Page 1

FD

1

REFRIGERANT DEHUMIDIERS

FD

SERIES

Model FD360

M.FD360

Installation, Operation

& Maintenance Manual

Page 2

FD

2

INDEX

DECLARATION OF CONFORMITY pag.3

TECHNICAL DATA pag.4

DEHUMIDIFIER CAPACITY – FAN PERFORMANCE pag.5

CHAPTER 1: GENERAL POINTS

1.1 INTENDED USE & MODEL VERSION pag.6

1.2 UTILITY AND CONSERVATION OF THE MANUAL pag.6

1.3 NORMS REFERENCES pag.7

1.4 GENERAL SAFETY NORMS pag.7

CHAPTER 2: INSPECTION TRANSPORT AND SITE HANDLING

2.1 INSPECTION pag.8

2.2 LIFTING AND SITE HANDLING pag.8

2.3 UNPACKING pag.8

2.4 LOCATION pag.9

CHAPTER 3: INSTALLATION

3.1 CLEARANCES pag.9

3.2 ELECTRICAL CONNECTIONS pag.10

3.2.1 Generality pag.10

3.2.2 Main supply connection pag.10

3.2.3 Remote humidistat connections pag.11

3.3 CONNECTION TO THE CONDENSED WATER DRAINAGE FITTING pag.11

3.4 DUCTWORK UNIT CONNECTION pag.11

CHAPTER 4: START UP

4.1 PRE-START CHECK pag.12

4.2 START UP pag.12

4.3 SIGNALLING LEDS PANEL pag.12

4.4 FUNCTIONING LIMITS pag.13

4.5 DEFROSTING pag.14

4.6 MACHINE STOP (STAND-BY) pag.14

4.7 HUMIDITY CONTROL pag.14

CHAPTER 5: CONTROL AND SAFETY DEVICES

5.1 CONTROL DEVICES pag.15

5.1.1 Humidity control switch pag.15

5.2 SAFETY DEVICES pag.15

5.2.1 High pressure switch pag.15

5.2.2 Low pewssure switch pag.15

5.2.3 Defrost thermostat pag.15

5.2.4 Control device of the phase sequences pag.16

CHAPTER 6: MAINTENANCE AND PERIODIC CHECKS

6.1 IMPORTANT WARNINGS pag.16

6.2 GENERAL OBSERVATIONS AND ADVISES pag.16

6.3 POWER SAVINGS pag.17

CHAPTER 7: DISPOSAL OF THE UNIT AT THE END OF ITS LIFE pag.17

CHAPTER 8: TROUBLE SHOOTING

8.1 UNIT UNDER ALARM pag.18

CHAPTER 9: ELECTRIC DIAGRAMS pag.20

CHAPTER 10: DRAWINGS (LAY OUT) pag.21-22

Page 3

FD

3

DECLARATION OF CONFORMITY

(Community directives Low Voltage and Electro-magnetic

Compatibility)

FRAL Company s.r.l. Viale dell’Industria e dell’Artigianato 22/c – 35010 Carmignano

di Brenta – PD – hereby declares that the following products:

Dehumidifiers FD360 series

have been designed, manufactured and distributed according to safety and electromagnetic compatibility of the European Norms and Regulations:

MACHINES NORMS 2006/42/CE;

SECURITY REGULATIONS FOR LOW TENSION APPLIANCES 2006/95/CE;

ELECTROMAGNETIC COMPATIBILITY (EMC) – 2004/108/CE.

It is hereby certified that this Dehumidifier conforms to the:

IEC Regulations CEI-EN 60335-2-40, CEI-EN 55014-1, 55014-2.

The machine is built according to RoHS European Norms

Page 4

FD

4

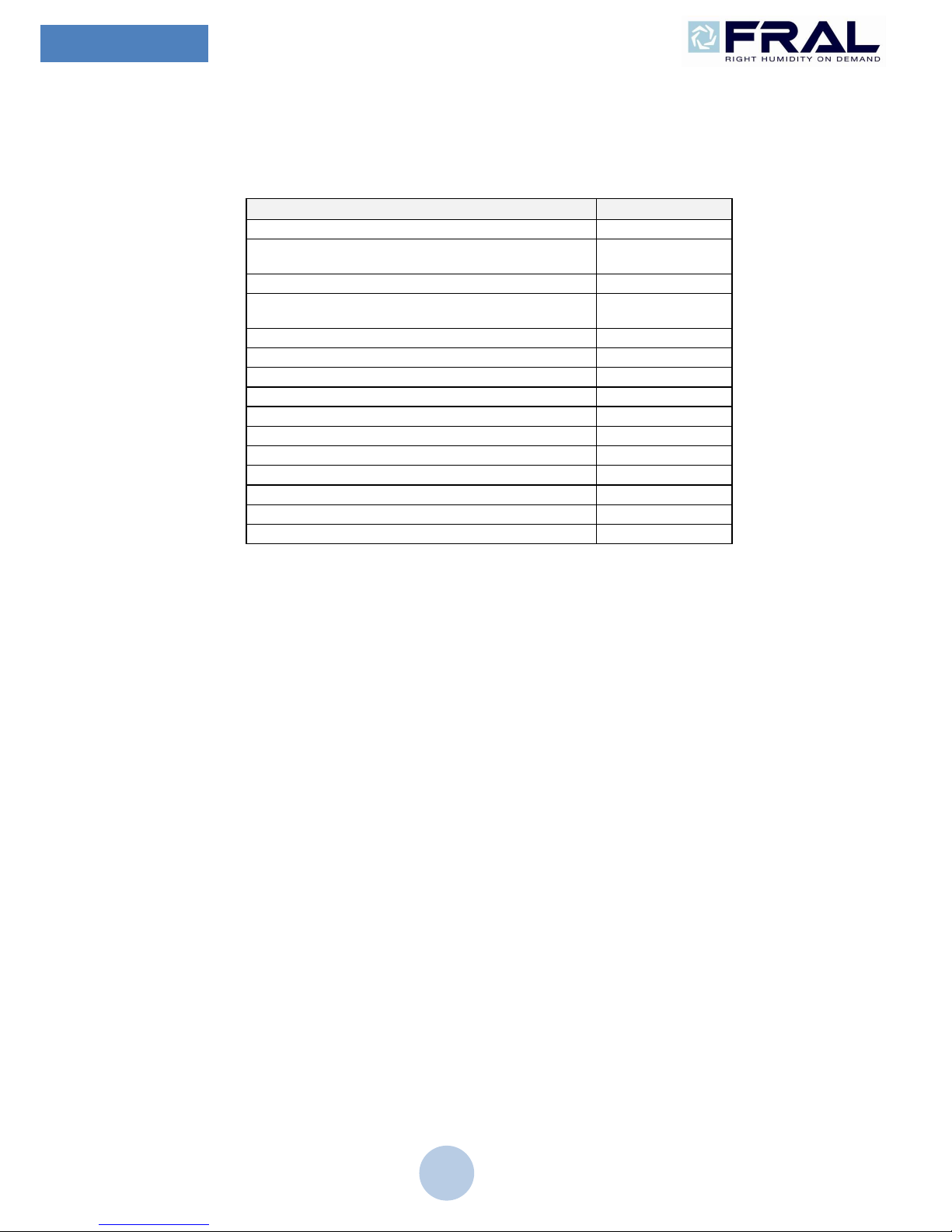

TECHNICAL DATA

Model

FD360

Drying capacity l/24h

*360

Rated Average Power Consumption (at 20°C, 60%

R.H.)

4500 W

Max. Power Consumption (at 35°C, 95% R.H)

5800 W

Max. Absorbed Current (at 35°C, 95% R.H.)

(Std. Vers. 380V/3Ph/60Hz)

11.0 A

Air flow range (m^3/h)

4600

Refrigerant

R410a

Sound Pressure Level (at 3 mts in free field)

61 db(A)

Functioning Temperature Range

7...35 °C

Functioning Relative Humidity Range

45...99 %

Condensed Water Drain Pipe Connection (male)

¾’’

Length (mm)

1180

Depth (mm)

900

Heigth (mm)

710

Weight with empty tank

150

Nominal power supply

400/3~+N/50

(1) Riferito a: temp. ambiente 32 °C umidità relativa 90%

Referred to: inlet air temp. 32 °C relative humidity 90%

(2) Riferito a: temp. ambiente 35 °C umidità relativa 80%

Referred to: inlet air temp. 35 °C relative humidity 80%

(3) Riferito a: temp. ambiente 25 °C umidità relativa 60%

Referred to: inlet air temp. 25 °C relative humidity 60%

(4) Per versioni S con sbrinamento a gas caldo

S version with hot gas defrost

Page 5

FD

5

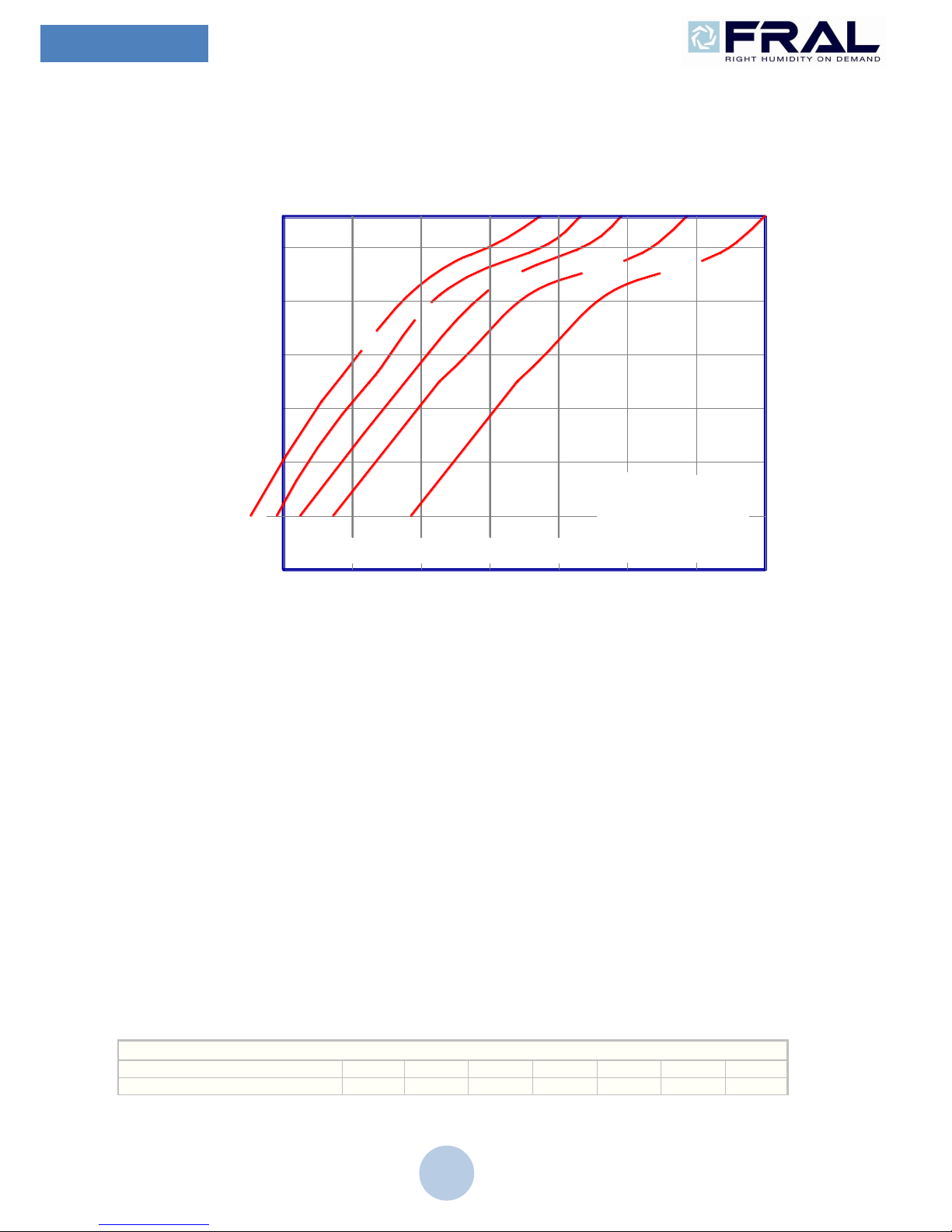

DEHUMIDIFIER CAPACITY

360

Condensed Water (liters/24 hours)

Air Temperature °C

FD

80

5

40

160

120

200

3010 15 2520

50%

60%

70%

80%

240

90%

Air Humidity

FAN PERFORMANCE

AIR FLOW WITH DIFFERENT HEAD PRESSURES

Available head pressure (Pa)

0

25

50

75

100

125

150

Air flow m³/h FD360 (min. fan speed)

3500

3400

3300

3100

3000

3000

2800

Page 6

FD

6

CHAPTER 1: GENERAL POINTS

1.1 INTEDED USE AND MODEL VERSION

The Fral Dehumidifier is intended exclusively for air Dehumidifier via a steam vapouration or a

ventilation unit approved by the manufacturer within the specified operating conditions. Any other

type of application without the express written consent of the manufacturer is considered as not

conforming to the intended purpose and may lead to Fral becoming dangerous.

Operation of the equipment in the intended manner requires that all the information in these

installation and operating instructions is observed (In particular the safety instruction).

FD series

FD 360

Standard Version (mod. FD 360)

Hot Gas Defrost (mod. FD 360/S)

Hot gas Defrost + Electric Heatres (mod. FD360S+4kW)

Both models are also available in DEHU-CLIMA versions see other specific manual.

All models can be configured with in-line airflow or top airflow (see chapter 10).

1.2 UTILITY AND CONSERVATION OF THE MANUAL

This Manual conforms to the requirements of the Norms 98/37/CE and subsequent modifications.

The Manual gives all necessary indications required for the transport, Installation, start-up and

maintenance of the machines, which must be strictly followed by the user for a correct functioning of

the same.

To this purpose, the user must also strictly comply with the security norms described in the Manual.

The manual must always follow the machine and must be kept in a place which will guarantee its

perfect conservation for the proper use from the operator.

GRAPHIC SYMBOLS AND INDICATIONS INCLUDED IN THE MANUAL:

shows that ATTENTION must be paid to all procedures and operations to be carried out

for ensuring the correct functioning of the machine, describes the operations that mus

be avoided , and finally informs the operator about the correct procedure and

operations to be followed for the proper use of the machine.

Page 7

FD

7

1.3 NORMS REFERENCES

The machines described in this manual hav been designed according to the pertinent CE Norms, in

conformity with the MACHINES DIRECTIVES cited in the previous paragraph.

The machines are also complying with the essential requirements of the following European Rules and

Directives:

Machine Safety Norms 89/392 CEE,

Electrical Safety Rules for the Low Tension Appliances 2006/95 CEE,

Electromagnetic Compatibility Norms2004/108 CEE,

Under Pressure Devices 97/23/CE.

1.4 GENERAL SAFETY NORMS

When installing or servicing the unit, it is necessary to strictly follow the rules reported on this manual,

to conform to all the specifications of the labels on the unit, and to take any possible precautions of

the case for workers.

Pressure in refrigerant circuit and electrical equipment present in the unit can be hazardous when

installing or servicing the unit

Therefore, all operations on the unit must be done only by trained people.

Not observing the rules reported on this manual, and every modification to the unit done

without explicit previous authorisation, will cause the immediate termination of the

warranty.

Attention: before every operation of servicing on the unit, be sure that the

electric supply is disconnected.

Close to the unit a switched electrical plug must be present.

Main supply must be protected with a differential switch.

Never modify settings of the safety devices.

Never sprinkle water over the unit and its electrical components.

This uni

must It must not be used under explosive atmosphere

Page 8

FD

8

CHAPTER 2: INSPECTION, TRANSPORT AND SITE HANDLING

2.1 INSPECTION

After receiving the unit, immediately check its integrity. The unit left the factory in perfect condition;

any eventual damage must be questioned to the carrier and recorded on the Delivery Note before it

is signed. Our firm must be informed, within 8 days, of the extent of the damage.

The Customer must prepare a written statement of any severe damage.

2.2 LIFTING AND SITE HANDLING

The lifting is obtained by using a forklift: fork must be inserted in the base pallet, and care must be

taken in order that the fork does not hit the section base or panel (see the picture below).

To unload the unit with a crane, pass bars under the machine and attach the necessary cable or chain

lifting devices to the bar, ensuring that they are clamped firmly; protect the sides of the chiller with

boarding or material of a similar nature.

2.3 UNPACKING

When unpacking the unit pay attention not to damage the unit.

The package is made up by different materials: wood, paper, nylon etc.

It’s a good rule to keep them separately and deliver to the proper collecting centre in order to reduce

their environmental impact.

Lifting method with a crane Lifting method with a forklift

Protection boarding

Spacing bars

3m min

Page 9

FD

9

2.4 LOCATION

Consideration must be given to the following points when determining the most suitable site/location for the

unit installation:

location arrangement in order to guarantee adequate air flow (no narrow spaces)

electrical power supply location;

accessibility for servicing/maintenance and repair of the unit and/or its components;

floor loading strength and ability to support the operating weight of the unit;

Possible objection to operating noise.

CHAPTER 3: INSTALLATION

3.1 CLEARANCES

Absolute care must be taken to ensure adequate air volume to the air intake and fan discharge, and to avoid air

recirculation through the unit that will deeply reduce its performances.

For these reasons it is necessary to observe the following clearances (see the pictures in the following pages):

- air folter suction side: 0,5 mt min.

- fan side: 0,8 mt min.

- electric board side: 0,8 mt min.

- top side: 0,2 mt min.

Top side

0,2 mt. min.

Supply side

0,8 mt. min.

Electric

board side

0,8 mt min.

Suction side

0,5 mt. min

Page 10

FD

10

3.2 ELECTRICAL CONNECTIONS

3.2.1 Generality

Before every operation on the electric section, be sure that the electric supply is disconnected.

Main supply must be protected with a differential switch

Close to the unit a main switch must be present.

It must be verified that electric supply is corresponding to the unit electric nominal data (tension, phases,

frequency) reported on the label in the front panel of the unit.

Power connections must be made using a three-wire cable + neutral wire + ground cable.

Power cable and line protection must be sized according norm and laws according with

absorbed current of the machine (see technical data).

The line voltage fluctuations must not be more than ±5% of the nominal value, while the voltage unbalance

between one phase and another must not exceed 2%. If those tolerances should not be respected, please

contact our Firm to provide proper devices.

Electric supply must be in the limits shown: in the opposite case warranty will terminate

immediately.

Electrical connections therefore must be always done according to the instructions reported on

the wiring diagram enclosed with the unit and norms and laws.

Ground connection is compulsory. Installer must connect ground cable with a dedicated terminal on the

apposite terminal block.

3.2.2 Main supply connection

The Electric Power Supply Connection must be carried out according to the indications given in the Electric

Diagram, by connecting the cable supplied with the machine and according with safety norm.

Models FD360 must be electrically powered with 3 phase-neutral-earths.

The compressor has only one allowable rotation direction; therefore, the machine has a control device for

the phases sequence; in case that it may show a wrong sequence, the device inform you with a blinking light;

in this case two phases must be interchanged.

Pay much attention to above indications because the compressor will be damaged if the rotation direction is

not correct.

Page 11

FD

11

3.2.3 Remote humidistat connections

Remote humidistat connection must be realised according with electric diagram.

Connections must be done according to the electric wiring diagram specifications.

3.3 CONNECTION TO THE CONDENSED WATER DRAINAGE FITTING

Connect condensed water drainage fitting (¾’’ M) to a draining pipe.

It should be always avoided to form a doubble siphon, which could obstruct the water flowing with the

consequent risk of flooding the area.

3.4 DUCTWORK UNIT CONNECTION (see pag.5 for airflow performances)

All the units are provided with a centrifugal fan that can be ducted.

If only one side should be ducted, a flanged connection with overall dimensions larger than discharge hole

should be used.

If either suction side should be ducted, remove suction air filter and its panel, use a flanged connection with

overall dimensions larger than suction hole located on the front of the unit and install an air filter into the

suction ductwork.

It is very important to install an air filter into the suction ductwork if the filter of the machine

itself has been removed . If this filter should not be present, serious damage could occur to the

units.

Page 12

FD

12

SECTION 4: START UP

4.1 PRE-START CHECK

Check that all power cables are correctly connected and all terminals are fastly fixed.

The voltage at the phase R S T clamps must be the one indicated on the unit label ± 5% tolerance. If this

should not happen, please, contact our Factory.

Caution: before proceeding to start up, check that all the cover panel be

located in the proper position and locked with fastening screws.

4.2 START UP

Before to proceed to start up, close electrical line main switch (not supplied with the unit): the green led (line)

will be lit up.

All the units are provided with microprocessor control that manages all the various functions of the unit.

To start the unit, activate humidity switch by rotating the knob or by pressing the instrument keyboard,

depending on the type of instrument installed): the green light (WORKING) will be ON.

For temporary stop (night-time, weekend, etc.) never break the power supply and strictly

follow the procedures illustrated at paragraph 4.6.

4.3 SIGNALLING LEDS PANEL

Units are provided with signalling light panel that indicates unit

operational status. Below is reported a brief description of their meaning.

Electrical supply RED Light (POWER):

indicates that unit is properly electrically supplied.

Compressor RED Light (WORKING):

indicates humidistat call and running compressor status.

Alarm GREEN Light (ALARM): indicates the unit alarm status.

Defrost Light (RED): indicates that the defrost cycle is on.

Page 13

FD

13

4.4 FUNCTIONING LIMITS

Following Diagram represents FD units application.

It is strongly recommended to let the units operate within the below reported limits.

Exceeding these limits it is not granted neither normal operation nor unit reliability and

integrity (for special applications, please contact our Company).

In standard unit applications Table, on the left side is indicated operating limit extension, if unit is provided

with hot gas defrost.

Led status

signalling panel

Operating Table – standard units

Page 14

FD

14

4.5 DEFROSTING

The frost which covers the battery, obtrsucts the passage of the air, reduces the air contact surface and,

consequently, the performance; if the frost accumulation is excessive, it can seriously damage the whole

system.

All units are provided with Desfrost System.

The standard versions have their defrost simply throughy the periodic stop of the compressor, using the heat of

the environment itself.

In the versions with Hot Gas Defrost System, the defrosting is controlled by the electronic system in

combination with a thermostat, the bulb of which is installed inside the evaporator. The defrosting phase in the

Hot Gas System takes place only when the thermostat activates it in presence of freeze.

During the defrosting time the DEFROST light is ON.

4.6 MACHINE STOP (STAND BY)

If the machine is connected, it works with automatic system controlled by a humidostat. When the humidostat

activates the defrost system, only the light Power is ON

When one wishes to turn off the machine, the knob of the humidostat must be set on position OFF.

Before the first Start-up, the machine must be kept in STAND-BY position at-least for 4 hours.

4.7 HUMIDITY CONTROL

It is possible to use a controller with the machine. In this case must be used a humidistat (duct or room) to be

connected to the terminal boxes of the electric panel board in place of the standard humidistat.

It is also possible to have an ON-OFF switch to be electrically connected in series to the humidistat.

Page 15

FD

15

CHAPTER 5: CONTROL AND SAFETY DEVICES

5.1 CONTROL DEVICES

All the control devices are tested on factory before the unit is delivered.

Their operating mode is described in the following paragraphs.

5.1.1 HUMIDITY CONTROL SWITCH

Humidity control switch (Humidistst) enables or disables unit operation depending on the humidity value

desired.

To verify its correct operation, rotate the control knob clock wise (or set the desired value through the

instrument keyboard if a keyboard instrument should be present) and set the humidity desired value close to

lower limit. At this point verify that fan and compressor (after a time delay) will be started in sequence. Verify

as well that the unit is stopped when humidity set is reached.

5.2 SAFETY DEVICES

All the safety devices are set and tested on factory before they are delivered.

Their operating mode is described in the following paragraphs.

All service operations on control and safety devices must be done by TRAINED PEOPLE ONLY:

wrong setting values of the mentioned devices could cause serious damage to the unit and

injuries to the people.

5.2.1 HIGH PRESSURE SWITCH

High pressure switch stops the unit when the discharge pressure exceeds its pre-set limit value.

The reset is manual (by pressing the push-button at the top of the pressure switch located in the electric panel)

and can be done only when pressure is decreased below the device reset value (see table below).

5.2.2 LOW PRESSURE SWITCH

Low pressure switch stops the unit when the suction pressure decreases below its limit pre-set value.

The reset is automatic and it occurs only when pressure is higher than the device differential resetting value

(see table below).

5.2.3 DEFROST THERMOSTAT

This device signals to electronic control that defrost procedure is needed (see paragraph 4.5).

When defrost cycle is activated, defrost thermostat will control its conclusion.

CONTROL DEVICES

ACTIVATION

DIFFERENTIAL

REINSERTION

High pressure switch (bar)

29

7.7

Manual

Low pressure switch (bar)

0.7

2.2

Automatic

Defrost temperature switch (°C)

1 3 Automatic

Page 16

FD

16

5.2.4 CONTROL DEVICE OF THE PHASE SEQUENCES (not available in model FD160)

Since the SCROLL compressors can function only in one rotating direction, this device controls that the phases

be correctly connected.

In case they may not be correctly connected, the machine will not start; a light will begin to flash in the relays

and on the panel the green light ALARM will be ON,

CHAPTER 6: MAINTENANCE AND PERIODIC CHECKS

6.1 IMPORTANT WARNINGS

All this operation described in this chapter MUST BE DONE BY TRAINED PEOPLE ONLY

Before every operation of servicing on the unit, be sure that the electric

supply has been disconnected.

In the inner side of the unit movable parts are present. Be very careful when operating in their

surroundings.

A portion on the compressor shell and discharge line are usually at high

temperature level. Be very careful when operating in their surroundings.

Aluminium coil fins are very sharp and can cause serious wounds.

Be very careful when operating in their surroundings.

After servicing operations, close the unit with cover panels, fixing them with locking screws.

6.2 GENERAL OBSERVATIOTIONS AND ADVISES

It is a good rule to carry on periodic checks in order to verify the correct working of the unit:

Check that safety and control devices are working correctly (monthly).

Make sure that all the terminals on the electric board and on the compressor be well locked. Periodic

cleaning of the sliding terminals of the contactors should be done: if any damage is found, please replace

the contactors (monthly).

Make sure that there is no oil leakage from compressor (monthly).

Check that the electric resistance in the compressor crankcase be properly functioning (monthly: low

temperature units only).

Clean draining pan and pipeline (monthly).

Clean finned coils filters with compressed air in the opposite direction of the airflow. If filters should be

fully clogged, clean them with a water jet to be sprayed against the air flow side (monthly or more

frequently if the unit operates on a dusty environment).

Check mounting of fan blades and their balancing (every 4 months).

Make sure that the unit is not too noisy (every 4 months).

Page 17

FD

17

6.3 POWER SAVINGS

To reduce power consumption, take care of following suggestions :

Make sure that room in which unit should operate has doors and windows firmly closed;

Set the humidity control switch to the proper value: lower set values than necessary (even few points)

may cause great capacity loss with consequently longer operating periods: it is advisable to set humidity

values below 60% only if strictly necessary.

For the machine which has a second condenser (monoblock or split system) check every month if the

heat exchanger is clean and free from room dust, and check the efficiency of the motorfan.

CHAPTER 7: DISPOSAL OF THE UNIT AT END OF ITS LIFE

Once the unit is arrived at the end of its life and needs to be removed or replaced, the following operations are

recommended:

the unit refrigerant has to be recovered by trained people and sent to proper collecting centre;

compressor lubricating oil has to be recovered and sent to proper collecting centre;

the frame and various components, if no longer usable , have to be dismantled and subdivided according

to their nature; in particular, copper and aluminium, which are present in conspicuous quantity in the

unit.

These operations allow easy material recovery and recycling process, reducing environmental impact.

It is recommended to follow the pertinent norms in the disposal of the wasted materials.

Page 18

FD

18

CHAPTER 8: TROUBLE SHOOTING

In the following pages are reported the most common troubles that can cause the unit to stop or to operate in

an uncorrect way.

Concerning the solutions, it is necessary to take an extreme care on the actions to adopt: an

excessive confidence may cause serious accidents to inexperienced people. It is advisable, once

the cause is detected, to contact our servicing people or trained people only.

8.1 UNIT UNDER ALARM

When red light is lit up, the unit is stopped and set under alarm condition.

To restore normal operating mode, it is necessary to detect and remove the cause of the alarm

PROBLEM

LED ON

PROBABLE CAUSE

CORRECTIVE ACTION

A

Unit does not

start

but alarm green

led

is off

None

Power supply missing

Provide power supply,

replace fuses

Power supply

led

Humidistat on set

Set a lower set point

Power supply

led,

Compressor thermal

protection enabled,

compressor defective

Let the compressor cool

down, replace compressor

defective

Power supply

led,

Compressor thermal

protection enabled,

compressor defective

fan defective

Let the compressor cool

down, replace compressor

defective, replace fan

defective

Any led

Electronic board or led

Board defective

Replace defective board

Page 19

FD

19

PROBLEM

LED ON

PROBABLE CAUSE

CORRECTIVE ACTION

B

Fan starts,

compressor

does not start,

but red alarm led

Power supply

led, running led

Compressor thermal

Protection enabled,

compressor defective

Let the compressor cool

Down, replace

compressor defective

Any led

Electronic board or led

Board defective

Replace defective board

PROBLEM

LED ON

PROBABLE CAUSE

CORRECTIVE ACTION

C

Fan starts,

compressor

does

not start, but red

alarm led is on

Red alarm led

Air filter clogged

Clean filter and reset unit

Red alarm led

Low refrigerant charge

Charge the system

Red alarm led

Open panel, low air

flow, suction side

obstructed, high

pressure switch on

Close the panel, clear

Suction side, reset high

pressure switch

Any led

Electronic board or led

Board defective

Replace defective board

Page 20

FD

20

CHAPTER 9: ELECTRIC DIAGRAM

Page 21

FD

21

CHAPTER 10: DRAWINGS (lay out)

INSTALLATION

DUCTING

Min. Distance 200 mm

INSTALLATION

WALL

CEILING

INSTALLATION

ON TROLLEY

Page 22

FD

22

DIMENSIONAL DRAWINGS

FD360

Mod. 360

Assieme

3 lug 05

in line version

Scarico Condensa 3/4"M

Waste condensed water fitting 3/4"M

Lato Filtro Aspirazione

Suction Filter Side

Pannello Frontale

Front Panel

Quadro Elettrico

Electric Panel

Mod. 360

Assieme

3 lug 05

Lato Filtro Aspirazione

Quadro Elettrico

Electric Panel

On Top supply version

Suction Filter Side

Pannello Frontale

Front Panel

Scarico Condensa 3/4"M

Waste condensed water fitting 3/4"M

Loading...

Loading...