FRANCO BELGE 174 05 05 Technical Manual

Technical manual

to be saved

by the user

for future reference

Document n° 979-3 EN ~ 28/08/2000

Les Fonderies Franco-Belges

59660 MERVILLE

Phone : 03.28.43.43.43

Fax : 03.28.43.43.99

RC Hazebrouck 445750565B

Subject to modifications

Belfort

Oil fired stove

Model : 174 05 05

(EN 1)

CAN/CSA approved / ANSI/UL approved

Description of the applia nce

Installation instructions

Operating instructions

Spare parts

English

Norsk

CONTENTS

Description of the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Package....................3

Optional equipment ..............3

Specifications .................3

Description ..................3

Operatingprinciple ..............4

Installationinstructions...................................... 4

Positionoftheunit ..............4

Chimney ....................4

Mounting the levelling feet ..........5

Topflueoutlet.................5

Rearflueoutlet ................5

Chimney connector ..............5

Externaltank..................6

Levelling....................6

Pre-utilisationcheck .............6

Oilflowadjustment ..............6

Chimney draught ...............7

Doorclosingpressure ............7

Maintenance of the Chimney .........7

Operatinginstructions ...................................... 8

Fuel.......................8

Lightingprocedure ..............8

Operating procedure .............8

Shuttingdown.................8

Maintenance of the stove ...........8

Recommendation ...............9

Trouble shooting .............. 10

Spareparts.............................................11

FRANCO BELGE congratulates you on your choice.

FRANCO BELGE, which has been granted the ISO 9001 certification, guarantees the

quality of its appliances and is committed to meet its customers’ needs.

FRANCO BELGE, which can boast a 75-year experience in the industry of heating devices,

uses state-of-the-art technologies

to design and manufacture its whole range of products.

CONTENTS Page Page

Document n° 979-3 EN ~ 28/08/2000

174 05 05 BELFORT Oil fired stove

2 Technical manual

1. Description of the unit

1.1.

Package

¤ 1 package. The stove is supplied completely

assembled exceptthe fourlevelling feet that are placed

on the burner.

1.2.

Optional equipment

¤Groundvat

¤ Glow-plug ignitor

1.3.

Specifications

Model...................... 1740505

Nominalheatoutput............ kW 5

.....................BTU/hr 18.000

Oil consumption at :

-maximumspeed............litre/h 0,58

................... USgal/hr 0,16

-minimumspeed.............litre/h 0,17

................... USgal/hr 0,045

Chimney dra ught required at :

-maximumspeed............. Pa 15

..................... in.w.g. 0,06

-minimumspeed ............. Pa 8

..................... in.w.g. 0,032

Weight ................... kg 67,6

....................... lbs 149

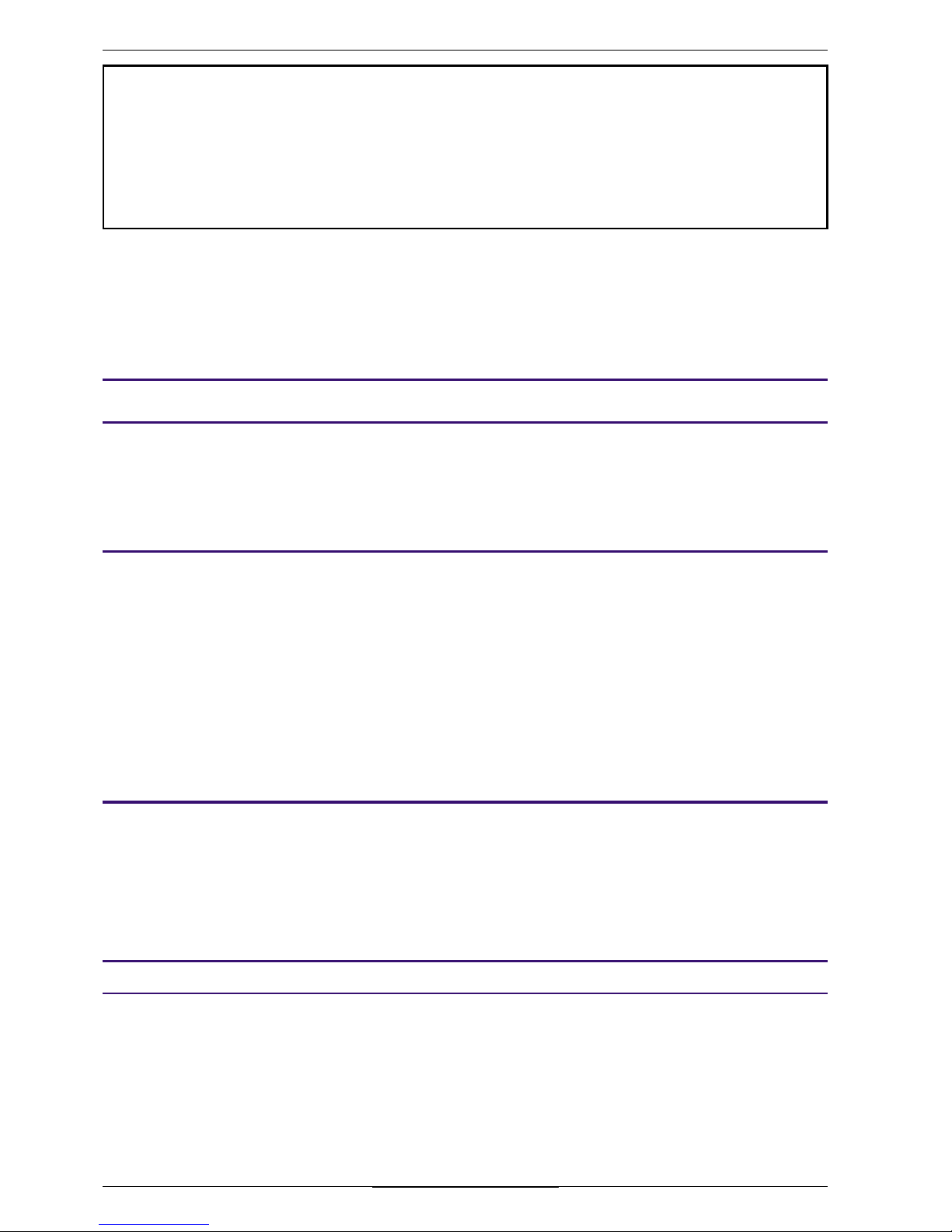

Figure 1 - Minimum clearances to combustible walls

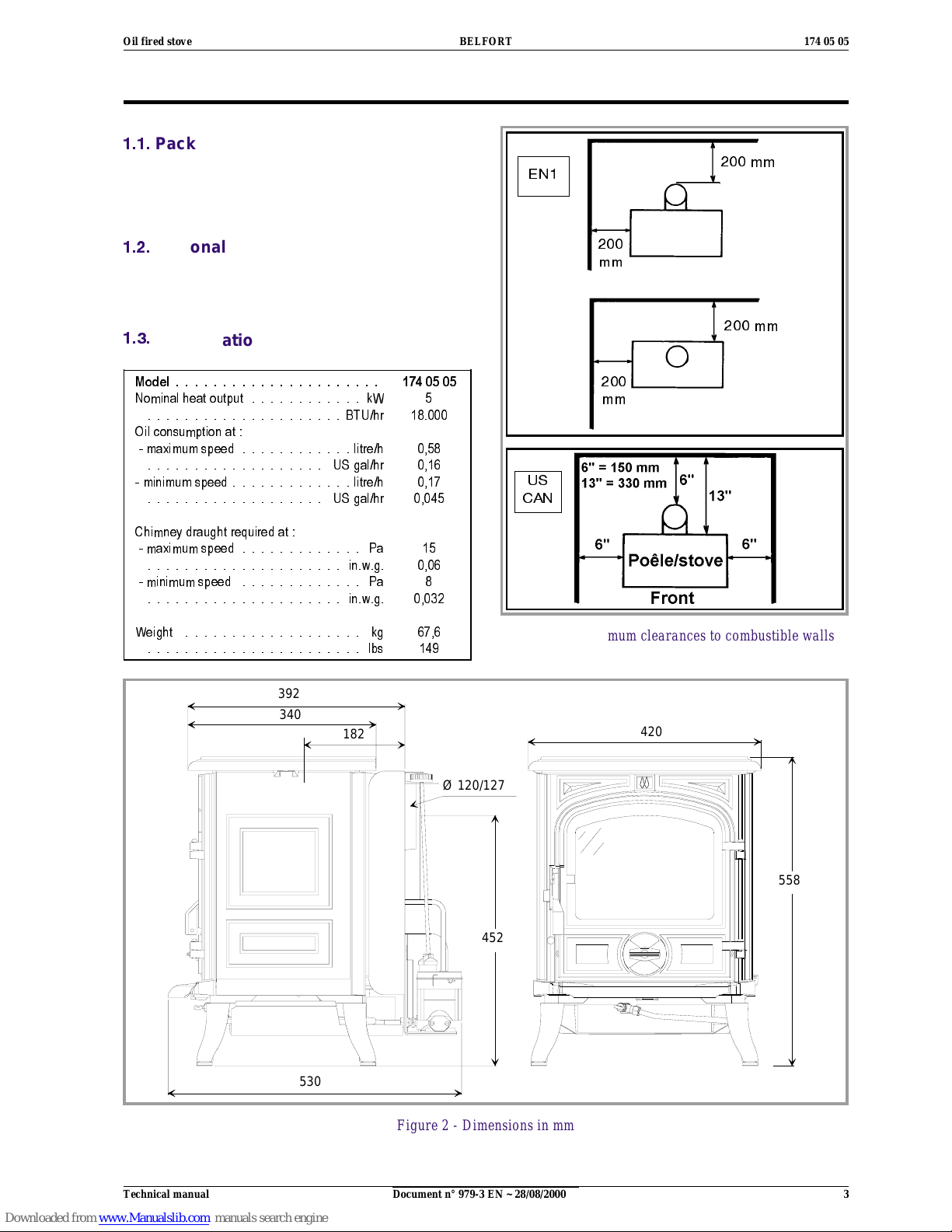

392

340

182

Ø 120/127

452

530

558

420

Figure 2 - Dimensions in mm

200 mm

200

mm

200 mm

200

mm

US

CAN

EN1

Document n° 979-3 EN ~ 28/08/2000

Oil fired stove BELFORT 174 05 05

Technical manual 3

1.4. Description

Flued oil stove with vaporizing burner

(Norm EN 1).

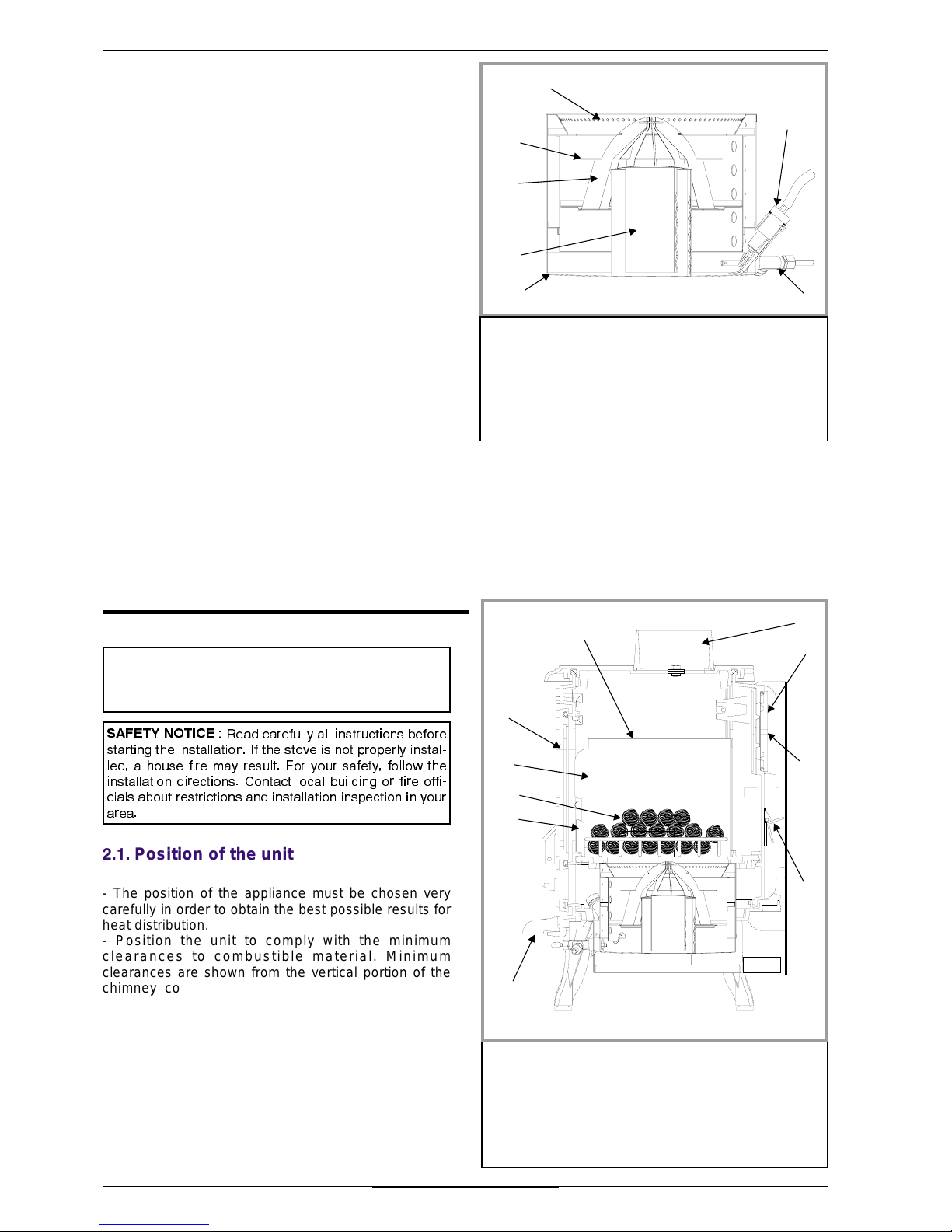

1.5. Operating principle

Furnace oil is fed to the burner floor (fig. 3) where is it

ignited by means of a firestarter (or t he Glow-plug

ignitor # 6). The heat produced by this flame brings the

burner temperatureto the required level to vaporize the

fuel. Oil will only burn as a vapour not a liquid.

Room combustion air enters the burner through the air

inlet holes.

In the center of the burner is the catalyser (# 4, fig. 3)

which aids in vaporizing the fuel. When the stove is

operation, the catalyser glows red. The stove should

not be used with out both the catalyser (# 4 , fig. 3),

catalyser top (# 3) and ring (# 2).

A de-scaling lever (# 7, fig.3) can be pushed and pulled

in and out as well as turning slightly at the same time to

keep the inlet pipe clear of carbon buildup.

The stove float regulator contains a filter to trap

impurities.

A safety lever controls fuel flow. Oil can only enter the

float chamber when the safety lever is depressed.

Oil temperature variations will affect the oil flow into the

float chamber. A float in the chamber raises the fuel

level available to the burner.

The float regulator is also controlled by a control knob

which turns from “0" (off) to ”6" (high setting).

A draught regulator (# 1, fig. 13, p. 7) ensures a

constant air intake to the burner regardless of external

factors.

2. Installation instructions

SAFETY NOTICE

: Read carefully all instructions before

starting the installation. If the stove is not properly instal-

led, a house fire may result. For your safety, follow the

installation directions. Contact local building or fire offi-

cials about restrictions and i nstallation inspection in your

area.

2.1. Position of the unit

- The position of the appliance must be chosen very

carefully in order to obtain the best possible results for

heat distribution.

- Position the unit to comply with the minimum

clearances to combustible material. Minimum

clearances are shown from the vertical portion of the

chimney connector. Check that no overhead cross

members in the ceiling will be cut. Reposition unit if

necessary, being careful not to move closer than the

minimum clearances.

- Outside air : For the oil stove to function properly, an

adequate supply of combustion air is required.

2.2. Chimney

- Ensure that the flue has sufficient draught (refer to

technical details).

1

2

3

4

5

6

7

Figure 3 - Burner

1 -Airholes

2 - Upper ring

3 - Catalyser top

4 - Catalyser

5 - Burner

6 - Glow-plug ignitor

(optional)

7 - De-scaling lever

1

2

4

5

3

6

7

8

9

10

Figure 4 - Description

1 - Blanking plate

2 - Main door

3 - Flue collar

4 -Baffle

5 -Tray

6 - Sliding door

7 - Supplementary baffle

8 - Draught control

9 - Ceramic coal

10 - C oal support

USA / CANA DA : The installation of this stove must

comply with state and localrequirements and the standard CSA B139.

Document n° 979-3 EN ~ 28/08/2000

174 05 05 BELFORT Oil fired stove

4 Technical manual

- Minimum flue diameter, 10 cm (4" I.D).

- The chimney must be at least 4.5 m (15 ft high).

- The flue must not be shared with any other appliance.

- Downdraughts caused by obstacles close to the

chimney top may sometimes be prevented by fitting an

anti-downdraught cap to the top of the chimney.

- The chimney must have a constant cross section. Too

large a flue could affect the chimney draught.

- The chimney must be soundly constructed, in order to

prevent cold air infiltration.

- The flue must be well insulated, water and air tight. A

chimney witha coldinternalsurfacecan prevent a good

chimney draught and condensation will occur.

- The flue must be swept at least once a year.

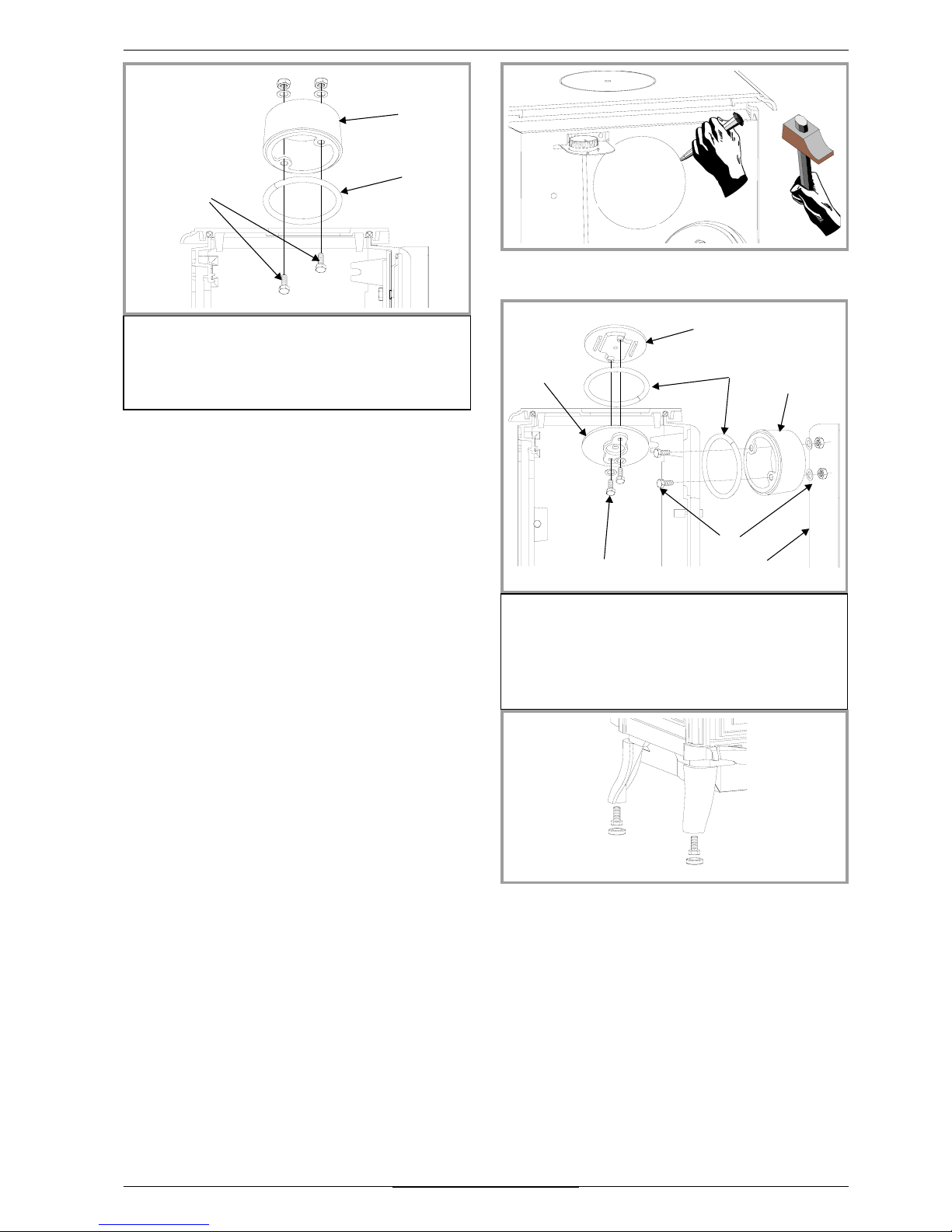

2.3. Mounting the levelling feet

Fit the 4 screws and the 4 caps supplied (on the

burner) into each leg of the stove (fig. 8).

2.4. Top flue outlet

Figure 5

- Open the main door, remove the ceramic coal grate

with theirs coal (# 9 and 10, fig. 4, p. 4) and remove the

internal baffle (# 4 and 7, fig. 4, p. 4).

- Fix the sealing rope in thegroove on the top and fit the

flue spigot using the two bolts and washers supplied,

ensuring there is a good seal.

- Replace the internal baffles.

The cut-out of therear heat shield must not be remove

in the case.

2.5. Rear flue outlet

Figure 7

- Open the main door, remove the ceramic coal grate

with theirs coal (# 9 and 10, fig. 4, p. 4) and remove the

internal baffle (# 4 and 7, fig. 4, p. 4).

- Remove the rear heat shield and the cut-out on it

(fig. 6).

- Remove the blanking plate 5 and the clamp 4 from the

back and refit them on the top with the 2 screws and

washers supplied 7, ensuring there is a good seal 2.

- Set the ceramic rope in the groove and fix the flue

collar at rear with 2 bolts and washers supplied.

- Reinstall the internal baffles.

- Replace the rear heat shield.

2.6. Chimney connector

- The appliance must be as close as possible to the

chimney. Avoid horizontal flue connection pipes which

can dangerously restrain functioning of the appliance.

- The connector pipe must be either 24 ga. black

painted or blued steel or 316 grade 20 ga. stainless

steel or 1 mm vitreous enamelled steel, with a

maximum diameter of 127 mm (5" O.D.). Single wall

3

1

2

Figure 5 - Top flue outlet

1 - Flue collar

2 - Sealing rope

3 - Screws, washers and

bolts

Figure 6 - Back panel

7

5

2

1

3

4

6

Figure 7 - Rear flue outlet

1 - Flue collar.

2 - Sealing rope.

3 - Back panel.

4 -Clamp.

5 - Blanking plate.

6 - Screws, washers and

bolts.

7 - Screws and washers.

Figure 8 - Levelling

Document n° 979-3 EN ~ 28/08/2000

Oil fired stove BELFORT 174 05 05

Technical manual 5

Loading...

Loading...