Fracino Bambino, Classic, Contempo, Romano Installation Instructions Manual

Installation

Instructions

For Model(s):

Fracino Bambino

Fracino Classic & Contempo

Fracino Romano

Only to be carried out

by qualified engineers.

23

Warranty

24

Warning

Services and

equipment required

for installation

Preparing the area

for installation

(All except Romano)

Preparing the area

for installation (Romano)

Preparing the machine

for installation

Legend

Remove the red air

release valve clip

Priming the boiler

with water

(except Romano)

Powering up for the

first time

Boiler pressure gauge

and pump pressure

Adjusting the pump

pressure

Bleeding and removing

airlocks

Terms and Conditions

Items Not Covered by

Warranty

3

4

8

11

14

Installation

overview

Preparing

for installation

Installing the

coffee machine

Before turning

the machine on

Turning the

machine on

Connecting the

Waste Pipe

Connecting the

Water Supply

Connecting the

Water Softener

Connecting the

Power Supply

Contents

A A

B

C

D

A

B

C

D

Connecting the power

supply

Initially setting grinder

blades

Grinding Coffee

Adjusting coffee measure

Re-adjusting the grinder

blades

18

Installing the

coffee grinder

A

B

C

D

E

A

B

A

B

C

D

A

B

5

6

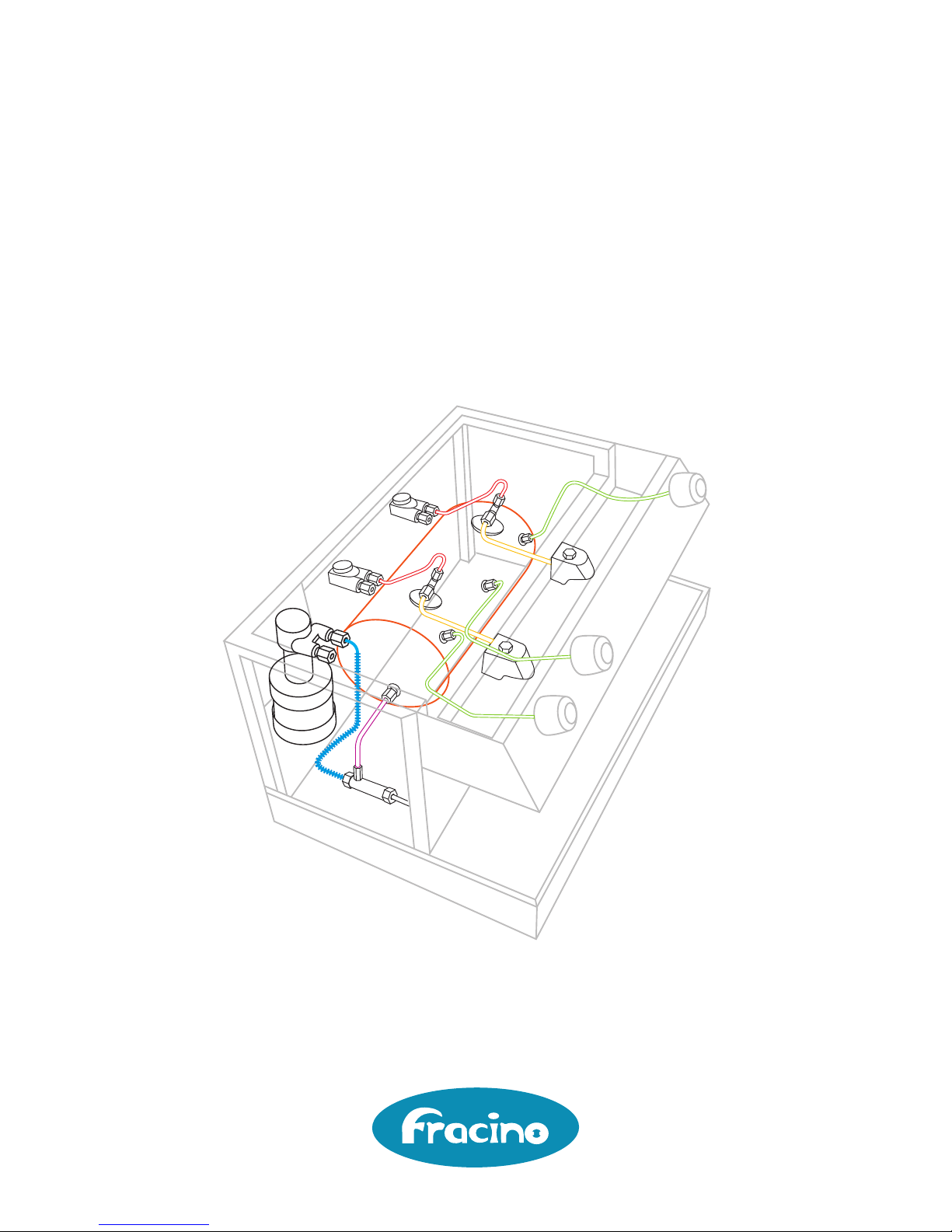

Installation

Overview

3

1

4

7

Cold

Water

(15mm)

Waste

PowerPower

Power

(2nd Position

Switch or plug)

9

10

11

23

8

300mm

11

Please ensure a gap of 300mm is maintained

above the top tray of the machine to allow for

cup storage and service access.

1

Coffee Machine.

2

Grinder – 13 amp socket required.

3

Power connection for coffee machine

(must be within 1 metre). Switch or plug.

4

1.5” (Minimum Diameter) Stand pipe for

waste as for washing machine.

5

¾'' B.S.P Washing machine type valve

for mains cold water with isolator handle.

7

Counter.

8

Under counter or under grinder

Knock-out drawer.

6

Water Softener (DSU) / inline filter

if required.

9

Hole in counter: 2'' Diameter.

10

Alternative position for power supply

(must be within 1 metre). Switch or plug.

Preparing for

Installation

Services and

equipment

required for

installation

A

4

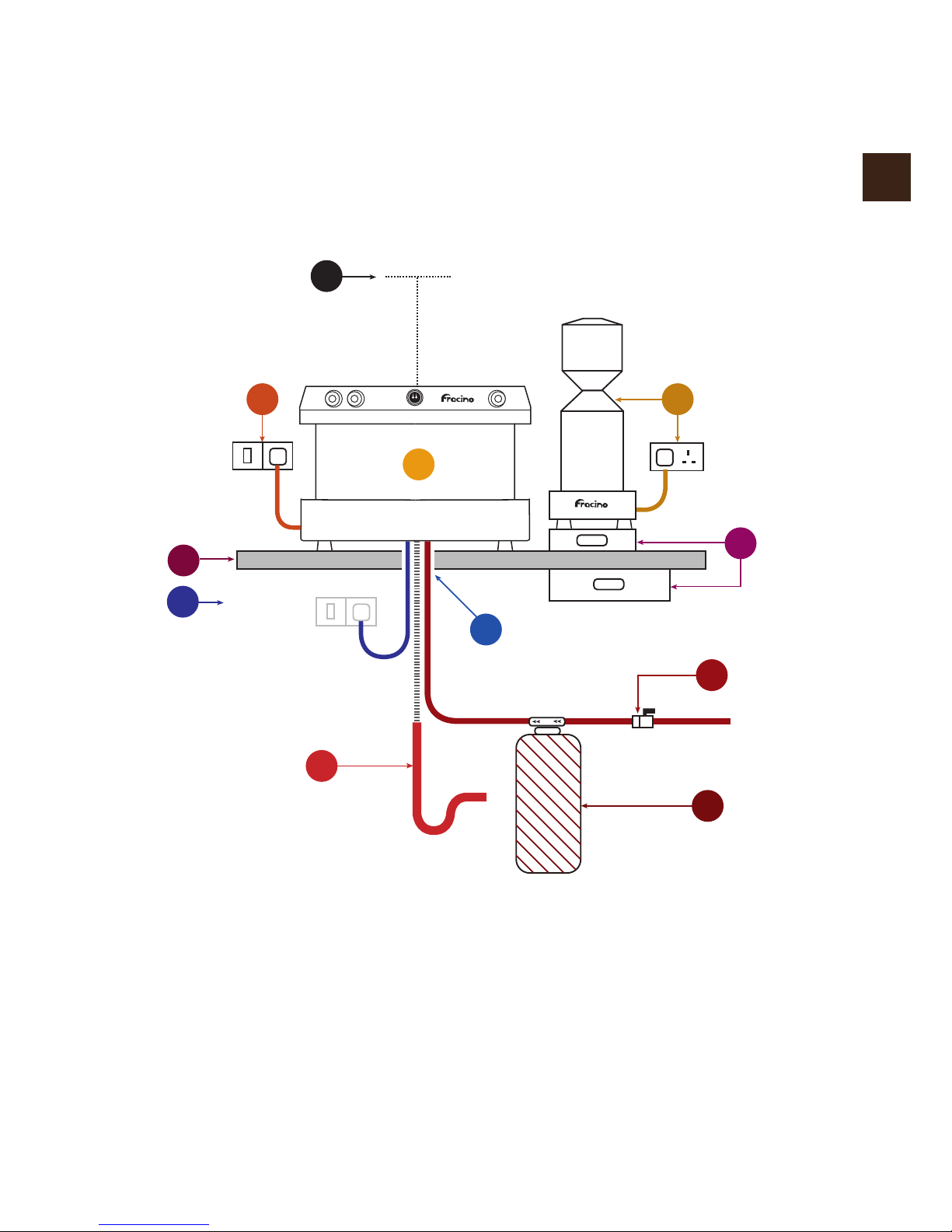

All machines require a mains water & power supply as specied below. It is highly

recommended that a mains waste outlet is provided but a bucket is sufcient if not

available. All services must be in place prior to installation. ALL CALLS TO UNPREPARED

SITES ARE FULLY CHARGEABLE.

Mains water:

15mm mains cold water supply with ¾'' BSP standard washing machine stop cock.

Note: Min inlet water pressure : 100kPa (1 Bar)

Max inlet water pressure : 600kPa (6 Bar)

If water pressure in excess of 600kPa (6 Bar) a Pressure Reducing Valve must be tted.

Mains waste:

1 ½'' (minimum diameter) stand pipe for exi hose.

Water and waste connections to be directly beneath the location of the machine

Power supply: As below

Note: Socket to be located on the same side of the coffee machine that the grinder will

stand. (Recommended right hand side - see installation overview).

Grinders - All models 13amp

Coffee Machines - Standard Power Ratings

Coffee Machines - Alternative Power Ratings

Note: Alternative power ratings must be specied on order if required.

1 Group 2.7kw 13amp

2 Group* 4.0kw 20amp single phase

3 Group 7.5kw 32amp single phase

4 Group 7.5kw 32amp single phase

* Except Bambino which is 2.85KW / 13amp. 4kw available as an

alternative power rating on 20amp single phase supply

Group kw amp

Group kw amp

2 Group 2.85kw 13amp

2 Group* 4.0kw 20amp single phase

2 Group 7.5kw 32amp single phase

3 Group 9.0kw 45amp single or three phase

4 Group 9.0kw 45amp single or three phase

* Bambino model only

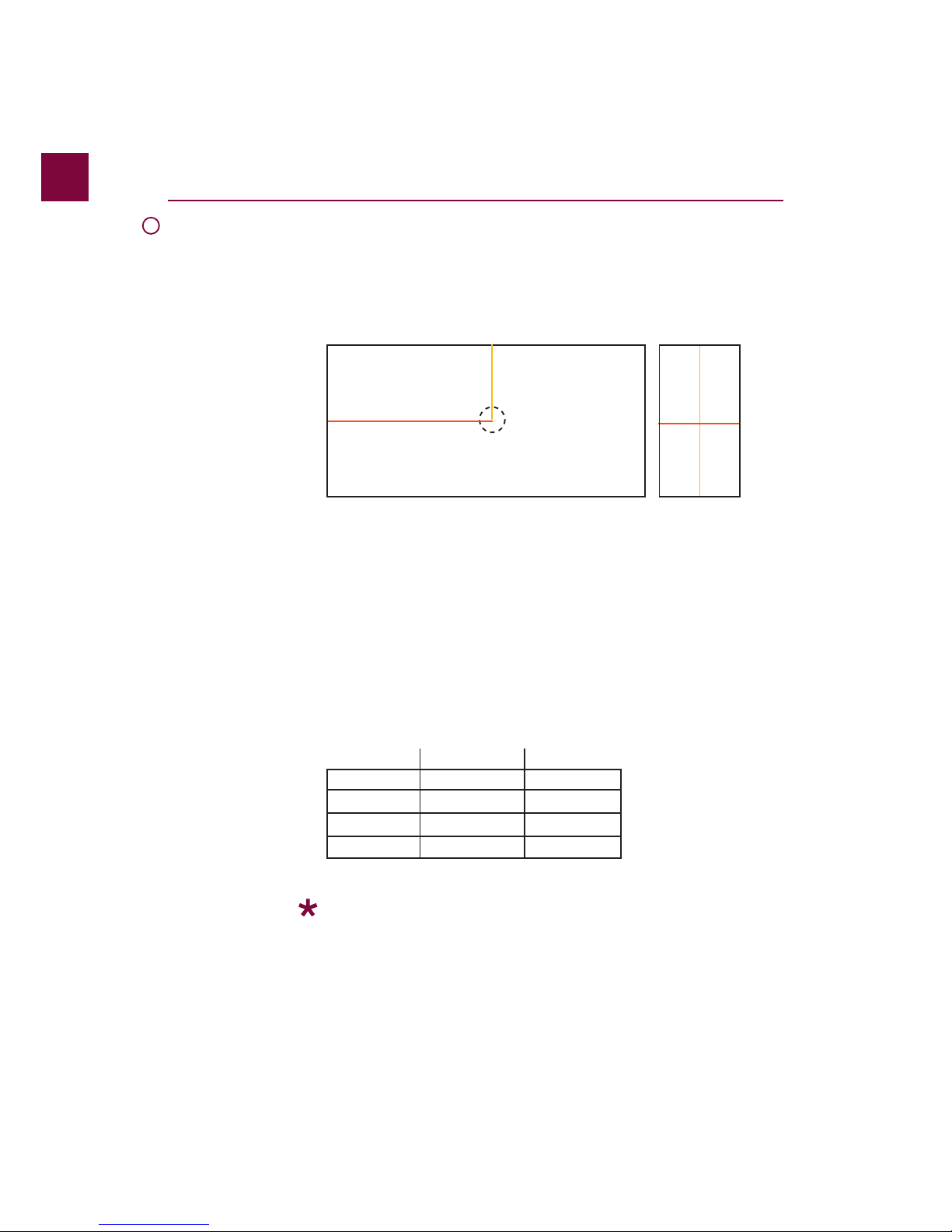

Preparing the area

for installation

(All except

Romano)

5

B

(1) Depth from the back of the machine to the hole.

(2) Length from the side of the machine to the hole.

(3) Hole in counter: 2'' Diameter

(4) Depth needed for grinder

(5) Width needed for grinder

Work out the location of the coffee machine on the bar or counter and find the position.

Drill a 2’’ hole using the measurements below as a guide. All the coffee machines power

and waste connections feed from the bottom at the centre of the coffee machine. These

connections then feed down through the 2’’ hole in the bar or counter.

Note: The power connections for the coffee machine and grinder must be within 1 metre

behind or beneath the machine. The power point must be easily accessible at all times.

The water and waste connections for the coffee machine must be directly beneath it.

All services, including hole in bar counter, must be in place prior to engineer arriving to install

the coffee machine.

Ensure that the surface the coffee machine is to be placed on is sufficiently strong and stable

enough to carry the weight of the coffee machine.

(1) (4)

(3)

(2)

(5)

Plan view for drilling counter for Coffee Machine Area for Grinder

1 Group (1) 110mm (2) 235mm

2 Group (1) 110mm (2) 300mm

3 Group (1) 110mm (2) 400mm

4 Group (1) 110mm (2) 500mm

Grinder (4) 450mm (5) 240mm

Group Depth Length

6

Preparing the area

for installation

(Romano)

C

(1) Depth from the back of the machine to the hole.

(2) Length from the side of the machine to the hole.

(3) Hole in counter: 2'' Diameter

(4) Depth needed for grinder

(5) Width needed for grinder

Work out the location of the coffee machine on the bar or counter and find the position.

Drill a 2’’ hole using the measurements below as a guide. All the coffee machines power

and waste connections feed from the bottom at the centre of the coffee machine. These

connections then feed down through the 2’’ hole in the bar or counter.

Note: The power connections for the coffee machine and grinder must be within 1 metre

behind or beneath the machine. The power point must be easily accessible at all times.

The water and waste connections for the coffee machine must be directly beneath it.

All services, including hole in bar counter, must be in place prior to engineer arriving to install

the coffee machine.

Ensure that the surface the coffee machine is to be placed on is sufficiently strong and stable

enough to carry the weight of the coffee machine.

(1) (4)

(3)

(2)

(5)

Plan view for drilling counter for Coffee Machine Area for Grinder

1 Group (1) 110mm (2) 240mm

2 Group (1) 110mm (2) 360mm

3 Group (1) 110mm (2) 480mm

Grinder (4) 110mm (5) 240mm

Group Depth Length

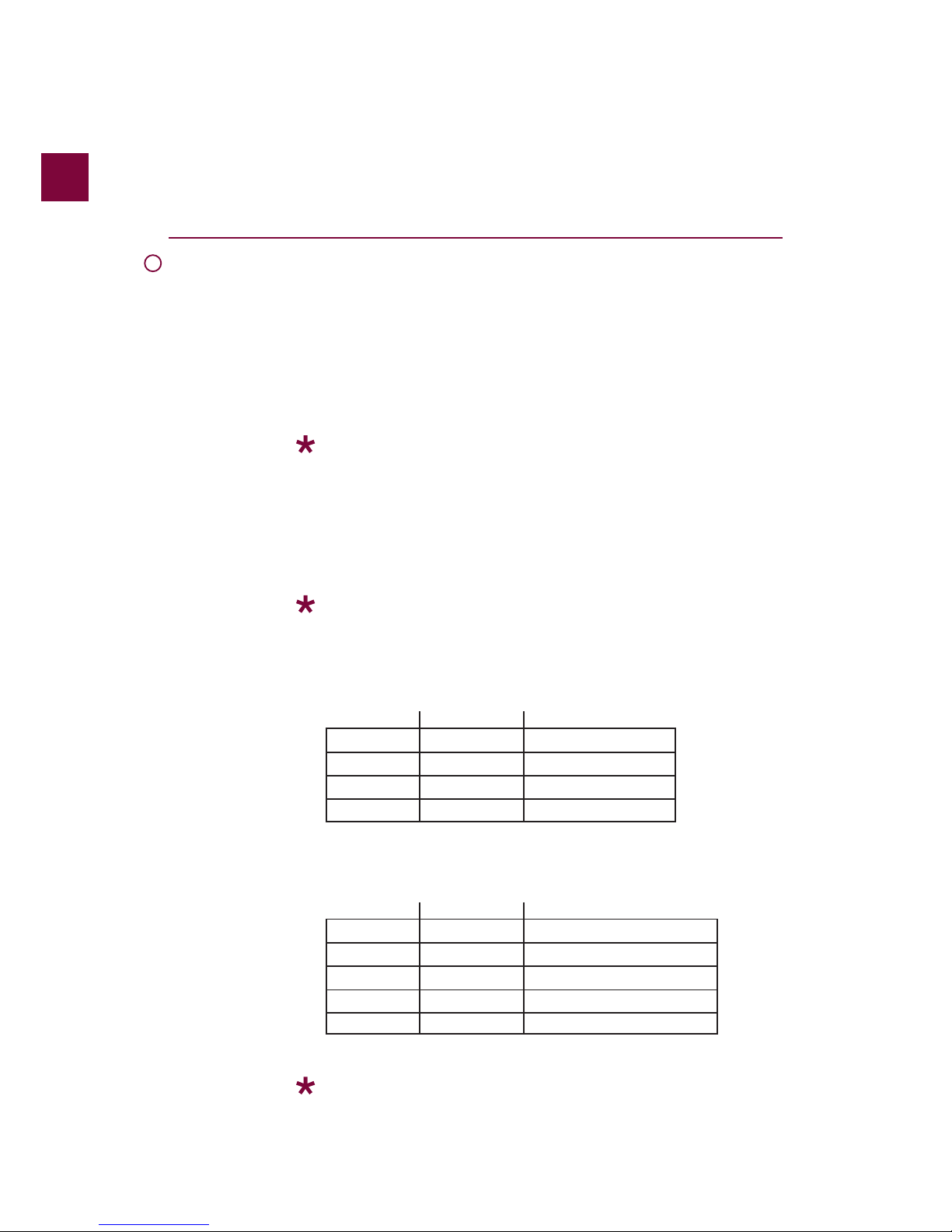

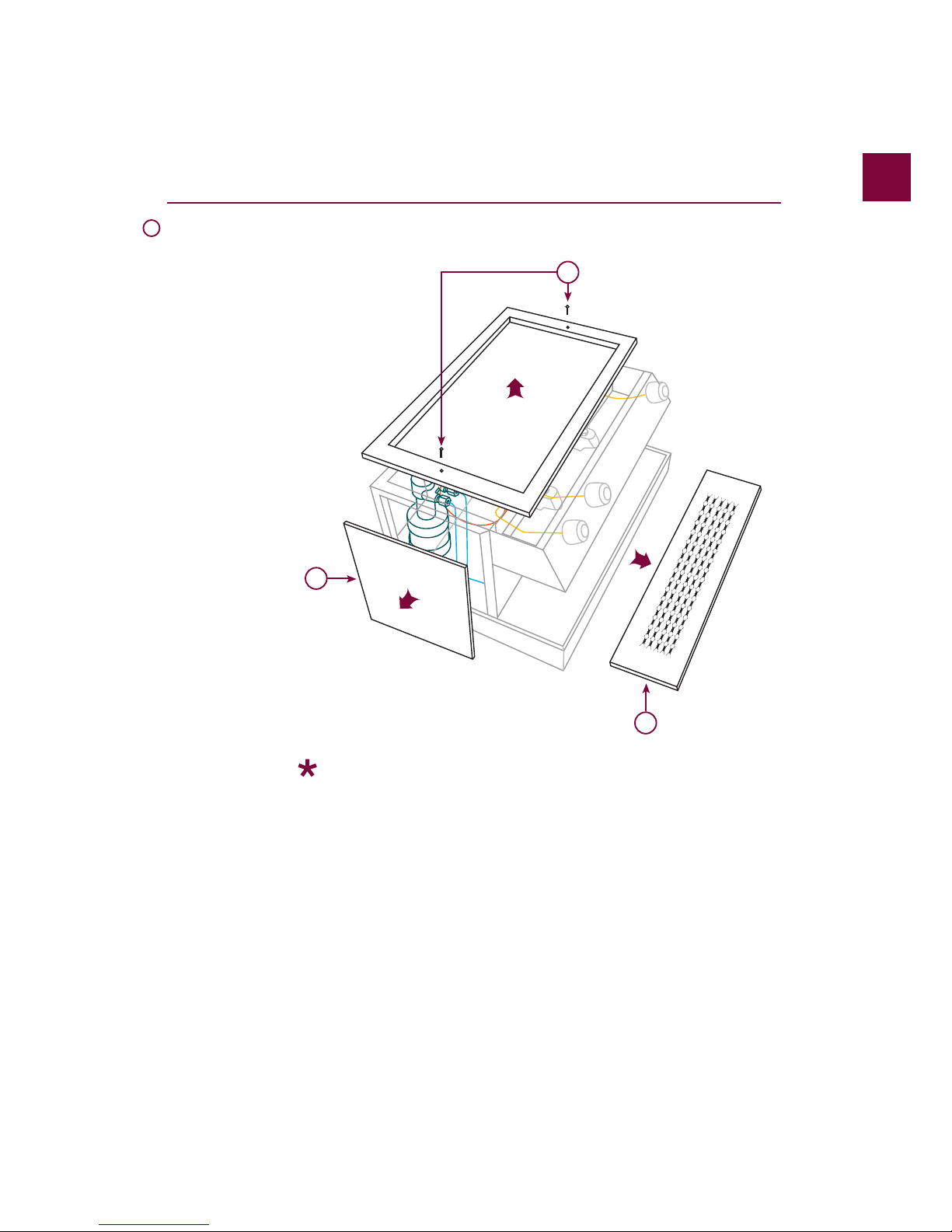

Note: Remove all packaging before working on / installing the machine and remove plastic

protective coating from stainless steel.

All except Romano

1) Remove the top tray of the machine by locating and unscrewing the two M4 screws at

either end of the tray. Carefully lift off the top tray and place somewhere flat.

2)The sides of the machine just need a gentle tug to remove. They are fixed using ball studs

for quick and easy access.

3) Remove the drip tray to reveal the waste funnel. This is done by lifting it upwards at the

front as it simply rests in place again for easy access and cleaning.

Romano only

1) Remove the top tray of the machine by locating and unscrewing the 2 x M5 screws from

each side of the top tray which hold the side panels and the 2 x M4 screws at either end.

Carefully lift off the top tray and place somewhere flat.

2)The sides of the machine just need a gentle tug to remove. They are fixed using ball studs

for quick and easy access.

3) Remove the drip tray to reveal the waste funnel. This is done by lifting it upwards at the

front as it simply rests in place again for easy access and cleaning.

7

Preparing the

machine for

installation

D

2

3

1

8

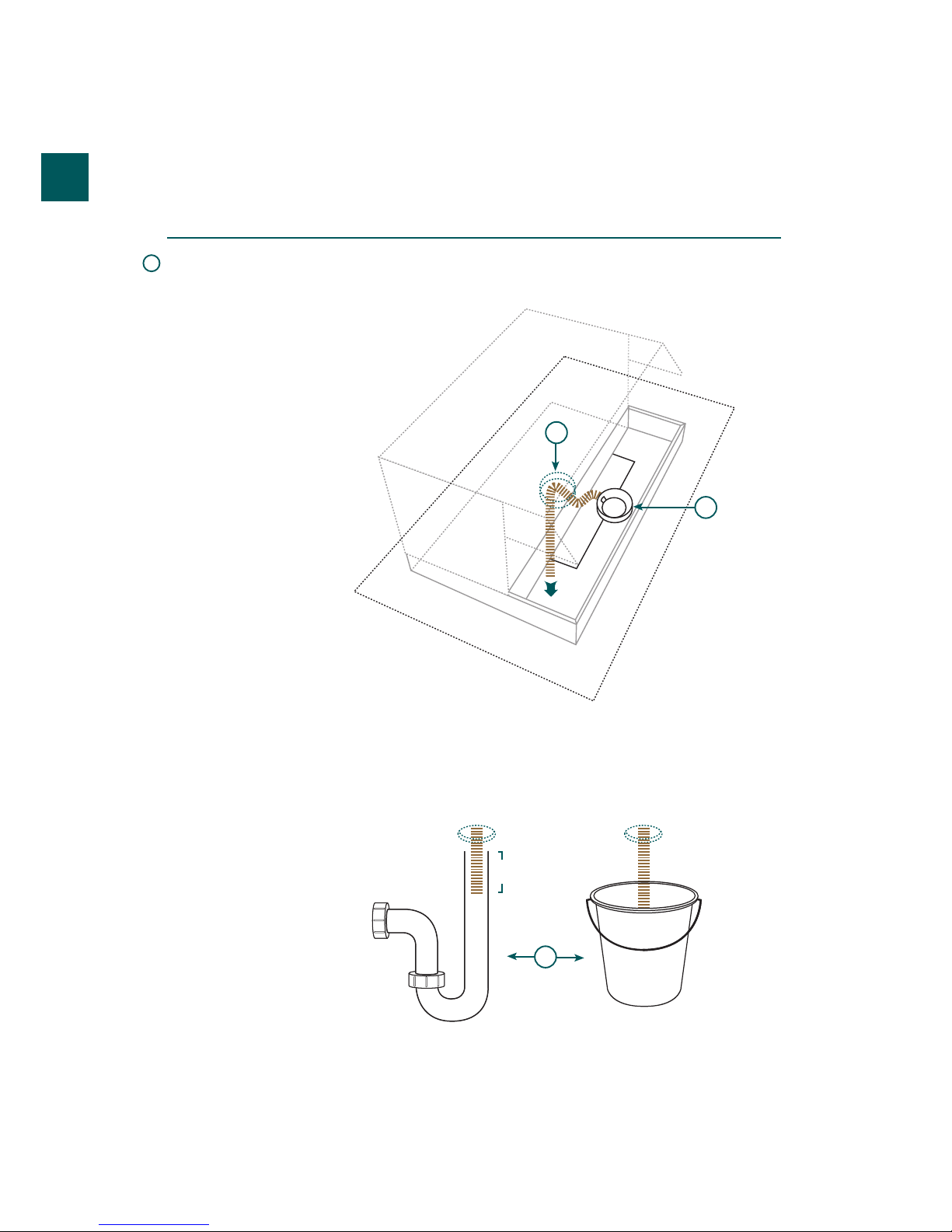

Installing the

coffee machine

Connecting

the waste

pipe

A

1) Fit the grey push-on flexible waste hose onto the round waste funnel located in the centre

of the machine and tighten with the wormdrive clip provided. 2) Then feed the waste hose

under the machine and down through the 2” hole already cut out. Pull taught and ensure no

kinks are present in pipe.

3) Place the waste pipe into a bucket below the machine or into the stand pipe with a ‘P’ or

‘S’ trap to prevent smell. Ensure waste pipe is cut to length and is only 75mm into the

bucket or stand pipe. It must not touch the bottom as this will block and cause floods under

the machine. Clip or cable tie the pipe into position to prevent it from moving.

1

2

3

75mm

Loading...

Loading...