Franke DW6160C Catalog

FRANKE STYLE

2

3

CONTENT

WHY FRANKE FILTRATION

WHY FRANKE FAUCETS

WHY FRANKE STAINLESS STEEL SINKS

WHY FRANKE COMPARISON

WHY FRANKE FIRECLAY SINKS

WHAT’S NEW

SINKS

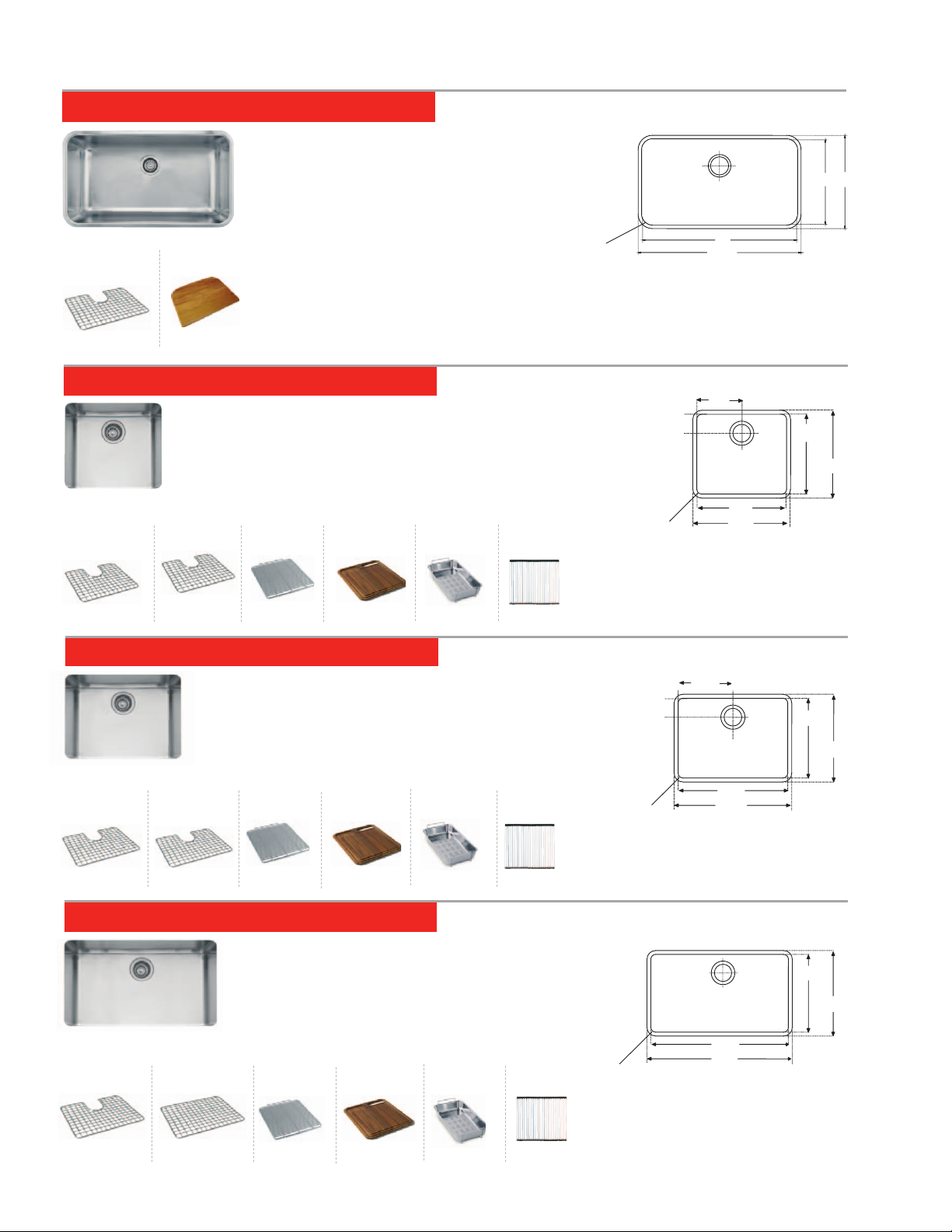

STAINLESS STEEL UNDERMOUNT SINKS

Accessory Undermount Bowls

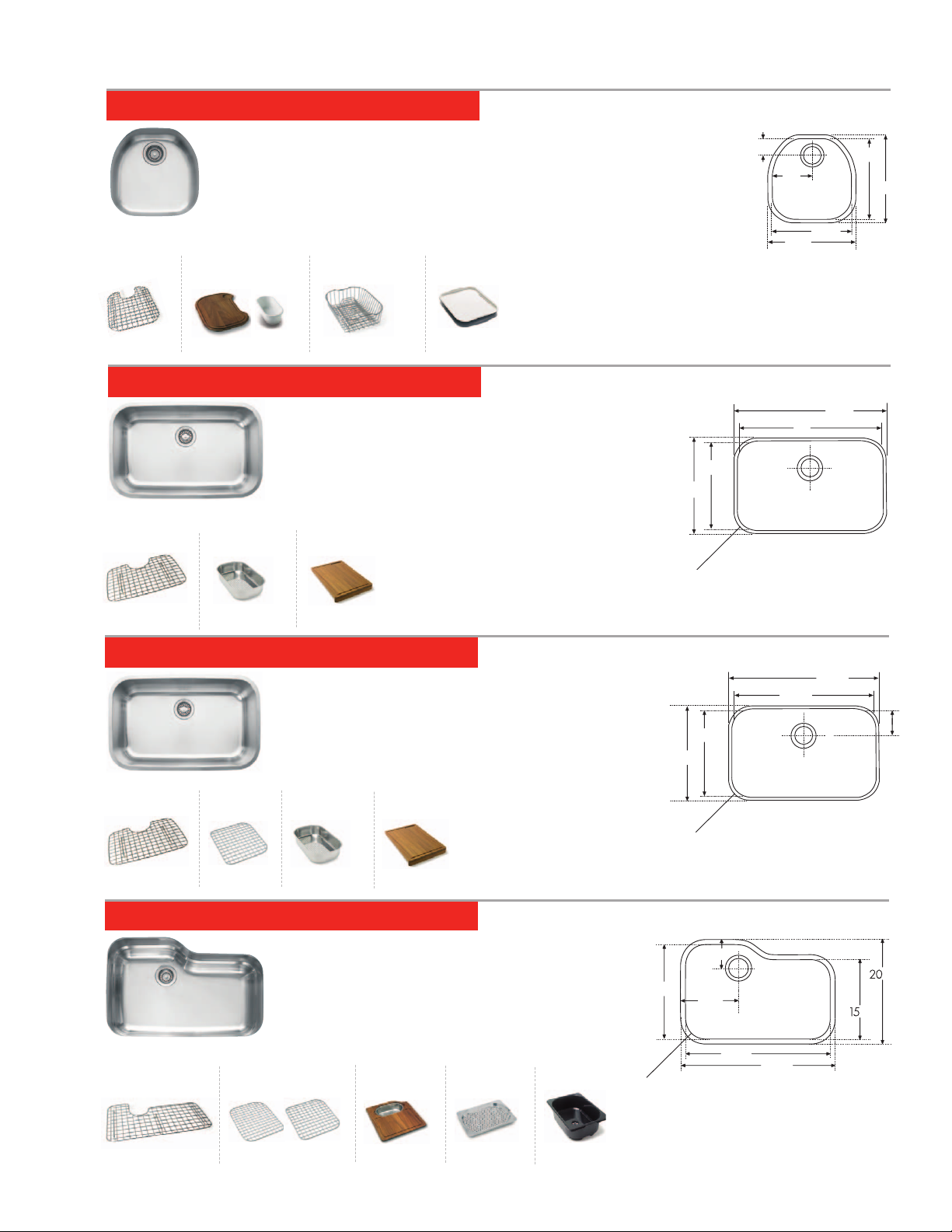

Single Undermount Bowls

Double Undermount Bowls

Triple Undermount Bowls

Culinary Work Station

STAINLESS STEEL APRON FRONTS

FIRECLAY APRON FRONTS

FIRECLAY UNDERMOUNTS

FAUCETS

KITCHEN FAUCETS

Single Hole Faucets

Side Spray Faucets

POT FILLERS

BAR AND PREP FAUCETS

POINT-OF-USE FAUCETS

FILTRATION

ACCESSORIES

RAIL SYSTEM

GRIDS

CUTTING BOARDS

ACCESSORIES

WASTE DISPOSERS

QUICK REFERENCE GUIDE

OVERVIEW OF CABINET SIZES

4-5

6-7

8-9

10

11

12-16

19

25

35

43

44

46

50

54

59

63

66

68

70

76

80

82

84

86

88

90-91

92-93

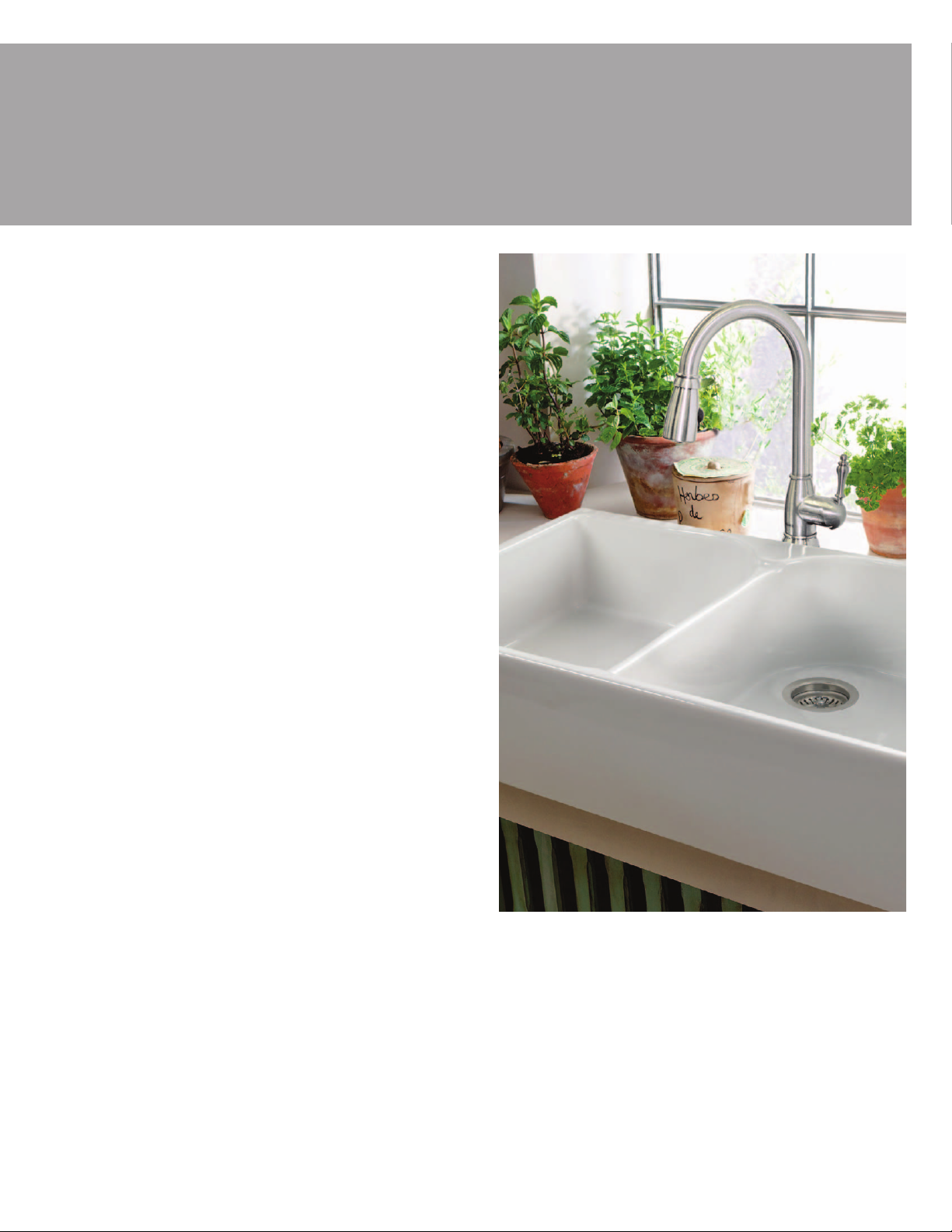

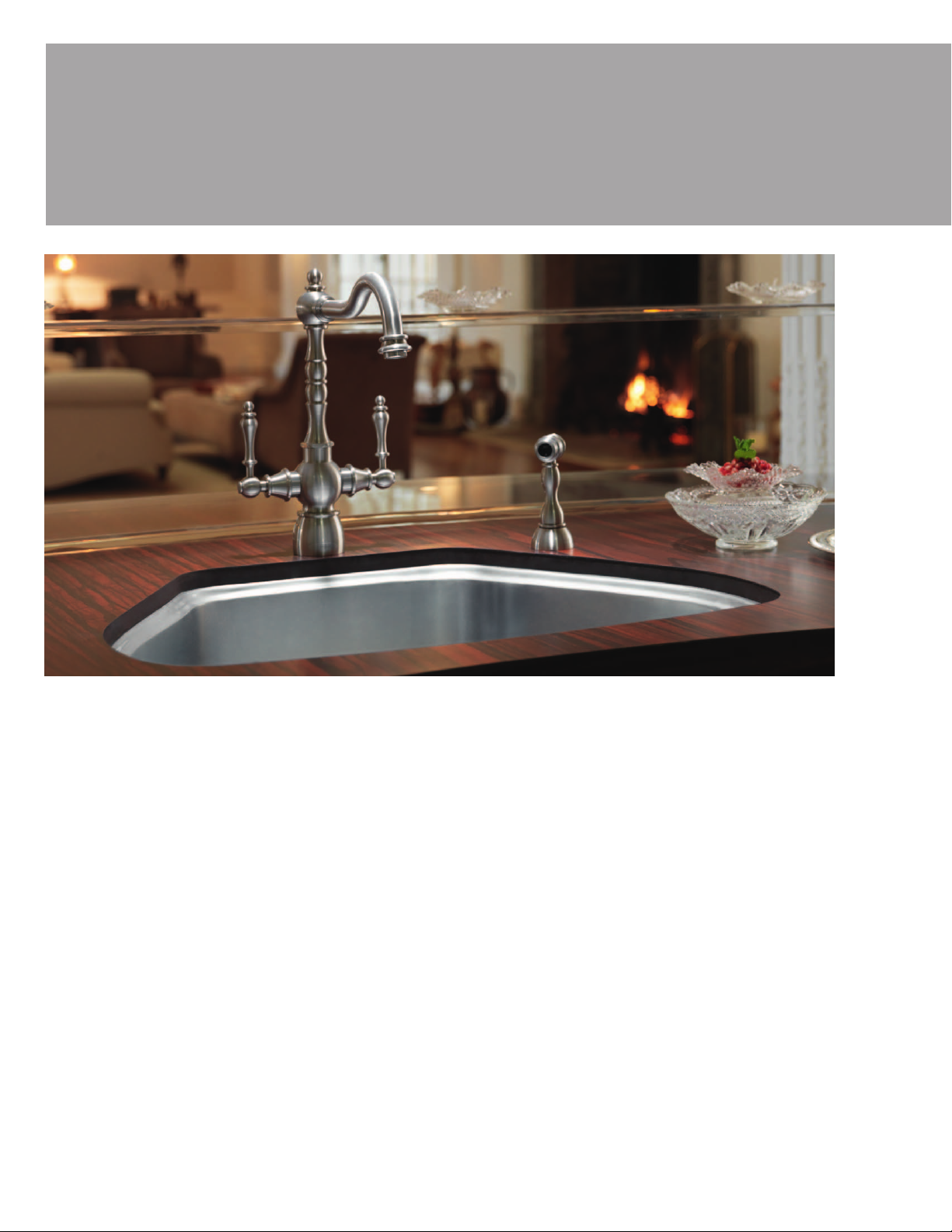

Pictured Above:

FHPD180 kitchen faucet and MHK720 fireclay sink.

On the Cover:

FF2400R kitchen faucet, LB5200 hot and filtered cold water

dispenser and MHX-PKX11028 stainless steel apron front sink.

4

WHY FRANKE WATER FILTRATION

Water filtration is a popular topic these days. Research indicates that

approximately 70% of American households use some type of

home water filtration. But why? It’s a very common question with

a simple answer: peace of mind. You and your loved ones drink

and come in contact with tap water many times every day. This is

something that most people don’t even consider and Franke thinks

it should stay that way. A water filtration system is a straightforward,

convenient way to make sure that there’s just H2O in your glass

and no unexpected little “extras.” Whether the goal is to achieve

better tasting water from the tap or ease your uncertainty about

actual water quality, opting to use a filtration system can provide

some much needed reassurance.

POU Filtration

Our filtration products fall into a category known as Point-of-Use

or POU filtration systems. What this means is that water is being

filtered immediately before it is dispensed, or just before it flows

from the tap. A filter housing containing a filter cartridge is

plumbed directly into the water line below your kitchen counter.

Filtered water is then dispensed as it is needed from a separate

faucet adjacent to the kitchen sink. These faucets are commonly

referred to as both POU faucets or dispensing heads.

Inside the filter canister is a filter cartridge. Franke filter cartridges

consist of a ceramic outer shell and an enclosed activated

carbon block core. Each cartridge utilizes a multistage filtration

process which occurs as follows:

Stage 1 – Microfiltration occurs as water passes through the

ceramic shell of the filter cartridge. Particulate and pathogenic

cysts ranging from .5 to .8 microns in size are removed during

this stage.

Stage 2 – The composition of the ceramic matrix both kills and

inhibits the growth of bacteria.

Stage 3 – An activated carbon block core removes chlorine and

organic compounds thereby improving the taste, odor, and safety

of the water.

Stage 4 – Two of our cartridge models (FRX02 & FRC06) also

contain heavy metal removal media for the removal of lead and

other heavy metals. See page 79 for chart.

Combining these elements creates an extremely effective

mechanical filtration and chemical reduction process. Although

the life of a filter cartridge can vary depending on water quality,

each cartridge is generally good for six months for a family of

four with normal usage, often even longer.

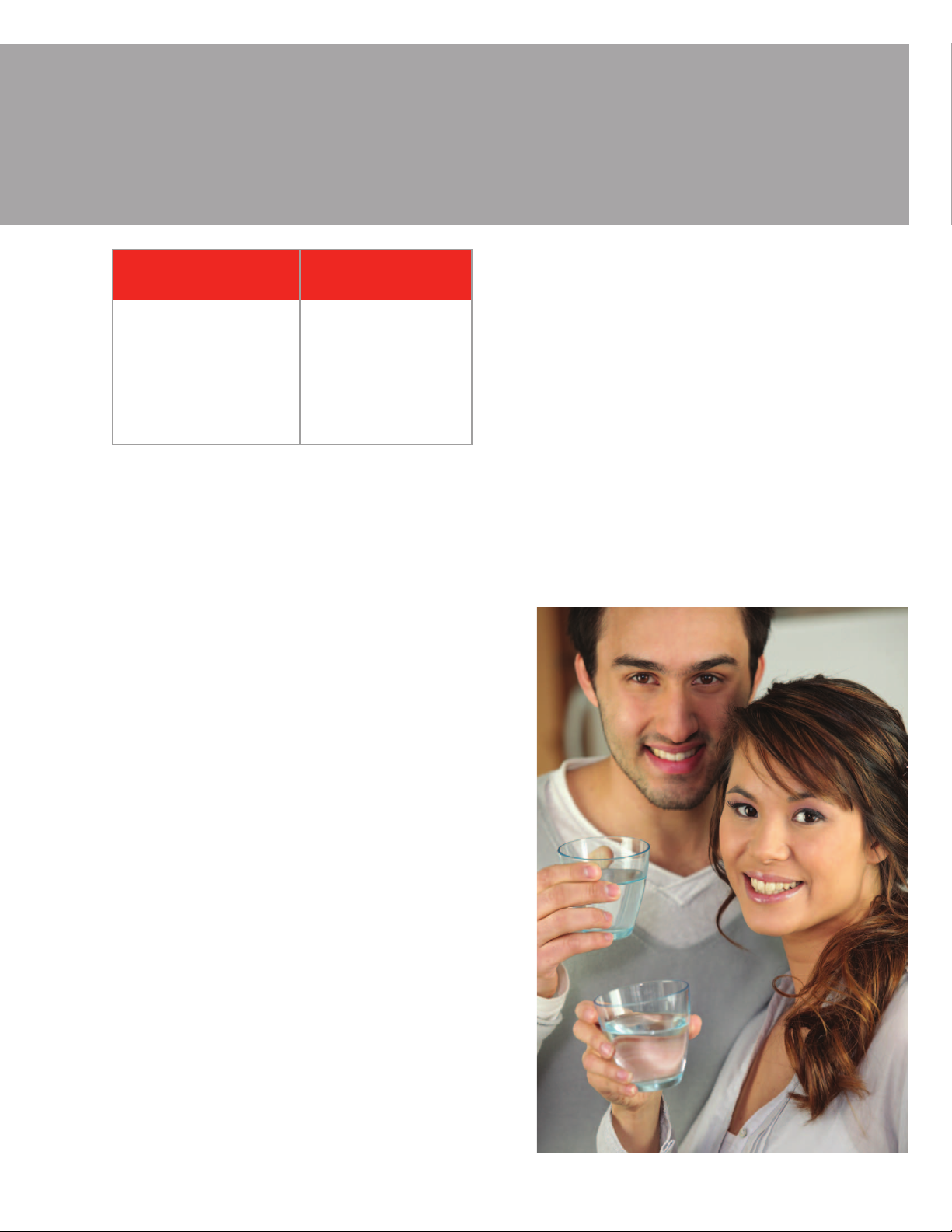

Benefits of Filtration

The fact is that there are, indeed, undesirable things finding their

way into drinking water. Water with chemicals and impurities can

5

WHY FRANKE WATER FILTRATION

have an unpleasant odor or taste making it difficult to enjoy.

Ingesting water with specific contaminants can even cause

serious health issues. The table above shows some of the most

common contaminants found in drinking water in the United

States and the results you can expect from the use of a Franke

filtration system.

Additional Benefits

What a Franke filtration system takes out of the water might be

the most important, but not the only, benefit. Our filtration

systems are easy to maintain and require no electricity or

additional power supply. Unlike a reverse osmosis (RO) system,

we won’t waste three gallons of your water for each gallon that

is purified and our filters won’t strip your water of essential

minerals. Most Franke system components are long-life reusable

elements made of natural and recyclable materials. In fact, if

your municipality issues a “boil water advisory” due to cysts

(Cryptosporidium, Giardia, etc.) you can continue using water

filtered with your Franke filtration system without any boiling or

extra preparation.

Quality & Environmental Responsibility

All Franke filtration products are manufactured using high-quality

components and precise assembly techniques. Unlike other

water filtration companies, we don’t cut corners. One example

of our commitment to quality is that the activated carbon cores

of our filters are manufactured with coconut shell carbon, one

of the most expensive types. But coconut shell carbon happens

to be a highly effective substance for chemical reduction and

therefore, increases the overall performance of our systems.

Despite the additional cost of some system components,

Franke filtration systems are still priced equivalently or below

those of the competition. Performance isn’t the only thing we

take into consideration; giving our customers the best value

possible is just old fashioned good business.

Our products incorporate both naturally biodegradable and

highly recyclable materials. All filter housings are manufactured

with either stainless steel or engineering grade plastic polymers.

These materials are frequently and easily recycled. Franke filter

cartridges are made of, by weight, approximately 95% naturally

biodegradable materials. These environmentally responsible

material usage principles are in stark contrast to many filtration

systems that utilize “throw away” parts and replacement cartridges.

Franke consistently considers the environment during the development

of every new product to ensure minimal environmental impact

during use.

One Less Thing to Worry About

Many families and busy “on-the-go” individuals face hectic daily

schedules with barely a minute to breathe let alone worry about

potentially harmful chemicals coming out of the tap. A water filtration

system can help you be more confident at home and give you

great tasting enjoyable drinking water at a moment’s notice.

We recognize that our customers have a choice in water filtration

products and that trust is difficult to earn but easy to lose. In

light of those facts, we will continue striving to provide top-quality

filtration products that deliver exceptional results and allow our

customers to live more confidently every day.

CONTAMINANTS REMOVAL

Cysts (Cryptosporidium) >99.99%

Bacteria (E. Coli) >99.99%

Free Chlorine >96.00%

Lead (specific models) 98.3%

Particulate matter >98%

6

Design Superiority

Franke’s line of kitchen faucets includes all the elements of

today’s design choices – traditional, transitional, contemporary

and country. With everything from top flight European models,

with a sleek minimalist line, to sumptuous classic models that

are the centerpiece to any kitchen, the addition of a Franke

faucet can give a lift to an existing kitchen or make a statement

all its own in new surroundings.

A Franke faucet is created by artisans and perfected to the ideal

proportions and functionality. Our faucets are available in up to

four finishes, with companion point-of-use faucets and soap

dispensers to complete the ensemble. We understand the need of

every homeowner to provide their kitchen with the right accent to

match the interior.

At Franke, we are always seeking to evolve to meet the needs of

our discerning customers. New products are constantly being

developed to offer as many choices as possible.

Composition

Lead-free brass

Franke faucets are made of brass, which is an alloy of copper

and zinc; the proportions of zinc and copper can be varied to

create a range of brasses with varying properties.

To enhance the machinability of brass, lead is often added in

concentrations of around 2%. Since lead has a lower melting

point than the other constituents of the brass, it tends to migrate

towards the grain boundaries in the form of globules as it cools

from casting. The pattern the globules form on the surface of the

brass increases the available lead surface area which in turn

affects the degree of leaching. In addition, cutting operations

can smear the lead globules over the surface. These effects can

lead to significant lead leaching from brasses of comparatively

low lead content.

Regulations

In October 1999 the California State Attorney General sued 13

key manufacturers and distributors over lead content. In April

2001 manufacturers agreed to reduce lead content to 1.5%, or

face a requirement to warn consumers about lead content.

On January 1, 2010, the maximum amount of lead in "lead-free

brass" in California was reduced from 4% to 0.25% lead. The law

put into place statewide is now known as California Assembly

Bill 1953 (or AB1953).

Franke lead-free faucets use less than 0.20%. As of January 2014,

all faucets sold in the United States must be made of lead-free

brass to comply with the law initiated in California, which will

become a national plumbing safeguard.

Faucets must also pass several environmental regulations. The

National Sanitation Foundation 61(NSF61) regulation, which limits

contaminants in drinking water, applies to kitchen faucets,

lavatory faucets and drinking water dispensers.

To receive NSF Certification of a faucet, manufacturers first submit

a list of all materials including the formulation used in the product.

NSF Toxicologists then review the material formulations to determine

potential contaminants that may extract from the faucet and into

the drinking water. NSF then conducts an inspection of the

manufacturing facility to verify material formulations, material

suppliers, quality control procedures and operations. Product

samples are randomly selected for testing at NSF laboratories.

Faucets undergo a rigorous three-week testing sequence, where

they are filled with an extractant water specified in the Standard.

Selected water samples are analyzed for contaminants. NSF

toxicologists compare the contaminant levels to the maximum

allowable levels established in ANSI/NSF Standard 61. If all

contaminant levels of the product meet the requirements of the

Standard, the product can be certified. Only then is the manufacturer

allowed to display the NSF Mark on the product signifying NSF

Certification.

All Franke faucets are NSF61 certified and all but 4 of the

current models are AB1953 compliant.

Ceramic disc cartridges are the highest quality type of valves

available today on the market. The ceramic discs used in Franke

valves provide a better seal against water because of the tight

tolerances between the discs. The discs are polished glass-smooth,

so there are no microscopic rough edges on their surfaces.

Unlike cartridges that use rubber in the waterway, ceramic discs

WHY FRANKE FAUCETS

Photography by Nordic Kitchen and Bath Showroom

7

WHY FRANKE FAUCETS

are lapped and polished to a degree of flatness that can only be

measured in lightbands. Lapping is a machining operation in

which two surfaces are rubbed together with an abrasive between

them, by hand movement or by way of a machine, and is used to

obtain very accurate and flat surfaces. The discs themselves

have diamond-like hardness—they are impervious to line debris,

mineral buildups, and other common problems that affect valve life.

Ceramic discs last much longer due to their high wear resistance

and offer very precise, ergonomic control. These are an excellent

choice for people with arthritis and even a child can easily turn

one of these faucets off and on.

A great benefit of ceramic disc cartridges is their durability. Ceramic

is very strong, so there is virtually no wear of the discs with use.

If a particle from galvanized pipe or a small rock gets into the

valve, it can score the surfaces, but these occurrences are rare.

If a ceramic disc faucet drips, don't try to force the handle

closed—just move the handle gently back and forth a few times

to dislodge any particles.

Information on certification

All Franke faucets are manufactured under the supervision and

testing of local and international standards institutes, from

IAPMO to CSA to NSF.

Manufacturing process

Franke faucet manufacturing includes the complete production

process from permanent mold casting and forging, through

machining, to robotic grinding, polishing and buffing, completing

the faucet finish in chrome plating, powder coating, or special

finishes, such as oil rubbed bronze, to final assembly and delivery.

1. There are two methods used to make Franke faucet bodies:

A. Machining

While many people may have never heard of the term, CNC

has touched almost every form of the manufacturing process

in one way or another. The name stands for Computer

Numerical Control.

CNC machines typically replace (or work in conjunction with)

some existing manufacturing processes. Everything that an

operator would be required to do with conventional machine

tools is programmable with CNC machines, including: placing

the drill in the spindle, activating the spindle, positioning the

workpiece under the drill, machining the hole, and turning off

the spindle.

Machining is the process needed to shape the body into the

required size and dimensions. This involves first cutting the

bars into short slugs and automatically feeding them into a

CNC machine which has a multi-spindle and multi-axis design.

This machine performs turning, milling, and drilling operations.

For some of the most intricate Franke designs, machining is

the optimal method to achieve symmetry and uniformity of

detail.

B. Hot forging

This is an alternative to machining and this method can

produce a near-net shape in about three seconds with little

waste. Forging is the process of shaping metals by forming

them into the desired shape. In hot forging, heated metal is

forced into a die that is almost the same shape as the faucet

body. The pressure is slowly increased over the course of

several seconds to make sure the die is completely filled with

metal. Only minor machining is required to produce the exact

dimensions.

The next steps in the process are:

2. Polishing and buffing

Robotic automatic polishing chambers are used for some parts

as well as manually controlled robotic machines for delicate work

on faucet details.

3. Plating

Plating increases durability by adding an extra layer of protective

coating.

After machining, the parts are ready for the finishing process.

Those components that come into contact with water may first

require a special surface treatment to remove any remaining

lead. This involves a leaching process that eliminates lead

molecules from the brass surface. The conventional finish is

chrome since this material is most resistant against corrosion.

First a base coating of electroplated nickel is applied, followed

by a thin coating of electroplated chromium. The chrome layer is

deposited from a plating bath containing certain additives that

improve corrosion resistance.

This process is fully approved by environmental authorities.

4. Epoxy powder coating

After plating, powder coating is used to create our old world

bronze finishes. This can produce much thicker coatings than

conventional liquid coatings without running or sagging.

Powder coating overspray can be recycled and thus it is possible to

achieve nearly 100% use of the coating. Powder coating production

lines also produce less hazardous waste than conventional liquid

coatings and this is in line with Franke’s corporate philosophy

regarding sustainability and the environment.

5. Assembly

Depending on the type of faucet, some are partially or fully

manually assembled and others are put through semi-automatic

assembly and testing lines.

6. All Franke faucets are bench-tested prior to submission

to national certification boards, such as IAPMO and CSA.

Franke offers a limited lifetime warranty on manufacturing

defects on all faucets.

8

WHY FRANKE STAINLESS STEEL SINKS

What Puts The “Luxury” In Franke Luxury Stainless Steel:

Why It Makes A Better Sink

Seventy percent of sinks are made of stainless steel. As the

world’s largest purchaser of stainless steel, Franke has its choice

of the best raw materials. But that is only the beginning of the

evolution from fine to Franke. By lavishing this material with cost,

care and craftsmanship, Franke creates a stainless steel that is

“uncommon.” Let us tell you about the choices, the processes and

the skills that Franke invests to raise its stainless steel systems to the

quality, beauty and longevity its discerning customers deserve.

The “Why” of Stainless Steel

The reasons almost 70% of all sinks are stainless steel:

• Does not alter the essence and flavor of food

• Surface is easy to clean

• Requires very little upkeep

• 100% recyclable, making it right for today’s environmentally

conscious world

• Resists corrosion and has hygienic and aseptic properties

• Does not require the labor-intensive application of an added

surface treatment

The “What” of Stainless Steel

Stainless steel is an alloy of iron, chromium and nickel, generated

to create advantages that individual pure metals do not offer. So

it’s a whole greater than the sum of its parts. The name refers to

the rust resistant properties of the metal which is “stain-less,” but

not “stain-proof.”

These are its ingredients:

• Austenite is a nonmagnetic solid solution of carbon in iron,

used in making corrosion-resistant steel of the kind used for

making cutlery, hospital and food-service equipment, and

tableware.

• Chromium (Cr) is a hard, malleable, glossy, gray chemical

element with no odor or taste, used in alloys to give them

corrosion resistance and a glistening look. It is most responsible

for the corrosion resistance of stainless steel.

• Nickel (Ni) is a hard, ductile, silvery-white chemical element,

a high-luster metal with a high level of corrosion resistance.

• Passivation Layer -- When stainless steel contains a sufficient

amount of chromium, a hard, invisible, virtually impenetrable film

of chromium oxide forms on the surface. Although only a few

atoms thick, this prevents further surface corrosion when the

stainless steel is exposed to corrosive materials and prevents

any corrosion from spreading into the metal's internal structure.

By definition, stainless steel resists corrosion, the gradual

degradation of a metal or alloy especially by oxidation or

chemical reaction (Gold, platinum and palladium are the only

metals not subject to corrosion). But the level of corrosion

resistance varies, based on factors in manufacturing:

• Chemical composition of the metal

• Temperature and temperature variations

• Oxygen content and exposure to oxygen

Even slight variations in chemical compositions result in wide

variation in quality. In other words, NOT ALL STAINLESS STEEL

IS CREATED EQUAL.

There are several different types and many different grades of

stainless steel, so to deserve its “luxury” designation, Franke

insists on creating and maintaining “differences that make

a difference to you.”

Gauge of Franke Stainless Steel

“Gauge” describes the thickness of the sheet of stainless steel on a

scale from 8 to 30, the lower the number, the thicker the sheet of

stainless steel. Gauge is a significant factor because a heavier gauge

can help prevent denting and bowing. It also contributes to noise

reduction from garbage disposals and items making contact with

the sink. That doesn’t mean though that thicker is always better.

For instance, the thicker the gauge, the more difficult (and at times

impossible) it is to “deep draw,” or craft from a single sheet to

reduce welding marks during manufacturing. So, Franke carefully

selects the proper gauge, best fitted to the manufacturing processes.

• Franke full-size deep drawn sinks are 16 or 18 gauge

• Franke full-size hand fabricated sinks are 16 gauge

• Franke’s smaller accessory bowls are 18 or 20 gauge

Grade of Franke Stainless Steel

The three most common grades available in stainless steel sheet

metal are: 304, 316 and 410. Grade 304 is made up of at least 8%

nickel (Franke’s contains 10%). It is the most frequently used of

the three grades, valued for its ability to provide corrosion resistance

and to maintain the capacity of the sheet metal to be bent, welded,

stamped and/or drawn. Franke relies on these properties to

achieve the elegance and detail of its designs.

Franke’s Standards for “Uncommon” Stainless Steel

Franke insists on an alloy of 18% chromium and 10% nickel

content by mass. This higher nickel and chromium content

provides a level of corrosion resistance and integrity that is

superior to any other category of stainless.

Franke stainless steel is ductile, meaning that it is malleable

(moldable). This ensures that it can be formed without cracking or

breaking into parts.

Franke insists that its stainless steel be nickel-rich because when

nickel is added, the Austenite structure of iron is preserved. This

crystal formation makes such steels non-magnetic and less delicate

at low temperatures. And it further contributes to the corrosion

resistance.

9

Franke places high value on two important physical properties:

• Thermal Conductivity

Austenitic stainless steels (i.e. T304 grade) have lower

thermal reaction than carbon steels, helping you maintain

the chosen water temperature in the sink.

• Thermal Expansion Rate

While stainless steel is most commonly used for its corrosion

resistance, it is also valued for its ability to endure exposure to

high temperatures. Because of its high chromium content,

Franke’s stainless steel has the added benefit of high temperature

strength and resistance to scaling (oxidation) at elevated

temperatures. Its chromium content accounts for its resistance

to oxidation. As an austenitic steel, with chromium contents of

at least 18%, it can be used at temperatures up to 1598 degrees,

essential when working with pots and pans that need to be set

down and are at temperatures upwards of 500 degrees.

Sources and Sustainability of Franke Stainless Steel

Eco-friendly stainless steel is 100% recyclable, and Franke stainless

steel is composed of nearly 70% recycled material. In light of that

commitment, it is important to consider the sources of Franke

stainless steel. Much of the world’s stainless steel comes from

low cost countries, but Franke chooses to invest in high cost

stainless steel from Germany, Spain, Belgium and Finland.

Franke takes pride in the fact that its European mills use only

the most modern production equipment, further ensuring the

purity of its recycled steel materials.

Manufacturing Processes for Franke Stainless Steel Sinks

Franke uses a proprietary deep draw manufacturing process

that also includes annealing when necessary.

Deep Draw

Deep draw is the method used for creating parts from flat sheet

metal. The process involves pressing a disk into a die with a punch

to form a variety of shapes, radii, diameters and lengths as the

metal progresses through several work stations. Since existing

technology does not enable the draw to create as deep a shape as

desired in one draw, greater depths require multiple steps called

“draw reductions.” The greater the depth, the more reductions are

required.

Annealing

Deep drawing may also be accomplished with fewer reductions by

using an annealing process in which the piece is heated. While it

adds cost to the manufacturing process, it is done to prevent the

stainless steel from thinning out to a lesser gauge in the

course of manufacturing. The duration of time the piece is

exposed to this temperature is kept to a minimum to prevent

surface scaling and to control grain growth. This is how Franke

eliminates the occurrence of “orange peel” texture on the stainless

steel and maintains its smoothness to the touch.

Sheet Metal Tolerances

In order to maximize sink capacity, Franke raises the bar on sheet

metal tolerances, by developing and perfecting processes that enable

us still to use a deep draw process on tight radii in deep bowls.

While this is the most advantageous process, unfortunately,

these tight tolerances raise the cost of manufacturing

significantly in order to deliver benefits expected by

Franke’s discerning consumers.

Hand Fabricated Sinks

The joints are welded together and then a molten filler material is

applied further to achieve a more perfect joining of the sink sides

and corners. Here, the “Franke difference” is that we avoid

Intergranular corrosion, which means:

• Austenitic stainless steels contain a small amount of carbon.

• Upon exposure to drastically high temperature, such as welding,

the carbon causes ingrained chrome to develop chromium carbide

around it, blocking adjoining sections of the chrome it needs to

prevent its own corrosion. The Franke solution to this problem

is to use a minimum carbon content stainless to avoid such

corrosion.

Circle Weld

For Franke’s multi-bowl configurations, each bowl is circle welded

to the frame, not seam welded. This prevents any unsightly weld

seams from showing on the center saddle of the sink. This, of

course, costs more than seam welding, but it is the Franke difference

that helps us meet the expectations our customers have of a high-end,

luxury stainless steel kitchen sink.

Franke Finish

Sheet metal can be purchased pre-polished. There is a reason Franke

never does so for its deep drawn sinks. While it could reduce costs

in the manufacturing process, the Franke difference is a finish best

achieved in the post-manufacture process. A Franke sink’s silky

luster comes from machine and hand-finishing operations that

enable the sink to keep its beauty over its long life. Many feel that

the look of a Franke hand-finished sink actually improves with age.

And Franke’s luxurious and desireable ultra satin surface makes

our stainless steel easier to clean. It is also an important sanitary

feature. The smooth surface obtained by our manufacturing and

polishing methods ensures better corrosion resistance.

Care & Maintenance of Franke Stainless Steel

Type 304 stainless steels (Austenitic) are vulnerable to potential

damage from abrasives, bleaches and cleansers containing chlorine.

Inevitably, stainless steel sinks are subjected to some very

aggressive chemicals. What helps them withstand such abuse

includes dilution by running water and thoroughly rinsing the sink to

remove any lingering damaging substances. If this ongoing cleaning

and use of water is not routine, the passive layer is vulnerable

to corrosion.

For this reason, you should NEVER use:

• Abrasive or chlorine-based cleansers

• Rough or heavy duty sponges

• Steel wool pads

Instead, you should use only:

• A soft cloth

• Mild soap (remember, avoid any chlorine-based cleansers)

That is the path that leads from merely fine to Franke, and

to years of enjoying the quality, beauty and longevity that

define Franke Stainless Steel sink systems. Welcome.

WHY FRANKE STAINLESS STEEL SINKS

10

High Chromium Content: 18/10

High Grade Stainless Steel

70% Recycled Uncontaminated Stainless Steel

Deep Draw Annealing Process

(deeper manufactured bowls with tighter radius)

Low Carbon Steel

Circle Weld (hidden seam)

Post-Manufacture Polishing for Ultimate Finish

Lower Chromium Content

Lower Quality Stainless Steel from Low Cost Countries

Less/No Use of Recycled Stainless Steel - or

assurance of no contamination

Cold Formed Bowls (risk of cracking or splitting)

Unknown Carbon Content

Seam Weld (visible seam)

Pre-Manufacture Polish (lower quality appearance)

p

p

p

p

p

p

p

O

O

O

O

O

O

O

FRANKE

OTHER

WHY FRANKE COMPARISON

11

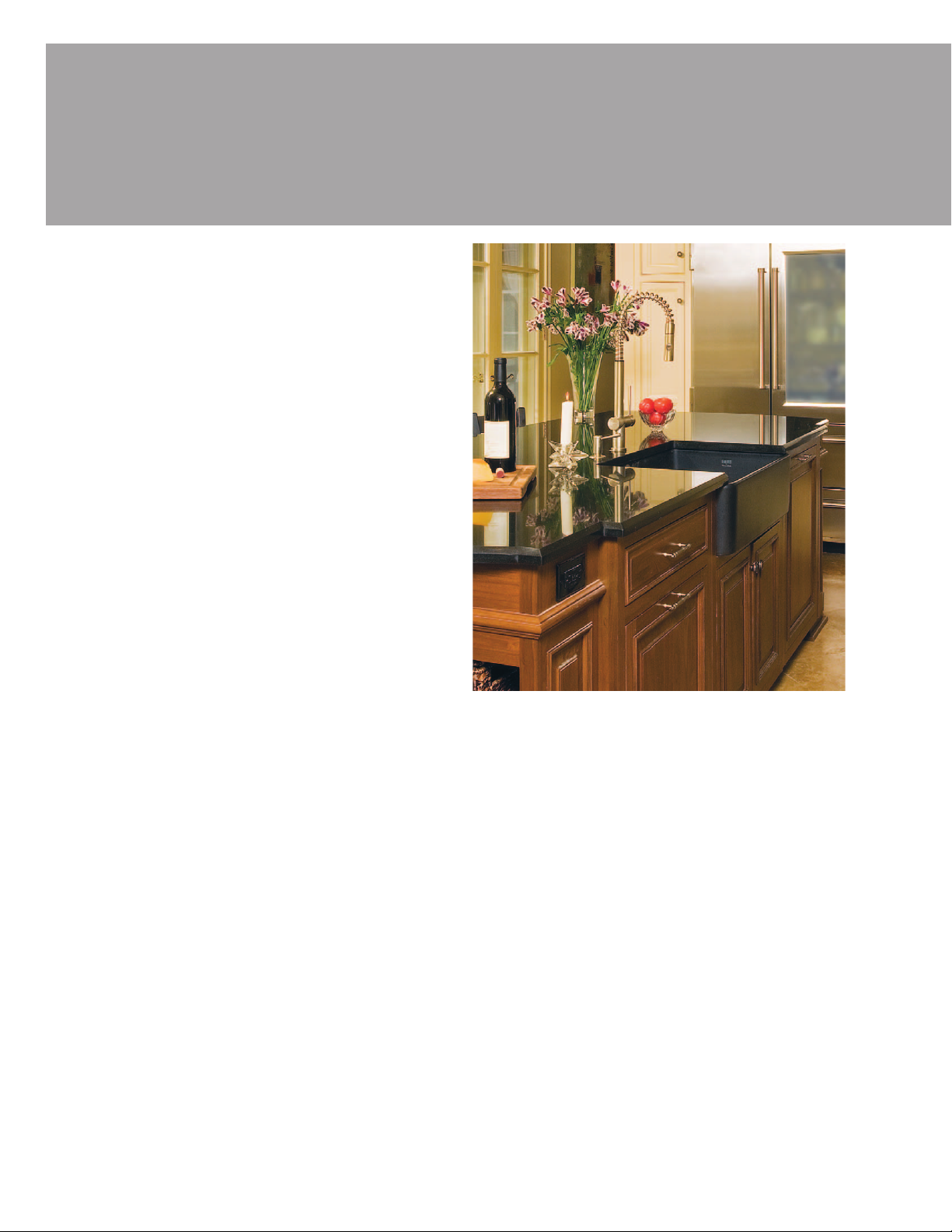

WHY FRANKE FIRECLAY SINKS

Franke Fireclay sinks are all handcrafted and many are created

by the respected and world-renowned firm of Villeroy & Boch,

which has been making fine ceramic creations for more than

260 years. Still a family-owned business, Villeroy & Boch has

served as Royal and Imperial Porcelains Manufacturer for royalty

and aristocrats for centuries, as well as becoming popular with

the present-day consumers due to the quality of their beautiful

and distinctive designs.

How Fireclay is made

Fireclay begins with a liquid ceramic mixture called ‘Slip’, which

is comprised of quartz, china clay or ball clay (kaolinite) and

chamotte (a ceramic raw material consisting of silica and alumina)

which is injected into porous plaster molds at high pressure.

Much attention is paid to the quality of the raw materials and

the purity of all components is strictly controlled. The cleanliness

of the machinery and tools is crucial to the outcome, as well

as controlling of the levels of humidity and consistency of the

temperatures during the process.

When not quite dry, the still fragile pieces are fettled manually

and the uneven places smoothed with coarse and soft sponges

and water to create an even surface. Waste outlet and tap fitting

holes are then punched out, each according to the individual

design of the sink. At the same time, the first manual total quality

inspection is completed. With large fireclay sinks, the drying

time at room temperature takes several days. The final drying in

the dryer reaches a maximum temperature of 160 degrees

Fahrenheit and takes about 40 hours.

After drying, the sinks are fettled once again by hand, with the

final glaze sprayed on the surface. The thickness of the glaze is

0.7mm to 1.0mm before firing and the consistency of color is

closely monitored to assure uniformity.

The sink is then fired for 20 hours in a tunnel kiln at 2,200

degrees Fahrenheit before the craftsman makes the last of

numerous inspections as the sink is completed.

At each stage of production, after de-molding, after drying and

after glazing, the product is assessed for visual damages and

imperfections on the surfaces before being handed over to the

next phase of production.

The shrinkage involved in the firing process from start to finish

can result in a linear shrinkage of up to 5% which can yield a 2%

final variance in the size of each sink.

Each sink is tested to stringent tolerance guidelines using regularly

calibrated testing equipment, which detects the actual size of

the pieces, faucet hole sizes, impurities and deformations.

Quality control assures that there is no over formation, that the

surfaces are smooth, with no hairline cracks and ensures correct

angles and shapes. Technological precision in the manufacturing of

these sinks allows the Franke product to have thinner and sleeker

walls, as opposed to the chunkier proportions in some other

fireclay sink products. The desired outcome is highly dependent

on an accurate and exact production process which includes

the highest quality raw materials, water content, exposure to

temperatures and handling by people. Franke product comes

from state-of-the art production facilities.

For undermount sinks, the unglazed mounting rim is ground flat to

ensure a perfect fit in the countertop. Premium finishing guarantees

even surfaces for optimum fitting and perfect sealing and individual

pieces are ground with rotating disks in a wet polishing operation

to assure a perfectly leveled installation surface. The sink is then

carefully packed to prevent damage during transport.

Care and Maintenance

Franke sinks offer:

• Extremely hard, scratch-resistant surfaces

• Hygienic surfaces with a smooth, dirt-repellent finish

• Durability

• Insensitivity to acids and alkalis

The Franke finish allows:

• Less cleaning time, with stains from tea, coffee, red wine or

limescale easily removed

• Fewer cleaning agents; aggressive cleaning is unnecessary

• Reduced water consumption needed to clean a fireclay surface

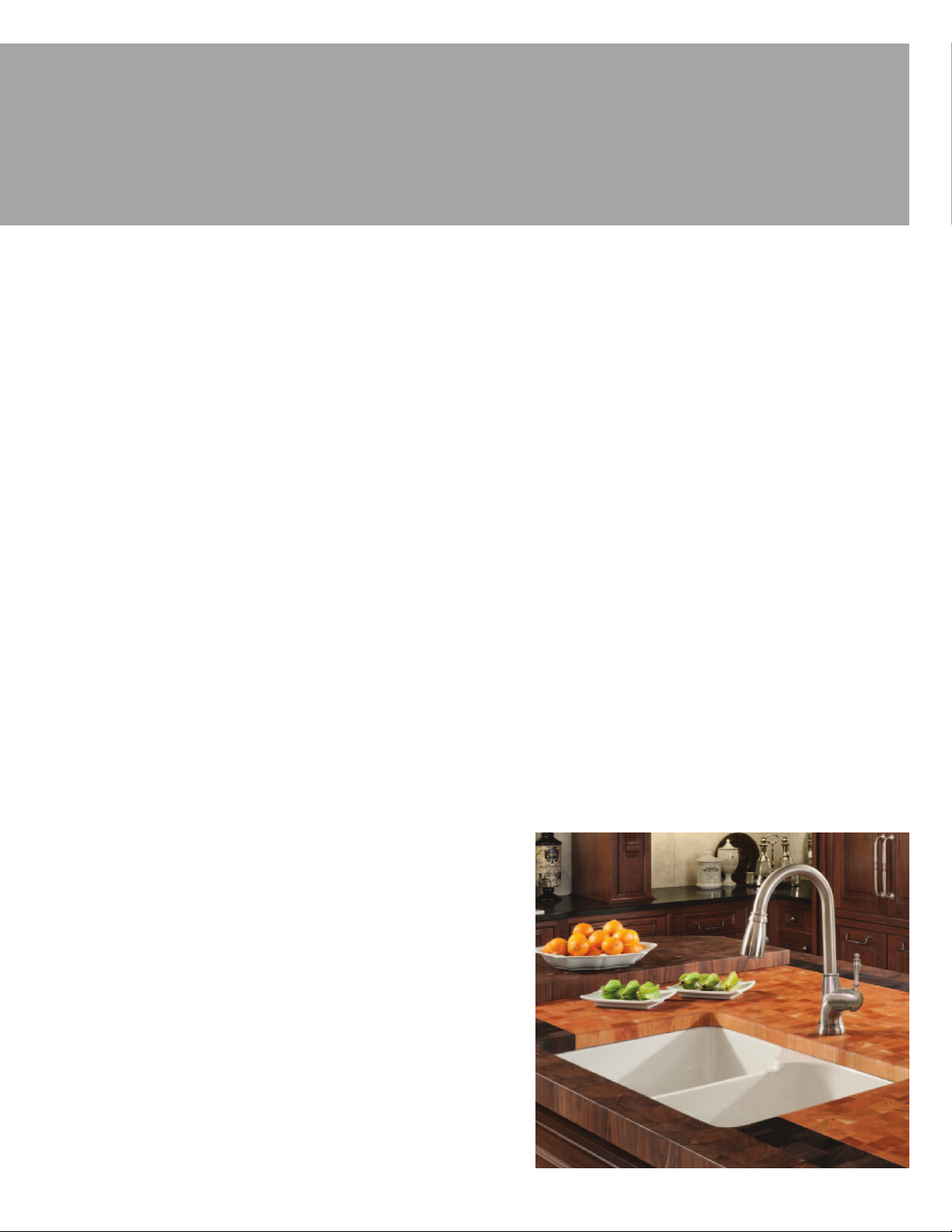

Photography by Woodmode

12

WHAT’S NEW

The metal sprayhead on these faucets affirms Franke’s luxury standard, as well as guarantees durability

and long-lasting performance.

• Easily retractable with nylon mesh hoses

• Elongated, ergonomic handle with forward motion only (no interference with backsplash)

• Dual-jet spray

• Available in Chrome, Old World Bronze and Satin Nickel

• Meets lead-free NSF372 requirements

• ICC certified

• Ceramic cartridge, leak-free operation

• Solid brass with metal sprayhead

See pages 60 and 69 for model options

Pictured: FF2400R kitchen faucet and FFBP2400R bar faucet

2400R SERIES FAUCETS

13

WHAT’S NEW

A new addition to the FF2400 and FF2400R family of products, these filtered drinking water and instant

hot taps coordinate perfectly with the design features and finishes of the kitchen and bar/prep faucets.

• New cartridges are reliable and long lasting; cycle-tested for 500,000+ uses

• More robust lever design with strengthened pivot pin to prevent breakage

• Available in three finishes: Chrome, Old World Bronze and Satin Nickel

• More flexible connecting tubes are kink-resistant

• Meets AB1953 (CA) Lead-Free requirements, NSF372

• ICC certified

Also available in Franke Value Offer packages

See pages 71 and 73 for all model options

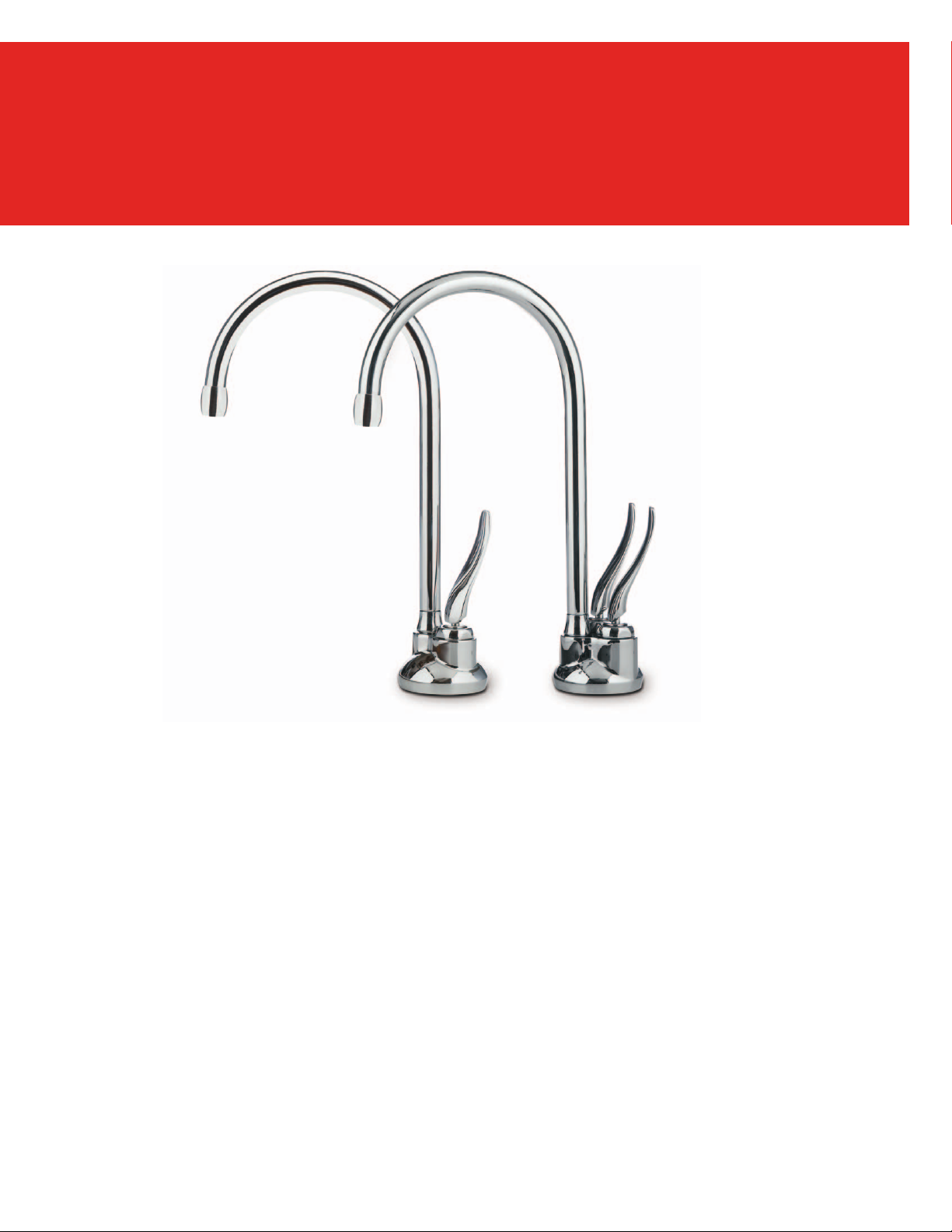

Pictured: LB5100 and LB5200 Little Butlers

®

DW5000, LB5100 AND LB5200 POINT-OF-USE FAUCETS

14

Featuring filtered drinking water taps in addition to the hot only and hot/cold versions, these robust new

point-of-use faucets have been cycle-tested for 500,000+ uses.

• New improved cartridges

• More robust lever design with strengthened pivot pin to prevent breakage

• Available in four finishes: Chrome, Old World Bronze, Polished Nickel and Satin Nickel

(DW8000/LB8100, LB8200 in Chrome and Satin Nickel only)

• More flexible connecting tubes are kink-resistant

• Meets AB1953 (CA) Lead-Free requirements, NSF372

• ICC certified

• New families include: DW6100, LB6100, LB6200, DW8000, LB8100, LB8200, DW7000, LB7100, LB7200,

DW9000, LB9100 and LB9200

Also available in Franke Value Offer packages

See page 72-75 for additional model options

Pictured: LB9100 and LB9200 Little Butlers

®

NEW, IMPROVED POINT-OF-USE PRODUCT FAMILIES

WHAT’S NEW

15

WHAT’S NEW

Introducing technological advancements in our line of waste disposers along with the longest warranties

in the industry.

• NEW! Space saving shell design

• NEW! Snap and Lock mounting system (patent pending)

• Permanent Magnet Motor outperforms comparable induction motor designs

• Motor reaches full torque on first revolution for jam-resistance

• ALL models are safe for septic system use

Available in:

• ½ HP and ¾ HP contractor models with galvanized steel components

• 1 HP full feature with stainless steel components

• ¾ HP full feature with stainless components

• ¾ HP batch feed model

See page 88 and 89 for model options

Pictured: FWD100R, FWD75BR, FWD75R, WD75R and WD50R

FRANKE WASTE DISPOSERS

16

WHAT’S NEW

Franke Prestige sinks are now available in a 9" depth.

• New deeper sinks (large bowls) in highest quality stainless steel

• Type 304 austenitic stainless steel with 18% chromium and 10% nickel

• Deep drawn

• Circle welded double bowls with no seams on center saddle

• 18 gauge stainless steel

• Silky luster with Franke trademark Metabo finish

• Accessories include: bottom grid, colander and large drain basket

• New families include: PCX1102109, PCX12009 (and PCX12009LH), PCX16009 (and PCX16009LH)

See pages 30 and 39 for additional model options

Pictured: PCX12009

PCX 9" DEPTH SINKS

17

GDX11023 shown with FF2900 faucet and SD-500 soap dispenser

18

Undermount sinks are meant to subtly exhibit the beauty of the solid

surface selected for the kitchen design. Yet, Franke has many sink designs

that enable you to showcase your countertop and create a conversation

piece of their own.

• Ideal combination with solid surface countertops for a very clean look

• Quickly wipe debris from the countertop right into the sink

• There is no sink edge beyond the countertop

• Style and designs that work in both modern and traditional kitchens

• Enhances the appearance of other high-end materials

Pictured: KBX110-18 shown with KB18-31S shelf grid, KB70C colander and KB-36RM roller mat

STAINLESS STEEL

UNDERMOUNT SINKS

19

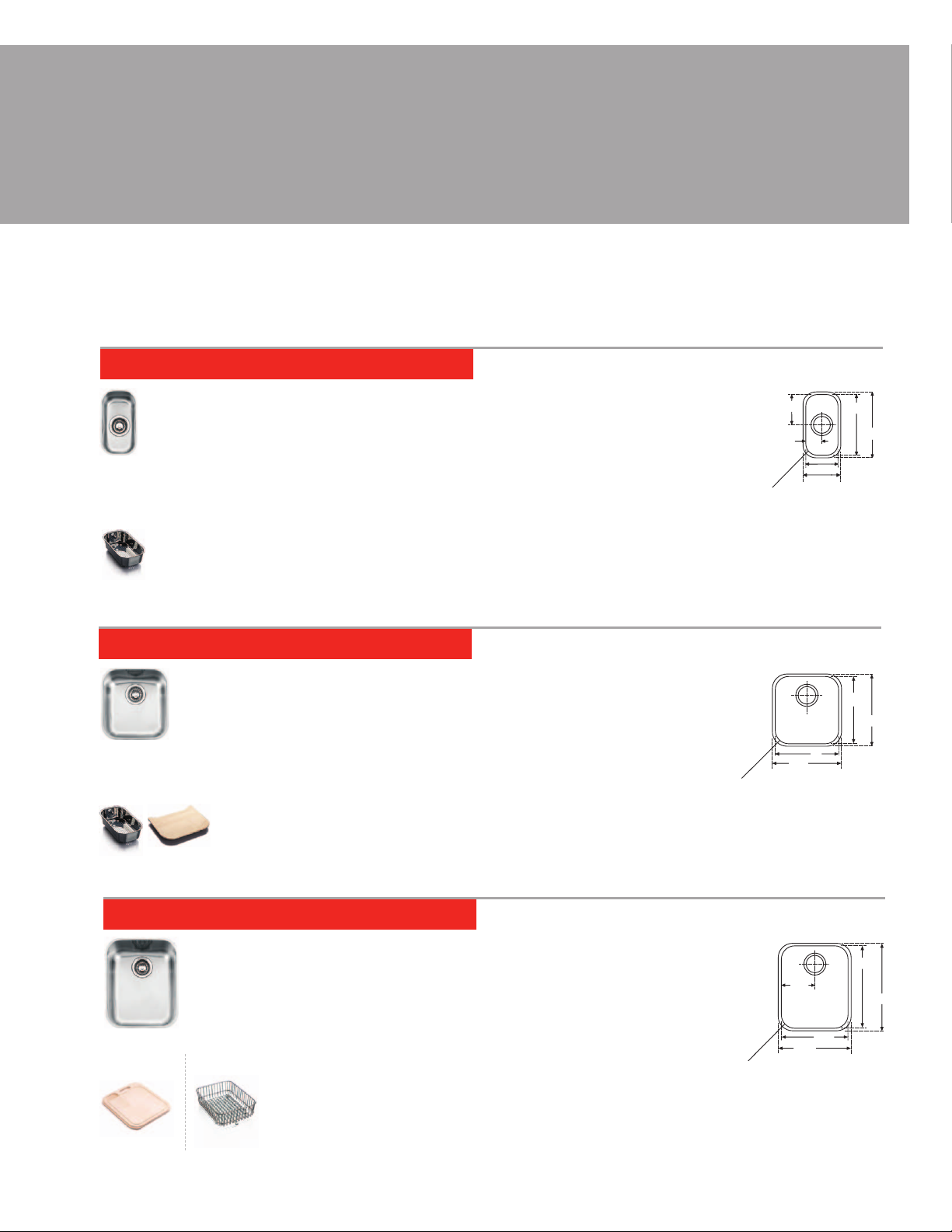

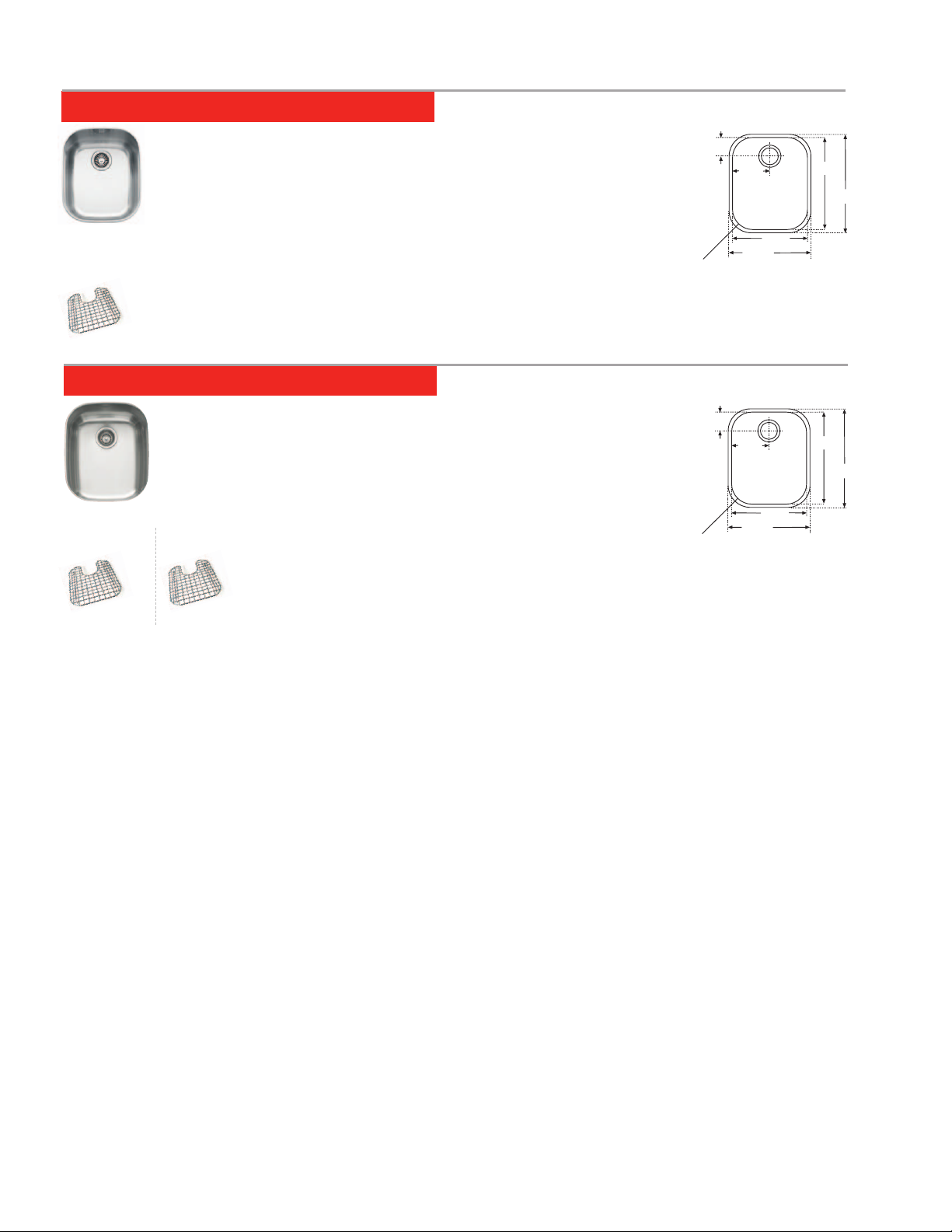

Interior Dimensions:

6Z"x 12g"x 5a"

Exterior Dimensions:

7w"x 13d"

Minimum Cabinet Size: 12"

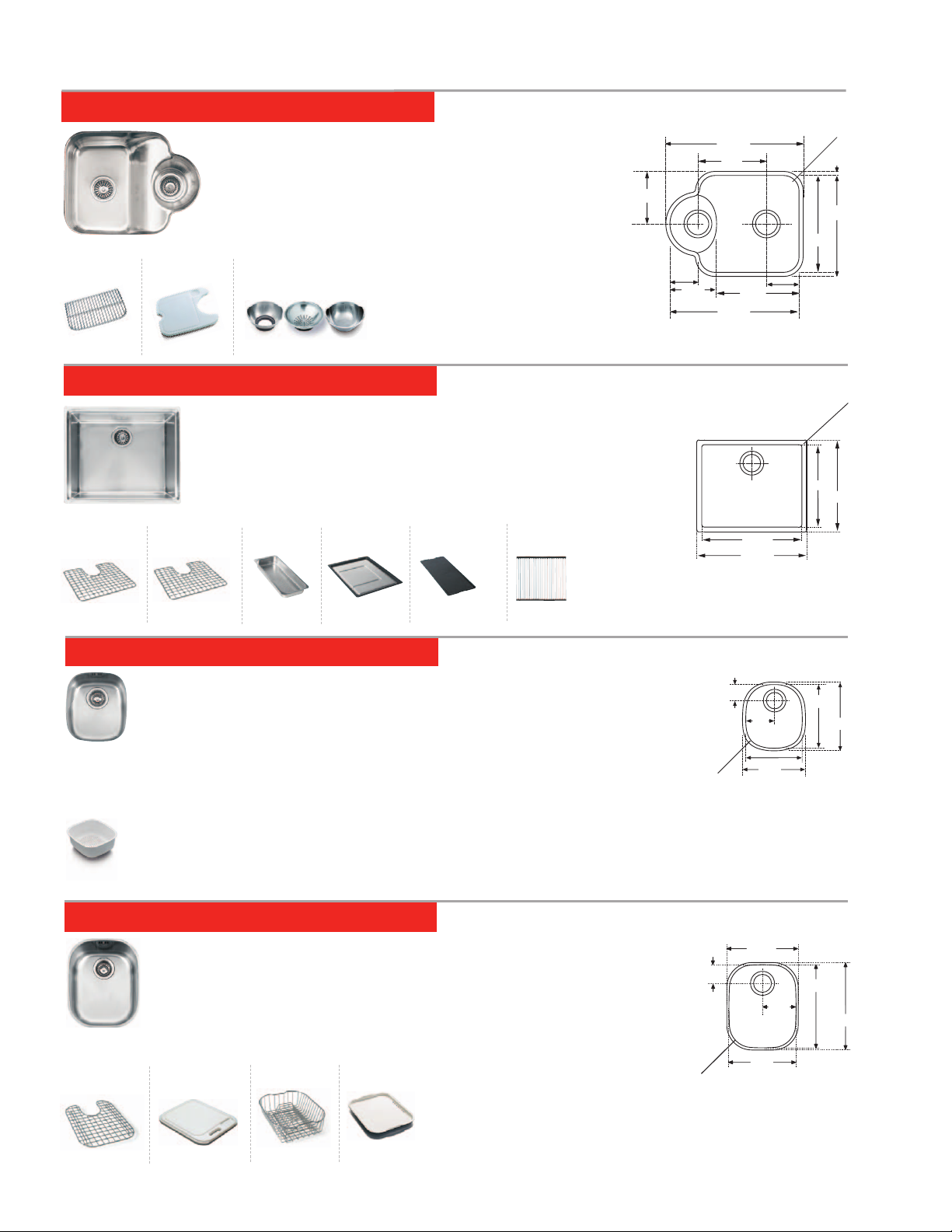

ARTISAN

6Z

12g

3d

13d

7w

6b

R 58.5mm

Note: All accessories sold separately unless otherwise indicated.

Design of custom accessories subject to change without notice. Franke recommends using template when making final cutout.

It is necessary to have the sink and accessories on hand when making final cutout to ensure proper fit. Franke will not be responsible for any erroneous cuts in the countertop.

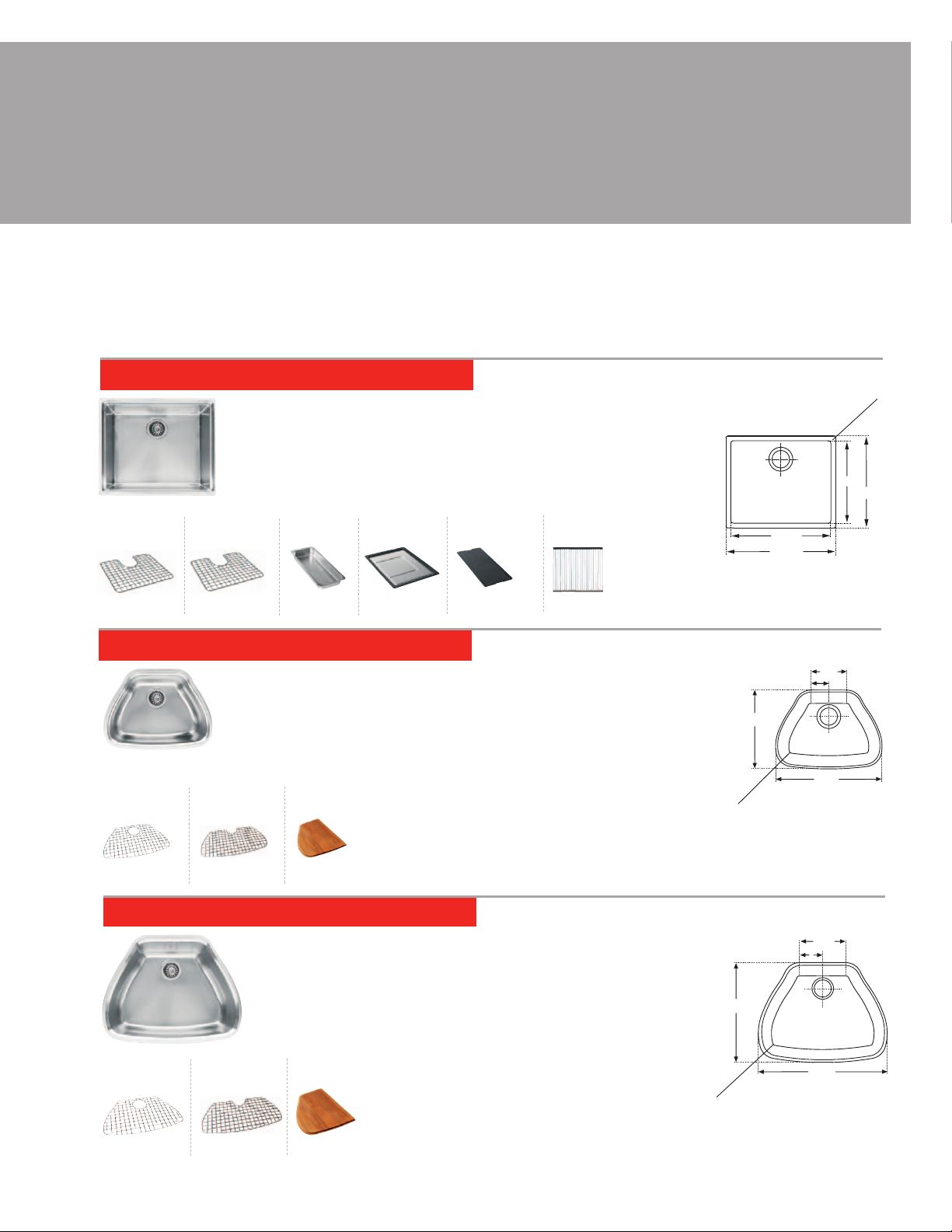

Interior Dimensions:

13" x 13e" x 7a"

Exterior Dimensions:

13e"x 14>"

Minimum Cabinet Size: 18"

13

13e

14>

13e

R 68.5mm

13e

17a

6j

17B

14>

R 68.5mm

ARX1106

ARTISAN

ARX11013

ARTISAN

ARX11014

Colander

Polished Stainless

Drain Basket

Polished Stainless

Cutting Board

Solid Wood (S)

Interior Dimensions:

13e"x 17a" x 7j"

Exterior Dimensions:

14>"x 17B"

Minimum Cabinet Size: 18"

AR-70S

AR-40C (Cutting Board)

AR-70S (Colander)

Cutting Board

Solid Wood with Optional Polished

Stainless Colander

AR-50S

ACCESSORY UNDERMOUNT BOWLS

AR-40S

20

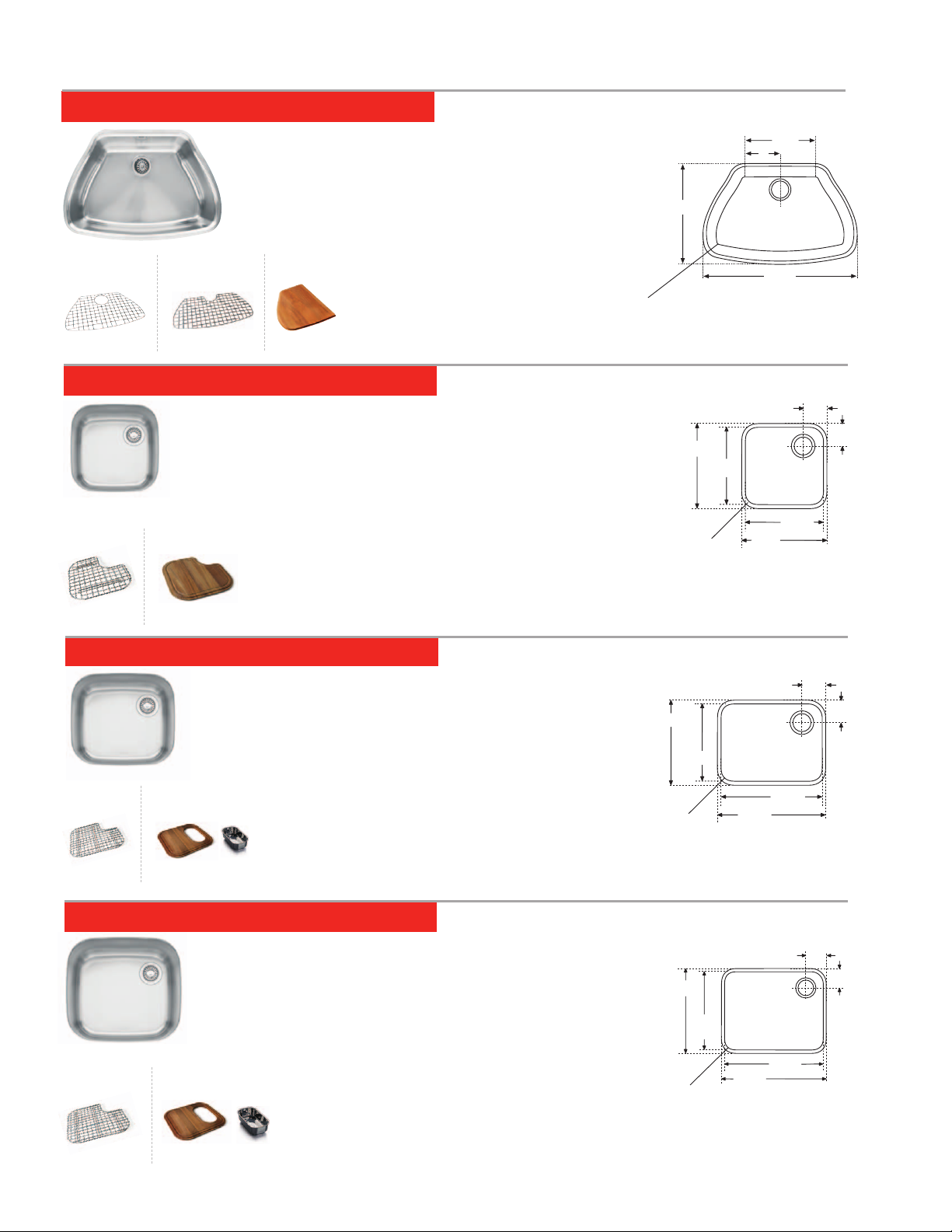

Colander

Stainless

Cutting Board

Black/Stainless Steel

Drain Board

Stainless

Included

Included

Included

Bottom Grid

Stainless

Shelf Grid

Stainless

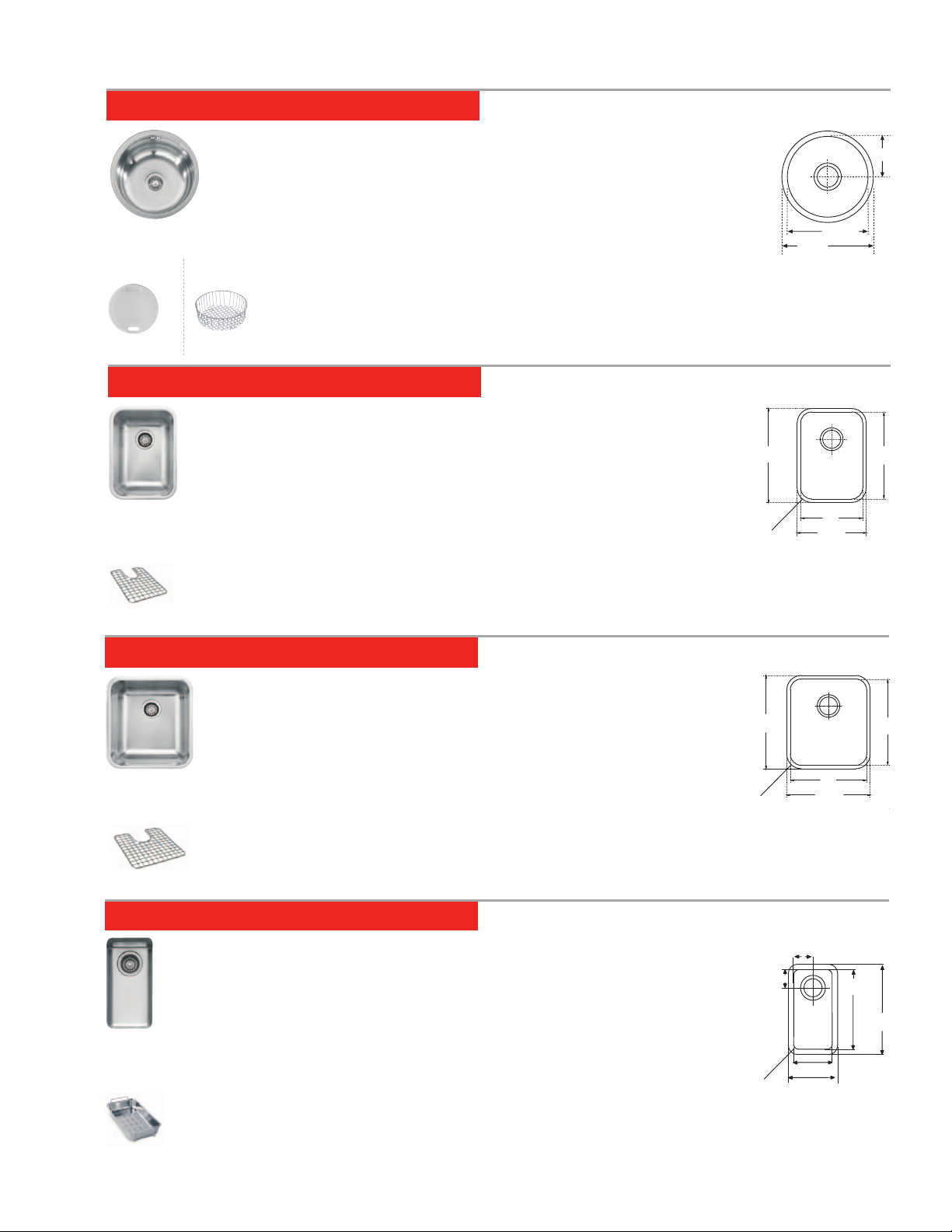

CE19-36S

CE19-31S

17c

16w

13d

14c

6Z

3g

R 113mm

Note: All accessories sold separately unless otherwise indicated.

Design of custom accessories subject to change without notice. Franke recommends using template when making final cutout.

It is necessary to have the sink and accessories on hand when making final cutout to ensure proper fit. Franke will not be responsible for any erroneous cuts in the countertop.

CP-50C

Drain Basket

Coated Stainless

Cutting Board

Solid Wood (S) or

White Synthetic (W)

CP-40S

CP-40W

CP-60W

Bottom Grid

Coated Stainless (C)

or Stainless (S)

RG-36C-RH

RG-36S-RH

Drain Tray

White

11C

13d

5j

14c

12>

3e

R 83mm

Colander

White (W)

CP-80W

4Z

8c

14m

18a

Z

16e

22z

9z

5e

11g

23m

R 82.5mm

Grid

Polished Stainless

Cutting Board

White Synthetic

Included

Included

Included

Three Bowls

Polished Stainless

(Prep, Colander & Measuring)

BEACH

BBX160

Interior Dimensions:

22z"x 16e" x 6j"

Exterior Dimensions:

23m"x 18a"

Minimum Cabinet Size: 27"

ACCESSORY UNDERMOUNT BOWLS

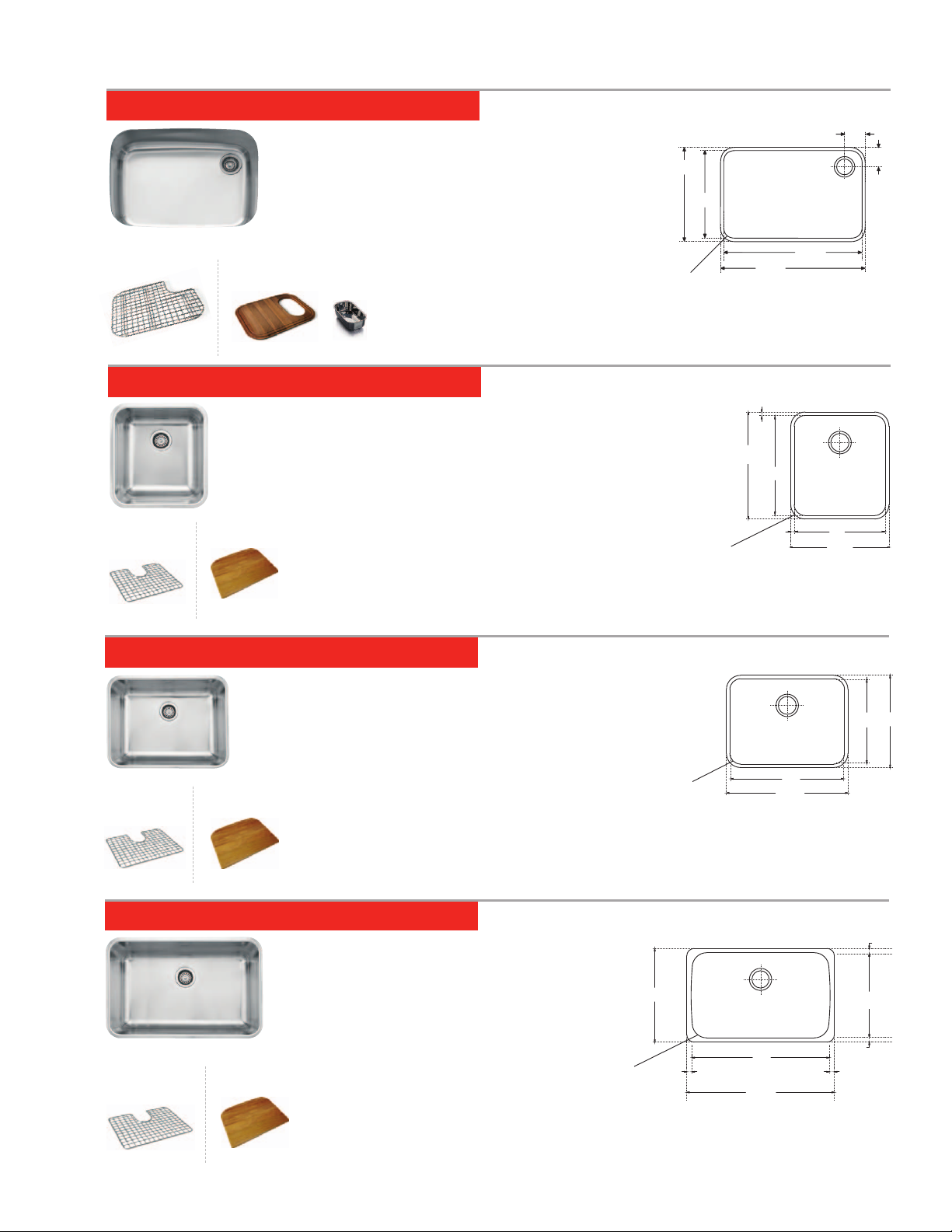

CENTINOX

COMPACT

COMPACT

21C

16a

19Z

18b

R 12.4mm

Interior Dimensions:

19Z"x 16a" x 8"

Exterior Dimensions:

21C"x 18b"

Minimum Cabinet Size: 24"

CEX11019

Interior Dimensions:

11C"x 13d" x 5j"

Exterior Dimensions:

12>"x 14c"

Minimum Cabinet Size: 15"

Interior Dimensions:

13d"x 16w" x 6j"

Exterior Dimensions:

14c"x 17c"

Minimum Cabinet Size: 18"

CPX110

CPX11013

Roller Mat

Stainless

KB-36RM

21

16a

8z

17j

Cutting Board

White Synthetic

ER-40W

Drain Basket

Stainless

ER-50S

Note: May be used as a

topmount or undermount

(has polished rim)

Note: All accessories sold separately unless otherwise indicated.

Design of custom accessories subject to change without notice. Franke recommends using template when making final cutout.

It is necessary to have the sink and accessories on hand when making final cutout to ensure proper fit. Franke will not be responsible for any erroneous cuts in the countertop.

18e

17

13e

12

R 73mm

Bottom Grid

Coated Stainless (C)

or Stainless (S)

GD12-36C

GD12-36S

Bottom Grid

Coated Stainless (C)

or Stainless (S)

GD15-36C

GD15-36S

R 73mm

18e

17

16e

15

17b

9m

7j

3Z

15e

3e

R 25mm

Colander

Polished Stainless

KB-70C

Interior Dimensions:

15" x 17" x 9"

Exterior Dimensions:

16e"x 18e"

Minimum Cabinet Size: 18"

Reference page 27 and 28 for full size bowls.

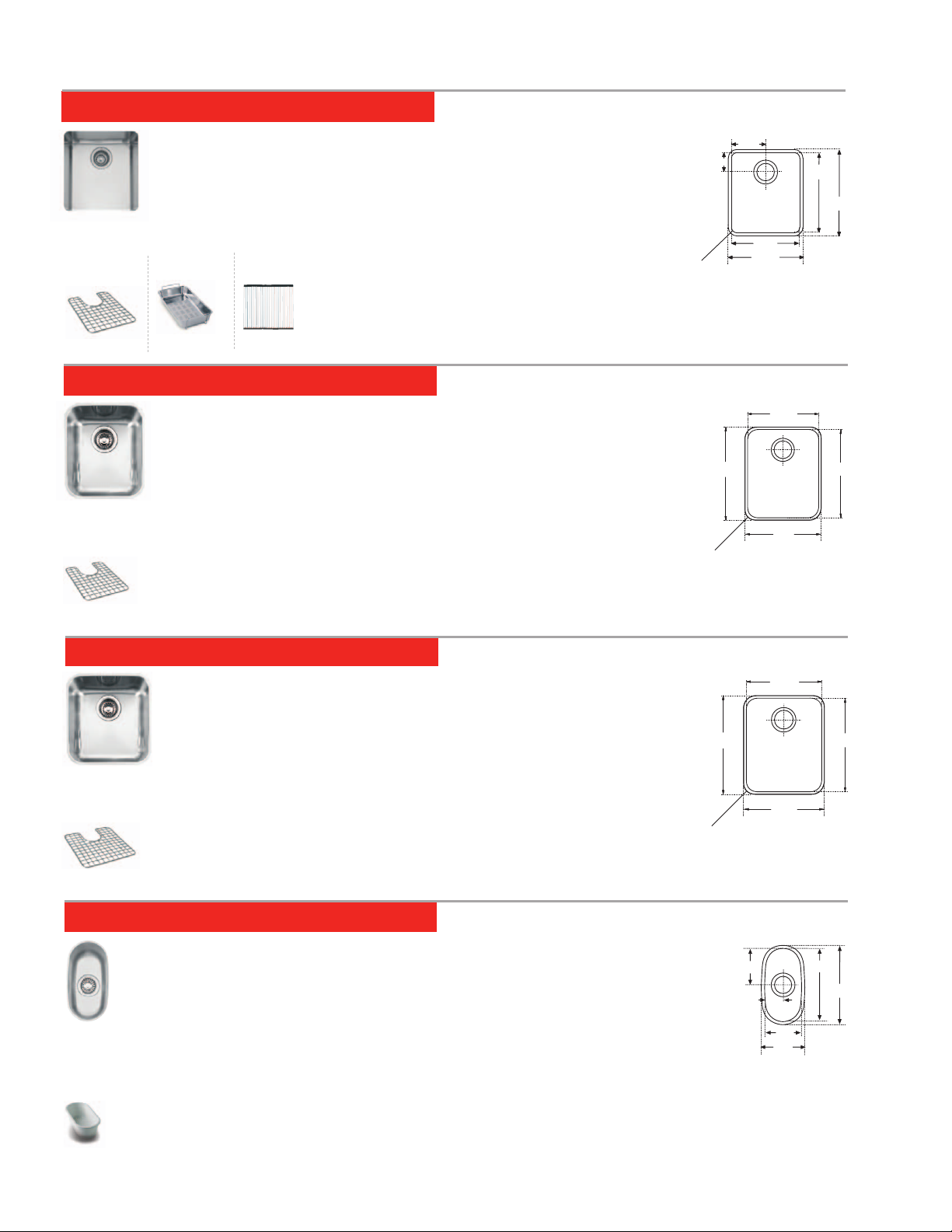

GRANDE

Interior Dimensions:

7j"x 15e" x 5j"

Exterior Dimensions:

9m"x 17b"

Minimum Cabinet Size: 12"

Reference page 28 for full size bowls

and pages 36 & 37 for double bowls.

GDX11015

KUBUS

KBX110-8

ESPIRIT

ERX110

Interior Dimensions:

16a"x 7a"

Exterior Dimensions:

17j"x 7a"

Minimum Cabinet Size: 21" (undermount)

18" (topmount)

GRANDE

GDX11012

Interior Dimensions:

12" x 17" x 8"

Exterior Dimensions:

13e"x 18e"

Minimum Cabinet Size: 15"

Reference page 27 and 28 for full size bowls.

ACCESSORY UNDERMOUNT BOWLS

22

Note: All accessories sold separately unless otherwise indicated.

Design of custom accessories subject to change without notice. Franke recommends using template when making final cutout.

It is necessary to have the sink and accessories on hand when making final cutout to ensure proper fit. Franke will not be responsible for any erroneous cuts in the countertop.

15b

17w

18w

R 45mm

16d

14c

17w

18w

R 45mm

15a

PR-70W

PR-70BK

Colander

White (W)

or Black (BK)

Bottom Grid

Coated Stainless (C)

or Stainless (S)

LA15-36C

LA15-36S

Bottom Grid

Coated Stainless (C)

or Stainless (S)

LA14-36C

LA14-36S

15e

17b

14B

13d

6C

3e

R 25mm

Colander

Polished Stainless

Roller Mat

Stainless

KB-70C

KB-36RM

KB13-36C

KB13-36S

Bottom Grid

Coated Stainless (C)

or Stainless (S)

7a

14c

3>

15e

7a

8g

KUBUS

KBX110-13

Interior Dimensions:

13d"x 15e" x 7j"

Exterior Dimensions:

14B"x 17b"

Minimum Cabinet Size: 18"

Reference page 28 for full size bowls

and pages 36 & 37 for double bowls.

ACCESSORY UNDERMOUNT BOWLS

LARGO

LARGO

PRESTIGE

Interior Dimensions:

14c"x 17w" x 8a"

Exterior Dimensions:

15a"x 18w"

Minimum Cabinet Size: 18"

Reference pages 37, 38 & 39

for full size double bowls.

LAX11014

Interior Dimensions:

15b"x 17w" x 9q"

Exterior Dimensions:

16d"x 18w"

Minimum Cabinet Size: 18"

Reference pages 37, 38 & 39

for full size double bowls.

Interior Dimensions:

7a"x 14c" x 5w"

Exterior Dimensions:

8g"x 15e"

Minimum Cabinet Size: 12"

Reference page 30 for full size bowls

and page 39 for double bowls.

LAX11015

PCX1107

23

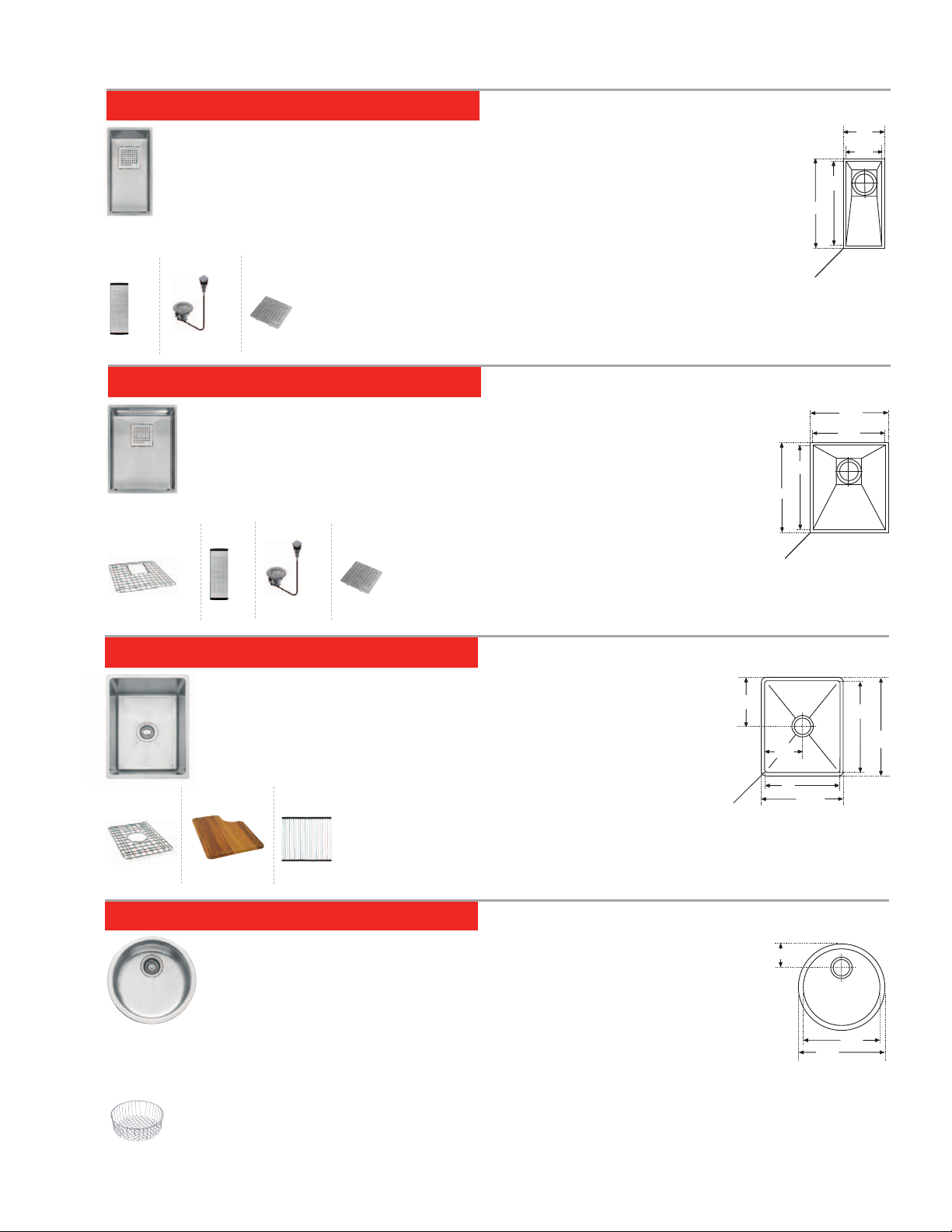

PROFESSIONAL SERIES

Drain Basket

Stainless

RBN-50C

Bottom Grid

Coated Stainless

PS13-36C

Cutting Board

Solid Wood

PS13-40S

KB-36RM

Roller Mat

Stainless

PX-13S

Bottom/Shelf Grid

Stainless

Twist Waste Kit

FRTWIST-SN

Drain Cover

Stainless

PKXCVR

Included

Colander

Stainless

PX-70S

Twist Waste Kit

FRTWIST-SN

Drain Cover

Stainless

PKXCVR

Included

Colander

Stainless

PX-70S

7a

8q

16w

17e

R 5mm

Note: All accessories sold separately unless otherwise indicated.

Design of custom accessories subject to change without notice. Franke recommends using template when making final cutout. For Fireclay models,

the sink must be used as the template. It is necessary to have the sink and accessories on hand when making final cutout to ensure proper fit. Franke will not be responsible for any erroneous cuts in the countertop.

13d

14>

16w

17e

R 5mm

13

14>

19w

18a

9e

6w

R 19mm

Note: May be used as a

topmount or undermount

(has polished rim)

4b

14 e

17 a

Interior Dimensions:

13" x 18a" x 7w"

Exterior Dimensions:

14>"x 19w"

Minimum Cabinet Size: 18"

Reference pages 32, 33 & 34 for full size bowls

and page 40 for double bowls.

Interior Dimensions:

14e"x 6>"

Exterior Dimensions:

17a"x 6>"

Minimum Cabinet Size: 21" (undermount)

18" (topmount)

PSX110138

ROTONDO

RBX-110

PEAK

PKX1108

Interior Dimensions:

7a"x 16w" x 7a"

Exterior Dimensions:

8q"x 17e"

Minimum Cabinet Size: 12"

Reference pages 30 & 31 for full size bowls

and page 40 for double bowls.

PEAK

PKX11013

with Integral Franke Ledge

Interior Dimensions:

13d"x 16w" x 9j"

Exterior Dimensions:

14>"x 17e"

Minimum Cabinet Size: 18"

Reference pages 30 & 31 for full size bowls

and page 40 for double bowls.

ACCESSORY UNDERMOUNT BOWLS

24

RG-36C

RG-36S

Bottom Grid

Coated Stainless (C)

or Stainless (S)

RG-31C

RG-31S

Shelf Grid

Coated Stainless (C)

or Stainless (S)

Note: All accessories sold separately unless otherwise indicated.

Design of custom accessories subject to change without notice. Franke recommends using template when making final cutout.

It is necessary to have the sink and accessories on hand when making final cutout to ensure proper fit. Franke will not be responsible for any erroneous cuts in the countertop.

15

9

/ 1 6

18B

19Z

7Z

16b

3e

R 113mm

15

9

/ 1 6

18B

19Z

7Z

16b

3e

R 113mm

RG-36C

RG-36S

Bottom Grid

Coated Stainless (C)

or Stainless (S)

REGATTA

RGX110

Interior Dimensions:

15>"x 18B" x 9z"

Exterior Dimensions:

16b"x 19Z"

Minimum Cabinet Size: 18"

Reference page 41 for

full size double bowls.

ACCESSORY UNDERMOUNT BOWLS

REGATTA

Interior Dimensions:

15>"x 18B" x 9z"

Exterior Dimensions:

16b"x 19Z"

Minimum Cabinet Size: 18"

Reference page 41 for

full size double bowls.

RXX110 with Integral Franke Ledge

25

R 84.1mm

7z

3>

15e

21q

19

Cutting Board

Solid Wood

CQ19-40S

(Note: 2 boards will provide full sink coverage)

Bottom Grid

Coated Stainless (C)

or Stainless (S)

CQ19-31C

CQ19-31S

Top Grid

Coated Stainless (C)

or Stainless (S)

CQ19-36C

CQ19-36S

Cutting Board

Solid Wood

CQ24-36C

CQ24-36S

Bottom Grid

Coated Stainless (C)

or Stainless (S)

CQ24-31C

CQ24-31S

Top Grid

Coated Stainless (C)

or Stainless (S)

CQ24-40S

(Note: 2 boards will provide full sink coverage)

Note: All accessories sold separately unless otherwise indicated.

Design of custom accessories subject to change without notice. Franke recommends using template when making final cutout.

It is necessary to have the sink and accessories on hand when making final cutout to ensure proper fit. Franke will not be responsible for any erroneous cuts in the countertop.

R 84.2mm

9m

4Z

20w

26d

24a

21C

16a

19Z

18b

R 12.4mm

Interior Dimensions:

19Z"x 16a" x 8"

Exterior Dimensions:

21C"x 18b"

Minimum Cabinet Size: 24"

CENTINOX

Interior Dimensions:

19" x 13w" x 7j"

Exterior Dimensions:

21q"x 15e"

Minimum Cabinet Size: 24"

CEX11019

CENTENNIAL

CQX11019

CENTENNIAL

CQX11024

Interior Dimensions:

24a"x 18a" x 9z"

Exterior Dimensions:

26d"x 20w"

Minimum Cabinet Size: 30"

SINGLE UNDERMOUNT BOWLS

Colander

Stainless

Cutting Board

Black/Stainless Steel

Drain Board

Stainless

Included

Included

Included

Bottom Grid

Stainless

Shelf Grid

Stainless

CE19-36S

CE19-31S

Roller Mat

Stainless

KB-36RM

26

Bottom Grid

Coated Stainless (C)

or Stainless (S)

Cutting Board

Solid Wood Includes

Polished Stainless Colander

GN20-36C

GN20-36S

GN20-45SP

GN16-36C GN16-40S

Bottom Grid

Coated Stainless

Cutting Board

Solid Wood

Cutting Board

Solid Wood

CQ29-36C

CQ29-36S

Bottom Grid

Coated Stainless (C)

or Stainless (S)

CQ29-31C

CQ29-31S

Top Grid

Coated Stainless (C)

or Stainless (S)

CQ29-40S

(Note: 2 boards will provide full sink coverage)

Note: All accessories sold separately unless otherwise indicated.

Design of custom accessories subject to change without notice. Franke recommends using template when making final cutout.

It is necessary to have the sink and accessories on hand when making final cutout to ensure proper fit. Franke will not be responsible for any erroneous cuts in the countertop.

Bottom Grid

Coated Stainless

Cutting Board

Solid Wood Includes

Polished Stainless Colander

17Z

18B

3j

3j

15Z

16j

R 99mm

19Z

20j

3j

3j

17Z

18B

R 99mm

GN18-36C GN18-45SP

15b

16j

3j

3j

15b

16j

R 99mm

14d

7c

20w

31b

29z

R 84.2mm

CENTENNIAL

CQX11029

Interior Dimensions:

29z"x 18a" x 9z"

Exterior Dimensions:

31b"x 20w"

Minimum Cabinet Size: 33"

SINGLE UNDERMOUNT BOWLS

EUROPRO

EUROPRO

EUROPRO

Interior Dimensions:

15b"x 15b" x 7j"

Exterior Dimensions:

16j"x 16j"

Minimum Cabinet Size: 21"

GNX11016

Interior Dimensions:

17Z"x 15Z" x 7j"

Exterior Dimensions:

18B"x 16j"

Minimum Cabinet Size: 21"

Interior Dimensions:

19Z"x 17Z" x 9j"

Exterior Dimensions:

20j"x 18B"

Minimum Cabinet Size: 24"

GNX11018

GNX11020

27

Bottom Grid

Coated Stainless (C)

or Stainless (S)

GD28-36C

GD28-36S

Cutting Board

Solid Wood

GD28-40S

Bottom Grid

Coated Stainless (C)

or Stainless (S)

GD23-36C

GD23-36S

Cutting Board

Solid Wood

GD-40S

Bottom Grid

Coated Stainless (C)

or Stainless (S)

GD18-36C

GD18-36S

Cutting Board

Solid Wood

GD-40S

Cutting Board

Solid Wood Includes

Polished Stainless Colander

GN28-36C

GN28-45SP

Bottom Grid

Coated Stainless

Note: All accessories sold separately unless otherwise indicated.

Design of custom accessories subject to change without notice. Franke recommends using template when making final cutout.

It is necessary to have the sink and accessories on hand when making final cutout to ensure proper fit. Franke will not be responsible for any erroneous cuts in the countertop.

27>

28e

3j

3j

19Z

20j

R 99mm

21w

18

j

19e

j

19e

R 73mm

R 73mm

17

18e

24e

23

17

19a

30a

28

1z

1z

1z

1z

R 73mm

Interior Dimensions:

23" x 17" x 9"

Exterior Dimensions:

24e" x 18e"

Minimum Cabinet Size: 27"

GRANDE

Interior Dimensions:

28" x 17" x 9"

Exterior Dimensions:

30a" x 19a"

Minimum Cabinet Size: 33"

GDX11023

GRANDE

GDX11028

EUROPRO

GNX11028

Interior Dimensions:

27>"x 19Z" x 11e"

Exterior Dimensions:

28e"x 20j"

Minimum Cabinet Size: 33"

GRANDE

GDX11018

Interior Dimensions:

18" x 19e" x 9"

Exterior Dimensions:

19e"x 21w"

Minimum Cabinet Size: 21"

SINGLE UNDERMOUNT BOWLS

28

15e

17b

21g

10C

3e

22C

R 25mm

Cutting Board

Solid Wood

Bottom Grid

Stainless

Shelf Grid

Stainless

Colander

Polished Stainless

Grid

Stainless

KB28-36S KB28-31S KB-40S KB-70CKB17-31C

Roller Mat

Stainless

KB-36RM

Cutting Board

Solid Wood

Grid

Stainless

Shelf Grid

Stainless

KB-40S KB-70CKB17-31C

KB21-36C

KB21-36S

KB21-31S

Colander

Polished Stainless

KB-36RM

Roller Mat

Stainless

Bottom Grid

Coated Stainless (C)

or Stainless (S)

Shelf Grid

Stainless

KB18-31S

Cutting Board

Solid Wood

Grid

Stainless

KB-40S KB-70CKB17-31C

Colander

Polished Stainless

KB-36RM

Roller Mat

Stainless

KB18-36C

KB18-36S

Bottom Grid

Coated Stainless (C)

or Stainless (S)

Bottom Grid

Coated Stainless (C)

or Stainless (S)

GD31-36C

GD31-36S

Cutting Board

Solid Wood

GD-40S

Note: All accessories sold separately unless otherwise indicated.

Design of custom accessories subject to change without notice. Franke recommends using template when making final cutout.

It is necessary to have the sink and accessories on hand when making final cutout to ensure proper fit. Franke will not be responsible for any erroneous cuts in the countertop.

17

18e

31

32e

R 73mm

15e

17b

27

>

28

e

R 25mm

3e

15e

17b

17e

8j

19q

R 25mm

KUBUS

KUBUS

KUBUS

GRANDE

Interior Dimensions:

17e"x 15e" x 9z"

Exterior Dimensions:

19q"x 17b"

Minimum Cabinet Size: 24"

KBX110-18 with Integral Franke Ledge

Interior Dimensions:

21g"x 15e" x 9z"

Exterior Dimensions:

22C"x 17b"

Minimum Cabinet Size: 27"

Interior Dimensions:

27>"x 15e" x 9z"

Exterior Dimensions:

28e"x 17b"

Minimum Cabinet Size: 33"

KBX11021 with Integral Franke Ledge

KBX11028 with Integral Franke Ledge

GDX11031

Interior Dimensions:

31" x 17" x 9"

Exterior Dimensions:

32e" x 18e"

Minimum Cabinet Size: 36"

SINGLE UNDERMOUNT BOWLS

29

Cutting Board

Solid Wood

Colander

Polished Stainless

Bottom Grid

Stainless

OA-40SOA-60S

OA-36S

OA-31S

Shelf Grid

Stainless

OA-40S

Cutting Board

Solid Wood

Colander

Polished Stainless

OA-60S

OA-36S

Bottom Grid

Stainless

OC-36C

OC-36S

Bottom Grid

Coated Stainless (C)

or Stainless (S)

Shelf Grids

Coated Stainless (C)

or Stainless (S)

Cutting Board

Solid Wood with

Stainless Colander

OC-45SP

Colander

Polished Stainless

OC-60S

Utility Bowl

Black Synthetic

OC-80BKOC-31C-LH

OC-31S-LH

OC-31C-RH

OC-31S-RH

Note: All accessories sold separately unless otherwise indicated.

Design of custom accessories subject to change without notice. Franke recommends using template when making final cutout.

It is necessary to have the sink and accessories on hand when making final cutout to ensure proper fit. Franke will not be responsible for any erroneous cuts in the countertop.

18B

16j

29B

27B

5

R 89mm

18B

6

29m

z

g

30Z

R 83.5mm

11e

Bottom Grid

Coated Stainless

Cutting Board

Solid Wood with

Optional Colander

16w

16w

8q

17w

17w

3e

Small Drain Basket

Coated Stainless

Small Drain Tray

White

CP-50C

CP-60WNA-36C

NA-40C (Cutting Board)

NA-70W (Colander)

19

16w

28

30w

Interior Dimensions:

27B"x 16j" x 8j"

Exterior Dimensions:

29B"x 18B"

Minimum Cabinet Size: 33"

OCEANIA

Interior Dimensions:

29m"x 18B" x 9z"

Exterior Dimensions:

30Z"x 20z"

Minimum Cabinet Size: 33"

OXX110 with Integral Franke Ledge

ORCA

NOBEL

NAX110

Interior Dimensions:

16w"x 16w" x 7a"

Exterior Dimensions:

17w"x 17w"

Minimum Cabinet Size: 21"

OCEANIA

OAX110

Interior Dimensions:

27B"x 16j" x 8j"

Exterior Dimensions:

29B"x 18B"

Minimum Cabinet Size: 33"

SINGLE UNDERMOUNT BOWLS

ORX110 with Integral Franke Ledge

Loading...

Loading...