FRANCO BELGE Belfort 174 05 05 Technical Manual

Technical manual

to be saved

by th e user

for future reference

Document n° 979-3 EN ~ 28/02/2000

Les FonderiesFranco-B el ges

59660 MERVILLE

Phone : 03.28.43.43.43

Fax : 03.28.43.43.99

RC Hazebrouck 445750565B

Subject to modifications

Belfort

Oil fir ed stove

Model : 174 05 05

(EN 1)

Description of the a pplian ce

Installation instructions

Operating instructions

Spare par ts

English

Norsk

Description of the unit ........................................3

Package....................3

Optional equipment ..............3

Specifications.................3

Description ..................3

Operatingprinciple..............4

Installationinstructions .......................................4

Positionoftheunit ..............4

Chimney....................4

Mounting the levelling feet ..........5

Topflueoutlet.................5

Rearflueoutlet ................5

Chimney connector ..............5

Externaltank .................6

Levelling ....................6

Pre-utilisation check .............6

Oilflowadjustment ..............6

Chimney draught ...............7

Doorclosingpressure ............7

MaintenanceoftheChimney.........7

Operatinginstructions ........................................8

Fuel ......................8

Lighting procedure ..............8

Operating procedure .............8

Shuttingdown.................8

Maintenanceofthestove...........8

Recommendation ...............9

Trouble shooting .............. 10

Spareparts..............................................11

FRANCO BELGE congratulates you on your choice.

FRANCO BELGE, which has been granted the ISO 90 01 certification, guarantees the quality of its

appliances and is committed to meet its customers’ needs.

FRANCO BELGE, which can boast a 75-year experience in the industry of heating devices, uses

state-of-the-art technologies to design and manufacture its whole range of products.

This document contains instructions on how to install your appliance and and make full use of its

functions, both for your comfort and safety.

CONTENTS Page Page

Document n° 979-3 EN ~28/02/2000

174 05 05 BELFORT Oil fired stove

2 Technical manual

1.Description of the unit

1.1. Package

¤ 1 package. The stove is supplied completely

assembled exceptthe four levelling feet that areplaced

on the burner.

1.2.Optional equipment

¤ Ground vat

¤ Glow-plug ignitor

1.3.

Specifications

Model ...................... 1740505

Nominal heat output . . . . . . . . . . . . kW 5

. . . . . . . . . . . . . . . . . . . . . . BTU/hr 18.000

Oil consumption at :

-maximumspeed ............litre/h 0,58

.......................gal/hr 0,16

- minimum speed . . . . . . . . . . . . . litre/h 0,17

.......................gal/hr 0,045

Chimney draugh t required at :

-maximumspeed ............. Pa 15

-minimumspeed.............. Pa 8

Weight .................... kg 67,6

1.4.Description

Flued oil stove with vaporizing burner

(Norm EN 1).

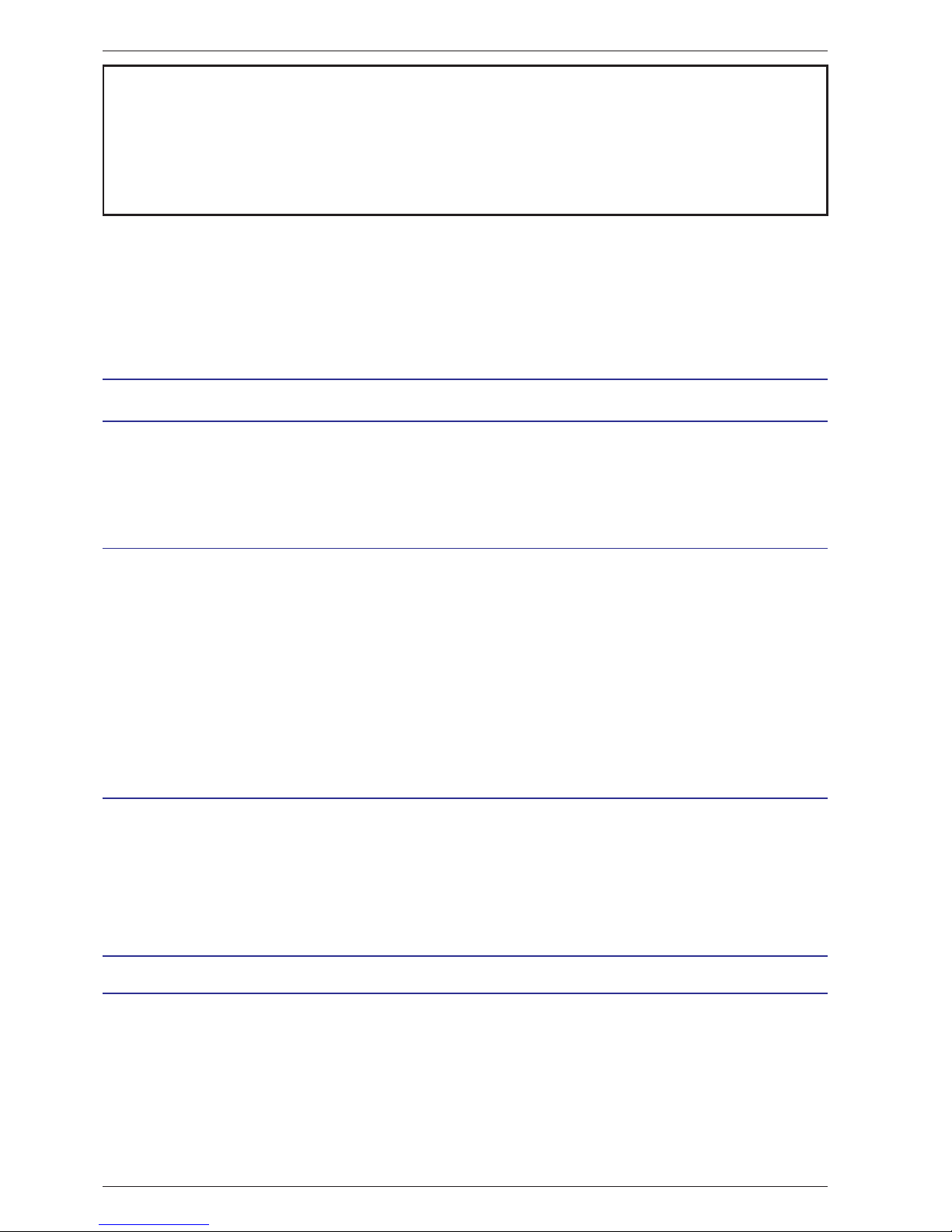

Figure 1 - Minimum clearances to combustible walls

392

340

182

Ø 120/127

452

530

558

420

Figure 2 - Dimensions in mm

200 mm

200

mm

200 mm

200

mm

Document n° 979-3 EN ~28/02/2000

Oil fired stove BELFORT 174 05 05

Technical manual 3

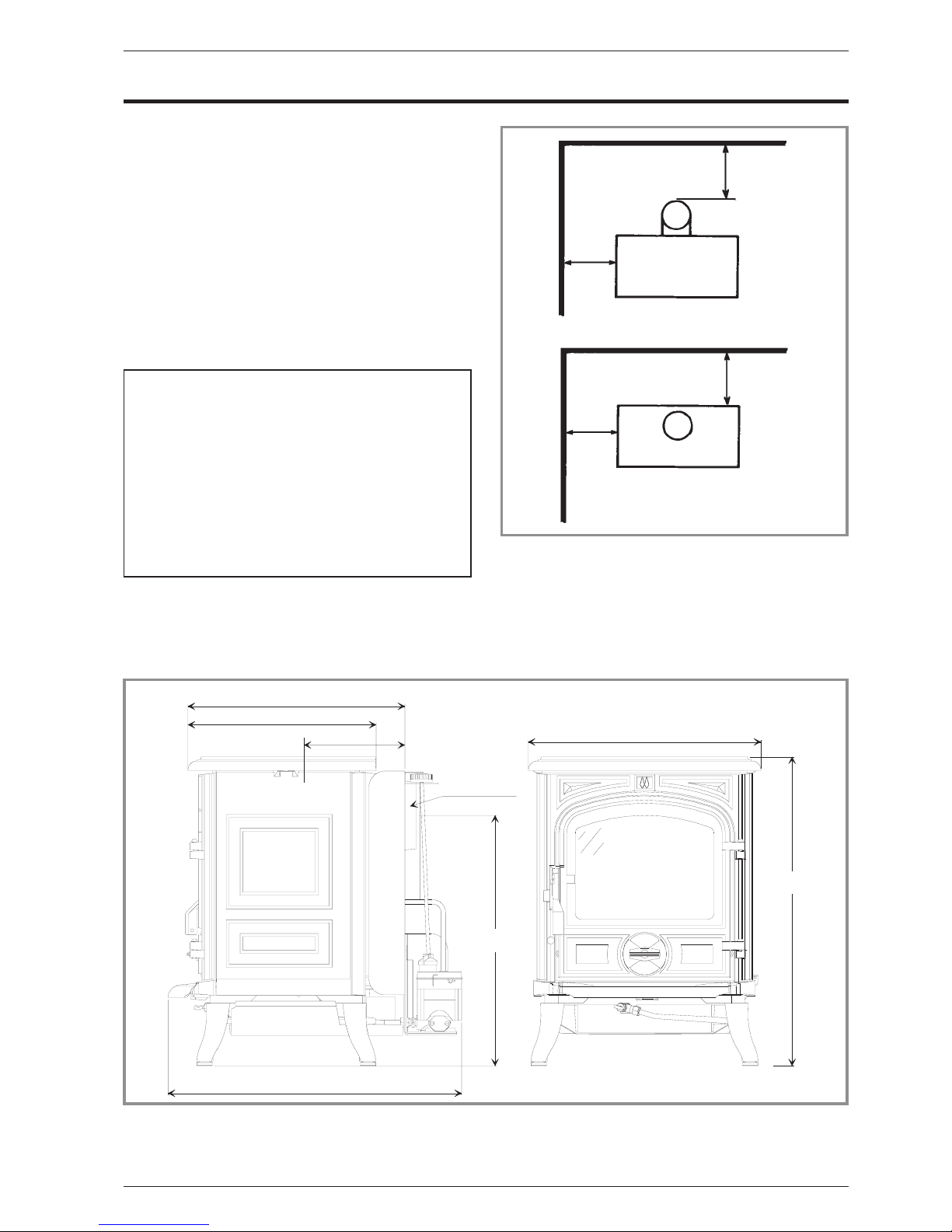

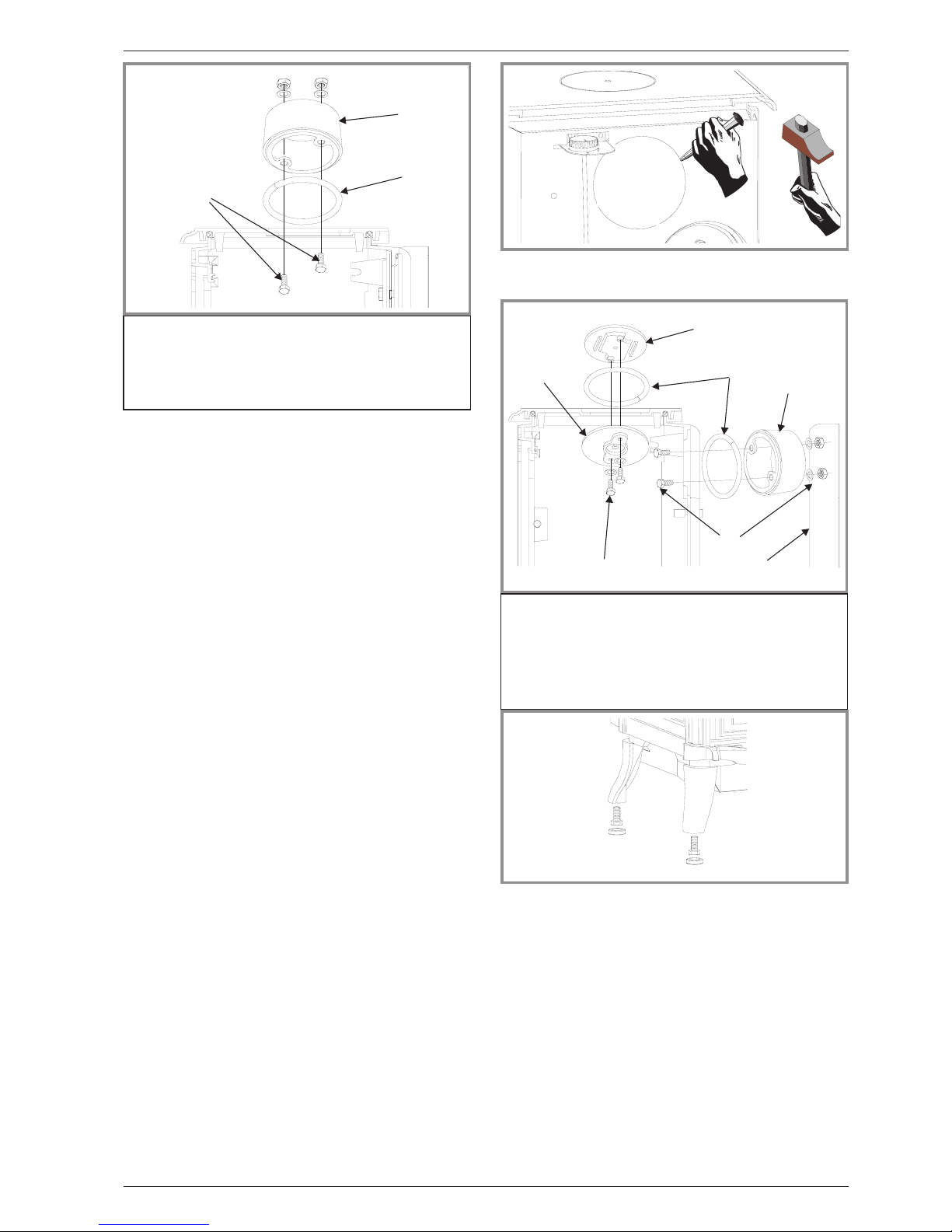

1.5. Operating principle

Furnace oil is fed to the burner floor (fig. 3) where is it

ignited by means of a firestarter (or the Glow-plug

ignitor # 6). The heat produced by this flame brings the

burner temperatureto the required level to vaporize the

fuel. Oil will only burn as a vapour not a liquid.

Room combustion air enters the burner through the air

inlet holes.

In the center of the burner is the catalyser (# 4, fig. 3)

which aids in vaporizing the fuel. When the stove is

operation,thecatalyserglowsred.The stove should not

be used with out both the catalyser (# 4, fig. 3),

catalyser top (# 3) and ring (# 2).

A de-scaling lever (#7, fig.3) can be pushed andpulled

in and out as well as turning slightly at the sametime to

keep the inlet pipe clear of carbon buildup.

The stove float regulator contains a filter to trap

impurities.

A safety lever controls fuel flow. Oil can only enter the

float chamber when the safety lever is depressed.

Oil temperature variations will affect the oil flow into the

float chamber. A float in the chamber raises the fuel

level available to the burner.

The float regulator is also controlled by a control knob

which turns from “0" (off) to ”6" (high setting).

A draught regulator (# 1, fig. 12, p. 6) ensures a

constant air int ake to the burner regardless of external

factors.

2.Installation instructions

SAFETY NOTICE : Read carefullyall instructions before

starting the installation. If thestove is not properly installed, a house fire may result. For your safety, follow the

installation directions. Contact local building or fire officials about restrictions and installation inspection in your

area.

2.1.Position of the unit

- The position of the appliance must be chosen very

carefully in order to obtain the best possible results for

heat distr ibution .

- Position the unit to comply with the minimum

clearances to combustible material. M inimum

clearances are shown from the vertical port ion of the

chimney connector. Check that no overhead cross

members in the ceiling will be cut. Reposition unit if

necessary , being careful not to move closer than the

minimum clearances.

- Outside air : For the oil stove to function properly, an

adequate supply of combustion air is required.

2.2. Chimney

- Ensure that the flue has sufficient draught (refer to

technical details).

- Minimum flue diameter, 10 cm (4" I.D).

- The chimney must be at least 4.5 m (15 ft high).

- The flue must not be shared with anyother appliance.

- Downdraughts caused by obstacles close to the

chimney top may sometimes be prevented by fitting an

anti-downdraught cap to the top of the chimney.

- The chimney must have a constant cross section. T o o

large a flue could affect the chimney draught.

1

2

3

4

5

6

7

Figure 3 - Burner

1 - Air holes

2 - Upper ring

3 - Catalyser top

4 - Catalyser

5 - Burner

6 - Glow-plug ignitor

(optional)

7 - De-scaling lever

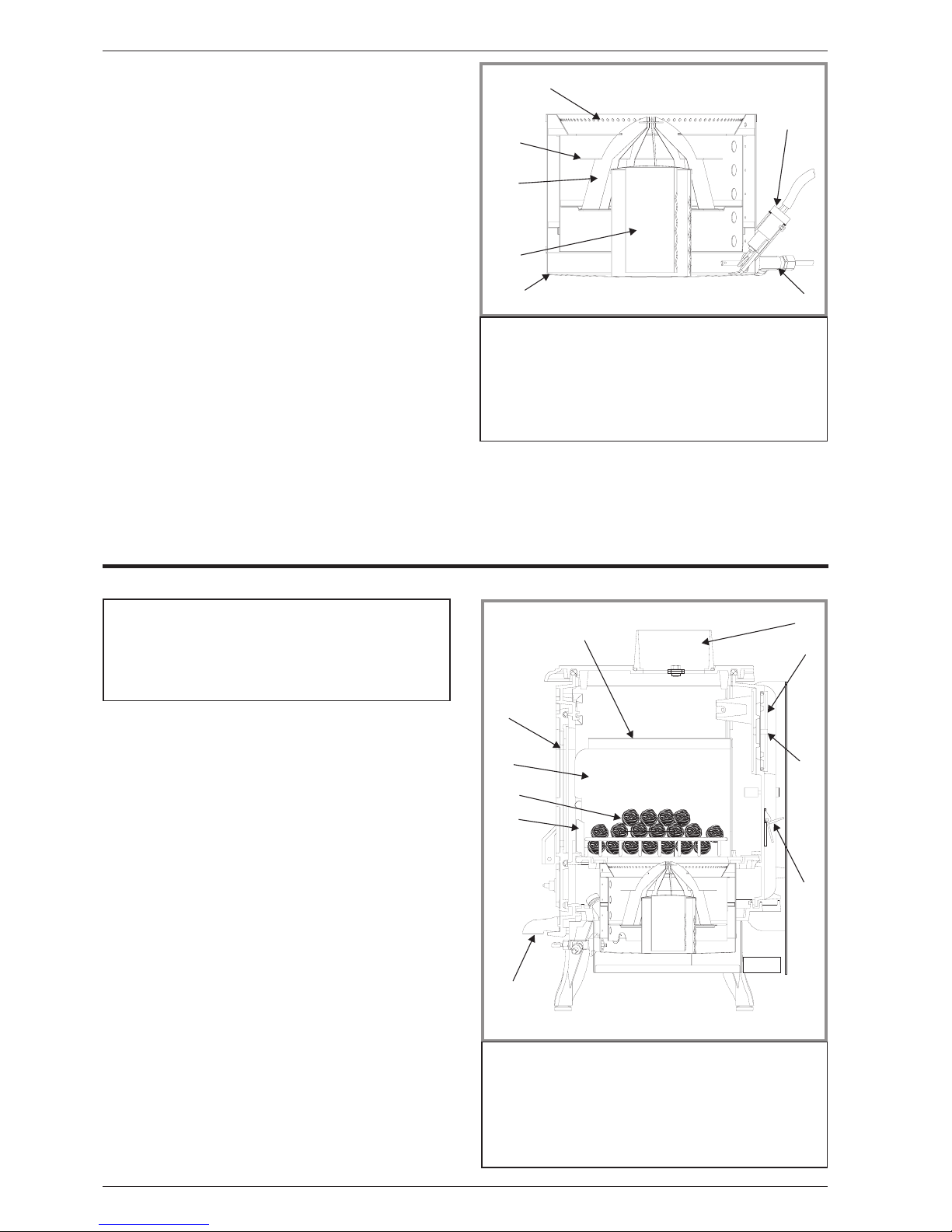

1

2

4

5

3

6

7

8

9

10

Figure 4 - Description

1 - Blanking plate

2 -Maindoor

3- Flue collar

4 - Baffle

5 -Tray

6- Sliding door

7 - Supplementary baffle

8 - Draught control

9 - Ceramic coal

10 - Coal support

Document n° 979-3 EN ~28/02/2000

174 05 05 BELFORT Oil fired stove

4 Technical manual

- The chimney must be soundly constructed, in order to

prevent cold air infiltration.

- The flue must be well insulated, water and air tight. A

chimney witha coldinternalsurfacecan prevent a good

chimney draught and condensation will occur.

- The flue must be swept at least once a year.

2.3.Mounting the levelling feet

Fitthe 4 screws and the 4 capssupplied (on the burner)

into each leg of the stove (fig. 8).

2.4.Top flue outlet

Figure 5

- Open the main door, remove the ceramic coal grate

with theirs coal (# 9 and 10,fig. 4, p. 4) and remove the

internalbaffle(#4and7,fig.4,p.4).

- Fix the sealingrope in the groove on the topand fit the

flue spigot using the two bolts and washers supplied,

ensuring there is a good seal.

- Replace the internal baffles.

The cut-out of the rearheat shieldmust not be remove

in the case.

2.5.Rear flue outlet

Figure 7

- Open the main door, remove the ceramic coal grate

with theirs coal (# 9 and 10, fig. 4, p. 4) and remove the

internalbaffle(#4and7,fig.4,p.4).

- Remove the rear heat shield and the cut-out on it

(fig. 6).

- Remove the blanking plate 5 and the clamp 4from the

back and refit them on the top with the 2 screws and

washers supplied 7, ensuring there is a good seal 2.

- Set the ceramic rope in the groove and fix the flue

collar at rear with 2 bolts and washers supplied.

- Reinstall the internal baffles.

- Replace the rear heat shield.

2.6. Chimney connector

- The appliance must be as close as possible to the

chimney. Avoid horizontal flue connection pipes which

can dangerously restrain functioning of the appliance.

- T he con nec tor pipe must be either 24 ga. black

painted or blued steel or 316 grade 20 ga. stainless

steelor1 mm vitreous enamelled steel, with a maximum

diameter of 127 mm (5" O.D.). Single wall pipe may be

utilized being careful to maintain clearances to any

combustible surface.

Once the stove hasbeen properly installed the chimney

draught must be checked with a draught meter.

If the chimney draught is excessive or irregular, a

3

1

2

Figure 5 - Top flue outlet

1 - Flue collar

2 - Sealing rope

3 - Screws, washers and

bolts

Figure 6 - Back panel

7

5

2

1

3

4

6

Figure 7 - Rear flue outlet

1 - Flue collar.

2 - Sealing rope.

3 - Back panel.

4 -Clamp.

5- B lanking plate.

6 - Screws, washers and

bolts.

7 - Screws and washers.

Figure 8 - Levelling

Document n° 979-3 EN ~28/02/2000

Oil fired stove BELFORT 174 05 05

Technical manual 5

draught stabilizer (barome tric damp er) must be

installed to the connector pipe.

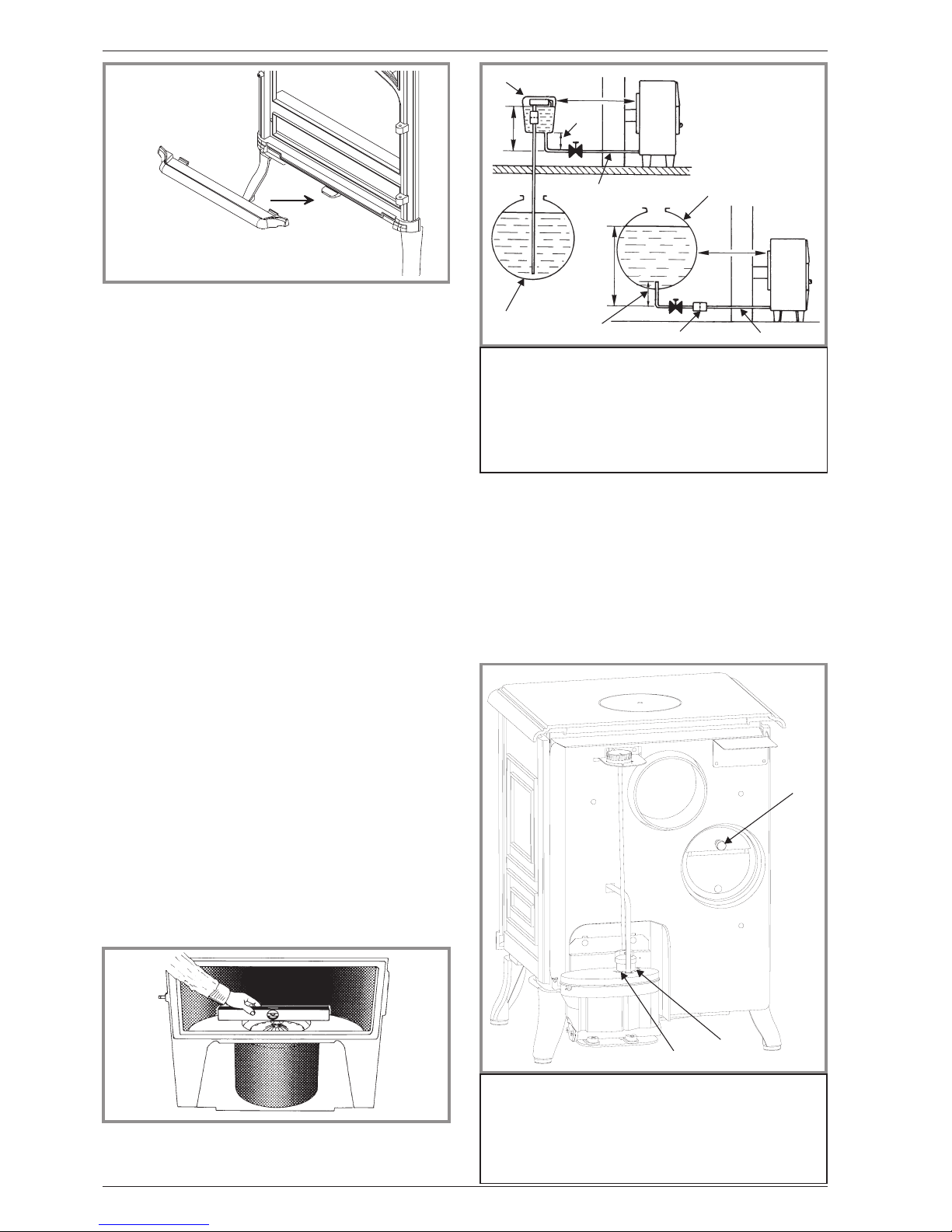

2.7.External tank

A barometric fuel tank should not be positioned where

it will be in the direct rays of the sun or adjacent to a

source of intense heat.

If the tank is more than 8 ft (2,5 m) higher than thestove a

pressure reducer must be installed on the oil line (max.

working pressure : 300 mbar).

If the tank islower than the stove a liftpump will have to be

utilized.

A clearance of 6“ (15 cm) must be maintained between

the external/remote tank and the stove.

2.8. Levelling

It is essential to ensure that the appliance sits level on

the floor. Adjust the levelling feet (fig. 8).

Use a spirit level across the burner pot to check the

level (fig. 10).

2.9. Pre-utilisation check

Check the condition of the filler seals, that the door

closes correctly, that the window is not damaged, that

the smoke passages are not obstructed by packaging

or removable parts. All removable parts, fuel retainer,

baffle, must be correctly installed.

2.10. Oil flow adjustment

The float regulator hasbeen adjusted at thefactoryand

should not need further adjustment. If the burner does

not work correctly, check possible causes before

readjusting the settings :

- Chimney draught

- Fresh air inlet

- Oil supply.

Low setting (Refer to # 2, fig. 12) :

- set the regulating knob on “1" and let the burner run

for a few minutes. The flamemust completely cover the

bottom of the burner and the catalyser body must be

glowing red hot.

- if the flame is too small, the stove will soot up quickly ;

increase the flame by turning the setting screw (# 2)

A

Figure 9 - Fitting the tray

Figure 10 - Burner level check

1

5

3

6

2

7

1

3

4

6

2

7

Figure 11 - Gravity or pumped oil supply

1 -2,5mmaxi

2- At least 0,25 m

3 - Oil Tank

4 - Filter

5 - Suction pump with

reserve and filter

6 - Pipe Ø 6x8 mm

7 - At least 0,15 m

1

2

3

Figure 12 - Adjustment devices

1 - Adjustment of the draught regulator

2 - Adjustment screw for low setting

3 - Adjustment screw for high setting

Document n° 979-3 EN ~28/02/2000

174 05 05 BELFORT Oil fired stove

6 Technical manual

clockwise.

- if the flameis too high, reducethe flameby turning the

setting screw (# 2) counter clockwise.

High setting (Refer to # 3, fig. 12) :

- set the regulating knob on “6" and let the burner run

fora few minutes. The flame must be shaped like a cone

and reach the upper part of the door.

- if the flame is too low, increase the flame by turning the

setting screw counter clock wise.

- if the flameis too high, reducethe flameby turning the

setting screw clockwise.

Please note - Very important : The adjustmentsof the

float regulator are very sensitive. The high and the low

setting screws mustnever be turned more thana 1/4 of

a turn at a time in any direction from theirinitial setting.

When making any adjustments, allow 3 to 5 minutes

between adjustments to allow burner to stabilize to

previous adjustment before proceeding, if necessary.

2.11. Chimney draught

Once the s tove has been properly installed, the

chimney draught must be checked.

The adjustment of the draught will be made with the

barometric damper located at the back of the stove

(# 1, fig. 12).

The reading of the draught must be done once the unit

is hot (minimum 30 minutes of use).

Refer to the specifications p. 3 for minimum draught

requirement on low setting and on high setting.

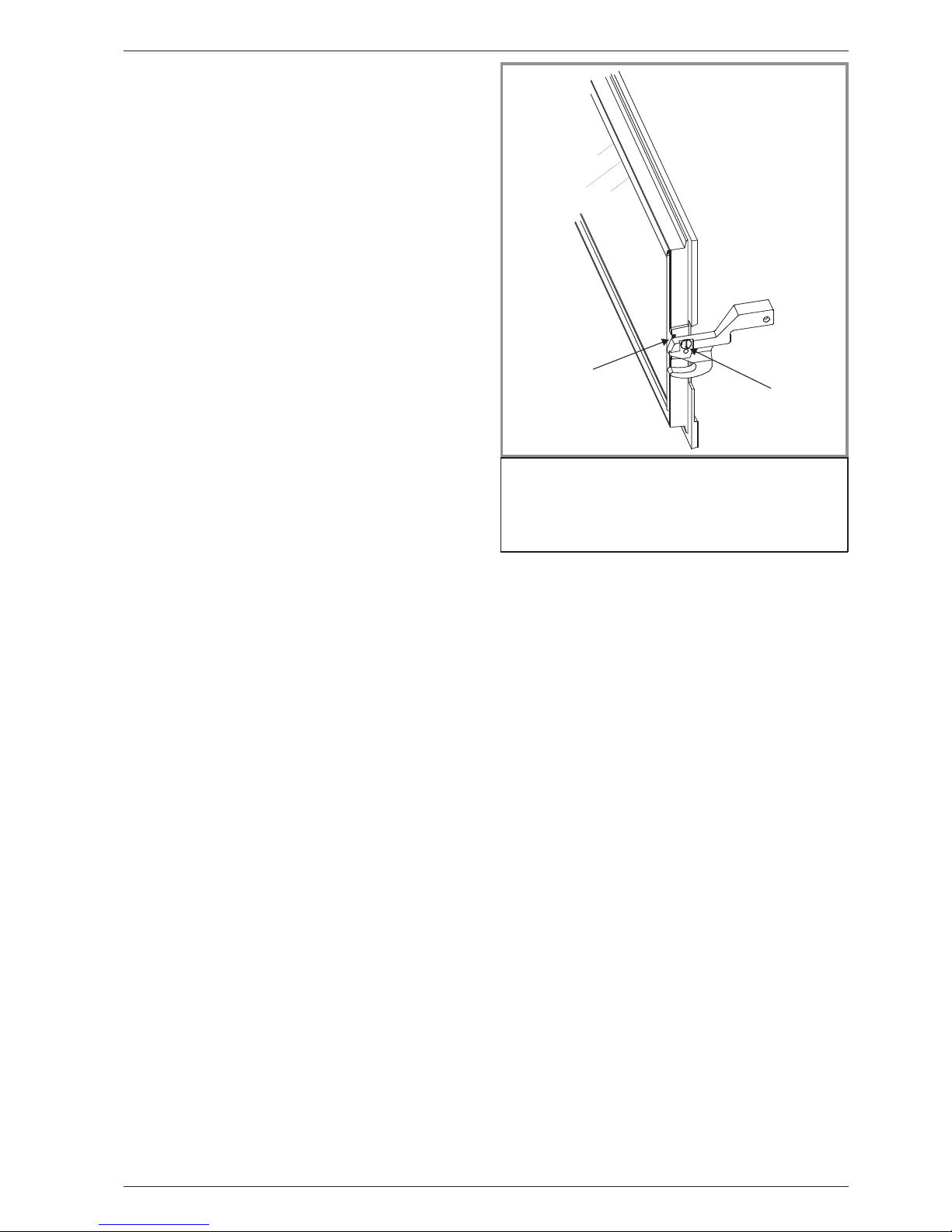

2.12. Door closing pressure

The closing latch rotates around a pressure screw

positioned cam (fig. 13).

- Loosen pressure screw 1.

- Turn cam to desired position 2.

- Tighten pressure screw 1.

2.13. Maintenance of the Chimney

Chimney and chimney connector should be inspected

at least once every three months during the heating

season to determine if a soot build up has occurred. If

soot has accumulated, it should be removed to reduce

the risk of a chimney fire.

1

2

Figure 13 - Door closing pressure

1 - Pressure screw

2 -Cam

Document n° 979-3 EN ~28/02/2000

Oil fired stove BELFORT 174 05 05

Technical manual 7

3.Operating instructions

3.1.Fuel

Warning

: Your stov e is fitted with a specific float

regulator for a specific oil.

¤ Kerosene 28 sec. (1,8 cst at 25°C)

The fuel oil must be free from any dirt and water which

could disturb the s tove in operation.

3.2.Lighting procedure

- Be sure the control knob is to “0" (# 1, fig. 14).

- Turn on oil supply,

- Push down gently on the safety lever (# 2, fig. 14).

This will allow the oil to flow into the float regulator.

- Open the front door, and remove the catalyser from

burner (# 2, 3 and 4, fig. 3, p. 4). Make sure the inside

of the pot is clea n thoroughly, and there is no oil

accumulation.

- Place 2 tablespoons of methylated spirit or gelled

alcohol in the bottom of the pot. Light the starter gel or

methylated spirit with a fireplace match or long butane

lighter. Place the catalyser back into the burner, being

sure it is centered in the burner. Shut the main door.

- Allow the catalyser to heatapproximately 30 to45 sec.

Turn dail to “1" position.

- Allow 10 to 15 minutes for oil fire and draught to

stabilize. The catalyse r should glow red before

adjusting the control knob to a higher setting.

3.3.Operating procedure

Allow 10 to 15 minutes after lighting to adjust the

control knob to a higher setting, usually between a “2"

and ”4" setting.

When increasing the heat output,movethecontrolknob

only 1 number at a time, allowing 5 minutes between

moves for the flame to re-adjust to new setting.

If the burner stops during operating, immediately turn

off the control knob (position “0") and wait until the

burner is completely cool before repeating the lighting

procedure.

3.4.Shutting down

- Set dial to the “0" position (# 1, fig. 14).

- R aise the safety lever of the float regulator

(# 2, fig. 14).

- Allow the flame to burn out completely before opening

the door.

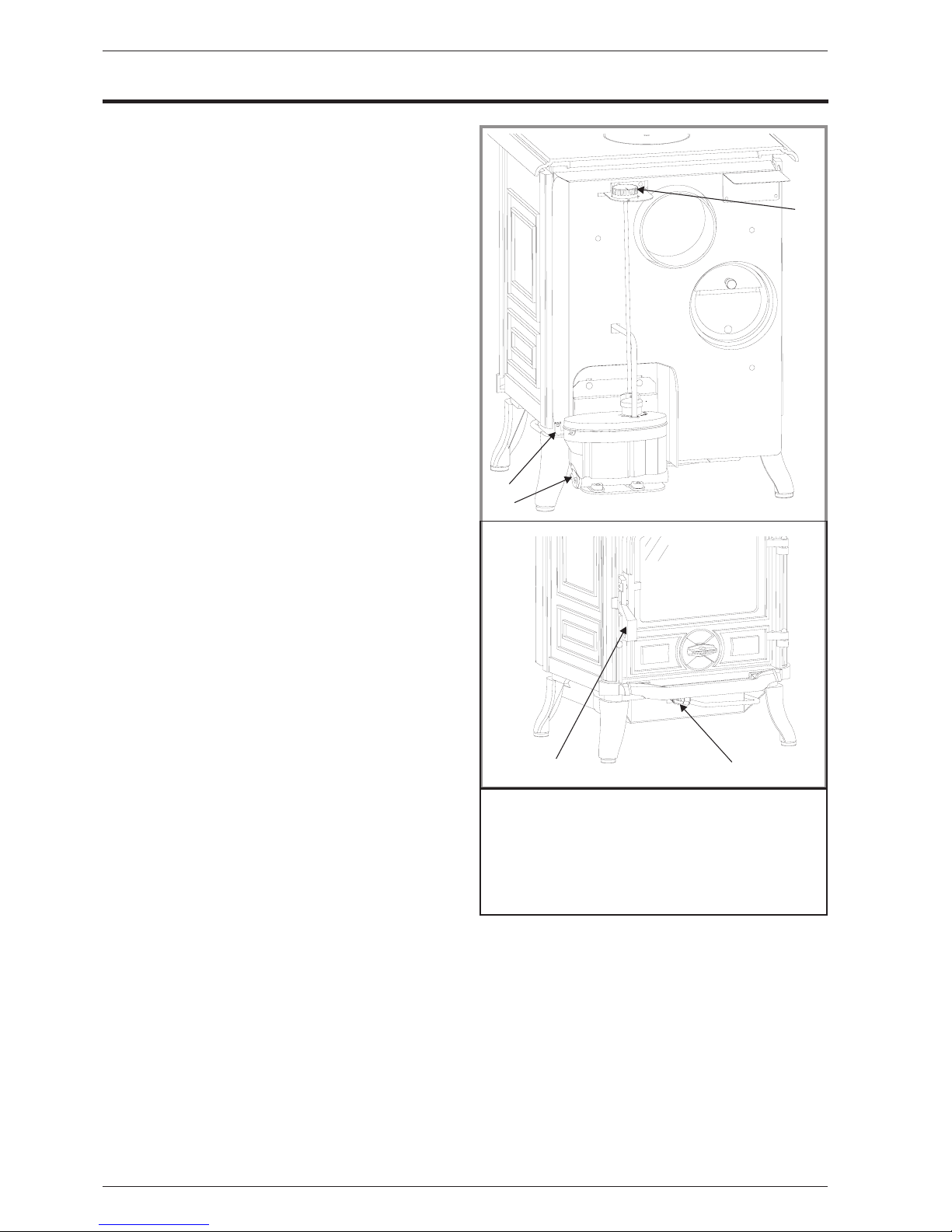

3.5.Maintenance of the stove

Every week : operate thede scaling lever (# 4,fig.14).

- Pull the rod,then push therod in rotating 360 degrees

two or three times (CAUTIO N : The rod is HOT).

Every3or4months: Clean the burner completely.

- Remove all the parts of the catalyser

(# 2, 3 and 4, fig. 3, p. 4)

- Using a soft bristle brush (a small clean paint brush),

carefully brush off the catalyser. Loosen any carbon

sootfromthebottomoftheburnerwitha puttyknife, and

vacuum clean. Ensure that thesmall air holes in burner

are free of carbon.

At least oncea year / End of heating season : Clean

or replace all the oil filters in the oil supply line.

To clean the filter of the float regulator

:

-settheregulationknobinclosedposition“0"

(# 1, fig. 14),

- turn off the tankvalve or the valve of the oil supply line,

- rai se the safety lever of the float regulator

(# 2, fig. 14),

- place a smallcontainer (or asmall rag) underthe float

regulator filter opening in order to collect the oil

contained in the float regulator,

- remove the filter cover plate located under the float

1

3

2

Figure 14 - Operating devices

1 - Regulation knob.

2 - Safety lever.

3 - Access to float regulator filter.

4 - De-scaling lever.

5 - Door handle.

4

5

Document n° 979-3 EN ~28/02/2000

174 05 05 BELFORT Oil fired stove

8 Technical manual

regulator (# 3, fig. 14) with a screwdriver,

- remove the tubular filter from thefloat regulator. Clean

it with oil using a soft brush, never a wire-brush,

- r eplace the filter in the float regulator, install the cover

plate and secure with the screw.

Clean all the enamelled panels of the stove with a dry

or slightly damp soft cloth.

Use a soft clean cloth to wipe the frontglass when the

unit is running at a low burning rate. When the main

door is opened for cleaning, the flame will be disturb,

and turn to a yellow flame. Clean quickly, but gently.

Close the door, the flame will return to a normalburning

position.

N.B. : The appearance of cracks when burning the

enamelled units is quite usual and tends to disappear

when the appliance is cooling down. It should not be

considered as a defect but rather as a patina of the

enamel which does not affect its quality nor its service

ability.

3.6.Recommendation

The adjustment of the stove has been made at the

factory and checked by your installer. Any anomaly of

operation should be reported to him at once.

This room heater is a high heat producing appliance

and may cause severe burns if touched on the glass

front door, or on top directly over the burner - keep

children away - Do not use for drying wet clothing.

CAUTION : Never light the burner if there is oil in the

burner pot. Clean out oil before lighting.

Racing : An audible fluttering sound is an indication

that there istoo much oil in thepot burner and/ora lack

adequate draught.

- turn off oil supply and set the control knob in closed

position “0" (# 1, fig. 14, p. 8).

- until fire has decreased to proper burn rate.

Do not overfire : If the stove or chimney connector

starts to glow, you are overfiring.

Document n° 979-3 EN ~28/02/2000

Oil fired stove BELFORT 174 05 05

Technical manual 9

Loading...

Loading...