FRANCO BELGE Hekla 634 10 44, Hekla 634 10 45 Technical Manual

Description of the appliance

Installation instructions

Operating instructions

Spare parts

Warranty certificate

Document n° 1204-1 ~ 02/05/2005

STAUB FONDERIE

SARL with the capital of 6 359 540

Head Office Address

2, rue Saint Gilles

68230 TURCKHEIM

RCS Colmar

SIREN 444 881 953

Address

Administration and manufacturing

BP 73

59660 MERVILLE (FRANCE)

Telephone : 00 333 28 43 43 00

Fax : 00 333 28 43 43 99

Subject to modifications.

Hekla

Insert fire

IGBsfIn-NFD35-376

Model : 634 10 44

Model : 634 10 45

ES EN NL PL IT

FR IT EN NL PT

Technical manual

to be saved

by the user

for future reference

2 Technical manual “1204”

“Hekla” - ref. 634 10 44/634 10 45

CONTENTS

Description of the unit ...................................p.3

Specifications . . . . . . . . . . . . . . . p. 3

Optional equipment. . . . . . . . . . . . p. 3

Description . . . . . . . . . . . . . . . . p. 4

Working principle . . . . . . . . . . . . . p. 4

Installation instructions...................................p.5

The room . . . . . . . . . . . . . . . . . p. 5

Flue . . . . . . . . . . . . . . . . . . . . p. 5

Connection to flue . . . . . . . . . . . . p. 5

Chimney built around the hearth . . . . p. 6

Insertion inside an existing chimney . . p. 6

Electrical connection . . . . . . . . . . . p. 8

Hot air outlets . . . . . . . . . . . . . . . p. 8

Flue baffle mounting . . . . . . . . . . . p. 9

Access to the fans . . . . . . . . . . . . p. 9

Maintenance of the chimney . . . . . . . p. 9

User instructions ......................................p.10

Fuel . . . . . . . . . . . . . . . . . . . p. 10

Lighting . . . . . . . . . . . . . . . . . p. 10

Air convection principle . . . . . . . . . p. 10

Combustion . . . . . . . . . . . . . . . p. 10

De-ashing . . . . . . . . . . . . . . . . p. 11

Recommendations . . . . . . . . . . . p. 11

Cleaning of the insert fire. . . . . . . . p. 11

Trouble shooting . . . . . . . . . . . . p. 11

Spare parts .........................................p.12

FRANCO BELGE congratulates you on your choice.

FRANCO BELGE, which has been granted the ISO 9001 certification, guarantees the quality of its

appliances and is committed to meet its customers’ needs.

FRANCO BELGE, which can boast a 75-year experience in the industry of heating devices, uses

state-of-the-art technologies

to design and manufacture its whole range of products.

This document contains instructions on how to install your appliance and make full use of its

functions, both for your comfort and safety.

Warning to the user

A wood stove should only be installed by competent personnel, in the strict application of

normal practices and all safety precautions.

An incorrectly installed wood stove can cause serious accidents (chimney fires, burning of

plastic insulation materials, in partition walls, etc.).

The manufacturer’s responsibility shall be limited to the supply of the equipment.

1. Description of the unit

1.1.

Specifications

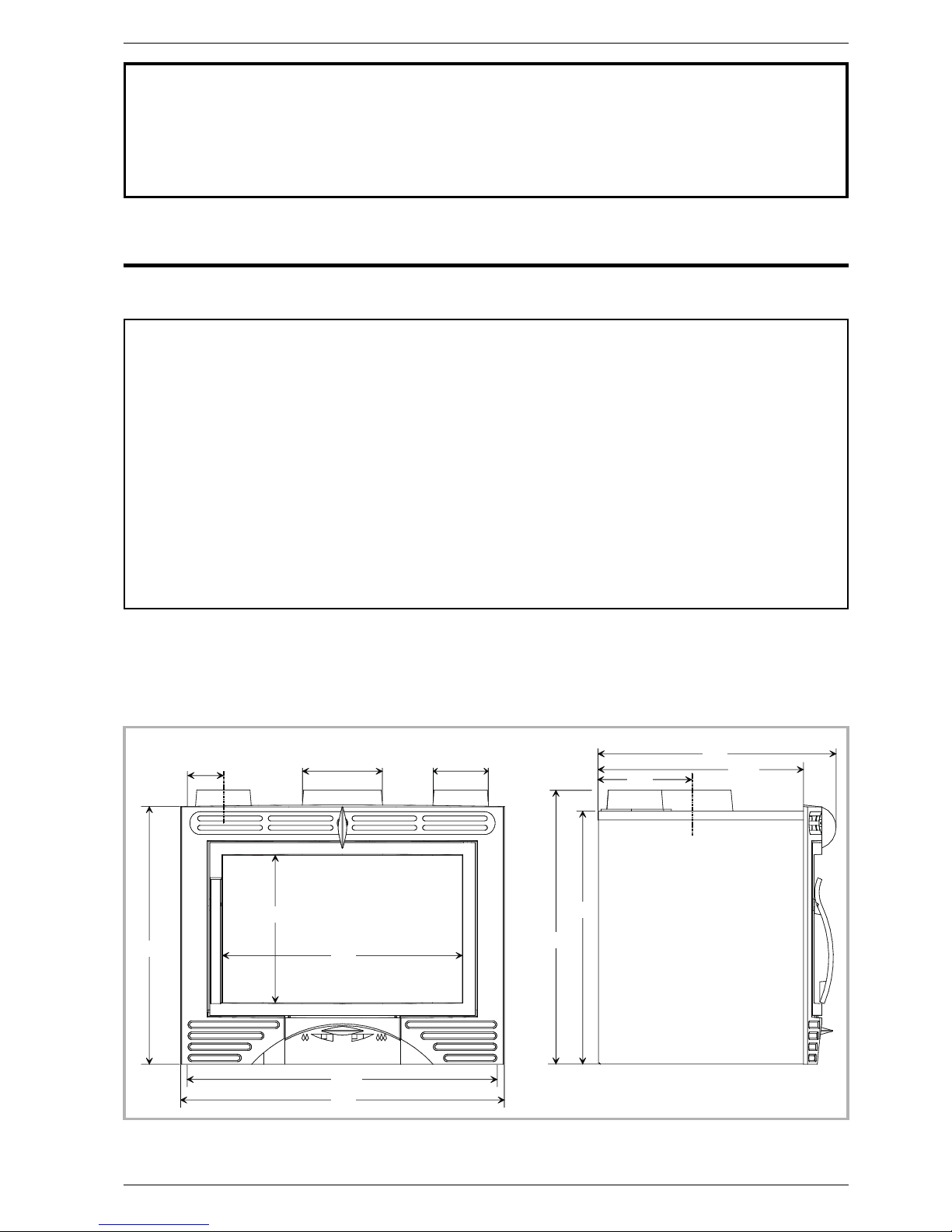

Model .....................................6341044 ......6341045

Normal heat output ....................kW..........10...........10

Firebox dimensions

width x depth x height .................. mm.......585x325x350.....585x325x350

Logs dimensions :

- length...........................cm..........50...........50

- diameter .........................cm........10to16 .......10to16

Ash pan capacity ....................liters .........2,5..........2,5

Weight ...........................kg.........115..........115

Autonomy at minimum rate ................hr..........7...........7

Corrected heating volume.................m

3

.........400..........400

Firebox draught at maximum rate ............Pa..........10...........10

Firebox draught at minimum rate .............Pa..........5 ...........5

Fans

- voltage (~ 50 Hz) .....................V.........230...........-

- Electrical power consumed................W.........2x35..........-

1.2. Optional equipment

-

Kit variator of speed for the ventilation

-

Kit handle brassplated (KP 1013 D) or chrome (KP 1013 N)

Technical manual “1204” 3

“Hekla” - ref. 634 10 44/634 10 45 Description of the unit

581

333

541

730

703 *

571 *

537

464 *

213

82

619

O.D.

O.D.

Ø180

ext.

Ø125

ext.

Figure 1 - Dimensions in mm

* Part to insert

1.3. Description

Insert fire,IGBsfIn-NFD35-375

I : Intermittent-burning heating appliance.

G : Wood burnt on grate

B : Wood burning

sf : semi-close cast iron firebox with a decorated

hearth plate and fire dogs.

In : Insert fire

•

Hot air convector made of double stainless steel walls

forming the heat exchanger.

•

(model 634 10 44 only) Two fans with automatic start to

accelerate the hot air convection.

•

A door made of “vitroceramic” glass which can resist to

temperatures of up to 750° C and also acts as a sparks

guard.

•

Combustion speed regulated with an air flap situated

on the main door.

•

Draught flue damper with a frontal control.

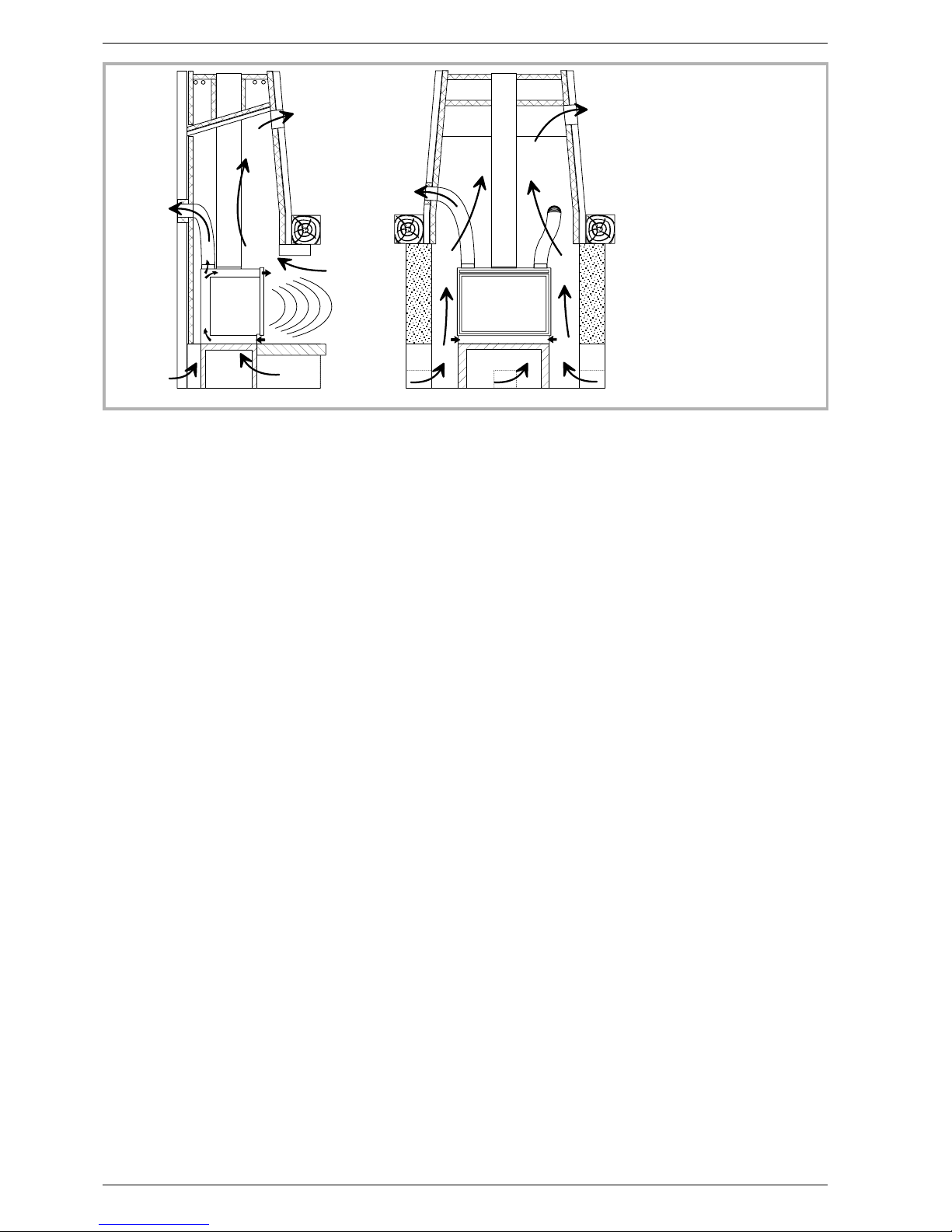

1.4. Working principle

The insert is made to fit into an existing chimney. It can

also be used as the hearth of a chimney about to be

built.

Strong heat will come through the glass door by

radiation.

The air is collected at the bottom of the appliance

around the ash pan, spreads around the fire where it

becomes hot and is passed out at the top of the unit to

convect its efficiently heated air around the room.

(model 634 10 44 only) The air leaving the heat

exchanger is accelereted by the automatic start of the

fans when the hot air temperature is more than 50 °C.

The fans stop when the air temperature fall down.

The speed is regulated with the primary air flap situated

on the main door.

A clever secondary air inlet around the glass door

completes the combustion of volatile components and

allows the door to remain clean.

The flue damper allows and even combustion speed

depending on the chimney draught.

4 Technical manual “1204”

“Hekla” - ref. 634 10 44/634 10 45 Description of the unit

1

1

2

2

2

2

2

2

1

1

2

1

3

Figure 2 - Heating principle

1 - Hot air diffusion

2 - Ambiant air

3 - Radiation

2. Installation instructions

2.1. The room

Ventilation :

For satisfactory operation with a natural draught, check

that sufficient air for combustion is available in the

room.

Chimney position :

For new chimney installations, select a central position

within the building, to provide a good heat distribution

around the building.

Hearth :

The hearth must be suitable for use with solid fuel

burning appliances and must comply with Current

Building Regulations. If in doubt, consult your Dealer or

local Building Inspector.

Rear wall and ceiling :

The appliance must not be positioned close to

combustible materials, wall & ceiling surfaces etc..,

Consult your Dealer or local Building Inspector if in

doubt.

2.2. Flue

Existing flue :

-

The flue must be in good condition and must provide

sufficient draught.

-

The flue must be suitable for the installation of solid

fuel burning appliances and comply with Current

Building Regulations.

-

The flue must be clean. It should be swept to remove

soot and dislodge tar deposits.

-

The flue must be well insulated. If the flue inner wall

surfaces are cold, a good thermal draw is impossible

causing condensation problems (tar formation etc).

-

The flue must not be shared with other appliances.

-

The recommended minimum flue height is 5 metres.

-

If the chimney has any down draught tendency, due to

its position in relation to nearby obstacles, an

anti-down draught cowl must be installed on the

chimney or the chimney height must be increased.

-

If the decompression in the chimney is excessive, a

draught stabiliser must be installed.

Chimney to be built / Flue non-existent :

-

The stove must not support the weight of the flue.

-

Consult a chimney specialist for advice on suitable

flue systems for solid fuel appliances.

2.3. Connection to flue

-

The stove must be installed as close as possible to the

chimney.

-

The stove should be connected to the flue by a smoke

pipe, approved for installation with combustion

products (e.g. 360 stainless steel 1 mm thick or

vitreous enamel.).

-

Pipe diameter must not be less than the appliance

spigot diameter.

-

The connection can be either vertical or horizontal. For

horizontal connections, avoid right angle bends.

-

The join between the connection pipe and the

stovepipe, and the flue, must be leak tight.

-

The connection pipe and any draught stabiliser must

have access for cleaning

Technical manual “1204” 5

“Hekla” - ref. 634 10 44/634 10 45 Installation instructions

4 0 c m

8 m

4 0 c m

4 0 c m

8 m

1 , 2 m

p e n t e < 1 5 °

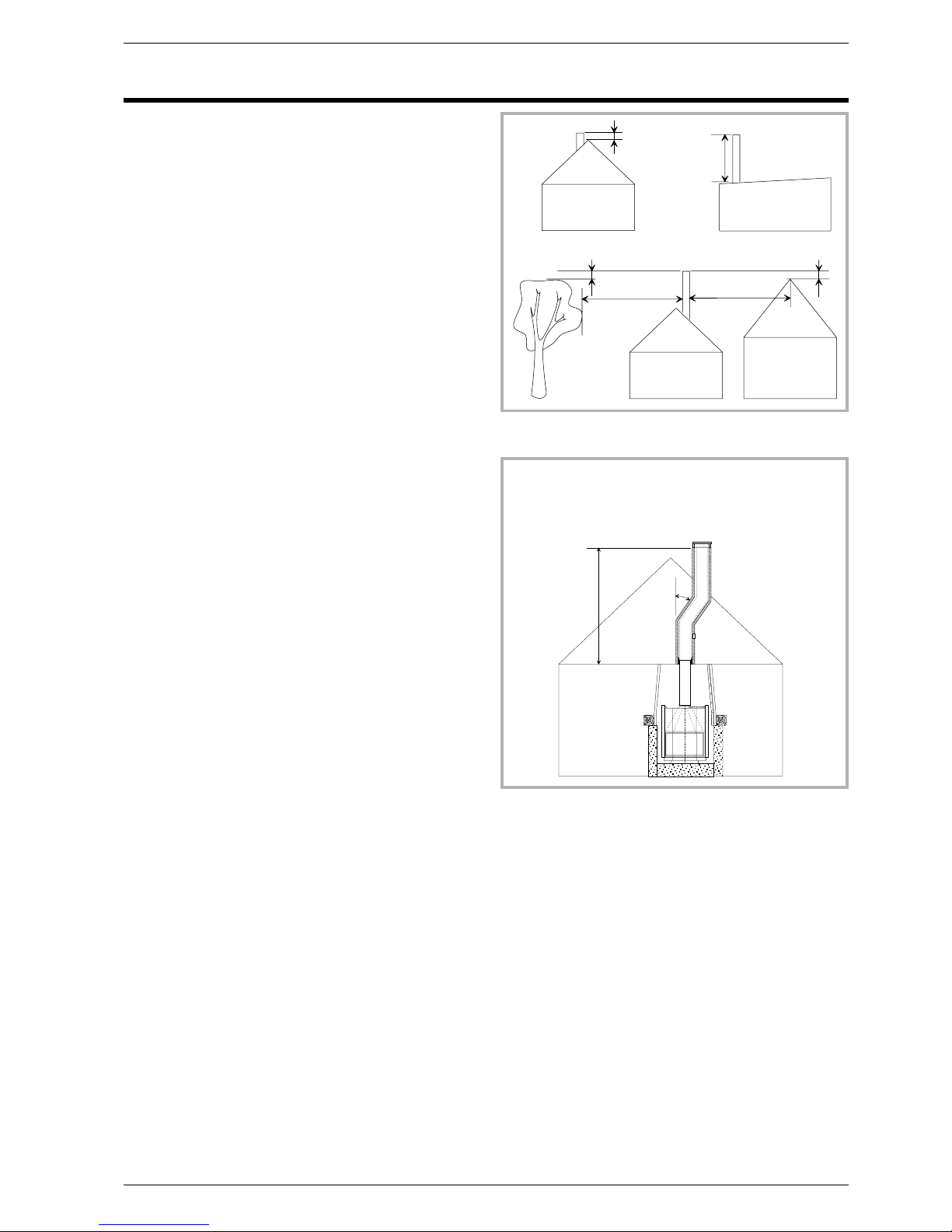

Figure 3 - Flue upper section height

H

=

=

=

< 4 5 ° s i H < 5 m

2 0 ° <

< 2 0 °

Figure 4 - Flue offset

Loading...

Loading...