365mm

Page 8

8

13

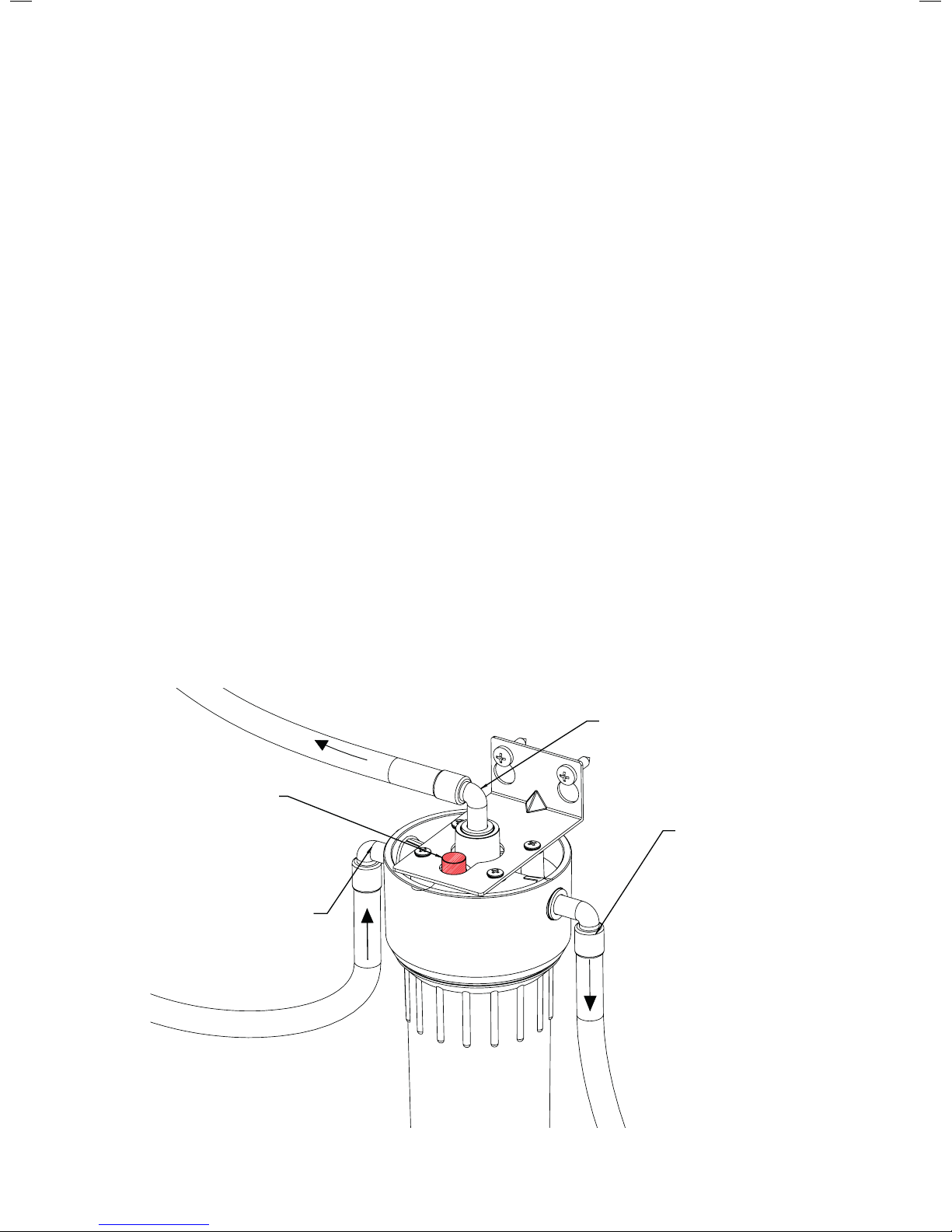

Install the boiler

Important note: Do not plug the boiler into the power supply

at this stage.

For ease of installation the boiler connections and the flexible

hoses are colour coded:

Green - Filtered water

Red - Boiling water

Black - Vent

1. Remove the protective caps from the three connections

on the top of the boiler.

2. Place the boiler (12) in position upright on a flat surface

inside the cabinet with the connections to the top.

3. Take the G¼” female nut (21.B) at the free end of the

filter outlet hose (green indicator). Carefully position the

flat silicon washer (15) inside the nut. Screw the nut onto

the G¼” male boiler inlet (green dot). Hand tighten using

the attached NutRunna

®

sufficient to make a watertight

seal. Do not overtighten.

4. Take the free end of the boiling water flexible hose

attached to the base of the tap (red indicator). Carefully

position the tapered silicon washer (14) on the G1/4”

male boiler outlet (red dot). Take the spare G1/4”

NutRunna

®

(10) and place over the nut. Screw the nut

onto to the G1/4” boiling water outlet of the boiler

(red dot). Hand tighten the nut firmly, sufficient to make a

watertight seal. Do not overtighten.

5. Take the push-fit elbow (13). Connect the elbow to the

grey push-fit stem on the end of the vent flexible hose

(18) (black indicator). Push the push-fit elbow firmly home

in place onto the metal spigot (black dot) protruding from

the top of the boiler.

6. Use the cable ties (9) to neatly secure the various flexible

hoses out of harm’s way.

Install the filter change indicator module

1. Install the 2x AA batteries (4) in the module (2). A “bleep”

will confirm that they are correctly installed.

2. Choose a convenient location for the module, on the side

of the cabinet or the boiler, making sure that the attached

power cable is within easy reach of the mating cable

attached to the base of the tap.

3. Secure the module in place using the self-adhesive Velcro

pad provided.

4. Plug the two cables together.

5. The LED light on the tap will glow RED followed by GREEN

and the emit an audible BEEP before turning off.

The LED indicator:

Red - Indicates that the water filter cartridge needs

replacing.

Yellow - Indicates that the two AA batteries in the module

need replacing.

Flat silicone

washer

Tapered silicone

washer

Female-female

push fit elbow

Flat silicone

washer

Tapered

silicone

washer

Female-female

push fit elbow

Page 9

9

Commissioning the system

1. Install the filter cartridge into the filter housing. (Refer to

the separate Cartridge Change Instructions in the filter

system box).

2. Turn on the water supply.

Operate the boiling water function for 3 minutes to

flush the system. (Please see the OPERATING THE

OMNI TAP overleaf.)

3. Turn the tap off and check the connections for leaks.

4. Plug the boiler into the mains electricity supply socket.

5. Remove the warning strip covering the “ON -OFF” switch

on the front of the boiler and turn the switch to the “ON”

position. Check the top LED (Plug logo) on the boiler

turns green to indicate power is on. The lower LED (Mug

logo) will turn red to indicate the boiler is heating up.

6. Wait for 10 minutes and then check that water is

discharging from the vent pipe. Important note: If water

does not start to discharge from the vent pipe into the

cup after 10 minutes, switch off the power, operate the

boiling water function on the tap to release the pressure,

and refer to the Troubleshooting Guide overleaf.

7. Allow approximately 20 minutes for the boiler to reach full

operating temperature, indicated by the lower LED

turning green.

8. Operate the tap boiling water function for a minute to

exhaust trapped air from the system.

9. The system is now ready for use. Please demonstrate to

the homeowner the procedure for replacing the water

filter cartridge and explain the importance of scheduled

cartridge changes to maintain the quality of the filtered

drinking water and the boiler warranty.

Top LED indicates

power on/off

Bottom LED

Red=tank is heating

Green=ready

Warning strip

Top LED indicates

power on/off

Bottom LED

Red = tank is heating

Green = ready

Warning strip

Page 10

10

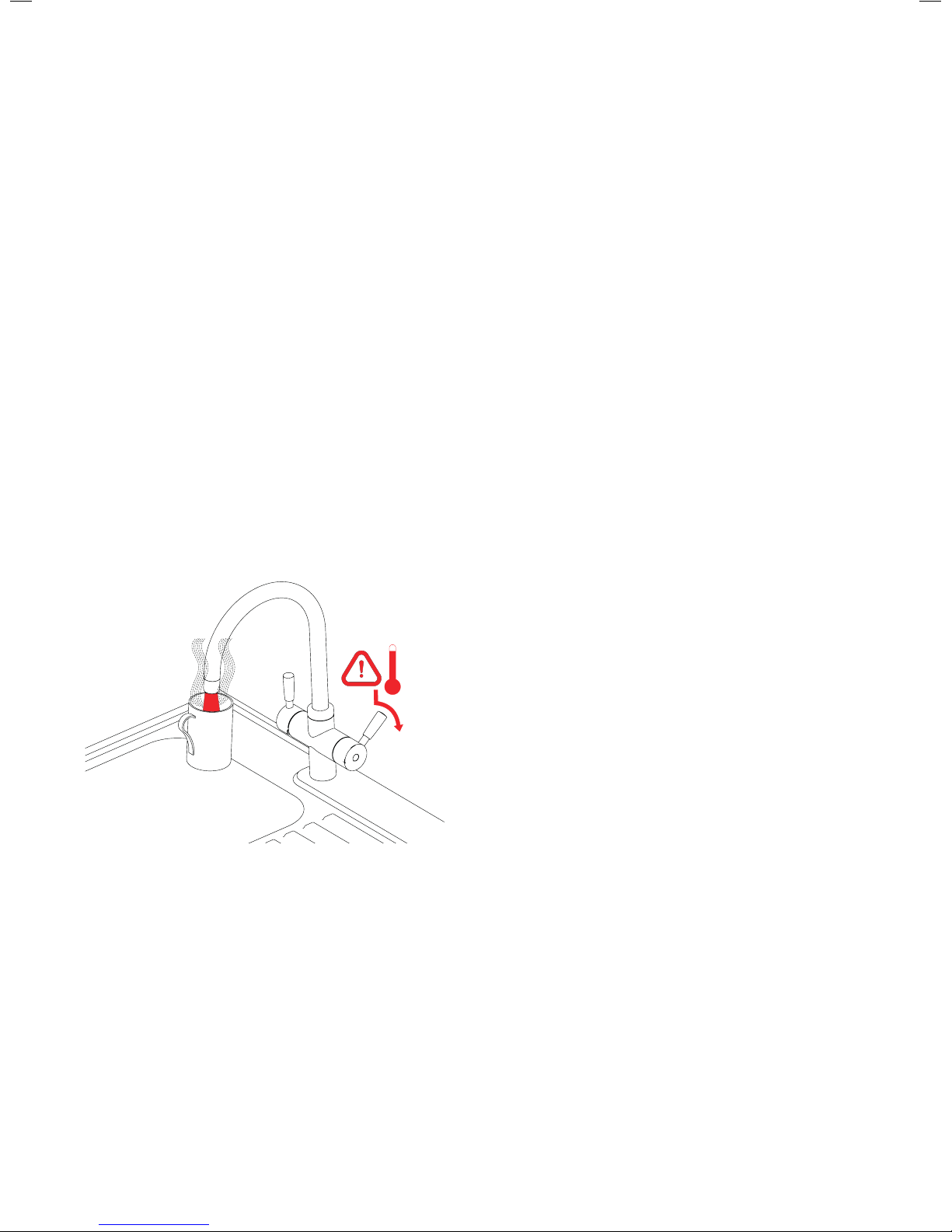

Operating the Omni tap

The body of the tap is clearly marked to show the 4 functions.

Normal unfiltered mains hot and cold water.

The hot and cold water is controlled in the normal manner

by the lever opposite the boiling/cold filtered water lever.

Boiling Filtered water

Remove the red safety clip (3)

Depress the boiling water lever to release

the safety lock and rotate it against the

spring pressure.

Guide the boiling water lever back to the ‘’OFF” position.

Note: Do not just release the handle or it will pass through

the “off” position and turn on the cold filtered water.

The correct way to dispense the boiling water is to contain

the end of the spout inside the vessel you are filling; gradually

lowering the container as it fills.

Cold filtered water

The cold filtered water function is controlled

by turning the boiling filtered water lever in

the opposite direction, but without the need

to depress the lever to disconnect the safety

lock beforehand.

Mains Cold

Mains Hot

Filtered Boiling

Filtered Cold

Removable

Safety

Clip

Mains Cold

Mains Hot

Filtered

Cold

Filtered

Boiling

Removable

Safety

Clip

Care and maintenance

Cleaning the Omni tap

The Omni tap is manufactured in stainless steel and is

therefore extremely durable and stain resistant. All that is

required to keep it in good condition is a regular wipe over with

a damp cloth - Franke offer a micro-fibre cloth for this purpose

that can be purchased on line at www.frankefilterflow.co.uk—

and an occasional wash with a proprietary moisturising hand

cleaner or the application of a small amount of baby oil on a

soft cloth or tissue will also help to keep the finish bright and

free of smears.

Changing the batteries in the filter cartridge change module

If necessary separate the module from the Velcro pad and

slide off the battery cover at the side of the module. Remove

the battery carrier and replace the two old AA batteries with

two new ones. Press the reset button.

Removing the boiler

1. Disconnect the electricity supply to the boiler.

2. Operate the boiling water function and run the boiling

water until the water flowing from the spout runs cold.

3. Shut off the water supply to the boiler.

4. Operate the boiling water for a second time until the water

stops flowing to release the pressure in the boiler.

5. Disconnect the hoses from the boiler using a suitable

container to catch residual water.

6. Remove the boiler carefully, unscrew the brass drain nut

at the base and pour out the water it contains.

100°c

Page 11

11

Water filter maintenance

1. The water filter supplied with this unit is designed to both

protect the boiler and provide high quality drinking water

free of sediment, chlorine and other potentially harmful

contaminants.

2. Changing the filter cartridge every 6 months will keep the

boiler in good condition and maintain the quality of the

filtered drinking water. Franke will not accept

responsibility for boiler failures due to the build-up of

limescale if the filter cartridge has not been replaced at

the recommended 6 month intervals.

3. The occasional wash in warm soapy water is sufficient to

keep the plastic housing clean. Under no circumstances

should the plastic filter housing come into contact with

any proprietary cleaners such as kitchen sprays, bleach

etc. as contact with certain chemicals can degrade the

plastic and cause it to fail.

4. The plastic housing must be replaced every 10 years

due to the tendency of plastic materials to degrade and

weaken over time.

5. A smear of WRAS approved silicon grease applied to the

filter sump thread and to the rubber sealing ring in the

head of the filter at each cartridge change will make it

easier to unscrew the sump. Only a WRAS approved

alternative grease must be used for this purpose.

Non-approved greases may degrade both the seal and

the plastic housing and lead to eventual failure. Small

tubes of WRAS approved silicon grease are available at

www.frankefilterflow.co.uk.

6. The standard replacement filter cartridge for the Franke

Omni system is the Franke 08. The Franke 08 will

remove sediment, chlorine and other chemicals as well

as prevent limescale from damaging the boiler. It should

be replaced every 6 months. Other filters are available

for specialist applications, for more information visit

www.frankefilterflow.co.uk

Changing the filter cartridge

1. Operate the switch on the front of the boiler to switch off

the boiler power supply.

2. Shut off the water supply to the filter using the adjacent

stop-valve.

3. Press the red button at the top of the filter unit to exhaust

the pressure in the system. It will not be possible to

unscrew the filter canister if this operation is not carried

out.

4. Place a shallow container in the cabinet to catch any

water residues when removing the filter sump. Grip the

sump firmly and turn it firmly to the left to break the seal.

Unscrew the sump by hand until it separates from the

head of the filter.

5. If the old cartridge does not automatically fall free press

down on the top mount of the cartridge to release it.

Remove the old cartridge and discard the remaining water

in the sump.

6. Remove the new filter cartridge from its packaging, wet

the “O” seal and place it in the filter sump. Position the

sump, with the cartridge inside, under the filter head and

screw it in place. The cartridge should engage

automatically. Tighten the sump sufficient to make a water

tight seal.

7. Turn the water supply ‘on’ and check the system carefully

for leaks.

8. Operate the system and run the filtered water for a few

moments until the water runs clear. Run the boiling water

for a moment to release any trapped air.

9. Turn the boiler power supply back on.

Page 12

12

Frequently asked questions &

troubleshooting guide

The boiling water flow is agitated and noisy

Please bear in mind that your Franke Omni system is

dispensing boiling water, rather than ver y hot water, and as a

consequence there will be the normal steam, agitation and

noise associated with boiling water. Initially this may be

alarming, but read through the technique suggested below

and practice it a few times. Soon you will gain confidence and

using the tap will be second nature.

Operate the boiling water function. Discharge a small amount

of water until steam appears. Turn off the boiling water,

position the vessel over the outlet of the tap spout and

continue to dispense boiling water by maintaining pressure

on the handle. Gradually lower the vessel while keeping the

spout just above the surface of the water.

Please take a moment to visit www.franke.co.uk for a short

video demonstration of an Omni in use to accompany the

above instructions.

The flow of boiling water splutters more than shown

in the video

• Check that the stop valve is fully open and for kinks in the

flexible hoses; particularly the boiling water hose.

• If this does not resolve the issue, check the water

pressure using a gauge rather than estimating to ensue a

reliable reading. As previously stated it should fall

between 1.5 bar (22 psi) 5 bar (73psi).

• If the problem persists, remove the filter cartridge and try

running the system without the cartridge installed to

determine whether the cartridge is blocked and restricting

the flow.

Water fails to discharge from the vent tube after power

has been switched on to the boiler for 10 minutes

• Check there is power to the boiler. The ‘Plug’ LED should

be green. Check there are no kinks in the vent hose.

Water is continually dripping/running into the

vent assembly

Water continuously discharging from the vent indicates that

the water pressure is too high; above the 5 bar (73 psi)

stipulated maximum. In normal operation the pressure relief

valve will allow water to drip for approximately 20 minutes

after the boiler is switched on. Thereafter it will drip

periodically; after water is drawn off and as the boiler comes

back up to temperature.

Check the water pressure at a low demand period (mid

morning or mid afternoon). If it exceeds 5 bar (73 psi)

it will be necessary to install a 3-4 bar pressure reducing valve.

A suitable valve can be purchased at

www.frankefilterflow.co.uk or from a plumber’s merchant.

While waiting for the pressure relief valve to be fitted turn

off the boiler.

100°C

Caution!

Page 13

13

The vent assembly is overflowing

• Check that the has been hole has been properly cut in the

waste pipe.

The hot water flow from the tap is slow (not the

boiling water)

• Check the hot water pressure. A minimum of 0.8 bar

pressure is required.

The filtered cold and boiling water flow from the

tap is slow

• Generally this indicates that the filter cartridge is clogged

with contaminants and needs replacing. You can check by

operating the filtered water with no cartridge in the filter

housing.

The flow of filtered water has slowed to an unacceptable

level inside the 6 months change period

• The period between cartridge replacements is not

guaranteed; it is an estimate based on filtering mains

water of average quality. Please bear in mind that water

quality varies from locality to locality and situation to

situation. In areas with higher than average turbidity

(particle contamination) more frequent cartridge changes

may be necessary.

The boiling water function is dispensing cold water

instead of boiling water

• Check that the electrical supply is correctly connected.

• Check the 13amp fuse in the plug.

• If you are still experiencing problems after completing

these steps please contact Franke FilterFlow on 01603

875 468

Unsightly deposits on the surface of a cup of tea

• In hard water areas a ‘scum’ can appear on the surface of

hot tea. Although unsightly it is completely harmless. The

cause is related to the precipitation of calcium and

magnesium in hard water regions and a reaction with the

tea bag material. Changing tea bags will often remedy the

problem. Alternatively you can consider switching to a

Franke 06 cartridge which will remove the calcium and

magnesium however please note this filter will need to be

change more frequently, perhaps every 2- 3 months. The

life of the Franke 06 is dependent on the hardness of the

water supply and the volume of water passed through it, so

is impossible possible to predict, however the return of the

‘scum’ on hot drinks is an indication it should be replaced.

Foam is forming on the surface of hot drinks

• This is caused by a combination of the agitation of the

boiling water creating millions of tiny air bubbles and the

amount of oil in the teabag material. To reduce the problem

try filling the teapot or cup with boiling water and allowing

the water to settle before dropping the tea bag in rather

than running the boiling water directly onto the teabag, or

perhaps experiment with different brands of tea bag.

Milky or cloudy appearance of the filtered water

• A new filter cartridge has a significant amount of air

trapped in the microporous structure of the cartridge.

This will form tiny bubbles and give the water in the glass

a milky appearance that will soon disperse when left to

stand for a few moments. This may continue for 2 to 3

weeks until the cartridge is fully conditioned.

Tiny black specks in the water

• Tiny black specks may appear initially in the water. These

are harmless particles of carbon; residues from the

manufacturing process. Allow the filtered water to

continue flowing for a while until they are completely

flushed through.

Condensation is dripping from exposed copper pipes

adjacent to the boiler

• This can be reduced by wrapping insulation around the

pipes in question.

Page 14

14

Guarantee

This Franke product carries a 3 year warranty against material

and manufacturing defects. The warranty will be valid from the

date of purchase as shown on the sales invoice. Please keep

the invoice for your records. This appliance is intended for

domestic use only. The warranty does not apply to products

installed outside a domestic environment.

Warranty

What is covered by the Franke guarantee?

• The repair or replacement of all or part of your system

if your system is found to be defective due to faulty

materials or manufacture within 3 years of purchase

at Franke’s discretion.

• If any part is no longer available, or out of manufacture,

Franke reserve the right to replace it with a suitable

alternative.

Terms and conditions of the Franke 3 year guarantee

• The guarantee is valid for the UK and Republic of Ireland.

• The guarantee becomes effective at the date of purchase

or at the date of delivery if this is later. Proof of purchase

is required under the terms of the guarantee.

• The guarantee provides benefits in addition to your

statutory consumer rights.

Franke does not guarantee the repair or replacement of a

product that has failed for any of the following reasons:

• Faulty installation, repairs or alterations not in accordance

with the installation guide.

• Normal wear and tear.

• Accidental damage or faults caused by negligent use

or care; misuse; neglect; careless operation and failure

to use the system in accordance with the Omni operating

guidelines.

• Failure to maintain the water filter in accordance with

the instructions.

• The use of anything other than genuine Franke

replacement parts, including the water filter cartridge.

The use of the filter system for anything other than

normal domestic household purposes.

• Failures of, or failures caused by, parts not supplied with

the Omni system.

How do I make a claim under my Franke 3 year guarantee?

• If you are in doubt about what is covered by your

guarantee, or wish to discuss a claim, please call Franke

FilterFlow on 01603 875 468 Monday to Friday between

the hours of 9.00am and 5.00pm.

• If you are calling for the first time please have your receipt

to hand so that we can record your date of purchase.

• Franke FilterFlow is the exclusively appointed after sales

agent and water filter supplier for the Franke Omni 4in1

Boiling Water System.

• The company reserves the right to alter, change or modify

product specifications without prior notice.

Page 15

15

Declaration of conformity

The Omni boiler complies in accordance

with the following directives:

2006/95/EC Low Voltage Directive

2011/65/EU RoHS Directive

2009/125/EC Eco Design Directive

Protection Level: IP20

The Omni boiler conforms to the

requirements of the relevant EU guidelines.

The symbol on the product or on its

packaging indicates that this product may

not be treated as household waste. Instead

it shall be handed over to the applicable collection point for the

recycling of electrical and electronic equipment.

By ensuring this product is disposed of correctly, you will help

prevent potential negative consequences for the environment

and human health, which could otherwise be caused by

inappropriate waste handling of this product.

For more detailed information about recycling of this product,

please contact your local city offi ce, your household waste

disposal service or the shop where you purchased the product.

The Franke Omni 4-in

-1 system is a product designed in

conjunction with Greg Rowe Ltd, England, and is protected by

the following patent applications

GB1515295.2, GB1515293.7, EP15182884.5, US14/837,640,

and in China.

NutRunna

®

is a registered trademark.

© Greg Rowe Ltd. All Rights Reserved

Page 16

After Sales Service

Franke FilterFlow

Old Winery Business Park

Chapel Street

Cawston, Norfolk

NR10 4FE

Phone: +44 (0)1603 875 468

Email: info@frankefilterflow.com

Franke UK Limited

West Park, MIOC

Styal Road,

Manchester

M22 5WB

Phone: +44 (0)161 436 6280

Fax: +44 (0) 161 436 2180

Email: info.uk@franke.com

www.franke.co.uk www.frankefilterflow.co.uk

Loading...

Loading...