FRANCO BELGE Savoy Classic 134 08 05 Technical Manual

Description of the ap pliance

Installation instructions

Operating instructions

Spare parts

Warranty certificate

Document n° 986-11 ~ 03/12/2007

STAUB FONDERIE

Head Office Address

2, rue Saint Gilles

68230 TURCKHEIM

RCS Colmar

SIREN 444 881 953

Address

Administration and manufacturing

BP 73

59660 MERVILLE (FRANCE)

Telephone : 00 333 28 43 43 00

Fax : 00 333 28 43 43 99

Subject to modifications.

SAVOY Classic

Multifuel stove

Model : 134 08 05

DIN EN 13240 : 2005-10

Net output : 7,7 kW (Wood)

Net output : 6,4 kW (Smokeless fuels)

Technical manual

to be saved

by the user

for future reference

SARL with the capital of 10 000 000 €

2 Technical manual “986”

“Savoy” - ref. 134 08 05

CONTENTS

Product information ·······················································p.3

Package ..........................p.3

General characteristics ..............p.3

Description ........................p.3

Principle of operation ...............p.3

Installation instructions····················································p.4

Warning to the user .................p.4

Location of the unit .................p.4

Chimney ..........................p.4

Assembly of flue collar ..............p.5

Chimney connector .................p.5

Mounting the tray...................p.6

Pre-utilisation check ................p.6

Door closing pressure ...............p.6

Maintenance of the Chimney .........p.7

Instructions for user·······················································p.8

Fuel..............................p.8

Instruction for use with wood .........p.9

Instructions for use with solid fuel .....p.9

Cleaning ..........................p.9

Maintenance of the Chimney .........p.9

Maintenance of the stove body........p.9

Recommendations..................p.9

Trouble Shooting ..................p.10

Spare parts······························································p.11

FRANCO BELGE congratulates you on your choice.

FRANCO BELGE, guarantees the quality of its appliances and is committed to meet its

customers’ needs.

FRANCO BELGE, which can boast a 80-year experience in the industry of heating devices, uses

state-of-the-art technologies

to design and manufacture its whole range of products.

This document contains instructions on how to install your appliance and make full use of its

functions, both for your comfort and safety.

This appliance is meant to burn wood and smokeless fuels safely

WARNING

Incorrectly installed, this appliance can be dangerous and possibly cause serious accidents.

We recommend that you engage the services of a professional engineer for its installation

and the regular maintenance requirements.

1. Product information

1.1. Package

•

1 package : Stove complete.

1.2. General characteristics

Reference ................ 1340805

FUEL : WOOD

Chimney draught required ......Pa 12

Volume heated ............m

3

280

Usable firebox dimensions

- width ................mm 450

- depth ................mm 240

- height ................mm 365

Log dimensions

- Lenght maxi .............cm 40

Ash pan capacity ..........litres 3

Net weight ...............kg 100

Flue gas temperature .........°C 341

Nominal output ............kW 7,7

Efficiency................% 72,6

Co (13% O

2

)..............% 0,42

Flue gas mass flow ..........g/s 7

Fuel rate ...............kg/h 2,4

Refuelling interval ..........mn 102

FUEL : ANTHRACITE (SMOKELESS FUELS)

Tested with fuel brand name “phurnacite” entering in

category A, table B2 frpm the standard EN 13240.

Nominal heat output .........KW 6,4

Chimney draught required ......Pa 18

Flue gas temperature .........°C 165

Efficiency................% 73

Co (13% O2) ..............% 0,5

Fuel rate ...............kg/h 0,8

Refuelling interval ..........mn 132

1.3. Description

•

Multifuel stove in conformity with DIN EN 13240 :

2005-10

•

Intermittent-burning heating appliance wood and

smokeless fuels.

•

Fuel burnt on grate

•

Enclosed combustion chamber with refractory brick

walls.

•

Removable appliance, to be installed near a wall.

•

Detachable flue spigot for rear or top chimney

connection.

•

Detachable top for easy handling and cleaning (rear

smoke exit only).

•

Adjustable air controls for controlling the burning rate.

•

Spin wheel for lighting.

•

Large ash-pan.

1.4. Principle of

operation

The appliance is

designed for operation

with the door closed.

Heat is mainly diffused by

radiation, through the

window and body of the

appliance.

Combustion occurs on

the grate, with draught

entry through the top of

the combustion chamber

when using wood and

under the grate when

using smokeless fuels.

Technical manual “986” 3

“Savoy” - ref. 134 08 05 Product information

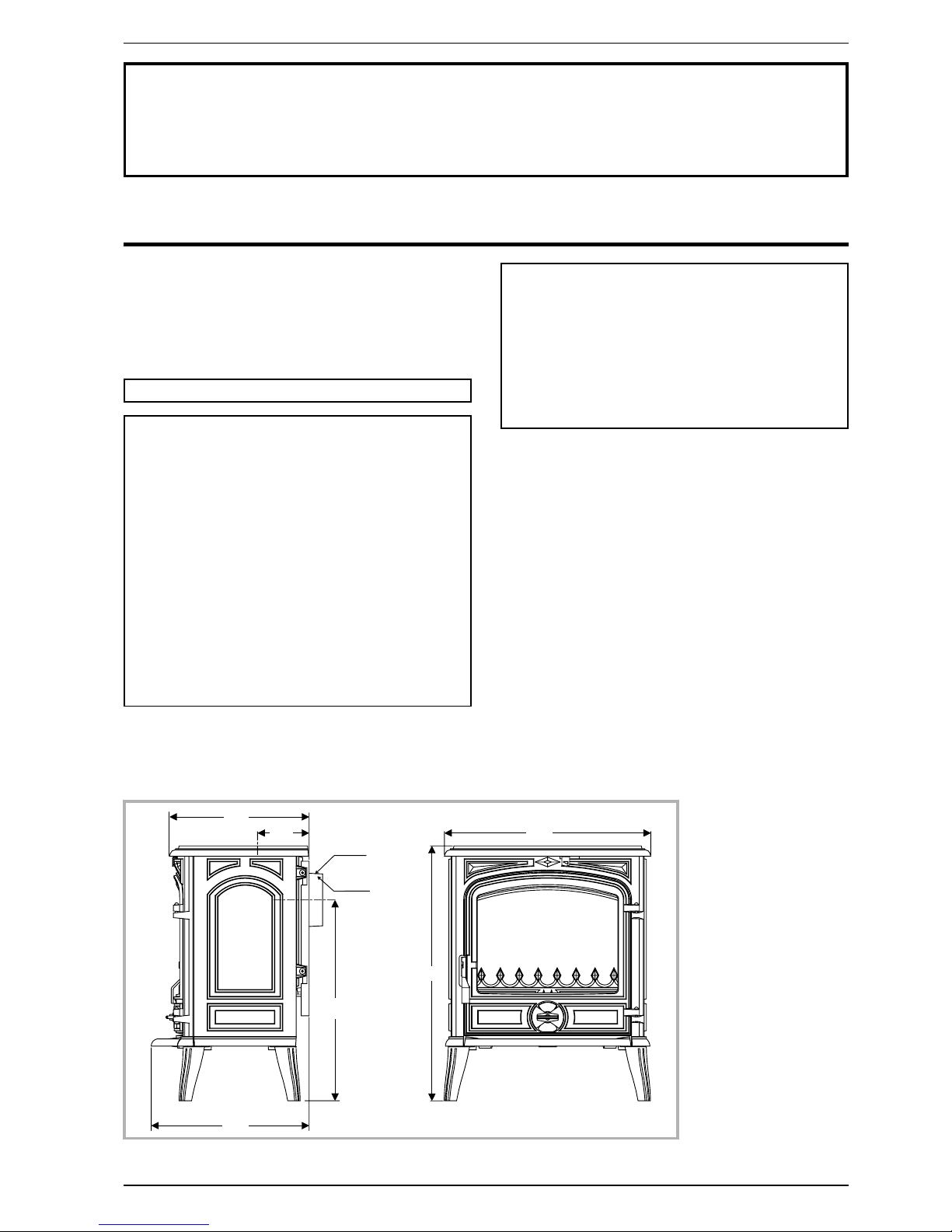

6 6 0

1 3 4

5 2 0

4 0 9

5 3 5

Ø 1 2 5

Ø 1 3 9

3 6 0

Figure 1 - Dimensions in mm

2. Installation instructions

2.1. Warning to the user

All the local and national regulations, and in

particular those relating to national and European

standards, must be observed when installing the

appliance.

An incorrectly installed heating appliance can

cause serious accidents (chimney fires, burning of

plastic insulation materials, in partition walls, etc.).

The insulation of both the appliance and the

exhaust gas pipe has to be reinforced and done

according to the Standards and the Building

Regulations for safety reasons.

Failure to respect the mounting instructions leads to

engage the responsibility of the one doing the

installation.

The manufacturer’s responsibility shall be limited to the

supply of the equipment.

2.2. Location of the unit

Ventilation :

For satisfactory appliance operation with a natural

draught, check that sufficient air for combustion is

available in the room.

Position of the unit :

For new installations, select a central position within the

house, to provide a good heat distribution around the

building.

The heat distribution towards the other rooms will be

made through the communicating doors.

These rooms must be in negative pressure or must

include ventilation gratings.

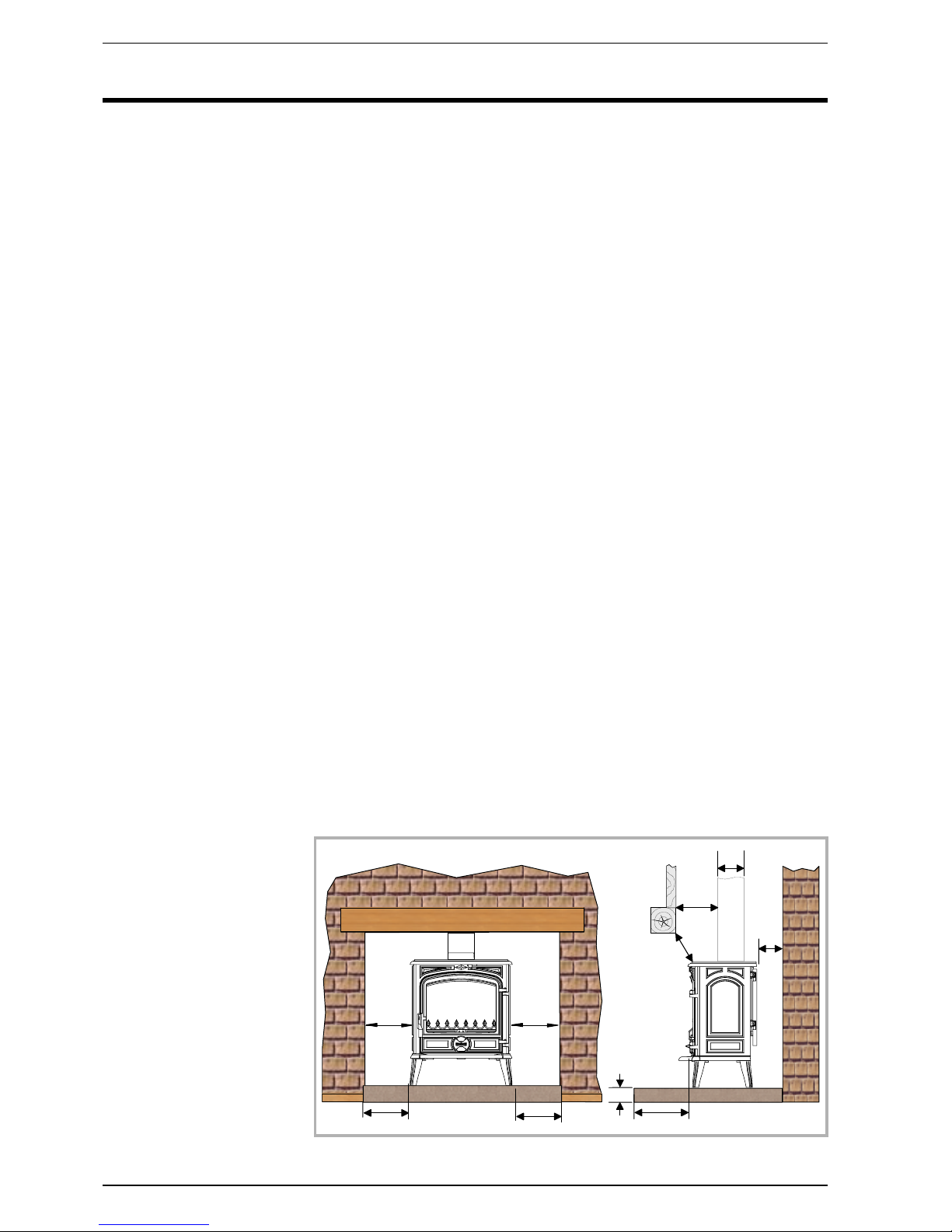

Floor and walls :

Make sure they are not combustible or covered with

combustible material (as per the Building regulations).

Otherwise it must necessary to install a

non-combustible protection.

There must be a clearance of at least 150 mm at each

side of the appliance and at the back of the appliance

from a non-combustible wall.

This distance must be

extended to a minimum

clearance of 350 mm from any

combustible materials.

This measurement may be

reduced to a minimum gap of

50 mm when the

non-combustible wall is at

least 200 mm thick.

When using a single wall flue

pipe, there must be a

clearance (A) of at least three

times its diameter (B) from

any combustible materials.

If the appliance has to be

located in an opening, this

distance must be extended to

a minimum clearance (A) of

375 mm from the pipe or the

stove body to any combustible

materials.

Hearth :

The appliance must stand on a fireproof hearth.

It is possible to provide a hearth made of non

combusible board/sheet material or tiles at least 12 mm

thick.

Constructional hearths should be constructed of solid

non combustible material at least 125 mm thick

(including the thickness of any non combustible floor

under the hearth).

The hearth must protrude at least 225 mm in front of the

stove and 150 mm each side.

If the hearth is constructed on timber, there must be a

clearance of at least 250 mm from the timber to the top

surface of the hearth.

See section J of the Building regulations.

2.3. Chimney

The chimney must comply with Current Building

Regulations. If in doubt, consult your Dealer or local

Building Inspector.

Existing flue :

-

The flue must be suitable for the installation of fuel

burning appliances, otherwise it must necessary to

install a tubing

-

The flue must be in good condition and must provide

sufficient draught (refer to technical details p. 3 ).

-

The flue must be clean. It should be swept to remove

soot and dislodge tar deposits.

-

The flue must be well insulated. If the flue inner wall

surfaces are cold, a good thermal draw is impossible

causing condensation problems (tar formation etc.) to

occur.

-

The flue must be watertight.

-

The chimney must have a constant cross section.

-

The flue must not be shared with other appliances.

-

The chimney must be at least 4.5 m (15 ft high).

-

In case of a flat roof or when the roof gradient is lower

than 15°, the stack must be 1,2 m (4 feet) high at least.

-

The capping must not restrain the draught.

4 Technical manual “986”

“Savoy” - ref. 134 08 05 Installation instructions

1 5 0

1 5 0

1 5 0

3 0 0

1 5 0

B

A

A

C

1 5 0

Figure 2 - Clearances

-

If the chimney has any down draught tendency, due to

its position in relation to nearby obstacles, then an

anti-down draught cowl must be installed on the

chimney or the chimney height must be increased.

-

If the chimney draught is excessive or irregular, a

draught stabiliser (barometric damper) must be

installed to the connector pipe.

Chimney to be built / New flue:

The chimney must comply with Current Building

Regulations. If in doubt, consult your Dealer or local

Building Inspector.

-

The flue must not be supported by the stove.

-

Consult a chimney specialist for advice on suitable

flue systems for solid fuel appliances.

-

It must be distant from any combustible material

(walls, cross members)

-

It must permit an easy sweeping.

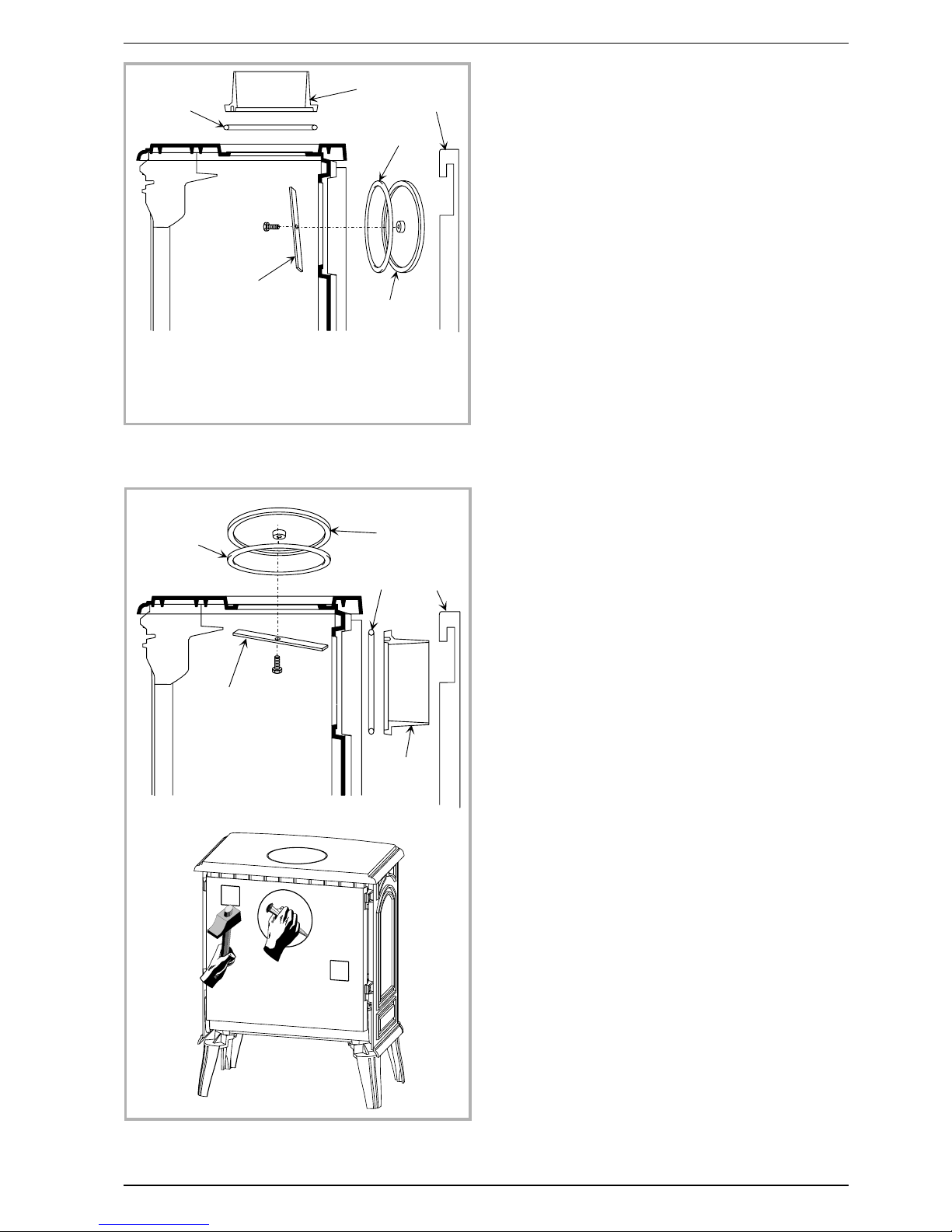

2.4. Assembly of flue collar

The stove is supplied with a connection flue collar with

an inner diameter of 125 mm and an outer diameter of

139 mm.

2.4.1. Flue outlet on the top

Figure 3

-

Remove the flue baffle (fig. 9, p. 7)

-

Fit the sealing rope 2 in the groove on the top and fix

the flue collar 1 with 3 bolts and washers supplied.

-

Replace the flue baffle

2.4.2. Flue outlet at rear

Figure 4

-

Remove the retainer fuel (fig. 8, p. 7), the two side

bricks and the flue baffle (fig. 9, p. 7).

-

Remove the rear heat shield and remove the cut-out

on it.

-

Remove the blanking plate 3 and the clamp 4 and refit

in the top, ensuring there is a good seal.

-

Fix the flue collar 1 at rear with the bolts and washers

supplied, ensuring there is a good seal.

-

Replace all the internal parts in the reverse order.

-

Replace the rear heat shield.

2.5. Chimney connector

-

The appliance must be installed as close as possible

to the chimney.

-

The connector pipe must be approved for installation

with combustion products (e.g. 316 grade 1 mm thick

stainless steel or vitreous enamelled steel).

-

Pipe diameter must not be less than the appliance

spigot diameter.

-

If there is no other solution, the reduction can not be

more than one diameter lower than the flue spigot and

be situated as distant as possible from the flue

connection of the appliance.

-

The connection can be either vertical or horizontal. For

horizontal connections, avoid right angle bends.

-

The join between the connection pipe and the

stovepipe, and the flue, must be leak tight.

Technical manual “986” 5

“Savoy” - ref. 134 08 05 Installation instructions

1

2

3

4

2

5

Figure 3 - Flue outlet on the top

1

2

3

4

2

5

Figure 4 - Rear flue outlet

1 - Flue collar

2 - Ceramic rope

3 - Blanking plate

4 - Clamp

5 - Rear heat shield

Loading...

Loading...