Franke La Marzocco GB5, La Marzocco FB-70, La Marzocco Linea, La Marzocco FB-80 Training Manual

Page 1

Franke Coffee Systems

North America Inc

5601 1st Ave South

Seattle,WA 98108

Ph 800.310.5710 Fax 206.782.2124

www.franke-cs.com

Page 2

La Marzocco Training Manual

The La Marzocco is set apart from most other espresso machines due to its two-boiler system. Having separate coffee and steam boilers allows the machine to achieve and maintain

exceptional thermal balance.

Single boiler espresso machines’ brewing water comes from a heat exchanger located

inside the steam boiler. Brewing water temperature is solely dependent on the pressure of

the water in the boiler used for steaming. As the steam boiler’s pressure rises and falls during normal operation so does the water temperature in the heat exchanger used for brewing.

The LaMarzocco has a separate boiler for each function. A coffee boiler to heat water for

brewing espresso and a steam boiler used to generate steam for preparing milk and hot

water for tea or americanos. This two-boiler system allows for the perfect brewing temp

even if the steam boiler has been under extremely heavy steaming or water usage.

Page 3

Safety & Tools

Safety Precautions

Before performing maintenance on the steam boiler:

* Turn the machine off.

* Depressurize the steam boiler by opening one or both steam arms.

The only exception would be when rebuilding the steam assemblies, then it will be necessary to close the ball valves located on the steam tank.

Before performing maintenance on the coffee boiler:

* Turn the machine off.

* Turn off the incoming water supply.

* Depressurize the coffee boiler by opening the expansion valve.

When performing maintenance on any electrical wiring in the machine, apart from taking

voltage or amp readings ensure the machine is unplugged from the wall outlet.

Tools

Certain maintenance procedures may require one of the following tools, which are unique

to the La Marzocco.

1. Sight Glass Tool

2. Heating Element Wrench

3. Diffuser Tool (only for machines prior to April 2003)

Other tools required are common tools available at most hardware stores:

* Combination metric wrench set ranging from 10mm to 26mm

* Metric Allen wrench set

* Multi-meter

* 3/16 x 4" Standard screwdriver

* 1/4 x 4" Standard screwdriver

* Stubby standard screwdriver

* #2 Phillips screwdriver

* Mini Screwdriver set

* Fuse puller

* Small wire brush

* Wire stripper/crimpers

* Diagonal cutters

* Slip-joint pliers

* Needle-nose pliers

* Snap-ring pliers

* 6, 8 & 10" Adjustable wrenches

* Teon tape

* Food Grade lube gel

* Fuses - (5 x 20mm) 40mAmp, 125mAmp, 1 amp, 10amp and 6.3 amp

Page 4

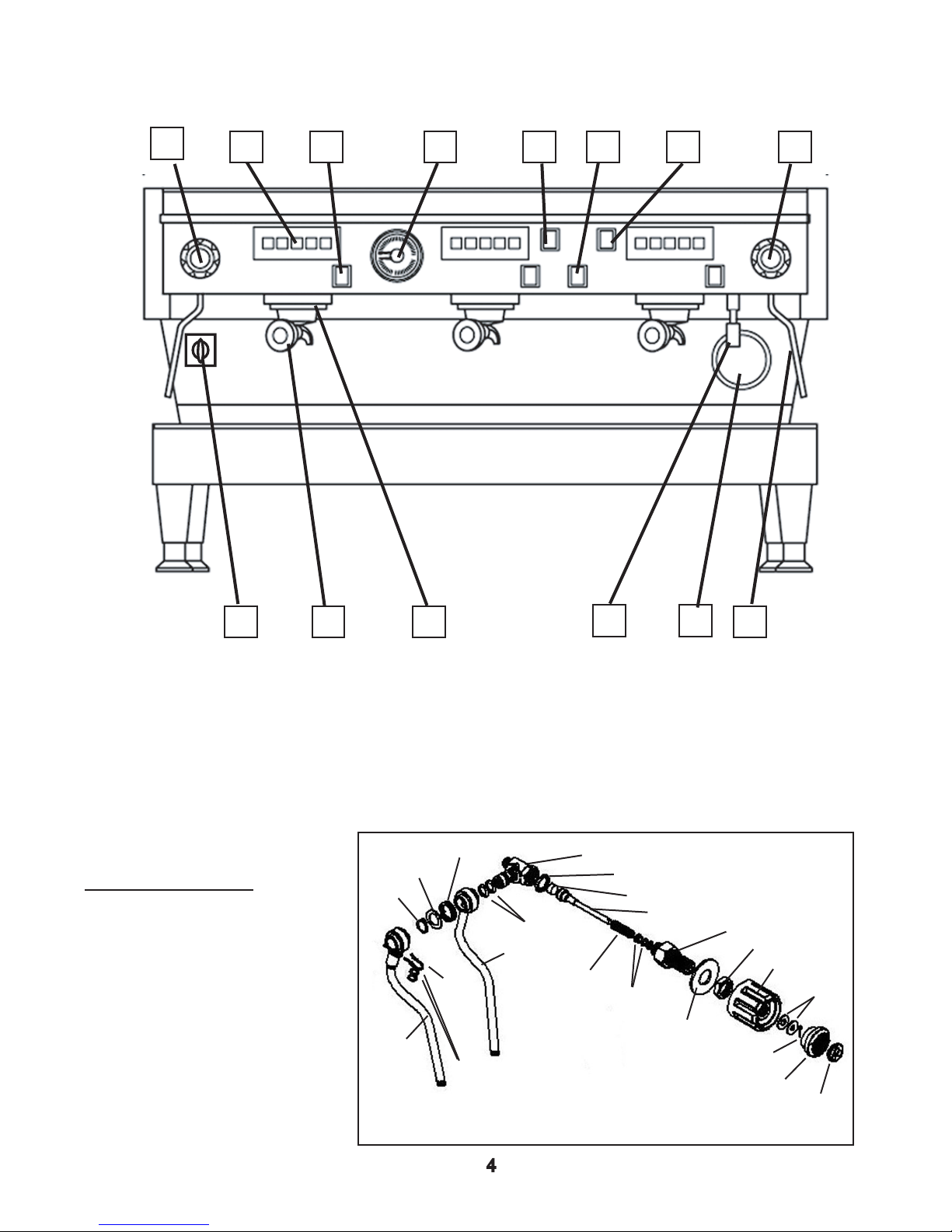

Machine Overview, Linea

1

4 3 2

8 7 6 5

10 9

11

12 13

1. Steam Knob, Left 8. Steam Knob, Right

2. Keypad 9. Main Switch

3. Semi-automatic Dispense Switch 10. Portalter

4. Dual-scale Pressure Gauge 11. Group Head

5. Coffee Boiler Heating Element Indicator Light 12. Hot Water Nozzle

6. Hot Water Dispense Switch

13. Sight Glass

14. Steam Wand

Steam Valve Body

Crush Washer

Steam End Gasket

Steam Shaft

Shaft Spring

Shaft O-Rings

Washer

1 & 8 Steam Knobs

The steam knob allows the

barista to open and close the

steam assembly to prepare the

milk used in milk-based drinks.

Washer

Circlip

Swivel

Steam

Wand

Wand

Spring

Wand O-Rings

Steam Wand

Hairpin

Clip

Wand

O-Rings

14

Steam Valve Housing

Mounting Nut

Knob

Washers

Cotter Pin

Bezel

Insert

Page 5

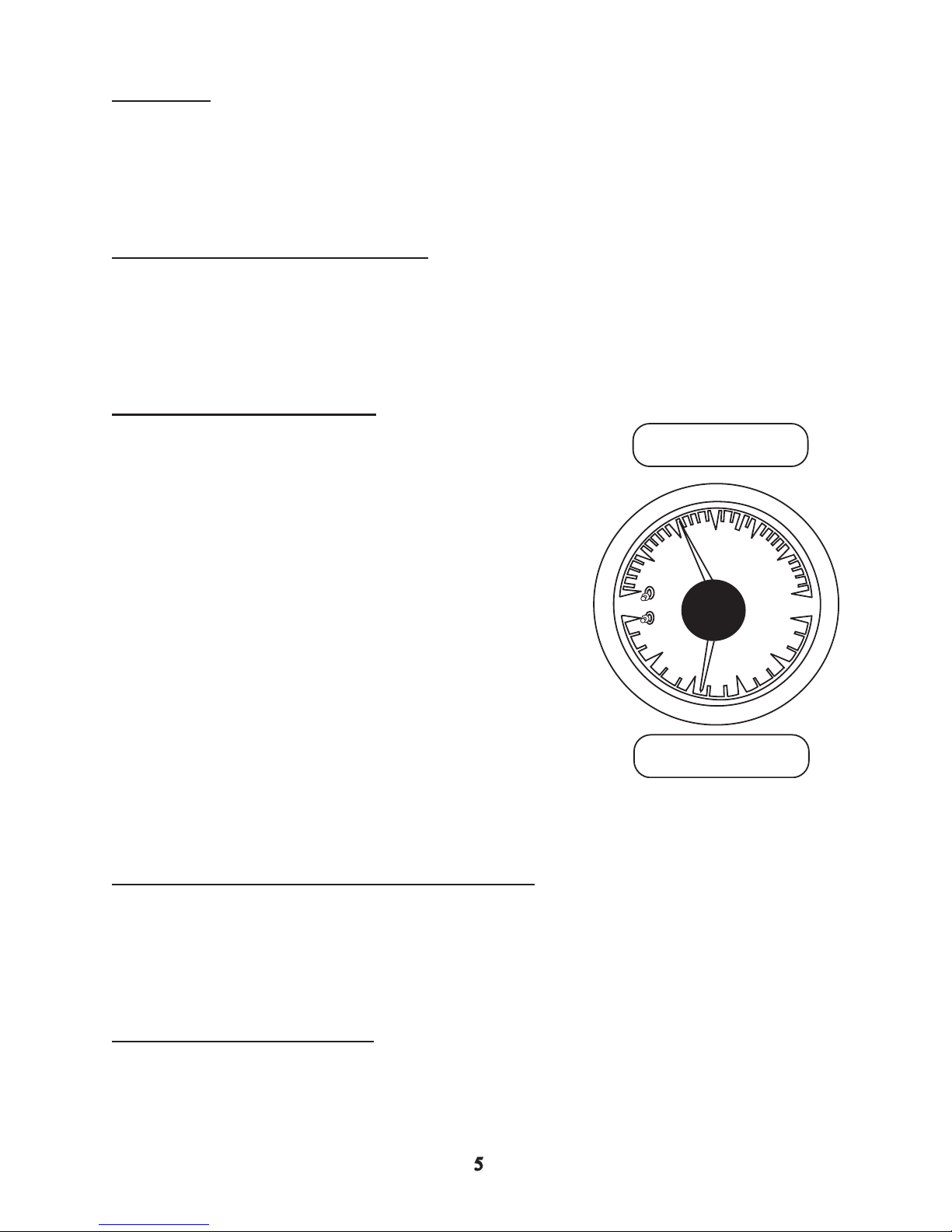

2. Keypads

BOILER

PRESSURE

DISPENSING

PRESSURE

0,5

1

1,5

2

2,5

3

15

12

9

3

6

The keypads contain up to four seperate product buttons, single ristretto, single shot,

double ristretto, and double shot. Generally, the buttons are programmed to dispense 3/4

oz, 1 oz, 1-1/2 oz, and 2 ounces respectively, but they can be programmed to any desired

volume.

3. Semi-Automatic Dispense Switch

The semi-automatic dispense switch allows you to brew with the machine while bypassing the electronic keypads. Activating the switch sends power directly to the group

valve allowing water to ow through the group head. This switch is generally used when the

fuse in the control box has blown.

4. Dual-Scale Pressure Gauge

The pressure gauge is divided into two sections,

top and bottom. The top portion of the gauge reads

the steam pressure in the rear boiler. The steam

pressure is factory set to 1.2 bar. The bottom

portion of the gauge reads the brewing pressure in

the front boiler. The gauge will read the static water

pressure going to the espresso machine, when the

machine is turned off. When the machine is turned

on, the heating elements will activate, heating the

water in both boilers. As the water heats up in the

front boiler, it expands. The front boiler is a closed,

totally saturated vessel, with no room for the water to

expand into. This causes the pressure to increase,

evidenced by the bottom protion of the gauge

climbing. Once the gauge needle reaches 12 bar,

the expansion valve, located in the drain box,

should unseat and prevent the pressure from climbing higher than 12 bar. If the gauge does

not reach or exceeds 12 bar, adjust the barrel of the expansion valve accordingly.

5. Coffee Boiler Heating Element Indicator Light

This red light illuminates whenever the heating element in the front, or coffee, boiler is

activated. When the water in the coffee boiler reaches the temperature the thermostat has

been set to, the thermostat will cut power to the heating element and the light will go out.

During initial machine start-up, wait for this light to go out before brewing.

6. Hot Water Dispense Switch

Depressing this switch activates the hot water solenoid valve, allowing the valve to open

and water from the steam boiler to exit the hot water nozzle. Steam pressure must be

present in the steam boiler to force water through the valve.

Page 6

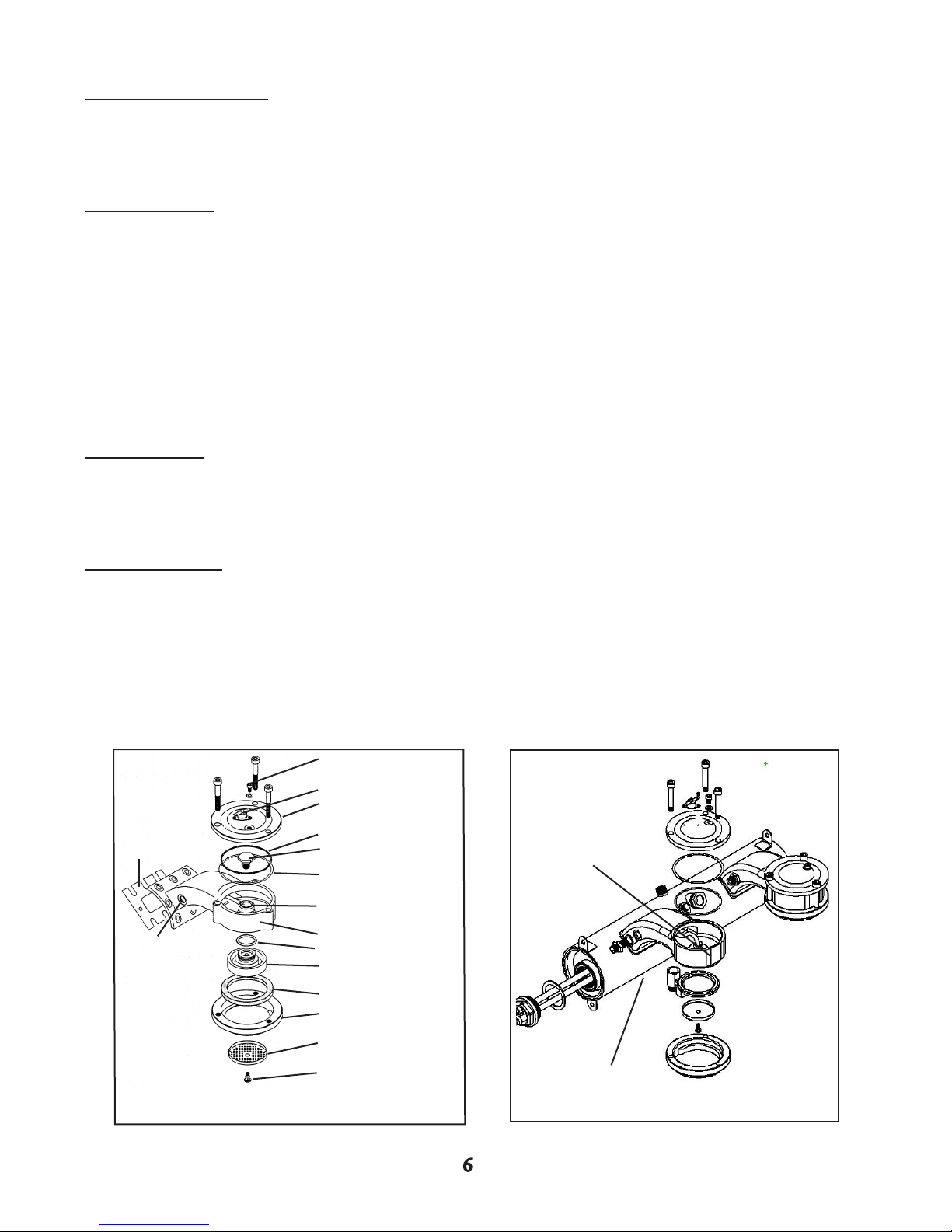

7. Manual Fill Switch

Depressing this switch activates the auto-ll valve, allowing cold water to ow into the

steam boiler. This switch would only be used if the fuse in the control box has blown.

9. Main Switch

The main power switch has three positions: OFF, FILL and RUN (or 0,1,2 on older machines.)

Off - The machine is off

Fill - The electonics are activated, but NOT the heating elements. This allows the machine

to auto-ll prior to the elements heating up.

Run - The electronics as well as the heating elements are activated allowing the machine to

build steam pressure and the coffee boiler to heat up.

10. Portalter

The portalter holds the ground coffee dosed from the grinder. The portalter, dosed and

tamped with coffee is then inserted into the group head to brew espresso.

11. Group Head

The group head is where the brewing water meets with the ground coffee in the portalter

to brew espresso.

The La Marzocco’s group head is called a saturated group. It is either a nickle-plated brass

group, (machines manufactured prior to March 2003) or a stainless steel group, (machines

manufactured from March 2003 to the present).

Brass Group

Group to Boiler

Gasket*

Exit port to Flowmeter

Bleed Screw

Thermal Limiter

Group Cap

O-ring

Banjo Bolt

Fiber Gasket

Banjo Tube

Group Head

O-ring

Diffuser Block

Portalter Gasket

Bayonet Clamp Ring

Stainless Group

The banjo tube has been

redesigned, the banjo bolt is

no longer required.*

Diffuser Screen

Diffuser Screw

Group is welded

to the boiler*

Page 7

12. Hot Water Nozzle

The hot water nozzle is installed on the outlet of the hot water valve. When the valve is

energized, hot water from the steam boiler is forced, by steam pressure, through the valve

and out of the nozzle.

13. Sight Glass

The sight glass indicates the amount of water in the steam boiler only,as the coffee boiler is

always fully saturated with water. The sight glass should read between 2/3 and 3/4 during

normal operation.

Body

O-ring

Glass

Fiber Gasket

Securing Bezel

Fitting

Washer

Bleed Screw

14. Steam Wand

The steam allows the barista to prepare milk for drinks suchs as lattes, cappuccinnos, and

mochas. The La Marzocco uses stainless steel wands that rotate 360 degrees.

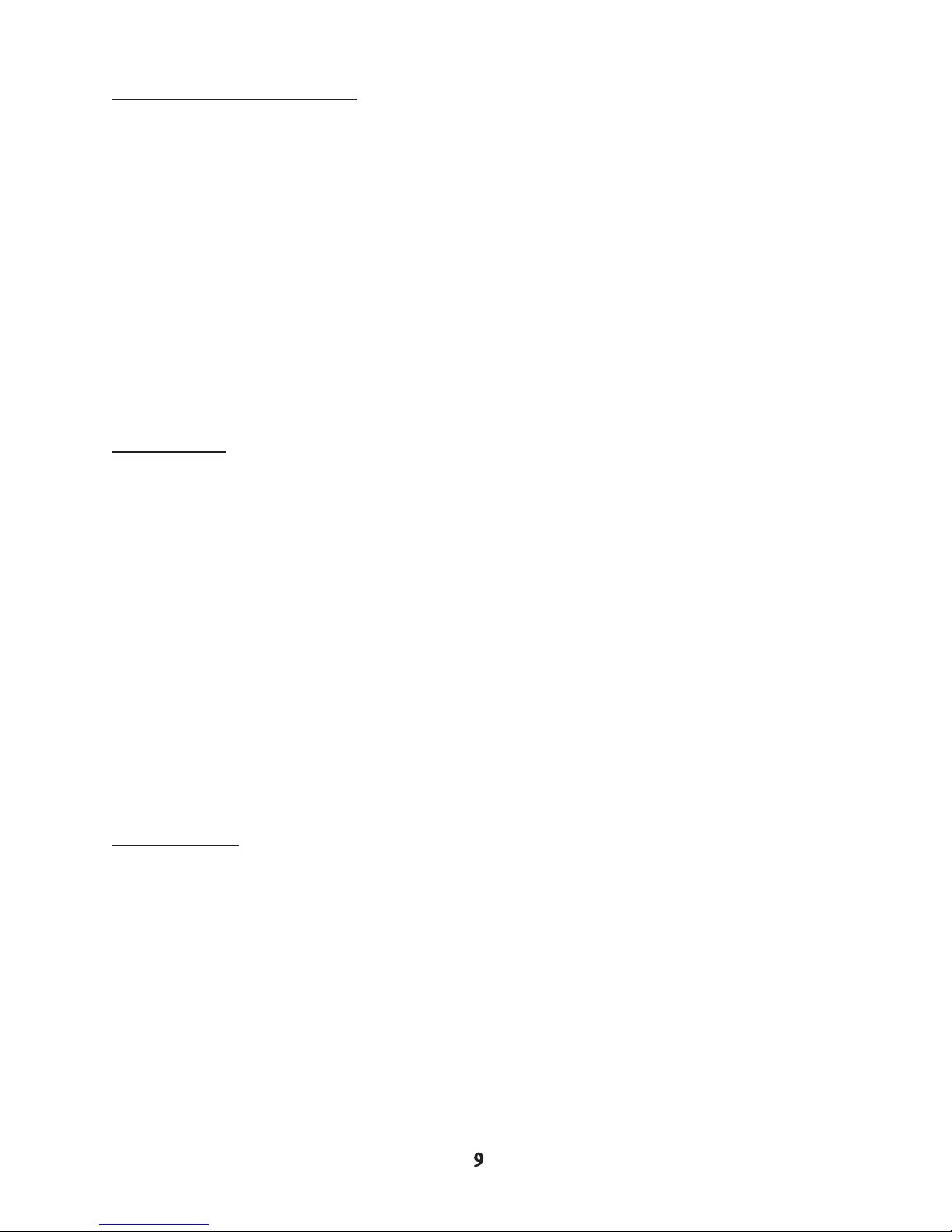

Body Panels

For most repairs, it may be necessary to remove a body panel.

1. Top Trim

2. Upper Surround Panel

3. Left Side Panel

4. Right Side Panel

5. Front Panel

1

6

7

4

Steaming

6. Cup Tray

7. Cup Tray Grates

8. Group Cover

2

5

8

9. Drip Tray & Grates

3

9

Page 8

Installation

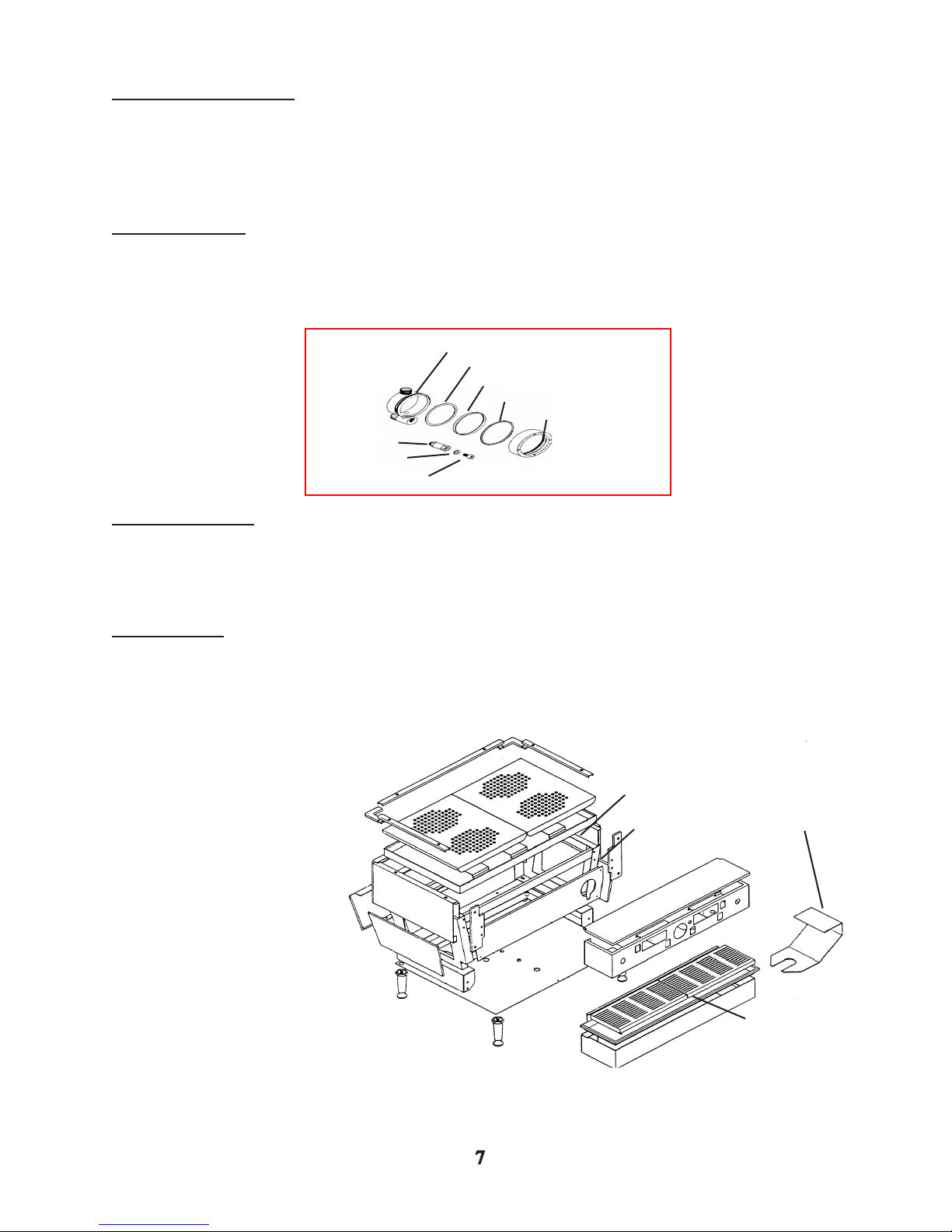

Contents

When unpacking the machine, the following items should be included:

* 4 NSF Legs (6 for a 4 group machine)

* Pump & motor assembly

* Portalters

* Drain Hose

* Tamper

* PuroCaff Cleaner

* Owners manual

* Inlet hoses, 24”, 48”, and 84” lengths

* Warranty card with water test strip attached

Water Requirements

A dedicated water line with its own shut-off valve should be placed within four feet of machine instal-

lation location. The shut-off valve should be equipped with a male 3/8 compression tting.

The machine operates best with water between 0-3 grains of hardness. Higher hardness levels may

cause damage due to scale forming inside the machine. If the supply water has a hardness above

3 grains per gallon install the appropriate water softener. ENSURE ALL SOFTENING/FILTERING

CARTRIDGES HAVE BEEN ADEQUATELY FLUSHED BEFORE CONNECTING TO THE MACHINE.

ESI recommends our H2O for Espresso system. This cartridge provides both a carbon block to lter

out tastes and odors as well as ion exchange resin for softening of the incoming water. The cartridge also incorporates a 20% bypass to neutralize the pH allowing for a water “recipe” that provides the best tasting espresso.

In some areas of the country, the use of a Reverse Osmosis system, is necessary. When using an RO system, ensure a small percentage of raw water bypasses the RO system and is then

reintroduced into the RO water fed to the espresso machine. This helps prevent corrosion due to

aggressive water properties. The “postmix” water should then be fed through a carbon block lter to

remove tastes and odors.

Power Requirements

The following voltages and amperage ratings apply.

* 1AV OR EE – 208 - 240v, 20amp

* 2AV OR EE– 208 - 240v, 30amp

* 3AV OR EE– 208 - 240v, 50amp

* 4AV OR EE– 208 - 240v, 50amp

There are two electrical cords attached to the machine. The smaller diameter cord supplies pow-

er to the pump motor assembly and should be connected to the pump motor, NOT plugged

into a wall outlet.

Drainage Requirements

Ensure the drain hose provided with the machine runs downhill to an appropriate oor drain.

Page 9

First time machine start-up

Once the machine has been properly installed:

* Turn on the water supply.

* The coffee boiler(s) will automatically begin to ll.

* Locate the group caps and loosen the bleed screw 1/4 turn until a water bead is visible.

Once a water bead is visible, re-tighten the bleed screw snugly.

* Once the groups have been bled, turn the main power switch to the FILL position. Within 6

seconds, the rear (steam) boiler will automatically begin to ll .

* Once the rear (steam) boiler has lled, (check the sight glass to ensure the rear boiler has

lled to the appropriate level, between 2/3 - 3/4 full), turn the main power switch to

the RUN position.

* While the boilers are heating, press any dispense switch and ensure the pump pressure

(bottom scale of the gauge) reads 9 bar while dispensing. Adjust if necessary.

* Wait for the boilers to heat fully indicated by the coffee boiler heating light going off and the

top scale of the pressure gauge reaching 1.2 - 1.5 bars.

Pre-infusion

Pre-infusion is the dampening of the coffee grounds allowing them to expand in the portalter prior

to the actual brewing process beginning. This seems to improve the coffee avor of single shots.

To program the machine to pre-infuse, perform the following:

* Turn the main power switch to the OFF position.

* While holding the far left (single ristretto) button on the left most keypad turn the power

switch to FILL.

* The light above the “Swirl” button will illuminate indicating that the control box has received

the pre-infusion command.

To disable pre-infusion, perform the following:

* Turn the main power switch to the OFF position.

* While holding the second button on the left most keypad turn the power switch to the FILL

position.

* The light above the “Swirl” button will illuminate indicating that the control box has received

the pre-infusion command.

Programming

* Using the left most keypad, depress and hold the continuous pour (swirl) button for about 5

seconds.

* Once all of the lights on the keypads begin blinking press the button you wish to program.

* Once the desired volume has been reached, (measure from the bottom of the crema),

push the button again.

* Repeat this procedure for each button.

*Any programming performed on the left group will carry over to all of the groups to the

right. After programming the left group, verify that groups to the right are dispens

-ing the proper volume. You can also individually program the right groups without

affecting the others.

Page 10

Temperature and Pressure Adjustments

Machines ship from ESI with the coffee boiler thermostat adjusted to heat and brew water for

espresso at 197 degrees Fahrenheit or 92 degrees Celsius. If you prefer to adjust the tempera-

ture to t your coffee roast perform the following:

* Make certain that the machine is at operating temperature and that the coffee boiler

heating indicator light is off.

* Remove the top cover from the machine and locate the thermostat between the groups.

* Turn the main switch to the OFF position.

* Using a long insulated screwdriver adjust the thermostat clockwise to increase tempera

ture and counter-clockwise to lower temperature.

* This adjustment is very sensitive and only slight adjustments should be made. Each 1/4

turn represents a 3 degree Fahrenheit temperature change.

*Turn the main switch back to the RUN position.

If your steam pressure gauge does not read 1.2 bar, adjust the pressure switch as follows:

*Turn the main switch to the OFF position.

* Remove the top panel of the machine.

* Locate the pressure switch in the back, top, left-hand corner of the machine.

* For machines equipped with Sirai pressure switches (Rectangular switch approximately

2” x 4”), remove the screw and lift cover from pressure switch to access the adjust

ment screw. There will be arrows pointing towards - and +. Turn towards - to lower

the steam pressure and turn towards + to raise steam pressure.

* For machines equipped with Giemme pressure switches (Round switch approximately

1-1/4 in diameter), locate the samll adjustment screw in the center of the switch

and adjust very delicately towards - to decrease the presure and + to increase the

presure.

*Turn the main switch back to the RUN position.

Page 11

Section 1 Questionnaire

1. What’s unique about the La Marzocco espresso machine compared to other traditional machines

on the market?

2. Why are two boilers in an espresso machine better than having only one?

A. The heat exchangers require less maintenance.

B. More stable brewing temperature.

C. The machine uses less electricity.

D. You can operate the machine at a higher steam pressure.

3. What safety precautions must be carried out before performing maintenance on the coffee boiler?

A.

B.

C.

4. What are the three special La Marzocco tools?

A.

B.

C.

5. There are two electical cords coming out of the machine. What are each of them for?

6. What must you do to the coffee boiler after initial installation before you operate the machine?

7. Explain why the bottom portion of the pressure gauge travels up and down between 3 bar and 12

bar during normal operation?

8. What design change allows for a more stable and effecient brew temperature on machines

manufactured after March 2003?

9. How should the water supplying the machine be treated to ensure its quality?

Page 12

10. What are the proper steps to take when programming the machine?

A. Turn the machine offand hold down the continuous pour button while turning the machine

on.

B. Press and hold the continuous pour button until the LED above the button illuminates.

Then press the button you wish to program.

C. Press the continuous pour and the button you wish to program at the same time. When

the lights blink, press the button you wish to program again.

11. Which keypad do you program to facilitate programming of the entire machine?

12. Why don’t we generally recommend using water treated by reverse osmosis, except in extenuating circumstances?

A. It’s more expensive and complicated to use than lter/softening cartridges.

B. It can cause the water to become very agressive, causing corrosion.

C. It can remove too much of the TDS in the water, causing the auto-ll system to not func-

tion properly.

D. The coffee usually doesn’t taste as good.

13. If circumstances require you to use RO water, what step should you take to alleviate the negative side effects of RO water in espresso machines?

14. Explain the three positions of the main power switch.

A. Off -

B. Fill -

C. Run -

15. What does the red light on the machines control panel indicate when illuminated?

16. How do you initiate the pre-infusion feature of the La Marzocco?

Page 13

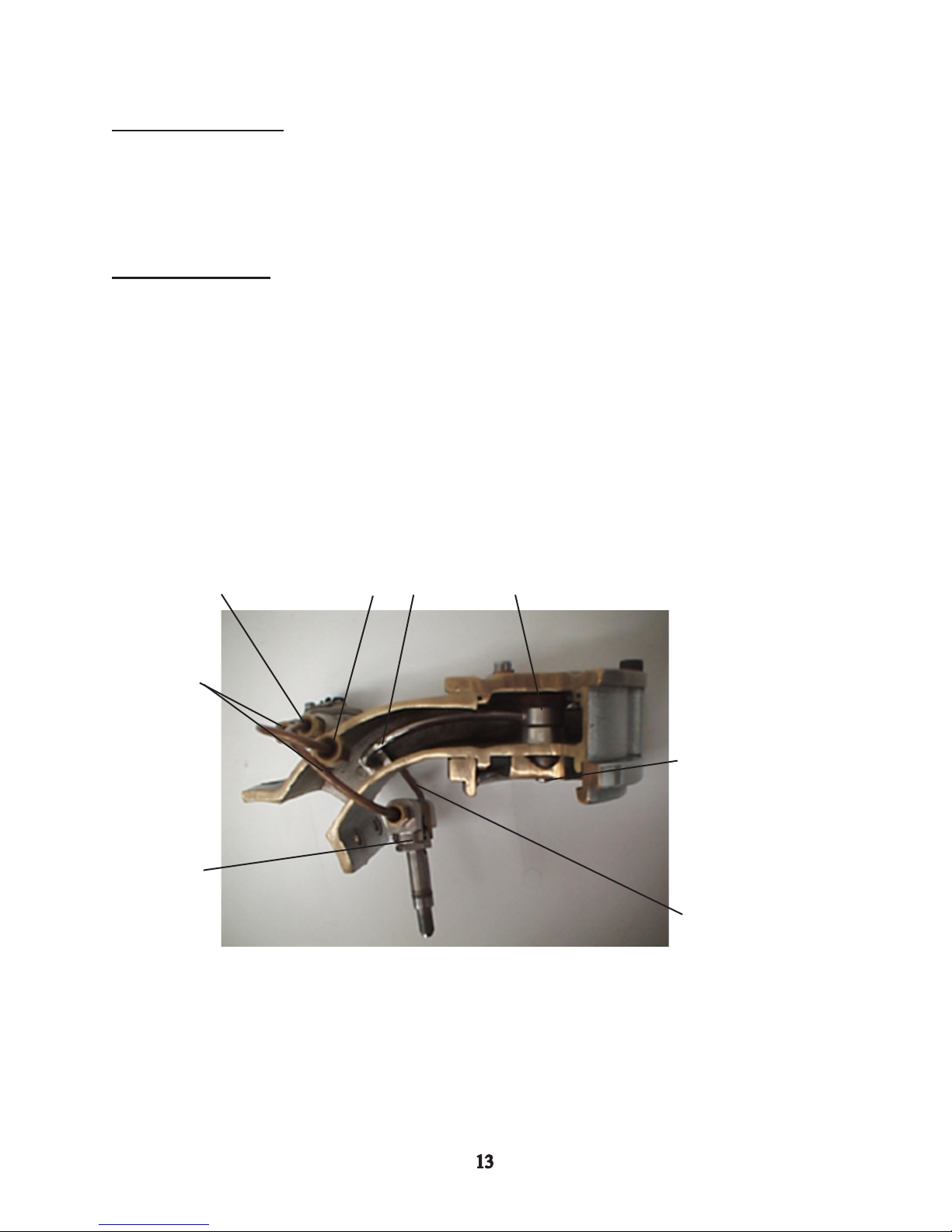

4. Hydraulic System

Tubing and ttings

* Virtually all of the ttings on the LaMarzocco are of the compression or are type. Most are made

from brass, which will strip or crack if over-tightened.

* It is important when working with tubing not to bend or twist the sections you are working with, as

this will restrict the water ow or cause fatigue or leaks in the tubing.

Boilers & Groups

The La Marzocco uses hollow plated brass group castings attached to a stainless steel boiler on

machines manufactured prior to March 2003, and stailess steel groups welded to the boiler on machines manufactured beginning March 2003.

*In auto-volumetric models, the water from the group exits through a small tube on the left side of

the group and ows to the owmeter, which meters the volume of the water. From the

owmeter the water passes through to the group valve. From the group valve, the water

then ows back into a small tube inside of the group head and then to the diffuser block, the

diffuser screw, diffuser screen and nally to the ground coffee in the portalter

Below is a cutaway of a grouphead. Below the photo is the sequence of water ow through the

group to the portalter.

2

1

6

7

3

8

4

5

1. Water exits the group head and travels through a tube to the owmeter.

2. Water enters the owmeter and rotates the impellor.

3. Water exits the owmeter and travels through a tube to the group valve.

4. Water passes through the group valve...

5. And travels through a tube to the banjo tube inlet.

6. Water enters the banjo tube and ows to the banjo bolt.

7. Water passes through the banjo bolt and down towards the diffuser block.

8. Water passes through the diffuser block and enters the diffuser screw and screen where it

then meets with the tamped coffee in the portalter.

Page 14

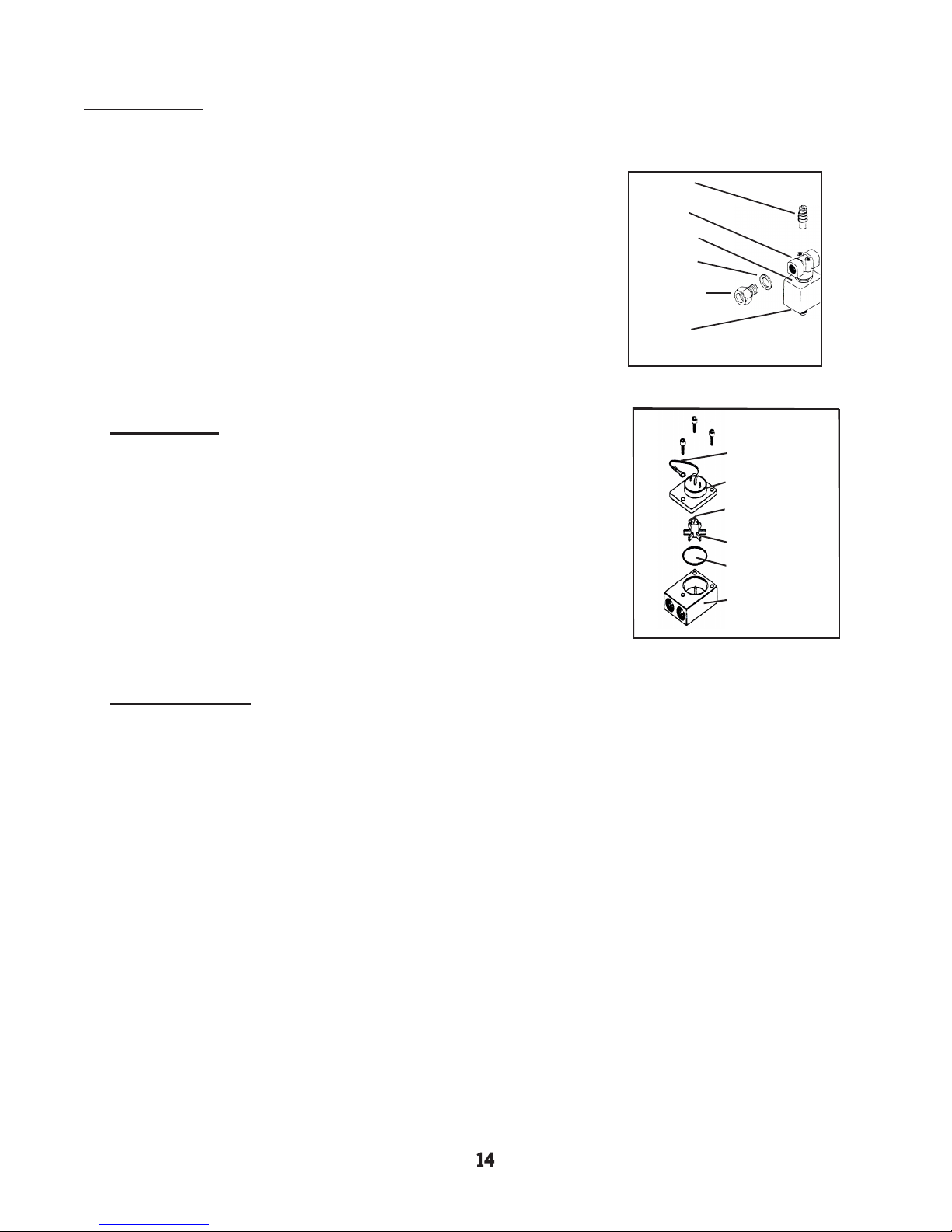

Group Valves

Each group has a three-way solenoid valve mounted underneath each head to allow for water

ow through the group.

* Each valve consist of valve body, valve stem, spring-loaded

piston and a coil.

* The valve is mechanically closed by spring pressure.

* The coil receives electrical power when the brew switch or

keypad is depressed.

* When energized, the coil creates a magnetic eld which opens

the piston, allowing water to ow through the valve body.

* When the valve closes, pressurized water from the valve outlet to

Valve Piston

Valve Body

Solenoid Coil

Brass Washer

Fitting for tube from

Flowmeter

Valve Shaft

the diffuser block discharges through the bottom of the

valve stem to the drain box.

Flowmeters

Ground Wire

The owmeters measure the volume of water passing through to the

groups.

* The Flowmeter is made up of an electromagnetic eld, an impeller

and a body.

* As water enters the Flowmeter body it causes the impeller to

rotate. The impeller has two small magnets imbedded in it.

As the impeller spins, the magnets pass the magnetic eld,

causing a switch to close, which sends a pulse signal to the

microprocessor.

Flowmeter Field

Magnets

Impellor

O-ring

Flowmeter Body

Autoll System

The autoll system maintains the water level in the steam boiler.

* The autoll system consists of an autoll circuit on the control box, an auto-ll probe and an

autoll valve.

* The autoll probe is a metal probe, which sticks down into the boiler. An electrical lead is at

tached to the top of the probe, approximately 1-2 vac travels through this probe from the

control box.

* As the water rises in the boiler, and reaches the probe, the 1-2 vac travels through the water

and grounds itself against the sidewall of the boiler. When this ground signal travels back

to the control box, it signals the auto-ll circuit to switch off the auto-ll valve.

* As water is depleted from the boiler it lowers below the probe causing the signal to be inter-

rupted. When the auto-ll circuit can no longer read a ground signal, it activates the

autoll valve allowing water to enter the boiler.

* The autoll valve consist of an electromagnetic coil and a valve.

* The valve is mechanically closed by spring tension. When the coil is energized it creates a

magnetic eld, which pulls the valve piston open, allowing water to pass through it.

Page 15

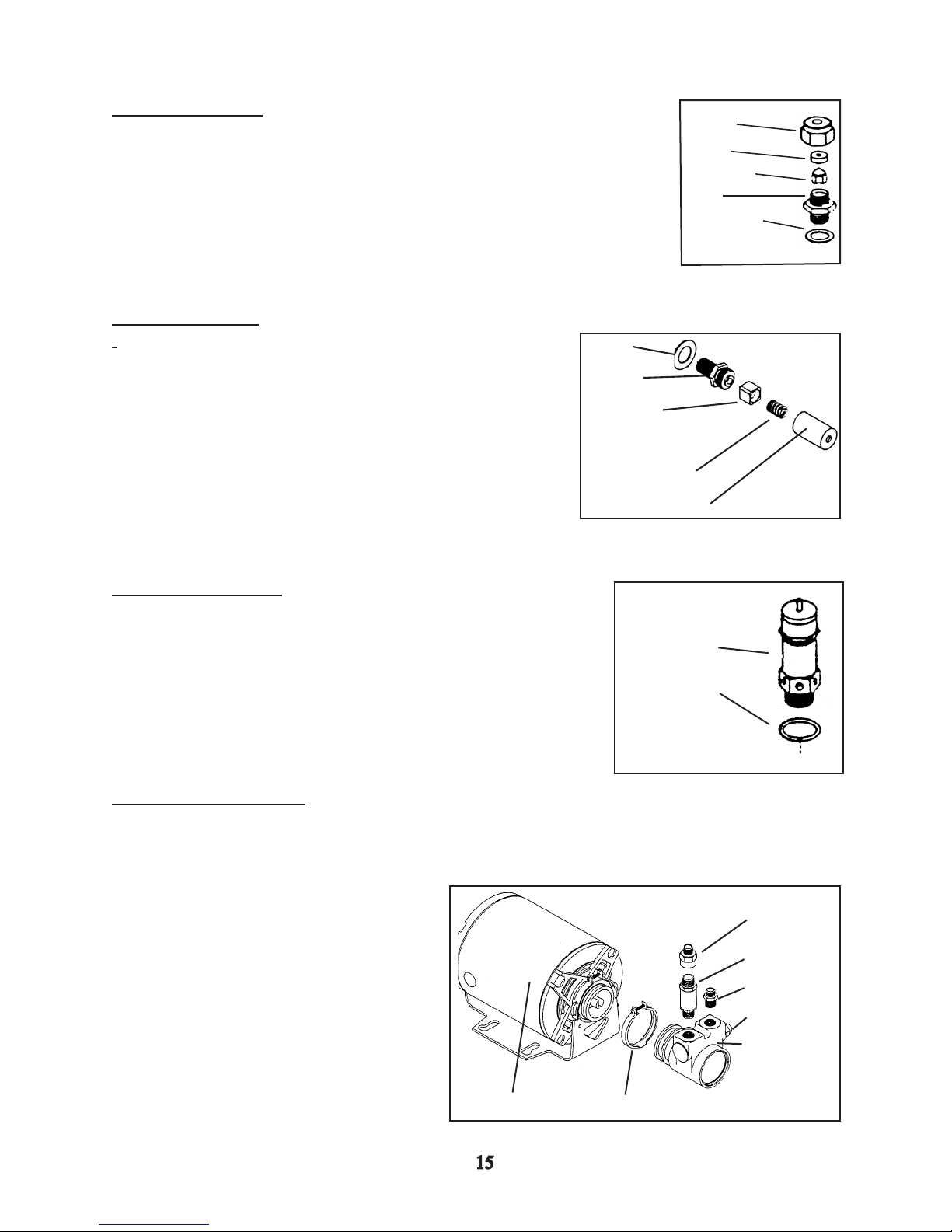

Vacuum Breaker

The vacuum breaker is a mechanical valve located on the steam boiler.

As pressure builds in the boiler, steam pressure lifts a plunger, sealing

the boiler, allowing steam pressure to increase above atmospheric

pressure.

Expansion Valve

The expansion valve relieves front boiler pressure at 12 bar.

* The expansion valve is located in the drain box, which is

underneath the drip tray.

*It consists of a valve body, a valve seal and spring, which

are enclosed by an adjustable brass barrel.

*The expansion valve is adjusted by adding or relieving

tension on the spring by turning the adjusting barrel.

Washer

Body

Valve

Seal

Top Cap

Gasket

Teon Cone

Body

Brass Washer

Spring

Barrel

Safety Relief Valve

The pressure relief valve relieves boiler pressure at 1.8 bar

preventing the boiler from over-pressurizing. It is factory

adjusted and sealed and cannot be adjusted.

External Boost Pump

The boost pump increases existing water

pressure to 135 psi or 9 bar, which is

required to properly brew espresso.

* The pump pressure can be adjusted by

adjusting the screw on the side of

the pump.

* Rotating the screw clockwise will

increase pump pressure, while

rotating counter-clockwise will

decrease pump pressure.

*Ensure your waterline is stable, as

uctuations in line pressure will

affect output pressure.

Motor

Relief Valve

Brass Washer

Outlet

Fitting

Check Valve

Inlet Fitting

Adjustment Screw

Pump

Clamp

Page 16

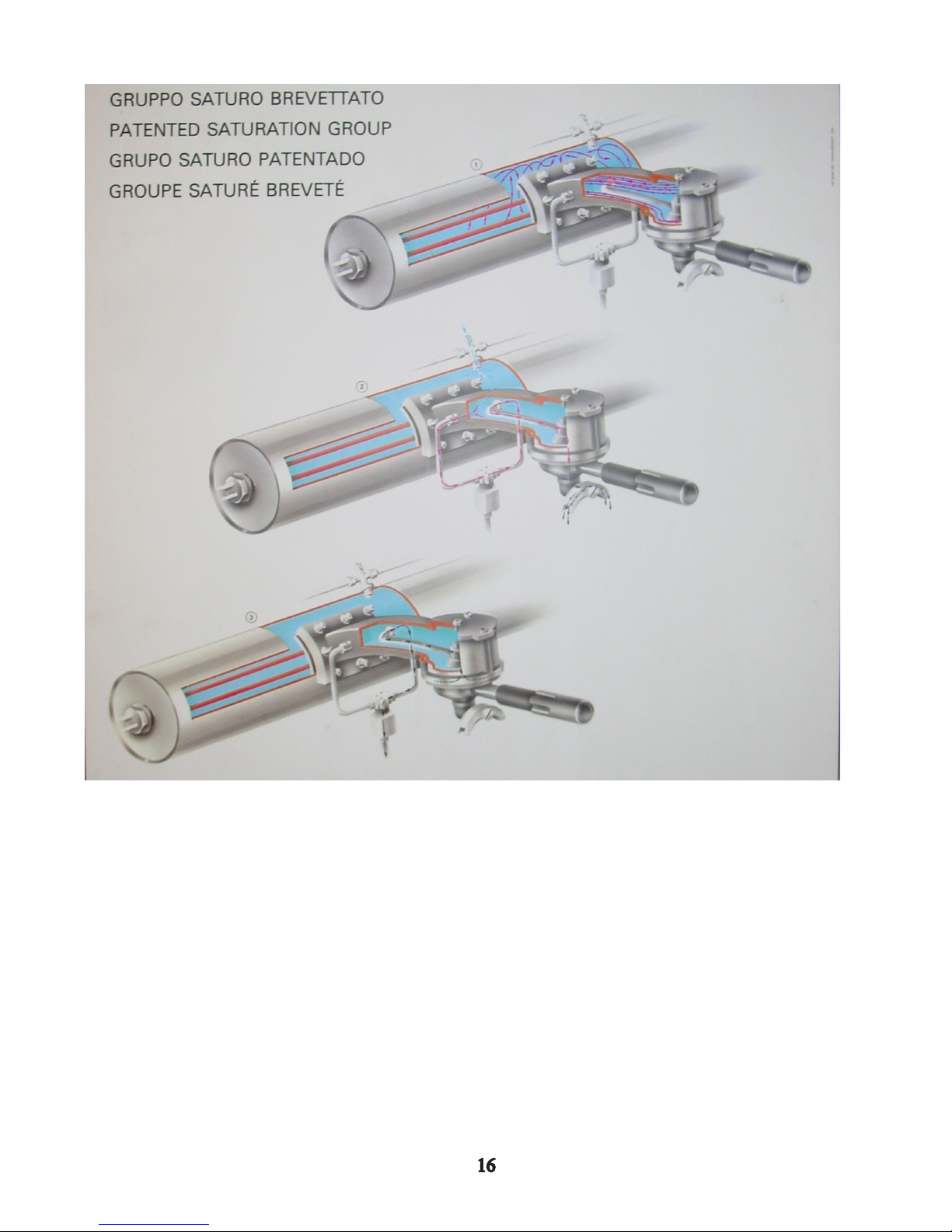

* Note - The boilers shown are from an EE, semi-automatic machine, an AV model would have

owmeters.

1. Circulation of water within the boiler and group head.

2. Water ow during the brew cycle.

3. Discharge of water after completion of brewing cycle.

Page 17

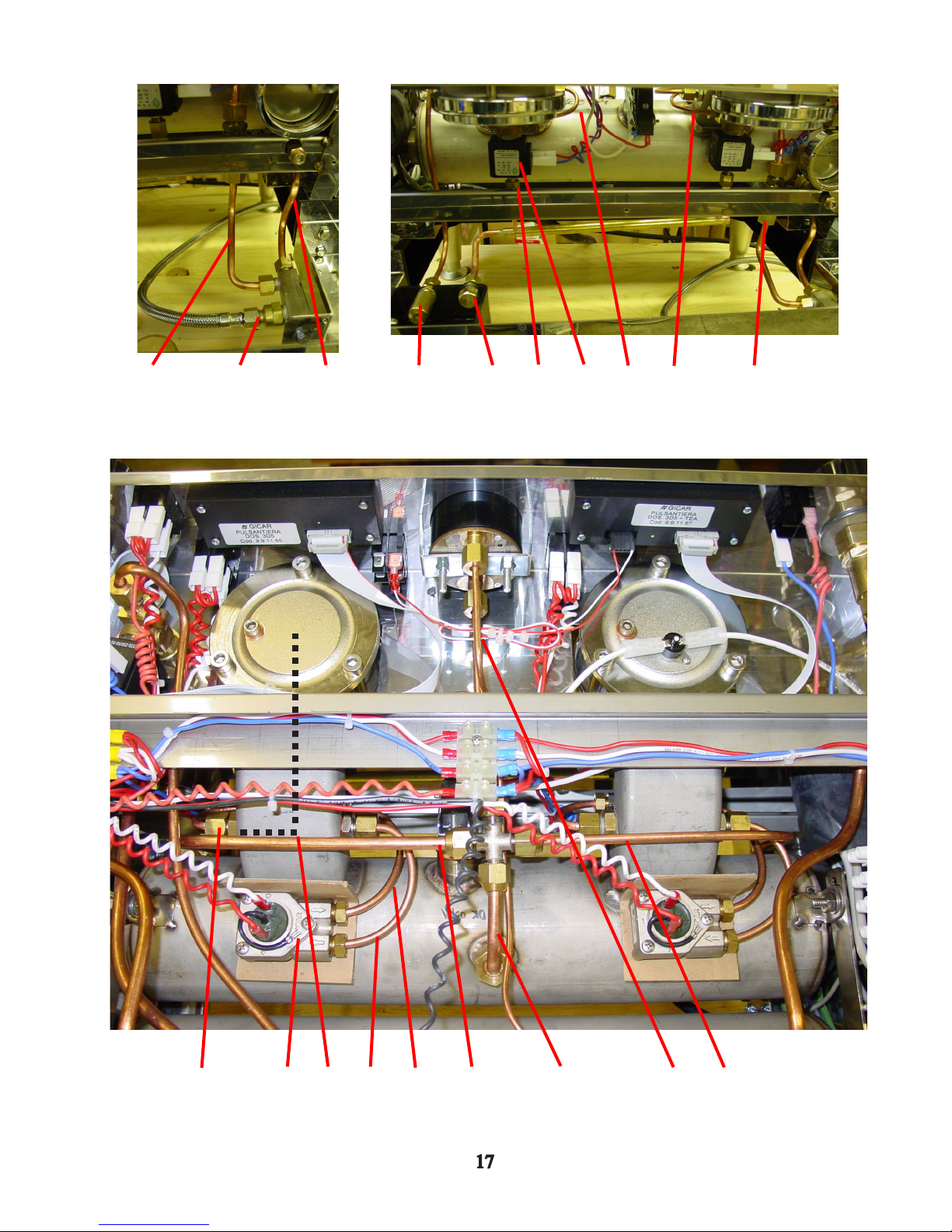

1 2 3 4 5 6

97 10

8

12 13 14 18

1511 16 17 19

Page 18

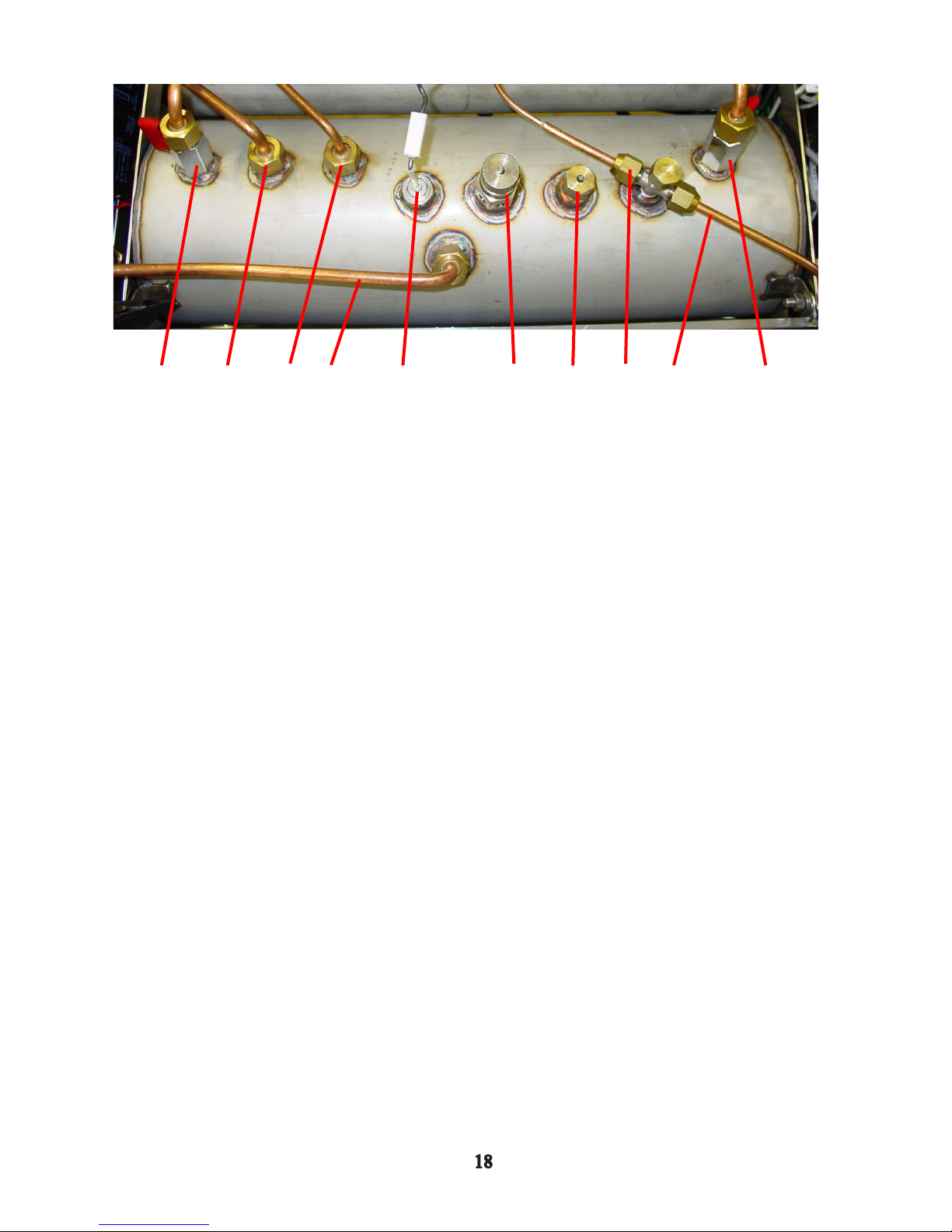

2420 25 26 2821 22 23 27 29

Hydraulic Lines and Components

1. Inlet water tube to the coffee boiler.

2. Inlet water line feeding the inlet manifold.

3. Inlet water tube to the steam boiler.

4. Expansion valve.

5. Discharge tting.

6. Discharge from the 3-way group valve.

7. Group valve.

8. Tube feeding water from the group valve to the banjo tube.

9. Tube feeding water from the owmeter to the group valve.

10. Check valve for the coffee boiler.

11. (Same tube as #8).

12. Flowmeter.

13. Banjo tube (located inside of the group head).

14. Tube feeding water from the group to the owmeter.

15. Tube feeding water from the owmeter to the group valve.

16. Tube feeding water from the coffee boiler check valve to the “X” tting.

17. Tube feeding water into the coffee boiler.

18. Tube feeding water to the gauge.

19. Tube feeding water to the expansion valve.

20. Tube feeding steam to the right steam assembly.

21. Tube feeding the top of the sight glass.

22. Tube feeding water to the hot water valve.

23. Tube feeding water to the steam boiler.

24. Auto-ll probe.

25. Pressure relief valve.

26. Vacuum breaker

27. Tube feeding steam to the pressure gauge.

28. Tube feeding steam to the pressure switch.

29. Tube feeding steam to the left steam assembly.

Page 19

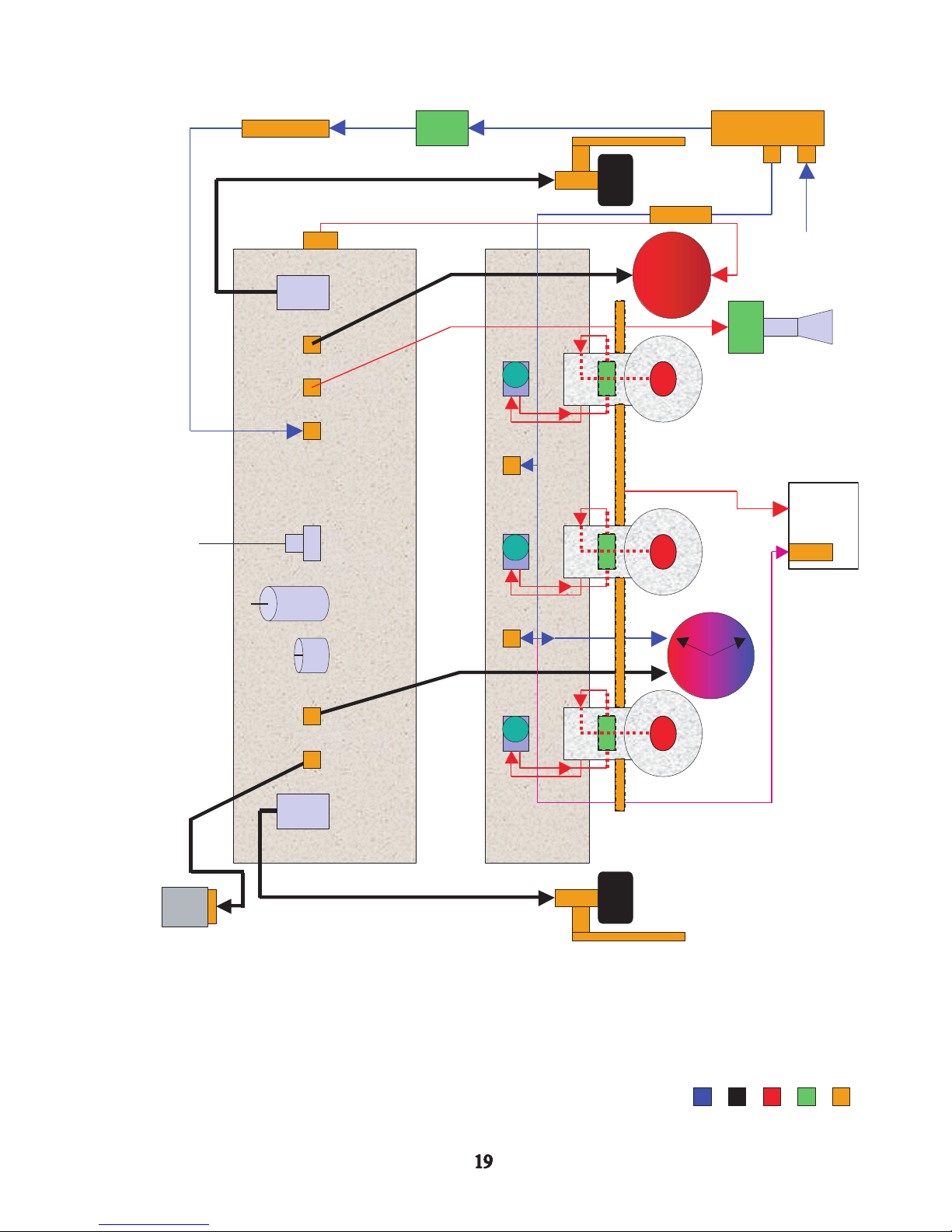

1

19

10

8

7

6

5

4

3

2

18

17

16

15

14

13

11

12

1111

1818

Brass Fitting/Tubing

Cold Water

Hot Water

1. Water Inlet

2. Auto-fill Valve

3. Inlet Check Valve

4. Left Steam Assy. Valve

5. Vacuum Breaker

6. Safety Valve

7. Auto-fill Probe

8. Right Steam Assy. Valve

9. Pressure Switch

10. Left Steam Assembly

11. Flowmeter

12. Dual Scale Gauge

13. Hot Water Valve

14. Sight Glass

15. Right Steam Assembly

16. Expansion Valve

17. Group Valve Drain Tube

18. Group Valve

19. Drain Box

20. Check Valve

21. Banjo Bolt

Solenoid Coil

Steam

20

21 2121

LaMarzocco Hydraulic Schematic

9

Page 20

Section 2 Questionnaire

1. What material are the machines tubes made from? What precaution should you take in working

with them?

2. What is the order of water ow while brewing in an AV machine?

A. Banjo tube, group, owmeter, group valve, diffuser block.

B. Group, owmeter, group valve, banjo tube, diffuser block.

C. Flowmeter, banjo tube, group, group valve, diffuser block.

D. Diffuser block, banjo tube, group valve, owmeter, group.

3. Explain how the machine maintains the water level in the steam boiler.

4. What does the vacuum breaker do?

5. Why must the group valve be a 3-way valve?

6. What problem can cause damage to the machine’s entire hydraulic system?

7. What products are dispensed from the steam boiler?

8. When backushing the machine, what specic areas of the hydraulic system are being cleaned?

9. Describe what kind of water should be fed to the espresso machine.

Page 21

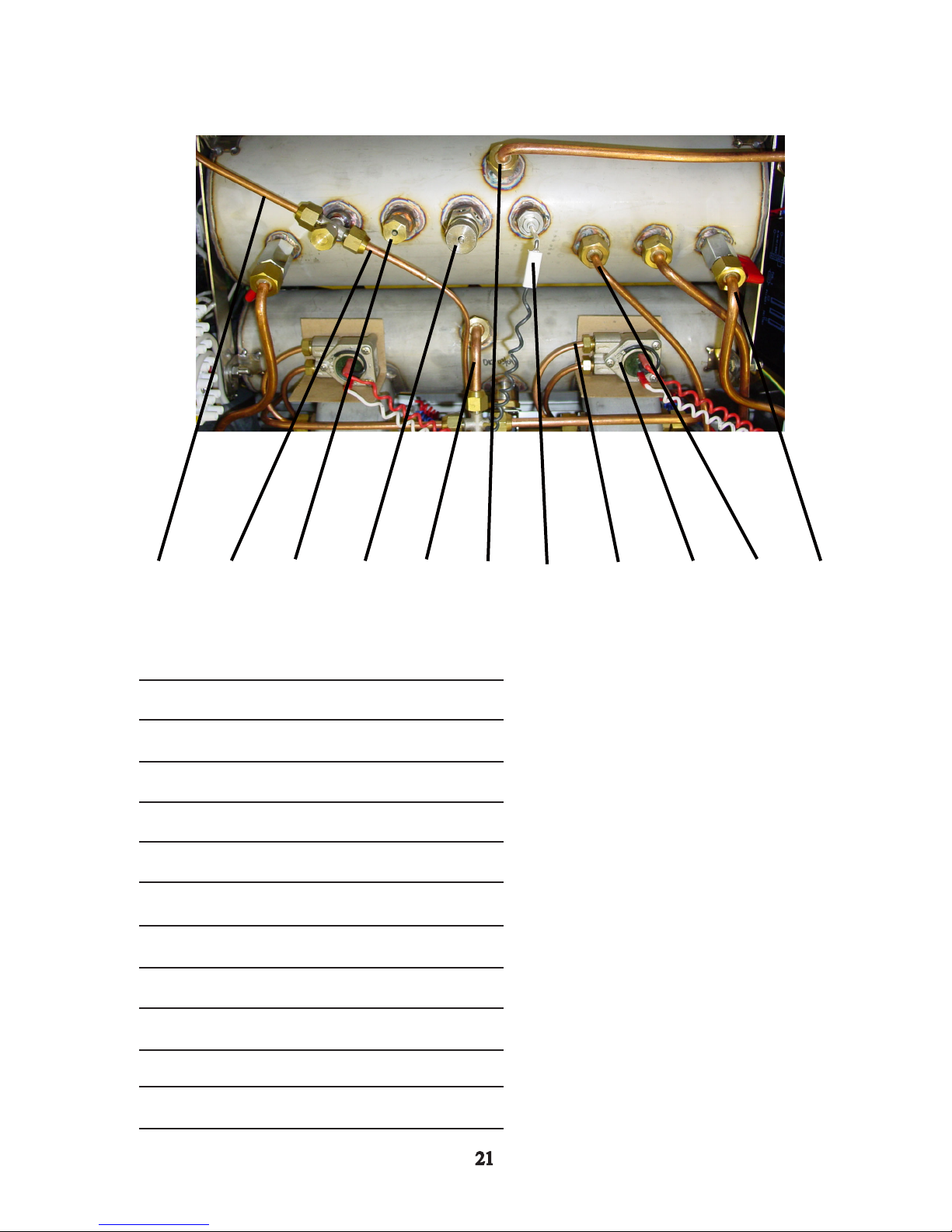

A B

10. Identify the hydraulic compents in the above picture.

A.

B.

C.

D.

E.

F.

G.

H.

I.

C D

E F G H I J K

J.

K.

Page 22

5. Electrical System

Safety

* Always ensure power is off at the circuit breaker before removing or cutting any wires on the

machine.

* Never apply power to the machine without rst insuring that all connections are properly insulated

and no live wires are touching the frame.

* Never replace a wire or fuse in a machine that is not of the same rating as the one you are replac

ing.

Using your Multi-meter

* Ensure power is off when measuring resistance.

* Ensure the lead you are testing voltage with does not come in contact with the frame.

* Do not use leads that are damaged.

Overview

* Power enters the machine through the power cord, which then enters a large terminal block, and

then to the main power switch.

* The main power switch has three positions:

* The rst position, “0”, is the off position.

* The second position, “1” (ll), provides power to the controller, pump, and the solenoid

coils.

* The third position, “2” (run), provides power to the heating elements.

Main High Voltage Wiring

The main wiring harness begins with the power cord and continues on throughout the machine.

* Two wires (one red, the other blue) provide ac power to the microprocessor as well as the valve

coils and brew switches.

* One leg is attached to all ac components at all times. (Unswitched leg)

* While the other leg is switched on either by the brew switch or the microprocessor, to activate the

component (switched leg).

* Each solenoid valve coil and the pump are supplied with one leg of 110v at all times.

* The control box and manual override switches provide the coils and pump with the second leg of

110v necessary to activate them.

Rocker Switches

All of the rocker switches on the LaMarzocco are double pole single throw.

* Contact is always made from top to bottom.

* Left and right sides are isolated from one another.

* Test rocker switches by turning the machine off and disconnecting the wires from the suspect

switch. Use a multi-meter to measure ohms from top to bottom with the switch on. A reading

of 0 ohms indicates a functional switch.

Page 23

Solenoid Coils

The solenoid valves operate by energizing an electromagnetic coil that causes a valve piston to

move downward, opening the valve.

* Test the coil by turning the machine off and disconnecting the wires, then read between the left

and right terminal with a multi-meter. The reading of a good coil should read between .7K

ohms and .8K ohms.

Thermostat

The thermostat controls the temperature of water in the front boiler.

* The thermostat rests in a well in the coffee boiler.

* The thermostat contains a bellows lled with a thermal uid that expands and contracts depend-

ing on the surrounding temperature.

* As the water heats in the coffee boiler it causes the uid in the

bellows to expand, which pushes up a piston.

* When the piston rises far enough, it actuates a switch, which turns

off the thermostat and cuts power to the heating element.

* When you adjust the screw on top of the thermostat you are

adjusting the distance the switch is from the piston.

Turning clockwise increases the distance causing the

piston to travel farther to actuate he switch, therefore in-

creasing the temperature of the water in the boiler. Turning

counter-clockwise has the opposite effect. Shorter distance

to travel and therefore lower water temperature.

* Each 1/4 turn of the adjustment screw represents approximately a 3 degree F change in temp-

erature.

Power from Switch

Power to Switch

Adjustment Screw

Bellows

Heating Element

Gasket

Each boiler has a heating element.

* The element for the steam boiler receives electrical power

from the pressure switch.

* The element(s) for the coffee boiler(s) receive electrical

power from the thermostat(s).

* As electrical power is applied to the element it heats up the

surrounding water in the boiler.

* To determine amp draw, divide wattage by incoming voltage.

Pump Motor

The pump motor turns the pump, which boosts existing water pressure. The LM uses several types

of motors.

* All motors feature an internal thermal overload protector.

* Some pump motors are equipped with a capacitor, which provides the initial “push” required to

start the motor.

*Over time the capacitor may weaken causing a slight delay in the motor turning on after the group

is activated.

Page 24

Control Box

The control box is the most complicated piece in the machine. It

can be divided into the following systems:

* Power supply - Turns high AC voltage into 18 volts DC (to

power the board relays), and 5 volts DC (to power the

microprocessor and logic circuits.)

* Auto-ll sensing circuit - Sends power to the auto-ll probe

looking for ground.

* Input - Ribbon cables carry information between the menu

button pads and control box.

* High voltage output - This provides power to the coils and pump

motor when the machine is called upon to brew

espresso.

Non-Mask & Mask

The power supply in the control box consists of:

* A 6.3 amp fuse, which protects the brain from a direct short to

ground.

* A 40mA fuse, on 4 groups only, which protects the rest of the

components in the event that something has shorted in

the DC system.

(i.e.: a Flowmeter)

* The transformer is the cube on the board. Its purpose is to

reduce the high AC voltage to 18v AC. The 18v AC then

passes through a bridge rectier, which is a series of

diodes, that convert the AC signal into DC, which then

goes through a 1000mfd capacitor, which lters out any

remaining AC signal.

*The best test point to verify DC voltage is on connector #2, pins 5 and 6, or from the red ow

meter wire to chassis ground.

There are three different versions of control boxes that have been used with the LaMarzocco. Until

approximately 1990 there was a Non-Mask Control Box. It has 8 pin connectors and colored ribbon

cables. Until approximately 1995 the Mask Control Box was in use. It has 10 pin connectors and

grey ribbon cables.

Wizard

Flowmeter

There are three electrical connections on the top of the owmeter:

* The “+” corresponds to the DC power supply and should always

read 16-22 volts.

* The “-” should go directly to a ring terminal attached to the hous

ing of the owmeter. This is the ground wire and should

always read 0 volts.

* The “0” is the signal output to the control box. The signal from

this terminal will switch rapidly from 18 volts to 0 volts.

* To test the owmeter disconnect the red and white wires and

measure ohms to verify that approximtely 2.2K ohms is

present between the “+” and “0” terminals. A reading of 0

indicates a problem requiring replacement of the sensor.

* The acceptable range is 1.8--2.4K ohms.

Field

Impellor

O-Ring

Body

Page 25

Pressure Switch

The pressure switch controls the steam pressure in the rear boiler by opening and closing the electrical circuit to the heating element.

* The pressure switch receives power generally to the bottom set of input leads. When the steam

pressure lowers in the boiler (usually .9 to 1.0 bar) the contacts close allowing power to

ow from the bottom leads through to the top leads and then to the heating element.

* As the steam pressure rises and reaches 1.2 bar the contacts open and cut the power to the heat

ing element.

Sirai Pressure Switch

Controls pressure and takes

the amp load of power to the

heating element.

Quick Guide to Testing Electronic/Electrical Components

Giemme Pressure Switch and Contactor

Controls pressure by opening and closing the contactor, which

sends power to the element and carries the amp load.

Capacitor Set your multi-meter to its highest ohms setting. Place your leads on the

capacitor terminals. The tester’s display should read a value that rapidly

decreases then suddenly begins increasing after reaching zero, now reverse

the leads on the capacitor, if the same decreasing then increasing readout

occurs the capacitor is good.

Flowmeter 1.8--2.4k Ohms between the “-” and “+” terminals means eld is good.

Solenoid Coils .7 - .8k Ohms between terminals means coil is good.

Fuses Continuity between fuse ends means fuse is good.

Pressure Switch 110v between top and bottom terminals while contacts closed means switch

is good.

Heating Elements Appropriate amp draw while pressure switch closed means element is good.

Rocker Switches 0 Ohms reading from top to bottom means switch is good.

Page 26

R

E

L

A

Y

F

R

A

M

E

G

R

O

U

N

D

T

O

G

R

E

E

N

T

H

E

R

M

A

L

L

IM

IT

S

W

IT

C

H

S

T

E

A

M

T

A

N

K

W

IT

H

S

E

R

IA

L

N

U

M

B

E

R

B

O

O

3

9

0

Y

E

A

R

,

M

A

C

H

IN

E

S

S

T

A

R

T

IN

G

F

A

N

S

A

R

E

IN

19

96

M

O

D

E

L

R

E

D

B

L

U

E

R

E

D

G

R

E

E

N

GROUND

B

L

A

C

K

R

E

D

1

0

B

B

A

A

B

L

U

E

G

R

E

E

N

W

H

IT

E

R

E

D

JUMPERS (2)

R

E

D

F

U

S

E

4

0

m

a

M

IC

R

O

P

R

O

C

E

S

S

O

R

2

20

V

A

C

.

F

A

N

W

H

IT

E

W

H

IT

E

W

H

IT

E

W

H

IT

E

B

L

U

E

B

L

U

E

B

L

U

E

R

E

D

R

E

D

R

E

D

R

E

D

R

E

D

R

E

D

R

E

D

R

E

D

R

E

D

R

E

D

R

E

D

R

E

D

R

E

D

R

E

D

R

E

D

W

H

IT

E

B

L

U

E

R

E

D

W

H

IT

E

B

L

U

E

R

E

D

W

H

IT

E

B

L

U

E

B

L

U

E

W

H

IT

E

R

E

D

S

O

L

E

N

O

ID

A

U

T

O

F

IL

L

S

T

E

A

M

B

O

IL

E

R

(4

)

RIBBON CABLES

H

O

T

W

A

T

E

R

S

O

L

E

N

O

ID

G

R

O

U

P

F

O

U

R

S

O

L

E

N

O

ID

G

R

O

U

P

F

O

U

R

B

R

E

W

S

W

IT

C

H

M

A

N

U

A

L

F

IL

L

S

W

IT

C

H

G

R

O

U

P

T

H

R

E

E

S

O

L

E

N

O

ID

G

R

O

U

P

T

H

R

E

E

B

R

E

W

S

W

IT

C

H

R

IG

H

T

E

LE

M

E

N

T

)

L

IG

H

T

(

O

N

W

IT

H

L

E

F

T

E

L

E

M

E

N

T

)

L

IG

H

T

(

O

N

W

IT

H

G

R

O

U

P

T

W

O

S

O

L

E

N

O

ID

G

R

O

U

P

T

W

O

B

R

E

W

S

W

IT

C

H

G

R

O

U

P

O

N

E

S

O

L

E

N

O

ID

G

R

O

U

P

O

N

E

B

R

E

W

S

W

IT

C

H

1

3

0

P

S

I

L

1

L

2

C

O

N

N

E

C

T

O

R

P

U

M

P

M

O

T

O

R

F

R

A

M

E

G

R

O

U

N

D

T

O

P

O

S

IT

IO

N

T

W

O

:

C

O

N

T

R

O

L

V

O

LT

A

G

E

A

N

D

H

E

A

T

IN

G

E

L

E

M

E

N

T

S

P

O

S

IT

IO

N

O

N

E

:

C

O

N

T

R

O

L

V

O

L

T

A

G

E

O

N

LY

T

W

O

P

O

S

IT

IO

N

O

N

/

O

F

F

S

W

IT

C

H

2

2

0

V

A

C

.

P

U

M

P

M

O

T

O

R

P

U

M

P

P

R

O

G

R

A

M

S

W

IT

C

H

K

E

Y

P

A

D

G

R

O

U

P

F

O

U

R

S

W

IT

C

H

H

O

T

W

A

T

E

R

K

E

Y

P

A

D

G

R

O

U

P

T

H

R

E

E

K

E

Y

P

A

D

G

R

O

U

P

T

W

O

K

E

Y

P

A

D

G

R

O

U

P

O

N

E

65432

1

109

8

7

4

0

m

a

1

0

A

1

2

3

4

P

P

U

M

P

F

U

S

E

1

0

A

M

IC

R

O

P

R

O

C

E

S

S

O

R

S

T

E

A

M

B

O

ILE

R

LE

V

E

L

P

R

O

B

E

G

R

O

U

P

F

O

U

R

F

L

O

W

M

E

T

E

R

G

R

O

U

P

T

H

R

E

E

F

L

O

W

M

E

T

E

R

G

R

O

U

P

T

W

O

F

L

O

W

M

E

T

E

R

G

R

O

U

P

O

N

E

F

L

O

W

M

E

T

E

R

S

W

IT

C

H

P

R

E

S

S

U

R

E

L

E

F

T

H

A

N

D

T

H

E

R

M

A

L

L

IM

IT

S

W

IT

C

H

LE

F

T

H

A

N

D

T

H

E

R

M

O

S

T

A

T

R

IG

H

T

H

A

N

D

T

H

E

R

M

A

L

L

IM

IT

S

W

IT

C

H

R

IG

H

T

H

A

N

D

T

H

E

R

M

O

S

T

A

T

E

L

E

M

E

N

T

R

IG

H

T

F

R

O

N

T

E

L

E

M

E

N

T

L

E

F

T

F

R

O

N

T

E

L

E

M

E

N

T

S

T

E

A

M

B

O

IL

E

R

4

3

2

1

12

111098765

ELECTRICAL LAYOUT

1014

L

A

M

A

R

Z

O

C

C

O

F

IR

E

N

Z

E

L

A

M

A

R

ZO

C

C

O

F

IR

E

N

Z

E

L

A

M

A

R

Z

O

C

C

O

F

IR

E

N

Z

E

L

A

M

A

R

Z

O

C

C

O

F

IR

E

N

Z

E

+

0

-

+

0

-

+

0

-

S

e

a

t

t

le

,

W

a

.

9

8

1

0

7

1

1

2

4

N

W

.

5

3

r

d

.

La Marzocco

MB 04-29-96 HALF

4AV WITH RELAY ON STEAM TANK

DATE

DESCRIPTION

REV.

DWG. NO.

TITLE

PROPRIETARY INFORMATION

DATE:

DRAWN BY:

TOLERANCES

SCALE

THIS DRAWING IS THE PROPERTY OF

LA MARZOCCO INT. AND IS NOT

WITHOUT THE WRITTEN CONSENT OF

LA MARZOCCO INT.

TO

BE USED, COPIED OR REPRODUCED

ALL DIMENSIONS IN MILLIMETERS

O TO 6 : }

6 TO 315 : }

OVER 315 : }

.5

1.2

3

2 1

R

L

1

2

1

R

L1

-

0

+

Page 27

3

AM

P

RAME

R

O

U

ND

TO

RE

E

N

ST

EAM

T

ANK

T

H SE

RIAL

N

UMBER BO

O

39

0

BLUE

R

ED

K

1 AM

P

C

RO

PR

O

CESS

O

R

N

T

E

T

E

T

E

T

E

D

D

D

D

D

D

D

D

D

ED

E

D

I

T

E

E

D

I

T

E

I

T

E

LENOID AUTO

F

IL

L

E

AM BO

ILER

RO

UP

F

O

UR

O

LENOID

R

O

UP

F

O

U

R

CH

F

IL

L

S

WI

T

CH

R

O

U

P

T

HREE

LENO

ID

R

O

U

P

T

HREE

CH

G

HT

ELEMENT

)

F

T

ELEMEN

T

)

T

WO

LE

NOID

RO

UP

T

WO

S

WI

T

CH

ROUP ON

E

LE

NOID

RO

UP ON

E

EW

S

WI

T

CH

RAME

RO

UN

D

TO

SIT

ION

T

WO

: CONT

RO

L VO

LT

AG

E AND

HEAT

ING ELEMEN

T

S

SIT

ION ONE : CONT

R

O

L VO

LT

AG

E ONLY

R

P

G

RO

UP

F

O

UR

PAD

G

ROU

P

T

HREE

E

1

PR

O

CESS

O

R

EAM BO

ILE

R

O

BE

R

O

UP

T

WO

LO

WMET

ER

ER

CH

G

HT

-

HAND

H

E

R

MO

ST

A

T

R

0

W

a.

9

8

10

7

2

4

N

W

.

5

3rd.

Page 28

Non-Mask

Non Mask control box and

keypads use 8 pin connectors.

Control box has internal programming key attachment.

Keypad has all red LED’s and

square buttons.

Mask control box and keypads

use 10 pin connectors. Programming key connection is external,

located on the bottom pin set.

Keypad has four green LED’s

over the shot buttons and one

amber LED over the continous

pour button.

Mask

Wizard

Wizard control box and keypads

use 16 pin connectors. There

are two keypads available, the

standard keypad and the chronos

keypad with a timer function.

Page 29

Section 3 Questionnaire

1. What safety precaution should be adhered to before performing maintenance on any electrical

component, apart from taking voltage and amperage readings?

2. Which statement best describes the La Marzocco’s high voltage circuit operation?

A. Each high-volt component receives 0 volts while the machine is operational. When the

keypad or semi-automatic brew switch is activated, 110 volts ows to the

component to activate it.

B. Each high-volt component receives 110 volts while the machine is operational. When the

keypad or semi-automatic brew switch is activated, an additional 110 volts ows to

the component to activate it.

C. Each high-volt component receives 0 volts while the machine is operational. When the

keypad or semi-automatic brew switch is activated, 220 volts ows to the component

to activate it.

3. Explain how the coils on the solenoid valves open the valve to allow water to ow through the

valve.

4. What generation of electronics does the La Marzocco currently use? What is the major difference

between this generation of electronics and the electronics used in the past?

5. What component controls voltage to the coffee boiler’s heating element?

6. What component controls voltage to the steam boiler’s heating element?

7. There is a four-position terminal block behind, and to the right of each group, match the terminal

position with its proper denition. (Match the description on the left with the number on the

right.)

A. 110vac traveling to the contol box

B. 110vac traveling to the solenoid valve

C. 110vac traveling to the control box

Red

Blue

White

Red

3

2

1

D. 110vac traveling to the pump motor

Page 30

Troubleshooting

Manual

Page 31

Table of Contents

Problem 1 - Shot volumes are inconsistent.

Solution 1 - Limit rinsing of the portalters with water from the brew group. Page 32

Solution 2 - Inspect the owmeter for proper operation. Page 32

Solution 3 - Ensure the group heads are bled of any air. Page 33

Solution 4 - Check for and repair a faulty ground connection. Page 34

Problem 2 - The buttons on the keypad won’t respond but the manual override does.

Solution 1 - Check the fuse on the control board. Page 35

Solution 2 - Check the keypads for proper operation. Page 36

Problem 3 - A single LED ashes above a selected keypad product button.

Solution 1 - Ensure the grind is not too ne and/or the tamp too hard. Page 37

Solution 2 - Check for and repair a faulty ground connection. Page 37

Solution 3 - Inspect the owmeter for proper operation. Page 38

Problem 4 - All of the LEDs on every keypad are blinking.

Solution 1 - Ensure the water supply is turned on and the lters/softeners are Page 39

operating properly.

Solution 2 - Inspect the auto-ll valve for proper operation. Page 39

Problem 5 - The espresso seems cold and under-extracted.

Solution 1 - Limit rinsing of the portalters with water from the brew group. Page 41

Solution 2 - Reset the thermal limit switch or replace if necessary. Page 41

Solution 3 - Adjust the coffee boiler’s thermostat, replace if necessary. Page 42

Problem 6 - The dispensing pressure is incorrect.

Solution 1 - Adjust the external boost pump. Page 44

Problem 7 - The machine is making a high-pitched squealing noise while brewing.

Solution 1 - Adjust the pump and/or expansion valve. Page 44

Problem 8 - No steam pressure.

Solution 1 - Ensure the main power switch is in the proper position. Page 45

Solution 2 - Ensure the heating element is receiving voltage and is operational. Page 45

Solution 2.1 - Replace the heating element. Page 46

Solution 3 - Ensure the pressure switch is functioning properly. Page 47

Problem 9 - The steam assembly and/or wand is leaking.

Solution 1 - Rebuild the steam assembly. Page 48

Problem 10 - Water leaks from around the portalter while brewing.

Solution 1 - Replace the portalter gaskets. Page 51

Problem 11 - Shot volumes are consistently short.

Solution 1 - Replace the group valve plungers. Page 52

Problem 12 - The steam boiler overlls.

Solution 1 - Inspect the auto-ll valve for proper operation and/or foreign object. Page 54

Solution 2 - Inspect the auto-ll probe for scale build-up. Page 55

Problem 13 - No water ow from the grouphead.

Solution 1 - Inspect the owmeter for scale build-up. Page 56

Solution 2 - Inspect the group valve for proper operation. Page 56

Solution 3 - Inspect the group for a missing diffuser screen and screw. Page 56

Unclog the banjo tube if necessary.

Page 32

Problem 1 - Shot volumes are inconsistent.

Solution 1 - Limit rinsing of the portalters with water from the brew group.

Excessive rinsing of the portalters with water from the brew group

will gradually drive down the temperature in the brew boiler. This

lowering of the brew temp will result in espresso shots that are less

than ideal: weak extraction, very little crema, and unusually high

volume.

Use water from the machine’s hot-water tap to rinse portalters.

Solution 2 - Inspect the owmeter for proper operation.

On automatic models, the owmeter measures the quantity of water owing to the brew group.

The owmeter uses an impeller, imbedded with two magnets, to actuate a hal-effect switch to

send pulse signals to the control box. The control box counts the pulses received from the ow-

meter to gauge water volume.

Important! - Before proceeding with solution 2, the following steps must be accomplished.

1. Turn off the main water supply to the machine.

2. Locate the expansion valve in the drain box.

3. Turn the barrel of the expansion valve counter-clockwise to relieve pressure in the

front boiler.

4. When the lower portion of the gauge reads 0 bar, you may proceed.

1. Remove the machine’s top panel.

2. Remove the red

and white wires from

the owmeter eld.

Measure DC voltage

from the red wire to

ground, you should

get a reading of 18vdc

+/- 10%.

Any other reading indicates a faulty transformer on the control

board.

3. Using a multi-meter, test the owmeter

eld for an electrical short. Place both

leads on the terminals of the eld. A functional owmeter will result in a reading of

2.2k ohms +/- 10%.

If the ohm reading is not within the proper

range, the eld is faulty and should be

replaced.

If the reading is with the proper range,

proceed to step 4.

Page 33

4. Remove the three

screws that secure the

eld to the owmeter

body.

5. Remove the

owmeter eld.

6. Inspect the impellor for smooth rotation

and scale build-up on

the magnets. Replace if

necessary.

7. Inpect the owmeter jet for scale

build-up. Clean out the

jet if necessary.

8. Replace the o-ring. 9. Reinstall the ow-

meter impellor.

10. Reposition the owmeter eld.

11. Resecure the three

screws.

12. Reconnect the terminal leads. Ensure the red wire is attached to the

“+” terminal and the white wire is attached to the “0“ terminal.

Reprogram the machine and check for proper operation.

Solution 3 - Ensure the group heads are bled of any air.

The La Marzocco uses a hollow, water-lled group casting, sometimes referred to as a saturated group. This design allows the convection of heat through the group. During installation,

the air is bled from the system, to enable larger volumes of water in the group head, resulting in

more stable brewing temperatures.

1. Turn the machine off 2. Remove the

control panel

cover.

3. Using a 5mm allen

wrench, loosen the

bleed screw 1/4 turn.

4. Once any air has

been relieved, tighten

the bleed screw securely.

Page 34

Solution 4 - Check for and repair a faulty ground connection.

The control board on the AV, or automatic models, as well as the auto-ll board on the EE or

semi-automatic models, each have step-down transformers that drop 220vac down to 24vac.

The voltage that has been dropped down is then passed through a rectifyer which converts the

AC voltage into DC voltage. AC voltage alternates it’s direction of ow, whereas DC voltage

ows in one specic direction, either towards positive (+), or towards negative (-). Without a

proper ground connection, the DC voltage has no reference point for 0 or neutral. This causes

sporatic behavior in DC componets such as the owmeters which can cause erratic shot volume.

1. If you identify a faulty

ground connection.

4. Place a ring terminal

over the wire end.

2. Cut and strip the end of

3. Twist the wire end.

the ground wire.

5. Crimp rmly. 6. Remove a boiler

mounting nut and install

the ground wires ring

terminal to the bolt.

7. Replace the boiler

mount nut and tighten

securely.

Page 35

Problem 2 - The buttons on the keypad won’t respond, but the

manual override does.

Solution 1 - Check the fuse on the control board.

The control board stores the shot volume settings and controls the auto-ll circuit. The control board

uses a 6.3 amp fuse to protect it against damage due to faulty electrical/electronic components. If

this fuse trips, it causes the machine’s automatic functions to stop.

Important! Before proceeding with solution 1, the following steps must be accomplished.

1. Turn the machine off.

2. Disconnect the power cord from the wall outlet.

1. Remove the machines left-side panel

by removing one phillips-head screw.

5. If the fuse appears functional, carefully remove it

from the board.

2. Remove the

control board

bracket and pull

the unit from the

side of the machine.

6. Ohm out the fuse using a multi-meter.

3. Remove the

three phillips-head

screws and lift off

the control box

cover.

7. Replace the fuse if a

reading greater than zero

ohms is registered.

Replace only with a fuse of

the same size and rating.

4. Locate the fuse

and visually inspect

for burn marks or

damage.

Replace if discolored

or damaged.

Return the machine to service.

Page 36

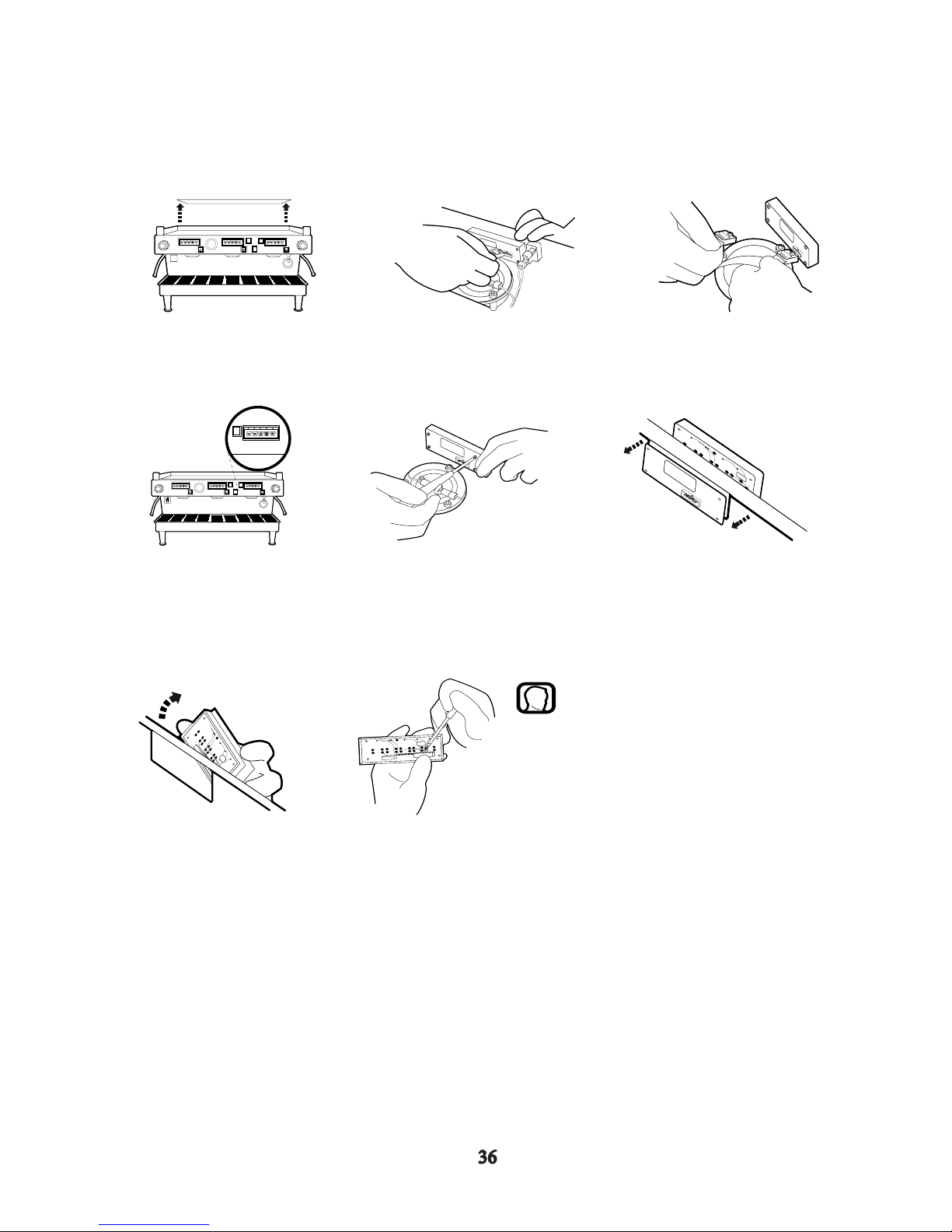

Solution 2 - Check the keypads for proper operation.

The keypads allow the operator to program shots to the desired volume, and to engage the pre-infusion feature. The keypads are connected to the controller by an 8 - 16 pin ribbon cable (depending on

model).

1. Remove the machine’s top

panel.

4. Test the suspect keypad.

If it is now functioning, you

have identied a faulty

ribbon cable. Replace the

cable.

2. Remove the ribbon cable

from the functioning keypad.

5. If the keypad still fails to

function, replace it.

6. Remove the four screws on

the back of the keypad.

3. Switch the cables between

a functioning keypad and the

suspect keypad.

7. Separate the back cover

from the keypad.

8. Remove the keypad

from the front of the machine.

9. Check the solder joints and

connections for evidence of water

damage.

If water damage is apparent, it

may be possible to displace the

moisture and restore functionality by cleaning the keypad with

contact cleaner.

Page 37

Problem 3 - A single LED ashes above a selected keypad

product button.

Solution 1 - Ensure the grind is not too ne and/or the tamp too hard.

If the grind is too ne and/or the tamp too hard, water-ow may be restricted. This slows down or

stops the movement of the owmeter’s impellor causing the control board to not register a proper

pulse signal. A ashing LED above the selected keypad button signals the operator that something

is wrong.

1. Ensure the LED consis-

tently goes into ashing

mode when you press it.

2. When coffee is packed too

tightly, water ow is restriced.

Tamp with less pressure.

3. You can also try adjusting

the grind coarser.

Solution 2 - Check for and repair a faulty ground connection.

The control board on the AV, or automatic models, as well as the auto-ll board on the EE or semi-

automatic models, each have step-down transformers that drop 220vac down to 24vac. The voltage

that has been dropped down is then passed through a rectier which converts the AC voltage into

DC voltage. AC voltage alternates it’s direction of ow, whereas DC voltage ows in one specic di-

rection, either towards positive (+), or towards negative (-). Without a proper ground connection, the

DC voltage has no reference point for 0 or neutral. This causes sporatic behavior in DC componets

such as the owmeters which can cause erratic shot volume.

See Problem 1, Solution 4 for detailed instructions.

Page 38

Solution 3 - Inspect the owmeter for proper operation.

On automatic models, the owmeter measures the quantity of water owing to the brew group. The

owmeter uses an impeller imbedded with two magnets to actuate a hal effect switch to send pulse

signals to the control box. The control box counts the pulses received from the owmeter to gauge

water volume.

Important! - Before proceeding with solution 3, the following steps must be accomplished.

1. Turn off the main water supply to the machine.

2. Locate the expansion valve in the drain box.

3. Turn the barrel of the expansion valve counter-clockwise to relieve pressure in the

front boiler.

4. When the lower portion of the gauge reads 0 bar, you may proceed.

Refer to Problem 1, Solution 2 for more detailed instructions.

1. Remove the machine’s

top panel.

5. Remove the owmeter

eld.

2. Remove the leads

from the owmeter

eld.

6. Inspect the impellor for smooth rotation

and scale build-up on

the magnets.

3. Using a multi-meter,

test the owmeter eld

for an electical short.

Also check the red

wire for 18vdc.

7. Inpect the ow-

8. Replace the o-ring.

meter jet for scale

build-up.

4. Remove the

three screws.

9. Reinstall the

owmeter impellor.

10. Reposition the

owmeter eld.

11. Resecure the

three allen head

screws.

12. Reconnect the

terminal leads.

Page 39

Problem 4 - All of the LEDs on every keypad are blinking.

The autoll valve allows water to ow into the steam boiler. The control board on the machine will

not allow the autoll valve to remain activated for no more than approximately 120 seconds. If the

autoll valve remains activated for more than 120 seconds, the machine will shut power to the autoll coil off, and cause all of the LEDs on every keypad to start blinking to indicate that the autoll

circuit has timed-out.

Solution 1 - Ensure the water supply is turned on and the lters/softeners are

operating properly.

If the water supply is turned off or the in-line water lters and/or softeners are clogged, water ow

into the machine will either be cut off completely or restricted. Lack of water ow into the machine

will cause the autoll circuit to time-out.

Solution 2 - Inspect the auto-ll valve for proper operation.

Important! - Before proceeding with solution 2, the following steps must be accomplished.

1. Turn off the main water supply to the machine.

2. Locate the expansion valve in the drain box.

3. Turn the barrel of the expansion valve counter-clockwise to relieve pressure in the

front boiler.

4. When the lower portion of the gauge reads 0 bar, you may proceed.

1. Remove the machine’s top panel.

5. Disconnect the inlet

and outlet tubes and

remove the autoll

valve from the machine.

2. Remove the machine’s right side panel

and surround.

6. Remove the endcap from the valve

stem.

3. Remove the control

box mounting bracket

from the machine.

7. Remove the coil

retaining nut.

4. Disconnect the

power leads going to

the solenoid coil.

8. Remove the coil

from the valve stem.

Page 40

9. Using a 22 mm

wrench, loosen the

valve stem from the

valve body.

10. Remove the valve

stem and plunger.

11. Inspect the

plunger for a damaged or worn seal.

Inspect the valve

stem and seat for

scale build-up.

Replace as nec-

12. Reinstall the valve

plunger and stem.

Reinstall the stem to

the valve body.

13. Reinstall the valve

coil and retaining nut.

Reinstall the valve

stem cap.

17. Reattach the power leads to the coil.

18. Replace the control board bracket.

19. Replace the machine’s surround and right side panel.

20. Replace the machine’s top panel.

14. Using a 14 mm

wrench, tighten the cap

to the stem.

15. Reinstall the valve. 16. Tighten both ttings.

Page 41

Problem 5 - The espresso seems cold and under-extracted.

Solution 1 - Limit rinsing of the portalters with water from the brew group.

Excessive rinsing of the portalters with water from the brew group

will gradually drive down the temperature in the brew boiler. This

lowering of the brew temp will result in espresso shots that are less

than ideal: weak extraction, very little crema, and unusually high

volume.

Use water from the machine’s hot-water tap to rinse portalters.

Solution 2 - Reset the thermal limit switch or replace if necessary.

If the temperature of the group cap reaches 266 F, the thermal limiter will trip, cutting power to the

heating element.

Important ! Before proceeding with solution 2, the following safety measures must be taken.

1. Turn the machine off.

2. Disconnect the machine’s power cord from the wall outlet.

1. Inspect the thermal limiter to

determine whether or not it has

tripped. If tripped, the red or

black reset button will protrude

upward slightly. Press down

rmly to reset.

4. Loosen the two screws

securing the thermal limiter

to the group cap.

2. Replacement of the

thermal limiter may be

necessary if it fails to

reset properly.

5. Remove and

replace the thermal

limiter.

3. Disconnect the two

wires on either side of the

thermal limiter.

6. Tighten the securing

screws and reattach the

wires. Test for proper operation.

Page 42

Solution 3 - Adjust the coffee boiler’s thermostat. Replace if necessary.

The temperature in the coffee boiler is controlled by a thermostat. If the thermostat is set improperly

or is not functioning properly, the water temperature for brewing espresso will be inconsitent, resulting in espresso shots that are less than ideal.

Important ! Before proceeding with solution 3, the following safety measures must be taken.

1. Turn the machine off.

2. Disconnect the machine’s power cord from the wall outlet.

1. Measure the temperature of the water leaving the group head. This is most accurately measured

by using a portalter equipped with a digital thermometer.

2. Most coffees brew best between 195 - 205 F. If the temperature of the brewing water is outside of

the proper brewing range, adjustment of the thermostat is required.

3. Remove the machine’s control panel cover. Locate the metal adjustment screw at the top of the

thermostat and, using a 1/4 x 14” screwdriver, adjust the thermostat.

Turn the screw clockwise to increase the brewing temperature. Turn counter-clockwise to decrease

the brewing temperature. Each 1/4 turn of the screw equals approximately 3 degrees F.

If adjustment of the thermostat does not seem to have any effect on the brewing temperature, most

likely the thermostat’s switch is faulty and should be replaced.

4. Remove the small phillips

screw securing the on/off

knob and remove the knob.

5. Remove the phillips screws

securing the machine’s front

panel. Remove the panel from

6. Remove the plastic

insulator screw from the

thermostat.

the machine.

Page 43

7. Remove the blue and

white wires from the lower

portion of the thermostat.

8. Remove the upper wire.

9. Remove the upper gauge

tube and carefully move it to

the side.

10. Remove the lower

gauge tube and carefully

move it to the side.

13. Pull the thermostat from

the well.

11. Using a small Phillips

screwdriver, remove the trim

screws.

14. Apply a liberal amount of

thermal compound to the bellows on the new thermostat.

12. Gently ex the panel

downward and then rotate the

thermostat 90 degrees.

15. Use a small cable tie to aid

in inserting the thermostat.

16. Insert the thermostat and

cable tie together.

17. Clip off the cable tie when

approximately 1/2” has been

inserted.

18. Press rmly on the thermostat to fully seat it into the well.

Page 44

Problem 6 - The dispensing pressure is incorrect.

Solution 1 - Adjust the external boost pump.

The water pressure required to properly brew espresso is 9 bar. Most municipalities supply

water between 3-5 bar. Most espresso machines incorporate a boost pump to increase the incoming water pressure to the required 9 bar to properly brew. If the dispensing pressure portion

of the gauge is not a 9 bar while brewing, adjust the pump pressure.

l

1. Locate the adjustment screw on the side of the pump. Load

a portalter with coffee and insert it into a group head. Press

the manual dispense switch and notice the brewing pressure

on the lower portion of the gauge. Using a at-tip screwdriver,

turn the screw clockwise to increase brewing pressure. Turn

counter-clockwise to decrease brewing pressure.

Problem 7 - The machine makes a high-pitch squealing noise

while brewing.

The La Marzocco uses an expansion valve to bleed off excessive pressure from the coffee

boiler. The expansion valve should be set to relieve pressure at 12 bar. If the expansion valve is

set too low and the pump pressure is too high, water will discharge through the expansion valve,

making a squealing noise.

Solution 1 - Adjust the pump and/or expansion valve.

1. Ensure the dispensing

pressure is set to 9 bar while

brewing.

2. Activate one of the group heads and allow water to exit

the group until the red heating element indicator light illuminates. While the light is illuminated the dispensing pressure

portion of the gauge should start to climb. Adjust the expansion valve so that it starts to releive pressure at 12 bar. Turn

the expansion valve barrel clockwise to increase pressure

and turn counter-clockwise to decrease pressure.

Page 45

Problem 8 - No steam pressure.

If no steam pressure is present in the steam boiler, there are several items to check. The main

power switch, the heating element, and the pressure switch.

Solution 1 - Ensure the main power switch is in the proper postition.

1. For power to run to the heating elements, the main power switch must

be in the “2” or “Run” position.

If the switch is in the “1” or “Fill” position, all other functions except the

heating elements will operate. This may lead the operator to believe the

machine is operational.

Solution 2 - Ensure the heating element is receiving voltage and operational.

1. Remove the machines top

and left side panel.

3. If the heating element requires replacement, following the instructions on the following page.

2. Using a multi-meter equipped with an amp clamp, check the amperage the element is pulling. To determine the proper amperage

an element should pull, divide the wattage of the element by the

voltage going to the element.

If the amperage is zero, turn the machine off, disconnect the leads

powering the element, switch the multi-meter to ohms and check

the element for continuity. If the continuity is zero, the element is

damaged and must be replaced.

If the amperage is lower than it should be. Switch the multi-meter to

ac voltage and check the voltage at the elements leads. The proper

voltage reading should be between 208-230. If the voltage is too

low, check the pressure switch for proper operation (Problem 8,

Solution 3). You can also check the wall outlet to ensure voltage is

Page 46

Solution 2.1 - Replacing the heating element.

1. Turn the machine off and

depressurize the steam boiler.

Remove the 5mm bolt located at

the bottom of the sight glass.

4. Using a 7mm nut-driver,

remove the nuts and wires from

the element terminals.

2. Remove the machines

top and left side panel.

5. Using either a heating element wrench in conjuction with

a pry bar or a 42mm socket,

unscrew the heating element.

3. Trim the heat-shrink

from the heating element

terminals. Be carefull not

to cut the insulation on

the wires.

6. Pull the element from

the end of the boiler.

7. Inspect the old element

for damage or excessive

scale build-up.

10. Install and tighten the new

element.