Page 1

franke filTerflow mini carTriDge housing

Installation Guide & Technical Information

Please retain for future reference

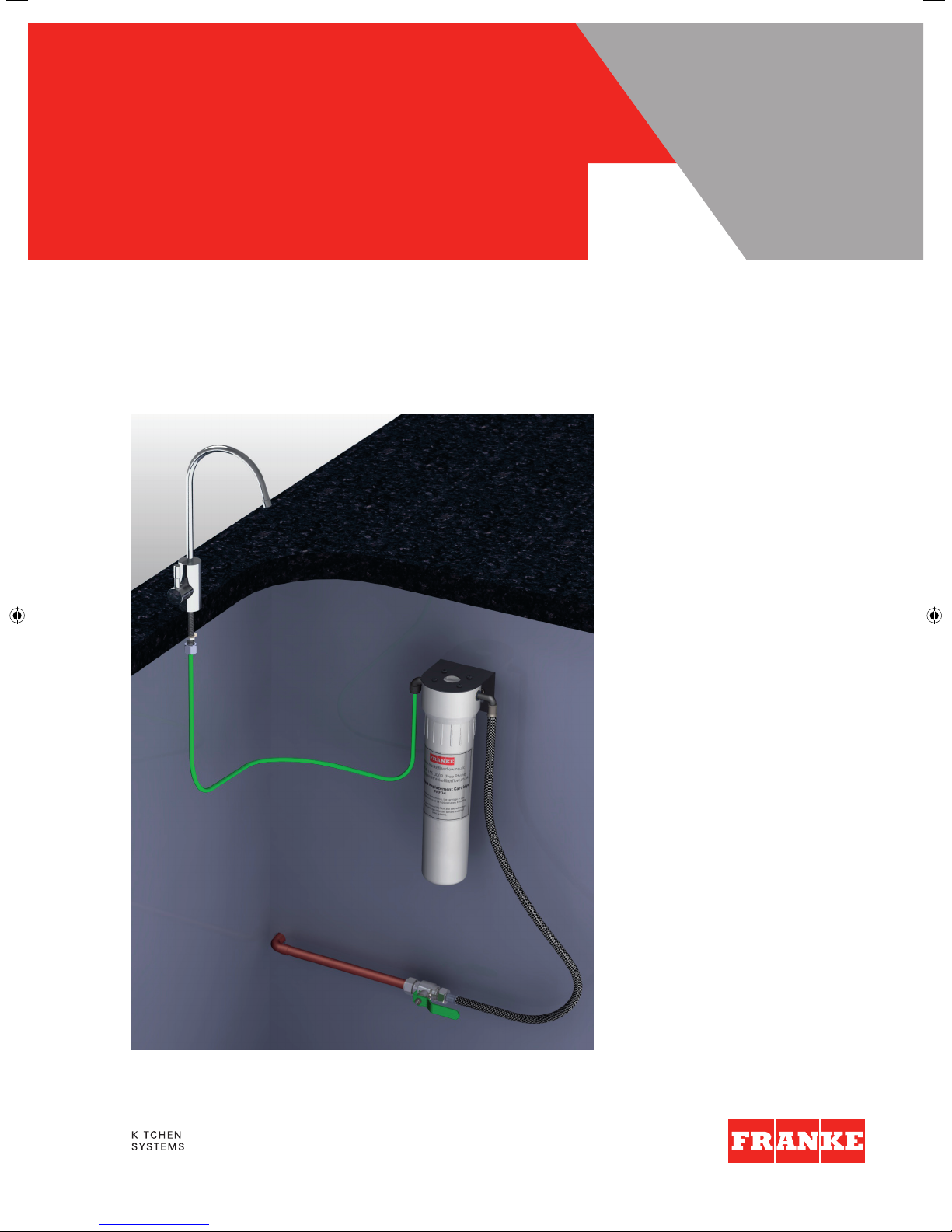

Franke FilterFlow Mini

Typical installation

Page 2

Thank you for purchasing

a franke filTerflow waTer

filTer sysTem

Replacement Filter Cartridges

We recommend that only genuine replacement cartridges and

spare parts are used to service your Franke FilterFlow. These

can be obtained on-line at www.FrankeFilterFlow.co.uk or call

freephone 0808 165 0008

Filter Cartridge Replacement Period

Franke FilterFlow filter cartridges should be replaced at 6 monthly

intervals in order to maintain their filtration performance.

Register your Franke FilterFlow

We invite you to register your FilterFlow purchase to access

our free cartridge replacement reminder service and direct

debit scheme. Register online at www.FrankeFilterFlow.co.uk,

use the freepost card provided, or call freephone

0808 165 0008 and talk to a member of our customer

service team.

If you are considering carrying out the installation of your

FrankeFlow water filter as a DIY project, we respectfully

suggest you consider the risks associated with installing

water appliances. Franke recommend you engage the

services of a qualified installer to install and commission

your Franke FilterFlow system.

Please keep this guide in a safe place. It will enable you to get

the best performance from your FrankeFlow filter now and in

the future.

SECTION 1:

HOW THE SYSTEM OPERATES

The Franke FRF02 multi stage water filter cartridge* supplied

as standard with your FilterFlow mini system is capable of

removing a wide range of possible water contaminants.

*For Northern Ireland, Franke FilterFlow systems are supplied

with a Franke FRF01 filter cartridge, to suit local water

conditions.

The FRF02 cartridge comprises an outer shell of micro porous

ceramic enclosing an inner section of composite carbon block.

This ceramic and carbon combination will reduce sediment,

harmful bacteria, cysts, chlorine and lead.

The FRF01 cartridge is an advanced carbon block with a white

pre-filter wrap and mesh. This cartridge will reduce sediment,

cysts, chlorine and lead and is suited to areas with low flow

and high levels of sediment.

Your Franke FilterFlow water filter system is designed to connect

exclusively to Franke FilterFlow Mini filtered water dispenser taps.

The component parts of the system are precision manufactured to

the highest quality standard, using premium food grade materials.

Correctly installed and maintained your FilterFlow water filter will

provide many years of trouble free use and a convenient, secure

supply of high quality drinking water. Your Franke FilterFlow is

supplied as a complete system with the parts required for

connection to your Franke Mini dispenser tap and the cold mains

water, including a Franke multi-stage filter cartridge.

2

Page 3

SECTION 2:

IMPORTANT THINGS TO CONSIDER

Water Supply (Water Fittings) Regulations 1999

Familiarise yourself with the requirements of the Water Supply

Regulations 1999: www.legislation.gov.uk/uksi/1999/1148/

contents/made

Maximum Working Pressure 6 bar/90psi

Measure the pressure during the ‘low demand’ period, when

the pressure will be at its highest e.g. mid-morning, mid-afternoon or late evening. If the pressure exceeds 6 bar/90psi, it

will be necessary to install a suitable pressure reducing valve

in the supply line upstream of the filter stop valve. (A suitable

pressure reducing valve is available online

at www.FrankeFilterFlow.co.uk/)

Minimum Pressure 1.5 bar/23psi

This is the minimum pressure recommended to achieve an

acceptable flow.

Filter Housing

The filter housing is precision engineered in ABS plastic and

will require no routine maintenance beyond regular lubrication

of the large sump ‘O’ Seal (see Lubrication below) and an

occasional wipe with a damp cloth.

Important. Under no circumstances should the housing come

in to contact with household cleaners as this may cause the

housing to fracture. Do not install the housing where it is

permanently exposed to daylight, as over time extended

exposure will degrade the plastic. As a precaution the housing

should be replaced every 10 years.

Taking care of the green flexible tubing

Although the tube can withstand significant water pressure do

not stretch , kink or expose the green plastic tubing to a naked

flame during installation. Do not allow the tube to come in to

contact with solvents and proprietary cleaners.

Lubrication

Applying a smear of grease to the large ‘O’ seal on the head of

the housing at each cartridge change will ensure the two parts

of the filter housing are easy to separate and re-assemble.

Important. Use only WRAS (Water Research Advisory Service)

approved silicon grease to lubricate the rubber seals, as rubber

and plastic parts will degrade and eventually fail if the wrong

grease is used. A suitable grade of silicon grease is available to

purchase online at www.FrankeFilterFlow.co.uk

Periods away from home

If you are planning to leave the premises where the filter is installed

for an extended period it is advisable to isolate the filter system.

Turn off the water supply to the filter using the filter stop valve. Turn

the filtered water tap on and off a few times to release the pressure

in the system. When you return just turn the water supply back on

and run the water for a few minutes before use.

SECTION 3:

PLANNING YOUR INSTALLATION

Although your Franke FilterFlow system is designed for ease of

installation, careful planning and preparation before commencing the installation will ensure the procedure is straightforward

and trouble-free.

Choosing the Location

Choose the most convenient place to tee into the 15mm cold

water supply to install the stop valve. Decide the best place to

position the filter unit within the kitchen cabinet. Bear in mind

the need for easy access to make future filter cartridge changes a simple process. Ensure the braided flexible hose and the

flexible plastic tube can be fitted without stretching or

kinking.

Installing the Filter System above the Ground Floor

Extra care should be taken when installing water appliances

above the ground floor. To reduce the risk of potentially

catastrophic flooding, install an automatic shut-off device at

the outlet of the filter stop valve.

Backflow Prevention

To comply with UK Water Supply (Water Fittings) Regulations

1999, a suitable check valve (non-return valve) arrangement

should be installed upstream of the filter stop valve.

Plumbing Connections

The stop valve supplied with the system is for connection to

15mm copper pipework. For alternative connection options

please contact Franke FilterFlow customer service.

3

Page 4

SECTION 4:

PRINCIPAL COMPONENTS

SECTION 5:

INSTALLATION

Shut off the mains water supply

Install the stop valve

Install the stopvalve (K) in the chosen position in the adjacent

15mm pipework. Note. For DIY installation a self piercing valve

is available as an alternative to the stop valve;

visit www.FrankeFilterFlow.co.uk

Secure the filter housing

Unscrew the housing head (C) and separate it from the sump

(J). Mark the positions for the two bracket supporting screws

(F). Screw in both screws, leaving their heads protruding

approximately 3mm to allow the bracket (D) to be easily lifted

on and off the screws.

Note. Depending on the nature of the cabinet it may be

necessary to position a batten behind the panel to make a

secure fixing. Remember the weight of the housing will

increase when filled with water.

DESCRIPTION PART NUMBER

Mini Dispenser Tap Supplied Separately

A 1/4” Plastic Tube— Green 9.2 02 10

B 3/8” Push-fit Elbow Connector 9.0 32 0 0

C Filter Housing Head N/A

D Bracket N/A

E Filter Cartridge FRF02 (FRF01 in Republic of Ireland)

F Wood Screws x 2 9.240 01

G ‘O’ Seal for Filter Sump 9.0 62 31

H Inlet Hose 9.2 8001

J Filter Housing Sump N/A

K Stop Valve 15mm comp x 1/2” BSPM 9.13000

4

Page 5

Install the filter cartridge and assemble the filter housing

Unpack the new filter cartridge (E) and screw it into the

housing head. Hand tighten the cartridge suf ficient to make a

watertight seal.

Important. Do not overtighten the cartridge. Over tightening

may shear off the threaded section of the cartridge.

Connect the filter housing to the stop valve

Select the stainless steel braided inlet hose (H). Connect the

end with the 1/2”BSP female nut to the male thread of the

stop valve (K). Tighten the nut with a suitable spanner sufficient to make a watertight seal. Important. Do not be tempted

to overtighten the nut as it may distort the washer and cause

the joint to leak.

Connect the filter housing to the FilterFlow Mini tap

When you are installing a Franke FilterFlow Mini tap with the

system refer to the part of the instructions explaining how to fit

the green plastic tube (A) to the shank of the tap before the

tap is inserted through the hole in the work surface. Note the

green tube is supplied with the filter kit, not the tap.

Take the free end of the green plastic tube and the push-fit

connector (B). Push the end of the tube fully home into the

female collet of the connector. Fit the male stem of the

push-fit connector elbow into the outlet of the filter housing

head and push it fully home.

Important note

— making the push-fit connections

Make sure that the tube and the stem of the connector is

pushed fully home. Initial resistance will be felt as the stem

engages the internal ‘O’ seal. It is essential to continue to push

the stem past the seal to the final stop. The stem should enter

10mm (3/8”) when fully engaged. Failure to fully engage the

connector may result in subsequent failure of the joint.

Turn the water on

Check to make sure all the connections are secure. Close

the stop valve and turn the lever of your filter tap to the ‘ON’

position. Turn on the mains water supply. Turn on the stop

valve. Check that the filtered water is running from the tap

spout. Important. For optimum removal performance adjust

the stop valve to set the filtered water flow to fill a one litre

jug in approximately 30 seconds..

SECTION 6:

MAINTENANCE

Routine maintenance

Apart from the scheduled filter cartridge replacement, the filter

unit will require very little routine maintenance, beyond

occasional lubrication of the head ‘O’ Seal (J).

Important. Use only WRAS approved silicon grease for this

purpose – an approved grease is available to purchase from

Franke FilterFlow; visit www.FrankeFilterFlow.co.uk or contact

customer service on 0808 165 0008.

5

Page 6

6

SECTION 7:

FREQUENTLY ASKED QUESTIONS

Limescale still forms in my kettle

The FRF02 and FRF01 cartridges supplied as standard with

Franke FilterFlow systems will not reduce limescale. They are

first and foremost a health and security cartridge, designed to

significantly reduce possible harmful waterborne contaminants

in both hard and soft water regions. Calcium and magnesium,

the minerals associated with limescale in water, are left intact

as they are considered beneficial to health and contribute to

its pleasant taste. However, if the cosmetic concern relating to

scale reduction is your primary concern, you can switch to an

FRF05 Carbon Dealk cartridge on your next cartridge change

date. Visit www.FrankeFilterFlow.co.uk for more information

and to view the range of specialist cartridges.

Unsightly deposits on the surface of a cup of tea

In hard water areas a ‘scum’ can appear on the surface of hot

tea. Although unsightly it is completely harmless. The cause is

related to the precipitation of calcium and magnesium in hard

water regions and a reaction with the tea bag material.

Changing tea bags will often remedy the problem. Alternatively

you can consider switching to a FRF05 cartridge (refer to

previous paragraph).

Milky water

With a new system a significant amount of air is trapped in the

microporous structure of the cartridge. This will form tiny

bubbles and give the water in the glass a milky appearance that

will soon disperse when left to stand for a few moments. This

may continue for 2 to 3 weeks until the cartridge is fully

conditioned..

Tiny black specks in the water

Tiny black specs may appear initially in the water. These are

harmless particles of carbon; residues from the manufacturing

process. Allow the filtered water to continue flowing for a while

until they are completely flushed through.

The filtered water flow slows to an unacceptable level

FRF02 cartridge- A significant reduction in flow is an indication

that the ceramic shell of the cartridge is blocked with contaminants. This often occurs soon after a new system is installed

due to plumbing residues, solder fluxes etc, becoming trapped

on the surface of the filter cartridge. If this happens inside the

recommended 6 month change cycle you may clean the

cartridge to restore the flow. Remove the cartridge (refer to

cartridge change instructions), hold the cartridge under warm

running water and abrade the outer surface vigorously with a

non soapy abrasive pad sufficiently to restore the white colour

of the surface.

FRF01 cartridge– The FRF01 cartridge is not cleanable and will

therefore need to be replaced once it becomes blocked with

contaminants.

SECTION 8:

CHANGING THE CARTRIDGE

IN YOUR FRANKE FILTERFLOW

Cartridge Replacement Cycle

The recommended filter cartridge change cycle is 6 months

Important. The period between cartridge replacements is not

guaranteed; it is an estimate based on filtering mains water of

average quality. Please bear in mind that water quality varies

from locality to locality and situation to situation. In areas with

higher than average turbidity (particle contamination) more

frequent cartridge changes may be necessary.

Before you begin

No special tools are required for this operation. All you will need

is a suitable receptacle to catch any spillage and a cloth or a

sponge handy. A rubber glove is provided to hold the wet

cartridge.

Lubricating the rubber seals

For ease of assembly we recommend that a film of silicone

grease is applied to the filter housing ‘O’ Seal, at least every

other cartridge change, to maintain the smooth operation of

the unit. Important note Only a WRAS approved silicon

lubricant should be used for this purpose. Small tubes of a

WRAS approved silicon grease can be purchased from Franke

FilterFlow at www.FrankeFilterFlow.co.uk

Disposing of the Spent Cartridge

You may dispose of the cartridge in your normal household

waste. Both the ceramic and carbon components of the FRF02

& FRF01 cartridges are biodegradable. You are welcome to

return either the plastic parts or the complete cartridge to

Franke FilterFlow for recycling. Should you decide to return the

cartridge please allow it to dry naturally and return it in the

original packaging.

Page 7

7

1. Locate the shut-off valve

and turn off the mains water

supply to the filter housing.

5. Screw the new cartridge in

to the head. Tighten it firmly

to make a seal. Do not over

tighten as this may cause the

threaded section to shear.

2. Turn the dispenser tap to

“ON” to release the pressure

in the system. Leave the tap

in the on position.

Important note. If the tap is

not left on the pressure

trapped in the system will

make it impossible to unlock

the filter housing sump from

the head.

6. Screw the sump to the

head and tighten it firmly.

Re-mount the assembled

housing on the two retaining

screws.

3. Have a bowl to hand. Grip

the sump firmly and turn it to

the left, just sufficient to

break the seal. Lift the filter

housing assembly off its two

supporting screws.

7. Turn the water supply ‘on’ and check the system

carefully for leaks. Leave the filter tap in the ‘on’

position and allow the water to run for a minimum

of 10 minutes to flush the system.

Check the flow rate. We recommend no more than

30 seconds a litre for optimum performance. If the

flow is too fast it can be regulated by adjusting the

stop valve.

4. Hold the housing over the

bowl and continue to

unscrew sump. Carefully

remove the sump and empty

the water it contains. Set it to

one side. Unscrew the filter

cartridge and discard it.

Page 8

Warranty

What is covered by the Franke FilterFlow guarantee?

- The repair or replacement of your drinking water filter

system if your system is found to be defective due to faulty

materials or within 2 years of purchase, at the discretion

of Franke FilterFlow.

- If any part is no longer available or out of manufacture,

Franke FilterFlow will replace it with a functional alternative.

Terms and conditions of the Franke FilterFlow 2 year guarantee

- The guarantee is valid for the UK and Republic of Ireland.

- The guarantee becomes effective at the date of purchase

(or the date of delivery if this is later).

- Proof of purchase is required under the terms of the guarantee.

The guarantee provides benefits which are additional to,

and do not affect your statutory rights as a consumer.

What is not covered by the guarantee?

- The Franke FilterFlow kitchen tap – see separate installation

guide for tap warranty details.

Franke FilterFlow does not guarantee the repair or

replacement of a product as a result of:

- Normal wear and tear.

- Accidental damage, faults caused by negligent use or care,

misuse, neglect, careless operation or handling of the filter

system which is not in accordance with the Franke FilterFlow

operating guidlines.

- Use of the filter system for anything other than normal

domestic household purposes.

- Use of parts not assembled or installed in accordance with

the instructions of Franke FilterFlow.

- Faulty installation, repairs or alterations (not in accordance

with the installation guide).

How do I make a claim under my Franke FilterFlow

2 year guarantee?

If you are in any doubt as to what is covered by your guarantee

or wish to discuss a claim please call us on 0808 165 0008

between the hours of 9.00am and 5.00pm, Monday to Friday.

If you are calling for the first time please have your receipt to

hand so we can record your date of purchase.

The company reser ves the right to alter, change or modify

product specifications without prior notice.

After Sales Service

Franke FilterFlow

3 Old Winery Business Park

Chapel Street

Cawston, Norfolk

NR10 4FE

Phone +44 (0)808 165 0008

Fax +44 (0) 844 358 0166

Email info@frankefilterflow.com

www.frankefilterflow.co.uk

Franke UK Limited

West Park, MIOC

Styal Road

Manchester

M22 5WB

Phone +44 (0)161 436 6280

Fax +44 (0) 161 436 2180

Email info.uk@franke.com

www.franke.co.uk

Loading...

Loading...