Page 1

3-IN-1 INSTANT BOILING WATER SYSTEM

EN

3-in-1 Instant boiling water system

Installation and user manual

Page 2

EN

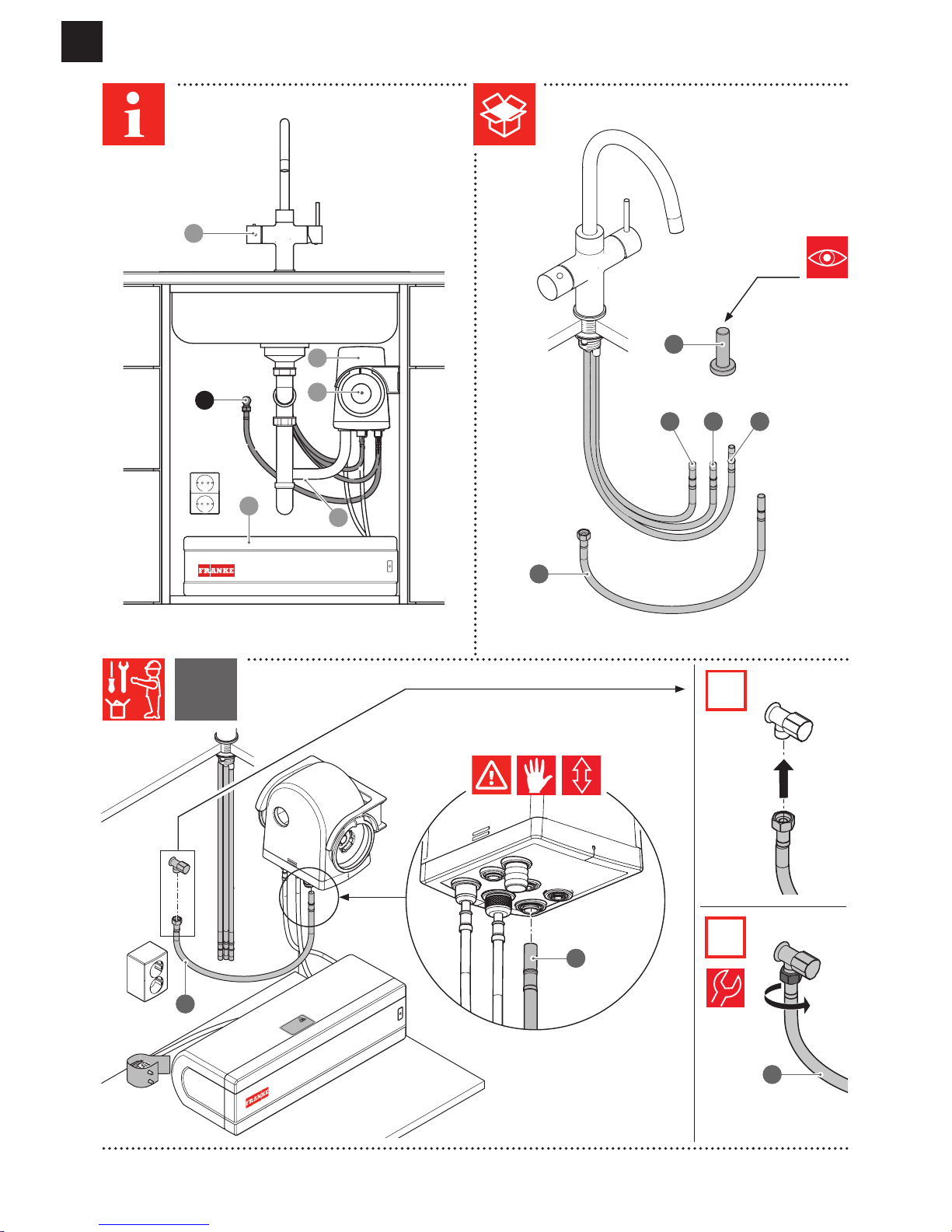

2

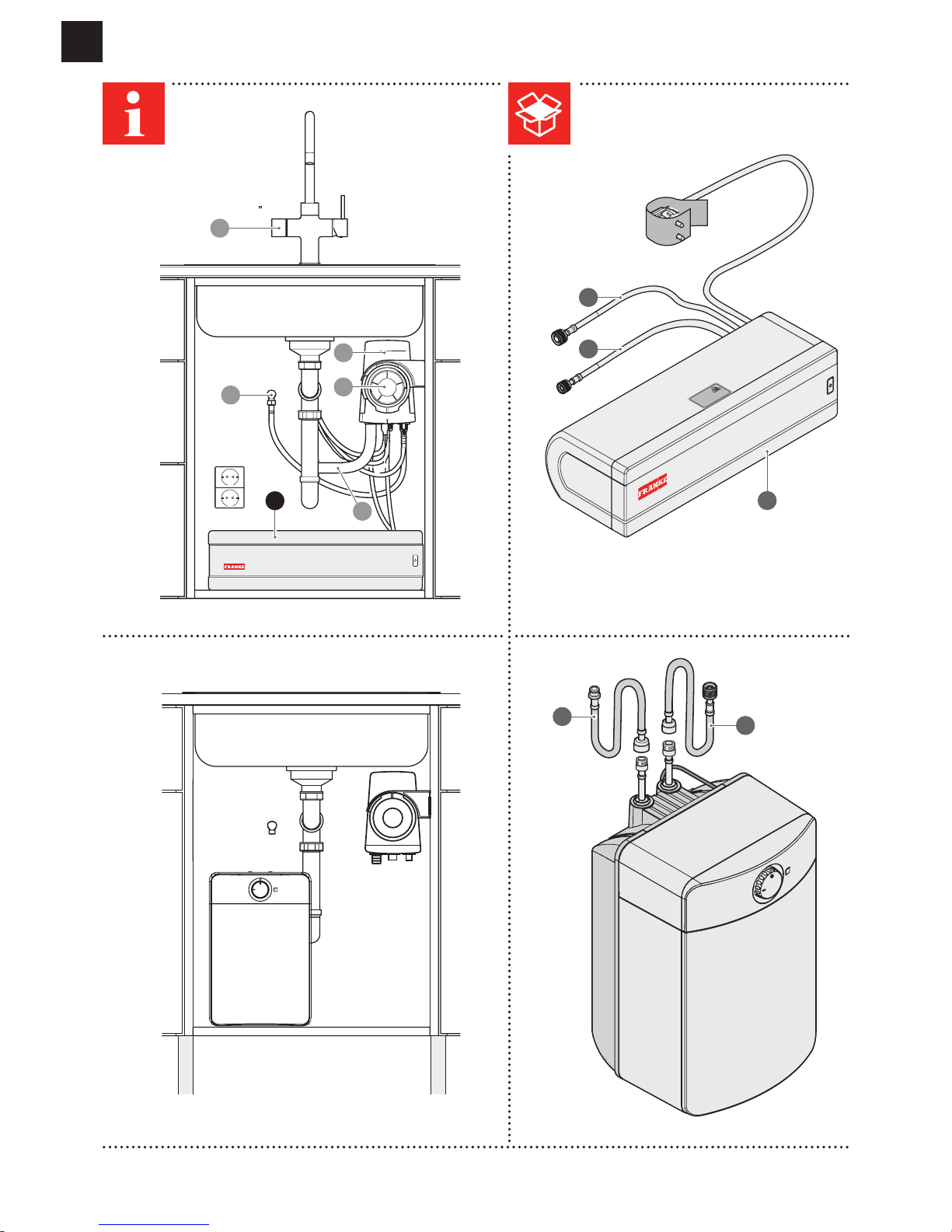

3x

A

B F

H

J

I

C G

D E

1

2

6

5

4

3

Page 3

EN

H

I

J

J

J

1

2 3

4

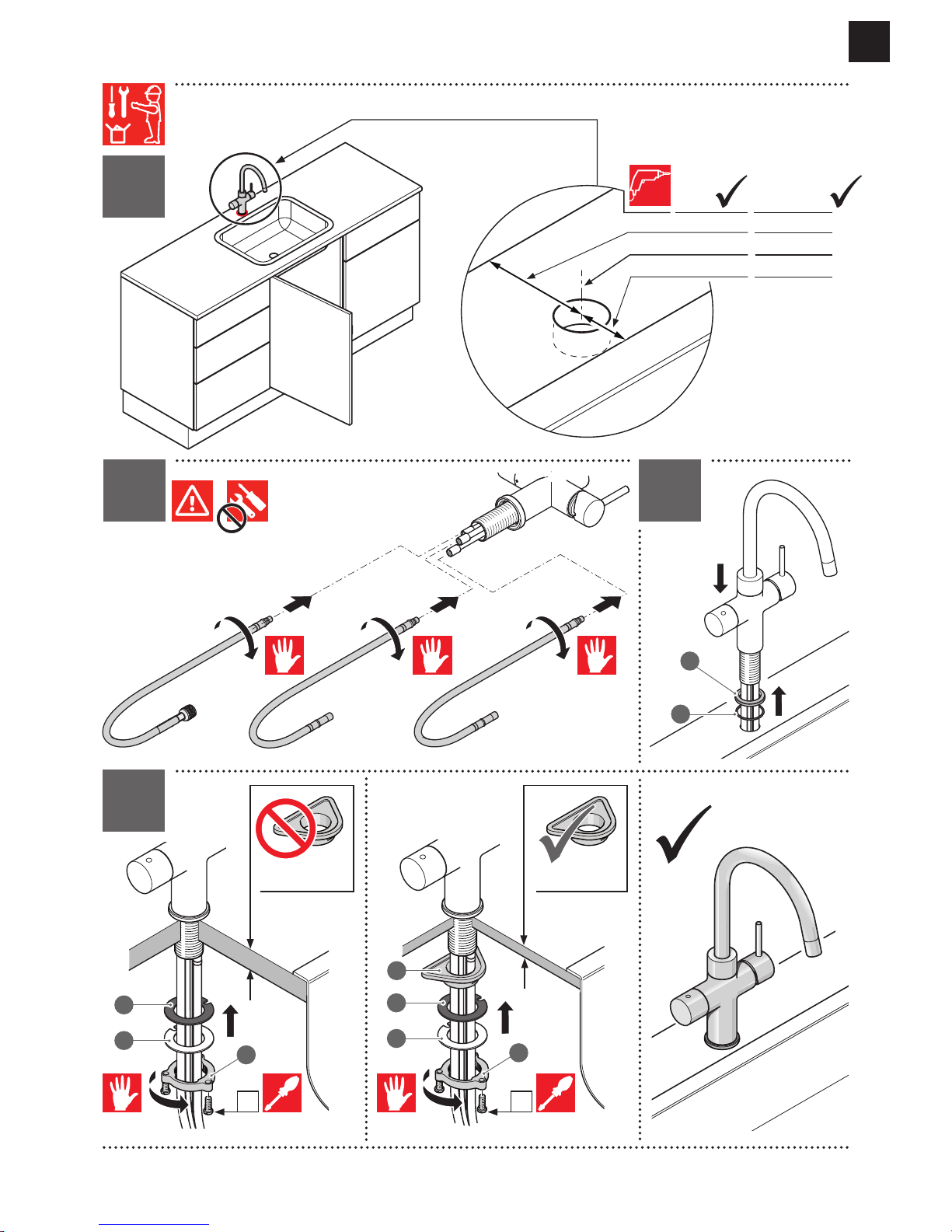

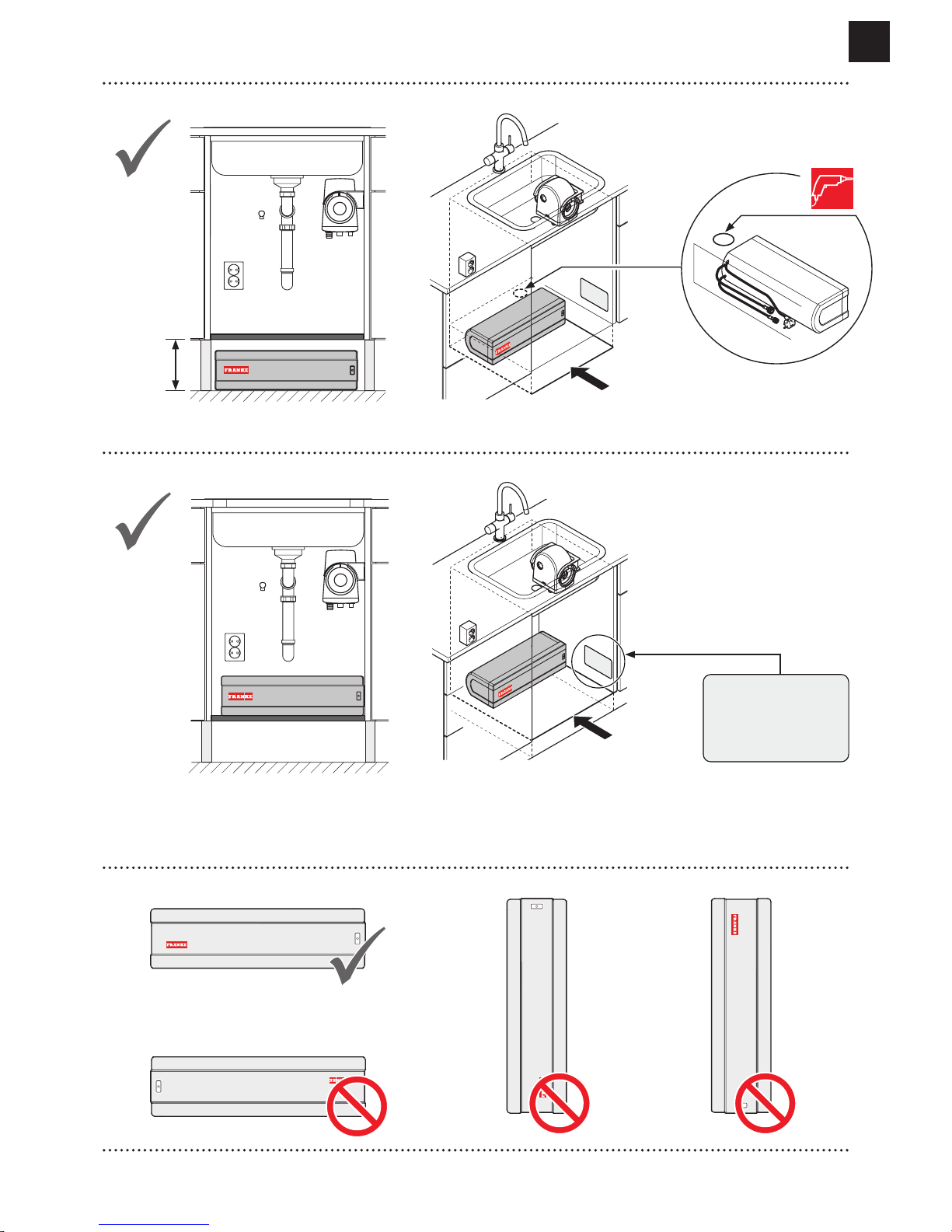

< 10 mm

3x

> 10 mm

3x

RVS

min 30 mm

min 40 mm

Ø 35 mm

Chroom

min 30 mm

min 60 mm

Ø 35 mm

min 30 mm min 30 mm

min 40 mm min 60 mm

RVS Chrome

∅ 35 mm ∅ 35 mm

B

C

F

F

D

G

G

E

E

Page 4

EN

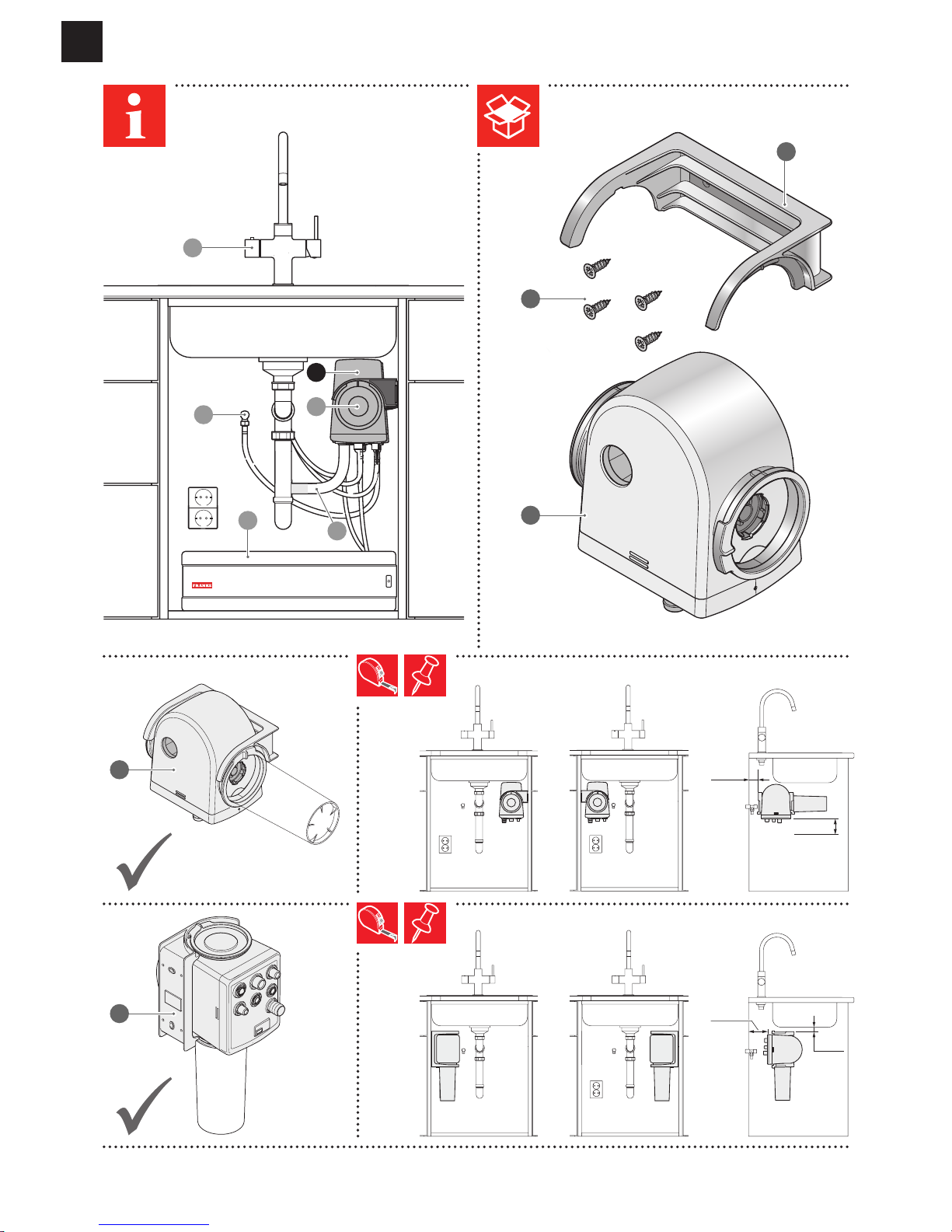

>10 cm

> 2 cm

> 10 cm

> 2 cm

>10 cm

> 2 cm

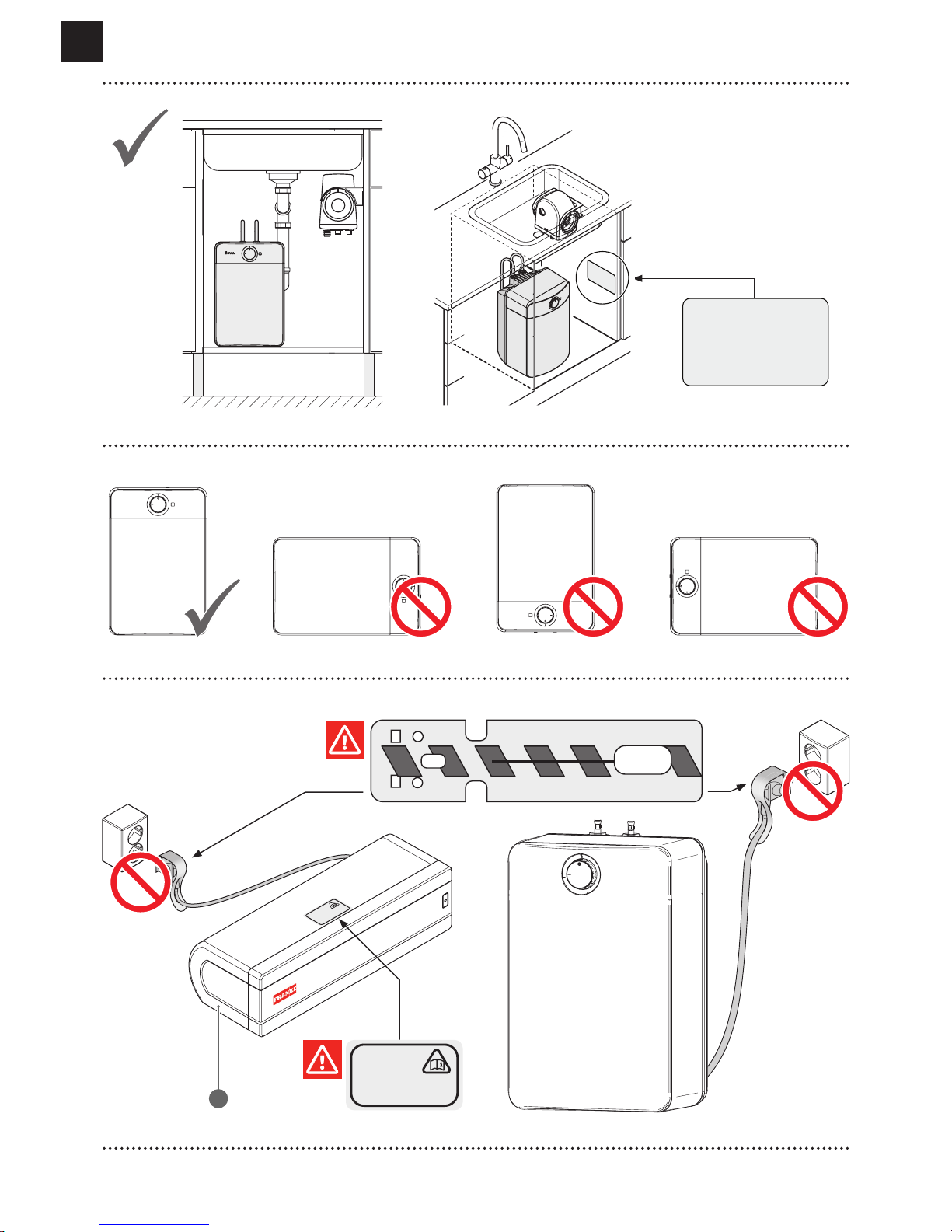

1

2

6

5

4

3

M

M

M

L

K

Page 5

EN

M

M

M

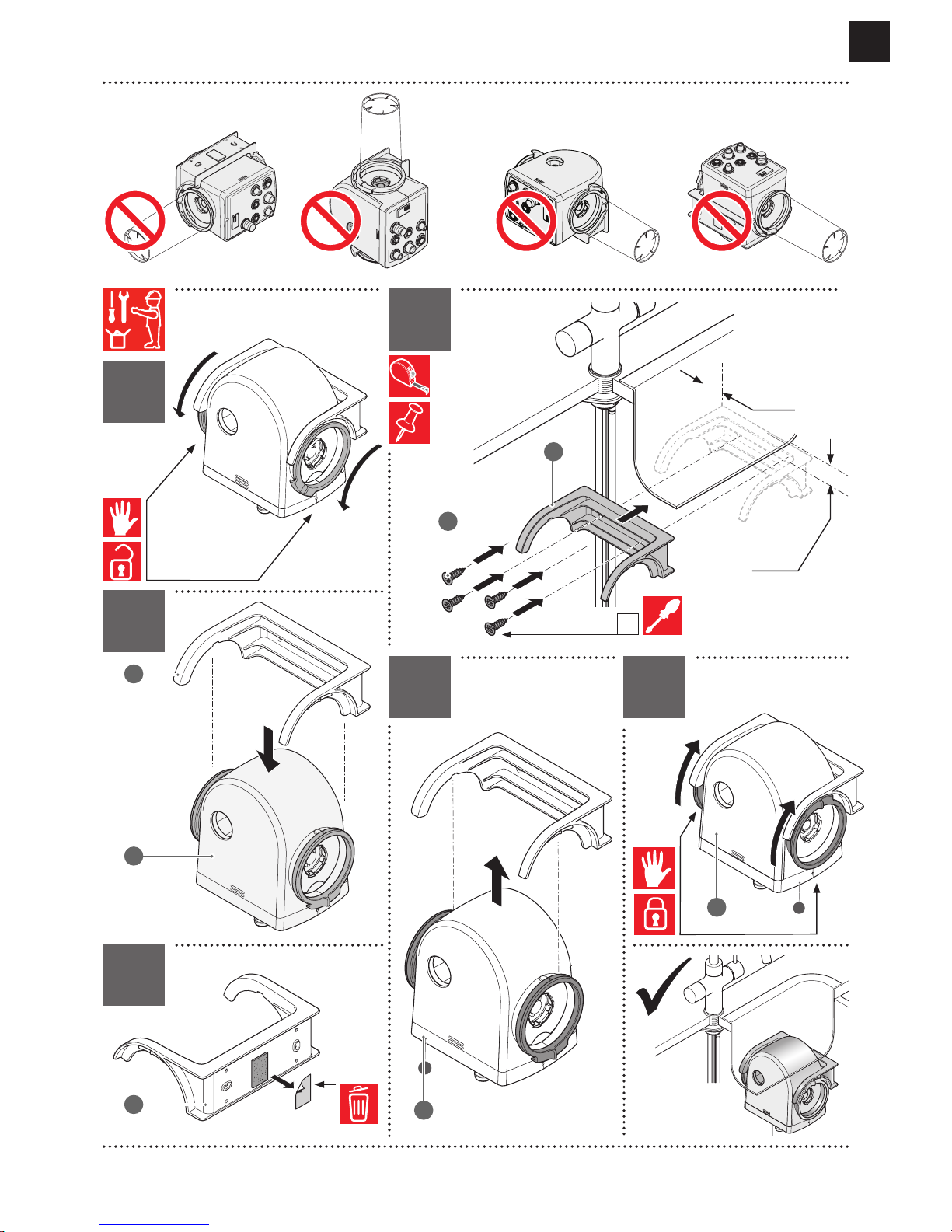

> 6 cm

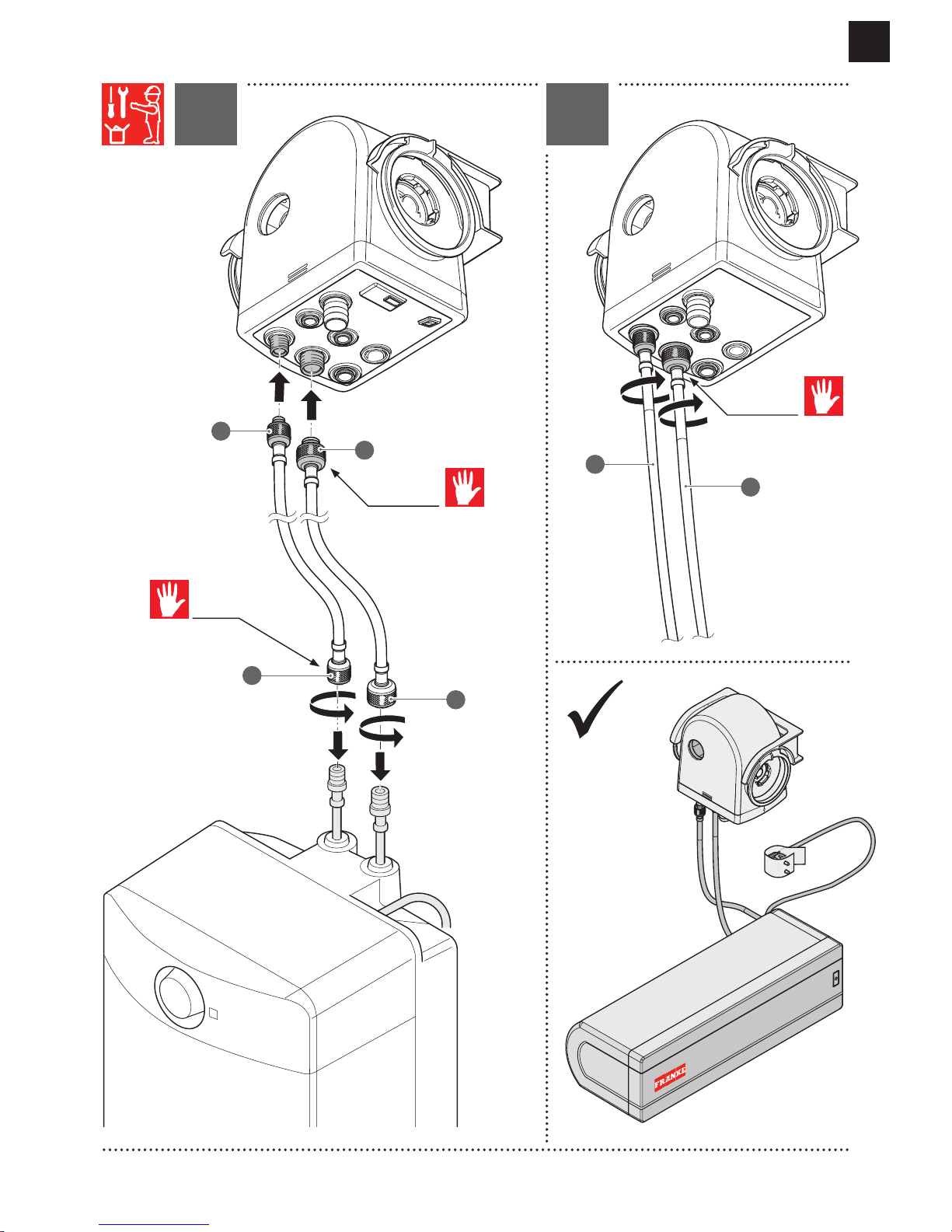

1

2

4

5 6

3

4x

> 2 cm

L

K

K

M

M

M

H

Page 6

EN

DEZE ZIJDE BOVEN

THIS SIDE UP

DIESE SEITE NACH OBEN

CE CÔTÉ VERS LE HAUT

1

2

6

5

4

3

N

O

P

N

O

Page 7

EN

TYPE- & SERIENUMMER

TYPE- & SERIENUMMER

TYPE- & SERIENUMMER

TYPE- & SERIENUMMER

TYPE- & SERIAL NUMBER

TYPE- & SERIENUMMER

TYPE- & SERIENUMMER

TYPE- & SERIAL NUMBER

TYPE- & SERIAL NUMBER

Ø 60 mm

> 150 mm

Page 8

EN

I

DEZE ZIJDE BOVEN

THIS SIDE UP

DIESE SEITE NACH OBEN

CE CÔTÉ VERS LE HAUT

DEZE ZIJDE BOVEN

THIS SIDE UP

DIESE SEITE NACH OBEN

CE CÔTÉ VERS LE HAUT

VUL EERST DE BOILER MET WATER!

ZUERST DEN SPEIGER MIT WASSER FÜLLEN!

FIRST FILL THE WATER HEATER WITH WATER!

REMPLIR D’ABORD LE BOILER AVEC L’ EAU!

DEZE ZIJDE BOVEN

THIS SIDE UP

DIESE SEITE NACH OBEN

CE CÔTÉ VERS LE HAUT

VUL EERST DE BOILER MET WATER!

ZUERST DEN SPEIGER MIT WASSER FÜLLEN!

FIRST FILL THE WATER HEATER WITH WATER!

REMPLIR D’ABORD LE BOILER AVEC L’ EAU!

DEZE ZIJDE BOVEN

THIS SIDE UP

DIESE SEITE NACH OBEN

CE CÔTÉ VERS LE HAUT

TYPE- & SERIAL NUMBER

TYPE- & SERIENUMMER

TYPE- & SERIENUMMER

P

Page 9

EN

1 2

N

N

N

O

O

O

Page 10

EN

I

DEZE ZIJDE BOVEN

THIS SIDE UP

D

IESE SEITE NACH OBEN

CE CÔTÉ VERS LE HAUT

1

2

Option

1

1

2

6

5

4

3

R

Q

Q

Q

Q

I

J

H

Page 11

EN

H

I

DEZE ZIJD

E BOV

EN

THIS

SIDE UP

D

IE

SE SEIT

E

N

AC

H

O

BEN

CE C

Ô

TÉ

V

ERS LE

H

AU

T

Option

2

3

I

I

J

J

H

H

Page 12

EN

R

R

DEZE ZIJD

E

BOV

EN

THIS

SID

E U

P

DIE

SE

SEIT

E NAC

H

O

BEN

CE C

Ô

TÉ

V

ERS

LE

H

AU

T

R

1

2

H

H

J

J

I

I

R

R

Page 13

EN

> 12 cm

1

1

2

6

5

4

3

T

V

U

S

Page 14

EN

32

5

6

4

T

V

U

U

S

S

Page 15

EN

1

2

3

4

120.0305.558

W

W

1

2

6

5

4

3

W

Page 16

EN

5

Page 17

EN

TABLE OF CONTENTS

About this manual 19

Safety information 19

Gener a l 19

3-in-1 tap 20

Boiler 20

M Box 20

Filter cartridge 20

Water quality requirements 20

Installation instructions 20

Product Information 21

Syste m 21

3-in-1 tap 21

Boiler 22

M-Box 22

Installation instructions for push fitting 23

Icon legend 23

Installation 24

General starting points for installation 24

Installation video 24

Installation steps 24

Switching on for the first time 25

Flushing 25

Operation 26

Operation of mixer lever 26

5 litre boiler status indicator LED 26

Boiler ECO mode 27

Emptying boiler 27

Messages and Malfunctions 28

Boiler messages 28

Reset maximum protection of 10 litre boiler 28

Page 18

EN

Troubleshooting 29

Maintenance 31

General maintenance 31

Replacing filter cartridge 31

Descaling tap sieve 31

M- Box 31

Disposal 32

Declaration of Conformity 32

Page 19

EN

ABOUT THIS MANUAL

This manual contains important information on the

safe and proper installation and commissioning of

the product.

FRANKE reserves the right to make modifications

to the product without prior notice. All information

correct at time of issuance.

Carefully read the user manual before using the

device.

Keep the user manual.

Use the device described in this user manual only

according to the intended use.

Symbol

Meaning

Warning symbol. Warning against risks of

injury.

Actions in safety and warning notes to

avoid injury or damage.

Action step. Specifies an action to be done.

Result. Result of one or more action steps.

Precondition that has to be fulfilled before

performing the following action.

SAFETY INFORMATION

General

Install the product as described in this manual and

in accordance with the applicable installation, safety

and local water supply regulations!

Do not use the product for purposes other than

those for which it is intended as described in this

manual.

The product must not be modified.

This product and/or system may be operated by

children above the age of 12 and by persons with

reduced physical, sensory or mental capacities, or

who lack the necessary experience or knowledge,

only under supervision or after being instructed

in the safe use of the product and when they are

aware of the hazards that may arise from the use

of the product and/or system.

Cleaning and maintenance by the user must not

be performed by children or by persons with

reduced physical, sensory or mental capacities, or

who lack the necessary experience or knowledge,

without supervision.

Prevent children from playing with the product

and/or system.

This product and or system is intended for use in

domestic and similar environments, such as:

- Staff kitchens in stores, offices and other

working environments;

- By guests in hotels, motels and other similar

residential environments;

- Bed and breakfast accommodation and

other similar residential environments.

Use in other environments in consultation with the

manufacturer of the product and/or system.

If the power lead with plug is damaged, it must be

replaced by the manufacturer, the manufacturer’s

customer service or a qualified person in order to

avoid risks.

If necessary, lubricate O-rings only with silicone

oil.

In order to avoid freezing, the product may only

be installed in frost-free rooms.

Safety instructions must be observed in order

to avoid physical injury and/or damage to the

product and/or system.

Maintenance instructions must be observed in

order to avoid damage and excessive wear.

As a result of the ongoing improvement of our

products and/or systems, illustrations in this

document may differ from the appliance as

delivered.

If available, you can download the latest version of

the manual via our website: www.franke.com

Franke cannot be held responsible for costs,

damage or personal injury if the product is not

operated in accordance with the instructions

given in this manual.

Tap, M-Box and boiler model may differ from the

model illustrated in the manual.

Ensure there is sufficient ventilation for the tank

to avoid overheating

Page 20

EN

3-in-1 tap

Avoid burns and scalding and pay attention when

using hot water. The temperature of the hot water

may be higher than 55°C.

Avoid burns and scalding and pay attention when

using boiling water. The temperature of the water

may be higher than 100°C.

Tiled and stone sinks will not withstand boiling

water; the difference in temperature can cause

these to crack. Always open the cold water tap

when pouring out boiling water and preferably

pour the boiling water directly into the drain.

Boiler

Before commissioning, ensure that the boiler is

filled with water.

Never pick up or carry the boiler with the hoses or

the mains lead.

M Box

The appliance is not intended for connection to

the hot water supply (hot-fill).

The drain hose must be connected with a

steady down gradient in order to ensure the

correct function of the siphon in the M-Box. The

connection point of the drain hose should be

downline of the sink siphon.

Filter cartridge

The use of a water filter is mandatory to protect

the product against lime scale deposits.

After storage at a temperature of 0°C, the

filter must first be stored for 24 hours at room

temperature before it is installed.

The filter cartridge must not be opened or

damaged.

The filter cartridge and the system must be

intensively flushed after a prolonged standstill

period and/or during maintenance work (2 litres

of flushing water after 1 week standstill; 10 litres

of flushing water after 4 weeks’ standstill).

The filter cartridge must be replaced if, after

commissioning, it has not been in operation for 3

months.

Water quality requirements

pH value

7 – 9.5

Iron content (Fe)

< 0.2 mg/l

Chlorine content (Cl)

< 150 mg/l

Conductivity

< 125 mS/m

Chemical additions

Not permitted

Installation instructions

NEVER use serrated tools in order to avoid

damage. Where necessary, always use the

appropriate tools for tightening the coupling.

Minimum bending radius after installation

∅

min.

∅

min :

DN 6 = ∅ 50 mm

DN 8 = ∅ 60 mm

DN10 = ∅ 70 mm

DN13 = ∅ 90 mm

min. 2 ∅ e

Without bends after installation

Without bend immediately after connection

Without tension after installation

Without torsion after installation

Page 21

EN

PRODUCT INFORMATION

System

Water supply pressure (min.)

200 kPa

/

29 psi / 2 bar

Water supply pressure (max.)

400 kPa

/

58 psi / 4 bar

Flow rate boiling water 2 - 4 l/min *

Flow rate cold water 5 - 9 l/min *

Flow rate

hot water 5 - 9 l/min *

* The flow rate varies, depending on the water supply pressure and the type of tap.

3-in-1 tap

158

171

117

190

234,5

334,5

59 59

8078

52

MAX

34min

80

59 59

362,5

78

52

MAX

34min

239,5

15

189

171

110

158

Irena 3-in-1

80

59 59

362,5

78

52

MAX

34min

239,5

15

189

171

110

158

Minerva 3-in-1

191

407

276

96

∅35

96

181 29

ø

25

63,5

73

25º

200

330

304

96

∅35

96

180

63,5

73

25º

ø25

190

234,5

59 59

52

MAX

34min

Heli x 3 -in -1

200

330

304

96

∅35

96

180

63,5

73

25º

ø25

158

171

117

190

234,5

334,5

59 59

8078

52

MAX

34min

80

59 59

362,5

78

52

MAX

34min

239,5

15

189

Mondial 3-in-1

Page 22

EN

Boiler

203

218

300

452

299

145

522

200

188

406

5 litre boiler

191

96

∅35

96

181 29

ø

25

63,5

73

25º

203

218

300

452

299

188

406

10 litre boiler

Boiler

5 litre 10 litre

Dimensions [H x W x D] 145 x 522 x 200 mm

452 x 300 x 285 mm

Contents 4.7 l

10 l

Voltage 230 VAC

230 VAC

Power 1500 W

2200 W

Load 7.0 A

10 A

Energy consumption at standstill 25 W 28 W

IP classification IP 24D IP 24D

Storage temperature 115°C 108°C

Delivered water temperature 60° (±5)* and 100°C

60° (±5)* and 100°C

Heating time [ΔT 100 K] 23 min 35 min.

Operating pressure (max.) 600 kPa / 87 psi / 6 bar 600 kPa / 87 psi / 6 bar

Suitable for hot-fill ** No No

** The system must always be connected to a cold water supply.

M-Box

191

407

276

96

96

181 29

ø

25

63,5

73

25º

180

63,5

73

25º

ø25

203

218

188

406

M-box

Temperature of mixed water 55°C

Maximum water pressure 400 kPa / 58 psi / 4 bar

Filter system Franke Pro M filter

Filter cartridge dimensions [h x w] 245 x 95 mm

Ambient temperature 4 - 30°C

Please note that some parts may not be available in your country.

Page 23

EN

Installation instructions for push fitting

Installing the push fitting

Push the hose into the push fitting (fig. 2A).

Pull the hose carefully up and down and check

whether it is fitted securely (fig. 2B).

2A 2B

Remove the push fitting

Push in the ring on the push fitting (fig. 1C).

Pull the hose out of the push fitting (fig. 1D).

2C 2D

Icon legend

Product information

Scope of Delivery

Montage

Tooling Equipment

Do not use tools

Measure

Drill

Screw

Spanner

Cut

Tighten finger-tight

Check push fitting

Warning Sign / Caution / Hazard

Inspect

Determine position

Open

Close

Discard

Do not / Forbidden result

Do, OK! / Result

Installation step successfully completed

url / video link

Page 24

EN

INSTALL ATION

General starting points for installation

Perform the following steps before starting installation.

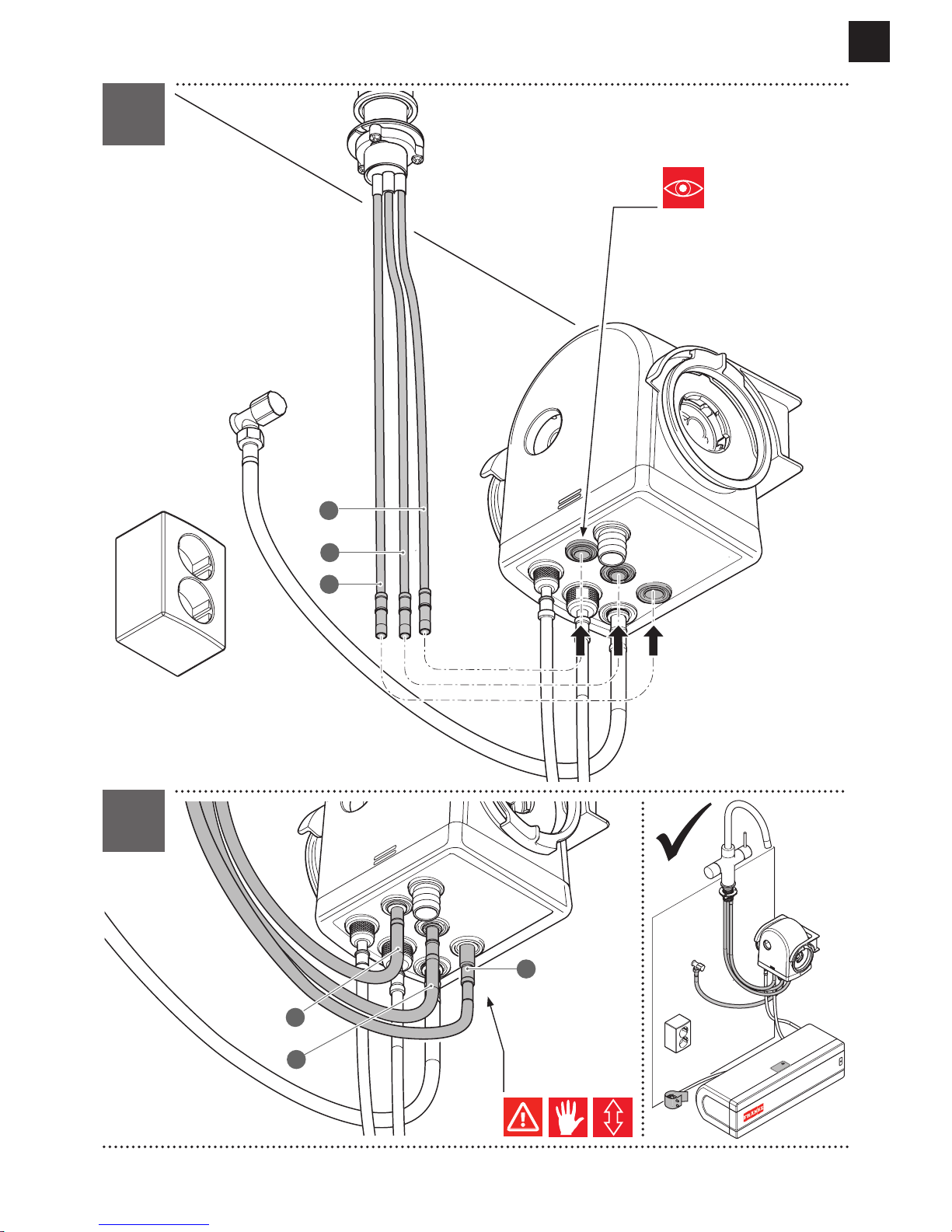

Stop valves must already be installed. See Option at page 9/10, if stop valves have not been installed.

Close the stop valves.

In existing installations, remove the tap, hoses and boiler if still in place.

Mark the existing cold and hot water connection.

Do not connect the M-Box to a hot water pipe.

There must be two wall plug sockets available for connection.

Installation video

https://youtu.be/4KPGVG_MoZg

Installation steps

Installing 3-in-1 tap (see page 2)

Installing M-BOX (see page 4)

Installing 5 or 10 litre boiler (see page 6)

Connecting 3-in-1 tap (see page 9)

Connecting 3-in-1 tap with hot water out of existing pipe (see page 11 )

Connecting the drain line (see page 12)

Commissioning (see page 14)

Page 25

EN

SWITCHING ON FOR THE FIRST TIME

Flushing

9 Ensure that the boiler is filled with water!

5 litre boiler

Operate the mixer tap and flush with warm water

for 1 minute (fig.3A).

Insert the plug into the wall plug socket, the LED

lights up white (fig. 3B).

Switch on the boiler, the LED lights up blue (fig. 3C).

3C3B

3A

9 Water reaches boiling temperature after 25 minutes.

Push and turn the selector knob and flush with

boiling and filtered water (fig. 3D; see ‘Operation

of selector knob‘)

Inspect the installation for leaks after

commissioning (fig. 3E).

3D 3E

WARNING: If, during heating, no expansion

water has escaped after 10 minutes:

Switch off the power supply immediately and turn on

the boiling water tap to relieve the water pressure.

Flush hot water for 1 minute.

Flush boiling water until the water is cold.

Repeat the process three times to flush the

complete system.

10 litre boiler

Operate the mixer tap and flush with warm water

for 1 minute (fig.3A).

Insert the plug into the wall plug socket.

Turn the ON/OFF knob to position „I” (fig. 3F)

to switch the boiler ON. The water will now be

heated.

3F

The status of the boiler is

signalled by a lamp alongside

the rotary knob. When the

water is being heated, this

lamp lights up red.

9 Water reaches boiling temperature after 35 minutes.

Push and turn the selector knob and flush with

boiling and filtered water (fig. 3D; see ‘Operation

of selector knob‘)

Inspect the installation for leaks after

commissioning (fig. 3E).

WARNING: If, during heating, no expansion

water has escaped after 10 minutes:

Switch off the power supply immediately and turn on

the boiling water tap to relieve the water pressure.

Flush hot water for 1 minute.

Flush boiling water until the water is cold.

Repeat the process three times to flush the

complete system.

Page 26

EN

OPERATION

Operation of mixer lever

Select cold water (fig. 4A).

4A

Select hot water (fig. 4B).

4B

Turn on mixer tap (fig. 4C).

4C

Operation of selector knob

Hold the object to be filled close to the tap so

that the object surrounds the delivery opening

of the tap. This will prevent (hot) water from

splashing.

For the optimum result when making coffee or

tea, allow around 1 cup of water to run out before

filling the pot. In this way the air bubbles in the

water disappear so that no foam forms on the

surface of the tea.

5 litre boiler status indicator LED

LED colour

(normal)

LED colour

(ECO mode)

LED

action

Boiler status Description

White White Steady Boiler OFF Wait mode

Blue Pale blue Steady Boiler ON - water cold Water temperature < 45 °C

Orange Violet Steady Boiler ON - water hot 45°C < Water temperature < 103°C

Red Pink Steady Boiler ON - water boiling Water temperature > 103°C

Green Green Steady ECO mode Water is not heated unless

water temperature is < 50°C

Page 27

EN

Boiler ECO mode

Switch on ECO mode:

- Hold depressed for 4 seconds, LED is green.

Switch off ECO mode:

- Hold depressed for 10 seconds, LED is not

green.

4E

4D

When the boiler is switched on, the temperature

of the water is automatically held constant so that

boiling water is available at any time of the day. In

order to prevent the temperature of the boiler being

unnecessarily held constant, you can use the energysaving ECO mode. After activation, ECO mode comes

into operation every day at the same time. The

duration of ECO mode is 6 hours and the LED should

light up green during this time.

If using a Switch, the setting of the ECO mode should

be cancelled when the boiler is switched off. ECO

mode then has to be set again.

Note: Before commissioning the boiler, see

"Flushing".

Switching off the boiler

5 litre boiler:

Press the ON/OFF knob; the LED lights up white

(fig 4D).

Remove the plug from the plug socket.

10 litre boiler:

Turn the ON/OFF knob to the „○” position

(fig 4E).

Remove the plug from the plug socket.

Emptying boiler

9 Remove the plug of the boiler from the wall plug

socket.

9 Turn on the boiling water tap.

9 Wait until cold water runs out.

9 Turn off the boiling water tap.

9 Close the stop valve.

9 Turn on the boiling water tap.

9 Wait until water no longer runs out.

9 Turn off the boiling water tap.

9 Disconnect the lines from the boiler.

Remove the boiler.

Allow the water from the hoses and the boiler to

drain into the sink.

Page 28

EN

MESSAGES AND MALFUNCTIONS

Boiler messages

Boiler malfunction LED

LED colour LED action Description

Red 1 second on / 1 second off Hardware fault

Red / white 1 second red / 1 second white Hardware fault - sensor is defective

Red / yellow 1 second red / 1 second yellow Boiled dry - no water in the boiler

Red / green 1 second red / 1 second green Boiler is upside down or installed upright

Red / orange 1 second red / 1 second orange Maximum protection has tripped - boiler too hot (*)

*) Switch off the boiler and contact Customer Services.

Reset maximum protection of 10 litre

boiler

9 This work may only be carried out on instruction

from Franke.

9 If the boiler was switched on while it was not filled

with water, you must not reset the boiler. In this

case the thermostat and the maximum protection

device must be replaced. Contact Franke or your

installation company.

9 Switch the boiler OFF.

9 Remove the plug of the boiler from the wall plug

socket.

9 Remove the ON/OFF knob by pulling it forwards

(fig. 5A).

9 Loosen the screw behind the ON/OFF knob

(fig 5B).

9 Remove the protective cap by carefully pushing

forwards (fig. 5C).

9 Reset the maximum protection device by pressing

the button (fig. 5D)

9 Carefully fit the protective cap again. Take care

that the wiring is not trapped.

9 Insert and tighten the screw.

9 Push the ON/OFF knob onto the shaft again.

9 Ensure that the boiler is filled with water.

Insert the plug into the plug socket.

Switch the boiler ON.

5A

5C

5B

5D

Reset message of 5 litre boiler

Reset the boiler if an error message is displayed.

Hold the ON/OFF knob depressed for 5 seconds.

The message is reset and the boiler switches OFF.

Now turn the boiler ON again.

If the same error message appears again, switch off

the boiler and contact Franke or your installation

company.

Page 29

EN

TROUBLESHOOTING

Water leaks

Cause Remedy

Connection leaking Inspect the coupling(s) and re tighten, if necessary

Hose(s) leaking Inspect the hose(s) and replace the leaking hose(s)

Boiler leaking

Remove the plug of the boiler from the wall plug socket. Shut off the

water supply. Contact Franke.

Tap leaking Shut off the water supply. Contact Franke.

M-Box leaking

Remove the plug of the M-Box and the boiler from the wall plug socket.

Shut off the water supply. Contact Franke.

Tap supplies no water

Cause Remedy

Hose(s) kinked Inspect the hose(s) and straighten the kinked hose(s)

The main water valve is closed Open the main water valve

The stop valve in the kitchen cabinet

is closed

Open the stop valve.

Filter not installed in M-Box Install filter in the M-Box.

Tap supplies no boiling water

Cause Remedy

Hose(s) kinked Inspect the hose(s) and straighten the kinked hose(s)

The M-Box is defective Contact Franke.

The water from the tap is not boiling

Cause Remedy

The plug of the boiler has not been

inserted into a wall plug socket.

Insert the plug into an earthed wall plug socket.

The wall plug socket has no power

supply

Check the electricity grid and repair the interruption.

The electric circuit has failed due to an excessive load. The boiler

cannot be connected to the same electric circuit as a dishwasher.

The boiler is OFF (wait mode) Switch the boiler ON.

The boiler has not heated up

completely.

Wait until the boiler has heated up.

The boiler has a fault. Reset the boiler.

The boiler is defective Contact Franke.

The M-Box is defective. Contact Franke.

Page 30

EN

Tap supplies no hot water

Cause Remedy

Hose(s) kinked. Inspect the hose(s) and straighten the kinked hose(s).

Boiler not functioning. See table “The water from the tap is not boiling”

Hot water appliance not functioning.

(if hot water is not being used from

the M-Box)

Consult the manual of your hot water appliance.

The boiler causes a short-circuit

Cause Remedy

There is a short-circuit in the electric

wiring or the heater element of the

bo iler.

Remove the plug of the boiler from the wall plug socket.

Contact Franke.

The boiler causes a short-circuit.

No expansion water from the M-Box

Cause Remedy

No water in the boiler. Fill the boiler with water.

The boiler is OFF (wait mode) Switch the boiler ON.

The boiler has a fault. Reset the boiler.

The boiler is defective Contact Franke.

Pressure relief valve in the M-Box is

defective.

Remove the plug of the M-Box and the boiler from the wall plug socket.

Shut off the water supply. Contact Franke.

Page 31

EN

MAINTENANCE

General maintenance

Clean the tap only with a little detergent and a

damp cloth. Then rinse the tap with some water

and wipe it down with a dry cloth.

Do not use cleaning agents containing a solvent

or acid, such as lime scale removers, household

vinegar or cleaning agents with acetic acid. These

substances damage the surface. The tap will

become matt and scratched.

Lime scale deposits can be prevented by drying

the tap after use.

If lime scale deposits nevertheless occur, remove

these using a citric acid-based cleaning agent.

Check regularly whether water drips out of the

inlet combination. This dripping is a sign that the

inlet combination is (still) working correctly.

Always use original Franke parts for maintenance

or repair. This guarantees the safety and proper

function of the product and safeguards any

warranty claims.

Replacement or repair of parts may only be

carried out by an approved servicing company or

by Franke Service.

Replacing filter cartridge

Filter (120.0305.558) lifespan

Water hardness (˚DH) Months

<10˚DH 12

10 -18˚DH 9

>18˚DH 6

The filter cartridge must be changed at regular

intervals. Neglecting to change the filter as

indicated by this manual may invalidate your

warranty.

Descaling tap sieve

Always use a citric acid-based descaling agent.

Other substances will damage the material!

Loosening and tightening can be made easier by

wrapping an elastic band around the sleeve of

the tap sieve. Take care that the sleeve of the tap

sieve is not damaged by the use of tools.

Over the course of time, lime scale deposits will

appear on and alongside the tap sieve (aerator).

Unscrew the sleeve of the tap sieve (fig. 7A ).

Clean the tap sieve using a suitable descaling

agent (fig. 7B).

Place the tap sieve into the sleeve (fig. 7C).

Place the gasket onto the tap sieve (fig. 7D) and

screw on the sleeve finger-tight (fig. 7E).

7B

7C

7A

7D

7E

M-Box

Check regularly whether water drips out of the

pressure relief valve. This dripping is a sign that

the inlet combination is (still) working correctly

(fig. 7I).

7F

Page 32

EN

DISPOSAL

The symbol on the product or on the

packaging indicates that the device must

not be disposed of in the domestic waste.

By disposing of the device in a proper

way you help to avoid harmful consequences to

environment and health.

Further information about recycling the device is

available from the competent authority, the local

refuse disposal service or the vendor of the device.

Dispose of the device, which is to be discarded,

via a specialised waste collection point for

electronic and electrical devices.

In accordance with the article of Legislative Decree

no. 15 dated 25 July, Implementation of Directive

2002/96/EC regarding the reduction of the

hazardous substances used in in electrical and

electronic appliances, and waste disposal”. The

barred dustbin symbol on the appliance indicates

that at the end of its working life the product must

not be disposed of as household waste.

Consequently, when the appliance has reached

the end of its working life the user must take it

to a suitable recycling centre for electronic and

electrotechnical waste, or return it to the dealer

when purchasing a new appliance of equivalent type.

Proper separate waste collection of the scrapped

appliance for subsequent recycling, treatment and

environmentally-friendly disposal helps prevent a

potentially negative impact on the environment and

health and facilitates recycling of the materials used

in appliance construction.

DECLARATION OF CONFORMITY

Franke declares that the following products:

Boiler 5 litres and Boiler 10 litres are in conformity

with the following specifications:

EN 60335-1:2002 incl. A1:2004, A11:2004

A12:2006 en/ et A2:2006

EN 60335-2-21: 2003, incl A1 en A2:2008

EN 62233: 2008

Degree of protection: IP24D (EN 60529)

These products are in conformity with the rules

of the low voltage guideline 2006/95/EC

and EMC guideline 2004/108/EC

Page 33

Page 34

Page 35

Page 36

www.franke.com

Argentina

Industrias Spar San Luis S.A.

Buenos Aires 1008

Phone +54 11 4311 7655

Belgium

Franke N.V.

9400 Ninove

Phone +32 54 310 111

Brazil

Franke Sistemas de Cozinhas do Brasil Ltda.

89219-512 Joinville, SC

Phone +55 47 3431 0501

Canada

Franke Kindred Canada Limited

Midland, ON L4R 4K9

Phone +1 866 687 7465

China

Franke (China) Kitchen Systems Co., Ltd.

Heshan, Guangdong, 529700

Hotline 400 882 9898

Czech Republic

Franke s.r.o.

190 00 Praha 9

Phone +420 281 090 411

Denmark

Franke Kitchen Systems Denmark

8520 Lystrup

Phone +45 8624 9024

Egypt

Franke Kitchen Systems Egypt S.A.E.

6th of October City

Hotline 16828

Finland

Franke Finland Oy

76850 Naarajärvi

Phone +358 15 341 11

France

Franke France S.A.S.

60230 Chambly

Phone +33 130 289 400

Germany

Franke GmbH

79713 Bad Säckingen

Phone +49 7761 52 0

Greece

Franke Hellas S.A.

19003 Markopoulo Attikis (Athens)

Phone +30 22991 500 00

Hong Kong SAR

Franke Asia Hong Kong Office

Causeway Bay

Phone +852 3184 1900

India

Franke Faber India Limited

Aurangabad - 431 136

Phone 1800 209 3484

Italy

Franke S.p.A.

37019 Peschiera del Garda

Numero Verde 800 359 359

Kazakhstan

Franke Kazakhstan Ltd.

040918 Almaty City

Phone +7 727 297 3812

Morocco

Franke Kitchen System SARL

21 000 Casablanca

Phone +212 522 674 200

Norway

Franke Kitchen Systems Norway

8520 Lystrup, Denmark

Phone +47 35 566 450

Poland

Franke Polska Sp. z o.o.

05-090 Raszyn

Phone +48 22 711 6700

Portugal

Franke Portugal S.A.

2735-531 Cacém

Phone +351 21 426 9670

Romania

Franke Romania SRL

Pantelimon 077145

Phone +40 21 350 1550

Russia

Franke Russia GmbH

199106 St. Petersburg

Phone +7 812 703 1540

Slovak Republic

Franke Slovakia s.r.o.

010 01 Žilina

Phone +421 41 733 6200

South Africa

Franke South Africa

Durban 4052

Phone +27 31 450 6300

Spain

Franke España S.A.U.

08174 Sant Cugat del Vallès

Phone +34 93 565 3535

Sweden

Franke Futurum AB

930 47 Byske

Phone +46 912 405 00

Switzerland

Franke Küchentechnik AG

4663 Aarburg

Phone +41 800 583 243

Thailand

Franke (Thailand) Co., Ltd.

Bangkok 10110

Phone +66 2 013 7900

The Netherlands

Franke Nederland B.V.

5700 AD Helmond

Phone +31 492 585 111

Tur ke y

Franke Mutfak ve Banyo

Sistemleri Sanayi ve Ticaret A.S.

41400 Gebze Kocaeli

Phone +90 262 644 6595

Ukraine

Franke Ukraina LLC

02081 Kyiv

Phone +38 044 492 0015

United Arab Emirates

Franke LLC

Ras Al Khaimah

Phone +971 7 203 4700

United Kingdom

Franke UK Ltd.

Manchester M22 5WB

Phone +44 161 436 6280

USA

Franke Kitchen Systems LLC

Smyrna, TN 37167

Phone 800 626 5771

Loading...

Loading...