Page 1

Building Morbic 12

Clinker dinghy

Customer name :

Plan number : MO12 -

© François Vivier – March 2017

7, avenue des Courtils – 44380 Pornichet - France

tél : 33 (0)6 74 54 18 60 or 33 (0)2 28 54 97 86

E-mail : fr@vivierboats.com – www.vivierboats.com

François Vivier Architecte Naval – SARL au capital de 8 000 € - Siren : 451 456 669 RCS Saint Nazaire

Page 2

March 2017 Building Morbic 12 Page 2/21

1. Plan package content

1.1. The present manual

1.2. Appendices

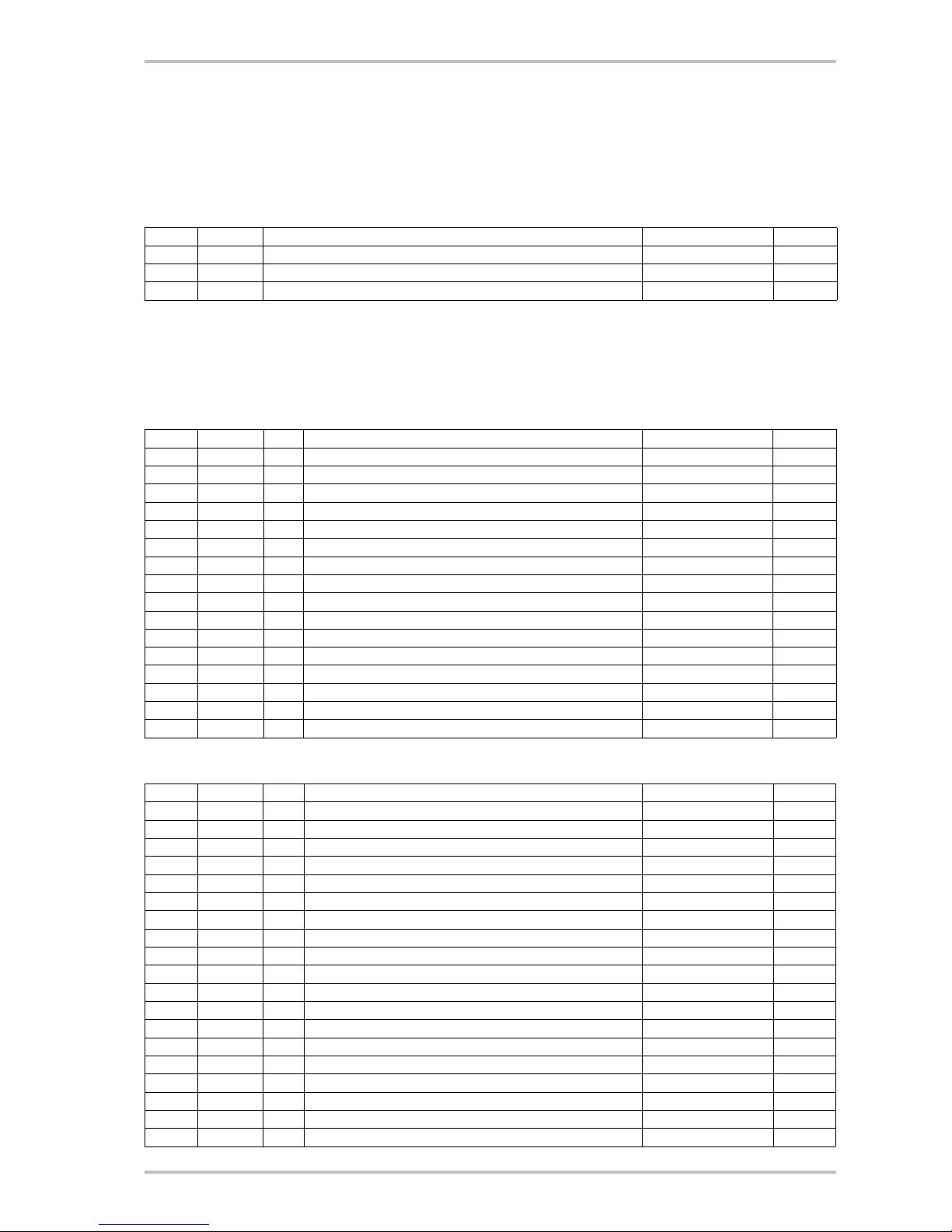

Numb Rev Titre Date Pages

1 8 Timber list 2 October 2013 2

2 10 Plywood list 18 April 2015 11

3 5 Fittings 2 October 2013 3

1.3. Manual of “wooden boatbuilding” sheets (mainly in French)

These documents are extracts from my book on wooden boat construction, “Construction bois les techniques modernes” (in French). Though only a few are presently translated, equivalent information in English is available from

other sources. For example, the websites of epoxy suppliers give comprehensive information in regard to saturation,

gluing, filleting, and sheathing. Sheet 44 is already translated and I intend to translate other ones. If you need some

technical advice, please tell me and I will answer your questions.

Numb Version Rev Titre Date Pages

05 Toutes 0 Imprégnation époxy 25 sept. 03 2

06 Toutes 0 Collages et joints congés 14 octobre 03 2

07 Toutes 0 Stratification sur bois 15 novembre 03 4

08 Toutes 0 Imprégnation et collage : solutions par temps froid 12 novembre 03 3

12 Toutes 1 Rivets à bateaux 15 novembre 03 2

15 Toutes 1 Scarf des panneaux de contreplaqué 9 novembre 03 2

16 Toutes 0 Pièces en lamellé-collé 30 décembre 03 4

22 Toutes 0 Montage de la structure sur chantier 8 avril 04 8

43 Toutes 0 Tenue provisoire des clins 6 novembre 03 1

44 Toutes 1 Liaison des bordés à clin 3 avril 04 3

51 Toutes 0 Bordé en contreplaqué cousu-stratifié 8 avril 05 4

71 Toutes 0 Bancs et planchers 7 octobre 03 1

72 Voile 1 Gouvernail à safran relevable 2 novembre 09 2

81 Voile 0 Mâts et espars ronds 17 octobre 03 3

82 Voile 0 Le gréement au tiers ou de misainier 10 octobre 03 3

91 Voile 0 Peintures et vernis 18 novembre 03 3

1.4. Plans (A3 format booklet)

Numb Version Rev Titre Date Scale

01 All 0 Hull lines (outside planking) 6 February 2008 1/15

12 All 3 Building frame 7 November 2010 1/15

21S Sloop 5 Longitudinal structure 2 October 2013 1/10

21T Balanced 6 Longitudinal structure 2 October 2013 1/10

22S Sloup 5 Transversal structure 19 September 2011 1/10

22T Balanced 7 Transversal structure 19 September 2011 1/10

25 Voile 3 Rudder 2 November 2009 1/10

31 Balanced 0 Balanced lug rig 6 February 2008 1/25

32 Sloop 1 Lug sloop rig 20 June 2008 1/25

33 Balanced 0 Battened balanced lug rig 31 October 2009 1/25

35 Balanced 0 Mast and spars balanced lug rig 6 February 2008 1/15

36 Sloop 0 Mast and spars sloop lug rig 7 August 2008 1/15

41 Sail 1 Oars 30 January 2009 1/10

S31 Sail 0 Sail mark 6 February 2008 1/1

51 All 1 Building frame dimensions 18 April 2015 1/10

52 All 0 Hull planking dimensions 20 December 2014 1/10

53 All 0 10 mm plywood parts dimensions 20 December 2014 1/10

54 All 0 Stem dimensions 20 December 2014 1/4

55 All 0 6 mm plywood parts dimensions 20 December 2014 1/10

This document is the property of François Vivier Architecte Naval. It shall not be copied, transmitted to any other person,

nor published as a whole or partly, without the written consent of the architect.

Page 3

March 2017 Building Morbic 12 Page 3/21

56 All 0 Rudder dimensions 20 December 2014 1/3

57 All 0 Timber parts 13 September 16 ½ & 1/4

2. Main characteristics

2.1. Dimensions

Hull length 3.67 m

Waterline length 3.35 m

Breadth 1.55 m

Waterline breadth 1.40 m

Draught (centreboard up) 0.17 m

Draught (centreboard down) 0.78 m

Depth under sole 0.56 m

Sail area (balanced lug) 7.6 m²

Sail area (sloop lug) 9.4 m²

Sail area (battened balanced lug) 7.8 m²

Buoyancy 230 litres

Light weight (without rig) 80 kg (about)

Light weight ISO (ready to sail) 110 kg (about)

The ISO light weight refers to the boat ready to sail with rig, centreboard, rudder, oars, anchor and mooring

line. This weight will vary according to choice of plywood and timber. Thus, it is recommended to weight the

boat prior ordering the trailer.

2.2. Boat presentation

Morbic 12 was designed to be:

✔ A dinghy, able to take 1 to 3 crew, with a performing balanced lug, as the International 12 feet which has

been an Olympic class.

✔ A "sail and oar" boat, able to sail anywhere. The moderate size makes Morbic 12 an ideal boat for fre -

quent single handling but she is able to take a crew of 3 and is fitted with 2 rowing thwarts.

✔ And also a simple motor boat, with its generous transom width. A cut-out in the transom allows to fit a

short-shaft outboard motor.

The small size of Morbic 12 allows such a multi-purpose use. Being light, she may be rowed easily, despite

her generous breadth giving stability for sail and motor. Morbic 12 is:

✔ A practical boat, the flat bottom making easy hauling on the strand,

✔ A modern design, with clinker plywood, for easy construction by a first time home builder,

✔ Simple with the pivoting and removable centreboard and minimal structure items,

✔ Safe with large side buoyancy tanks,

✔ Light and so effortless,

✔ 2 rig options : standing lug (picture) or sloop lug (with a jib).

✔ And all that keeping the lovely looking of a classic boat.

2.3. Motor version

There is also a purely motor version, without a centreboard and rudder and with a large locker forward. It is

built from a separate plan package.

2.4. Building time, tools

It is difficult to give an estimate of the time of construction, so much this one varies from one builder to an other, according to the experience possibly gained during former constructions. The tools you have at disposal

and you are able to master influence the working time. Some boats are true works of art, others are rather of

simple and rustic style.

The cutting up of timber takes also time which could be sub-contracted. Only basic portable tools are neces sary: drill, screw driver, jigsaw, electric plane (especially for mast and spars), without forgetting a good quantity of screw clamps.

The building time is about 200 hours, using precut timber. Construction time may be doubled for a first con struction project and if you want a high quality finish. These times are complete, including rig, fitting and paint ing. To build yourself such a boat supposes that you are looking mainly for the satisfaction of a beautiful work,

without being to much worried by time constraint.

This document is the property of François Vivier Architecte Naval. It shall not be copied, transmitted to any other person,

nor published as a whole or partly, without the written consent of the architect.

Page 4

March 2017 Building Morbic 12 Page 4/21

2.5. Compliance to regulations

WARNING

Morbic 12 is a boat that may capsize. Thus it is important:

to be equipped in order to withstand immersion into water,

to be prepared to right the boat,

to be always vigilant, to carry the sail appropriate for the wind and the sea state,

particularly if no external assistance is available.

Morbic 12 is designed in compliance with the requirements of the European Recreative Craft Directive

1994/25/CE amended 2003/44/CE.

It is designed to sail in the following categories:

✔ In category C, with a maximum of 2 persons on board (maximum loading 200 kg)

✔ In category D, with a maximum of 3 persons on board (maximum loading 250 kg)

The minimum crew is one person, as the boat may be right up by one person only in calm sea conditions. It is

recommended to be at least two on board when sailing in poor wind and sea conditions or away from any pos sible assistance.

The maximum power of the outboard motor is 3 kW.

The definition of these categories is pointed out below:

Category C (Inshore): designed for trips in coastal waters, large bays, estuaries, lakes and rivers where conditions up to, and including, wind force 6 and significant wave heights up to, and including, 2 m may be experienced.

Category D (Sheltered waters): designed for voyages in close coastal waters, small bays, lakes, rivers and

canals where conditions up to and including wind force 4 and maximum wave heights up to and including 0,3

m may be experienced.

NOTE: The significant wave height is the mean height of the highest one third of the waves, which approxim ately corresponds to the wave height estimated by an experienced observer. Some waves will be double this

height.

This document is the property of François Vivier Architecte Naval. It shall not be copied, transmitted to any other person,

nor published as a whole or partly, without the written consent of the architect.

Page 5

March 2017 Building Morbic 12 Page 5/21

3. Right of use and general information

3.1. Right of use

The purchase of plans gives the right to build one unit, by an amateur builder. They can be sold only by the

naval architect (François Vivier) or approved partners (see my web site).

Plan package, comprising the present manual and all the attached documents listed on page 2, is the prop erty of the architect. Except for the needs of construction and purchasing (sail plans, material lists...), the doc uments may not be reproduced, transmitted to a third party, nor published entirely or partly, without written au thorization from the architect.

3.2. Plan number

The plan number, registered on the front page of this manual, is specific to the purchaser and must be re called in any correspondence with the architect or Icarai (builder and kit seller).

Please inform the architect when the boat is first launched, and of change of address or ownership while

building.

3.3. Liability of the builder

Morbic 12 was designed with care and in full compliance with the European regulations. However, each boat

is built under the whole responsibility of its builder, and sails under the whole responsibility of its crew. Both

the architect and Icarai (boats from a kit) decline any liability in regard to people, legal entities, and property

resulting from construction and/or from use of a boat built from the plans.

3.4. Respect of the weights, scantlings, materials, and buoyancy

Amateur builders should be careful to note the necessity of respecting the plans and specifications, especially

scantlings and choice of materials, so that the boat does not become too heavy. Such extra weight would

make it less seaworthy, more difficult to launch and retrieve, and would involve a risk of overloading the road

trailer. Conversely, it is strongly dis-advised to reduce scantlings or to use materials of lower quality. Respect ing the specifications concerning volumes of buoyancy is an essential condition for compliance with EC regu lations.

3.5. E-mail assistance

If you encounter difficulties during construction, or if you have suggestions to make, please feel free to contact

the architect (preferably by e-mail or phone). Specify the number and the date of the plan (see front page).

We will answer your questions and, if necessary, update the plans to benefit other builders.

François Vivier Architecte Naval

7, avenue des Courtils – 44380 Pornichet - France

tél : 33 (0)6 74 54 18 60

e-mail : fr@vivierboats.com

www.vivierboats.com

Note: I am always happy to receive pictures and news about the boats I have drawn !

3.6. Supplies, kit

Materials and fittings needed for construction, in particular those specific to the boat, can be sourced from my

partners (see my web site): marine plywood (panels or NC cut parts), sawn timber, centreboard, fittings, sails,

outboard motor, trailer.

I have observed that to buy a kit allows the amateur builder to avoid bad surprises, un-compliant purchases,

high delivery costs and generally is a cheaper and easier way that to try to source all different materials and

equipments.

This document is the property of François Vivier Architecte Naval. It shall not be copied, transmitted to any other person,

nor published as a whole or partly, without the written consent of the architect.

Page 6

March 2017 Building Morbic 12 Page 6/21

4. Plywood Kit and full size patterns

New (April 2015): the Morbic 12 plan package comes now with dimensioned drawing. Therefore, kit or full size

patterns are optional.

4.1. NC cut plywood kit

The kit includes all the plywood parts necessary to the construction precut on numerically controlled machine.

The majority of parts are at final dimension or require only little fit. Refer to the appendix 2 which gives the

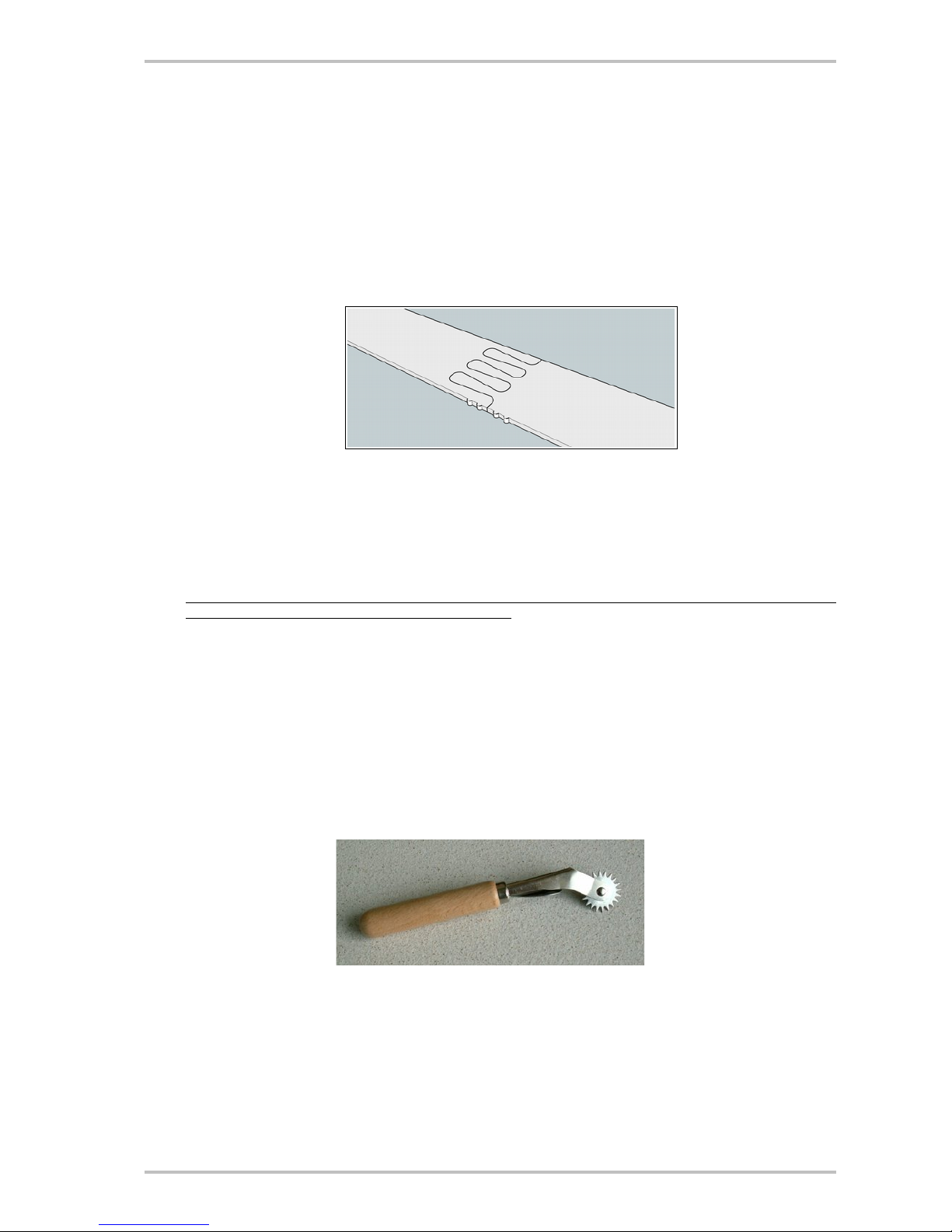

nesting plans of the parts in all panels. The planking strakes are assembled by “puzzle joint”, as shown on the

following sketch. You have to glue them together and get a plank ready to be placed on board with only ends

adjustments:

Puzzle joints require to be glass-epoxy sheathed inside, at least in areas which may be in contact with trailer

rollers or supports during launching and recovering.

The kit offers up the following advantages:

✔ Reduction of the construction time: you will save the time of marking and cutting many parts within many

plywood panels.

✔ Reduction of the need for space to scarf and cut out the panels.

✔ Reduction of the risk of construction error and improvement of the assembly accuracy.

Kit is to be ordered to boat-builder Icarai (see page 5) in France of other representatives abroad. If you buy

the kit, you do not have to order the polyester patterns.

The construction described in the following pages is based on the assumption you are working from

full size patterns. If you have the plywood kit, some task are deleted.

4.2. Full size patterns on polyester film

These patterns give the marking of moulds, bulkheads, centreboard case, transoms, planking, rudder...

Bevels are drawn. Position of battens and various pieces to be fixed on the bulkhead faces are also marked.

The support is a polyester film (also said mylar), very resistant to tearing and not subject to humidity variations. Marking are to be transferred to the plywood sheets.

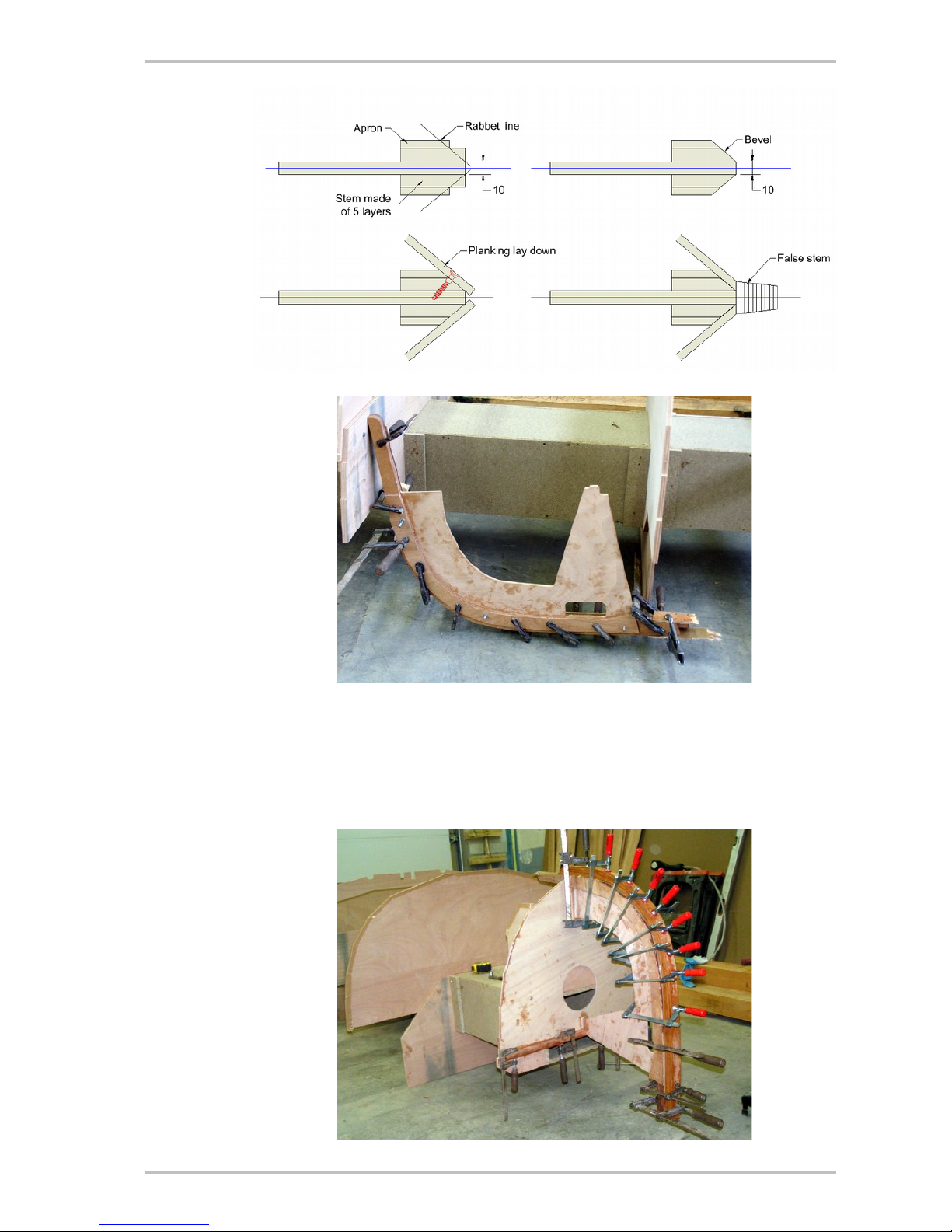

For that purpose, you may use a screwdriver grinded to form a spike. With a hammer, the wood is marked

through the film. You may also use carbon paper spread between film and plywood. An other very efficient

method is to use a tracing wheel as used by dressmakers :

Polyester patterns are delivered in a resistant tube and are to be ordered from François Vivier Architecte

Naval SARL according to current price list.

This document is the property of François Vivier Architecte Naval. It shall not be copied, transmitted to any other person,

nor published as a whole or partly, without the written consent of the architect.

Page 7

March 2017 Building Morbic 12 Page 7/21

5. Summary of the construction process

Before starting the construction, the general process of which is presented in the following pages, it is import ant to read the whole manual and plans for a good overall comprehension. That remains true at all stages. A

good preparation will avoid errors, sometimes not easily retrievable, and will save time.

The general process is as follows:

✔ Cut-out of the moulds and main girder from chipboard or MDF panels,

✔ Assemble the transom, the stem, the false stem, all made of several layers,

✔ Set up all elements on the building frame,

✔ Lay down clinker planking,

✔ Fit the false stem, make epoxy fillets on the outside hull,

✔ Turn over,

✔ Fit the gunwales, rub-rails, seat risers, buoyancy tanks,

✔ Sheath the sole and garboards,

✔ Fit the centreboard case, mast step and mast partner, foot rests,

✔ Turn over for outside hull finishing works,

✔ Sheath the sole and garboards,

✔ Fit the skeg

✔ Paint the hull

✔ Turn over again for inside finishing works,

✔ Painting and varnishing

✔ Fittings

The following tasks may be done at any moment and scheduled according to your own space and weather

constraints:

✔ Centreboard,

✔ Rudder,

✔ Mast and spars,

✔ Oars...

This document is the property of François Vivier Architecte Naval. It shall not be copied, transmitted to any other person,

nor published as a whole or partly, without the written consent of the architect.

Page 8

March 2017 Building Morbic 12 Page 8/21

6. Chronological description of construction

6.1. Building frame

Patterns

Appendix 2

Plan 12

Sheet 22

The building frame is based on a stiff main girder (250 X 350 mm), made of chipboard or MDF

panels. MDF is easier to work out and is chosen for NC cutting.

The fore face of the main girder will be used as support for the fore bulkhead of the boat. There fore, it has to be perfectly perpendicular to the other faces of the girder.

Doublers are screwed into the girder sides in order to make slots for the proper positioning of

girder supports and station moulds (see plan 12).

The main girder is supported by chipboard/MDF transverse parts. If preferred to ease work, the

main girder may be raised using saw horses or any other available means.

Then set down all six station moulds and check they are perfectly aligned and spaced. 3 of these

moulds are in fact bulkhead supports. Only bulkheads are part of the finished boat. Holes (6 mm

diameter) are drawn on the patterns (and already cut-out in the kit) to allow quick and good positioning of these bulkheads.

Look carefully at plan 12 to place properly the bulkheads (for or aft of station moulds).

Before bolting the bulkheads, protect the station moulds with plastic film to avoid gluing the hull

planks on these moulds. Notice that moulds are voluntarily recessed from the bulkhead outline in

the overlapping area.

6.2. Cut-out and assembly of structural parts

Patterns

Appendix 2

Appendix 1

Plan 12

Sheet 22

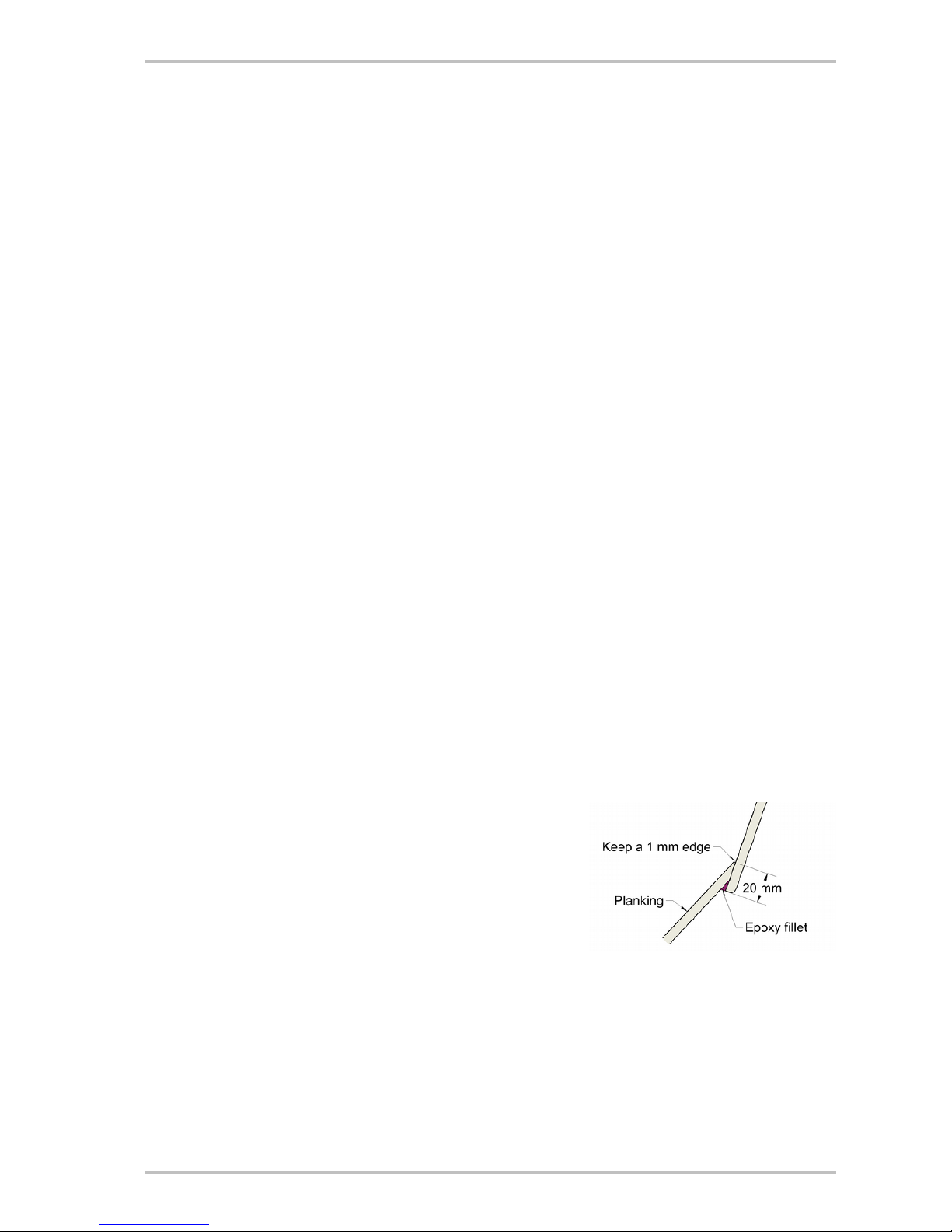

All parts are cut-out using the patterns. Several parts need to be pre-assembled:

✔ The transom is made of 2 layers. The inner layer is cut-out with 2 mortices in order to fit into

ends of side seats longitudinal bulkheads. Glue both layer using bolts into the alignment holes

to avoid slipping of parts when glue is curing. Afterwards, remove bolts and fill in the holes

with epoxy putty. Bolts may also be replaced by screws which may be kept in place. Upper

edges of both layers of transom are aligned. Other edges are slightly shifted. This allows to

get the proper bevel as follows:

Gluing of transom and centreboard (background)

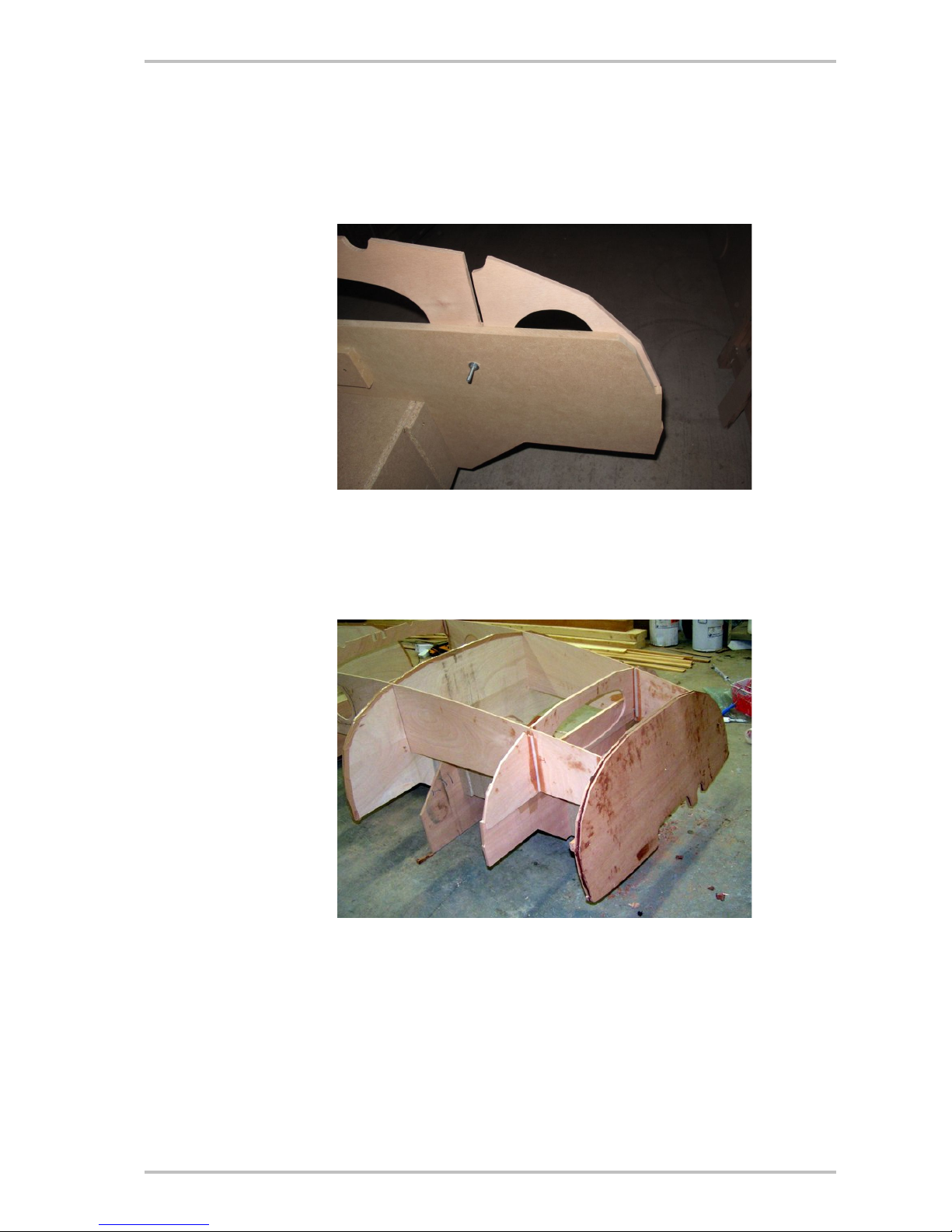

✔ The stem is made of 3 layers of 10 mm plywood. The centreline layer ensure a link with bulk -

head 5. An additional layer of 6 mm ply is glued over both sides to make an apron, increasing

the gluing area of the hull planking over stem bevels. As for the transom, use bolts to keep the

alignment of parts when glue is curing. The following sketch show how to get the stem bevel:

This document is the property of François Vivier Architecte Naval. It shall not be copied, transmitted to any other person,

nor published as a whole or partly, without the written consent of the architect.

Page 9

March 2017 Building Morbic 12 Page 9/21

Stem gluing

✔ Mark the clinker lines on the aprons to ease plank lay down. If you have the kit, small notches

give the position of clinker lines. The marked line is the edge of the « inside » plank, which is

laid down first.

✔ The false stem is laminated at this stage, using the stem as a mould. Note that cut-out have

been made in the centreline layer to allow clamping.

This document is the property of François Vivier Architecte Naval. It shall not be copied, transmitted to any other person,

nor published as a whole or partly, without the written consent of the architect.

Page 10

March 2017 Building Morbic 12 Page 10/21

✔ The fore bulkhead (# 5) is made of 2 layers of 6 mm plywood. The bevel is obtained in the

same way than for the transom. Add a batten on top (fore side) which will be used to lay down

the deck. Shift this batten upward (3 mm about) to allow bevelling according to sheer.

✔ The fore bulkhead and stem are assembled, taking care of orthogonality.

Then all parts are laid down on the main girder:

✔ Bolt bulkheads and stem to supporting station moulds:

Note that the mould is recessed from the bulkhead to avoid undue gluing during the planking process

✔ Set down the longitudinal bulkheads which must be glued to bulkhead 3. Add an epoxy fillet or

a batten inside the buoyancy tank.

✔ Lay down the transom which is glued to the ends of the longitudinal bulkheads. Glue inside

the transom the beam (35 X 25) which will receive the aft deck. It is better to bevel this beam

before gluing (take off the angle on plan 21).

See the epoxy fillet between transversal and longitudinal bulkheads

Transverse bulkheads have to be bevelled to receive the hull planking. Use a long batten to estim ate the quantity of wood to be planed off.

The mid-bulkhead (# 3 under main thwart) will be cut out at centreline at a letter stage, just before

setting down the centreboard case.

Longitudinal bulkheads do not require bevelling. Just do it if necessary when laying down the hull

planking.

This document is the property of François Vivier Architecte Naval. It shall not be copied, transmitted to any other person,

nor published as a whole or partly, without the written consent of the architect.

Page 11

March 2017 Building Morbic 12 Page 11/21

6.3. Strakes preparation

Appendix 2 The patterns give the final shape of strakes (hull planks). They may be cut without any margin, ex-

cept at ends. The average overlap between strakes is 20 mm. However, the actual overlap may

vary between 10 to 25 mm to take in account possible inaccuracies of the design and building pro cess.

The sole (bottom planking) is made of 2 scarfed planks. Cut-out first both parts, then assemble by

scarf taking care of a perfect alignment. For that purpose, draw the centreline on each plank.

When gluing, check alignment and hold in place with a few screws of nails in order to avoid any

slippage.

For other strakes, scarf firstly the full plywood panels, then mark from the patterns and cut-out.

Attention: this require space. If you build in a small room, it is better to scarf panels and cut-out

strakes before setting up the building frame.

Then sheath the inside face of sole, as it is easier to do it now that into the boat at a later stage.

For the same reason, you may also glue and screw from outside the foot rests on this sole.

6.4. Lay down of the sole and first strake (garboard)

Plan 12

Plan 21

Plan 22

Sheet 51

The sole, when glued to the structure, will make the boat definitely stiffer. Bulkheads are to be per fectly aligned before gluing. For that purpose, draw the centreline on the inner face of sole and on

each bulkheads. Check also the spacing of bulkheads (see plan 12). This plan gives also the posi tion of the fore end of the centreboard slot, in order to get the good longitudinal position of the

sole.

The fore end of the sole, or rectangular shape, will be plane away when fitting the false stem. In final, only a small amount of wood will be kept.

The liaison between the sole and the garboard is done on the stitch and tape principle. As the sole

is thicker than the garboard, it has to be planed out all around, on the outer side, to get an edge

thickness of 6 mm about. See plan 22.

In practice, only a few number of wires is required, in addition to some temporary screws into bulk heads. Then the joint is filled-up with epoxy putty. When cured, remove the wires and fill the re maining open joints. Fair and sheath with a glass tape.

The following tasks are made at later stages:

✔ Sheath all the sole and garboard area, to get a tough skin, wearing resistant.

✔ After turning over, apply epoxy fillet and glass tape on the sole/garboard joint and sheath the

sole and garboard area. There is often sand in the boat and a tough surface is also much better. Aft, sheath also the lower part of the longitudinal bulkhead (2 or 3 cm).

6.5. Lapstrakes lay down

Sheet 43

Sheet 44

Sheet 12

The recommended technique is to glue the strakes using temporary screw (sheet 44). They are

also glued to stem and transom. Strakes are normally laid down without adjustment. As already

written, the overlap may vary around the average 20 mm value.

The small thickness of strakes makes necessary in some area to fill-in a V joint with an

epoxy fillet (see sketch).

The general process is as follows:

✔ Mark and plane out the bevel on the previous strake.

✔ Lean the strake being fitted against the building frame, well positioned according to notches in

bulkheads/station moulds and according to marks on the stem. As said, the average overlap is

20 mm.

✔ Shape the ends of strakes as explained in sheet 44.

✔ Then glue the strake hold in place with some screws into stem, transom and bulkheads. Tem-

porary screws may be used into station moulds.

✔ Lay down alternately strakes on port and starboard sides.

This document is the property of François Vivier Architecte Naval. It shall not be copied, transmitted to any other person,

nor published as a whole or partly, without the written consent of the architect.

Page 12

March 2017 Building Morbic 12 Page 12/21

Strakes lay down

6.6. External completions of the hull

Plan 21 Before hull turning over:

✔ Fit the false stem. Shape this false-stem in order to get a flat surface on the fore end (14 to 16

mm wide) allowing to screw down a brass keel band.

✔ Apply epoxy resin on all plywood edges and add epoxy fillet into joints when required.

6.7. After turn-over

Plans 21 & 22

Lay down 2 transverse temporary battens over the hull, one at station 1 and the other at station

4.2, to check the hull is not twisted.

Lay down the fore deck and the aft decks/seats to check the curvature of the hull planking. If ne cessary, the hull may be squeezed with a rope or spread with temporary beams.

Check that the hull is well shaped. If necessary, it is possible to adjust the sheer line with a plane.

At this stage, the hull is still flexible. It will become stiff after adding other inside structure elements.

Then saturate all plywood strakes edges with epoxy resin, as already done outside. Sheath the

sole-garboard joint with a tape and sheath the full sole and garboards with cloth and epoxy as

shown on transverse structure plan.

6.8. Rub-rail, gunwale, quarter knee

Plans 21 & 22

Appendix 1

Lay down the gunwale (inside planking). Be careful as the glued parts are very slippery. In addition

to clamps, place some screws.

In order to ease gunwale adjustment at ends, it is made of two parts. The joint is just under the

thole board, so hidden when the boat is finished.

In the thole pins area, the gunwale is doubled with a second layer. Take care not to chamfer the

first layer in the doubled area, as well as in the quarter knees areas.

As we have not made any rabbet to cover the hull plywood edge, gunwale and rub-rail will be

placed about 2 mm above plywood edge as shown on the sketch. The slot will be filled up with

epoxy putty. If the gunwale is to be varnished, use wood powder to thicken epoxy in order to get

an appropriate colour. Then the full assembly may be planed out:

Cut out, adjust and fit (glue and screw) the quarter knees. Screw are preferably set from outside

planking. The quarter knees shape is given on the full size patterns.

A lower rub-rail may be added at the low edge of sheer-strake. It gives extra protection and a more

traditional look.

If the gunwale is varnished, it is preferable to cover screws with wooden bungs, or at least with

epoxy putty made with wood powder.

This document is the property of François Vivier Architecte Naval. It shall not be copied, transmitted to any other person,

nor published as a whole or partly, without the written consent of the architect.

Page 13

March 2017 Building Morbic 12 Page 13/21

Rub-rails and stem cleat on a Morbic 10

6.9. Seat riser

Plans 21 & 22

Appendix 1

A seat riser is placed at 170 mm under sheer line (see longitudinal structure plan) in the thwart(s)

area. At the after end, the seat riser is kept just over the sheer-strake edge (inside) and then is

closer to sheer line. In the side seat area, use a transverse batten laid over the longitudinal bulkheads to mark the position of seat riser on the hull planking. In the fore section, mark at 170 mm

under sheer line.

Glue the seat riser with small screws (temporary or not) from outside. It is preferable to bevel the

upper face before gluing:

In order to support the fore thwart (balanced lug only), the seat riser is doubled. This second layer

is glued and screwed from inside.

6.10. Buoyancy compartments

Patterns

Plans 21 & 22

Sheet 71

As shown on plans, there is 3 buoyancy compartments, one fore and one aft on each side. To

save weight and allow to stow some belongings in a dry space, they are not filled up with foam.

Therefore it is very important to have them perfectly watertight. In case of doubt, is is always possible to fill them with expanded polystyrene.

Compartments are closed with the fore deck and the side seats. Cut-out apertures at hatches diameter. Make epoxy fillets on all joints inside and apply paint before closing. Paint also the inside

face of deck and side seats, except in gluing areas.

At this stage, fit the upper frame at station 3, so it could be screwed through the bulkhead. It is cut

out around the seat riser. Insert a vertical long screw through the gunwale into the frame head. For

that purpose, drill a wide hole (4 mm for a 5 mm screw) and fill up with epoxy putty before screw ing. This prevents splitting wood and gives a good link.

Before closing the compartments, take care to have a continuous batten all around to ensure wa tertighness. In the fore compartment, glue a plywood batten under the gunwale. Leave a 10 mm

gap between gunwale and batten, corresponding the the deck thickness. Under the side seats,

glue the doublers 20 mm thick which allow to screw down the main thwart. Mark the position of the

srews on the upper side.

Aft, glue the curved beam made of 2 layers of 10 mm plywood.

Lay down the covers to check that all is well adjusted.

If you have chosen the sloop rig, the fore deck is lengthened afterwards with two layers of 6 mm

plywood. Make a partial scarf to make the joint with the fore part of deck (see detail on plan 21S).

Prepare the samson post which is screwed through the bulkhead 5. Carve a mortice in the fore

This document is the property of François Vivier Architecte Naval. It shall not be copied, transmitted to any other person,

nor published as a whole or partly, without the written consent of the architect.

Page 14

March 2017 Building Morbic 12 Page 14/21

side of post to receive the bowsprit tenon. The mortice is positioned in order that the bowsprit rake

is about 2° above horizontal. The fore deck is cut-out at samson post position.

Then, you are ready to glue the fore deck and the side seats. Apply a thick epoxy joint all around in

order to avoid any leak. After gluing, add epoxy fillets between deck and gunwale (fore) and

between side seats and hull planking (aft). Use masking tape to avoid epoxy overflow and get a

neat joint, in particular if you intend to varnish.

Aft compartment ready to be closed

Note also that bulkhead 3 has been cut out to receive the centreboard case

(attention : this is the first boat and the shape of this bulkhead is now modified)

If the compartments are not filled up with foam, the EU regulation (ISO standards) require a water tightness test. The small size of Morbic 12 allows to do that without special equipment as you may

turn the hull in various positions. Fill up each compartment with water and close the hatch covers.

Move to boat is every position to check there is no leak. Be careful as the boat is heavy. You need

several people to help and old mattresses or any other means to avoid damage to the hull. It is

preferable to test each compartment separately to avoid too much weight. Take pictures to be able

to give assurance that the test has been done.

6.11. Centreboard and centreboard case

Patterns

Plans 21 & 22

Appendix 1

Appendix 2

The centreboard is pivoting but may be easily taken out (boat in water) to reduce weight if the boat

is to be carried over a car top. It is streamlined is the same way than the rudder (see plan 25).

Posts and spacers, 25 mm wide, are adjusted at both ends and aft edges. Logs are to be cut-out

according to sole curvature (there is a pattern in the kit). Upper carlins are extended afterwards is

order to be used as supports for the main thwart.

The case sides are doubled outside in way of the pivot slide. The centreboard is made of two

10 mm plywood layers. Drill a hole for the pivot without any margin in order than the pivot is forced

into the hole. Add epoxy to ensure that the pivot may not be lost.

If the centreboard is made of okume plywood, it is preferable to epoxy sheath in order to give a

better resistance. Add some extra cloth of the fore and low edges before the general sheathing.

Centreboard case pre-fabrication

A notch is cut out in the centreboard handle. This allows to insert a shock-cord (8 mm diameter)

lashed between two eye clips screwed to logs. These eye clips are positioned just under the pivot

This document is the property of François Vivier Architecte Naval. It shall not be copied, transmitted to any other person,

nor published as a whole or partly, without the written consent of the architect.

Page 15

March 2017 Building Morbic 12 Page 15/21

position. This shock-cord maintains the centreboard either in raised or low position. In addition, it

prevent the centreboard to be lost in case of capsize.

Centreboard handle with the shock-cord laid into the notch

We have now added a second carlin (cleat on plans) allowing to jam

the shock-cord for a better hold of the centreboard in both position.

The case is fully pre-assembled before lay down on board. Cut-out the centreline part of the bulk head 3 and insert the case. Apply a thick coat of epoxy between logs and sole and screw through

the sole to ensure watertightness. Glue the posts 20 X 25 between case and bulkhead 3.

Remove excess epoxy before curing. When epoxy is cured, adjust the sole slot which was made

voluntarily shorter and narrower.

Attention : foot rests are to be fitted after the centreboard case.

6.12. Foot rests

Plans 21 & 22

Appendix 1

Foot rests are simple transverse battens epoxy glued to the sole. They are also screwed from out side. Therefore, they have to be fitted before hull epoxy sheathing. The plan shows standard posi tions which may be tuned to your own size.

Note that bulkhead 3 act as a foot rest for the fore thwart (balanced lug version). In order to give

extra strength and avoid damaging the plywood, a batten is fitted on the fore face of this bulkhead.

6.13. Mast partner and mast step (balanced lug version)

Patterns

Plans 21T &

22T

Appendix 1

Appendix 2

The mast partner (hole into the fore deck) is cut-out at the dimensioned position. A plywood dou bler is glued underneath to reinforce the deck. Drill a hole on port side of mast to give way to the

sail tack line (close to the mast ; position is dimensioned on plan 21T).

The mast step is made of two layers of 10 mm plywood, laid over the stem extension. Glue and

screw, on both sides of stem, wooden blocks allowing to screw down the mast step. Make a drain

to avoid any water retention into the mast step mortice. The mast step is extended on port side in

order to fasten an eye-bolt for the tack line purchase.

Note that if you are not satisfied with the boat balance under sail, it is easy to replace the mast

step with the mortice shifted forward or afterwards.

6.14. Mast partner and mast step (lug sloop version)

Patterns

Plans 21S &

22S

Appendix 1

Appendix 2

The mast partner is an open one (half circle). The mast is fasten to the partner by mean of a lash ing between two eye-bolts.

Drill a hole on port side of mast to give way to the sail tack line (close to the mast ; position is di mensioned on plan 21S).

The mast step is made of three layers of 10 mm plywood. An eye-plate is screwed down for the

tack line purchase .

This document is the property of François Vivier Architecte Naval. It shall not be copied, transmitted to any other person,

nor published as a whole or partly, without the written consent of the architect.

Page 16

March 2017 Building Morbic 12 Page 16/21

6.15. Skeg and external completion of the hull

Patterns

Plans 21 & 22

Appendix 1

To improve the link between hull and skeg, a 100 mm wide plywood doubler is glued on the sole at

centreline, between transom and bulkhead 1.

Then to boat is turned over again, upside down.

Sheath the sole and both garboards:

Fit the skeg which is screwed from inside with long screws. Epoxy fillets are made between skeg

and sole to improve the link. The profile of the skeg is given on the full size patterns. Otherwise,

you may draw this shape from the dimensions given on plan 21. Make a pattern with thin plywood

according to sole curvature and use the pattern to cut the skeg into the 26 mm thick timber. The

skeg is streamlined, reducing the thickness to 20 mm about (just a little more than the keel band)

at the lower and aft edges.

Paint the hull. Then it will not be necessary to turn over again.

Screw down the keel bands (brass half rod or bar, 12 mm wide). There is one keel band fore, from

stem head to stem aft end, and one aft on the skeg, extended to the lower rudder pintle.

This document is the property of François Vivier Architecte Naval. It shall not be copied, transmitted to any other person,

nor published as a whole or partly, without the written consent of the architect.

Page 17

March 2017 Building Morbic 12 Page 17/21

6.16. Inside arrangement

Patterns

Plans 21 & 22

Sheet 71

Appendix 1

Turn over again, boat upright.

Resume after deck and side seats installation and fit the trim (8 X 26) protecting the plywood

edges.

Temporary spans may be used to glue the side seats trims, not using screws.

Adjust the thwarts. The fore thwart (balanced lug rig only) is screwed down into the seat risers.

The main thwart is screwed from underneath through the 20 X 20 battens of the buoyancy com partments. If necessary, the thwart may also be screwed into the seat risers, through the seats

covers. In addition, two small “stop pieces” under the thwart on both sides of centreboard case ensure a better transversal attachment of the case.

On this beautiful Morbic 12, built in UK by boat-builder Adrian Donovan,

you can see the new arrangement he suggested to stow the oars.

6.17. Drain plug

Appendix 3 Fit a drain plug to empty the boat when on trailer. On this small boat, the drain plug may be loc-

ated at bottom of transom as shown on plan 22. The plug itself is inserted from outside. Limber

holes are made into bulkhead 1 to ensure proper water flow.

6.18. Thole pins and oars

Plans 21 & 22

Plan 41

Appendix 3

Sheet 81

Sheet 82

Rowing oars are lightly designed to allow rather long distance, even in open sea. There is no need

to control blade angle and the pivot point cannot move.

Bulls are fitted with 2 holes. The inner hole is the usual one. The outer one gives more pulling force

on the blades and is useful in bad wind or sea conditions.

Keep on board a paraffin fragment and rub the thole pin with it. It is an excellent lubricant, which

avoids any chafing noise and does not stain cloths or sail.

These rowing oars are not designed for sculling. If you need it for a short ride in harbour, do not

This document is the property of François Vivier Architecte Naval. It shall not be copied, transmitted to any other person,

nor published as a whole or partly, without the written consent of the architect.

Page 18

March 2017 Building Morbic 12 Page 18/21

force. If you intend to scull frequently, it is better to make a dedicated oar, in ash or Douglas fir,

2.7 m long.

Oars are simply stowed on the sole.

Each thole board is made of hardwood and screwed into gunwale. The upper face is transversely

well rounded to avoid damaging oars when rowing. In the longitudinal way, it has to be planed horizontal in order to keep oar blades vertical.

Both thole board and gunwale are drilled to receive the thole pin (14 mm brass rod). Do not drill

too wide, as the thole pin will move too much when the wood is dry, even if it is not possible to put

away the pin when the wood is wet. The pin top is to be well rounded to avoid hurting crew. A small

eye strap under gunwale allows to use a safety line in order not to lose the pin.

Thole pins are to be vertical in the longitudinal plan. This prevents the oars to go out from the pin

when rowing. Pins have to be inclined outwards in the transverse plan, corresponding to the average angle or oars (horizontal or in water).

It is also possible to use classic oars with bronze rowlocks (also said oarlocks or crutches). In that

case, a small safety line or chain is necessary to avoid loosing rowlocks in case of capsize.

6.19. Rudder

Plan 25

Appendix 3

Sheet 72

The rudder is made with a pivoting blade according to plan and sheet 72. There is one lifting line.

Make 2 knots for lower and tilted position. It is advisable to attach the end of the line to the hull, in

order to avoid any loss of rudder. If the rudder blade is made of okume plywood, sheathing is

preferable as for centreboard.

6.20. Rig (balanced lug version)

Plans 21T &

22T

Plans 31 or 33

Plan 35

Appendix 3

Sheets 81 & 82

This rig is ideal for single-handling or if you want to use oars with two rowers.

You have the choice between a vertical cut sail, more traditional, or a cross cut sail with battens,

more efficient.

Refer to plans and sheets. The tack line is rigged as shown on last page of sheet 82. It is driven

through deck, close to mast and come to a block at mast step. A purchase is rigged on side of

centreboard case, allowing direct tuning by the helmsman. The lug sail needs frequent tuning of

the tack purchase, according to wind force and point of sail. This purchase is an improvement not

shown on pictures.

This document is the property of François Vivier Architecte Naval. It shall not be copied, transmitted to any other person,

nor published as a whole or partly, without the written consent of the architect.

Page 19

March 2017 Building Morbic 12 Page 19/21

When you use the oars, the mast is lowered and stowed, step forward, under the fore thwart but

above the main thwart. The sail, rolled over the yard, is simply resting on thwarts, under fore deck.

Note: the sail plan show a vertical cut sail. It is also possible to have the same sail cross cut but

without batten. Many sail-makers are more comfortable with this method, resulting in a better

shape and performance.

It is also possible to add on boom a half jaw, as described in the next paragraph (sloop version). It

prevents the boom to shift forward, which happens when the tack is not properly tightened.

6.21. Rig (lug sloop version)

Plans 21S &

22S

Plans 32 & 36

Appendix 3

Sheets 81 & 82

Refer to plans and sheets. Refer to plans and sheets. The tack line is rigged as shown on last

page of sheet 82. It is driven through deck, close to mast and come to a block at mast step. A purchase is rigged on side of centreboard case, allowing direct tuning by the helmsman. The lug sail

needs frequent tuning of the tack purchase, according to wind force and point of sail. This pur chase is an improvement not shown on pictures.

The mainsail halyard is belayed on a cleat, screwed to mast under mast partner. This cleat allows

to belay halyards when the boat is unmasted.

The jib is tacked on bowsprit end. The jib tack line comes through a block and is led to a belaying

pin on the mast partner. A bobstay with a small purchase pull down the bowsprit against the stem

head. The purchase line is belayed on a cleat screwed on a bowsprit side. This purchase must be

well tighten. The jib halyard is led to the other belaying pin.

Jib sheets come to a cleat screwed on the aft edge of main thwart :

See mainsail and jib sheets arrangement

When you use the oars, the mast is lowered and stowed, step forward, above the main thwart. The

sail, rolled over the yard, is simply resting on thwarts, under fore deck.

It is possible to fit (glued with generous epoxy fillets) a half jaw on boom side as shown on the fol lowing sketch:

This prevent the boom to shift forward and hamper the jib and jib sheets. This half jaw is made of

plywood (3 lyers 6 mm). Glue a protective leather inside to protect the mast from chafing. Keep

enough play between jaw and mast to avoid jamming. With this half-jaw, the down-haul is attached

on the boom through the hole in the jaw. Therefore, the hole in the mast thwart has to be shifted

backward accordingly.

The half-jaw has to be located to get a 200 mm distance between the mast axis and the boom fore

This document is the property of François Vivier Architecte Naval. It shall not be copied, transmitted to any other person,

nor published as a whole or partly, without the written consent of the architect.

Page 20

March 2017 Building Morbic 12 Page 20/21

end.

Note: the sail plan show a vertical cut sail. It is also possible to have the same sail cross cut but

without batten. Many sailmakers are more comfortable with this method, resulting in a better

shape and performance. It is also possible to use the battened sail of plan 33.

6.22. Painting

Fiche 91 The sheer-strake may be painted with a different colour. Prefer a light colour for the hull, which en -

hance the clinker lines. A satin finish gives a more traditional appearance.

The inside may be varnished. However it is preferable to use a matt paint for the sole and gar boards, easier to maintain than varnish. You may also use a non skid paint for sole and garboards.

7. Equipments

7.1. Trailer

Morbic 12 may be carried over a car top. Check that the weight of the boat is in conformity with the

requirements of the car and the supporting bars.

A combination trailer, including a launching trolley with low pressure tyres which can be rolled on

sand beaches, is a good choice if the boat is currently launched from a beach.

Simple road trailer, without launching trolley, for ramp launching

7.2. Motor

Morbic 12 transom is designed to receive a short shaft outboard motor of 4 hp. In practice, a small

tender motor (2 to 3 hp) is fully adequate.

8. Under sail

Morbic 12 is a small boat, so sensitive to load under sail. Be careful to keep a convenient trim. The

crew must not be grouped aft nor too much forward.

When single-handed, the helmsman has to be seated close to the main thwart. In that case, the

use of a tiller extension is recommended.

This document is the property of François Vivier Architecte Naval. It shall not be copied, transmitted to any other person,

nor published as a whole or partly, without the written consent of the architect.

Page 21

March 2017 Building Morbic 12 Page 21/21

8.1. Capsize test

It is recommended to make a capsize and recovery test to check that you are able to do it in ad verse conditions and to detect any problem:

This document is the property of François Vivier Architecte Naval. It shall not be copied, transmitted to any other person,

nor published as a whole or partly, without the written consent of the architect.

Page 22

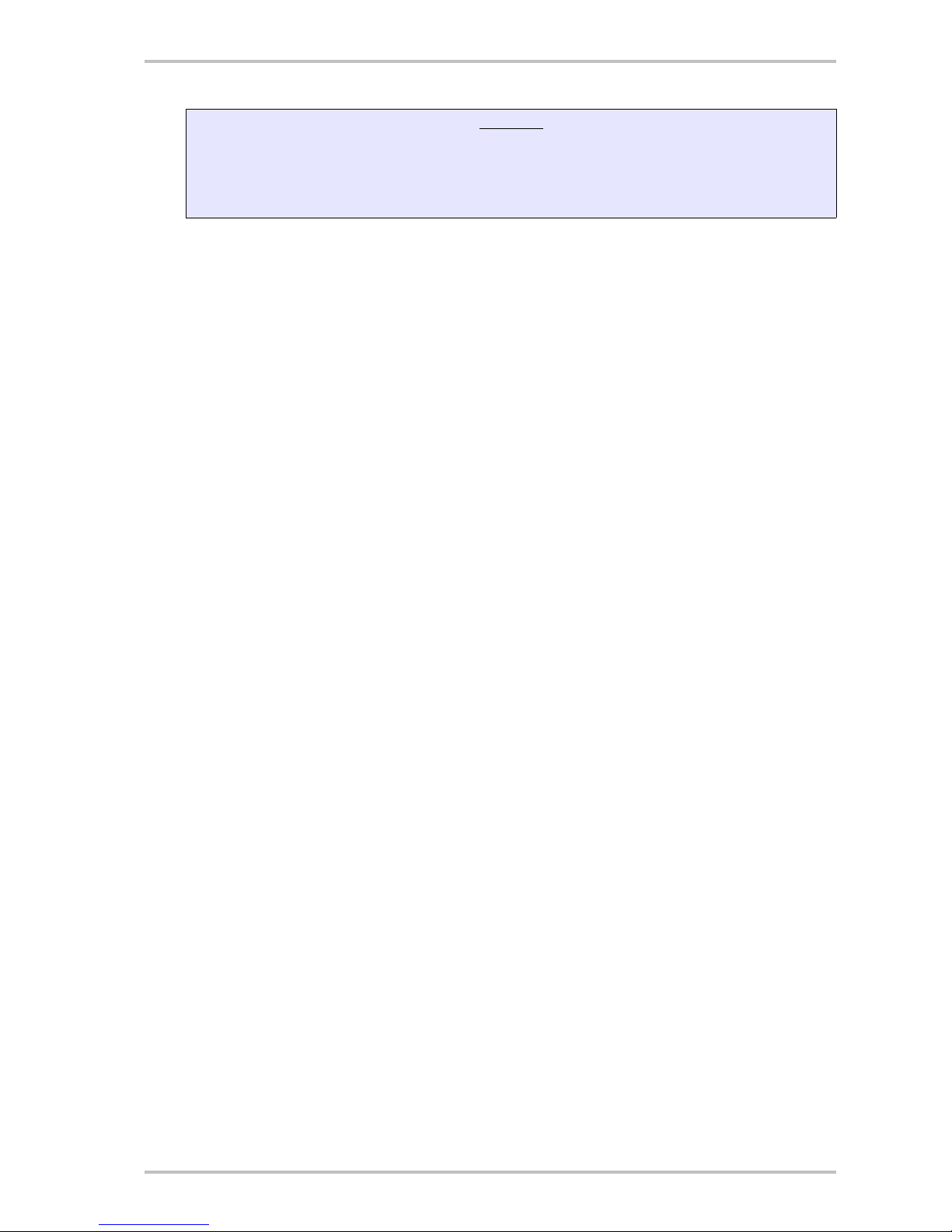

Morbic 12 – appendix 1 rev 8

Timber list

Items Version Wood

code

Quan-

tity

Thick.mmWidthmmLengthmmComments

Laminated false stem All A 10 3 30 1 100

Trim on stem head All A 1 10 32 120

Skeg All A or C 2 26 160 1 100

Aft gunwale All A 2 16 26 1 300

Fore gunwale All A 2 16 26 2 700

Rub-rail All A 2 16 26 4 000

Gunwale (layer 2) Balanced A 2 16 26 1 600

Gunwale (layer 2) Sloop A 2 16 26 900

Batten under side seats All A 2 20 20 1 750

Miscellaneous battens All A 1 20 20 4 000 Total length

Trim side seats All A 2 8 26 1 400

Trim aft deck All A 1 8 26 700

Trim mast partner All A 1 10 32 1 200

Doubler mast partner Sloop A 1 18 70 1 200

Seat riser All A 2 12 30 3 500

Seat riser (layer 2) Balanced A 2 12 30 500

Centreboard case logs All A 2 25 40 1 200

Centreboard case posts All A 1 25 30 1 000 Total length for 4 parts

Centreboard case spacer All A 1 20 25 450

Post between case and bulkhead 3 All A 2 20 25 350

Trim and cap centreboard case All A 1 10 38 700 Total length for 2 parts

Upper carlin centreboard case All A 2 16 26 800

Cleat to maintain the centreboard chockcord All A 2 16 26 500

Foot rest glued on bulkhead 3 Balanced A 2 16 26 250

Stem cheeks under mast step Balanced A 2 25 40 200

Beam between transom and aft deck All A 1 25 35 1 150

Tiller All A 2 21 70 1 200

Quarter knees, upper frames All A 1 20 150 900 Or equivalent area (figure 1)

Doublers to screw down the main thwart Sloop A 1 20 50 450

Page 23

October 2013 Morbic 12 Appendix 1 rev 8 - Page 2/2

Samson post Sloop A 1 56 56 600

Aft foot rests All A/C 3 30 30 400 Avoid oak, which does not glue properly

Fore foot rests Balanced A/C 4 30 30 200 Avoid oak, which does not glue properly

Fore thwart Balanced E 1 22 200 1 300

Aft or main thwart All E 1 22 220 1 500

Fore thole boards All C 2 30 45 250

Aft or main thole boards All C 2 35 45 250

Oars bulls (for 2 oars) All C 2 22 35 300 2 pairs for the balanced lug rigs

Oars wearing planks (for 2 oars) All C 2 10 50 400 2 pairs for the balanced lug rigs

Mast Balanced F 1 76 76 4 350

Mast Sloop F 1 76 76 4 400

Yard All F 1 50 50 3 100

Boom All F 1 50 50 3 100

Bowsprit Sloop F 1 50 56 1 200

Oars, loom (for 2 oars) All G 2 34 50 2 800 2 pairs for the balanced lug rigs

Oars, blades (for 2 oars) All G 4 34 40 1 100 2 pairs for the balanced lug rigs

Note : Given length takes into account end margins; given thickness and widths are dimension of final (planed) dimensions.

Figure 1, timber parts 20 mm thick:

Wood Code Main use Recommended species

A Glued main structure parts : stem, laminated

frames, gunwale…

Sipo, Sapele, Mahogany, Douglas fir

C Wearing parts Oak, Acacia, Iroko

E Thwarts Red pine, Douglas fir, Mahogany, Western red

cedar (the last one soft but light).

F Masts and spars Northern pine, Spruce, Douglas fir

G Oars Northern pine, Spruce

(Douglas fir or ash for a scull)

François Vivier Architecte Naval

2 October 2013

Page 24

Morbic 12– Appendix 2 - rev 10

Plywood list

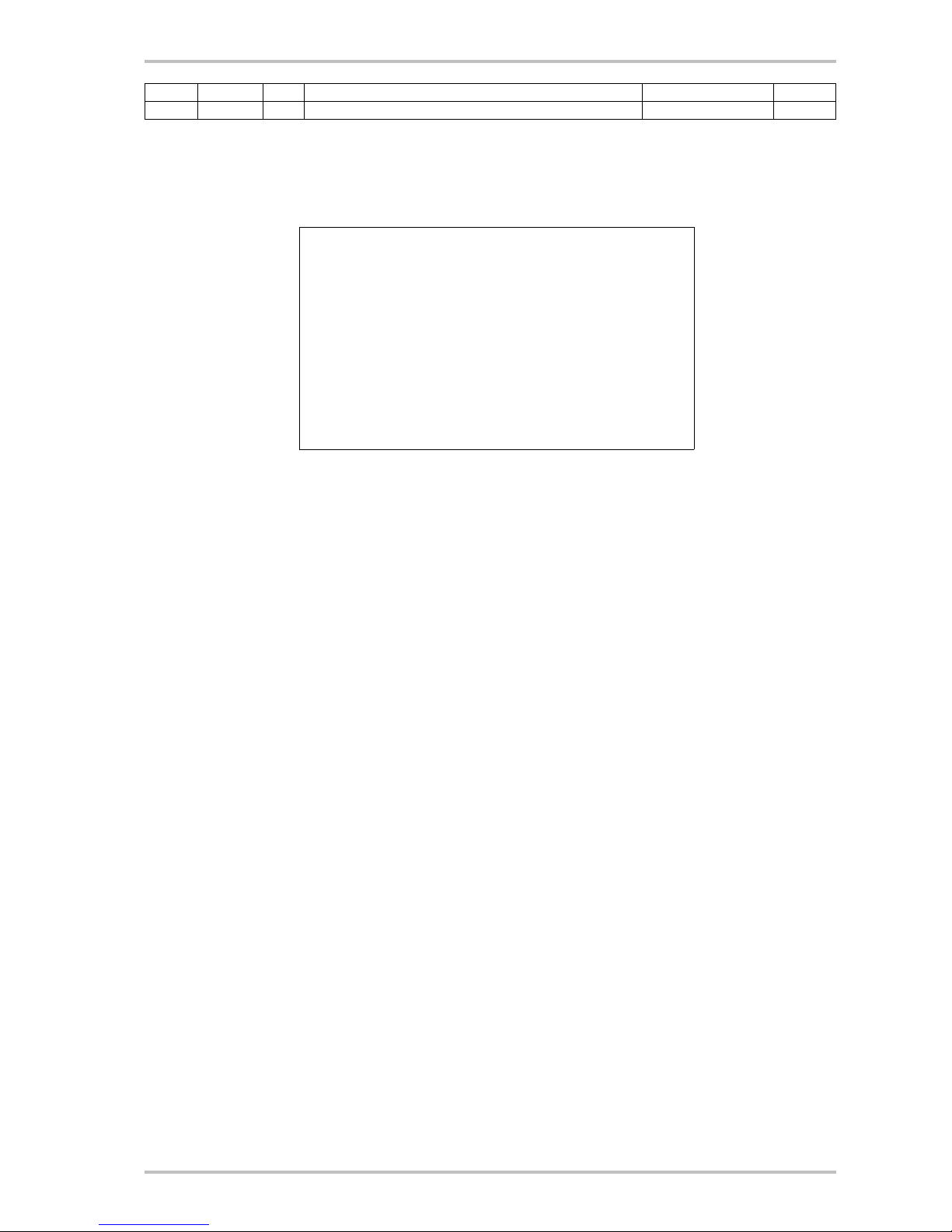

Type Format Thickness Quantity Use

Marine all okume/gaboon 2 440 X 1 220 9 to10 mm - 7 layers 1 Centreboard, rudder, transom

Marine all okume/gaboon 2 440 X 1 220 9 to10 mm - 7 layers 1 Bulkheads, sole

Marine all okume/gaboon 2 440 X 1 220 6 mm – 5 layers 2 Side seats....

Marine all okume/gaboon 2 440 X 1 220 6 mm – 5 layers 4 Planking

Chipboard or MDF 2 440 X 1 220 15 mm 2 Moulds

Chipboard or MDF 3 100 X 1 530 15 mm 1 Main building frame support

The first panel (centreboard, rudder...) may be replaced by a harder wood: sapele, mahogany, makore, sipo, meranti, moabi (this last one very strong but

heavier). It is also possible to use such species for all panels but the boat weight will be increased by 15% about.

If you want to varnish the boat, sapele or mahogany plywood will give a better aspect. If available, you may also use plywood with sapele or mahogany faces

and okume inside layers.

For planking, joints are of the “puzzle” type. It is required to sheath locally the joints on the inner side.

The following pages give the nesting diagrams of the plywood panels with identification of each part.

The same NC cutting applies for both version, sloop or standing lug (misainier). Some parts are used for one version only.

If you are using full size patterns or dimensioned drawings, see nesting plan of strakes is last page of appendix.

François Vivier

Architecte naval

18 April 2015

Page 25

78

Ø76

Trou d'étambrai misainier

Mast hole standing lug

Trou pour bitte sloup

Samson post sloop

132

Morbic 12 - Contreplaqué marine okoumé (ou sapelli, moabi) 10 mm - 2 440 X 1 220 Panneau 1/2

Morbic 12 - Okume (or mahogany) marine plywood 10 mm - 2 440 X 1 220

Panel 1/2

Doublante ponté arrière

Aft deck doubler

Tableau pli extérieur

Transom, outside layer

Tableau pli intérieur

Transom, inside layer

Dérive

Centreboard

Dérive

Centreboard

Trou d'alignement 6 mm

Alignment hole 6 mm

Safran

Rudder blade

Safran

Rudder blade

Ame gouvernail

Rudder core

Ponté avant

Fore deck

Support ponté avant

Fore deck support

Doublante ponté arrière

Aft deck doubler

Etrier gouvernail

Rudder head

Etrier gouvernail

Rudder head

Axe gouvernail

Rudder pivot

Morbic 12 - Echelle 1/10

Page 26

Morbic 12 - Contreplaqué marine okoumé 10 mm - 2 440 X 1 220 Panneau 2/2

Panel 2/2

Morbic 12 - Okume / Gaboon marine plywood 10 mm - 2 440 X 1 220

Scarf 70 mm

Doublante pour aileron

Doubler for skeg

Cloison 1

Bulkhead 1

Joues gouvernail

Rudder cheeks

Pli axial étrave

Stem core layer

Etrave

Stem

Cloison 3

Bulkhead 3

Sole (arrière)

Sole (aft)

Sole (avant)

Sole (fore)

890

22

355

Marge d'extrémité 20 mm

End margin 20 mm

Doublante étambrai (misainier)

Doubler mast partner (standing lug)

Emplanture (misainier)

Mast step (standing lug)

Emplanture (misainier)

Mast step (standing lug)

Emplanture (sloup)

Mast step (sloop)

Etrier gouvernail

Rudder head

Morbic 12 - Echelle 1/10

Page 27

Morbic 12 - Contreplaqué marine 6 mm - 2 500 X 1 220 Panneau 1/2

Banc latéral

Side seat

Banc latéral

Side seat

Ponté arrière

Aft deck

Puits de dérive

Centreboard case

Puits de dérive

Centreboard case

Apotres

Apron

Morbic 12 - Marine plywood 6 mm - 2 440 X 1 220 Panel 1/2

Doublantes sous ponté arrière

Doublers under aft deck

Morbic 12 - Echelle 1/10

Page 28

Morbic 12 - Contreplaqué marine 6 mm - 2 500 X 1 220 Panneau 2/2

Cloison longitudinale

Longitudinal bulkhead

Cloison longitudinale

Longitudinal bulkhead

Cloison 5 - pli arrière

Bulkhead 5 - Aft layer

Cloison 5 - pli avant

Bulkhead 5 - Fore layer

Panel 2/2Morbic 12 - Marine plywood 6 mm - 2 440 X 1 220

Doublante glissière puits

Doubler case slot

Etambrai (sloup)

Mast partner (sloop)

Demi-encornat

Boom jaws

Demi-encornat

Boom jaws

Morbic 12 - Echelle 1/10

Page 29

Marge d'extrémité 20 mm inclue

End margin 20 mm included

Nombre d'indentations = numéro de bordé

Number of indents = strake order

Page 30

Avant

Fore

Page 31

Panneau 1/2

Morbic 12 - chipboard panel 15 mm - 2 440 X 1 220

Panel 1/2

Couple 2

Station 2

Support poutre

Girder support

350

250

200

Supports couple 5

Station 5 supports

Couple 1

Station 1

Couple 4.2

Station 4.2

350

250

50

50

275

Morbic 12 - Aggloméré 15 mm - 2 440 X 1 220

900

510

160

400

15

95

90

Morbic 12 - Echelle 1/10

Page 32

Support poutre

Girder support

Couple 5

Station 5

Couple 3

Station 3

Couple 4.1

Station 4.1

Morbic 12 - Aggloméré 15 mm - 2 440 X 1 220

Morbic 12 - chipboard panel 15 mm - 2 440 X 1 220

Panneau 2/2

Panel 2/2

Gabarit de barre

Tiller pattern

Gabarit de membrure 3

Frame 3 pattern

Gabarit courbe de tableau

Quarter knee mould

Gabarit de carlingue puits de dérive

Centreboard case log pattern

Morbic 12 - Echelle 1/10

Page 33

2900

250

250

320

320

Morbic 12 - Aggloméré 15 mm - 3 100 X 1 530

Morbic 12 - chipboard panel 15 mm - 3 100 X 1 530

Panel 1/1

Panneau 1/1

Côté poutre

Girder side

Côté poutre

Girder side

Dessus poutre

Girder top plank

Dessous poutre

Girder bottom plank

Plats de positionnement des gabarits

Station moulds positionning plates

60 X 250

(20 pièces)

Morbic 12 - Echelle 1/12

Page 34

Galbord - bordé 1

Garboard - strake 1

Bordé / Strake 2

Bordé / Strake 3

Bordé / Strake 4

Bordé / Strake 5

Bordé / Strake 6

Avant

Fore

Arrière

Aft

4 panneaux CP marine okoumé 6 mm 2 500 X 1 220

4 plywood panels, okume marine grade, 2 440 X 1 220

Nota : les bordages 4 à 6 sont retournés (dedans - dehors)

Note : panels 4 to 6 are turned over (inside - outside)

Scarf 50 mm

Marge d'extrémité 20 mm inclue

End margin 20 mm included

Construction à partir des tracés vraie grandeur sur calques

Construction using full size patterns

Page 35

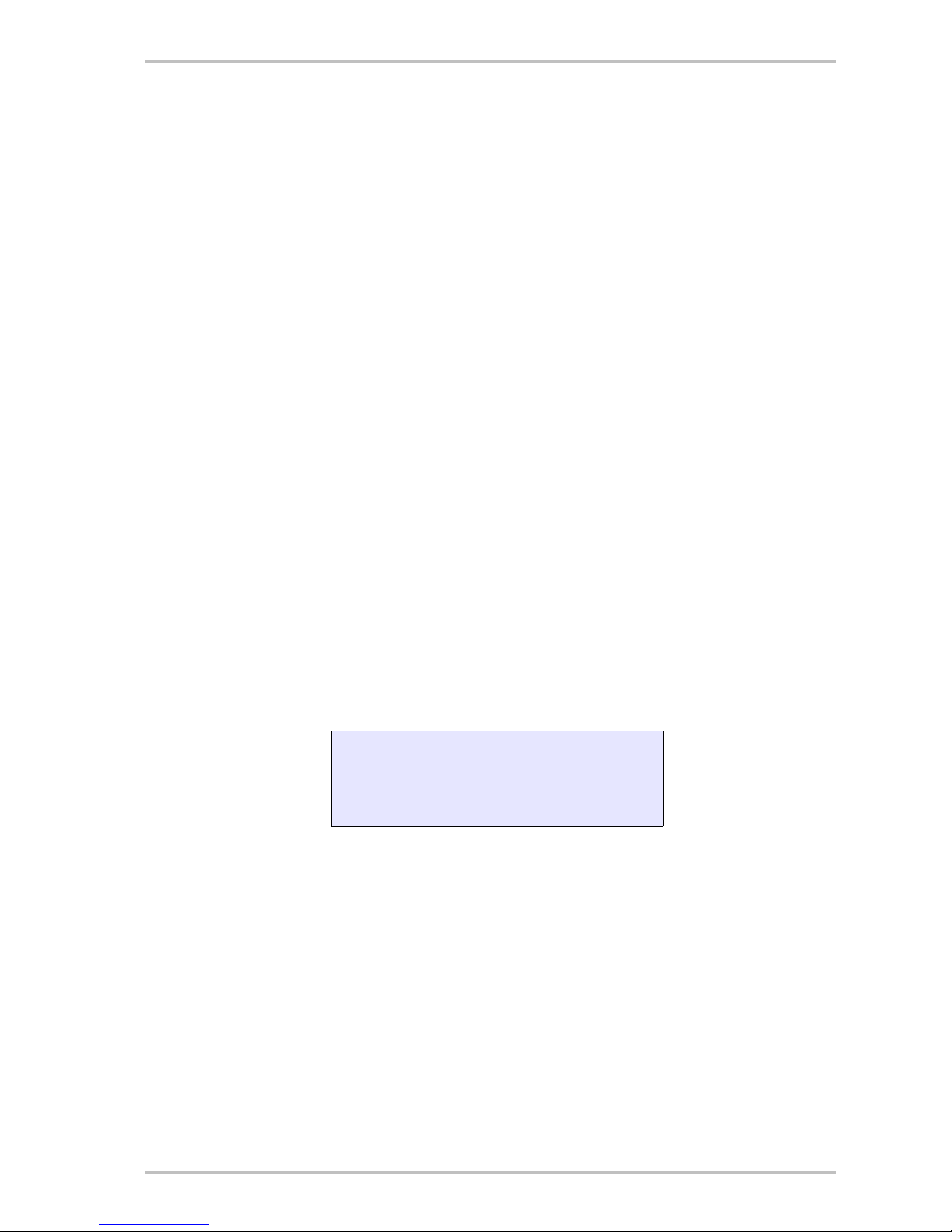

Morbic 12 – Appendix 4 rev 5

Fittings list

Article Version Use Quantity Dimension Obs.

Rudder gudgeon

(for pintle 10 mm

about.)

All Rudder 2 Classic Marine

S2 2 holes

vertical gudgeon

HL 2222

Rudder pintle

(pintle 10 mm

about.)

All Rudder 2 Classic Marine

S1 3 holes pintle

HL 2152

Note : it is also possible to adapt standard stainless steel fittings

Stainless steel

safety clip

All Rudder 1 Dinghy type

Mast traveller,

bronze or

galvanized,

preferably with

leather

All Mast 1 Inside diameter

85 mm about (76

mm mast). Rod

diameter 8 mm.

Cleat, ash or

teak

All One on mast 1 175 mm about

Cleat, ash or

teak

Sloop One jib sheet on

thwart, one on

bowsprit

2 175 mm about

Belaying pins

wood of brass

Sloop Each side of mast 2 Length 15 cm

Deck clip All Main sheet on

centreboard case

1 Medium size

Deck clip Sloop Tack line on mast

step

1 Medium size

Deck clip,

stainless steel

All Thole pin seizing

line

4 Small model

Deck clip,

stainless steel

All Centreboard shock-

cord

2 Small model

Bronze of brass

rod

All Thole pins,

centreboard pivot

50 cm Diam. 14 mm

Convex keelband or strips,

brass or bronze

All Keel band 2.5 m 6 X 12 to 8 X 16

Sheave All Mast head 1 Thickness 13 mm

Diameter 60

+ appropriate

stainless steel

pivot (8 mm)

Page 36

April 2011 Morbic 12 – sloop version Appendix4 rev 5- Page 2/3

Bronze sheet

lead

Sloop Mast head for jib

halyard,

Jib sheets on

gunwale

3 Opening 25 X 12

Or equivalent

modern lead

Stainless steel

eye-bolt

Sloop Bowsprit 1 Diameter 6 mm

Length 50 mm

Eye nut Sloop Bowsprit 1 Diameter 6 mm

Simple block Sloop Jib tack on bowsprit 1 For rope 8 mm

Fiddle block with

becket and cam

cleat

All Mainsheet 1 For rope 8 mm

Spring for fiddle

block

All Mainsheet 1 For block with

camcleat

Simple block with

becket

All Mainsheet 1 For rope 8 mm

Stainless steel

eye-bolt

Standing

lug

Tack line on mast

step

1 Diameter 6 mm

Length 40 mm

Micro double

block,

stainless steel

Sloop Bobstay purchase 1 For rope 6 mm

Micro block

simple with

becket

stainless steel

Sloop Bobstay purchase 1 For rope 6 mm

Simple block All Mainsail tack on

mast step

1 For rope 8 mm

Micro block

simple with

becket

stainless steel

All Mainsail tack

purchase

1 For rope 6 mm

Micro cheek

block

stainless steel

All Mainsail tack

purchase

1 For rope 6 mm

Page 37

April 2011 Morbic 12 – sloop version Appendix4 rev 5- Page 3/3

Cam-cleat All Mainsail tack

purchase

1 For rope 6 mm

Simple shackle

stainless steel

All Miscellaneous 2 5 mm

Simple shackle

stainless steel

Sloop Miscellaneous 3 5 mm

Draining plug,

brass or nylon

All Transom 1 For transom

thickness 20 mm

Dinghy type

hatch covers

All Buoyancy

compartments.

3 Diameter 200

mm about. You

may chose a

model with bag

(picture)

Shock-cord All Centreboard 1.2 m 8 mm

Polyester rope or

braid, preferably

hemp like

All Mainsail halyard 9 m 10 mm

Polyester rope or

braid, preferably

hemp like

All Mainsheet (12 m),

mainsail tack (2 m)

14 m 8 mm

Polyester rope or

braid, preferably

hemp like

Sloop Jib sheets (2 X 4),

jib halyard (9 m),

jib tack (4 m),

bobstay.

22 m 8 mm

Polyester rope or

braid, preferably

hemp like

All Rudder line,

mainsail tack

purchase, bobstay

purchase, mainsail

points

15 m 6 mm

Polyester rope or

braid, preferably

hemp like

All Sail lashing on yard,

reef pennants.

20 m 4 mm

Braid, preferably

brown

All Protection and small

lashings

50 m 3 mm

François Vivier Architecte Naval

2 October 2014

Page 38

Morbic 12 - Vertical / Body rev 5

2 novembre 2009

© François Vivier Architecte Naval

Equerrage pli extérieur

Bevel, outer layer

Découpe pli extérieur

Cut-out, outer layer

Découpe pli intérieur

Cut-out, inner layer

Mortaise pli intérieur

Mortice into inner layer

Tasseau / batten 35 X 25

Gabarit 5

Station mould 5

Cloison 5

Bulkhead 5

Cloison 5 pli avant

Bulkhead 5, fore layer

Mortaise cloison 5

Mortice bulkhead 5

Gabarit 4.1

Station mould 4.1

Gabarit 3

Station mould 3

Cloison 3

Bulkhead 3

Allonge de membrure

Upper frame

Gabarit 2

Station mould 2

Gabarit 1

Station mould 1

Cloison 1

Bulkhead 1

Trou d'alignement dans cloison et gabarit 1

Alignment hole in bulkhead and mould 1

Gabarit 4.2

Station mould 4.2

Trou d'alignement 3 dans cloison et gabarit

Alignment hole in bulkhead and mould 3

Trou d'alignement dans cloison et gabarit 5

Alignment hole in bulkhead and mould 5

Encoche dans gabarit 1

Notch in station mould 1

Page 39

Morbic 12 - Pièces diverses / miscellaneous parts rev 5

28 décembre 2009

© François Vivier Architecte Naval

10

Banc latéral

Side seat

Aileron

Skeg

Page 40

Avant

Fore

Morbic 12 - Bordés / Strakes

Recouvrement des clins 20 mm

Clinger overlap : 20 mm

28 août 2009

© François Vivier Architecte Naval

Tracés sans aucune marge latérale

1 à 2 cm de marge incluse aux extrémités

Bordages 4 à 6 retournés (dedans-dehors)

Shape without any side margin.

End margin included, 1 to 2 cm.

Strake 4 to 6 are turned over.

s

o

l

e

Découpe dérive (version voile)

Centrebord slot (sail version only)

G

a

l

b

o

r

d

/

G

a

r

b

o

a

r

d

(

B

o

r

d

é

/

s

t

r

a

k

e

1

)

G

a

l

b

o

r

d

/

G

a

r

b

o

a

r

d

(

B

o

r

d

é

/

s

t

r

a

k

e

1

)

B

o

r

d

é

/

s

t

r

a

k

e

2

B

o

r

d

é

/

s

t

r

a

k

e

2

B

o

r

d

é

/

s

t

r

a

k

e

3

B

o

r

d

é

/ s

t

r

a

k

e

3

Bor

d

é / strake

4

Bordé / strake

4

B

ord

é

/

s

tra

k

e 5

B

o

r

d

é

/

s

t

r

a

k

e

5

B

o

rdé

/

s

tra

k

e

6

B

o

r

d

é

/

s

t

r

a

k

e

6

Tracés sans aucune marge latérale

1 à 2 cm de marge incluse aux extrémités

Bordages 4 à 6 retournés (dedans-dehors)

Shape without any side margin.

End margin included, 1 to 2 cm.

Strake 4 to 6 are turned over.

Loading...

Loading...