Franco Belges Le Continental 174 07 53 Technical Manual

Technical manual

to be saved

by th e user

for future reference

Document n° 952-3 EN ~ 02/03/2000

Les FonderiesFranco-B el ges

59660 MERVILLE

Phone : 03.28.43.43.43

Fax : 03.28.43.43.99

RC Hazebrouck 445750565B

Subject to modifications

Le Continental

Oil fired stove

Model 174 07 53

(ANSI/UL & CAN/CSA approved)

Français

English

Description of the appli ance

Installation instructions

Operating instructions

Spare parts

Warranty certificate

Norsk

Descriptionoftheunit ........................................3

Description...................3

Optionalequipment..............3

Specifications.................3

Operatingprinciple..............4

Installationinstructions .......................................4

Positionoftheunit ..............4

Chimney....................4

Chimneyconnector..............4

Connection to a L.VENT chimney ......4

Pre-utilisation check .............5

Mounting the levelling feet ..........5

Levelling ....................5

Externaltank .................5

Oilflowadjustment..............6

Chimneydraught ...............6

Maintenance of the Chimney .........6

Operatinginstructions........................................6

Fuel ......................6

Lighting procedure ..............6

Operatingprocedure .............7

Shuttingdown.................7

Recommendation...............7

Maintenance of the stove ..........7

Troubleshooting ...............8

Spareparts...............................................9

CONTENTS Page Page

FRANCO BELGE congratulates you on your choice.

FRANCO BELGE, which has been granted the ISO 90 01 certification, guarantees the quality of its

appliances and is committed to meet its customers’ needs.

FRANCO BELGE, which can boast a 75-year experience in the industry of heating devices, uses

state-of-the-art technologies to design and manufacture its whole range of products.

This document contains instructions on how to install your appliance and and make full use of its

functions, both for your comfort and safety.

Document n° 952-3 EN ~02/03/2000

Continental Poêle à combustible liquide

2 Notice de référence

1.Description of the unit

1.1.Description

Flued oil stove with vaporizing burner (Norm EN1)

1.2.Optional equipment

¤ Ground vat

1.3.Specifications

Nominal Heat Output(NF D 35.001) . . . kW 6,5

...................... Btu/hr 26.000

Oil consumption at :

- maximum speed . . . . . . . . . . . . . . l/h 0,81

.......................gal/hr 0,22

- minimum speed . . . . . . . . . . . . . . l/h 0,25

.......................gal/hr 0,066

Chimney draft required at :

- maximum speed . . . . . . . . . . . . . . Pa 15

- minimum speed . . . . . . . . . . . . . . Pa 6

Weight .................... kg 55

USA/CANADA - Connectionto a L.VENTchimney :

Nominal heat output . . . . . . . . . . . Btu/h 19 600

........................kW 5.75

Oil consumption at nominal speed . USgal/h 0.198

........................ l/h 0.75

Chimneydraft.............. “w.c.g 0.06

........................ Pa 15

7

9

8

1

2

3

4

5

6

10

11

12

13

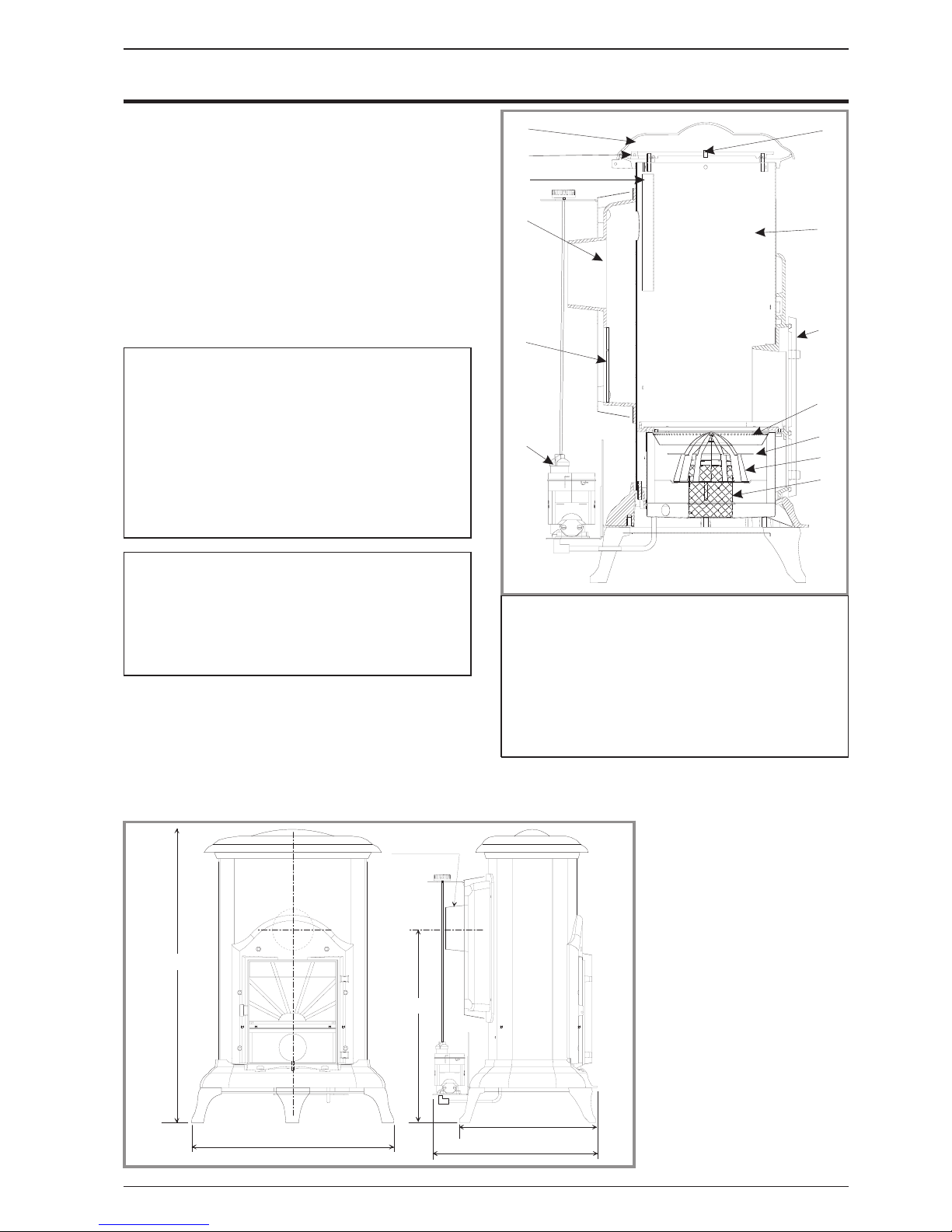

Fig. 1 - Description

1 - Cover

2-Topplate

3 - Flue baffle

4 - Flue box

5 - Draught regulator

6 - Carburettor

7 - Draught control

8 - Combustion chamber

9 - Main door

10 - Catalyser ring

11 - Catalyser cover

12 - Catalyser body

13 - Air inlet holes

540

460

Ø 120 / 127

805

530

350

805 mm - 31 3/4"

Ø 120 / 127 mm - Ø 5"

540 mm - 21 1/4"

530 mm - 20 4/5"

350 mm - 13 3/4"

460 mm - 18"

Fig. 2 - Dimensions in mm

Document n° 952-3 EN ~ 02/03/2000

Continental Poêleà combustible liquide

Notice de référence 3

1.4. Operating principle

Furnace oil is fed to the burner floor (fig. 1) where is it

ignited by means of a firestarter. The heat produced by

this flame brings the burnertemperature to the required

level to vaporize the fuel. Oil will only burn as a vapour

not a liquid.

Room combustion air enters the burner through the air

inlet holes (# 13, fig. 1).

In the center of the burner is the catalyser (# 12, fig. 1)

which aids in vaporizing the fuel. When the stove is

operation,the catalyser glows red. The stove should not

be used wi th out both the catalyser (# 12, fig. 1),

catalyser top (# 11) and ring (# 10).

A de-scaling lever (#1, fig.8) can be pushed and pulled

inandout aswell asturningslightlyat thesametimeto

keep the inlet pipe clear of carbon buildup.

The stove float regulator contains a filter to trap

impurities.

A safety lever controls fuel flow. Oil can only enter the

float chamber when the safety lever is depressed.

Oil temperature variations willaffect theoil flow intothe

float chamber. A float in the chamber raises the fuel

level available to the burner.

The carburetor is also controlled by a control knob

which turns from “0" (off) to ”6" (high setting).

A draft regulator (# 3, fig. 7) ensures a constant air

intake to the burner regardless of external factors.

2.Installation instructions

USA / CANADA : Theinstallation of this stove must com-

ply with state and local requirements and the standard

CSA B139.

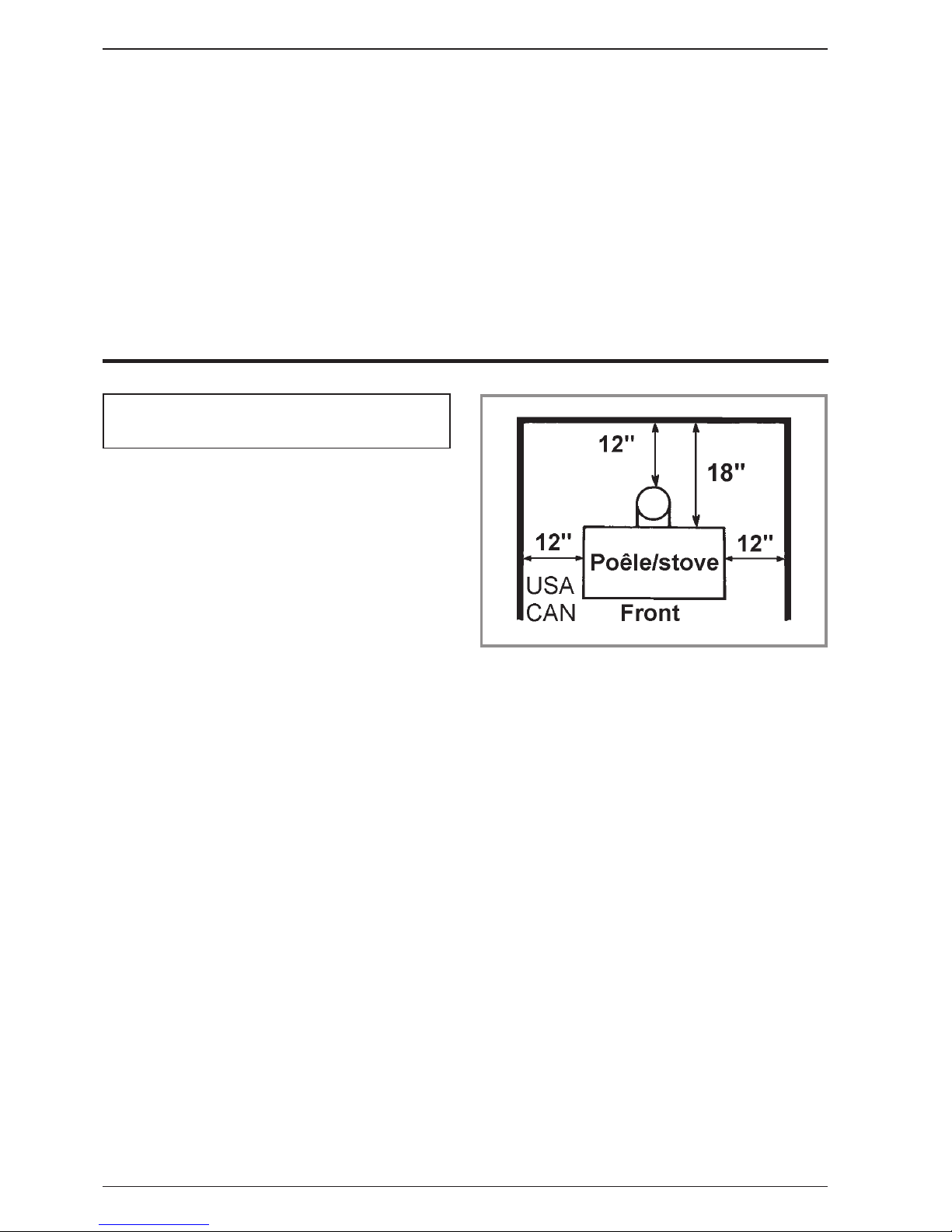

2.1.Position of the unit

- The position of the appliance must be chosen very

carefully in order to obtain the best possible results for

heat distribution.

- Position the unit to comply with the minimum

clearances to co mbustible material. M inimum

clearances are shown from the vertical portion of the

chimney connector. Check that no overhead cross

members in the ceiling will be cut. Reposition unit if

necessary, being careful not to move closer than the

minimum clearances.

- Outside air : For the oil stove to function properly, an

adequate supply of combustion air is required.

2.2. Chimney

- Ensure that the flue has sufficient draught (refer to

technical details).

- Minimum flue diameter, 10 cm (4" I.D).

- The chimney must be at least 4.5 m (15 ft high).

- The flue must not be shared with anyother appliance.

- Do wndraughts caused by obstacles close to the

chimney top may sometimes be prevented by fitting an

anti-downdraught cap to the top of the chimney.

- The chimney must have a constant cross section. Too

large a flue could affect the chimney draught.

- The chimney must be soundly constructed,in order to

prevent cold air infiltration.

- The flue must be well insulated, water and air tight. A

chimney with a coldinternalsurface can prevent a good

chimney drau ghtand condensation will occur.

-The flue must be swept at least once a year.

2.3.Chimney connector

- The appliance must be as close as possible to the

chimney. Avoid horizontal flue connection pipes which

can dangerously restrain functioning of the appliance.

The connector pipe should bestandard black paintedor

blued steel pipe of not less than 30 gage; 304 grade

stainless steel of not less than 30 gage; or 1 mm

viterous enamelled steel, with a maximum diameter of

5 inch O.D. - (127mm). It isthe installer’sresponsability

to conform to local building standards and requirements

with regard to installation.

Single wall pipe may be utilized being careful to

maintain clearances to any combustible surface.(fig. 3)

Once the stove hasbeen properly installedthe chimney

draught must be checked with a draught meter.

If the chimney draught is excessive or irregular, a

draught stabilizer (barometric damper) must be

installed to the connector pipe.

2.4.Connection to a L.VENT chimney

USA / Canada

: The 174 07 53 appliance is certifiedto

be connected to a 5" L.VENT chimney with its nominal

heatoutputlimitedto 19600 Btu/h (5.75 kw) .This will be

achieved by replacing the float-regulator (carburator)

(# 19 fig. 9).Please contact your dealer to have this

alteration done.

WARNING. FRANCO-BELGE is not responsible for

any incidental or consequential damages if this

operation is not done.

Figure 3 - Minimum clearances to combustible surfaces

Document n° 952-3 EN ~02/03/2000

Continental Poêle à combustible liquide

4 Notice de référence

Loading...

Loading...