Page 1

Manuale d’istruzioni 4

RO

Piano di cottura da incasso

User and installation instructions 10

Built-in hob

Conseils d’utilisation et d’installation 16

Table de cuisson encastrable

Gebrauchs- und Installationsanleitungen 22

Einbau-Gasmulde

Instrucciones para el uso e instalación 28

Placa de cocción empotrable

Instruções de utilização e instalação 34

Placa de encastrar

Οδηγίες χρήσης και εγκατάστασης 40

Εντοιχιζόμενη μονάδα εστιών

Kullanım ve kurulum için talimatlar 46

Ankastre Ocak

Инструкции по установке и эксплуатации 52

Встраиваемая варочная панель

Manual de instrucţiuni 58

Plită de gătit cu încorporare

Instrukcja obsługi 64

Płyta kuchenna do zabudowy

FHTL 604 3G TC

FHTL 604 4G

FHTL 755 4G TC

Page 2

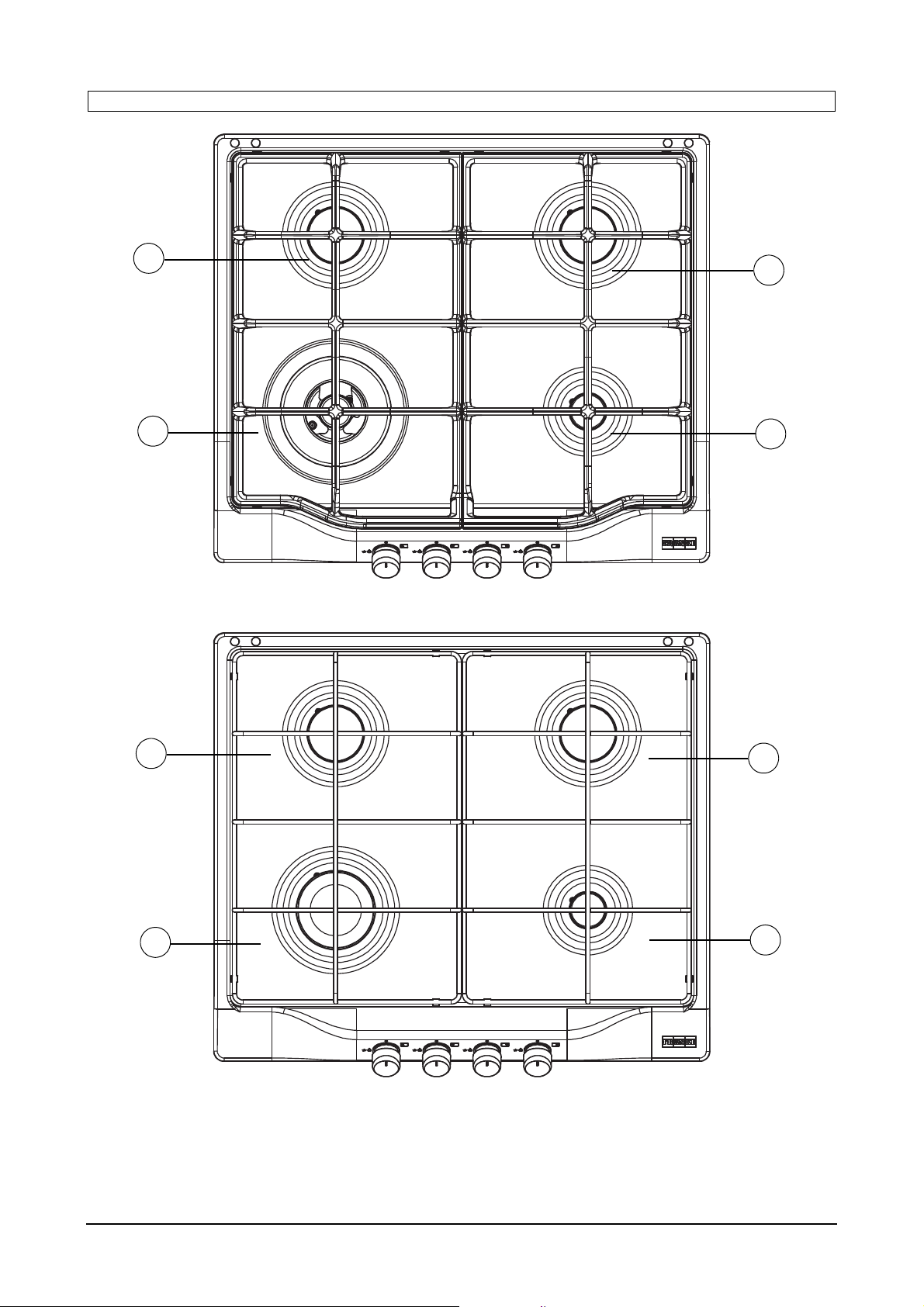

FHTL 604 3G TC

2

4

2

1

Fig. 1a

FHTL 604 4G

2

3

2

1

Fig. 1b

Fig. 1a/1b/1c

1

Page 3

2

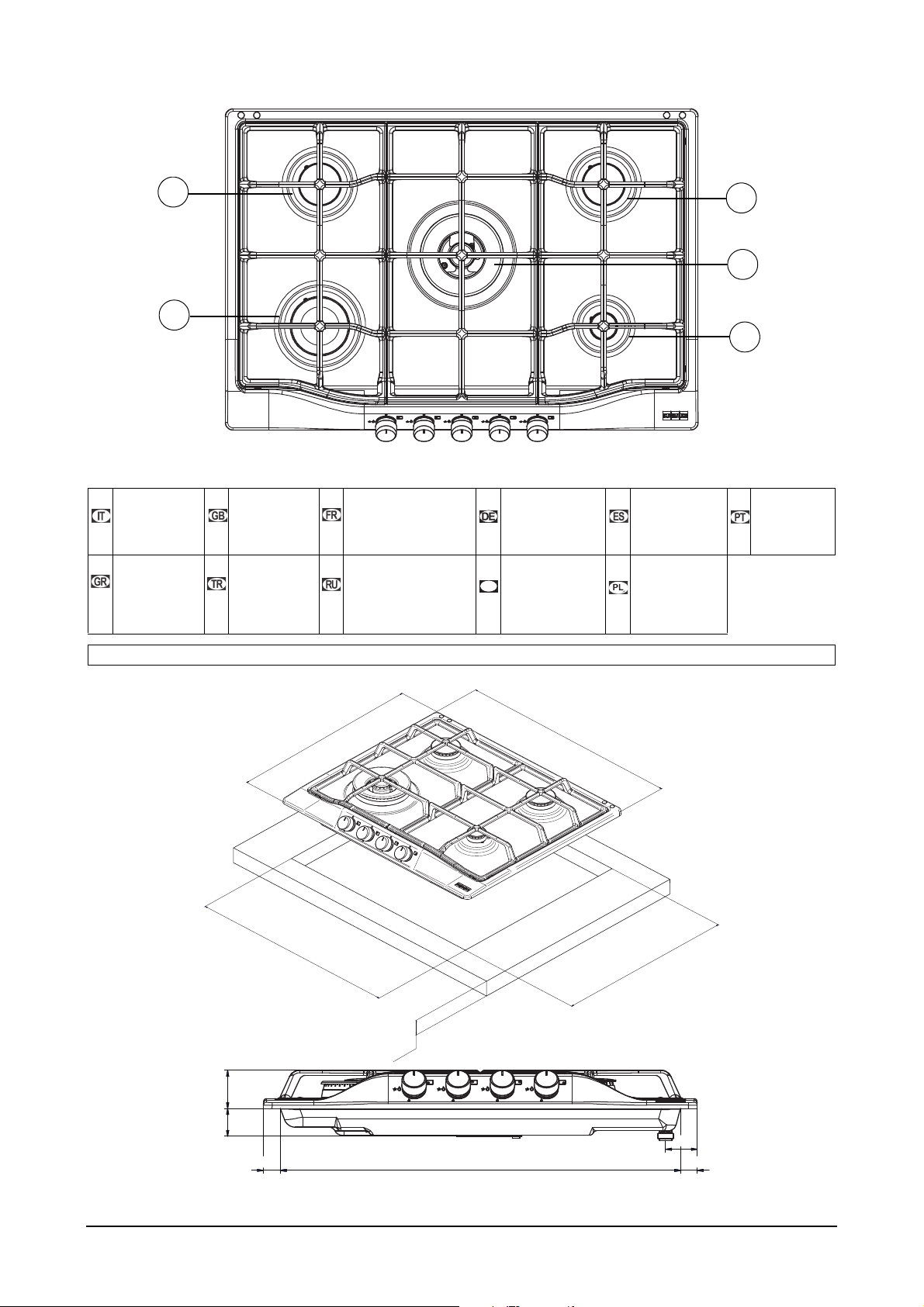

FHTL 755 4G TC

3

2

4

1

Fig. 1c

1) ausiliario

RO

5

9

0

5

1

0

5

50

m

i

n

.

4

8

0

4

0

23 544 23

43

3

8

5

2

FHTL 604 3G TC

FHTL 604 4G

Fig. 2a

Fig. 2b

2) semirapido

3) rapido

4) tripla

1) Βοηθητική

αχεία

2) Ημιτ

3) Τα

χεί α

4) Τρ

ιπλή

κορόνα

Fig. 2a/2b/2c/2d

1) auxiliary

2) semi-rapid

3) rapid

4) triple crown

1) Yardımcı

2) Yarı hızlı

3) Hızlı

4) Üç bilezikli

1) auxiliaire

2) semi-rapide

3) rapide

4) triple couronne

1) Вспомогательная

скоренного

2) У

действия

3) Бы

стродействующая

ойная корона

4) Тр

1) Zusatzbrenner

2) Normalbrenner

3) Schnellbrenner

4) Dreifacher

1) Auxiliar

2) Semirapid

3) Rapid

4) Triplă coro

ană

1) auxiliar

2) semirrápido

3) rápido

4) triple corona

1) pomocniczy

ej mocy

2) średni

3) dużej

mocy

4) potrójny

1) auxiliar

2) semi-rápido

3) rápido

4) tripla coroa

2

Page 4

5

5

0

m

i

n

.

4

8

0

4

0

51

0

7

5

0

FHTL 755 4G TC

Fig. 2c

Fig. 2d

Fig. 3

Fig. 4

Fig. 3 / Fig. 4

2

5

5

2

123

103

544

103

3

Page 5

Contents

Introduction...................................................................................................................................... 10

Use ................................................................................................................................................... 10

Hob cleaning and maintenance......................................................................................................... 10

Support............................................................................................................................................. 11

Safety instructions............................................................................................................................. 11

Installation......................................................................................................................................... 12

Technical Data................................................................................................................................... 14

Introduction

Thank you for choosing a Franke product. Before using the appliance, please read all the instructions and advice

contained in this manual. In this way you will be able to make best use of the appliance and also ensure its lasting

efficiency. Keep this booklet for further reference.

Use

Lighting the burners

In these models lighting is done with the knobs. To light the burners, proceed as follows:

1. Press and turn the required knob.

2. Keep the knob pressed down for 3-4 seconds to

to allow the thermocouple to heat up.

3. Then release the knob and, turning it anticlockwise (in mo

flame as required. If the flame does not stay alight, repeat the operations from step 1.

allow the sparks to ignite the gas coming out the flame spreader and

dels 604 and 1204, to the lighting symbol *), adjust the

Symbols

: cock closed;

: lighting and max. delivery;

: min. delivery.

Burner use

For lower gas consumption and better efficiency, it is advisable to use pots of widths suitable for the burners, making

sure the flame does not go beyond the edges (comply with the table on page 14).

Automatic safety valve

These hobs have a safety device that automatically closes the gas cock if the flame accidentally goes out due to draughts,

a pot spilling over, or a temporary interruption of the gas supply. This device is activated approx. 30 seconds after the

flame goes out.

Hob cleaning and maintenance

Before carrying out any hob cleaning or maintenance, always unplug the appliance or disconnect the power

by means of the main switch.

• Never use steam appliances, scouring pads, steel wool, muriatic acid or other products which cou

the surface.

• Do not leave acid or alkaline substances on the hob.

• Never use sharp objects, as they could damage the sea

• Do not use products containing sands, alka

dishwashers.

• To prevent scale deposits from forming, always thoroughly dry the applia

• Immediately remove any foods with high sug

• Remove grime with a damp cloth.

lis, acids, chlorides, oven sprays or detergents normally used to clean

ar content that spill onto the hob.

ls between the trim and worktop.

nce after going over it with a damp cloth.

ld scratch or mark

10

Page 6

• All the grates, burner caps and flame-spreaders can be cleaned (after removing them from the hob) with hot soapy

water, making sure to carefully dry them. DO NOT CLEAN IN A DISHWASHER. Make sure the gas outlet zones are

perfectly clean.

• The natural colour of the pot grids in the pot placing section may alter over time due to the heat.

Support

In case of any operation problems, contact the Franke Technical Service Centre (see attached list).

Never make use of unauthorised technicians.

Specify:

– the type of fault;

– the appliance model (Art.);

– the serial number (S.N.).

This information is given on the appliance dataplate on the warranty certificate.

Safety instructions

• This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instructions concerning

the use of the appliance by a person responsible for their safety.

• Children must be supervised to ensure that they do not play with the appliance.

• The manufacturer declines any liability for damage due to: incorrect installation, improper, wrong or unreasonable use.

Always contact qualified personnel in the following cases:

– installation (refer to the installation section);

– doubts regarding operation.

Contact an authorised service centre in the following cases:

– immediately after unpacking, in case of doubts about the integrity of the appliance;

– replacing or damaged power cable;

– appliance malfunction or poor operation, requesting original spare parts.

General instructions

To ensure safe and efficient operation of this appliance:

– only contact authorised service centres;

– always demand the use of original spare parts;

– the appliance is designed for non-professional, domestic use; do not modify its characteristics;

– the dataplate gives the symbols indicating the countries for which the instructions apply;

– appliance electrical safety is guaranteed only when it is connected to an earthing system in compliance with the

current regulations;

– this appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instructions concerning

the use of the appliance by a person responsible for their safety;

– do not touch the pot grids during use, since they become very hot. Keep children away from the appliance;

– only use the appliance for cooking food;

– before any cleaning or maintenance operations, or in case of malfunction, disconnect the appliance from the mains

power supply;

– always check that the control knobs are in the off position when the appliance is not in use.

Do not allow children to touch:

– the controls or the appliance in general;

– the packing elements (bags, polystyrene, staples, etc.);

– the appliance, during and immediately after use, since the hob becomes very hot;

– an unused appliance (make any potentially hazardous parts safe).

Do not:

– touch the appliance with wet parts of the body;

– use the appliance when barefoot;

– pull the appliance or power cable to unplug it;

– carry out improper or hazardous operations;

– leave the power cables of other electric appliances on hot parts of the appliance;

– expose the appliance to atmospheric agents;

– use the appliance as a support top;

11

Page 7

– use flammable liquids near the appliance;

gasket

gasket

flexible

steel tube

copper pipe

fig. 5

gasket

flexible steel hose

copper pipe

– use adapters, multi-sockets or extension leads;

– allow anyone except qualified personnel to install or repair the appliance.

Important

– Do not place unstable or deformed pots on the burners, since they may tip over or cause spills.

– If the appliance has a lid, make sure the burners are cold before closing it.

– Close the gas supply cock when the hob is not in use.

– Before installation, make sure the gas supply is compatible wi

th appliance specifications. The type of gas for which

the appliance is arranged is specified on the dataplate on the bottom of the tray. This appliance is not connected

to a fume extraction device and must be installed and connected in compliance with the current regulations.

y particular attention to the applicable regulations on ventilation. T

Pa

heat and humidity in the room where it is installed. Ensure the

he use of a gas cooking appliance produces

room is adequately ventilated: keep natural ventilation

openings open, or install a mechanical ventilation device (extractor hood with exhaust duct). In case of intensive

or prolonged use of the appliance, it may be necessary to provide additional ventilation, for example by opening a

window

, or more efficient ventilation, by increasing the fan speed (if present).

Installation

The necessary operations for installation, including gas and electrical connections, are described below. They must be

carried out by qualified personnel in accordance with current regulations, since their performance by unskilled persons

may constitute a hazard.

The manufacturer declines any liability for injury to persons or dama

these provisions. The gas connection must comply with the regulations in force in the country at the time of installation.

Preparing the cabinet

This handbook refers to a

class 3 built-in hob.

Prepare the hole in the top according to the measurements given in fig. 2.

In any case, it is essential to make the

opening in the most convenient position, bearing in mind that the gas pipe must

not come into contact with the sides of any oven under the hob.

Fitting in the cabinet

After carrying out the connection operations, apply the sealing strip around the hole and position the hob.

Carefully tighten the fixing hooks (fig. 3). Remove any excess sealing strip.

Note

If the appliance is not installed above an oven, a separator baffle must be arranged (fig. 4).

Connection to the gas supply

Connect the appliance to the gas supply in compliance with the current regulations, only after making sure it is arranged

for the type of gas to be used.

Otherwise, carry out the operations described in the section on “

injectors” (page 13). For liquid gas use pressure regulators complying with the

current regulations.

Connection to the gas supply can be made in two ways:

A Connect the gas hob using a 12 mm diameter rigid copper pipe, as shown

in fig. 5. T

o ensure a good seal, use the elastomer gasket supplied as an

accessory.

B Connect the hob using a continuous-surface flexible steel tube. Also in this

case, to ensure a good seal use the gasket supplied as an accessory.

Make sure to comply with the current regulations on gas systems.

After carrying out the connection use soapy water to check for

For United Kingdom, Northern Ireland and Republic of Ireland

ge to things due to failure non-compliance with

replacing

any leaks.

12

Page 8

Ventilation of rooms

BLUE

YELLOW/GREEN

BROWN

Make sure the room where the appliance is installed has permanent ventilation openings towards the outside or

ventilation ducts to ensure an adequate air flow, as prescribed by the current regulations. All openings made must:

2

1. have a section of at least 100 cm

2. be made in such a way that they cannot be

3. be provided with suitable protection to ensu

4. be at a suitable height from floor so that they do

If openings are made in the wall of an adjacent room, the latter must have direct ventila

;

obstructed from inside or outside;

re that the ventilation opening is not reduced;

not hinder the exhausting of fumes.

tion and must not be:

1. a bedroom

2. a common area of the building

3. a fire hazard area

Before testing and inspecting the appliance, make sure the room in which the ventilation ope

ning is made does not have

low pressure due to the operation of another user and that the ventilation between the two rooms is guaranteed by

permanent free openings, for example by increasing the gap between the bottom of the door and the floor. The

exhausting of fumes must occur by means of a hood which, in turn, must be connected to a chimney, flue, or directly to

the outside.

Accessing the hob

To access the tray containing the functional parts, proceed as follows:

• remove the grids, burner caps and flame-spreaders;

• remove the knobs, sliding them off their pins;

• remove the screws that fix the burners to the

hob;

• lift the hob.

Connection to the power supply

The FRANKE cooking hob comes with a 3-core power cable with free terminals.

If the hob is permanently connected to the power supply

, install a circuit breaker having a contact opening distance that

allows complete disconnection in the conditions of overvoltage category III. Make sure:

a) the plug and socket are suitable for a 16 A current;

b) both are easily accessible and positioned so that no live part can be accessed when

inserting or removing the plug;

c) the plug can be inserted without difficulty and is ac

d) that when the plug is inserted, the hob is not re

e) the terminals of two appliances are

f) a 3 x 0.5 mm

2

H05VV-F type cable is used when replacing the power cable;

g) to respect the polarities of the free term

not connected to the same plug;

inals (Brown=Live – Blue=Neutral – Yellow/

cessible with the appliance installed;

sting on it when installed in the cabinet;

Green=Earth).

NB: Make sure the characteris

tics of your household electrical power supply (voltage,

maximum output and current) are compatible with those of your FRANKE hob.

Replacing injectors

Important: all the appliances are factory-set for natural gas (G20).

If a different type of gas is to be use

d, change the injectors as follows:

1. remove the grids, burner caps and flame-spreaders;

2. unscrew the injectors and replace them with those provided

and suitable for the gas supply, making sure the marking

matches that given in the table (page 14);

3. refit the flame-spreaders, burner caps and grids;

4. these burners do not require air adjustment.

Important

When converting the appliance to a different type of gas, place the corresponding sticker (supplied as an accessory) in

the special space on the dataplate. For operation with LPG. (G30 or G31), the minimum flame adjustment screw must

be fully screwed down. These appliances are supplied in cat. II 2H3+.

13

Page 9

Minimum flame adjustment

A

– Remove the knobs (push-on type).

– Light the burners and adjust the minimum flame by turning the

adjustment

screw clockwise to decrease the flame and anticlockwise to increase it

(fig. 6). The screwdriver for adjustment is su

pplied w

ith the accessories.

Technical Data

Technical data FHTL 604 3G TC

Appliance category: II 2H3+ (G20=20 mbar >>

BURNERS RATED

POWER (kW)

Auxiliary 1.00 0.55 0.095 77 73 50 140

Semi-rapid 1.75 0.70 0.167 118 127 66 200

Triple crown 3.80 2.10 0.362 141 277 98 240

TOTAL INSTALLED GAS RATED POWER (kW) 8.30

TOTAL RATED CAPACITY - GAS G20 (m³/h) 0.791

TOTAL RATED CAPACITY - GAS G30/G31 (g/h) 604

POWER / VOLTAGE / CURRENT / FREQUENCY 0.6 W / 220-240 V / 16 A / 50-60 Hz

AIR NECESSARY FOR COMBUSTION (2 m³/h per kW of installed gas rated power) 16.60

REDUCED

POWER

(kW)

RATED

CAPACITY G20

(m³/h)

G30/G31=28-30/37 mbar)

G20

INJECTORS

20 mbar

(100/mm)

RA

CAP

G

TED

ACITY

30/G31

(g/h)

INJECTORS

/G31

G30

28-30/37 mbar

(100/mm)

RE

MAX

COMMENDED

POT Ø (mm)

Technical data FHTL 604 4G

Appliance category: II 2H3+ (G20=20 mbar >>

BURNERS RATED

POWER (kW)

Auxiliary 1.00 0.55 0.095 77 73 50 140

Semi-rapid 1.75 0.70 0.167 118 127 66 200

Rapid 3.00 1.10 0.286 129 218 85 220

TOTAL INSTALLED GAS RATED POWER (kW) 7.50

TOTAL RATED CAPACITY - GAS G20 (m³/h) 0.715

TOTAL RATED CAPACITY - GAS G30/G31 (g/h) 545

POWER / VOLTAGE / CURRENT / FREQUENCY 0.6 W / 220-240 V / 16 A / 50-60 Hz

AIR NECESSARY FOR COMBUSTION (2 m³/h per kW of installed gas rated power) 15.00

REDUCED

POWER

(kW)

RATED

CAPACITY G20

(m³/h)

G30/G31=28-30/37 mbar)

G20

INJECTORS

20 mbar

(100/mm)

RA

CAP

G

TED

ACITY

30/G31

(g/h)

INJECTORS

/G31

G30

28-30/37 mbar

(100/mm)

RE

MAX

COMMENDED

POT Ø (mm)

14

Page 10

Technical data FHTL 755 4G TC

Appliance category: II 2H3+ (G20

BURNERS RATED

POWER (kW)

Auxiliary 1.00 0.55 0.095 77 73 50 140

Semi-rapid 1.75 0.70 0.167 118 127 66 200

Rapid 3.00 1.10 0.286 129 218 85 220

Triple crown 3.80 2.10 0.362 141 277 98 240

TOTAL INSTALLED GAS RATED POWER (kW) 11.30

TOTAL RATED CAPACITY - GAS G20 (m³/h) 1.077

TOTAL RATED CAPACITY - GAS G30/G31 (g/h) 822

POWER / VOLTAGE / CURRENT / FREQUENCY 0.6 W / 220-240 V / 16 A / 50-60 Hz

AIR NECESSARY FOR COMBUSTION (2 m³/h per kW of installed gas rated power) 22.60

REDUCED

POWER

(kW)

=20 mbar >> G30/G31=28-30/37 mbar)

RATED

CAPACITY G20

(m³/h)

G20

INJECTORS

20 mbar

0/mm)

(10

RATED

ACITY

CAP

G30/G31

(g/h)

INJECTORS

/G31

G30

28-30/37 mbar

mm)

(100/

COMMENDED

RE

POT Ø (mm)

MAX

The use of larger pots than those specified can cause excessive overheating of the knobs and top and, in case

of prolonged use, yellowing of the cover (if in stainless steel).

Franke declines any liability for damage due to such use.

Total heat capacity: see dataplate on the bottom of the hob.

3

Air necessary for combustion: 2 m

/h per kW of installed power - see dataplate.

Power supply voltage 220/240 V 50-60 Hz.

The appliance complies with the following EC Directives:

– 90/396/EEC (Gas);

– 2006/95/EEC (Low Voltage);

– 2004/108 ECC (Electromagnetic Compatibility).

15

Loading...

Loading...