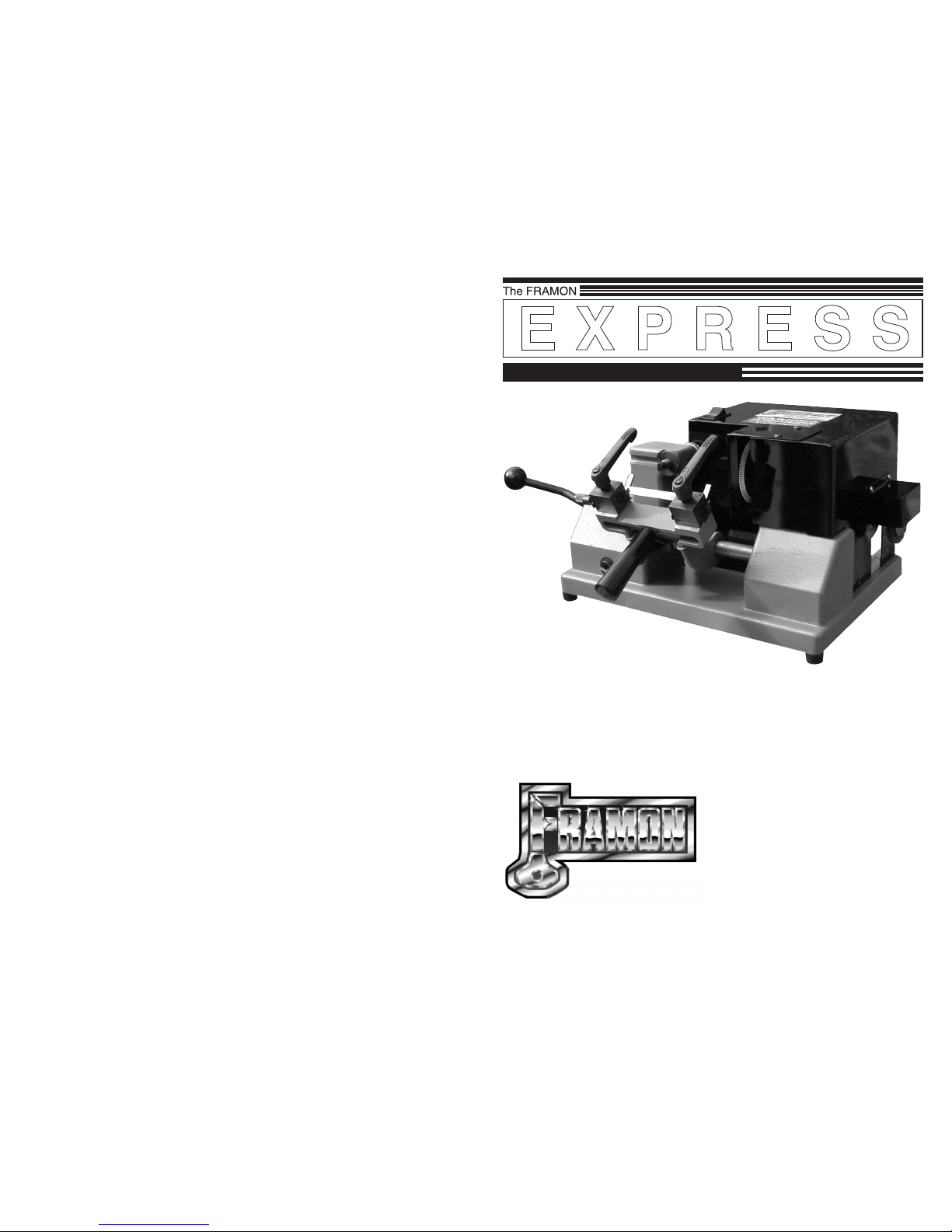

Semi-Automatic Duplicator

Instruction Manual

&

Parts Book

Framon Manufacturing Co., Inc.

909 Washington Avenue, Alpena, Michigan 49707

e-mail: express@framon.com

Internet: www.framon.com

(989) 354-5623

FAX: (989) 354-4238

CAUTION: The cutter supplied with

your EXPRESS Duplicator is designed

to cut brass keys only!

Do not attempt to cut steel keys!

Part No.

LKMS076

LKMS004

LKSH002

LKSH004

CNCMS13

LKSH121

LKMS077

LKSH112

LKSH122/123

LKSH024

LKSH108

LKMS450

ICMS561

DCSH114

LKSH109

CNCMS06

LK84S

LKSH471

LKMS460

ICMS452

DCMS252

DCSC090

LKSH110

LKSH003

LKSH001

DCMS603

LKMS003

LKMS075

Yoke Handle

LH Torsion Spring

Guide Casting

Yoke

Knurled Thumb Screw

Key Stop Knob

Black Plastic Ball

Lever Handle

Vise Bottom/Top

Guide

Guide Shaft

Key Stop

Adj Handle

Calibrated Ring

Lock Knob

Switch

Cutter

Cutter Guard

Main Guard

Brush Guard

Wire Brush

Brush Washer

Yoke Rod

Spindle Casting

Base

Bumper

RH Torsion Spring

Push/Pull Knob

Description

8 1

WARRANTY

The warranty on the Framon Express machine is in effect for

a period of one year from the date of purchase. Framon

Manufacturing will repair or replace, at out discretion, any

machine found to be defective in material or workmanship

within the first year. If any machine is returned to us in the

first year, Framon will absorb all costs for the repairs, including shipping to and from our facility. After one year, Framon

will charge the customer for parts, freight and a flat service

rate for labor. Machines will be repaired and shipped within

two days of receipt. This warranty is valid to the original purchaser of record only. Cutters are not covered by this warranty. Framon cutters are among the finest made today, but

we have no control over their use.

If you do need to return a machine to us for repair, make sure

of the following:

1. Contact us prior to returning the machine to advise us

that it will be on the way.

2. All machines must be packaged properly. If you must

use Styrofoam popcorn to package the machine, be

sure to wrap the machine in a plastic bag before shipping. Styrofoam breaks down in shipping and the small

pieces become lodged inside the motor windings and

other parts of the machine. UPS recommends that at

least two inches of packing be placed around each side

of the machine. Use a sturdy shipping box to return the

machine.

3. Be sure to insure the machine with the carrier for a reasonable amount.

4. Use a carrier that has tracking available.

5. We will not begin work on any machine that does not

have a letter explaining what work is to be done to the

machine, as well as a contact name, phone number,

and address.

INTRODUCTION

Congratulations on the purchase of your new Framon

EXPRESS semi-automatic duplicator. You now own what we

believe is one of the finest duplicators available today. We are

sure you will find the same built-in quality and precision

enjoyed by Framon owners the world over. Take a few minutes to read through this manual to assure proper setup and

use of your new machine.

MACHINE SETUP

CAUTION: Do not attempt to lower the yoke before completing these setup instructions. Damage to the machine may

result.

For shipping reasons, the lever handle, push-pull knob, and

yoke handle have all been removed. Prior to machine operation, these items must be installed:

1. Install the lever handle in the rear of the machine with

the

1

/4 - 28 socket head cap screw.

2. Install the push-pull knob into the yoke with a 5/16"

wrench (see figure 1).

3. Screw in the yoke handle (see figure 2).

4. To check for proper installation of push-pull knob,

lower the yoke slowly to assure the detent pin is seated properly. The yoke should now lock in the key load

position.

FIGURE 1

2 7

OPERATING PROCEDURE

Caution: Always wear proper eye protection.

To cut a standard cylinder key, insert the original key in the left

vise and tighten to secure. Insert the blank key in the right

vise, and tighten to secure. To assure proper key alignment,

use the flip-up shoulder stop (see figure 3). You may have to

loosen one of the keys to allow it to slide to the left or right to

properly line up the key.

4. Loosen the cap screw located in the small channel in the

front of the casting.

5. Load two identical blanks, one in each vise and raise the

yoke so the guide is resting on the tip of the key.

6. With slight pressure, move the bearing assembly so that

the cutter rests on the tip of the key blank (make sure a

tooth on the cutter is touching, not the gap between the

teeth).

7. Tighten the cap screw, maintaining proper alignment.

8. Tighten the

1

/

4

- 28 cap screws in the rear of the casting.

9. Reinstall the cutter guard.

DEPTH

1. Unplug the machine.

2. Loosen the jam stop (see figure 5).

3. Push jam stop towards front of the machine to relieve

pressure on the depth dial.

4. The depth dial is graduated in .001" increments. Rotate

the dial deeper or shallower accordingly.

5. Tighten jam stop, maintaining proper depth.

Note: You can also use this procedure to add a few thousandths of an inch to a worn key that you are duplicating.

If you encounter any problems adjusting your machine, feel

free to contact us at (989) 354-5623, 8:00 am until 4:30 pm

eastern time.

FIGURE 2

FIGURE 3

FIGURE 5

JAM STOP

6 3

SHOULDERLESS KEYS

A unique feature of the Express is the built-in tip stops for

shoulderless keys. When cutting a key such as Ford, the long

side of the tip stop, affixed to the right side of the vise with

thumb screws, should be used as a gauge. Slide the key into

the vise until it touches the tip stop and tighten the vise. Use

normal cutting procedure as outlined above.

USING THE ROTATING VISE AND SHIMS

The Express features a rotating vise to accommodate a wide

variety of keys. The wide side of the vise (the side without the

dots) can be used to cut a key with cuts as deep as .200". If

cutting a key with depths less than .200", rotate the entire vise

(both top & bottom) around until it snaps into place. You can

cut keys with root depths as small as .120".

Most keys will be held without tipping by one side of the vise

or the other. In the rare case that a key tips in both sides of

the vise, use the brass shims provided with your machine. If

the key is tipping upwards, place the shim flat on the top of

the key & clamp it in the vise. If the key tips down, place the

shim underneath the key. Shims are made of brass and it is

expected that you will cut into them. This will not affect the

ability of the shims to hold the keys properly.

DEEP CUTS

The Express is adjusted so that the cutter and guide will not

touch the vises when in the cutting position. If an extremely

deep cut is found on a key, push the yoke forward while cutting to reach the proper depth of cut.

ADJUSTMENTS

Every key machine will eventually need adjustment. Follow

the procedures below for spacing or depth adjustments.

SPACING

1. Unplug the machine.

2. Remove the cutter guard with the

1

/8" Hex Key provided.

3. Loosen two

1

/4 - 28 cap screws located in the counter

bores to the rear of the casting.

CAUTION: Cutter damage may result if shoulder stop is not

lowered!

Turn on the machine with the switch, located on the top of the

guard. With the keys properly aligned, put a small amount of

down pressure on the yoke handle, and pull out on the pull

knob below. The yoke is spring-loaded and care should be

taken not to allow the carriage to spring forward. Gently allow

the carriage to rise until the guide is touching the original key

to the left of the first cut on the key (see figure 4).

The first pass of a key should always be from left to right, or

bow to tip. Grasp the lever handle and move the carriage

through all cuts on the key, stopping at the tip of the key.

Make a second pass from right to left, stopping after the first

cut is completed. Due to the thickness of some blanks, an

additional pass may be required, or a slower first pass.

This procedure should be followed to cut all keys. Please

read on for cutting information for shoulderless keys and

those with very deep cuts.

FIGURE 4

LKMS077

Black Plastic Ball

LKSH121

Key Stop Knob

LKSH004

Yoke

LKSH002

Guide Casting

LKMS004

LH Torsion Spring

LKMS076

Yoke Handle

CNCMS13

Knurled Thumb Screw

LKSH112

Lever Handle

LKSH122/123

Vise Bottom/Top

LKSH024 Guide/

LKSH108 Guide Shaft

DCSH114

Calibrated Ring

LKSH109

Lock Knob

CNCMS06

Switch

LK84S

Cutter

LKSH471

Cutter Guard

LKMS460

Main Guard

ICMS452

Brush Guard

DCMS252

Wire Brush

DCSC090

Brush Washer

LKSH110

Yoke Rod

LKSH003

Spindle Casting

LKSH001

Base

DCMS603

Bumper

Assembly:

LKMS075

Push/Pull Knob

LKMS003

RH Torsion Spring

LKMS450

Key Stop

ICMS561

Adj Handle

PACKED WITH MACHINE

DCMS401

5

/

16

" Hex Key

DCMS402

3

/

32

" Hex Key

DCMS410 Brass Shim (2)

F2MS402

1

/

8

" Hex Key

LKMS350 Manual

NOT

SHOWN

ICMS601 Belt

CNCMS09 Vise Spring

DCMT002

1

/

6

HP Motor

4 5

Loading...

Loading...