USER MANUAL

TVNextTM (FR01-B3-V-0-054)

Last updated on June 2017

© 2016 FRACTUS ANTENNAS, S.L. - 1

TVNext

TM

(FR01-B3-V-0-054) – Mobile TV (VHF)

Fractus Antennas specializes in enabling effective mobile communications. Using Fractus

technology, we design and manufacture optimized antennas to make your wireless devices

more competitive. Our mission is to help our clients develop innovative products and accelerate

their time to market through our expertise in antenna design, testing and manufacturing.

TVNextTM

FR01-B3-V-0-054

Some Fractus Antennas products are

protected by Fractus patents.

All information contained within this

document is property of Fractus Antennas

and is subject to change without prior

notice. Information is provided “as is” and

without warranties. It is prohibited to copy

or reproduce this information without prior

approval.

Fractus Antennas is an ISO 9001:2008

certified company. All our antennas are

lead-free and RoHS compliant.

USER MANUAL

TVNextTM (FR01-B3-V-0-054)

Last updated on June 2017

© 2016 FRACTUS ANTENNAS, S.L. - 2

INDEX OF CHAPTERS

1. ANTENNA DESCRIPTION ................................................................................................. 4

2. QUICK REFERENCE GUIDE ............................................................................................. 4

3. ELECTRICAL PERFORMANCE ......................................................................................... 5

4. MECHANICAL CHARACTERISTICS .................................................................................. 8

5. ASSEMBLY PROCESS .................................................................................................... 10

6. PACKAGING ................................................................ .................................................... 12

USER MANUAL

TVNextTM (FR01-B3-V-0-054)

Last updated on June 2017

© 2016 FRACTUS ANTENNAS, S.L. - 3

TABLE OF CONTENTS

1. ANTENNA DESCRIPTION ................................................................................................. 4

2. QUICK REFERENCE GUIDE ............................................................................................. 4

3. ELECTRICAL PERFORMANCE ......................................................................................... 5

3.1. TVNextTM EVALUATION BOARD ................................................................................ 5

3.2. RADIATION PATTERNS AND GAIN .......................................................................... 6

3.3. CAPABILITIES AND MEASUREMENT SYSTEMS ..................................................... 7

4. MECHANICAL CHARACTERISTICS .................................................................................. 8

4.1. DIMENSIONS AND TOLERANCES ............................................................................ 8

4.2. SPECIFICATIONS FOR THE INK ............................................................................... 8

4.3. ANTENNA FOOTPRINT (as used in the evaluation board) ......................................... 9

5. ASSEMBLY PROCESS .................................................................................................... 10

6. PACKAGING ................................................................ .................................................... 12

USER MANUAL

TVNextTM (FR01-B3-V-0-054)

Last updated on June 2017

© 2016 FRACTUS ANTENNAS, S.L. - 4

1. ANTENNA DESCRIPTION

The TVNextTM is an off-the-shelf internal antenna solution specifically designed for general

handheld devices and applications operating in the FM band.

TVNextTM minimizes your product development cost and time. With its compact size and high

performance, the TVNextTM internal antenna is the optimal choice for your portable FM

application.

With its superior performance, small form factor, modularity and high isolation, the TVNextTM

antenna solution meets and exceeds all your customer requirements for an internal compact

and modular antenna.

TOP

BOTTOM

Material: The TVNextTM antenna is built on glass epoxy substrate.

APPLICATIONS

Mobile Phones

Personal Media Player (PMP)

Ultra Mobile PC (UMPC)

Laptops

BENEFITS

Reduced Form Factor

Modularity - SMD

Superior Performance

Easy to use (pick and place)

2. QUICK REFERENCE GUIDE

Technical Features

Frequency Range

180 – 220 MHz

Gain Curve

See page 6

Radiation Pattern

Omnidirectional

Flatness

< 2 dB gain variation

Weight (approx.)

0.6 g

Temperature

-40 to 85º C

Impedance

50 Ω

Dimensions (L x W x H)

20.0 mm x 10.0 mm x 1.6 mm

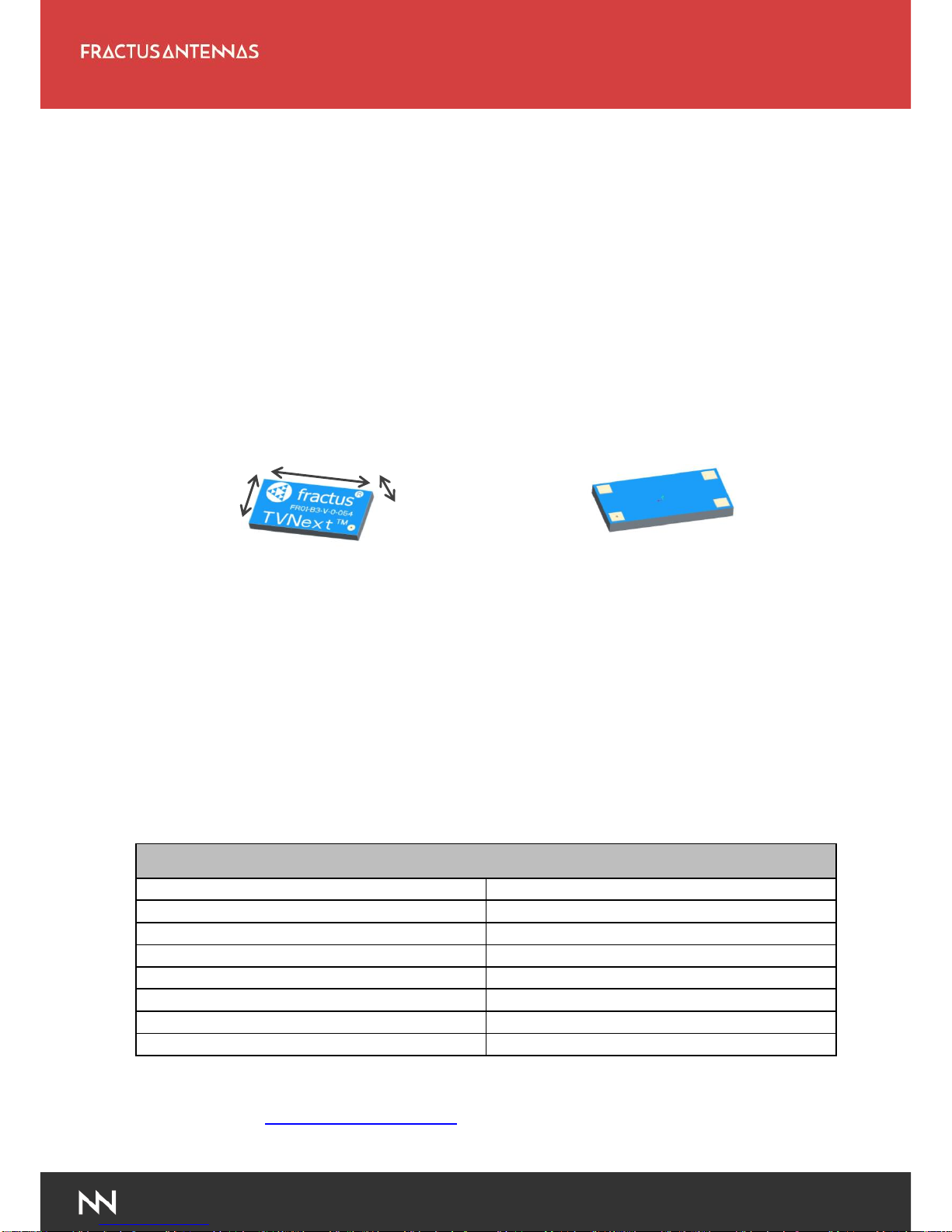

Table 1 – Technical Features. Measures from the evaluation board. See Figure 1.

Please contact info@fractusantennas.com if you require additional information on antenna

integration or optimization on your PCB.

10 mm

20 mm

1.6 mm

USER MANUAL

TVNextTM (FR01-B3-V-0-054)

Last updated on June 2017

© 2016 FRACTUS ANTENNAS, S.L. - 5

3. ELECTRICAL PERFORMANCE

3.1. TVNextTM EVALUATION BOARD

The configuration used in testing the TVNextTM antenna is displayed in Figure 1.

Measure

mm

A

112.0

B

60.0

C

128.0

D

47.5

Tolerance: ±0.2mm

Material: The evaluation board is built on

laminated substrate 1.0 mm thick (2 layers).

Figure 1 – TVNextTM Evaluation Board.

Matching network required:

Value

Part Number

210 nH

LQH31HNR21J032

140 nH

LQH31HNR14J032

Figure 2 – Matching network implemented in the Evaluation Board.

Note: Optimal matching network values may vary depending on the antenna environment.

Please, contact info@fractusantennas.com for additional support to integrate the antenna in a

specific application.

210 nH 140 nH

TVNext

USER MANUAL

TVNextTM (FR01-B3-V-0-054)

Last updated on June 2017

© 2016 FRACTUS ANTENNAS, S.L. - 6

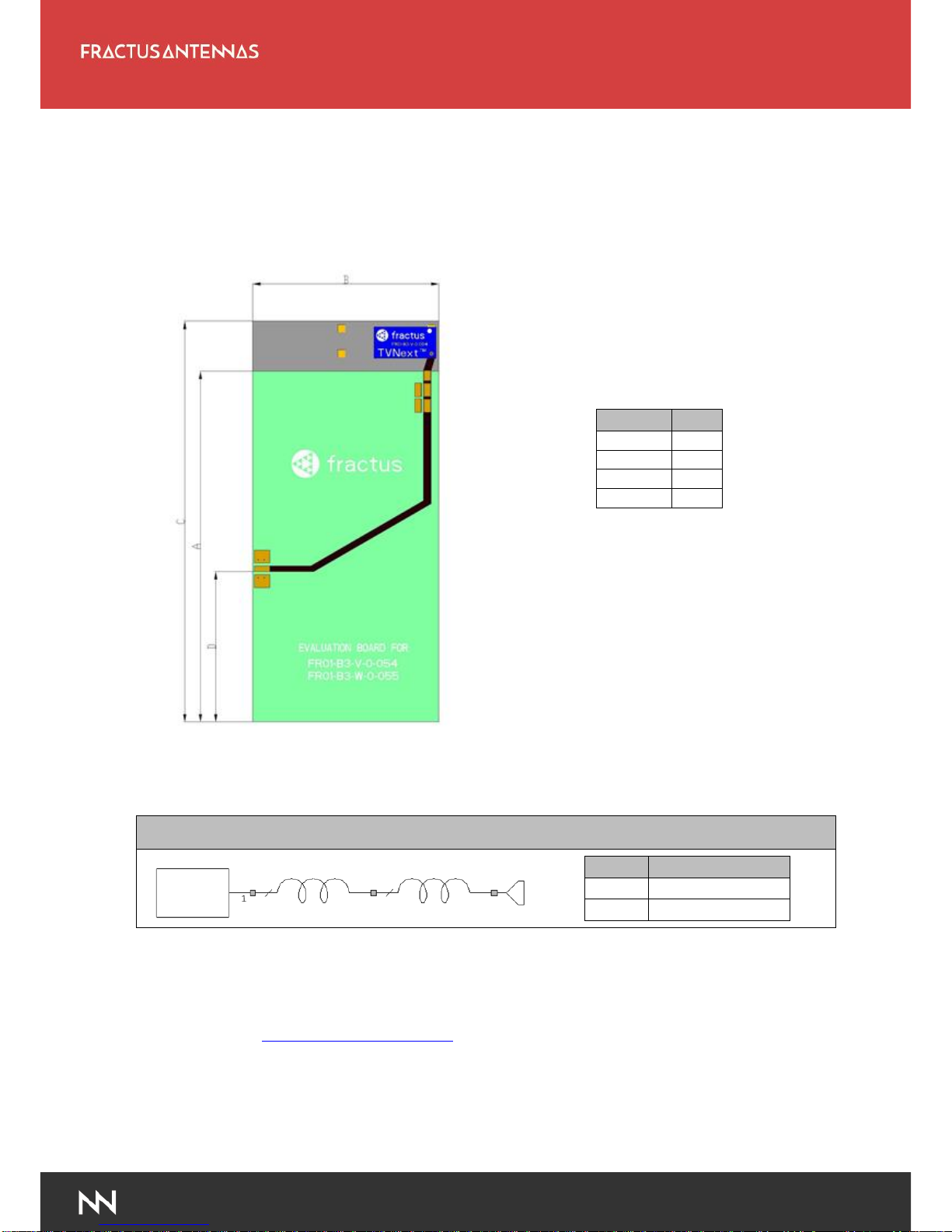

3.2. RADIATION PATTERNS AND GAIN

Table 2 – Typical antenna Gain across VHF bandwidth.

GAIN

Note: Please notify that this antenna is designed for reception.

Radiation Pattern

Radiation Pattern

-40

-35

-30

-25

-20

-15

-10

170 180 190 200 210 220 230 240

Frequency [MHz]

Gain [dB]

200 MHz

-30

-25

-20

-15

-10

-5

0

180

240

270

310

330

120

150

0

30

60

90

210

USER MANUAL

TVNextTM (FR01-B3-V-0-054)

Last updated on June 2017

© 2016 FRACTUS ANTENNAS, S.L. - 7

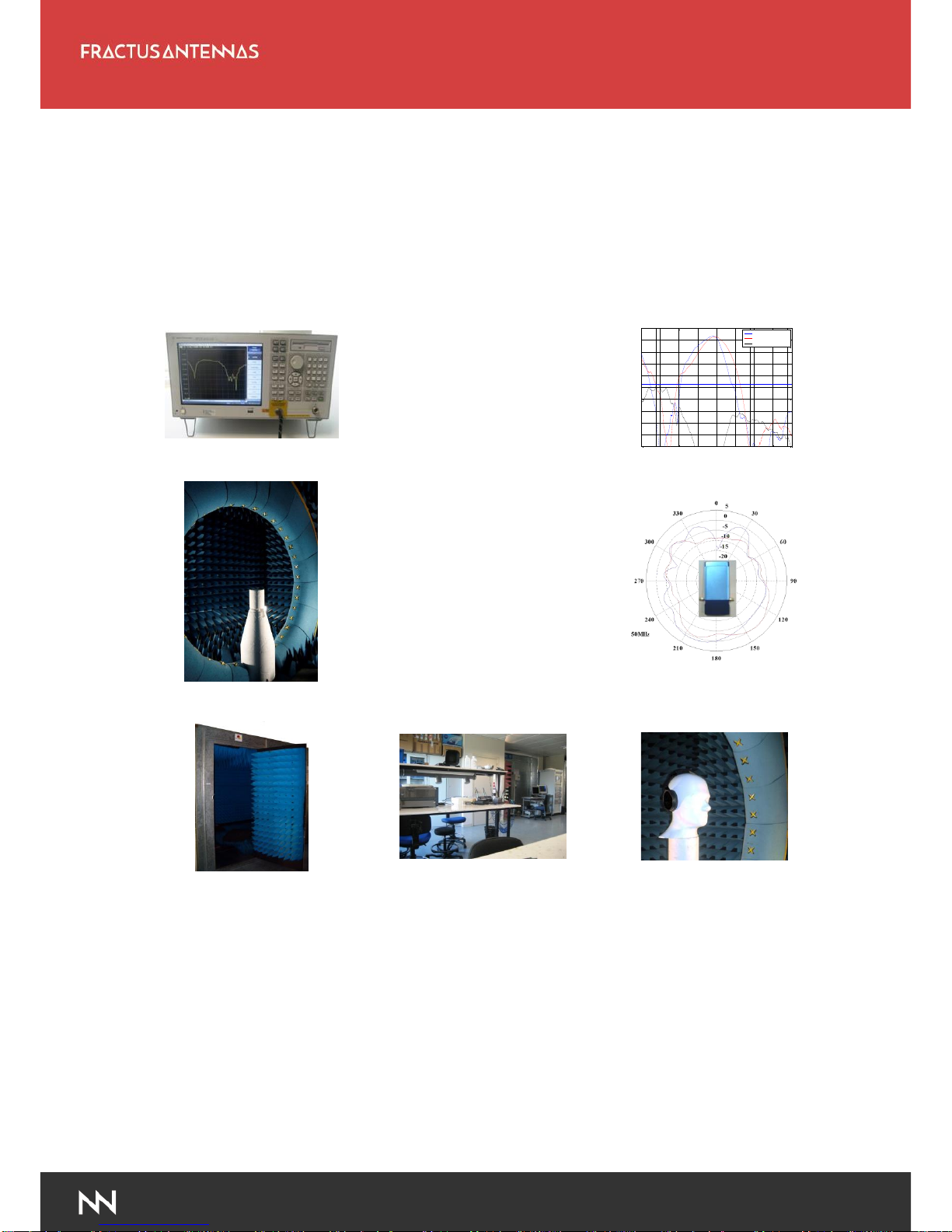

3.3. CAPABILITIES AND MEASUREMENT SYSTEMS

Fractus Antennas specializes in the design and manufacture of optimized antennas for wireless

applications, and with the provision of RF expertise to a wide range of clients. We offer turn-key

antenna products and antenna integration support to minimize your time requirements and

maximize return on investment throughout the product development process. We also provide

our clients with the opportunity to leverage our in-house testing and measurement facilities to

obtain accurate results quickly and efficiently.

Agilent E5071B

VSWR

&

S Parameters

Radiation

Pattern

&

Efficiency

SATIMO STARGATE 32

Anechoic chambers and full equipped in-house lab

2 2 .5 3 3.5 4 4.5 5 5.5 6

-20

-18

-16

-14

-12

-10

-8

-6

-4

-2

0

Return Lo ss (dB)

Freque nc y (GHz)

Left Ante nna

Right An tenn a

Isolatio n

VSWR=2

2 2 .5 3 3.5 4 4.5 5 5.5 6

-20

-18

-16

-14

-12

-10

-8

-6

-4

-2

0

Return Lo ss (dB)

Freque nc y (GHz)

Left Ante nna

Right An tenn a

Isolatio n

VSWR=2

USER MANUAL

TVNextTM (FR01-B3-V-0-054)

Last updated on June 2017

© 2016 FRACTUS ANTENNAS, S.L. - 8

4. MECHANICAL CHARACTERISTICS

4.1. DIMENSIONS AND TOLERANCES

TOP SIDE BOTTOM

Note: all antenna pads

have (feed point and

mounting pads) have

the same dimensions.

The yellow hole located on the front of the antenna provides a visual cue to mounting the

antenna. It is located above the feed point of the antenna and is included to decrease possible

manufacturing error.

Measure

mm

Measure

mm

A

20.0 0.2

C

1.6 0.2

B

10.0 0.2

D

2.0 0.1

Figure 3 – Antenna Dimensions and Tolerances.

The TVNextTM VHF antenna is compliant with the restriction of the use of hazardous substances

(RoHS).

4.2. SPECIFICATIONS FOR THE INK

Next figure shows the correct colors of the antenna:

Acceptable color range

USER MANUAL

TVNextTM (FR01-B3-V-0-054)

Last updated on June 2017

© 2016 FRACTUS ANTENNAS, S.L. - 9

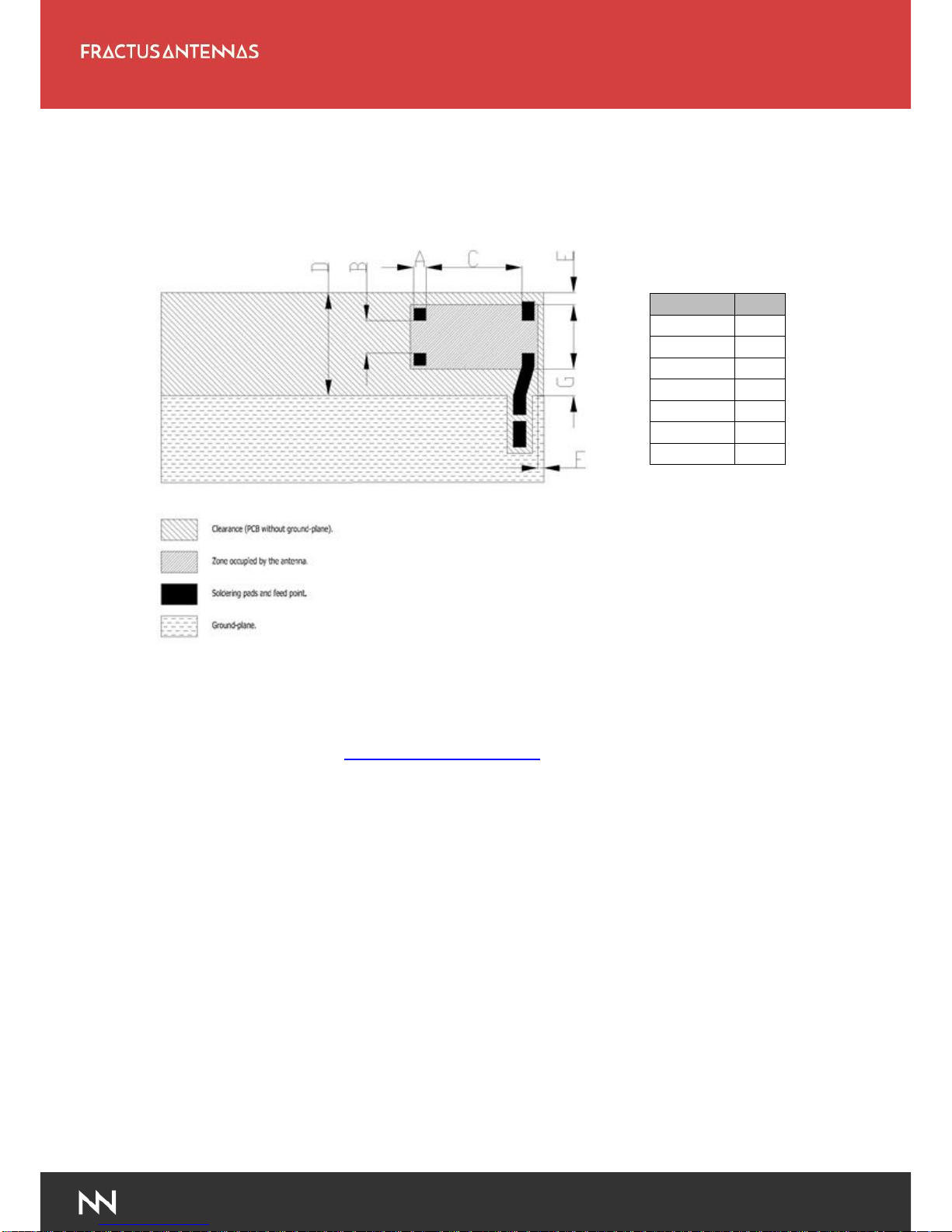

4.3. ANTENNA FOOTPRINT (as used in the evaluation board)

This antenna footprint applies for the reference evaluation board described on page 5 of this

User Manual.

Measure

mm

A

2.0 B 5.0

C

15.0

D

16.0

E

1.9

F

0.9 G 4.1

Tolerance: ±0.2 mm

Note: all the soldering pads

(feed point and mounting pads)

on the antenna layout have the

same dimensions.

Figure 4 – Antenna Footprint Details.

Other PCB form factors and configurations may require a different feeding configuration, feeding

line dimensions and clearance areas. If you require support for the integration of the antenna in

your design, please contact info@fractusantennas.com.

USER MANUAL

TVNextTM (FR01-B3-V-0-054)

Last updated on June 2017

© 2016 FRACTUS ANTENNAS, S.L. - 10

5. ASSEMBLY PROCESS

Figure 5 shows the back and front view of the TVNextTM VHF antenna, and indicates the

location of the feeding point and the mounting pads:

Figure 5 – Pads of the TVNextTM VHF chip antenna.

As a surface mount device (SMD), this antenna is compatible with industry standard soldering

processes. The basic assembly procedure for this antenna is as follows:

1. Apply a solder paste to the pads of the PCB. Place the antenna on the board.

2. Perform a reflow process according to the temperature profile detailed in Table 3, Figure 7

on page 11.

3. After soldering the antenna to the circuit board, perform a cleaning process to remove any

residual flux. Fractus Antennas recommends conducting a visual inspection after the

cleaning process to verify that all reflux has been removed.

The drawing below shows the soldering details obtained after a correct assembly process:

Figure 6 – Soldering Details.

NOTE(*): Solder paste thickness after the assembly process will depend on the thickness of the

soldering stencil mask. A stencil thickness equal to or larger than 127 microns (5 mils) is

required.

1

4

3

2

Antenna

PCB

Solder Paste

Antenna

PCB

~ 0.1* mm

1 1

3

Mounting Pads (2, 3, 4): solder the antenna mounting pads to the

soldering pads on the PCB. These pads must NOT be grounded.

Feed Pad (1): align the feed point with the feeding line on the PCB.

USER MANUAL

TVNextTM (FR01-B3-V-0-054)

Last updated on June 2017

© 2016 FRACTUS ANTENNAS, S.L. - 11

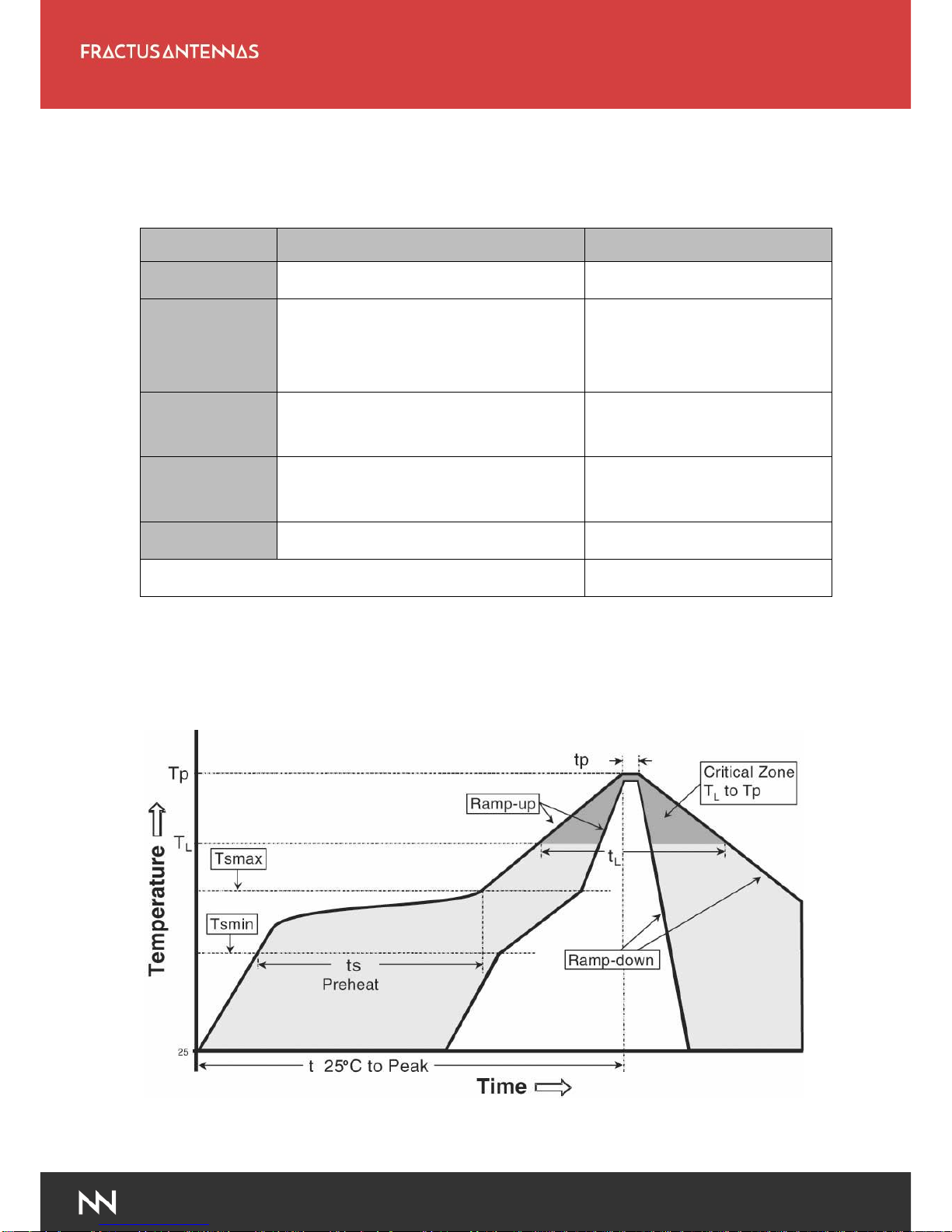

The TVNextTM VHF antenna should be assembled following either Sn-Pb or Pb-free assembly

processes. According to the Standard IPC/JEDEC J-STD-020C, the temperature profile

suggested is as follows:

Phase

Profile features

Pb-Free Assembly (SnAgCu)

RAMP-UP

Avg. Ramp-up Rate (Tsmax to Tp)

3 ºC / second (max.)

PREHEAT

- Temperature Min (Tsmin)

- Temperature Max (Tsmax)

- Time (tsmin to tsmax)

150 ºC

200 ºC

60-180 seconds

REFLOW

- Temperature (TL)

- Total Time above TL (tL)

217 ºC

60-150 seconds

PEAK

- Temperature (Tp)

- Time (tp)

260 ºC

20-40 seconds

RAMP-DOWN

Rate

6 ºC/second max

Time from 25 ºC to Peak Temperature

8 minutes max

Table 3 – Recommended soldering temperatures.

Next graphic shows temperature profile (grey zone) for the antenna assembly process in reflow

ovens.

Figure 7 – Temperature profile.

USER MANUAL

TVNextTM (FR01-B3-V-0-054)

Last updated on June 2017

© 2016 FRACTUS ANTENNAS, S.L. - 12

6. PACKAGING

The TVNext™ chip antenna is available in tape and reel packaging.

Measure

mm

W

32.0

A0

11.5

B0

22.0

K0

1.8

B1

22.0 max

D

1.6

D1

2.1 min

Wmax

32.3

E

1.5

F

14.2

K

2.1 max

P

16.5

P0

4.5

P2

2.0

Tolerance: ±0.2mm

Figure 8 – Tape Dimensions.

Figure 9 – Image of the tape.

Measure

mm

A max

330.0

G

32.4

t max

38.4

Tolerance: ±0.2 mm

Reel Capacity: 2000 antennas

Figure 10 – Reel Dimensions and Capacity.

Loading...

Loading...