TO BE USED WITH FRACINO USER MANUAL AND INSTALLATION MANUAL

V1.1

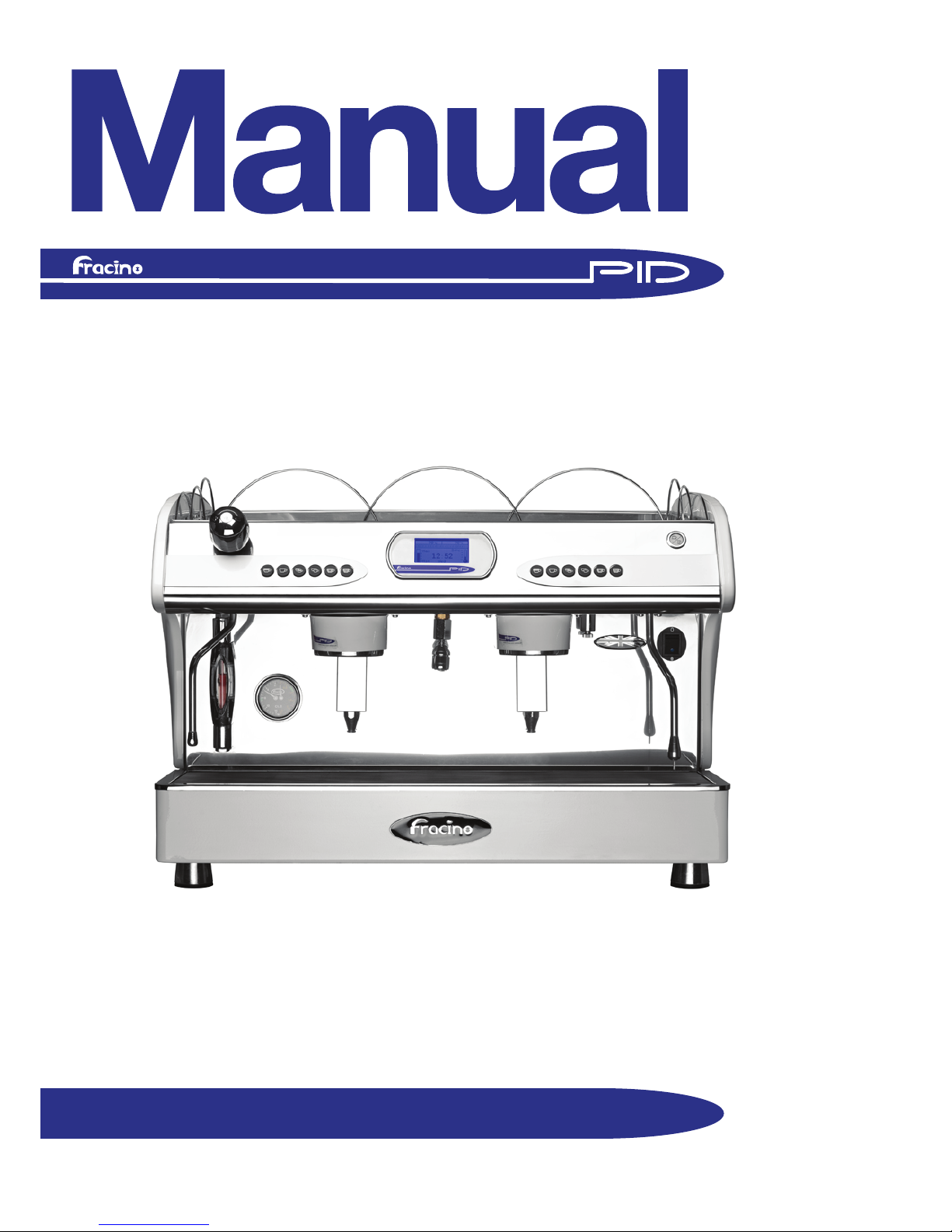

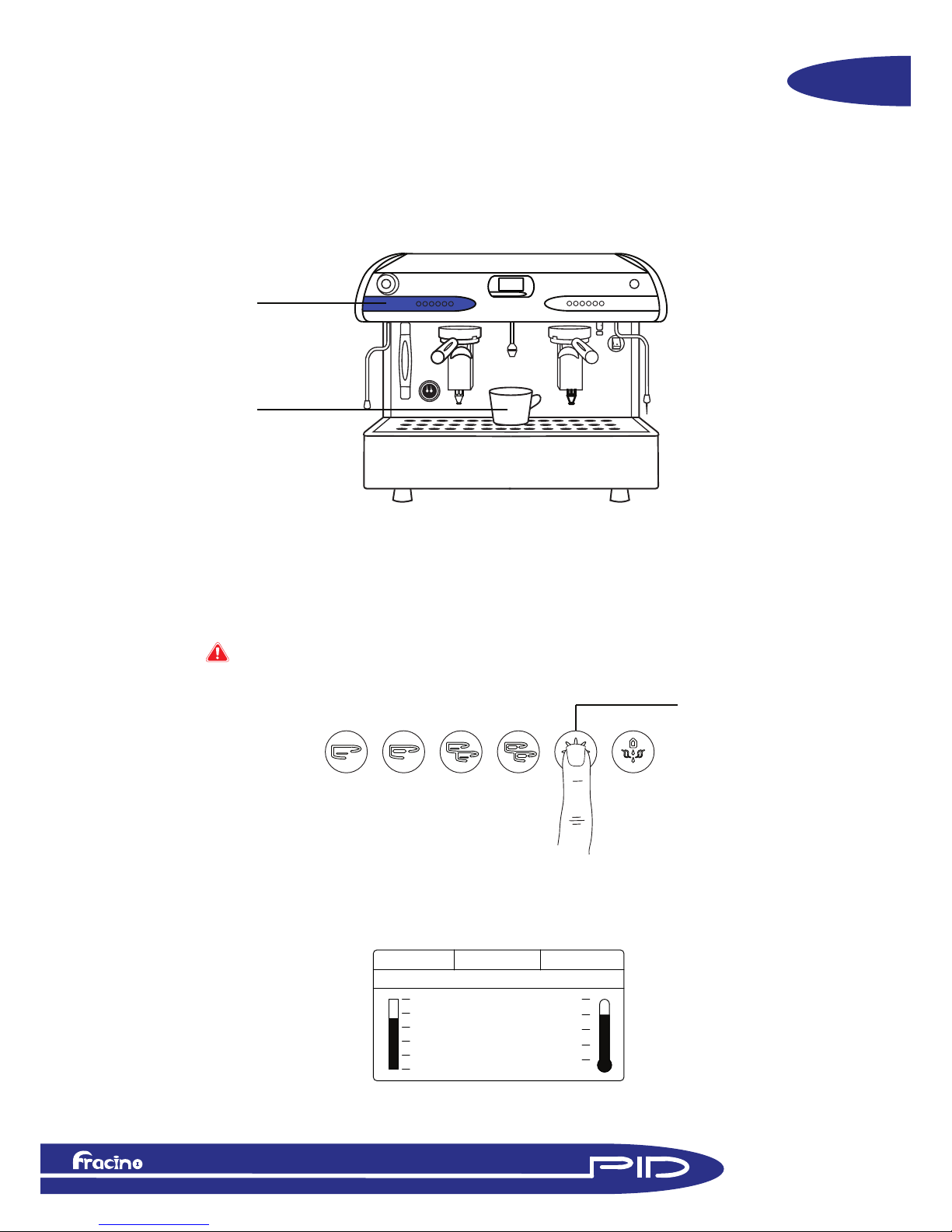

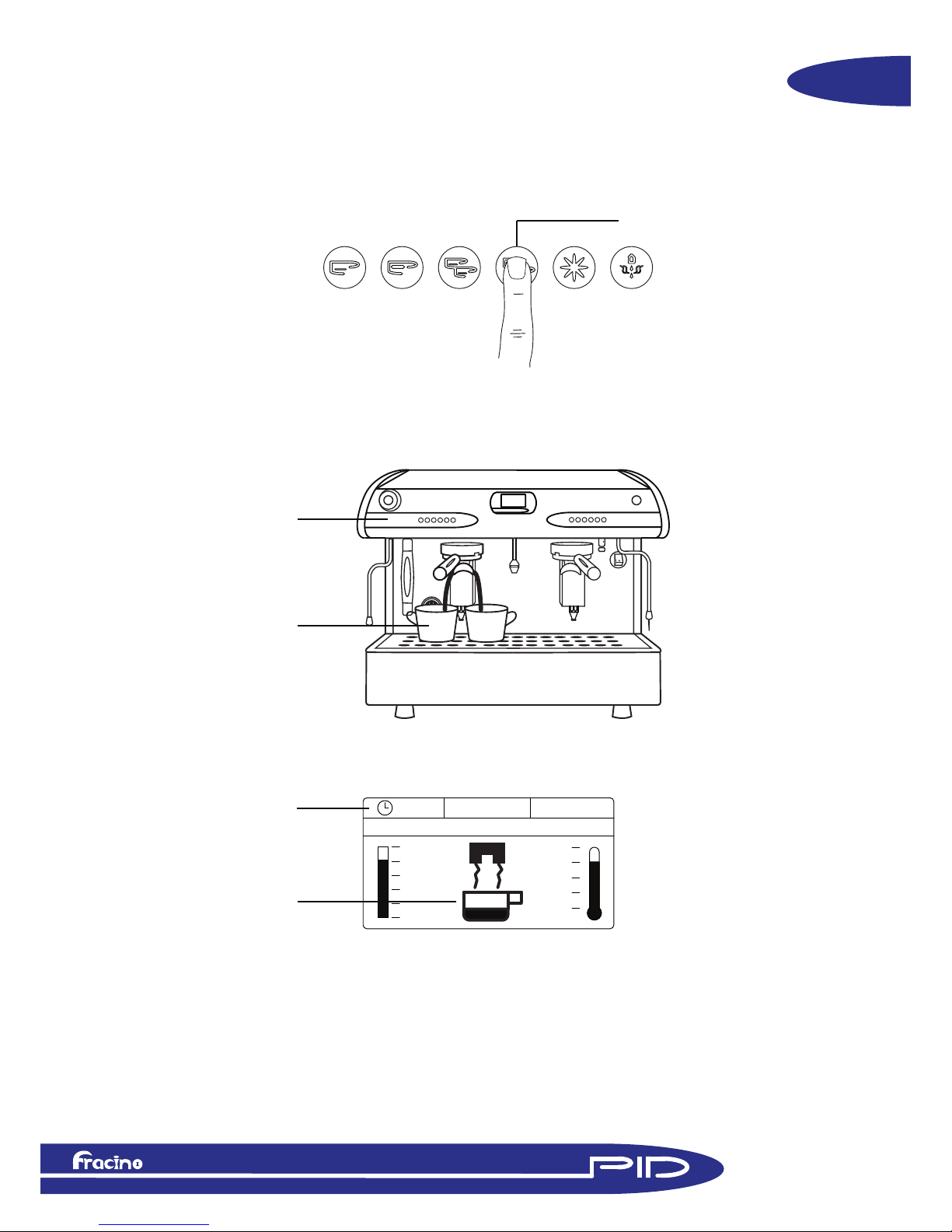

DISPLAY AND KEYPAD

OVERVIEW

T

o

GR1 T

o

GR2 T

o

GR3

FRACINO ROMANO

MAX

MIN

HH:MM

DAY

ToBOILER

1

2

3

7

4

8

5

6

Display

Normal Operation

1. Group 1 Temperature oC

2. Group 2 Temperature oC

3. Group 3 Temperature oC

4. Steam Boiler Temperature oC

5. Time

6. Day

7. Steam boiler water level indicator

8. Scrolling menu bar

Keypad

Group 1

K1GR1 K2GR1

K3GR1 K4GR1

K5GR1 K6GR1

K1GR1

K2GR1

K3GR1

K4GR1

K5GR1

K6GR1

PRIMARY FUNCTION SECONDARY FUNCTION

Single Espresso

Single Cappuccino

Double Espresso

Double Cappuccino

Manual Override

Hot Water Dispense

Scroll up when in program menu or technical menu

Scroll down when in program menu or technical menu

Select/enter when in program menu or technical menu

Enter program menu or techincal menu

1

Keypad

Group 2

K1GR2 K2GR2

K3GR2 K4GR2

K5GR2 K6GR2

K1GR2

K2GR2

K3GR2

K4GR2

K5GR2

K6GR2

PRIMARY FUNCTION SECONDARY FUNCTION

Single Espresso

Single Cappuccino

Double Espresso

Double Cappuccino

Manual Override

Steam Dispense*

Scroll up when in program menu

Scroll down when in program menu

Select/enter when in program menu

Enter program menu

*2 Group only, on a 3 group machines this is for hot water

Keypad

Group 3

K1GR3 K2GR3

K3GR3 K4GR3

K5GR3 K6GR3

K1GR3

K2GR3

K3GR3

K4GR3

K5GR3

K6GR3

PRIMARY FUNCTION SECONDARY FUNCTION

Single Espresso

Single Cappuccino

Double Espresso

Double Cappuccino

Manual Override

Steam Dispense

Scroll up when in program menu

Scroll down when in program menu

Select/enter when in program menu

Enter program menu

DISPLAY AND KEYPAD

OVERVIEW

2

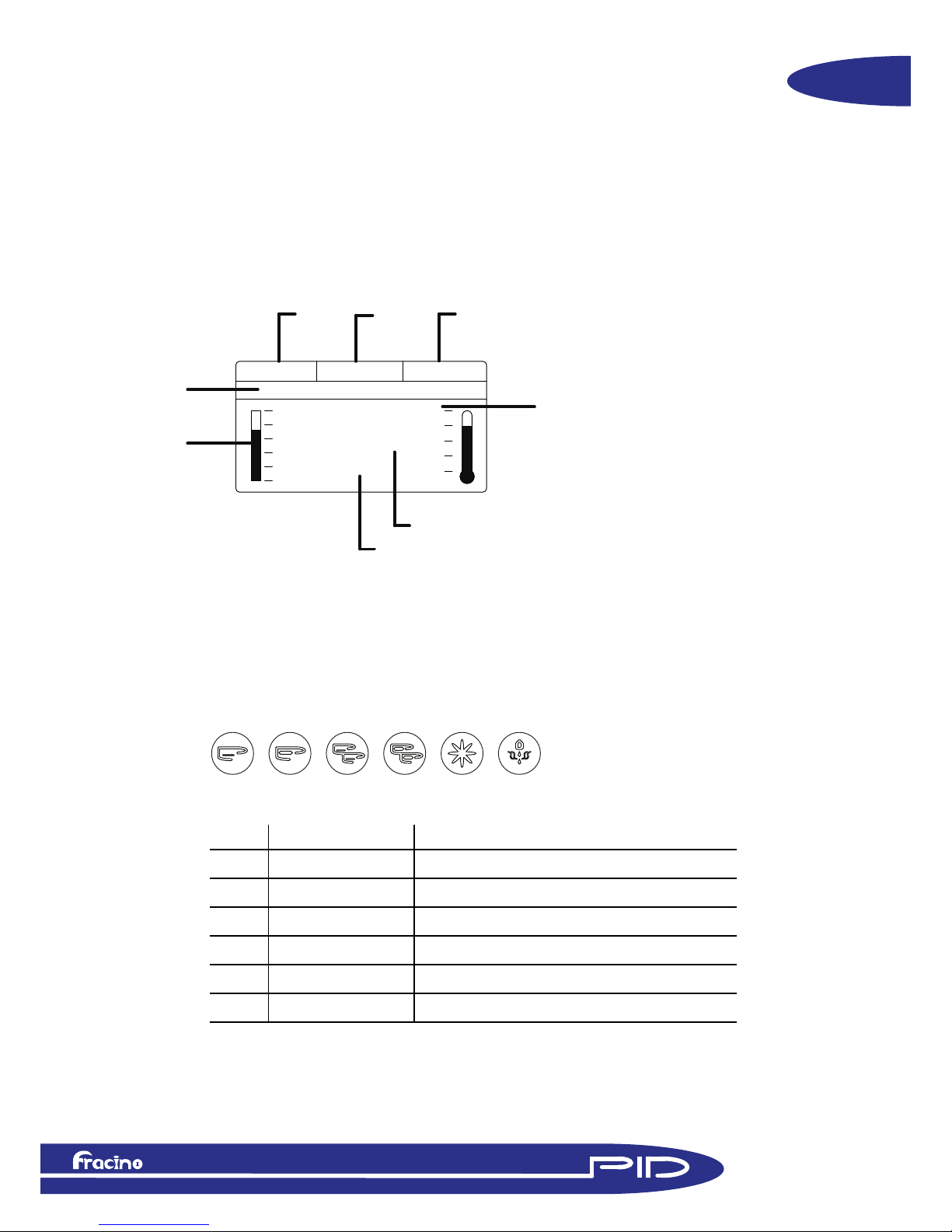

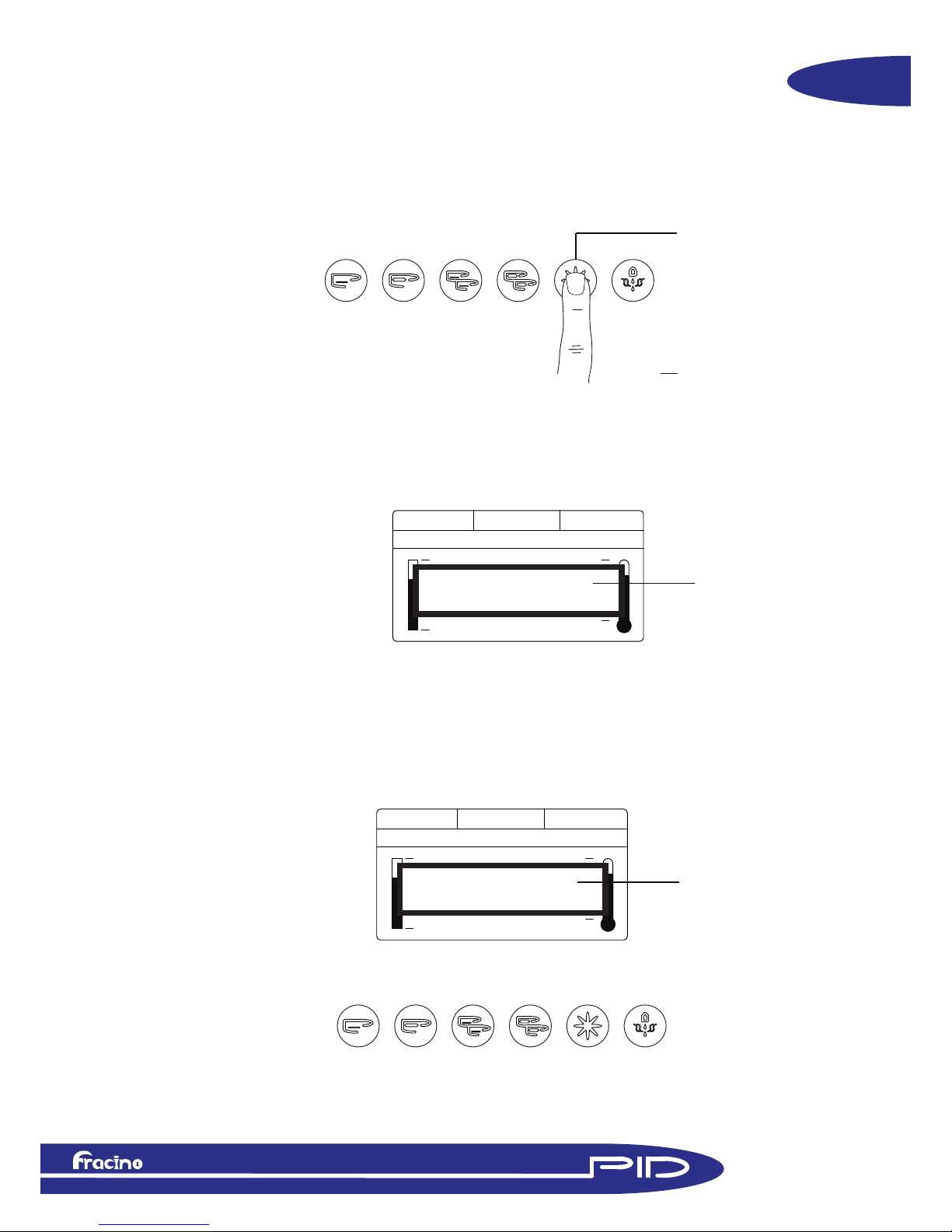

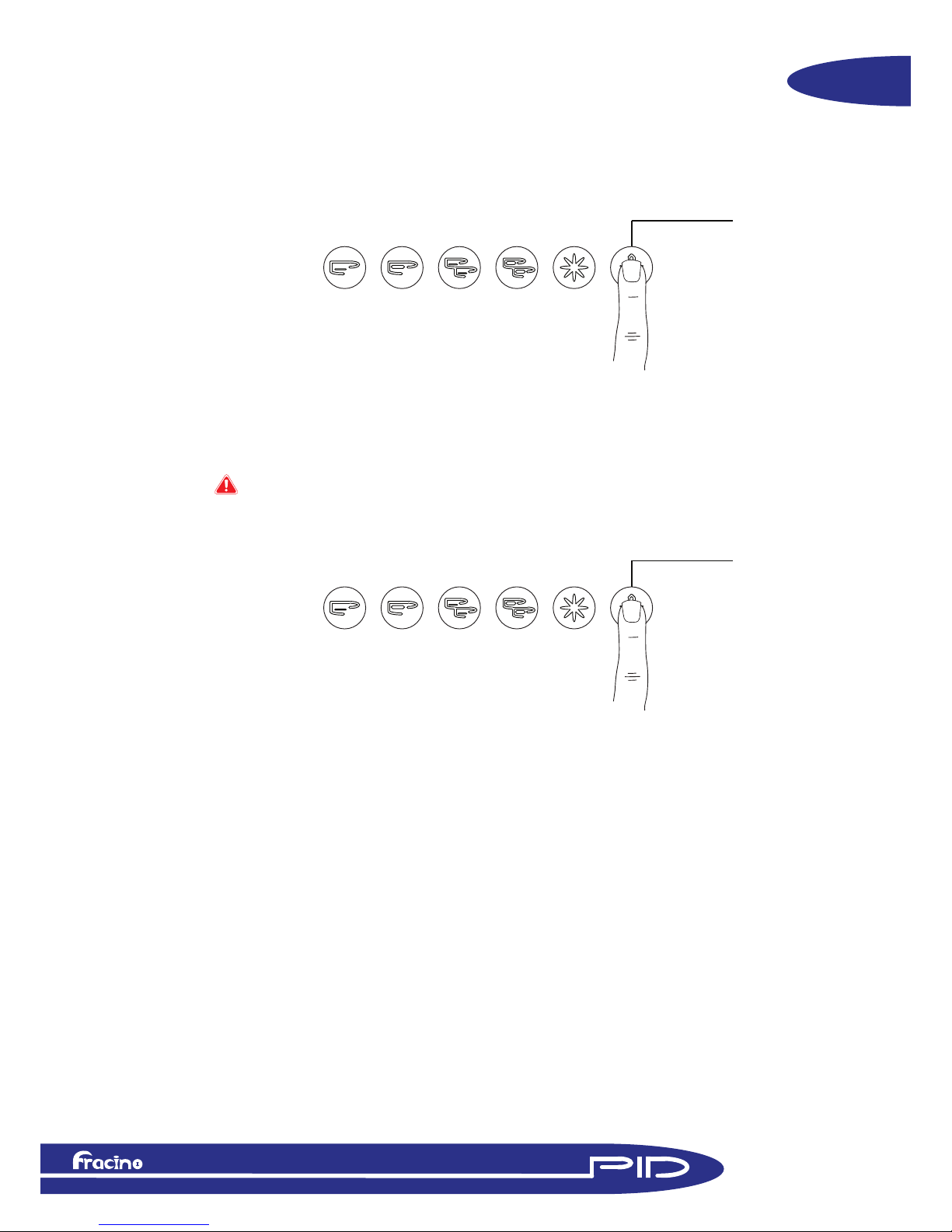

START UP

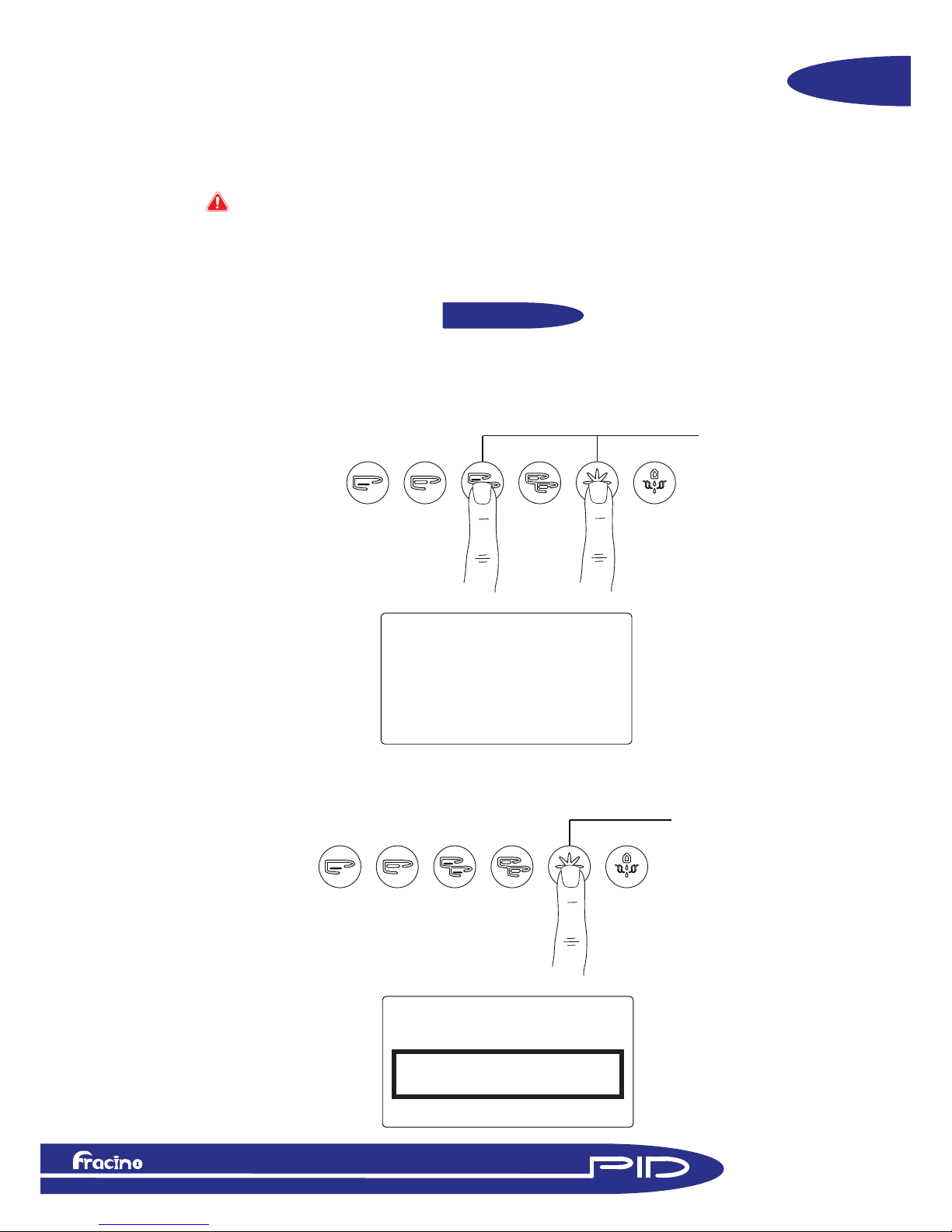

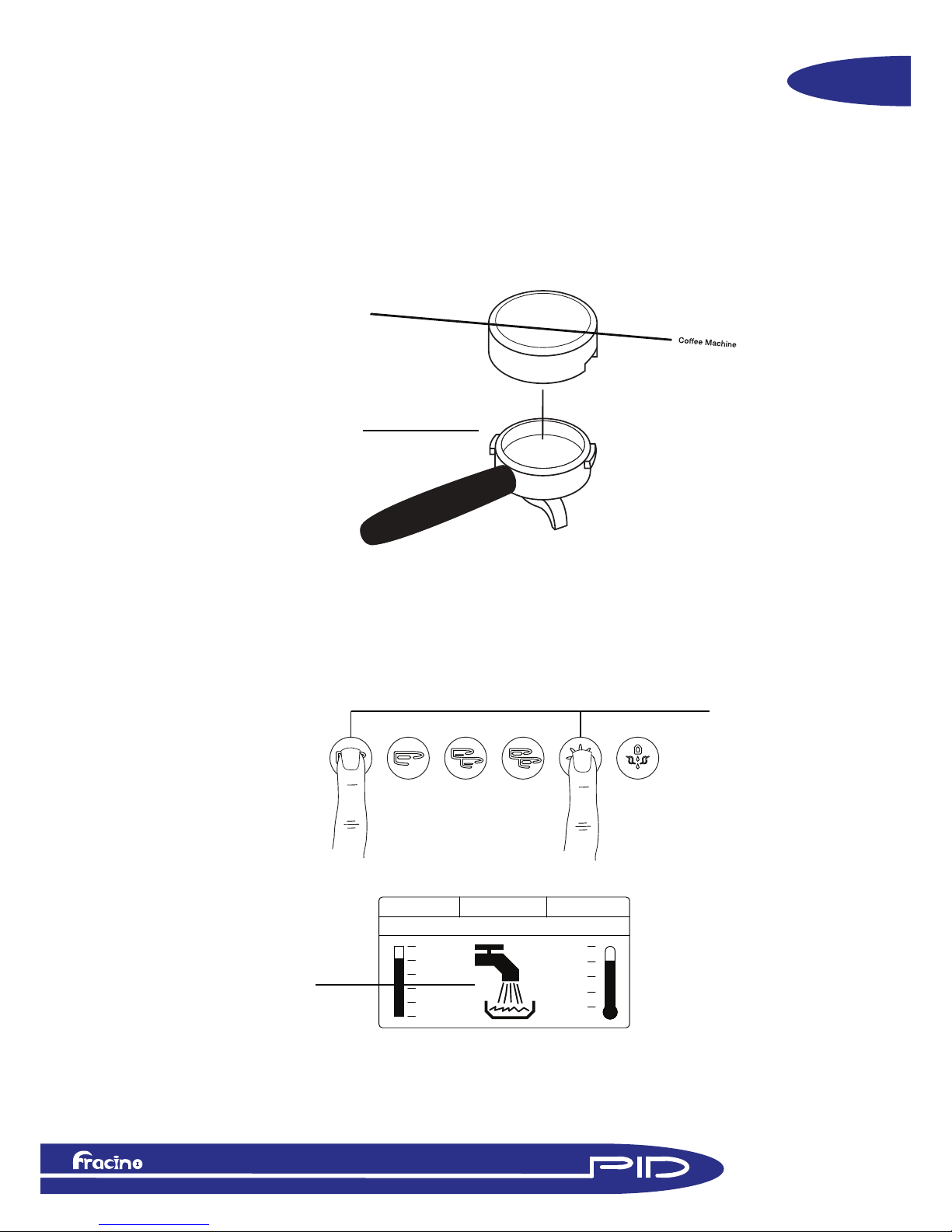

Initial start up

1

1. On the initial start-up, immediatly after installation, turn the machine on using the

black rocker switch on the fornt panel behind the right hand steam tube, the blue light

should illuminate indicating the power is on. The display and keypads should illuminate.

20oC 20oC 20oC

FRACINO PID

MAX

MIN

09:00

MONDAY

20oC

2. After a second or two the boiler will begin to fill, this is indicated on the boiler water level

indicator on the display, the water level can also be observed on the sight glass on the left

hand side of the machine, it may take several minutes for the boiler to fill.

2

2

NOTE: The machine may time out during the filling, this will be indicated by a buzzer

and a “!” symbol on the display, turn the machine off using the mains on/off rocker switch,

wait 5seconds and turn on again - the machine will continue of fill.

NOTE: For installation instructions, refer to the Installation Manual supplied

with the machine

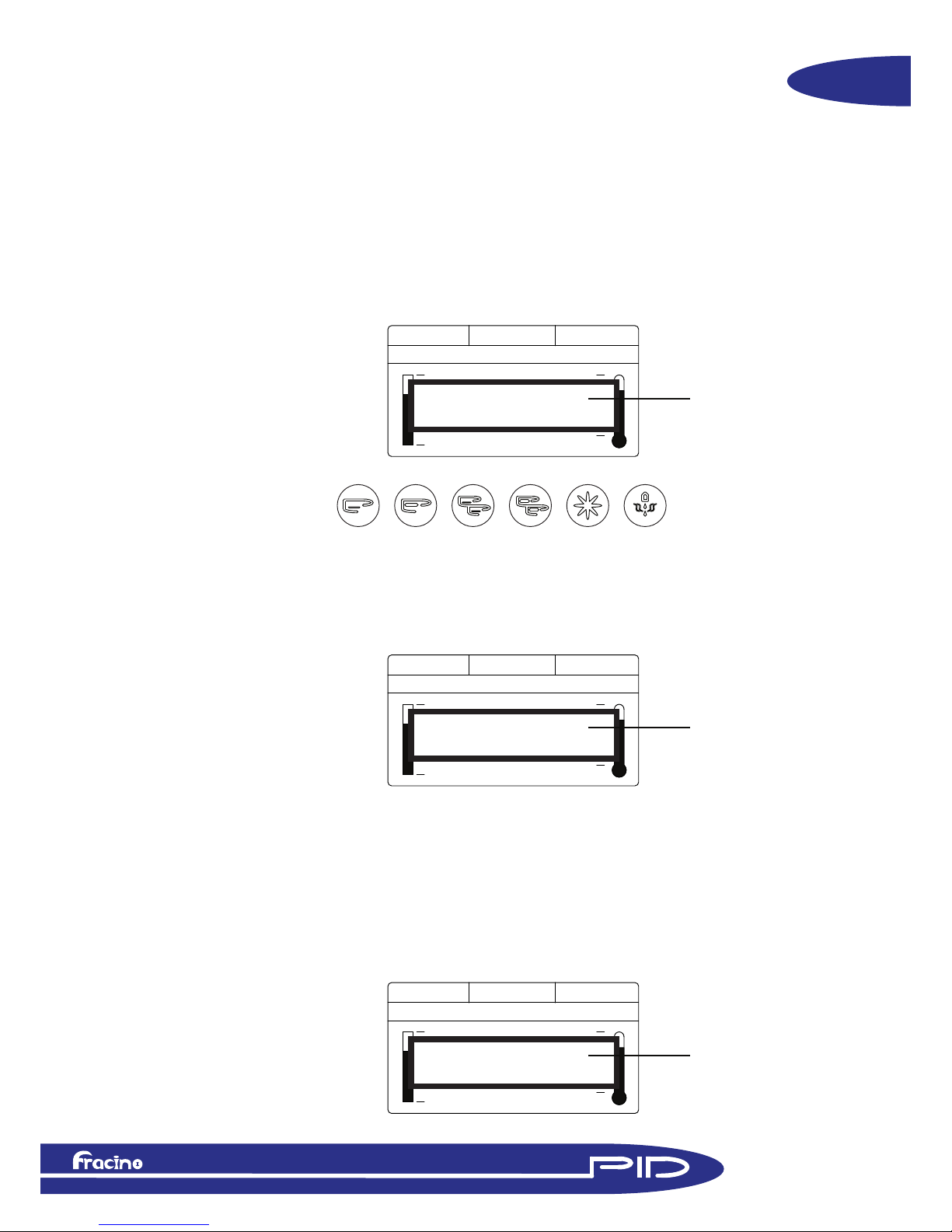

3

START UP

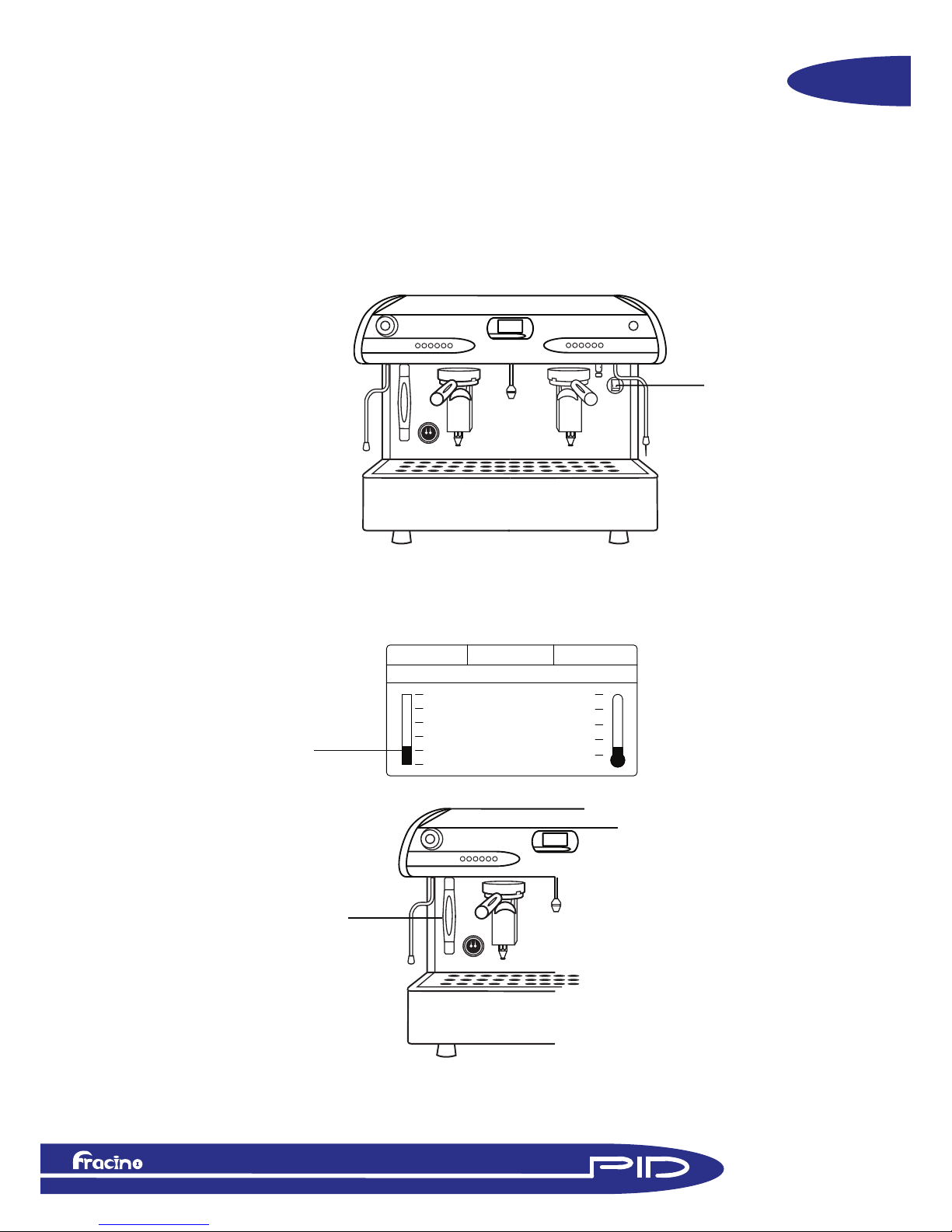

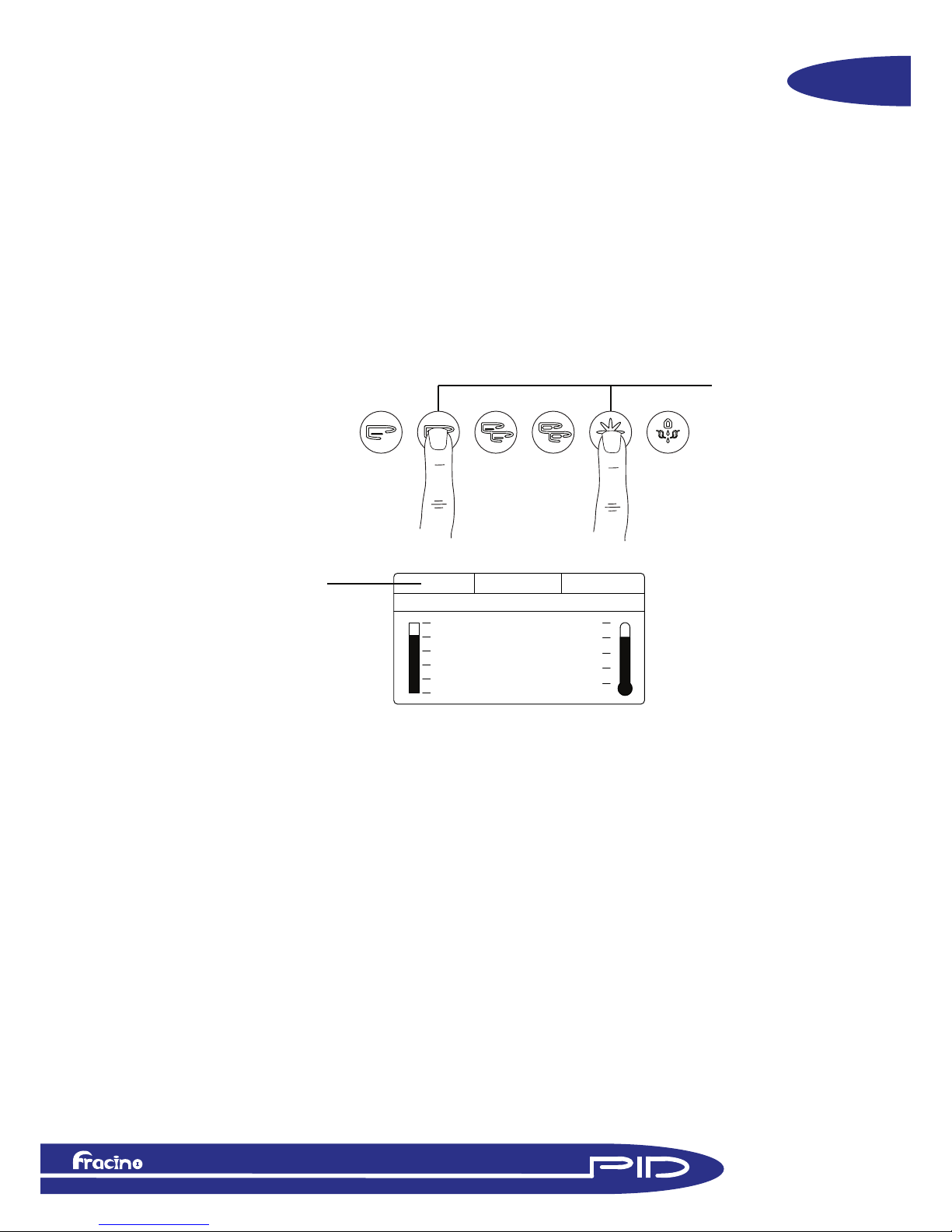

3. Immediatly after the boiler has filled press the star button on each group until water appears

from the bottom of the groups - this is to ensure the heat exchangers and group boilers are

full of water.

40oC 40oC 40oC

FRACINO ROMANO

MAX

MIN

09:00

MONDAY

35oC

4. After filling the boilers will start to heat, this is indicated on the groups by the heating element

symbol, which appears on the group temperature readout this symbol will appear when the group

heating element is on, as the group approaches its set temperature it will begin to pulse until the set

point is reached, it will then pulse to maintane the set point temperature.

3

4

5

5. The steam boiler temperature is indicated on the right hand side of the display. It is good practice

to open the steam valve by turning clockwise when the steam boiler is heating, this can be closed

when steam starts to appear from the steam tube. The steam pressure will build until it

reaches 1-1.2Bar.

5

6. It is advisable to leave the machine with the filer holders inserted in the groups for 10-15 minutes

to allow the groups to get hot and stabilize their temperature.

4

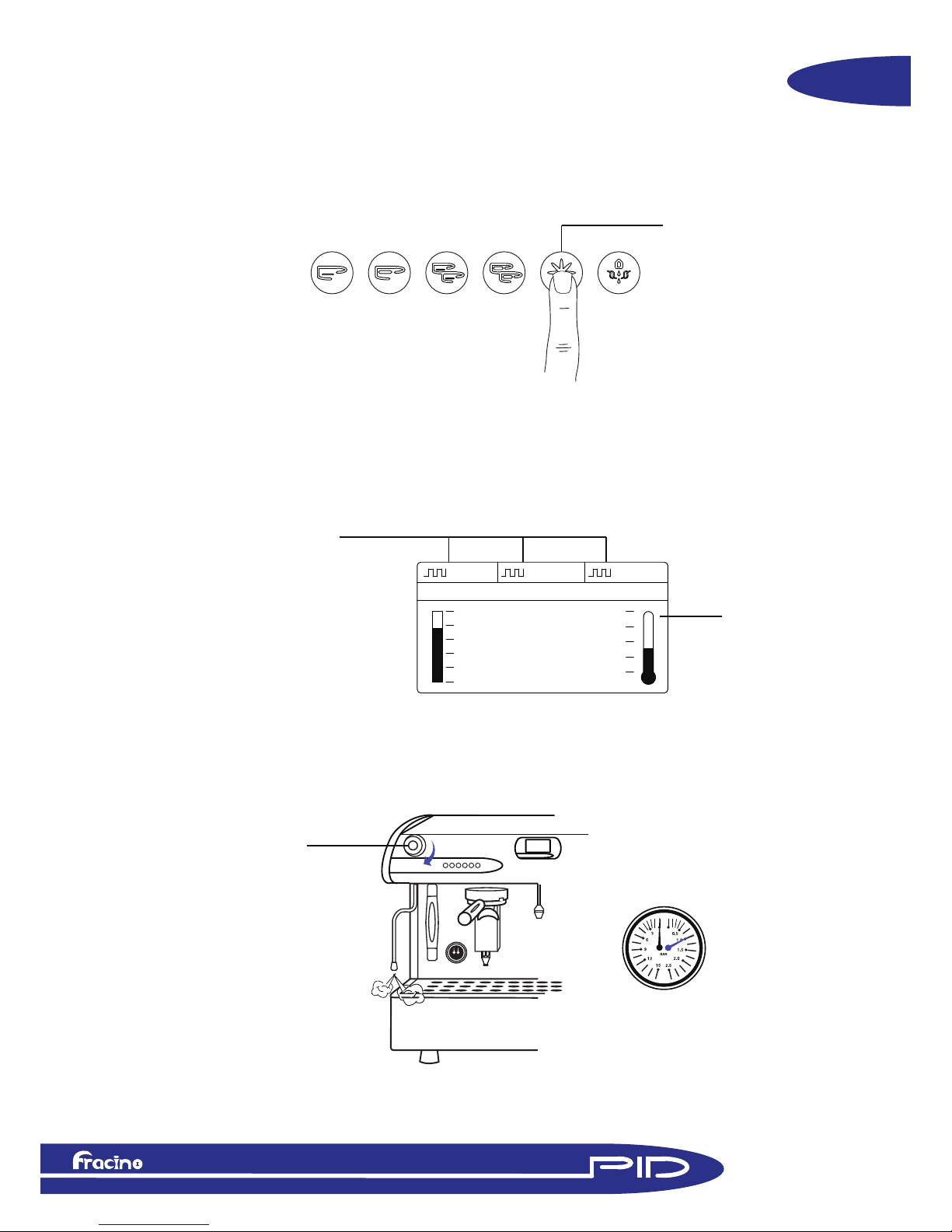

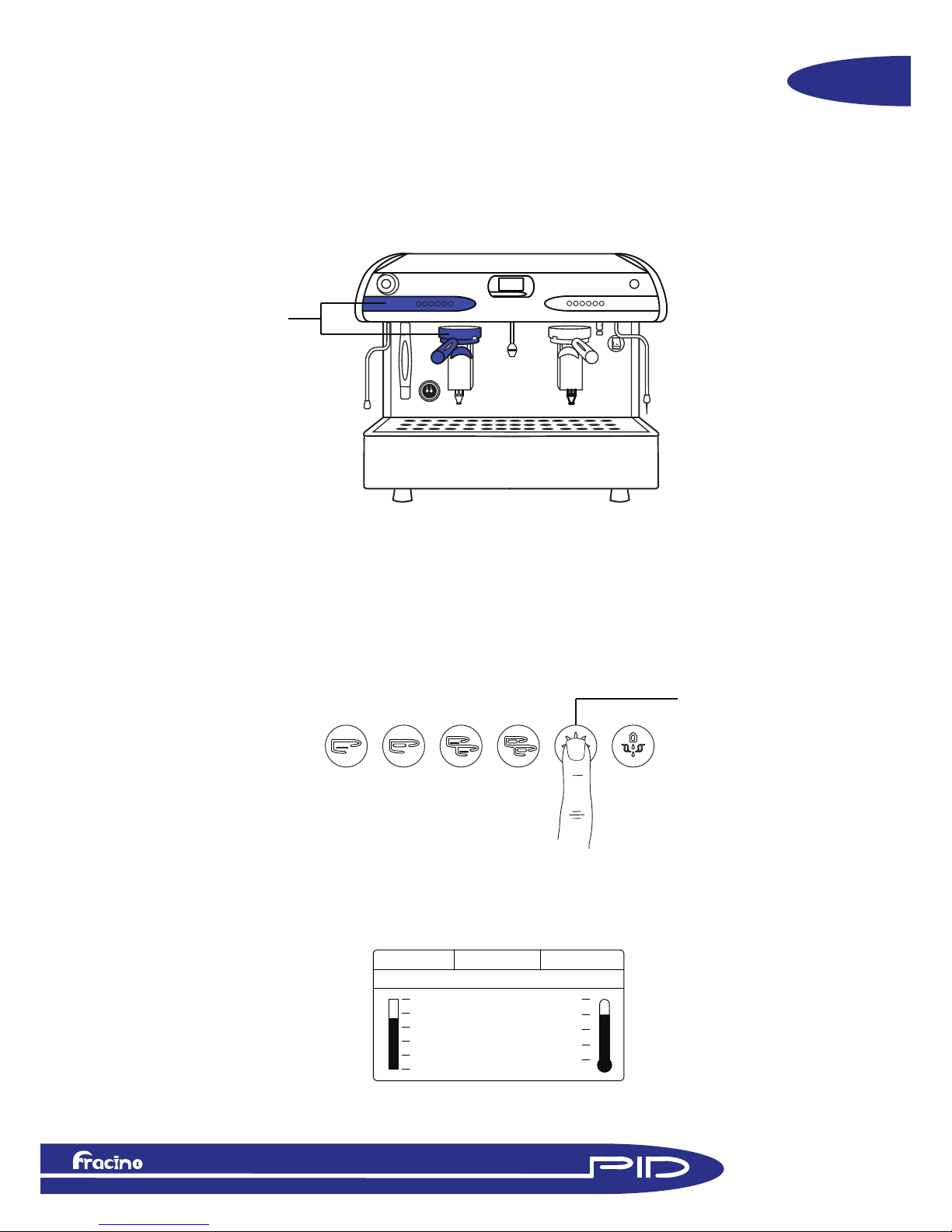

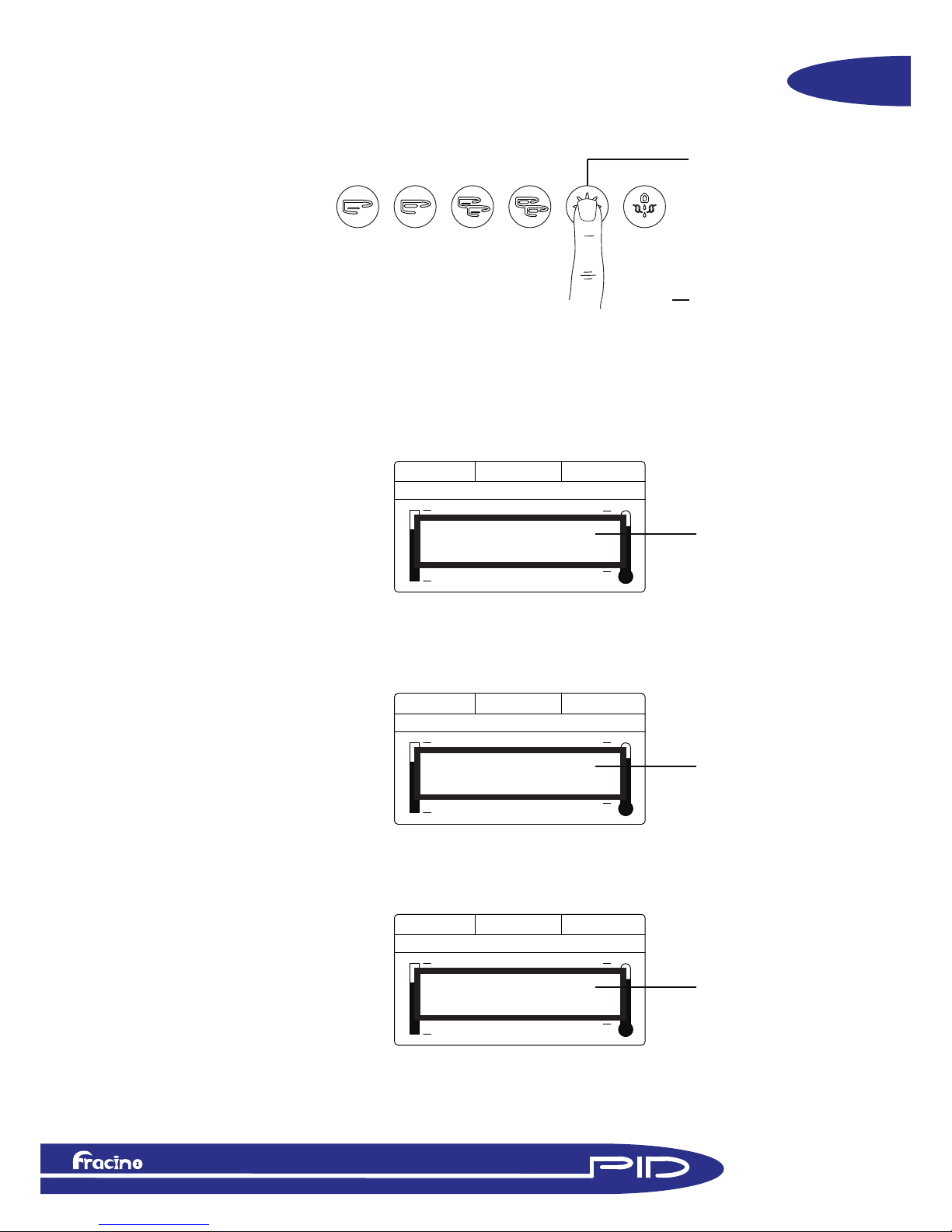

CLOCK AND

AUTO ON/OFF

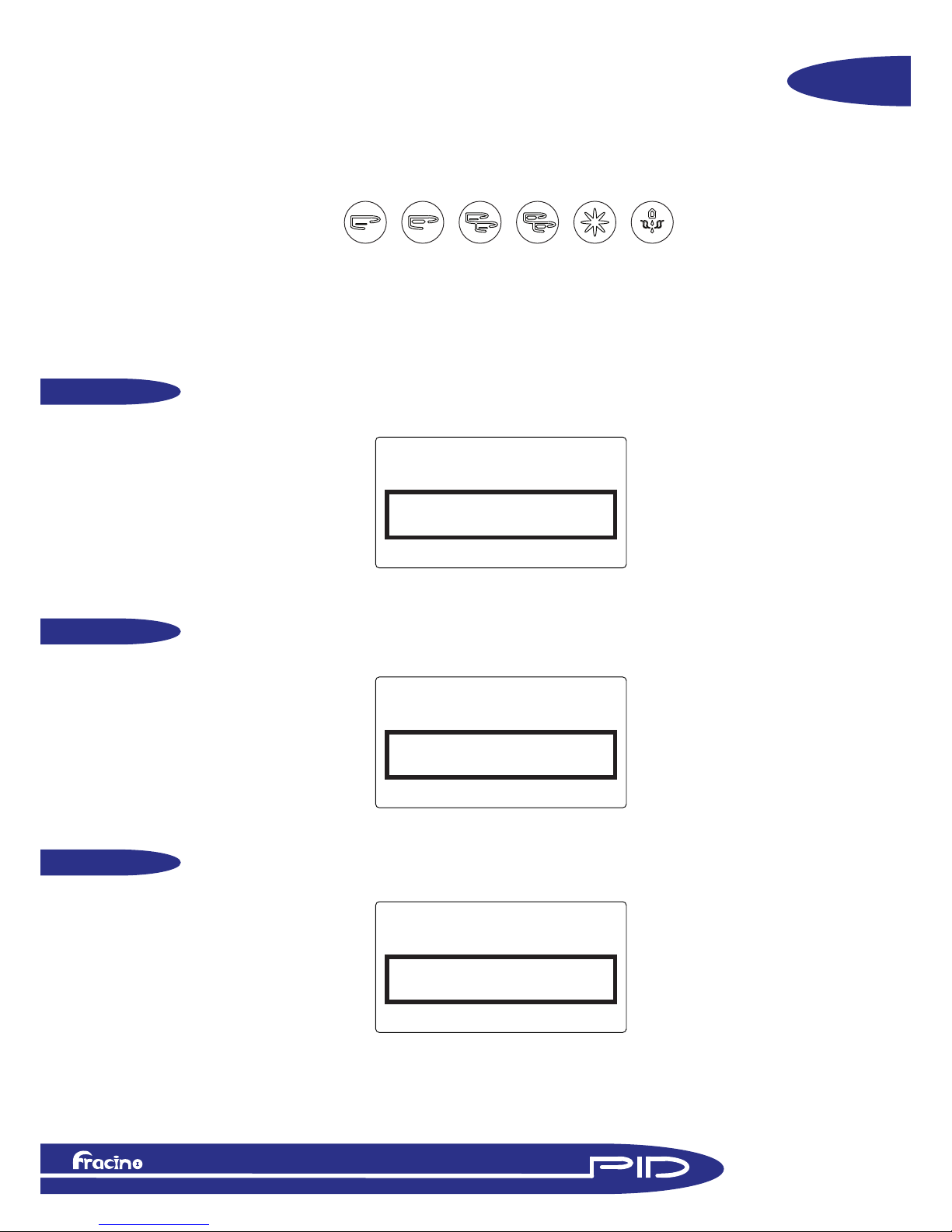

Changing Clock

T

o

GR1 T

o

GR2 T

o

GR3

FRACINO PID

MAX

MIN

ToBOILER

5 Seconds

1. To change the time on the clock, press and hold the star button for 5seconds to enter

the programming mode, remove finger from star button then press the star button for a

further 2 seconds, to enter the secondary programing mode, the display will show

“clock adjust”, as shown below

2 Seconds

1

clock adjust

1

2. Press the double espresso button to edit the time, the time and day should appear

with the hour flashing, use the single espresso (+) or single cappuccino (-) to

increase/decrease the hour respectively, press the double espresso button to scroll to

the minute adjust as required, press the double espress button to scoll to the day,

adjust as required

T

o

GR1 T

o

GR2 T

o

GR3

FRACINO PID

MAX

MIN

ToBOILER

clock adjust

HH:MM DAY

2

+ -

Enter

3. Press the double espresso button to move to the Auto ON/OFF setting menu

5

CLOCK AND

AUTO ON/OFF

Auto ON/OFF

T

o

GR1 T

o

GR2 T

o

GR3

FRACINO PID

MAX

MIN

ToBOILER

1. Press the double espresso button the hour should be flashing, use the espresso (+)

and Cappuccino (-) button to change to the require time, press the double espresso

button to scroll to the minute and adjust as required.

Auto ON/OFF

On : HH:MM

1

2. Press the double espresso to move to the OFF set time, set time as required using

the same proceedure as above.

+ -

Enter

T

o

GR1 T

o

GR2 T

o

GR3

FRACINO PID

MAX

MIN

ToBOILER

Auto ON/OFF

Off : HH:MM

2

NOTE: When using the Auto on/off the machine will go into stand-by mode and will not

isolate power from the machine.

T

o

GR1 T

o

GR2 T

o

GR3

FRACINO PID

MAX

MIN

ToBOILER

Closed on

day

3

3. The auto on/off can be programmed to skip a day in the week, i.e if Sunday is

selected the machine will turn off on Saturday, stay off on Sunday and turn back on

Monday. Use the single espresso and single Cappuccino to cycle through the days,

“-----------------” denotes that no day is selected.

6

PROGRAMMING

COFFEE MEASURES

Programming

Coffee Measures

T

o

GR1 T

o

GR2 T

o

GR3

DOSES SETTING SEL......

MAX

MIN

HH:MM

DAY

ToBOILER

1. The coffee measures are programmed from the left hand keypad, when complete the

settings are stored on all groups. If required each group can be programmed individually

by using the same proceedure using the corresponding group and keypad.

1

2. Put a single shot of coffee (7-8grams) in to a single filter, insert filter in to the the left

hand group and place a shot pot or espresso cup under the group.

5 Seconds

3. Press and hold the star button for 5seconds until the scroll menu reads:

“doses setting select with in 30sec”

3

7

PROGRAMING

COFFEE MEASURES

4. Press the single espresso button to start the brewing cycle, when the required

volume (approx. 30mL for a single espresso) has been dispensed press the single

espresso button to stop the brewing cycle.

5. Repeat the process to program the other buttons, using a single or double filter

as required, the programming must be done with in 30sec of each other, otherwise

it will timeout, if this happens press and hold the star button for 5 seconds as before

and continue from where you left off.

6. To exit the program you can either wait 30sec for the timeout or press and hold the

star button for 5seconds then press the star button to scroll through the menu until

the main display appears.

4 6

8

PROGRAMING

HOT WATER MEASURES

Programming

Hot Water Measures

T

o

GR1 T

o

GR2 T

o

GR3

DOSES SETTING SEL......

MAX

MIN

HH:MM

DAY

ToBOILER

1. The duration of the hot water dispensing can be adjusted using the left hand key pad

1

2. Place a cup, teapot or measuring jug on the drip tray grid under the hot water

nozzle

5 Seconds

3. Press and hold the star button for 5seconds until the scroll menu reads:

“doses setting select with in 30sec”

2

WARNING: Do not hold the cup, teapot or measuring jug, the water from the hot

water nozzle is extremely hot which presents a risk of scalding.

3

9

PROGRAMING

HOT WATER MEASURES

4. Press the Hot water button, Hot water will be dispensed from the nozzle

5. When the required amount of water has been dispensed press the hot water

button again to stop, the measure is now programmed press and hold the star button

for 5seconds then press the star button to cycle through the menu options until you

are out of the programing mode, alternitively wait 30seconds.

WARNING: Do not hold the cup, teapot or measuring jug, the water from the hot

water nozzle is extremely hot which presents a risk of scalding.

4

5

10

SECONDARY PROGRAMMING

MENU OVERVIEW

Entering

Secondary

Program menu

T

o

GR1 T

o

GR2 T

o

GR3

FRACINO PID

MAX

MIN

ToBOILER

clock adjust

2

5 Seconds

1. To enter the secondary programming mode press and hold the star button on group

1 for 5seconds to enter the programming measures mode, remove finger from star

button then press the star button for a further 2 seconds, to enter the secondary

programing mode, the display will show “clock adjust”, as shown below, pressing the

star button will scroll through the menus, pressing the double espresso will allow you to

enter the menu and adjust if available.

2 Seconds

1

2. Clock Adjust, allows the user to adjust the time and day that is shown on the display,

see “Clock and Auto on/off” section for more details

T

o

GR1 T

o

GR2 T

o

GR3

FRACINO PID

MAX

MIN

ToBOILER

auto on/off

3

3. Auto on/off, the machine can be programmed to go in to stand-by mode and come

back on at predetermined times, the times can be adjusted with this menu, see “Clock

and Auto on/off” section for more details.

T

o

GR1 T

o

GR2 T

o

GR3

FRACINO PID

MAX

MIN

ToBOILER

Counters

4

4. Counters, pressing the double espresso button will allow the user to scroll through

the various counters, such as the volume of water used, number of espressos

dispensed etc... see below for more details.

11

SECONDARY PROGRAMMING

MENU OVERVIEW

T

o

GR1 T

o

GR2 T

o

GR3

FRACINO PID

MAX

MIN

ToBOILER

litres

5

5.Litres, allows the user to see the volume of water that has passed through the

machine.

6. Coffees total, allows the user to see the total number of coffees dispensed.

T

o

GR1 T

o

GR2 T

o

GR3

FRACINO PID

MAX

MIN

ToBOILER

coffees total

6

7. Detailed drinks counter, allows the user to view the type and quantity of coffees

dispensed from each group, press the double espresso button to cycle through each

type and group.

T

o

GR1 T

o

GR2 T

o

GR3

FRACINO PID

MAX

MIN

ToBOILER

zzzzz GRP:y

XXX

7

Coffee type

Quantity

Group number

To re-set the counters, see Service Alarm section.

12

SECONDARY PROGRAMMING

MENU OVERVIEW

T

o

GR1 T

o

GR2 T

o

GR3

FRACINO PID

MAX

MIN

ToBOILER

Service

8

8. Service, allows the user to see the recommended number of drinks that can be

dispensed until the next service.

WARNING: The service counter is only an indication of when the next service is due,

services may be required more often depending on usage, water hardness etc. It is

also a legal requirement under the HSE PSSR Act of 2002 to have the boiler inspected

and tested annually, contact Fracino or authorised service agent for further information

or to have your boiler tested, a Written Scheme of Examination is available in the

supplied installation manual. THIS SERVICE COUNTER IS NOT AN INDICATION OF

WHEN THE BOILER IS DUE FOR INSPECTION OR TESTING

13

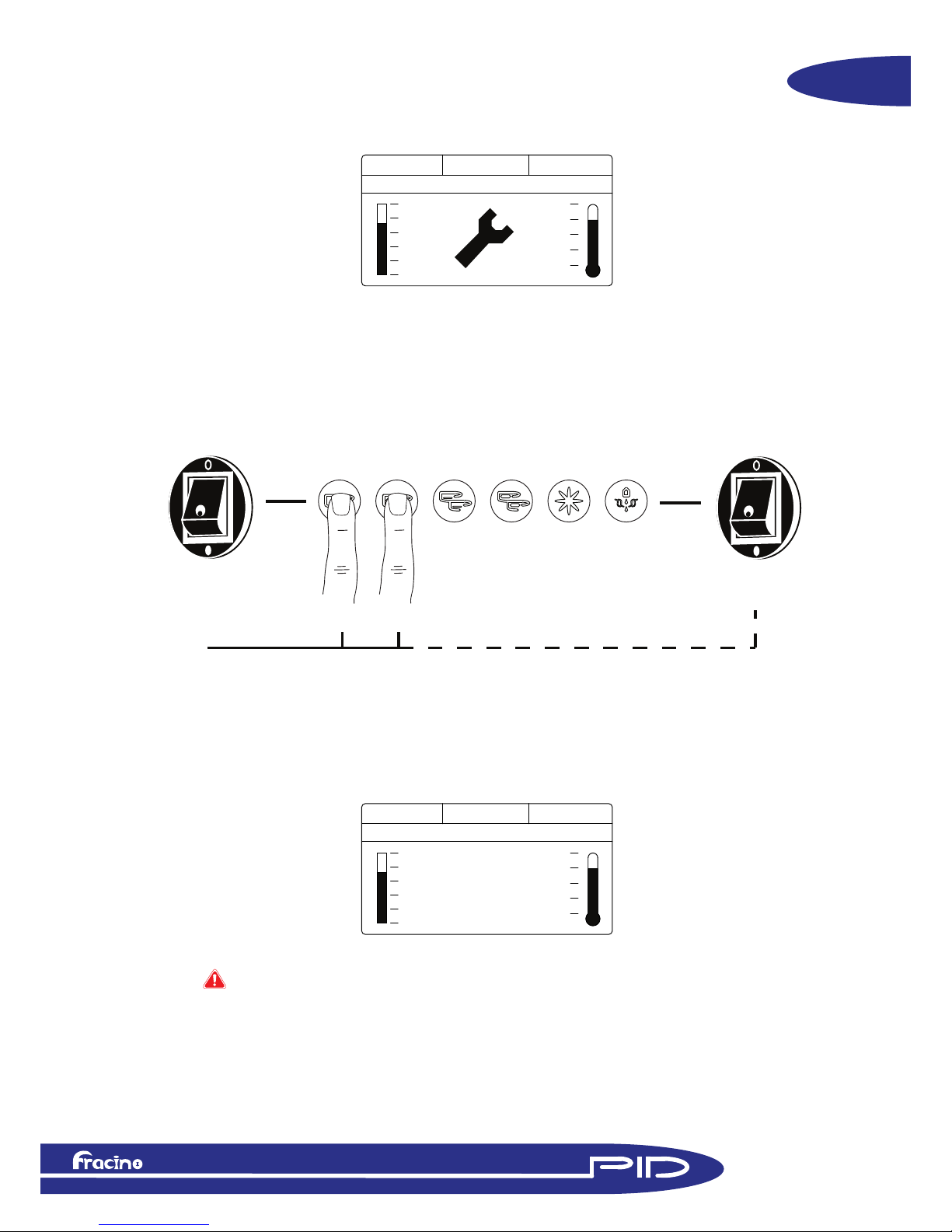

SERVICE ALARMS

Water Filter

Alarm

ToGR1 ToGR2 ToGR3

ChangeWaterFilter

MAX

MIN

ToBOILER

ToGR1 ToGR2 ToGR3

FRACINO PID

MAX

MIN

ToBOILER

If the spanner symbol appears with the “Change Water Filter” in the Scroll menu the

water filter needs to be replaced, contact Fracino or your local service agent to have

the filter replaced.

To change the volume of water that can pass through the machine before the water

filter alarm comes on, see 36 in the “Technical” section.

The water filter counter alarm is re-set by turning the machine off using the mains on/off

switch pressing and holding the double espresso and double coffee, then turning the

machine on again using the mains on/off switch whilst keeping the double espresso

and double coffee buttons pressed for 2 seconds - the alarm and counter should be re-set

WARNING: The water filter counter should only be re-set when the filter has been

replaced and should only be re-set by trained personnel.

14

Press and hold

Turn off Turn on

SERVICE ALARMS

Service

Alarm

ToGR1 ToGR2 ToGR3

Service 0121 328 5757

MAX

MIN

ToBOILER

ToGR1 ToGR2 ToGR3

FRACINO ROMANO

MAX

MIN

ToBOILER

If the spanner symbol appears with the “Service” in the Scroll menu the machine

requires a routine service, contact Fracino or a local service agent to have the machine

serviced.

To change the number of cycles required before the service alarm soundes, see

section 25 in the Technical section.

WARNING: The service counter should only be re-set when the machine has been

serviced.

15

Press and hold

Turn on

Turn off

The service counter alarm is re-set by turning the machine off using the mains on/off

switch pressing and holding the espresso and coffee buttons, then turning the

machine on again using the mains on/off switch whilst keeping the espresso

and coffee buttons pressed for 2 seconds - the alarm and counter should be re-set

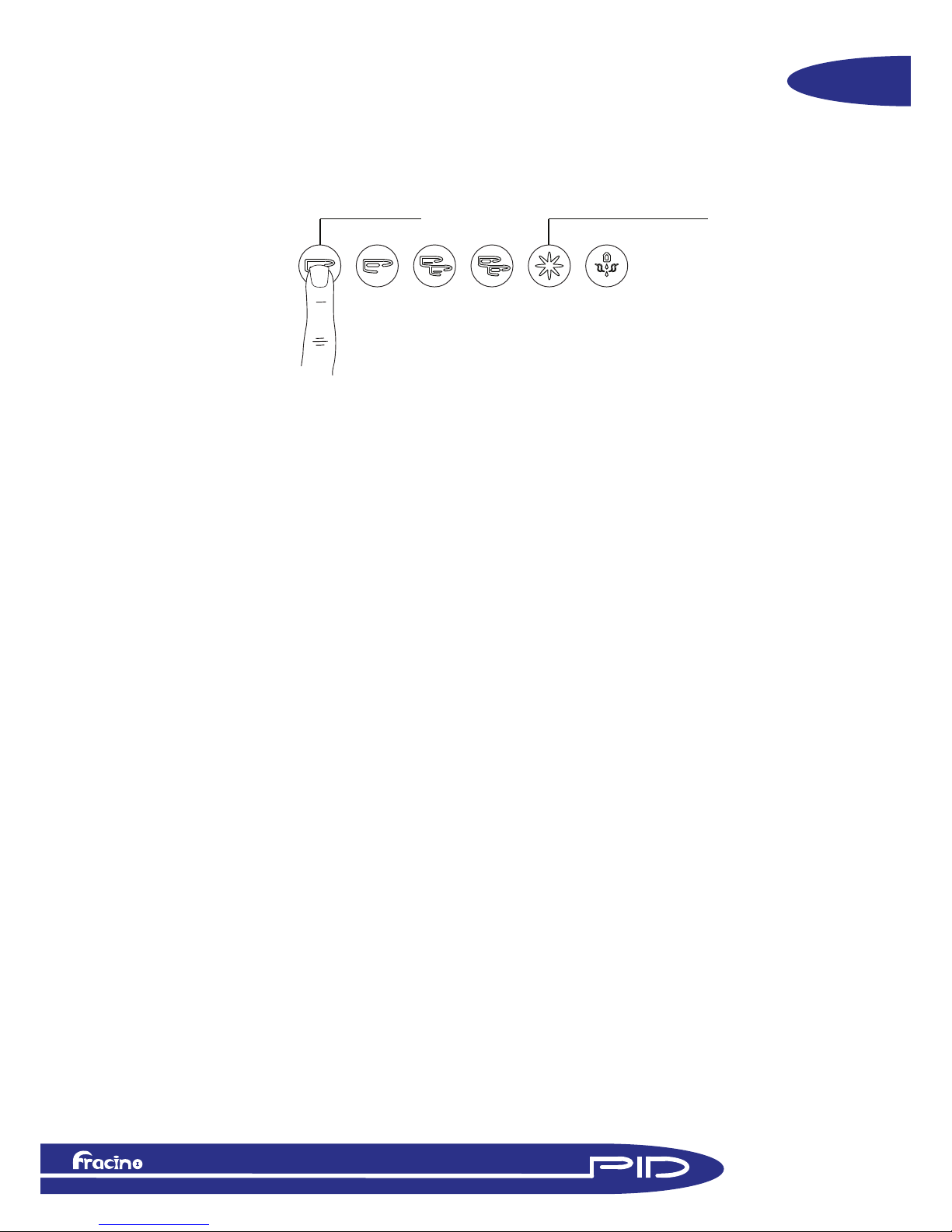

SHOT TIMER

1. When dispensing coffee the group temperature readout will show a shot timer,

shown in seconds, and dispensing symbol.

1

1

1

25 90oC 95oC

FRACINO PID

MAX

MIN

115oC

1

1

The shot timer can be used as a guide to the coarseness of the grind and tamping

pressure, ideally a double shot (60mL) should take between 20-30seconds.

16

TECHNICAL MENU

Entering

Technical

Menu

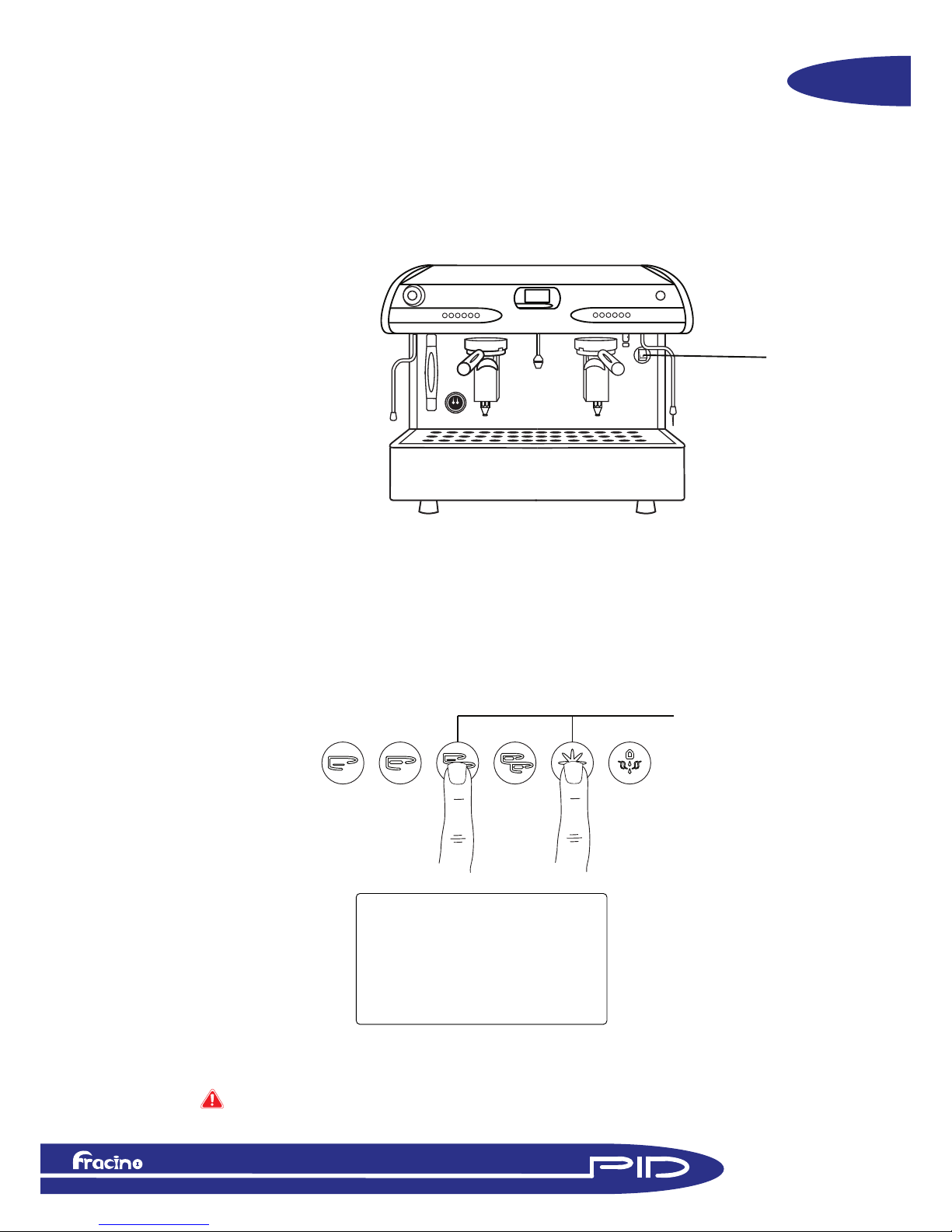

WARNING: Modifing the settings in the Technical Menu can may cause temperature

instability in the groups and/or cause the machine to function incorrectly, settings must

only be modified by trained persons. Service callouts to reset/reprogram settings maybe

fully charge-able.

OFF

DAY

1

HH:MM

1. To enter the technical menu, first turn the machine to stand-by mode, by pressing the

star and double espresso buttons on group 1 simultaneously.

2. Press and hold the star button for 10 seconds until the Technical Menu appears.

2

10 Seconds

OFF

DISPLAY MODE

reverse

USER

The “USER” symbol in this section denotes the features/settings that can

be changed by the user.

17

TECHNICAL MENU

4. DISPLAY MODE: Changes the display from dark lettering on a light background to

light lettering on a dark background. Use the + and - to switch between “reverse” and

“normal”.

6. COLOUR STATE ON: Changes the colour of the display, use + and - to cycle through

options.

OFF

DISPLAY MODE

normal

5. CONTRAST: Increases or Decreases the contrast between the lettering and background, use + and - to increase decrease value.

OFF

Contrast

50

+ -

SELECT

3. When in the Technical Menu the following secondary button functions are used.

“+” and “-” used to change settings

“SELECT” used to save setting and move to the next menu option

“ENTER” used to select a value

OFF

Color State ON

NOTE: The values shown in this chapter are the recommended values that should be

used for optimum performance.

USER

USER

USER

ENTER

18

TECHNICAL MENU

7. LANGUAGE: Changes the langauge of the display and menus, options are English,

Italian, German and Spanish, use + and - to cycle through.

9. SERVICE PHONE: Gives the phone number of Fracino or Fracino Service Agent,

use + and - to change numbers and Enter to select number, Press Select to cycle to

next menu.

OFF

Language

english

8. NAME: Allows the scroll menu on the main display to be customized, use + and - to

change character and Enter to select character, press Select to cycle to next menu. Up

to 14 Characters can be selected.

OFF

NAME

FRACINO PID

OFF

Service Phone

0121 328 5757

BLANK ! “ # $ % & ‘ ( ) * + , - . / 0 1 2 3 4 5 6 7 8 9 : ; < = > ? @ A B C

D E F G H I J K L M N O P Q R S T U V W X Y Z [ ] ^ _ ` a b c d e f

g h i j k l m n o p q r s t u v w x y z

10. KEYBOARD TYPE: Selects the type and layout of the keypad.

OFF

Keyboard

Esp Caf 2Es 2Caf

USER

19

TECHNICAL MENU

11. CONTINUOUS KEY: Allows the Star button to operate as a semi-automatic overide,

i.e. when the star button is pressed dispensing will start and will continue until it is

pressed again.

13. MIX TEA WATER: Allows cold water to be pumped in to the hot water system, when

dispensing hot water, to reduce the temperature of the water.

OFF

Continuous

Enabled

12. FIFTH TEA KEY: Allows the Star button to be used to turn the hot water valve on

and off, this MUST be kept “Disabled”

OFF

Fifth Tea Key

Disabled

OFF

Mixed Tea Water

yes

14. BUZZER: Enables or disables the buzzer to sound when pressing buttons or when

an alarm is detected.

OFF

Buzzer

enabled

USER

20

TECHNICAL MENU

15. STEAM BOILER GROUP: Selects which keypad controls the FAST Steam wand.

for a 2 group machine “2” should be selected, for a 3 group “3” should be selected, “0”

will disable the system.

17. PRE-BREW ON: The following will only appear if the pre-brew is selected, see above.

Use + and - to increase or decrease the time when the group solenoid will close after

starting the brewing process. Each type of coffee can have it’s own pre-brew times.

Use the Select button to scroll to the next type of coffee, the Pre-brew times will apply

to all of the groups.

OFF

Steam boiler group

2

16. PRE-BREW: Enables or Disables the Pre-brew system. The Pre-brew will close the

group solenoid after a pre-determined amount of time then stay closed for a predetermined amount of time before commencing with the main programmed measure.

OFF

PreBrewing

Enabled

OFF

PreBrew ON sec

Esp 1.0 Sec

Type of coffee

Time ON

17. PRE-BREW OFF: The following will only appear if the pre-brew is selected, see above.

Use + and - to increase or decrease the time when the group solenoid will open. Use

the Select button to scroll to the next type of coffee.

OFF

PreBrew OFF sec

Esp 1.0 Sec

Type of coffee

Time OFF

USER

USER

USER

21

TECHNICAL MENU

19. PROBE SENSITIVITY: Selects the sensitivity of the level probes use the +

and - buttons to select between “LOW”, “MED” and “HIGH”

21. NUMBER OF GROUPS: Selects the number of groups are on the machine, selecting “0” will disable all of the groups.

OFF

ProbeSensitivity

HIGH

20. LED IDLE: When Enabled the buttons will not be illuminated until selected, when

disabled all the buttons will be illuminated until selected, when selected the selected

button will flash.

OFF

LED idle

disable

OFF

Crono Grp

2

22. STEAM BOILER HEAT.: Selects the method of controlling the steam boiler pressure, selecting “Disabled” will prevent the steam boiler heating, “byPressureSwitch”

MUST be selected to function correctly

OFF

SteamBoilerHeat.

byPressureSwitch

USER

22

TECHNICAL MENU

24. SEQUENTIAL HEATING: Must be kept disabled

26. TEMPERATURE: Changes the temperature mode to Centigrade of Fahrenheit.

OFF

Sequent.Heating

Disabled

25. SERVICE CYCLES: Selects the number of dispensing cycles before the machine

should be serviced.

OFF

Service Cycles

50000

OFF

Temperature

o

C

27. BOILER TEMP.: This feature is disabled on the Fracino Romano PID

WARNING: The service counter is only an indication of when the next service is due,

services may be required more often depending on usage, water hardness etc. It is

also a legal requirement under the HSE PSSR Act of 2002 to have the boiler inspected

and tested annually, contact Fracino or authorised service agent for further information

or to have your boiler tested, a Written Scheme of Examination is available in the

supplied installation manual. THIS SERVICE COUNTER IS NOT AN INDICATION OF

WHEN THE BOILER IS DUE FOR INSPECTION OR TESTING

USER

USER

23

TECHNICAL MENU

28. STEAM BOILER PID PARAMETERS: These settings are redundant on the Fracino

Romano PID.

30. HEATING GROUP: This is to allow the same temperature to be set on all groups,

for example setting to 1 on a 2 group machine will only allow one group temperature

to be set.

OFF

kP kI kD

0.0 0.0 0.0

29. STEAM BOILER PID SETTING: This setting is redundent on the Romano PID.

OFF

PID settings

0oC

OFF

Heating Group

2

31. GROUP TEMPERATURE: Used to set the set point temperature for each individual

group. The temperature range for the set point temperature is 85 - 125oC in steps of

1oC.

WARNING: The maximum set point temperature for the groups must never be above

115oC - The Romano PID groups are fitted with high limit safety thermostats(HLS) which can

trip if the temperature is set too high, requiring the thermostats to be reset, service callouts

to re-set HLS, where the temperature has been set too high, may be fully charge-able.

OFF

Group Temperature 1

88oC

USER

24

TECHNICAL MENU

32. OFFSET TEMPERATURE: The group temperature is measured by a temperature

probe in the group boiler, this temperature is displayed in the main display and corresponds to the group temperature set point. When dispensing the water flows from the

group boiler, through the group solenoid which can reduce the temperature of the

coffee in the filter, the Off Set temperature compensates for this cooling effect.

33. GROUP BOILER PID SETTINGS: Changes the kP, kI and KD parameters on the

PID system

OFF

Offs Tset Coffee

6oC

OFF

kP kI kD

1.2 0.0 4.0

34. PID SETTING: Adjusts the temperature range for the PID system

OFF

PID Setting

20oC

WARNING: These settings have been optimised for the Fracino PID, changing the

values, from the values below may cause temperature instability in the groups

WARNING: These settings have been optimised for the Fracino PID, changing the

values, from the values below may cause temperature instability in the groups

25

TECHNICAL MENU

35. FILLING TIME OUT: Sets the time, in minutes, before the time out allarm will sound

when the steam boiler is filling, the time out can be set between 10-250 seconds.

OFF

FillingUp T-Out

240

36. WATER FILTER: Sets the volume of water in Litres before the water filter needs

replaced, the volume can be set between 0 and 5000 Litres.

WARNING: The hardness of the water supply and usage of the machine will determine

frequency of replacing the water filter, failure to replace the water filter at the correct

time my void the warranty.

OFF

Water Filter

5000

USER

USER

26

TROUBLESHOOTING

Steam Boiler

Filling

Time-Out

T

o

GR1 T

o

GR2 T

o

GR3

FillingUp Time-out

MAX

MIN

ToBOILER

CAUSE: The water in the steam boiler has not reached the level probe in the set

refilling time, ofter this will occur during initial start up, when the boiler is filling up from

empty.

SOLUTION: Turn the machine off using the main on/off switch, wait 2 seconds then

turn back on the machine should resume filling.

!

If a fault is detected then all the keypads will flash, the alarm will sound and the display

will give an error code in the scrolling menu and an error icon.

WARNING: The alarm will not sound if the buzzer has been disabled in the technical

menu, see section 14 of the Technical section

+

OTHER POSSIBLE CAUSES: The water supply to the machine has been turned off

SOLUTION: Check the water supply has been turned on.

WARNING: Failure to ensure the water supply is on will damage the high pressure

pump and will invalidate the warranty on the pump.

Boiler Over

Temperature

T

o

GR1 T

o

GR2 T

o

GR3

Alarm Boiler Temp.

MAX

MIN

ToBOILER

CAUSE: The temperature in the steam boiler has reached 140o C, and the heating

element has been deactivated. To get to this temperature there is likely to be a fault

with the Pressure switch and high limit thermostat.

SOLUTION: Contact Fracino or local service agent.

!

27

TROUBLESHOOTING

Steam Boiler

Temperature

Probe

Disconnected

ToGR1 ToGR2 ToGR3

SteamBoilerT.probeUnconn

MAX

MIN

ToBOILER

CAUSE: The steam boiler temperature probe has been disconnected or has developed

a fault.

SOLUTION: Ensure all connections on the temperature probe wire are correctly

connected and the probe is correctly connecting to the control box, if the fault still

remains contact Fracino or local service agent.

!

Flow Meter

Alarm

ToGR1 ToGR2 ToGR3

MAX

MIN

ToBOILER

CAUSE: Blank filter left in filter group handle

SOLUTION: Check filter handles and remove blank filter.

CAUSE: Coffee ground to finely

SOLUTION: Adjust grinder to increase the coarsness of the grinds

CAUSE: Groups blocked or group solenoid not working.

SOLUTION: Remove, inspect and clean group jet if required, inspect and replace group

solenoid if required.

CAUSE: Wire off or poor connection to the flowmeter.

SOLUTION: Check connections on the flowmeter, check polarity on flowmeters, check

connections on PCB.

FRACINO ROMANO

x

“x” Denotes group number

28

TROUBLESHOOTING

Over Temperature

on a Group

Boiler

ToGR1 ToGR2 ToGR3

Alarm Temper. Group X

MAX

MIN

ToBOILER

CAUSE: The temperature in group “X” has risen above 140oC, possibly caused by a

fault in the group temperature probe and/or a fault with the group high limit thermostat.

SOLUTION: Contact Fracino or a local service agent.

!

Temperature

Probe on

Group Boiler

Disconnected

ToGR1 ToGR2 ToGR3

ProbeUnconnectGroup X

MAX

MIN

ToBOILER

!

CAUSE: The temperature probe on group “X” has been disconnected or has developed

a fault.

SOLUTION: Ensure all connections on the temperature probe wire are correctly

connected and the probe is correctly connecting to the control box, if the fault still

remains contact Fracino or local service agent.

29

CLEANING

1. Wipe the outer case of the machine with a soft damp cloth (do not use a scouring pad).

Use a shower plate brush to dislodge dried coffee particles in the group and around the filter

holder washer to prevent build up of coffee. Brushes can be obtained from Fracino, part no.

FC54.

1

Daily Cleaning

2

1

2. Press the star button and allow water to flow water from the group for 10seconds,

to rinse away any coffee particles, repeat on each group

2

30

CLEANING

1. The group must be backwashed every day to clear the solenoids this is done by doing

the following proceedure. Insert a blank filter in to the filter and put in to group.

2

90oC 95oC

FRACINO ROMANO

MAX

MIN

115oC

2

Daily Cleaning

Backwashing

2. Press the single espresso button and the star button simultaneously to start the

automatic cleaning cycle. The cleaning cycle will last approximately 60seconds,

during which time it will pulse the pump several times after each pulse water

will be expelled out the group exhaust. The display will show the cleaning symbol,

when this disappears the cleaning cycle is complete and the filter can be removed.

1

88oC

3. Repeat the above in each group

31

CLEANING

1. Every day the backwashing process must be repeated using Fracino liquid quartz

detergent to reduce the build up of coffee in the groups and solenoid valves. Fracino

liquid quartz can be purchased through your dealer or from fracino direct, part no.

DET/LIQUID.

Daily Cleaning

Backwashing

with liquid

quartz

2. Pour 1/2 a cap full of the liquid quartz in to a blank filter and follow the backwashing proceedure as described in the previous section.

3. After the cleaning cycle with the quartz it is vital that the filter is removed from the

group and empied, reinsert the filter and repeat the backwashing proceedure without

any quartz to rinse the groups and solenoids to prevent blockages and preventing the

detergent tainting the taste of the coffee.

NOTE: After performing the backwashing proceedures as stated above the water in

the filter and the water coming out of the group exhaust should be clear.

32

TURNING OFF

GROUPS

2

Turning off

individual groups

1. Individual groups can be turned of to save energy and prolong the life of the

elements when they are not in use.

Note that the groups will require at least 10minutes to heat up.

2. To turn the a group off use the corresponding keypad, press the star button and

cappuccino button simultaneously. The display will show “OFF” in the group temperature

readout.

2. The group can be turned on by pressing the star and double cappuccino

single cappuccino button simultaneously, the “OFF” will disappear and

show the group temperature.

OFF 20oC 20oC

FRACINO PID

MAX

MIN

09:00

MONDAY

115oC

2

33

TURNING OFF

OFF

DAY

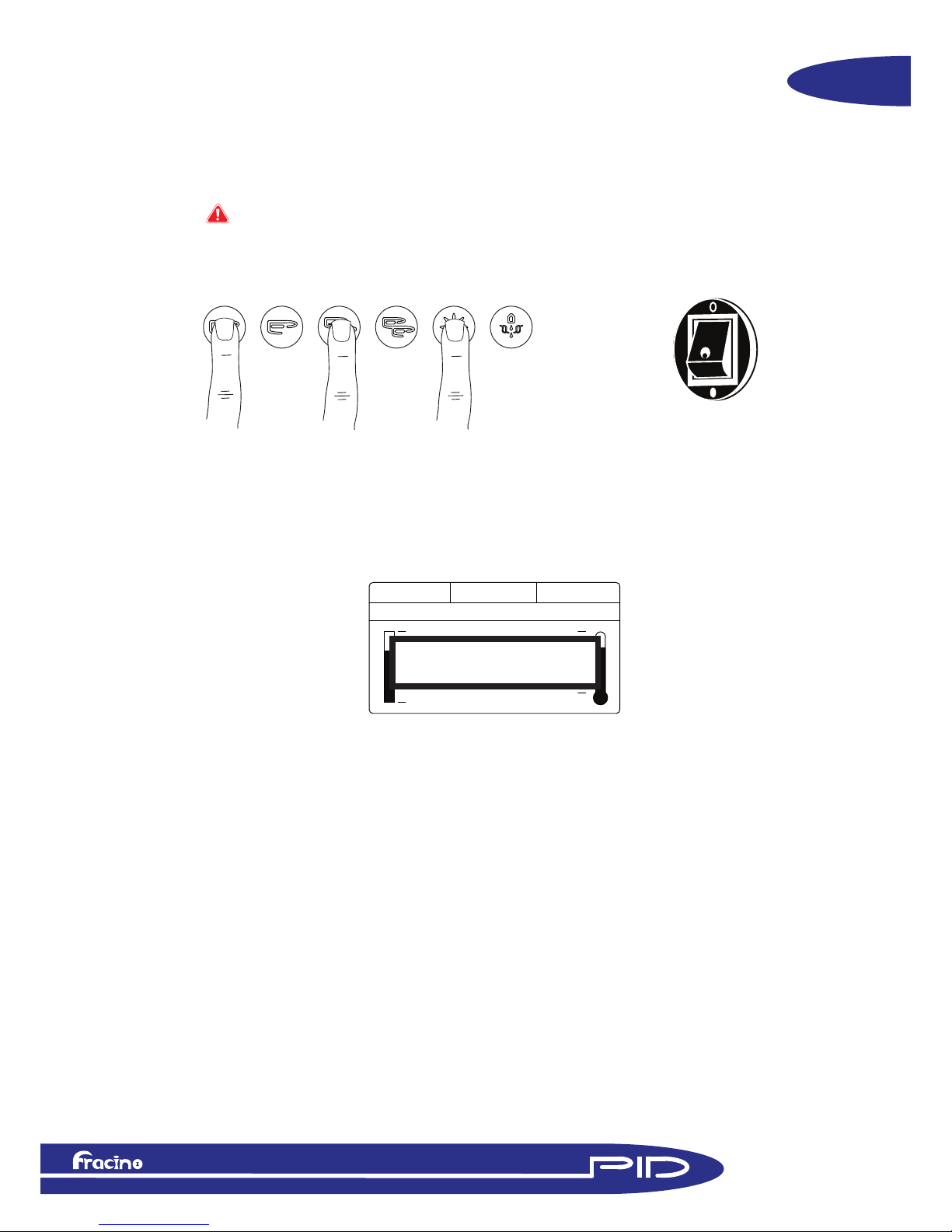

1. The machine can be put in to a stand-by mode which will cut power to the heating

elements and disable the buttons. To put the machine in stand-by press the star and

double espresso buttons on group 1 simultaneously, the display will show “OFF”

together with the time and day.

1

Turning off

1. The machine can be turned off by simply using the black rocker switch on the

front panel.

1

Turning off

stand by

HH:MM

2. To come out of stand-by mode press the double espresso button on group 1

WARNING: The stand-by mode does not fully isolate power from the machine and

must not be used for maintenance.

34

SERVICE ALARMS

Re-setting

Counters

ToGR1 ToGR2 ToGR3

FRACINO ROMANO

MAX

MIN

ToBOILER

Coffee Total

The coffee counter can be re-set if required by preforming the following proceedures

Press and hold the double espresso and cappucino buttons and hold for

3 seconds, until the display reads:

Enter the secondary programming menu as described in section XXx, and cycle

through to Coffee Total section

ToGR1 ToGR2 ToGR3

FRACINO ROMANO

MAX

MIN

ToBOILER

Coffee Total

Total Reset

35

FULL FACTORY RE-SET

ToGR1 ToGR2 ToGR3

MAX

MIN

ToBOILER

Preset valori

completato

Ensure the machine is turned off at the mains power switch press and hold the

single espresso, double espresso and star button on the group 1 keypad then

turn the power switch on whilst still holding the 3 keypad buttons, keep them

pressed for 3 seconds until the display read the following

Turn the mains switch off, wait 3 seconds then turn the machine back on, the

machine will start up in its default mode, to function correctly all setting will

need to be re-entered.

WARNING: Performing the procedures below will re-set all settings to a default

state, in order for the machine to function correctly after the full re-set, all settings

will have to be re-entered which should only be performed by trained personel.

+

36

Loading...

Loading...