FRANCO BELGE Burgundy 174 10 25, Burgundy 174 10 31 Technical Manual

Technicalmanual

tobesaved

bytheuser

forfuturereference

Documentn°809-5EN~15/04/1999

LesFonderiesFranco-Belges

59660MERVILLE

Phone:03.28.43.43.43

Fax:03.28.43.43.99

RCHazebrouck445750565B

Subjecttomodifications

Burgundy

Oilburningstove

1741025

1741031

EN1-NFD35-385

Françaisp.1-12

Englishp.13-24

Descriptionoftheappliance

Installationinstructions

Operatinginstructions

Spareparts

Warrantycertificate

Nederlandsbl.25-36

Descriptionoftheunit...................15

Package.............................15

Specifications..........................15

Description...........................15

Installationinstructions..................16

Positionoftheunit.......................16

Chimney.............................16

Chimneyconnector.......................16

Levelling ............................16

Mountingthetray........................16

Fittingofthehandle......................16

Fittingthe“visioflamme”....................16

Externaltank..........................17

Oilflowadjustment.......................17

Chimneydraught........................18

MaintenanceoftheChimney.................18

Operatinginstructions...................19

Fuel...............................19

Lightingprocedure.......................19

Operatingprocedure......................19

Shuttingdown.........................19

Recommendation........................19

Maintenanceofthestove...................19

Troubleshooting........................20

Spareparts.........................21

Page

CONTENTS

Documentn°809-5EN~15/04/1999

Burgundy Oilburningstove

14 Technicalmanual

1.Descriptionoftheunit

1.1.Package

-1package:Stovecomplete

-1package:Groundvatandmirrors

1.2.Specifications

NominalHeatOutput(NFD35-385)

........................kW 10

......................Btu/hr 34,130

Oilconsumptionat:...............

-maximumspeed.............litre/h 1,25

....................Impgal/hr 0.275

....................USgal/hr 0.33

-minimumspeed.............litre/h 0,25

....................Impgal/hr 0.055

....................USgal/hr 0.066

Chimneydraftrequiredat:...........

-maximumspeed..............Pa 20

......................in.w.g. 0.0802

-minimumspeed..............Pa 6

......................in.w.g. 0.024

Weight....................kg 118

........................lbs 260

Flueoutletdiameter(O/D).........mm 120/125

.........................in 5

1.3.Description

Fluedoilstovewithvaporizingburner(NormEN1)

Ø120/125mm

(5")

620mm(241/2")

402mm(16")

544mm(211/2")

505mm

(20")

678mm

(27")

383mm(15")

Ill.1-Dimensionsinmm

SAFETYNOTICE:Readcarefullyallinstru ction s

beforestartingtheinstallation.Ifthestoveisnot

properlyinstalled,ahousefiremayresult.Foryour

safety,followtheinstallationdirections.Contactlocal

buildingorfireofficialsaboutr estrictionsand

installationinspectioninyourarea.

Documentn°809-5EN~15/04/1999

Oilburningstove Burgundy

Technicalmanual 15

2.Installationinstructions

2.1.Positionoftheunit

-Thepositionoftheappliancemustbechosenverycarefullyinordertoobtainthebestpossibleresultsforheat

distribution.

-Positiontheunittocomplywiththeminimumclearances

tocombustiblematerial.Minimumclearancesareshown

fromtheverticalportionofthechimneyconnector.Check

thatnooverheadcrossmembersintheceilingwillbecut.

Repositionunitifnecessary,beingcarefulnottomove

closerthantheminimumclearances.

2.2.Chimney

-Ensurethatthefluehassufficientdraught(refertotechnicaldetails).

-Minimumfluediameter,10cm(4"I.D).

-Thechimneymustbeatleast4.5m(15fthigh).

-Thefluemustnotbesharedwithanyotherappliance.

-Downdraughtscausedbyobstaclesclosetothechimney

topmaysometimesbepreventedbyfittingananti-downdraughtcaptothetopofthechimney.

-Thechimneymusthaveaconstantcrosssection.Too

largeafluecouldaffectthechimneydraught.

-Thechimneymustbesoundlyconstructed,inorderto

preventcoldairinfiltration.

-Thefluemustbewellinsulated,waterandairtight.A

chimneywithacoldinternalsurfacecanpreventagood

chimneydraughtandcondensationwilloccur.

-Thefluemustbesweptatleastonceayear.

2.3.Chimneyconnector

-Theappliancemustbeascloseaspossibletothechimney.Avoidhorizontalflueconnectionpipeswhichcan

dangerouslyrestrainfunctioningoftheappliance.

-Theconnectorpipeshouldbestandardblackpaintedor

bluedsteelpipeofnotlessthan30gage;304grade

stainlesssteelofnotlessthan30gage;or1mmviterous

enamelledsteel,withamaximumdiameterof5inchO.D.

-(127mm).Itistheinstaller’sresponsabilitytoconformto

localbuildingstandardsandrequirementswithregardto

installation..Singlewallpipemaybeutilizedbeingcareful

tomaintainclearancestoanycombustiblesurface.

Oncethestovehasbeenproperlyinstalledthechimney

draughtmustbecheckedwithadraughtmeter.

Ifthechimneydraughtisexcessiveorirregular,adraught

stabilizer(barometricdamper)mustbeinstalledtothe

connectorpipe.

2.4.Levelling

Figure3and4

Itisessentialthattheappliancesitslevelonthefloor.Fit

the4screwsandthe4capssupplied(ontheburner)on

thefeet.Useaspiritleveltocheck.

2.5.Mountingthetray

Figure6

Toavoiddamagetotheashtrayduringtransport,ithas

beendisconnectedandstoredbehindthemaindoorofthe

oilstove.Toreinstalltheashtraytothefrontoftheoil

stove,tiltthetrayata45°angle,centerontotab‘A’and

lowerintoplace.

2.6.Fittingofthehandle

Figure5

Inordertoavoidthedamagingofthethreading,firstput

thehandleinoperatingpositionthenscrewitintothe

tapingofthelock.

2.7.Fittingthe“visioflamme”

Fittheglasses(#59,p.22)ontothereflector(#28,p.22).

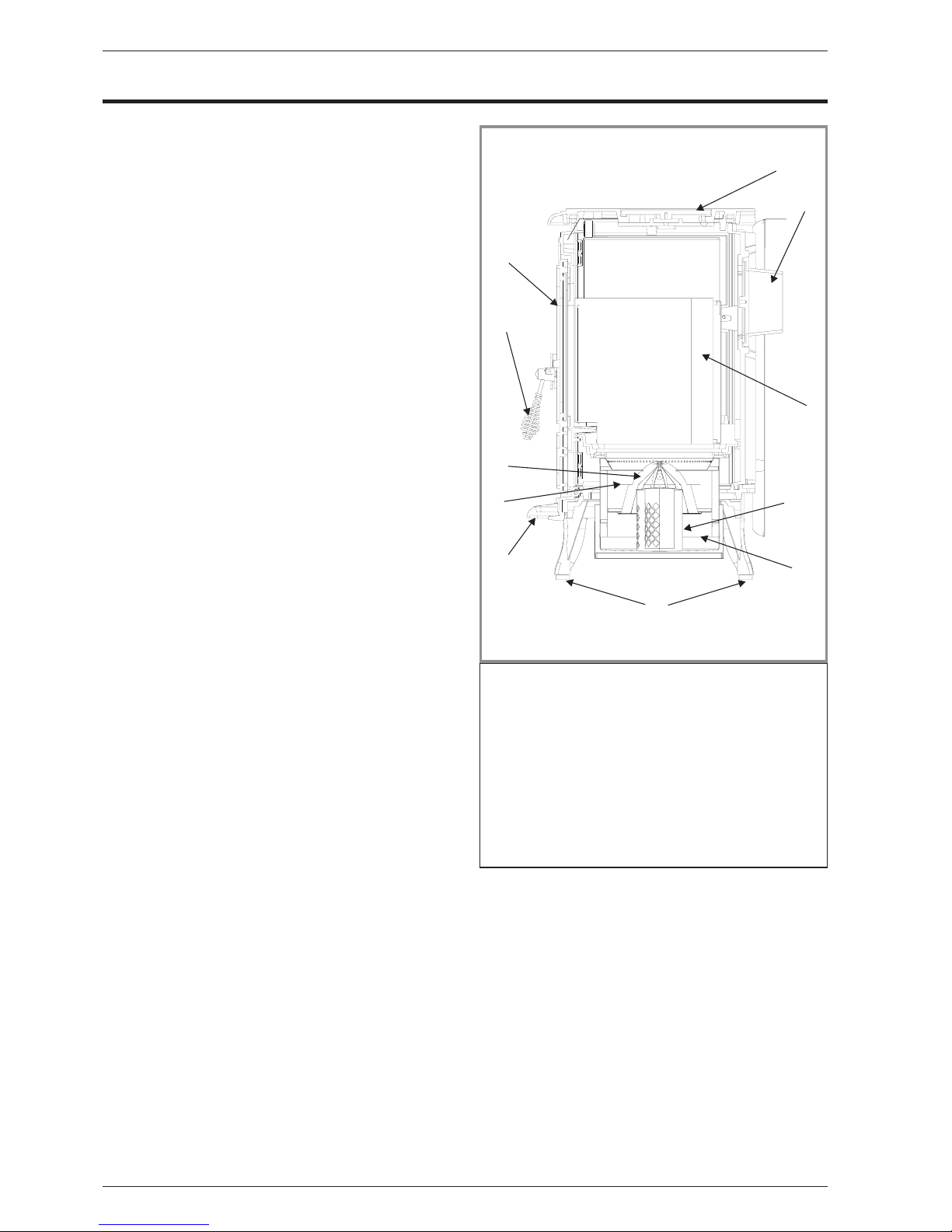

7

2

3

4

5

6

9

8

10

1

11

Ill.2-Cross section

1-Blankingplate

(notprovidedtobe

connectedtothe

chimney).

2-Maindoor.

3-Openingandclosing

ofthelowerdoor.

4-Catalysertop.

5-Upperring.

6-Catalyser.

7-Fluecollar.

8-Reflector.

9-Burner.

10-Tray

11-Screws

Documentn°809-5EN~15/04/1999

Burgundy Oilburningstove

16 Technicalmanual

Loading...

Loading...