FRANCO BELGE Savoie 174 08 02 Y Technical Manual

Description of the appliance

Installation instructions

Operating instructions

Spare parts

Warranty certificate

Technical manual

to be saved

by the user

for future reference

Document n° 1038-2 ~ 24/10/2001

Les Fonderies Franco-Belges

59660 MERVILLE

Phone : 03.28.43.43.43

Fax : 03.28.43.43.99

RC Hazebrouck 445750565B

Subject to modifications

SAVOIE

Oil burning stove

Model : 174 08 02 Y

(EN1)

English

Norsk

Description of the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Description . . . . . . . . . . . . . . . . . 3

Package . . . . . . . . . . . . . . . . . . 3

Optional equipment . . . . . . . . . . . . 3

Specifications . . . . . . . . . . . . . . . 3

Operating principle . . . . . . . . . . . . . 4

Installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warning to the user . . . . . . . . . . . . 4

Position of the unit . . . . . . . . . . . . . 4

Chimney . . . . . . . . . . . . . . . . . . 4

Mounting the levelling feet . . . . . . . . 5

Smoke exit . . . . . . . . . . . . . . . . . 5

Chimney connector . . . . . . . . . . . . 5

Levelling . . . . . . . . . . . . . . . . . . 5

External / remote tank . . . . . . . . . . . 6

Pre-utilization check . . . . . . . . . . . . 6

Oil flow adjustment . . . . . . . . . . . . . 6

Chimney draft required . . . . . . . . . . 7

Maintenance of the Chimney . . . . . . . 7

Door closing pressure . . . . . . . . . . . 7

Removing the burner . . . . . . . . . . . 8

Instructions for user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Fuel . . . . . . . . . . . . . . . . . . . . . 8

Lighting procedure . . . . . . . . . . . . . 8

Operating procedure . . . . . . . . . . . . 9

Shutting down . . . . . . . . . . . . . . . 9

Recommendations . . . . . . . . . . . . . 9

Maintenance of the stove . . . . . . . . . 9

Trouble shooting . . . . . . . . . . . . . 10

Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

CONTENTS Page Page

FRANCO BELGE congratulates you on your choice.

FRANCO BELGE, which has been granted the ISO 9001 certification, guarantees the

quality of its appliances and is committed to meet its customers needs.

FRANCO BELGE, which can boast a 75-year experience in the industry of heating devices,

uses state-of-the-art technologies

to design and manufacture its whole range of products.

This document contains instructions on how to install your appliance and and make full

use of its functions, both for your comfort and safety.

Savoie - ref. 174 08 02 Y

2 Technical manual "1038"

This appliance is an oil-fired stove.

WARNING

An incorrectly installed oil-fired stove can cause serious accidents. This appliance

should only be installed by competent personnel.

1.Description of the unit

1.1. Description

Flued oil stove with vaporizing burner. (Norm EN1)

1.2. Package

1 package : 1 stove

1.3.Optional equipment

•Visioflamme (mirrors)

•Glow-plug ignitor

•Ground vat

•Ceramic coals

1.4. Specifications

Model ...................... 1740802

NominalHeatOutput ............kW 8

atmaximumspeed ........... liter/hr 0,95

at m inim um speed . . . . . . . . . . . . liter/hr 0,25

Chimney draft required

atmaximumspeed ............. Pa 15

atminimumspeed.............. Pa 8

Weight .................... kg 100

200 mm

200

mm

200

mm

200 mm

Figure 1 - Minimum

clearances

535

660

554

545

506

Ø 125 int.

Ø 125 int.147

Figure 2 - Dimensions in mm

Description of the unitSavoie - ref. 174 08 02 Y

Technical manual "1038" 3

1.5.Operating principle

Heatis mainlydiffusedby radiation, through thewindow

and body of the appliance. The speed control is

obtained by control the oil flow into the burner.

The stove is fitted with a vaporizing burner (fig. 3).

Furnace oil is fed to the burner floor where is it ignited

by means of a firestarter (or with an optional electrical

igniter). The heat produced by this flame brings the

burner temperatureto the required level to vaporize the

oil. Oil will only burn as a vapour not a liquid.

Combustion air enters the burner through the air holes

(# 1, fig. 3). In the center of the burner is the catalyser

(# 2), which aids the the good combustion.

On the feed-line there is a de-scaling lever (# 5). The

de-scaling lever can be operated to keep the inlet pipe

clear of carbon buildup.

The stove float regulator (fig.4) contains a filter(# G)to

trap impurities. A safety lever controls oil flow (# B). A

float in the chamber raises the oil level available to the

burner.

Oil can only enter the float chamber when the safety

lever is depressed.

The carburetor is alsocontrolled by a control knob (# 2,

fig. 14, p. 8) which turns from “off" to ”high setting".

A draftregulator (# 1, fig. 9, p. 6) ensures a constantair

intake to the burner regardless of external factors.

2.Installation instructions

2.1.Warning to the user

An inc orrectly installed heating appliance can

cause serious accidents (chimney fires, burning of

plastic insulation materials, in partition walls, etc.).

The installation must be carried out according to local

building regulations.

The manufacturers responsibility shall be limited to the

supply of the equipment.

2.2.Position of the unit

Ventilation :

For s atisfac tory operation with a na tu ral draught,

check that sufficient air for combustion is available in

the room.

In houses equipped with mechanical ventilation, an

outside air intake must be installed for the chimney.

Chimney position :

For new chimney installations, select a central position

within the building, to provide a good heat distribution

around the building.

Position the unit to comply with the minimum

clearances to combustible material (fig. 1, p. 3).

2.3. Chimney

•The flue must be in good condition and must provide

sufficient draught. (refer to technical details p. 3).

•The flue must be suitable for the installation of fuel

burning appliances and comply with Current Building

Regulations.

•The flu e must be clean. It should be swept to remove

soot and dislodge tar deposits.

•Thefluemustbe well insulate d, water and air tight. A

chimney with a cold internal surface can prevent a

good chimney draught and condensation will occur.

•The flue must be watertight.

•The chimney must have a constant cross section.

1

3

2

2b

2c

4

5

2a

A

F

B

E

C

D

G

Figure 3 - Burner

1 - Air holes

2 - Catalyser

2a - Upper ring

2b - Catalyser top

2c - Catalyser body

3 - Burner pot

4 - Automatic ignition

(optional)

5 - De-scaling lever

Figure 4 - Float regulator

A - Control knob

B - Safety lever.

C - Main float

D - Safety float

E - Oil level regulator

F - Thermostat control

G - Filter

Installation instructionsSavoie - ref. 174 08 02 Y

4 Technical manual "1038"

•The flue must not be shared with any other appliance.

•The chimney m ust be at l eas t 4.5 m (15 ft high).

•If the chimney has any downdraught tendency, due to

its position in relation to nearby obstacles, an

anti-downdraught cowl must be installed on the

chimney or the chimney height must be increased.

•If the chimney draught is excessive or irregular, a

draught stabili zer (barometric damper) must be

installed to the connector pipe.

2.4.Mounting the levelling feet

Figure 5, # 4

Fit the 4 screws and caps supplied on the burner into

each leg of the stove.

2.5. Smoke exit

Figure 5 and 6

The rear exchanger is reversible (2 screws) so that the

smoke exit can be done at rear or on the top

2.6.Chimney connector

•The appliance must be as c lose as possible to the

chimney.

•The connector pipe must be approved for installation

with combustion products (either 24 ga. Black painted

or blued steel or 316 grade 20 ga. Stainless steel or

1 mm vitreous enamelled steel).

•Pipe diameter must not be less than the appliance

spigot diameter.

•The join between the connection pipe and the

stovepipe, and the flue, must be leak tight.

•The connection pipe and any draught stabiliser must

have access for cleaning.

2.7.Levelling

It is essential to ensure that the appliance sits level on

the floor.

- Use a spirit level across the burner pot to check the

level (fig. 7).

3

1

6

4

4

2

5

Figure 5 - Description

1 - Flue collar

2 - Blanking plate

3 - Draught regulator

4 - Control screws for

appliance leveling

5 - Flue baffle

6 - Burner

Figure 6 - Rear flue outlet

1 - Flue collar 2 - Blanking plate

2

1

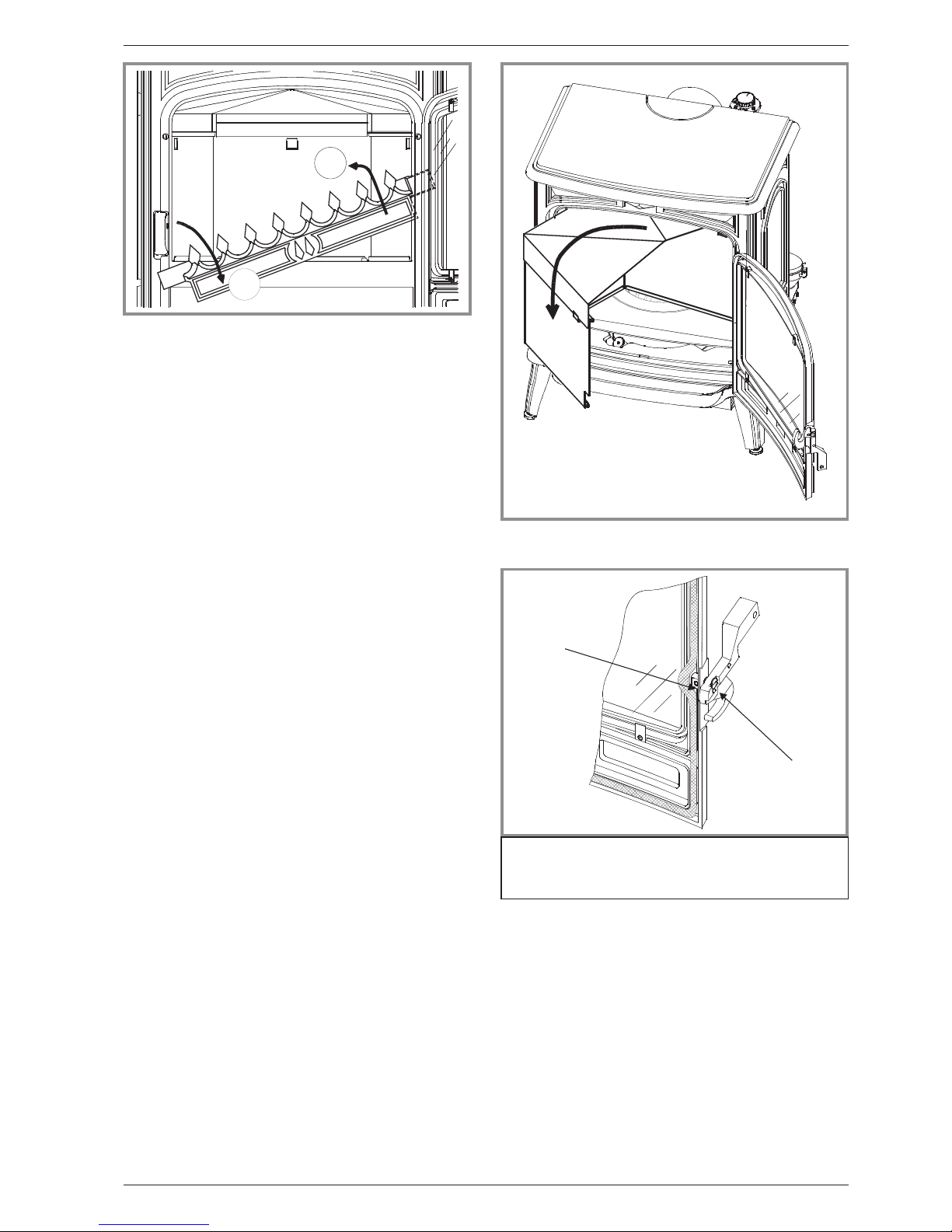

Figure 7 - Burner level check

Installation ins tructionsSavoie - ref. 174 08 02 Y

Technical manual "1038" 5

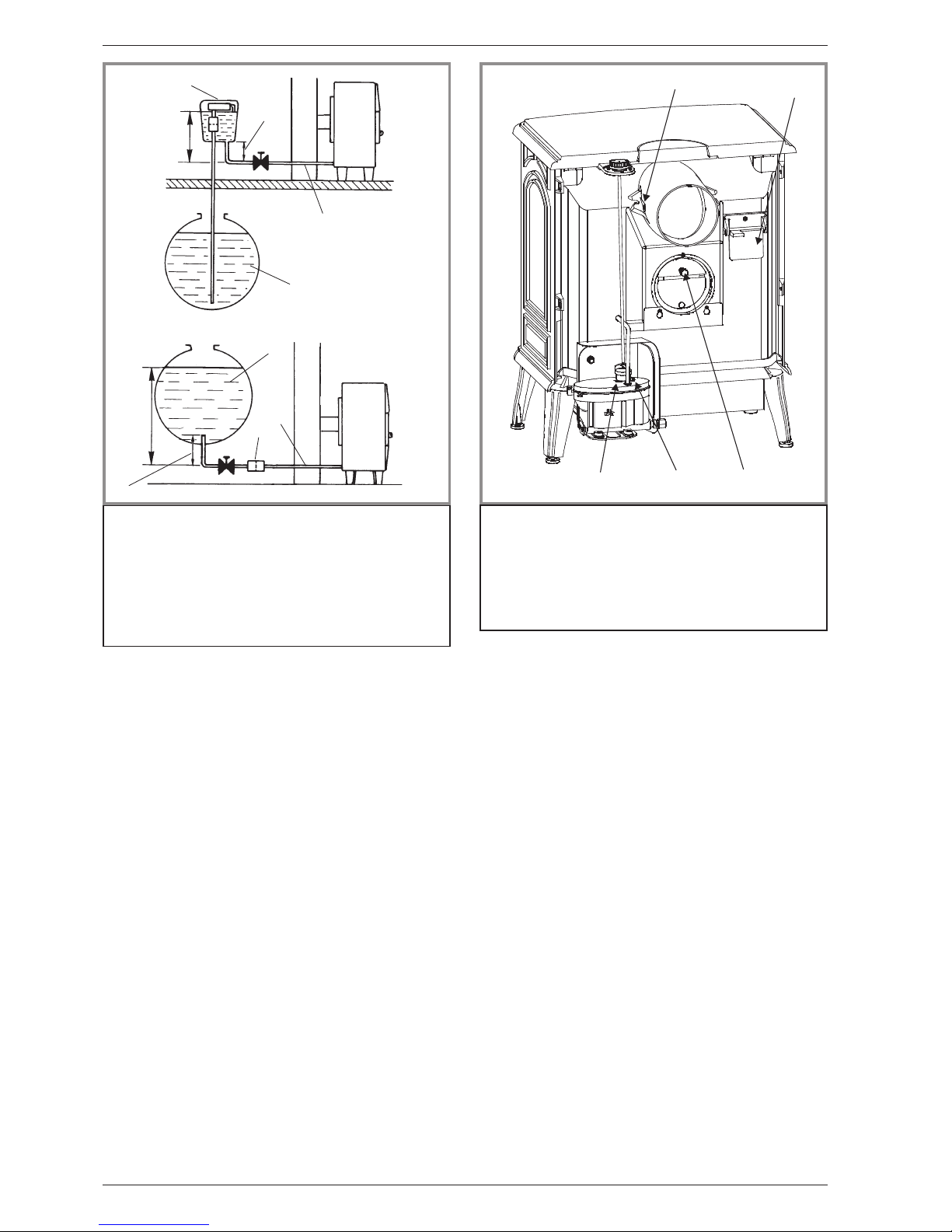

2.8. External / remote tank

Figure 8

•A barometric fuel tankshouldnot be positionnedwhere

it will be in the direct rays of the sun or adjacent to a

source of intense heat.

•If the tank is more than 8 ft (2,5 m) higher than the

stove a pressure reducer must be installed on the oil

line (max. working pressure : 300 mbar).

•If the tank is lower than the stove a lift pump will have

to be utilized.

•A clearance of6 “ (15cm) must bemaintainedbetween

the external/remote tank and the stove.

2.9.Pre-utilization check

- Check that the glasses are not damaged.

- Check that the door closes correctly.

- Check that all removable parts (baffle, catalyser, ring,

etc.) are correctly installed.

- Check that the seals of the smoke-line are in good

condition.

- Ch eck that the seals of the feed-line are in good

condition.

- Light the appliance by referring to the operating

instructions.

2.10. Oil flow adj ust ment

The floatregulator has been adjustedat thefactory and

should not need further adjustment.

The eventu al re-fit must be realized by a qualified

engineer.

If the burner does not work correctly, check possible

causes before readjusting the settings :

- Chimney draught

- Fresh air inlet

- Oil supply.

Minimum speed (# 3, fig. 9) :

- Set the regulating knob on minimum speed (# 3) and

let the burner run for a few minutes. The flame must

completely cover the bottom of the burner and the

catalyser body must be glowing red hot.

- If the flame is too small, the stove will soot up

quickly ; increase the flame by turning the setting

screw (# 3) clockwise.

- If the flame is toohigh, reducethe flame by turning the

setting screw (# 3) counter clockwise.

Maximum speed (# 2, fig. 9) :

- Set the regulating knob on maximum speed (# 2) and

let the burnerrun for afew minutes. Theflamemust be

shaped like a cone and reach the upper part of the

door.

- If theflameis toolow,increase theflameby turning the

setting screw (# 2) counter clockwise.

- If theflame is toohigh,reduce theflame[by turning the

setting screw (# 2) clockwise.

Figure 8 - Gravity oil supply

Pumped oil supply

1 -Max.2,5m

2 -Min.0,25m

3 - Tank

4 -Filter

5 - Suction pomp with

reserve and filter

6 - Pipe 3/8 in. O.D.

5

1

2

6

3

1

3

6

4

2

123

4

5

Figure 9 - Adjustment devices

1 - Adjustment of the

draught regulator

2 - Adjustment screw for

high setting

3 - Adjustment screw for

low setting

4 - Safety pressure door

5 - Draught control

Installation instructionsSavoie - ref. 174 08 02 Y

6 Technical manual "1038"

Please note - Very important : The adjustments of the

float regulator are very sensitive. The high and the low

setting screws must never be turned more thana 1/4 of

a turn at a time in any direction from their initial setting.

When making any adjustments, allow 3 to 5 minutes

between adjustments to allow burner to stabilize to

previous adjustment before proceeding, if necessary.

2.11. Chimney draft required

The reading of the draught must be done once the unit

is hot (minimum 30 minutes of use).

Refer to the specifications (page 3) fo r min im um

draught requirement. The eventual re-fit must be

realized by a qualified engineer.

The adjustment of the draught will be made with the

barometricdamper located at the backof the stove(# 1,

fig. 9)

2.12. Maintenance of the Chimney

Chimney condition should be checkedat leastonce per

year.

If the appliance is regularly used, the chimney should

be swept several times per year, together with the

stovepipeconnection section (andalso the fluebaffles).

- First remove the flue baffle (fig. 11)

- The barometric damper (draught regulator # 1, fig. 9)

should be checked at least once per year.

2.13. Door closing pressure

Figure 12

The closing latch rotates around a pressure screw

positioned cam.

- Remove gently the ceramics rope,

- Loosen pressure screw (# 1),

- Turn cam (# 2) to desired position,

- Tighten pressure screw (# 1).

1

2

1

2

Figure 10 - Removing the front grate

Figure 11 - Removing the flue baffle

Figure 12 - Door closing pressure

1 - Pressure screw

2 -Cam

Installation ins tructionsSavoie - ref. 174 08 02 Y

Technical manual "1038" 7

2.14. Removing the burner

To remove the burner :Remove the lower paneland the

magnet support, disconnect the feed line from the

de-scaler nut, unscrew the 4 burner fixing nuts.

3.Instructions for user

Franco Belge will not be responsible for damages on

parts of the appliance due to the useof prohibited fuel

or d ue to an alteration of the appliance or its

installation.

3.1.Fuel

Your stove is fitted with a specific float regulator for a

specific oil.

The fuel oil must be free from any dirt and water,which

could disturb the stove in operation.

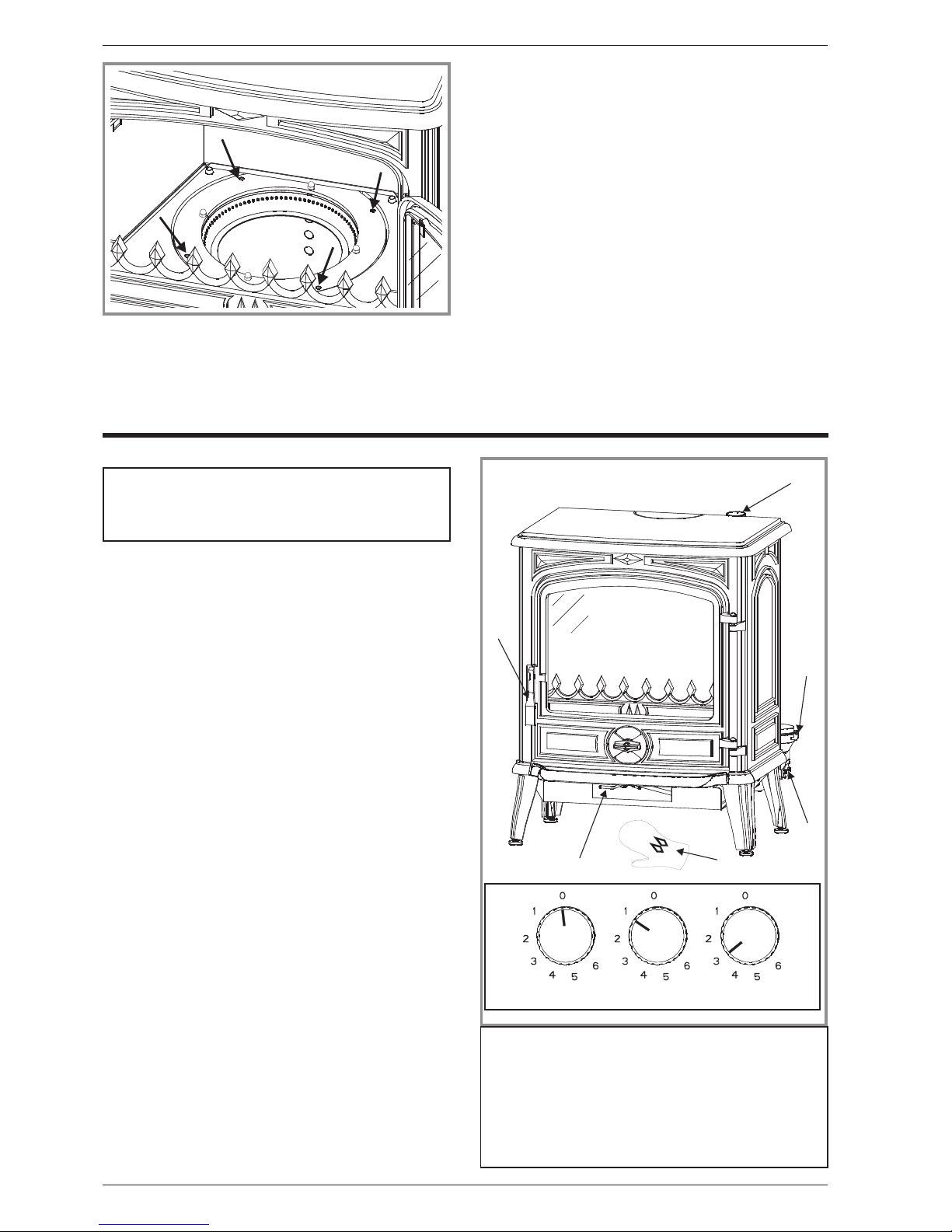

3.2.Lighting procedure

Figure 14

Don’t light the appliance when it is hot. Wait until the

burner is completely cool before repeating the lighting

procedure.

- Be sure the control knob (# 2A) is to “0".

- Turn on oil supply,

- Push down gently on the safety lever (# 4). This will

allow the oil to flow into the float regulator.

- Open the front door, and remove the catalyser from

burner(#2,3,4,fig.3,p.4).Makesuretheinsideof

the pot is clean thoroughly, and there is no oil

accumulation.

- Place 2 tablespoons of methylated spirit or gelled

alcohol in the bottom of the pot.

- Light thestartergel or methylatedspiritwith a fireplace

match or long butane lighter.

- Place the catalyser back into the burner, being sure it

is centered in the burner. Shut the main door.

- Allow the burner to heat approximately 30 to 45 sec.

Turn dial to “1" position (# 2B).

- Allow 10 to 15 minutes for oil fire and draught to

stabilize. The catalyser (or the ring) should glow red

before adjusting the control knob to a higher setting

(# 2C).

6

4

2

5

3

Figure 14 - Operating devices

1 - Gant de protection

2 - Regulation knob.

2A - Shutting down

2B - Lighting procedure

2C - Normal speed

3 - Opening and closing

of the window

4 - Safety lever.

5 - Access to regulator’s

filter

6 - De-scaling lever.

2A

2B

2C

1

Figure 13 - Removing the burner

Instructions for userSavoie - ref. 174 08 02 Y

8 Technical manual "1038"

3.3.Operating procedure

•Allow 10 to 15 minutes after lighting to adjust the

control knob to a higher setting, usually (# 2C) setting.

•When increasing the heat output, move the control

knob only 1 number at a time, allowing 5 minutes

between moves for the flame to re-adjust to new

setting.

•If the burner stops during operating, immediately turn

offthe control knobposition“0" (#2A)and waituntilthe

burner is completely cool before repeating the lighting

procedure.

3.4.Shutting down

Figure 14

- Set dial to the (# 2A) position.

- Raise the safety lever of the regulator (# 4).

- Allow the flame to burn out completely before opening

the door (# 3).

3.5.Recommendations

•The adjustment of the stove has been made at the

factory and checked byyour installer.In caseoftrouble

shooting, do the usual maintenance operations. If

problem persists call your installer.

•This room heater is a high heat producing appliance

and may cause severe burns if touched on the glass

front door, or on top directly over the burner - keep

children away.

•CAUTION : Never light th e burner if there is any

amount of oil in pot. Clean out oil before lighting.

•Too much oil in pot may cause a racing : a very high

flame generating vibrations.

In case of racing :

- Turn off oil supply.

- Set dial to the “0" position (# 2A, fig. 14, p. 8).

- Wait until the burner is completely cool before

repeating the lighting procedure.

•Do notoverfire.If the unitor chimney connector starts

to glow you are overfiring.

3.6.Maintenance of the stove

•Everyweek:operate the de-scaling lever (# 6, fig. 14,

p. 8). Pull the rod, then push the rod in rotating 360

degrees two or three times.

(CAUTION : The rod is HOT).

•Every3or4months: Clean the burner completely.

- Remove and brush off the parts of the catalyser, using

a soft bristle brush.

- Loosen any carbon soot from the burner with a putty

knife, and vacuum clean. Ensure that the small air

holes are free of carbon.

- When replacingtheburner,tightenthe nuts evenly and

connect the pipe so as to be airtight.

•At least once a year / Endof heatingseason : Clean

or replace the oil filters of the oil supply line (# 5,

fig. 14, p. 8).

To clean the filter of the float regulator :

- Set the regulation knob in closed position “0" (# 2A,

fig. 14, p. 8).

- Turn o ff the tankvalveor the valveof the oilsupplyline.

- Raise the safety lever of the float regulator (# 4,

fig. 14, p. 8).

- Place a small container (or a small rag) under the

regulator filter opening in order to collect the oil

contained in the regulator.

- Remove the filter cover plate located under the

regulator (# 5, fig. 14, p. 8) with a screwdriver,

- Remove the tubular filter from the regulator. Clean it

with oil using a soft brush, never a wire-brush.

- Replace the filter in the regulator, install the cover

plate and secure with the screw.

¤ Use a soft clean cloth to wipethe frontglass whenthe

unit is running at a low burning rate.

¤ When the main door is opened for cleaning, the flame

will be disturb,and turnto a yellowflame. Clean quickly,

but gently. Close the door, the flame will return to a

normal burning position.

¤ Clean all the enamelledpanels of thestove with a dry

or slightly damp soft cloth.

DO NOT CLEAN GLASS WHEN HOT.

Instructions for userSavoie - ref. 174 08 02 Y

Technical manual "1038" 9

Loading...

Loading...