FRANCO BELGE Bourgogne Technical Manual

Description of the appliance

Installation instructions

Operating instructions

Spare parts

Warranty certificate

Document n° 1091-6 ~ 25/10/2005

Bourgogne

Oil burning stove

Ref. 174 10 56

(NF EN 1)

Technical manual

to be saved

by the user

for future reference

STAUB FONDERIE

SARL with the capital of 6 359 540 &

Head Office Address

2, rue Saint Gilles

68230 TURCKHEIM

RCS Colmar

SIREN 444 881 953

Address

Administration and manufacturing

BP 73

59660 MERVILLE (FRANCE)

Telephone : 00 333 28 43 43 00

Fax : 00 333 28 43 43 99

Subject to modifications.

2 Technical manual “1091”

“Bourgogne” ref. : 174 10 56

CONTENTS

Description of the unit ...................................P.3

Description ................P.3

Package..................P.3

Optional equipment ...........P.3

Specifications. . . . . . . . . . . . . . . P. 3

Operating principle . . . . . . . . . . . . P. 4

Installation instructions...................................P.5

Warning to the user ...........P.5

Location of the unit............P.5

Chimney .................P.5

Smoke exit ................P.6

Chimney connector............P.6

Levelling .................P.6

External / remote tank ..........P.6

Pre-utilization check . . . . . . . . . . . P. 7

Oil flows adjustment . . . . . . . . . . . P. 7

Mounting the tray. . . . . . . . . . . . . P. 8

Chimney draught . . . . . . . . . . . . . P. 8

Maintenance of the Chimney . . . . . . P. 8

Fitting the “visioflamme” (optional) . . . P. 8

Instructions for user.....................................P.9

Fuel ....................P.9

Lighting ..................P.9

Operating procedure ...........P.9

Shutting down ..............P.9

Recommendations . . . . . . . . . . . P. 10

Maintenance of the stove. . . . . . . . P. 10

Removing the burner . . . . . . . . . . P. 10

Trouble shooting . . . . . . . . . . . . P. 11

Spare parts .........................................P.12

FRANCO BELGE congratulates you on your choice.

FRANCO BELGE, which has been granted the ISO 9001 certification, guarantees the

quality of its appliances and is committed to meet its customers’ needs.

FRANCO BELGE, which can boast a 75-year experience in the industry of heating devices,

uses state-of-the-art technologies

to design and manufacture its whole range of products.

This document contains instructions on how to install your appliance and make full use of

its functions, both for your comfort and safety.

This appliance is an oil-fired stove.

WARNING

An incorrectly installed oil-fired stove can cause serious accidents.

This appliance should only be installed by competent personnel.

1. Description of the unit

1.1. Description

Flued oil stove with vaporizing burner. (Norm EN1)

1.2. Package

•

1 package : Stove

1.3. Optional equipment

•

1 package : Visioflamme (mirrors : P 174 10 53)

•

1 package : Glow-plug ignitor

•

1 package : Coals kit (FC 0802)

1.4. Specifications

Model ................. 1741056

Nominal Heat Output .......kW 10

Oil consumption

at maximum speed .......litre/hr 1,27

at minimum speed .......litre/hr 0,25

Chimney draft required

at maximum speed .........Pa 17

at minimum speed .........Pa 8

Weight ................kg 118

Technical manual “1091” 3

“Bourgogne” ref. : 174 10 56 Description of the unit

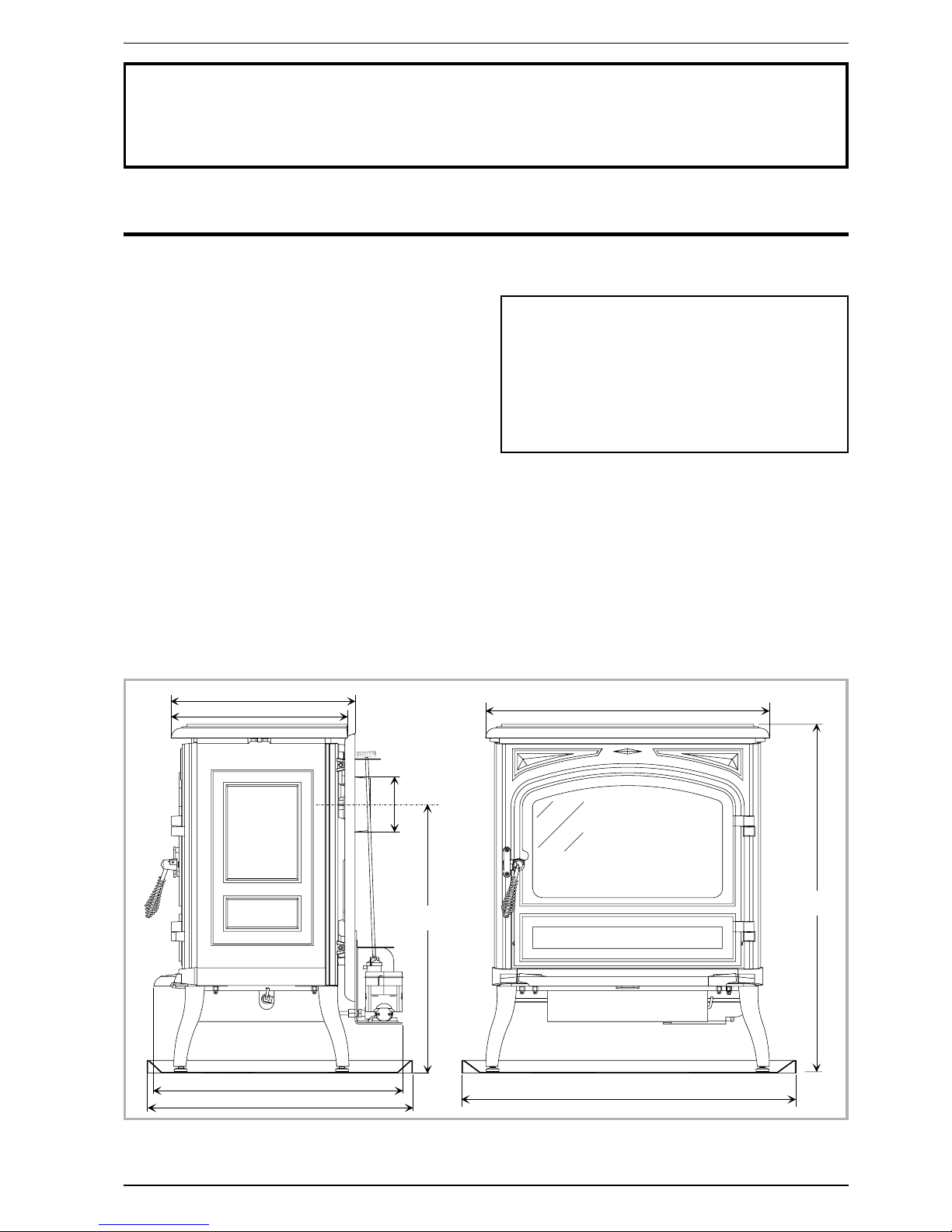

5 4 4

5 8 5

Ø 1 2 0 / 1 2 5

3 8 5

4 0 2

6 2 0

7 6 0

5 6 2

7 0 2

Figure 1 - Dimensions in mm

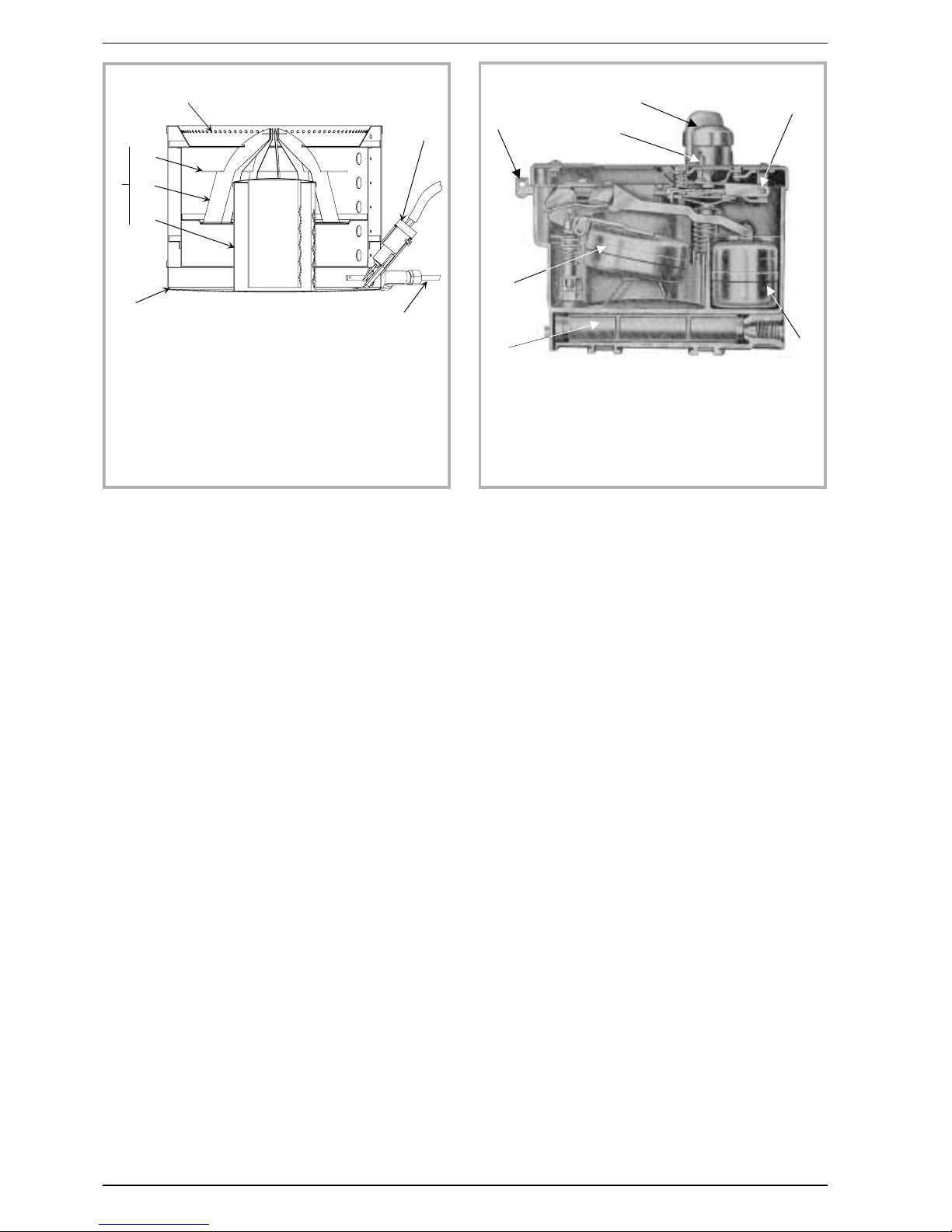

1.5. Operating principle

Heat is mainly diffused by radiation, through the window

and body of the appliance.

The speed control is obtained by control the oil flow into

the burner.

The stove is fitted with a vaporizing burner

Furnace oil is fed to the burner floor where is it ignited

by means of a firestarter (or with an optional electrical

igniter).

The heat produced by this flame brings the burner

temperature to the required level to vaporize the oil.

Oil will only burn as a vapor not a liquid.

Combustive air enters the burner through the air way

holes.

In the centre of the burner is the catalyser, which aids

the good combustion.

When the stove is in operation, the catalyser glows red.

The stove should not be used without the catalyser.

On the feed-line there is a de-scaling lever.

The de-scaling lever can be operated to keep the inlet

pipe clear of carbon build-up.

The stove float regulator contains a filter to trap

impurities. A safety lever controls oil flow. A float in the

chamber raises the oil level available to the burner.

Oil can only enter the float chamber when the safety

lever is depressed.

The float regulator is also controlled by a control knob

which turns from off to high setting.

A draft regulator ensures a constant air intake to the

burner regardless of external factors.

4 Technical manual “1091”

“Bourgogne” ref. : 174 10 56 Description of the unit

1

2

2 b

2 c

3

4

5

2 a

Figure 2 - Burner

1 - Air holes

2 - Catalyser

2a : Upper ring

2b : Catalyser top

2c : Catalyser body

3 - Burner pot

4 - Automatic ignition

(optional)

5 - De-scaling lever

Figure 3 - Float regulator

A - Control knob

B - Safety lever.

C - Main float

D - Safety float

E - Oil level regulator

F - Thermostat control

G - Filter

A

F

B

E

G

C

D

2. Installation instructions

2.1. Warning to the user

An incorrectly installed heating appliance can

cause serious accidents (chimney fires, burning of

plastic insulation materials, in partition walls, etc.).

The insulation of both the appliance and the

exhaust gas pipe has to be reinforced and built as

well as possible according to the norm to make sure of

the equipment operational reliability.

The installation must be carried out according to local

building regulations.

It is the installer’s responsibility to conform to local

building standards and requirements with regard to

installation.

The manufacturer’s responsibility shall be limited to the

supply of the equipment.

A remote acting fire valve must be fitted on the oil

supply line.

Flexible oil lines must not be used to make connections

between oil supply line and oil regulator valve.

2.2. Location of the unit

Ventilation :

For satisfactory operation with a natural draught,

check that sufficient air for combustion is available in

the room.

In houses equipped with mechanical ventilation, an

outside air intake of minimum 50 cm

2

must be installed.

Position of the unit :

For new installations, select a central position within the

house, to provide a good heat distribution around the

building.

The heat distribution towards the other rooms will be

made through the communicating doors. These rooms

must be in negative pressure or must include ventilation

gratings.

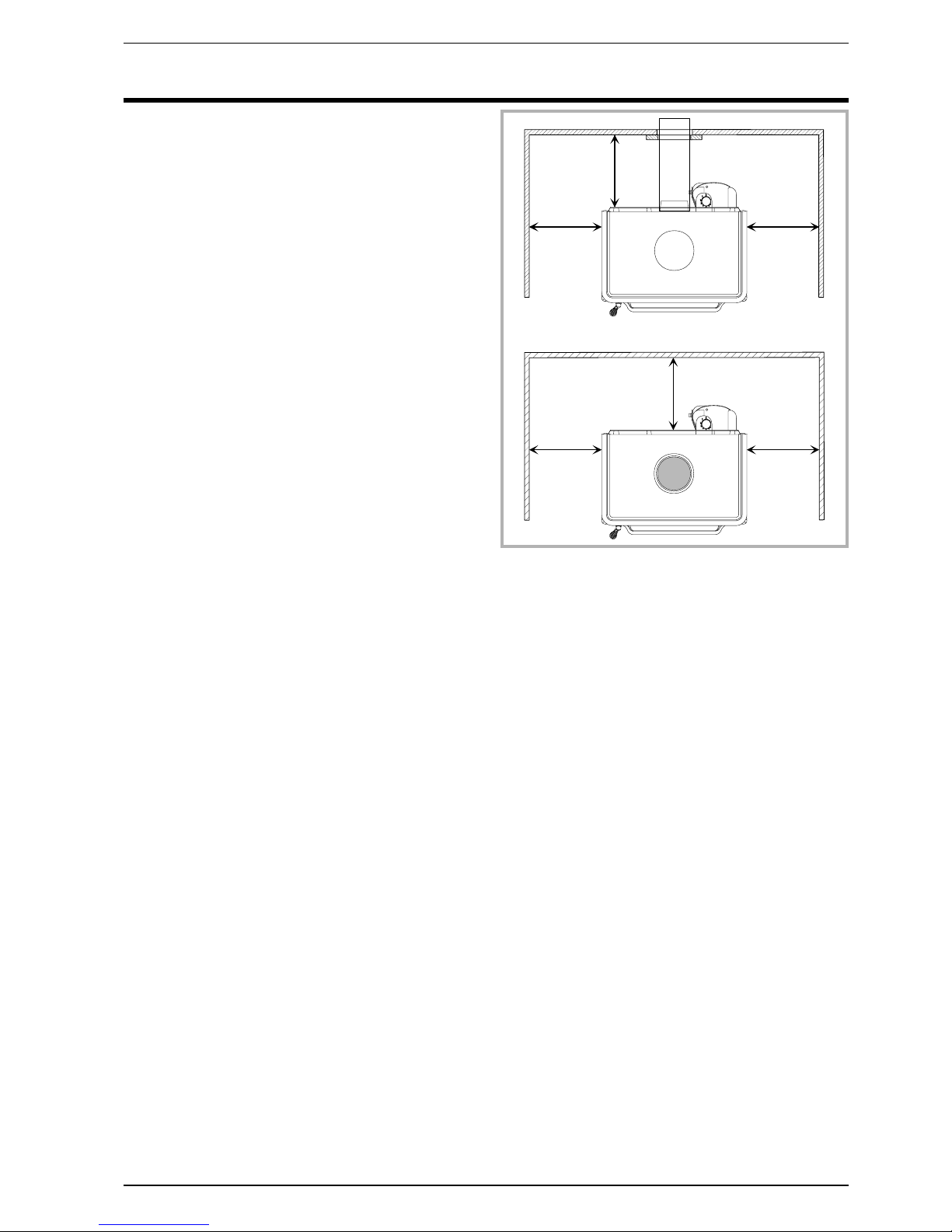

Floor and walls :

Make sure there are not combustible or covered with

combustible material.

Otherwise it must be necessary to install a

non-combustible protection.

Position the unit to comply with the minimum

clearances to combustible material (figure 4).

2.3. Chimney

The chimney must comply with Current Building

Regulations. If in doubt, consult your Dealer or local

Building Inspector.

The flue must be in good condition and must provide

sufficient draught. (refer to technical details page 3).

The flue must be suitable for the installation of fuel

burning appliances ; otherwise it must necessary to

install a tubing.

The flue must be clean. It should be swept to remove

soot and dislodge tar deposits.

The flue must be well insulated, water and air tight. A

chimney with a cold internal surface can prevent a good

chimney draught and condensation will occur.

The flue must be watertight.

The chimney must have a constant cross section.

The flue must not be shared with any other appliance.

The chimney must be at least 4.5 m (15 ft) high.

In case of a flat roof or when the roof gradient is lower

than 15°, the stack must be 1,2 m (4 feet) high at least.

The capping must not restrain the draught.

If the chimney has any downdraught tendency, due to

its position in relation to nearby obstacles, an

anti-downdraught cowl must be installed on the

chimney or the chimney height must be increased.

If the chimney draught is excessive or irregular, a

draught stabilizer (barometric damper) must be

installed to the connector pipe.

It must be distant from any combustible material (walls,

cross members)

It must permit an easy sweeping.

Technical manual “1091” 5

“Bourgogne” ref. : 174 10 56 Installation instructions

3 0 0

3 0 0

3 0 0

3 0 0

3 0 0

3 0 0

Figure 4 - Minimum clearances

Loading...

Loading...