Page 1

OPERATION MANUAL

Page 2

TABLE OF CONTENTS

Safety 2

General 3

Key Components 3

Function Buttons 4

Daily Operations 5

Operating Controls 5

Handle Colors 6

How to Make a Craft Beverage 7

Preheat the Brew Cylinder 7

Make a Beverage 8

Brew Cylinder Removal 11

Brew Cylinder Installation 12

Purge Valve Installation 13

Splash Guard Removal 13

Daily Cleaning 14

External Surfaces and Accessories 14

Weekly Cleaning 15

Brew Cylinder and Components 15

Purge valves 16

Quarterly Cleaning 17

Descaling 17

Troubleshooting 18

Error Messages on User Interface Screen 18

General Troubleshooting 18

Accessories 19

Warranty 20

of 201

Page 3

SAFETY

READ AND UNDERSTAND THE CONTENTS OF THIS

MANUAL BEFORE ATTEMPTING TO OPERATE.

This operation manual contains important instructions

and safety information about the BKON™ Craft Brewer.

Observe the following dangers, warnings, cautions and

notices when operatinging the BKON Craft Brewer:

EXPLANATION OF SAFETY SYMBOLS

DANGER

Indicates potentially life-threatening danger or grave

injury.

DANGER

Indicates potentially life-threatening danger or grave

injury from electrocution.

WARNING

Indicates risk of injury.

WARNING

Indicates risk of injury from Heat / Hot Surface.

CAUTION

Indicates risk of minor injury.

WARNING

Risk of burning or scalding

- Hot water and steam are released repeatedly during

the cleaning cycle.

- Keep hands away from the outlet (purge valve) while

in operation.

- The glass cylinder may be HOT to the touch.

- Do not disconnect “Hot Water” line before purging

lines of hot water or allowing sufcient time for water

in lines to cool.

WARNING

Risk of injury and / or damage to the machine

Making improper changes in the form of modications or

unauthorized repairs can lead to injury or damage to the

machine.

- Programming and settings may only be preformed

by authorized service technicians.

- Retrots and repairs may only be preformed by

authorized service technicians.

- Do not make any modications to the machine that

are not authorized by documentation provided by

Franke Foodservice Solutions, Inc.

CAUTION

Possible health hazard from heavy lifting

Lifting heavy objects can cause injury.

- Do not lift or move the machine without appropriate

help or equipment.

FOR YOUR SAFETY

This documentation has been created exclusively for

training the use of, and operating, the BKON Craft

Brewer..

DANGER

Electrical System

- Energized electrical circuits present a potentially life

threatening hazard.

- Ensure all electrical power circuits connected to the

unit and supply outlets or connections are completely

de-energized before performing any installation work

around power outlets or connections.

- Follow all lockout / tagout procedures for all electrical

circuits.

WARNING

Hot Water System

NOTICE

Improperly transporting the machine can cause faults or

damage.

- Always transport in an upright position.

- Transport the machine so that it is protected from

the elements, such as rain and moisture.

NOTICE

Using inappropriate tools can damage components of

the machine.

NOTICE

General Reminders.

- Do not discard any loose parts as they may be

required for proper installation and operation.

of 202

Page 4

GENERAL

The BKON™ Craft Brewer is designed for high volume use, for the creation of “quick serve / on demand” drinks prepared by a Barista

(operator). The machine ships from the factory in two parts: tower and supply center. The tower is where the product is brewed and

dispensed. A brew handle is used to hold product during a brew cycle.

Cold water should be supplied to the unit. During a cycle, 8 to 20 oz. of water passes through a process that will ultimately deliver

an expertly crafted beverage. A water supply connection is located on the front of the supply center and should be connected by the

certied installer per national and local municipality codes and regulations.

KEY COMPONENTS

Cylinder

Latching

Handle

Brew Cylinder

Brew Basket

Locking Handle

Drain Tray

Tower

User Interface Screen

Brew Basket

Brew Handle

Power Switch

Purge Valve

Supply Center (WVSC)

Purge Valve Tool

Exhaust Fan

Water Inlet

of 203

Page 5

Function Buttons

i

Green Tea White Tea

Black Tea

Spirits

Chai / Rooibos

Oolong Tea

Herbal / Fruit

Coffee

17:30

i

17:30

i

17:30

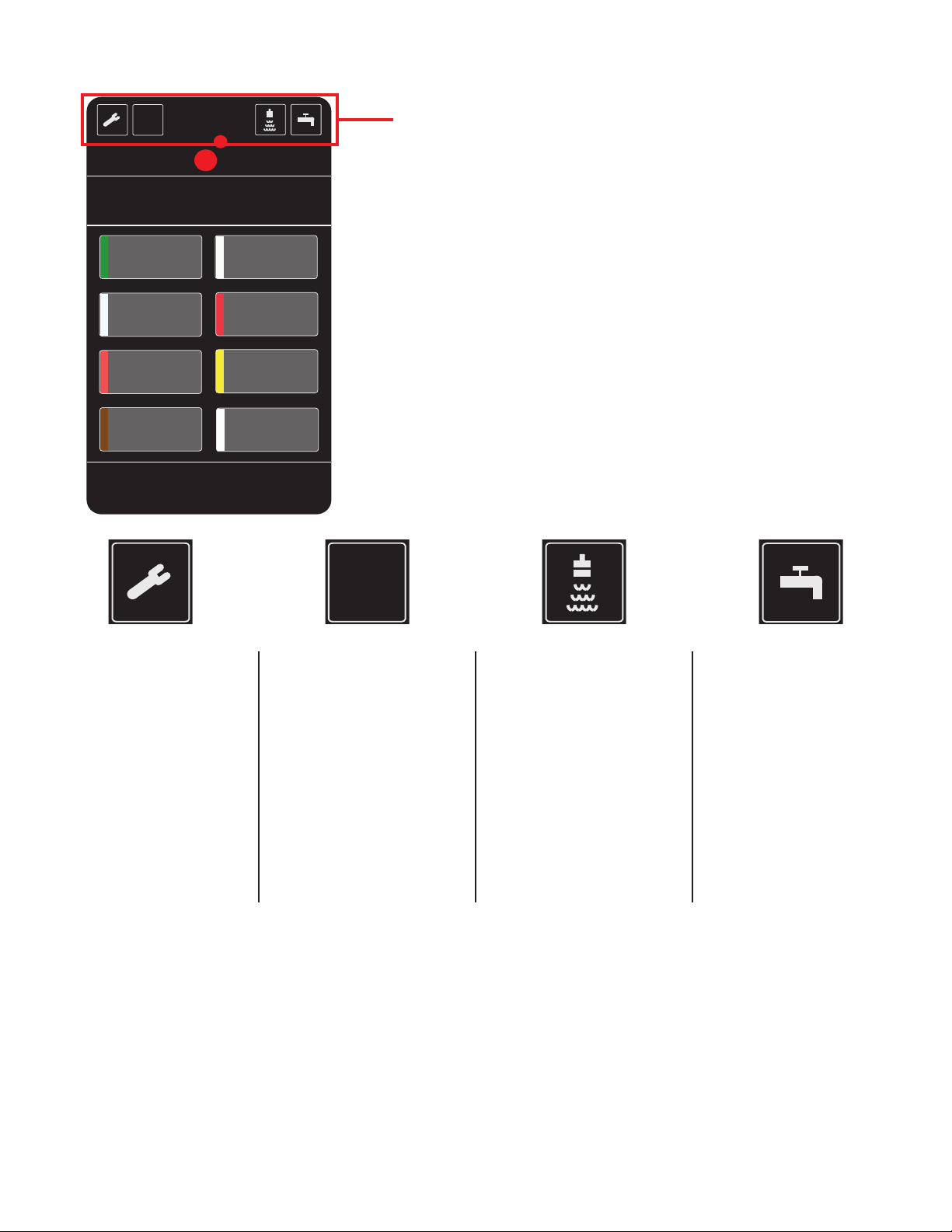

FUNCTION BUTTONS

Wrench Icon

Is used to access the

Maintenance / Service

menu. This menu provides

the means to:

Perform Cleaning

Test Tea Recipes

Update/Export Tea Recipes

Update Time and Date

Descale

Information Icon

This icon will list the follow

information:

BKON version number

Software versions

Menu le name

Brew counts

Rinse Icon

This function is used to

perform a manual rinse.

If the automatic rinse was

unable to remove some

beverage ingredients

from the side of the brew

cylinder, press the rinse

button to perform an

addition rinse to remove

ingredients.

Purge Icon

This function is used to

perform a manual purge.

If the automatic purge

was unable to remove all

the liquid from the brew

cylinder, press the manual

purge to perform an

addition purge to push out

the liquid.

of 204

Page 6

DAILY OPERATIONS

Operating Controls

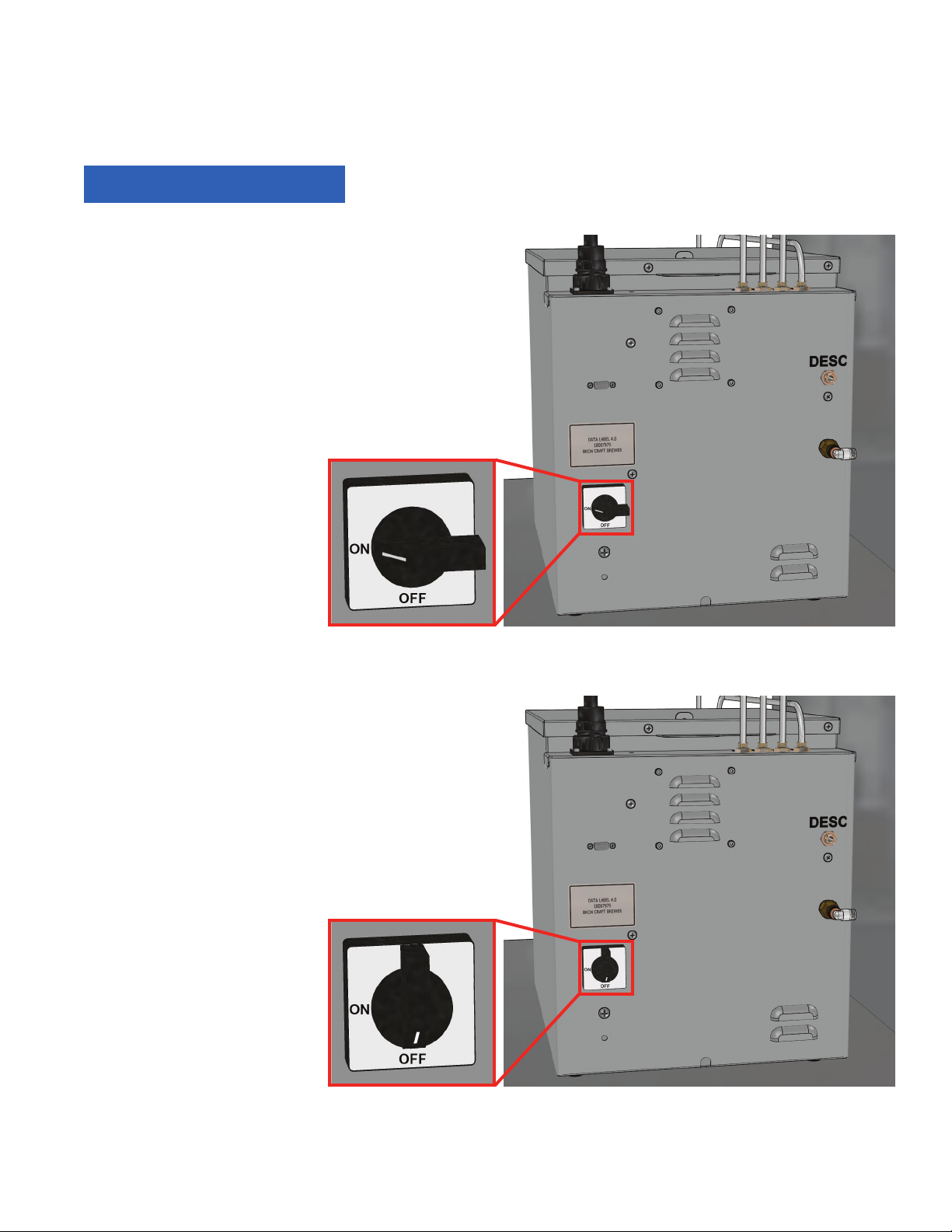

1. Power - Start Up

NOTICE

The BKON™ Craft Brewer has a power On/Off switch

mounted on the front of the Supply Center.

Rotate the black handle clockwise from the “OFF” to the

“ON” position. The craft brewer now has power. Once

power is turned on, the initialization sequence must

nish before drink preparation is possible.

When turning on machine, it is necessary to have the Brew Basket

and Brew Handle out of the machine until the User Interface is ready

and menus are available.

2. Power - Shut Down

The BKON™ Craft Brewer has a power On/Off switch

mounted on the front of the Supply Center.

When turning off, it is necessary to have the Brew

Basket and Brew Handle in the tower and the and

locking handle in the UP / UNLOCKED position.

Rotate the black handle counter clockwise from the

“ON” to the “OFF” position.

of 205

Page 7

HANDLE COLORS

i

Green Tea White Tea

Black Tea

Spirits

Chai / Rooibos

Oolong Tea

Herbal / Fruit

Coffee

17:30

BKON™ Color Method

Important: A color-coding system has been created to help ease workow and to avoid cross-contamination when

brewing with materials that may carry avors over to other products. Below is a color method applied to a

tea program. The same logic may be used for a coffee and tea program or for any other means to separate

products by colors.

Black / Oolong

PURE

Green / White

PURE

Other

FLAVORED

Coffee

Four colored brew handles and baskets are provided with each BKON brewer. Black, Green and Orange can

be used for tea and other craft brew beverages. The Brown handle and baskets should be used for Coffee.

The color of the touch screen buttons can also be customized to identify which basket should be used for a

particular product. This can be adjusted during recipe development within the Craft Cloud.

Disclaimer: Screen appearance will vary according to customer-specic

menus.

of 206

Page 8

i

Green Tea White Tea

Black Tea

Spirits

Chai / Rooibos

Oolong Tea

Herbal / Fruit

Coffee

17:30

HOW TO MAKE A CRAFT BEVERAGE

If the craft brewer has been idle or the brew chamber has been left open, a rinse cycle should be preformed to

preheat the brew cylinder before preparing a craft beverage.

Preheat the Brew Cylinder

1.

and handle

Insert a pitcher under the brew

handle

3.2.Insert an empty brew basket

Lower the brew handle locking

handle

4..

Select the manual rinse icon

5.

Raise the brew handle locking

handle

of 207

6.

Remove pitcher and brew

handle, empty pitcher

Brew cylinder is now preheated

Page 9

How to make a craft beverage

Make a Beverage

1.

Prepare purge valve. Lightly

press tip handle into valve to

clear debris

Ensure the basket and

handle colors match

Craft

Beverage Coffee

Place measured product in

2.

brew basket and place brew

basket with measured product

inside the brew handle

Paper

Coffee

Filter

Insert new brew handle into

3.

tower (with product)

Place cup under outlet

4.

5. 6.

Lower locking handle fully to

seal brewing cylinder

17:30

i

Green Tea White Tea

Oolong Tea

Herbal / Fruit

Coffee

Select beverage type

Black Tea

Chai / Rooibos

Spirits

of 208

Page 10

Coffee

Spirits

Chai / Rooibos

i

I

<

II III IV

Select Recipe...

17:30

Recipe

1

Recipe

2

Recipe

3

Recipe

5

Recipe

4

How to make a craft beverage

i

Select Recipe...

Fruit Tisane

small particle

Fruit Tea Blend s

Chamomile

Coffee

<

I

7.

Select beverage recipe Select drink size

8. 9.

17:30

Recipe 1

small

Fruit Tisane

large particle

medium

Fruit Tea Blend l

Chai / Rooibos

large

X

II III IV

Spirits

17:30

i

Recipe 1

Size: small

Brewing Process...

Chai / Rooibos

Coffee

Brew process begins

Spirits

X

10.

Beverage dispenses into cup

17:30

i

Recipe 1

Size: small

Brewing Complete

Chai / Rooibos

Coffee

<

11. 12.

Brew process is complete

Spirits

Raise locking handle

(unlocked)

of 209

Page 11

How to make a craft beverage

Hot

Surfaces

Serve beverage Remove brew handle from

13.

14. 15.

tower

16. 17. 18.

Empty product into knock box

Rinse brew basket Rinse brew handle

Remove brew basket from

handle

of 2010

Page 12

BREW CYLINDER REMOVAL

Raise cylinder locking handle -

1. 2.

- Raise cylinder locking handle

to release upper O-ring

Raise locking handle -

- Raise locking handle to

provide more space to

remove cylinder

3. Remove brew basket and

handle -

- Remove the brew basket and

handle if one is in place

Lower cylinder -

4.

- Lower glass cylinder from

upper O-ring

Angle and remove cylinder -

5. Lower locking handle

- Carefully angle back and lift

up cylinder

of 2011

6.

- Lower locking handle to

provide more space to angle

and remove cylinder

Page 13

8.

Remove rubber anges -

- Remove both rubber anges

- Clean the glass cylinder and rubber anges

Brew Cylinder Removal

7.

Lower locking handle

- Lower locking handle to

provide more space to angle

and remove cylinder

9.

Reassemble -

- Allow glass cylinder and rubber anges to dry

- Reattach the anges to the cylinder

- Reinstall cylinder in reverse order of removal

BREW CYLINDER INSTALLATION

1. Raise cylinder locking handle -

- Raise cylinder locking handle

Raise locking handle -

2. 3. Angle and insert cylinder -

- Raising locking handle will

provide more space to insert

brew cylinder

of 2012

- Carefully insert glass cylinder

in place from the customer

side of brew tower

Page 14

Brew Cylinder Installation

Raise cylinder -

4. Insert a brew basket and

- Raise cylinder in place to

ensure a tight seal on top

5. Lower locking handle

handle -

- Combine handle and basket,

insert under cylinder

6.

- Lower locking handle to seal

lower cylinder in place

Splash Guard RemovalPurge Valve Installation

7. 1.

Lower cylinder locking handle -

- Lower cylinder locking handle

to complete installation

Insert purge valves into brew

handles -

- Secure the purge valve into

the brew handle using the

purge valve tool

of 2013

1.

Press sides and lower splash

guard -

- A.) Lightly press sides of

splash guard inward

- B.) Lower spalsh guard

- Install in reverse order

Page 15

DAILY CLEANING

i

Green Tea White Tea

Black Tea

Spirits

Chai / Rooibos

Oolong Tea

Herbal / Fruit

Coffee

17:30

i

17:30

External Surfaces and Accessories

EXTERNAL

SURFACES AND

ACCESSORIES:

1. Insert brew

basket and handle

with purge valve

seated in place in

the handle.

2. Lower locking

handle.

3. Run manual rinse

cycle twice.

(Repeat steps 1-3

for each brew

handle).

4. Wipe exterior

surfaces (4a4d) with a clean,

damp cloth.

(Do not use

excessive

moisture. Ensure

screen (4d) is dry

after cleaning.)

4a

4b

4c

1

3

X 2

Per Brew

Handle

2

5

4d

5. Wash accessories.

(Parts shown are

dishwasher safe.

After washing,

rinse and sanitize

all parts, and

allow to air

dry prior to

reassembly.)

OR

For video instruction, go to the link below:

https://youtu.be/T4RLtptseIs

of 2014

Page 16

WEEKLY CLEANING

Brew Cylinder and Components

BREW CYLINDER AND

COMPONENTS:

1

32 oz

32

4

STEP 1/4: CLEANING

Operator attention is required to empty

the pitcher when prompted.

1-Insert brew basket in brew handle.

2-Place one BKON Cleaning Tablet

in the basket.

3-Insert brew handle and lock in place.

4-Place a 32 oz (950 ml) pitcher

under outlet and press Continue..

CANCEL

CLEANING COMPLETE

CAUTION: WATER is extremely hot.

Empty and clean pitcher.

Clean basket and brew handle.

Continue with the daily cleaning tasks.

Press Finish..

CONTINUE

Follow the on-screen instructions

STEP 2/4: RINSE 1 OF 2

CAUTION: WATER is extremely hot.

Empty pitcher and return under outlet.

Make sure the lock handle is in the

down position.

Press Continue when ready..

CONTINUE

NOTICE: On-screen instructions may vary by software version. Follow instructions on screen.

Emptying and Replacing Pitcher

(as described in on-screen instructions)

STEP 3/4: RINSE 2 OF 2

CAUTION: WATER is extremely hot.

Empty pitcher and return under outlet.

Make sure the lock handle is in the

down position.

Press Continue when ready..

CONTINUE

STEP 4/4: SANITIZE

CAUTION: WATER is extremely hot.

Empty pitcher and return under outlet.

Make sure the lock handle is in the

down position.

Press Continue when ready..

CONTINUE

FINISH

NOTICE:

Failure to perform cleaning

or descaling procedures, as

indicated per instructions,

may void warranty.

of 2015

Page 17

Purge valves

PURGE VALVES:

1. After wash cycle is

complete, remove purge

valves from all brew

handles using the purge

valve tool.

1 2

Weekly Cleaning

3

2. Make cleaning solution

by placing one (1) BKON

cleaning tablet into one

(1) 32 oz pitcher of hot

wa ter.

3. Poke each purge valve

with the purge valve tool.

4. Place purge valves into

cleaning solution, and

allow to soak overnight.

5. After soaking overnight,

thoroughly rinse cleaning

solution from purge

valves.

6. Using the purge valve

tool, insert purge valves

into brew handles.

(Do not overtighten.)

4

32 oz

5

32 oz

6

of 2016

Page 18

QUARTERLY CLEANING

i

17:30

Descaling

DESCALING:

1. Install suction cap and

tubing to descaling bottle,

and connect suction tube

to descaling port (as

shown). Leave the main

water line connected.

2. Insert an empty brew

basket and handle. Place

pitcher under purge valve.

Lower brew basket locking

handle.

3. Select the “WRENCH”

icon.

4. Select “Descaling”.

Note: For the remainder

of the descaling process,

follow the on-screen

instructions. Entire

descaling process may

take up to 20 minutes

and will require periodic

operator interaction.

5. Empty and wash the

brew handle, basket, and

pitcher.

CAUTION

on descaling label before performing this process. Use only BKON recommended descaling

products. Make sure pitcher is in place under brew basket during entire descaling process.

Wash pitcher thoroughly after use.

Read and understand the safety and rst aid instructions

Descaling Supplies

1

DESCALER

32 oz

DESCALER

2

3

17:30

i

Green Tea White Tea

Oolong Tea

Herbal / Fruit

Coffee

Black Tea

Chai / Rooibos

Spirits

6. Remove descaling bottle,

and dispose of properly.

To disconnect tubing,

press in the retaining ring,

and remove the tubing.

WARRANTY REQUIREMENT:

Run descaling cycle at least once

every 3 months.

NOTICE:

Failure to perform cleaning or

descaling procedures, as indicated

per instructions, may void warranty.

17:30

i

4 5 6

Maintenance / Service

Clean in Place

Time/Date

Update

Recipe File

Descaling

Load and Run

Dev Tea

Export to

Recipe File

of 2017

Page 19

TROUBLESHOOTING

Error Messages on User Interface Screen

Error Code Possible Cause Solution

Brew Chamber Glass

C:1 M:5

Brew Handle

C:2 M:5

Chamber Not Sealed

C:3 M:5

Temp. Sensor

C:11 M:5

thru

C:22 M:5

Flow Meter

C:40 M:5

Brew Chamber not installed correctly

Brew Handle not detected

Purge valve may be struck open or

clogged with debris

Brew chamber not sealed 4. Call for service

Temperature check failed

No water ow detected

Air in water lines

1. Remove and reinstall Brew Chamber.

2. Call for service.

1. Ensure brew handle and basket are in place when brewing.

2. Call for service.

1. Poke purge valve with purge valve tool to ensure ball

moves and is free of debris. Try a different purge valve or

brew handle.

2. Ensure brew handle and basket are in place and free of

debris.

3. Ensure brew basket locking handle is down and in place.

1. Restart machine and try again.

2. Call for service.

1. Check supply water.

2. Ensure drain from tower and drain from WVCS are not

connected to each other. Both should be connected to store

drain.

3. Cycle power and allow machine to reboot, purging air from

lines. Repeat up to 4 times.

4. Call for service.

General Troubleshooting

Symptom Possible Cause Solution

User Interface not on

Water leak

Did not purge drink Purge valve is stuck in the closed position

Purge or dripping during

brew cycle

Beverage level is

incorrect

Consistent poor

beverage quality

Main power off

Communication cable disconnected 3. Call for service.

Leak Between Tower and WVSC 1. Check water line connections

Drain lines leak

Leaking from inside WVSC 3. Call for service

Debris in purge valve

Purge valve spring has become too weak 3. Call for service.

Corrupt recipe 1. Try a different recipe in the same size.

Flowmeter malfunction 2. Call for service.

Wrong amount of tea / coffee 1. Check recipe and product measurement.

Poor incoming water quality 2. Make sure incoming water is in spec.

Corrupt recipe 3. Check recipe.

Chamber was locked during startup (result in

calibration error)

Beverage too hot or cold

of 2018

1. Check power cord and breaker.

2. Check connection on tower and WVSC.

2. Check drain line connections on Tower, WVSC and

store drain

1. Use manual purge or remove purge valve per

instructions, using purge valve tool. Once valve is

removed, use manual purge.

2. Punch with purge valve opener from inside brew

handle.

3. Try a different purge valve. Call for service

1. Use purge valve tool to remove debris from purge ball.

2. Replace purge valve.

4. Restart machine and ensure brew basket and handle

are not installed during start up.

5. Check recipe.

6. Call for service.

Page 20

ACCESSORIES

19006590

Brew Chamber

(Glass Only)

18007897

Brew Chamber Assembly

(glass and rings)

19006265

Silicone Ring

27801749

Purge Valve Tool

19006722

Drip Tray

Screen

19006993

Brew Basket

Black

19006996

Brew Basket

Green

19006994

Brew Basket

Orange

19006802

Coffee Basket

19006803

Coffee Cap

19006364

Brew Handle

(no color clip)

19006305

Purge Valve

19007372

Cleaning Tablets

18008739

Coffee Filters

(500 pcs)

18009328

Brew Handle Clips

(Black, Green,

Orange, Brown)

18008925

Descale Kit

(liquid and tube)

151044

Cleaning Brush

20.210001283

Drip Tray Cover

19006258

Plunger Gasket

x3

x3

x100

18008316

Coffee Brew Kit

19006351

Splash Guard

of 2019

Page 21

Franke Limited Warranty

Franke Foodservice Solutions (“Franke”) warrants new equipment manufactured in Franke’s own facilities and

installed in the United States and Canada to be free of defects due to poor materials or workmanship for the period

of time listed below (following the date of original installation):

Franke-Manufactured Equipment

- 1 Year Parts and Labor

Exclusions: Certain Franke parts that are expendable by nature and that need to be replaced frequently may

not be covered. Franke is not liable under these warranties for repairs or damages due to improper

operation, attempted repairs or installation by unauthorized persons, alterations, water quality, abuse,

re, ood or acts of God.

Additionally, this warranty may be voided in the case of:

- Failure to follow Franke instructions for use, care or maintenance

- Removal, alteration or defacing of the Franke-afxed serial number

- Service by a non-authorized service company

- Use of non-OEM (Original Equipment Manufactured) parts

WARRANTY

This warranty is conditional upon Franke receiving notice of any defect subject to this warranty within thirty (30)

days of its original discovery by the Buyer.

of 2020

Page 22

For Support, please call:

Tel + 1-800-5-FRANKE, opt. 2

(1-800-537-2 6 5 3, opt. 2)

Franke Foodservice Solutions Inc.

800 Aviation Parkway

Smyrna, TN 37167

www.frankeamericas.com

Franke Group, which includes both Franke Foodservice Solutions and Coffee Systems divisions, is one of the worlds leading suppliers of fully

automatic coffee machines and innovative, out-of-home hot-beverage solutions. Franke is BKON's exclusive global partner, providing engineering,

manufacturing, distribution and support for commercial systems that use BKON's patented Reverse Atmospheric Infusion

© 2016 Franke Foodservice Solutions, Inc. This media is the condential property of Franke Foodservice Solutions, Inc. and shall not be

reproduced in any form of media without the express written permission of Franke. BKON, BKON Craft Brewer, RAIN, Reverse Atmospheric

Infusion, and the red dot logo are trademarks of Bkon LLC. Franke mark used under license Franke Technology and Trademark Ltd., Switzerland.

Due to continuous product development, Franke Foodservice Solutions Inc. reserves the right to make changes in design and specications

without prior notice.

™

brewing technology.

(19006370 Rev. C, March 21, 2016)

Loading...

Loading...