Framus custom shop series User Manual

Manual for all Framus

Custom Shop Guitars

ENGLISH

Manual_FR_CS_2015_E.indd 1 18.11.15 15:05

ENGLISH

Manual_FR_CS_2015_E.indd 2 18.11.15 15:05

Markneukirchen in May 2015

Dear Customer,

“Made in Germany” stands for quality, and that, along with more than 60 years of tradition and experience

in guitar manufacturing, is what the Framus brand stands for.

As a pioneer, and one of the oldest electric guitar manufacturers in Europe, Framus is committed to the

tradition of guitar manufacturing. Here in Markneukirchen we continue to develop our own ideas and designs with this awareness in mind.

Technical innovation, the best selected woods and one of the most modern instrument manufacturing processes in the world are the foundations of our success. But there is still plenty of manual work necessary

for building our instruments and so we also provide our workers with cutting-edge in-house training. This

symbiosis of tradition, state-of-the-art technology and attention to detail helps us create instruments daily

that then nd their way to acionados all over the world.

Our claim is to make the individual wishes of musicians a reality. Unusual wood, pickup and color combi-

nations - as well as dierent type of nishes - have the power to make each guitar lover’s heart beat that

much stronger. Each satised customer, and our continued success worldwide, shows that Framus is on

the right path into the future.

Framus, a family-owned company, is very proud of its history. In this regard we founded the Framus Museum, which is unrivaled worldwide. Please come visit us here in Markneukirchen.

We wish you lots of fun and enjoyment with your new Framus guitar.

Yours truly,

Hans Peter Wilfer

Manual_FR_CS_2015_E.indd 3 18.11.15 15:05

Index

1) Tuners / Stringing and Tuning 5

2) Frets and the Plek

®

-Technology 5

3) String Action Setup and Gauges 6

4) Adjustmenrt of the Trussrod 6

5) Nuts 7

6) Pickup Setup 7

7) Bridges and Vibratos 8

8) Electronics Layout for all Models 11

AK1974 / AK 1974 S 13

AZ10 1PU 13

AZ10 2 PU 11

Diablo 11

Diablo Progressive 11

Diablo Progressive X 11

Diablo Supreme 11

Diablo Supreme X 11

Diablo 7-string 11

ES Humbucker 12

ES P90 11

Idolmaker 12

Idolmaker Stevie Salas Signature 13

Idolmaker 5’R 13

Mayeld Custom 11

Mayeld Legacy 11

Mayeld Pro 11

Panthera 12

Panthera Legacy 12

Panthera Supreme 12

Panthera Studio 12

Panthera Studio Supreme 12

Panthera 7-string 11

Panthera 8-string 11

Phil XG Signature Humbucker 13

Phil XG Signature P90 13

Wolf Homann Signature 12

9) Tips for Body, Neck and Fingerboard Care 14

10) Easy Access Electronics Compartment 15

11) Security Locks 15

12) User Kit 16

13) Warranty / Customer Service 16

Manual_FR_CS_2015_E.indd 4 18.11.15 15:05

Stringing your guitar is simple. First, make sure that the knurled head screw located at the back of the

tuner is loosened all the way. Next, insert the string through the hole in the tuning post, while tightening

it by pulling on it gently with one hand. Then lock the string in position by turning the knurled head screw

clockwise as far as it will go. Subsequently, tune the string to pitch as normal. If you would like to remove it again, loosen the string tension and turn the knurled head screw counter-clockwise until the string

comes loose.

See P. 10 for a description of the stringing/tuning-process with the Floyd Rose Vibrato.

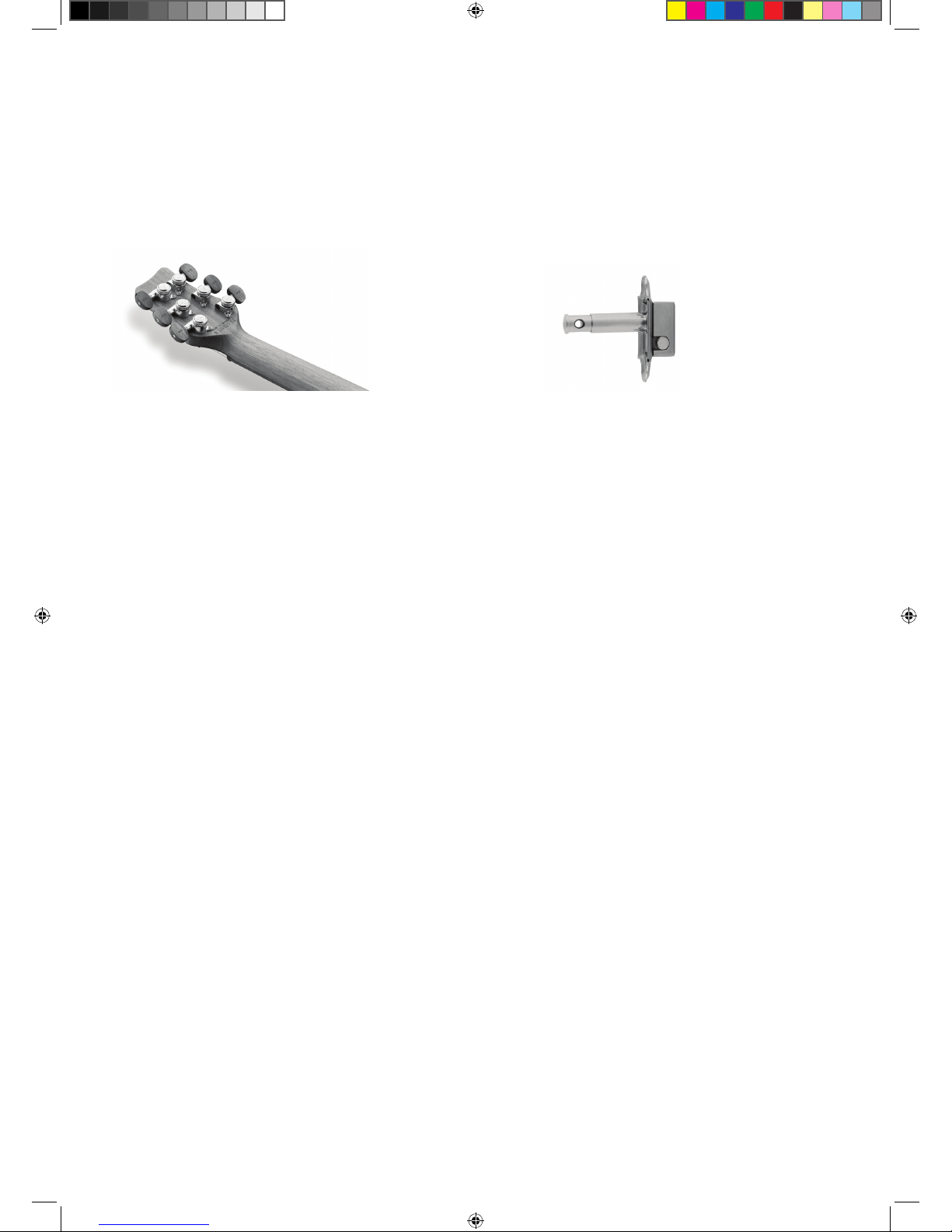

Graph Tech Machine Heads Framus Vintage Machine Head

5

1) Tuners - Stringing/Tuning

Locking Tuners:

2) Frets and Plek®-Technology

All of our Framus guitars made in Germany with the exception of the ES model come standard with Graph

Tech Ratio Locking Machine Heads which are famous for their tuning stability, smooth movement, and

ease of use.

Stringing/tuning:

The Plek® technology guarantees 100% perfect fret dressings on all Framus guitars. An optimal guitar

setup is provided thanks to this technology. The neck measuring procedure, accurate down to 1/100th of

a millimeter (10 µ), scans the ngerboard on all relevant points (basically every possible playing position on

the guitar). Measuring is done with the machine concurrently simulating string tension. Fret dressing is not

done with the usual manual sanding and fret crowning procedures, because the Plek® machine dresses

every fret individually according to the previous measurements with a custom-shaped wheel cutter. This

preserves the radius and shape of the fret even after the dressing is done. Tolerances that would normally

occur with manual fret dressing are thus eliminated.

The end result is a perfectly seated, dened string action along the ngerboard and optimal playability.

Plek

®

Technology means:

- Computer-driven fret dressing

- Dressing is done while simulating string tension

- Cutting procedure with an accuracy down to 1/100th of a mm (10 µ)

- Exact fret crowning

- Dened string action

- Optimal playability

For further information please visit: http://www.plek.de

Manual_FR_CS_2015_E.indd 5 18.11.15 15:05

6-String 25,5” Scale

Cleartone EMP 009“, 011“, 016“, 026“, 036“, 046“

6-String 24,75” String

Cleartone EMP 010“, 013“, 017“, 026“, 036“, 046“

7-String 25,5” String

Cleartone EMP 009“, 011“, 016“, 026“, 036“, 046“, 056“

AZ10 /LP10/MM10 Jazz Archtop 24,75” String

Cleartone EMP 013“, .017“, .026“, .034“, .044“, .054“

Wolf Homann Signature 25,5”

Cleartone EMP 010“, 013“, 017“, 026“, 036“, 046“

8-String 27” String

Cleartone EMP 009“, 011“, 016“, 026“, 036“, 046“,056“,064“

How often should I change strings?

Changing strings is a matter of individual preference. It also depends on many dierent factors. Hand

sweat and inappropriate room conditions can attack the strings and negatively inuence the sound of the

guitar and its playability. We recommend changing the strings once or twice a month to ensure brilliant

tone and playability.

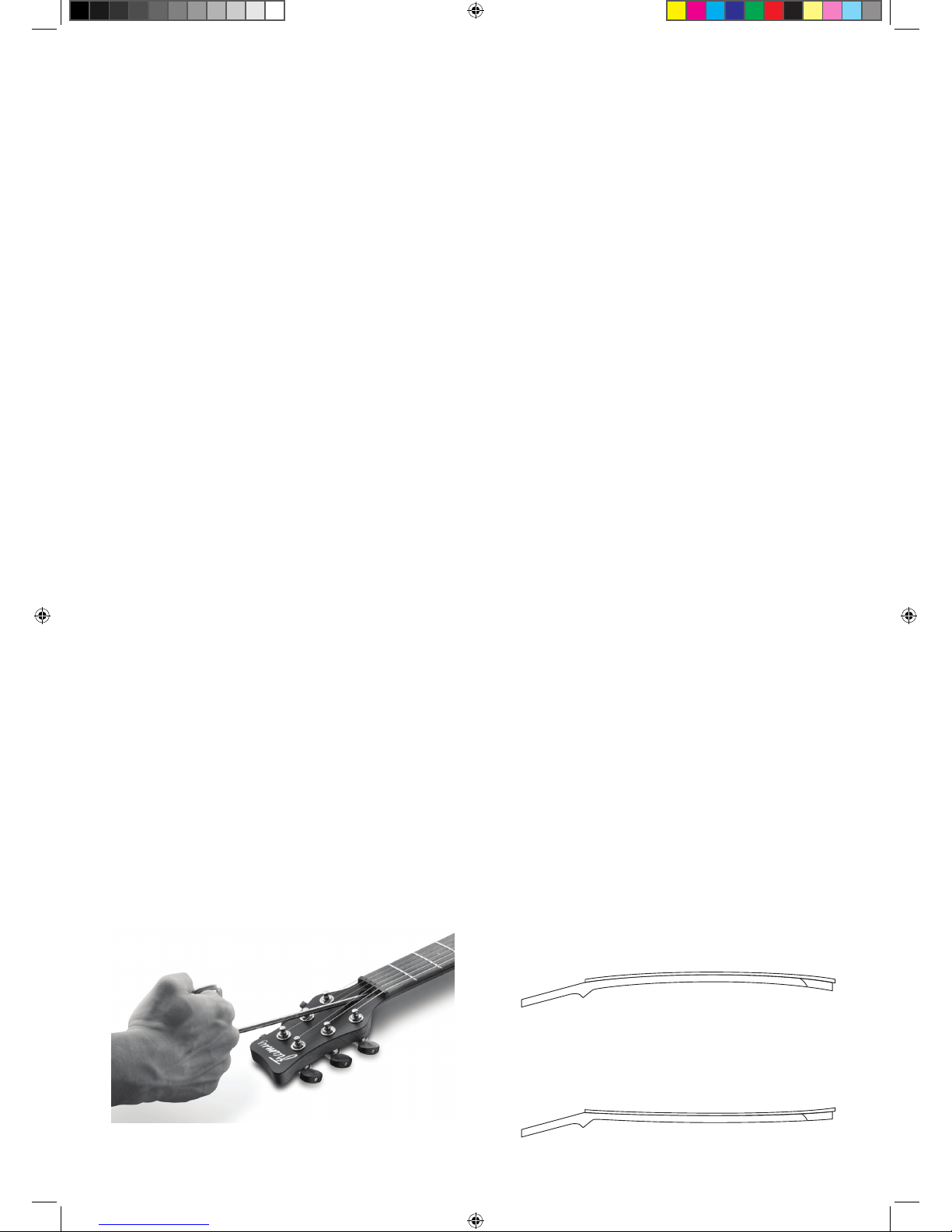

clockwise = back bow, fretboard straitens

counter clockwise = forward bow

6

3) String Action Setup and Gauges

String Action Setup:

Thanks to our collaboration with Plek®, optimal string action setup is predetermined, which in turn should

be perceived as comfortable by the majority of players.

Due to the physical characteristics of wood and strings in conjunction with the vibration process please

keep in mind that with a very low string action setup, string buzzing is quite possible. The guitar has an

optimal setup when your individual requirements are met. String gauge, playing techniques, pick gauge,

string attack, are all variables that cannot be considered when performing a factory setup.

Standard String Gauges (Framus Strings):

4) Truss Rod Adjustment

The neck is setup correctly if it has a slight forward bow. You can verify the neck’s relief by pressing the

lowest string at the rst and last fret (simultaneously). The gap between fret and string should be appro-

ximately between 0.1 and 0.3 mm (100µ-300µ) at the 9th fret. This value is independent from the actual

string action setup of the instrument.

Manual_FR_CS_2015_E.indd 6 18.11.15 15:05

Loading...

Loading...