Page 1

Image AnyPlace IA-200

User’s Manual

Version 1.01

Page 2

User’s Manual 0020D1.01 Image AnyPlace IA-200

Copyright Information

Copyright © 2009 Flexible Picture Systems

All Rights Reserved.

The information contained in this document is protected by copyright. All rights are reserved by

Flexible Picture Systems.

Product names mentioned herein are used for identification purposes only and may be trademarks

of their respective companies.

Flexible Picture Systems and Image AnyPlace are trademarks or registered trademarks of Flexible

Picture Systems.

Page 2 of 49 © Flexible Picture Systems

Page 3

Image AnyPlace User’s Manual 0020D1.01

Contact Information

Address Flexible Picture Systems

174 West Beaver Creek Rd

Richmond Hill, ON L4B 1B4, Canada

Tel: 905-707-1664

Fax: 905-707-2304

Website

Technical Support E-mail: support@flexiblepicturesystems.com

http://flexiblepicturesystems.com/

© Flexible Picture Systems Page 3 of 49

Page 4

User’s Manual 0020D1.01 Image AnyPlace IA-200

Revision History

Version Date Description

1.01 March 8, 2009 Initial release.

Page 4 of 49 © Flexible Picture Systems

Page 5

Image AnyPlace User’s Manual 0020D1.01

Table of Contents

Preface.........................................................................................................................................7

Limited Warranty...................................................................................................................................7

Return Material Authorization (RMA)............................................................................................7

FCC Statement .......................................................................................................................................7

Safety 8

Disconnecting Instructions...................................................................................................................11

1 Introduction...........................................................................................................................12

1.1 General Description......................................................................................................................12

1.2 Product Variations and Nomenclature .........................................................................................14

1.3 Features and Specifications..........................................................................................................15

1.3.1 Video and Audio Signals..................................................................................................15

1.3.2 Video and Audio Processing Capability...........................................................................15

1.3.3 Controls.............................................................................................................................16

1.3.4 Physical Characteristics....................................................................................................16

1.3.5 Panel Diagrams.................................................................................................................16

2 Installation and Operating Environment ............................................................................17

2.1 Setting up Your IA-200................................................................................................................17

2.2 Standby Mode ..............................................................................................................................17

2.3 Software Operating Environment.................................................................................................17

2.3.1 IA-200 Users (Keystone Correction Only).......................................................................17

2.3.2 Router Manager ................................................................................................................17

2.3.3 IA-200 Control Tool.........................................................................................................18

2.3.4 eWarp Designer 200 .........................................................................................................18

2.3.5 Edge Blending Utility 200................................................................................................18

2.3.6 Updater..............................................................................................................................18

3 User Interface........................................................................................................................19

3.1 IR Remote Control.......................................................................................................................19

3.1.1 OSD Navigation Buttons..................................................................................................20

3.1.2 Video Source Selection Buttons .......................................................................................20

3.1.3 IA-200 Special Feature Selection Buttons........................................................................20

3.2 Operational Modes.......................................................................................................................20

4 On Screen Display................................................................................................................25

4.1 OSD Menu Structure....................................................................................................................25

5 Keystone and Geometry Correction...................................................................................36

5.1 Operation of Keystone Control....................................................................................................36

5.2 User Warp Maps...........................................................................................................................36

6 Aspect Ratio Treatment .......................................................................................................38

© Flexible Picture Systems Page 5 of 49

Page 6

User’s Manual 0020D1.01 Image AnyPlace IA-200

6.1 Aspect Ratio Treatments..............................................................................................................38

6.1.1 Supported Aspect Ratios...................................................................................................38

6.1.2 Aspect Ratio Treatments Objectives.................................................................................39

6.1.3 Input and Output Combinations........................................................................................40

7 Input Modes Supported .......................................................................................................45

8 Latency Considerations.......................................................................................................47

8.1 Low Latency Mode Configuration...............................................................................................47

9 Glossary................................................................................................................................49

Page 6 of 49 © Flexible Picture Systems

Page 7

Image AnyPlace User’s Manual 0020D1.01

Preface

These sections provide information you must read before using the IA-200.

Limited Warranty

All Flexible Picture Systems products are designed and tested to the highest standards and backed

by a one year parts and labor warranty. Warranties are effective upon the first delivery date to the

customer and are non-transferable.

Warranty related repairs include parts and labor, but do not include repair of faults resulting from

user negligence, special modifications, abuse (mechanical damage), shipping damage, and/or

other unusual damages.

The customer shall pay shipping charges when the unit is returned for repair. Flexible Picture

Systems will pay shipping charges for return shipments to customers.

Flexible Picture Systems does not assume responsibility for consequential damages, expenses or

loss of revenue, inconvenience or interruption in operation experienced by the customer.

Warranty service shall not automatically extend the warranty period.

No other warranty, expressed or implied, shall apply.

Return Material Authorization (RMA)

In the event that a product needs to be returned for repair, call Flexible Picture Systems at 905707-1664 and ask for an Applications Engineer to issue a Return Material Authorization number,

or send an e-mail to

RMA Conditions

Refer to these conditions when returning a product:

• Prior to returning any item, you must receive a Return Material Authorization (RMA)

number.

• All RMA numbers must appear on the return-shipping label.

• All RMA numbers are valid for ten (10) days from the issue date.

• All shipping and insurance charges in all RMAs must be prepaid by the customer.

support@flexiblepicturesystems.com.

FCC Statement

This equipment has been tested and found to comply with the limits for Class B digital devices,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

© Flexible Picture Systems Page 7 of 49

Page 8

User’s Manual 0020D1.01 Image AnyPlace IA-200

against harmful interference in a residential/office installation. The equipment generates and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment

off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

• Consult the dealer or an experienced Radio/TV technician for help.

• Changes or modifications not expressly approved by the party responsible for compliance

could void the user's authority to operate the equipment.

Safety

Take note of all the safety instructions presented in this section before using the IA-200.

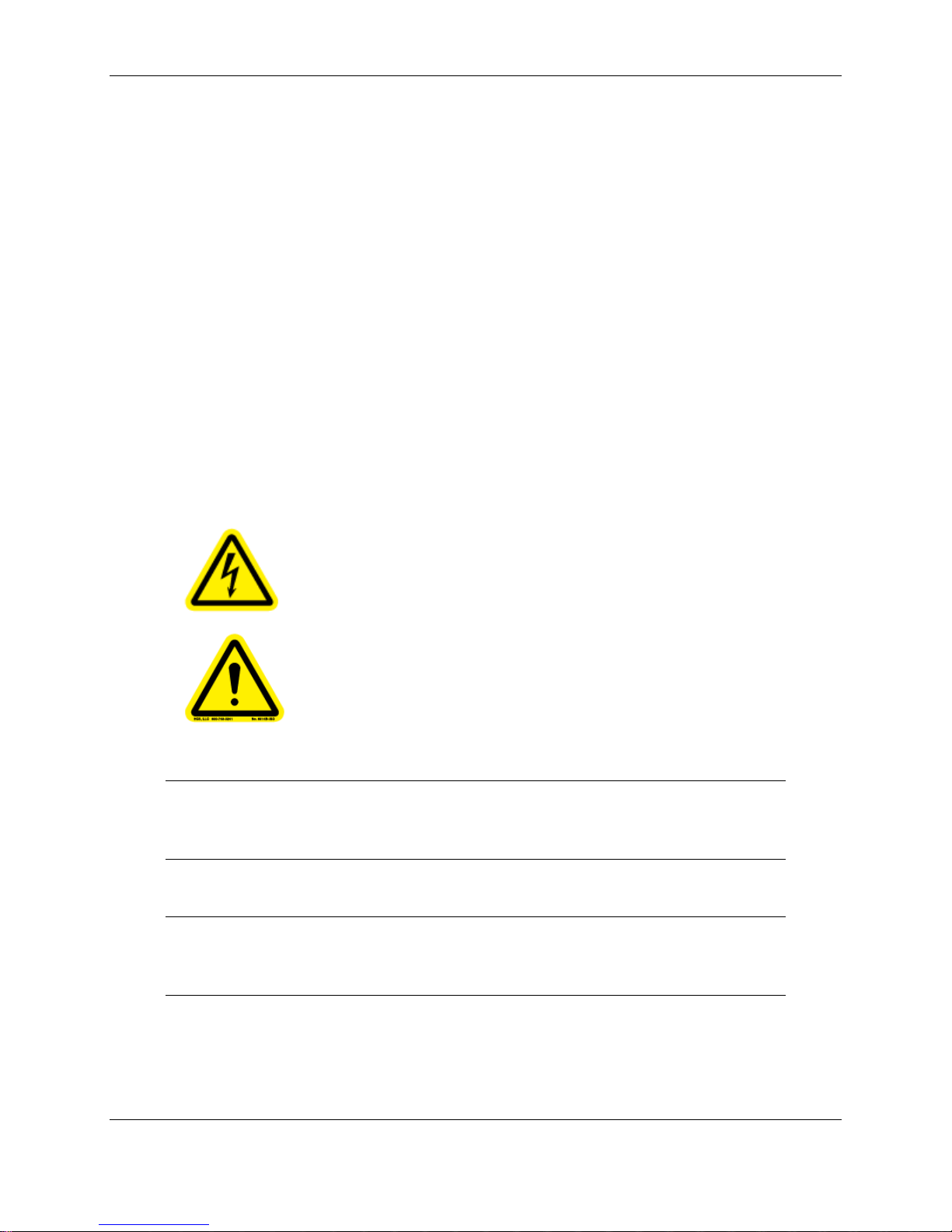

Warnings and Warning Symbols

The Lightning Flash with arrowhead symbol within an equilateral

triangle is intended to alert the user to the presence of un-insulated

"dangerous voltage" within the product enclosure, voltage that may be of

sufficient magnitude to constitute a risk of shock to persons.

The exclamation point within an equilateral triangle is intended to alert

the user to the presence of important operating and maintenance

(servicing) instructions in the literature accompanying the product.

Warning! To reduce the risk of fire or electric shock, do not expose this apparatus to rain

or moisture and objects filled with liquids, such as vases, should not be placed on this

apparatus.

Warning! This apparatus is intended to be connected to a power outlet that includes a

protective earthing connection (i.e. a third pin ground). do not remove the third pin of the

power cable or connect the unit in any way that does not connect this pin to ground.

Page 8 of 49 © Flexible Picture Systems

Page 9

Image AnyPlace User’s Manual 0020D1.01

Important Safety Label Information

A label indicating important safety information is located on the bottom surface of the IA-200.

Important Safety Instructions

General

• Read these instructions.

• Keep these instructions.

• Take note of all warnings.

• Follow all instructions.

Installation

• Do not use this apparatus near water.

• Do not block any ventilation openings. Install in accordance with the manufacturer's

instructions.

• Do not install near any heat sources such as radiators, heat registers, stoves, or other

apparatus (including amplifiers) that produce heat.

• Do not defeat the safety purpose of the polarized or grounding-type plug.

• A polarized plug has two blades with one wider than the other. A grounding type plug has

two blades and a third grounding prong. The wide blade and the third prong are provided for

your safety. If the provided plug does not fit into your outlet, consult an electrician for

replacement of the obsolete outlet.

• Protect the power cord from being walked on or pinched, particularly at plugs, convenience

receptacles, and the point where they exit from the apparatus.

• Only use attachments/accessories specified by the manufacturer.

• Use only with the cart, stand, tripod, bracket, or table specified by the manufacturer, or sold

with the apparatus. When a cart is used, use caution when moving the cart/apparatus

combination to avoid injury from tip-over.

Operation

• Clean only with dry cloth.

• Unplug this apparatus during lightning storms or when unused for long periods of time.

• Refer all servicing to qualified service personnel.

• Servicing is required when the apparatus has been damaged in any way, such as power-

supply cord or plug is damaged; liquid has been spilled or objects have fallen into the

apparatus; the apparatus has been exposed to rain or moisture, does not operate normally, or

has been dropped.

Installation

Attachments

Do not use attachments not recommended by the manufacturer, as they may result in the risk of

fire, electric shock, or injury to persons.

Water and Moisture

© Flexible Picture Systems Page 9 of 49

Page 10

User’s Manual 0020D1.01 Image AnyPlace IA-200

Do not use this unit near water; for example, near a bathtub, washbasin, kitchen sink or laundry

tub, in a wet basement, or near a swimming pool, water spa, or the like.

Heat

Do not use this unit near sources of heat, including heating vents, stoves, or other appliances that

generate heat. Also, do not place this product in temperature environments greater than 45ºC

(104ºF).

Mounting Surface

If not installing the unit in a standard equipment rack using the recommended mounting brackets,

place the unit on a flat, even surface. Do not place the unit on an unstable cart, stand, tripod,

bracket, or table. The unit may fall causing serious injury to a person and/or serious damage to

the appliance.

Portable Cart

An appliance and cart combination should be moved with extreme care. Quick stops, excessive

force, and uneven surfaces may cause the appliance and cart combination to overturn.

Ventilation

Locate the unit with adequate space around it so that proper heat ventilation is assured. Allow 10

cm (4 in) clearance from the rear and top of the unit, and 5 cm (2 in) from each side.

Slots and Openings

Slots and openings in the unit's case are provided for ventilation to ensure reliable operation of

the unit and to prevent overheating. These openings must not be blocked or covered. The

openings should never be blocked by operating the unit while placed on a bed, sofa, rug, or

similar surface. This unit should not be placed in a built-in installation such as a bookcase unless

adequate ventilation is provided.

Entry of Foreign Objects and Liquids

Never push foreign objects of any kind into this unit through the ventilation slots as they may

touch dangerous voltage points or short-circuit electrical/electronic parts that could result in fire,

or electric shock, or both. Never spill liquid of any kind onto the unit.

Electric Power

Only operate the unit from the type of electric power source indicated on the unit's labeling. If

you are not sure of the type of power supply that is available in your home or workplace, consult

your appliance supplier or local power company.

Grounding or Polarization

This unit is provided with a 3-pin, grounded, alternating current line plug. This plug will fit into

the power outlet only one way. This is a safety feature. Do not try to defeat the safety purpose of

the plug.

Power Cord Protection

Page 10 of 49 © Flexible Picture Systems

Page 11

Image AnyPlace User’s Manual 0020D1.01

Route power supply cords so that they are not likely to be walked on or pinched by placing items

upon or against them, paying particular attention to cords at plugs, convenience receptacles, and

the point where they exit from the product.

Overloading

Do not overload wall power outlets, extension cords, or integral convenience receptacles as this

can result in a risk of fire or electric shock.

Lightning

For added protection for this unit during a lightning storm, or when it is left unattended and

unused for long periods of time, unplug it from the power outlet. This will prevent damage to the

unit due to lightning or power surges.

Maintenance

Cleaning

Unplug this unit from the wall outlet before cleaning. Do not use liquid cleaners or aerosol

cleaners. Only use a soft cloth dampened with a mild detergent solution. Do not use strong

solvents such as alcohol, benzene, or paint thinner.

Damage Requiring Service

Unplug this unit from the power outlet and refer servicing to qualified service personnel under the

following conditions:

• When the power cord or plug is damaged.

• If liquid has been spilled or foreign objects have fallen into the unit.

• If the unit has been exposed to rain or water.

• If the unit does not operate normally, following the operating instructions. Adjust only those

controls that are covered by the operating instructions as improper adjustment of other

controls may result in damage and may require extensive work by a qualified technician to

restore the unit to normal operation.

• If the unit has been dropped or the case has been damaged.

• When the unit exhibits a distinct change in performance—this indicates a need for service.

Warning! Do not attempt to service this unit yourself as opening or removing covers

may expose you to dangerous voltage or other hazards. Refer all servicing to qualified

service personnel.

Disconnecting Instructions

In the event that power needs to be quickly disconnected from the IA-200 Processor, the user may

separate the power cable from the processor at the power entry module by firmly grasping the

power cable and pulling until the cable comes free.

© Flexible Picture Systems Page 11 of 49

Page 12

User’s Manual 0020D1.01 Image AnyPlace IA-200

1 Introduction

1.1 General Description

The Image AnyPlace IA-200 is a high performance video signal processor intended for use in Pro

AV applications. In addition to top ranked scaler features, the IA-200 adds Keystone Correction

capability (i. e. the ability to correct for the distortion caused by projecting off-axis onto a flat

screen). Variations on the IA-200 design add Image Geometry Correction (ability to correct for

projection onto a curved or irregular screen) and Edge Blending (the ability to invisibly blend

the overlapping output of 2 projectors) to the product. All IA-200 processors can be updated in

the field to add Image Geometry Correction and/or Edge Blending. Choosing the SDI option

(available at slight extra cost at the time of purchase) enables the user to add HD-SDI (and SDI)

input capability.

As a Scaler, the IA-200 offers the top quality image scaling provided by the Silicon Optix Realta

IC. All popular resolutions are supported on both input and output. In addition, the IA-200

functions as a switcher, supporting several different signal input types (see section 1.3.1).

As a Keystone Corrector, the IA-200 enables precision Keystone Correction for projection onto

any flat screen. All flat screen Keystone adjustments may be made with just 4 corner controls

internally available from the OSD (i. e. the user adjusts each corner of the projected image to

match the desired projection area in real time). In addition to off axis distortion, this approach

also simultaneously corrects for Screen/Projector Rotation, Screen Slant, and incorrect Screen

Aspect Ratio. The IA-200’s sub-pixel precision makes it an ideal choice of multiple projector

applications such as Projector Stacking for added brightness, and 2 projector 3D applications.

As a Geometry Correcter, the IA-200_EX extends precision Geometry Correction to image

shaping onto curved, spherical and even irregular screens. The IA-200_EX accomplishes this

sophisticated Geometry Correction using the eWarp Designer 200 PC based program. eWarp

Designer 200 enables the user to precisely shape the screen using a flexible grid

1

.

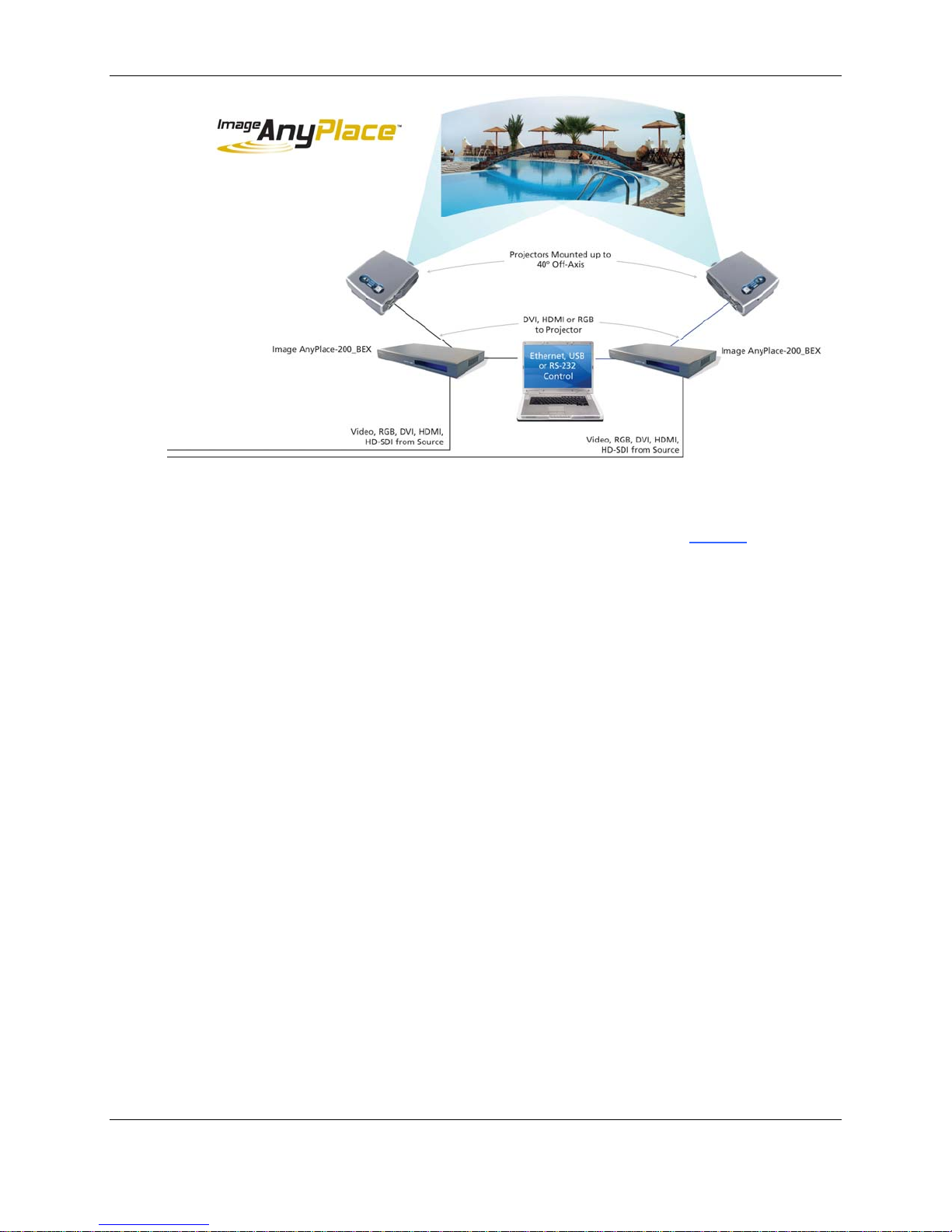

As an Edge Blender, IA-200_BEX adds Edge Blending to Keystone Correction and Geometry

Correction. Any number of projectors’ output may be blended on any type of surface. Edge

Blending is controlled by the Edge Blending 200 PC based program.

1

For Image AnyPlace IA-100 users: IA-100 grid files larger than 7x9 are compatible with IA-200; use the internal 4

point method of IA-200’s for 4 point Keystone Correction.

Page 12 of 49 © Flexible Picture Systems

Page 13

Image AnyPlace User’s Manual 0020D1.01

Figure 1: IA-200 Video Processor

In addition to its professional grade Scaler features and its unique Keystone Correction and

Geometry Correction and Edge Blending, the IA-200 adds HQV technology video processing

features to all video signals. Initially conceived in the military research labs of Lockheed Martin

and then refined and commercialized by Teranex and Silicon Optix, HQV video processing has

been the technology of choice of film and video professionals in broadcast and studio

environments for years. HQV signal processing includes the following powerful features:

• State-of-the-art, motion-adaptive de-interlacing for both SDTV and HDTV

• Temporal Recursive Noise Reduction

• Codec Noise Reduction (includes mosquito noise reduction and block artifact removal)

• Detail Enhancement

• Fully-automatic detection and correction for multiple film/video cadences (3:2, 2:2, vari-

speed, 6:4, 8:7, etc.)

• Brightness-Contrast Enhancement

• Color Space Conversion and Color Temperature Adjustment

For more information on HQV technology, visit

http://www.hqv.com.

© Flexible Picture Systems Page 13 of 49

Page 14

User’s Manual 0020D1.01 Image AnyPlace IA-200

Figure 2: Typical IA-200 Application

IA-200 is controlled through a simple 20-button IR remote control unit (see

navigation keys bring access to a simple, yet elegant OSD (On Screen Display). Video input

device selection is accomplished using dedicated IR remote buttons. Access to the HQV features

is also provided through dedicated IR remote buttons.

IA-200 provides the professional user with flexible control methodologies of RS-232, USB, and

Ethernet. For details on the control programming protocol, refer to the IA-200 Programming

Manual.

IA-200 is implemented in a compact and attractive desktop package that can be rapidly fitted to a

standard 19" rack using a separately ordered rack mounting kit, part number IA-200_RM.

1.2 Product Variations and Nomenclature

The IA-200 product has several different variations, described below:

IA-200 IA-200 scaler with Keystone Correction. Keystone Correction is

implemented internally. No PC software is required.

IA-200_EX Adds Geometry Correction to the IA-200. Geometry Correction is

implemented with the eWarp Designer 200 software (which creates the

grid based Warp Maps, and downloads them to the IA-200 hardware).

eWarp Designer 200 access is enabled through a serial number based

key, which is permanently stored (in the manufacturing process or by

field upgrade) on the IA-200 hardware. If you have an IA-200 and you

would like to add Geometry Correction, you can purchase an

IA-200_eWARP_Key.

IA-200_BEX Adds Edge Blending capability to the IA-200_EX. Blending is

implemented with the Edge Blending Utility 200 software (which creates

Figure 5). Simple

Page 14 of 49 © Flexible Picture Systems

Page 15

Image AnyPlace User’s Manual 0020D1.01

the blend regions, and downloads them to the IA-200 hardware). Edge

Blending Utility 200 access is enabled through a serial number based

key, which is permanently stored (in the manufacturing process or by

field upgrade) on the IA-200 hardware. If you have an IA-200 or IA-

200_EX and you would like to add Edge Blending, you can purchase an

IA-200_EB_Key. The Edge Blending Key is different than the eWarp

Key. The IA-200_BEX product definition includes both Keys.

IA-200_XXX_SDI Any of the IA-200 options can be ordered with or without SDI (actually

HD-SDI, but accepts SDI as well). Since the SDI option involves

hardware (i.e. connectors and components that are loaded or not at the

time of manufacture), no field upgrade is possible.

1.3 Features and Specifications

1.3.1 Video and Audio Signals

Table 1: Video and Audio Signals (see section 5 for resolution range)

Signal Type Input Output

Video

Audio

• Composite Video (NTSC, PAL, and

SECAM)

• S-Video (NTSC and PAL)

• Component (YPbPr for SDTV and HDTV in

American and European formats)

• Analog RGB (VGA to SXGA60Hz)

• DVI (VGA to QXGA)

• HDMI

• SDI (including HD-SDI and audio) (included

with SDI option only)

• S/PDIF

• Toslink

• HDMI

1.3.2 Video and Audio Processing Capability

These are the video and audio features supported:

• Scaling

• Extreme Keystone Correction (+/- 40º horizontal, +/- 30º vertical)

• Geometry Correction for projection on curved or irregular surfaces (with EX versions)

• Edge Blending for blending multiple projectors’ output (BEX versions)

• Audio Delay

• Input Switching

• Aspect Ratio Correction

• HQV Video Processing

• Analog RGB (VGA to

UXGA)

• DVI (VGA to QXGA)

• HDMI

• S/PDIF

• Toslink

• HDMI

© Flexible Picture Systems Page 15 of 49

Page 16

User’s Manual 0020D1.01 Image AnyPlace IA-200

o Temporal-Recursive Noise Reduction

o Codec Noise Reduction

o Fully-automatic cadence detection and correction

o Detail Enhancement

• Advanced motion-adaptive de-interlacing

1.3.3 Controls

IA-200 may be remotely controlled over 3 different interfaces, as well as the user operated IR

Remote. IA-200 may be controlled by any of IA-200’s application programs (eWARP Designer

200, IA-200 Control Tool, Updater and Router Manager) and for connection to Crestron/AMX

type systems:

• RS-232

• USB

• Ethernet

1.3.4 Physical Characteristics

These are the physical characteristics of the IA-200:

Dimensions 17.0" x 9.7" x 1.75"(43.2 x 24.6 x 4.4 cm)

Weigh 7 lbs. (3.2 kg)

Power 100-240V, 47-63 Hz, 27W (typical)

1.3.5 Panel Diagrams

Figure 3: Front Panel Drawing

Figure 4: Rear Panel Drawing

Page 16 of 49 © Flexible Picture Systems

Page 17

Image AnyPlace User’s Manual 0020D1.01

2 Installation and Operating Environment

2.1 Setting up Your IA-200

The IA-200 Quick Start Guide is intended to provide a quick list of steps that you can follow to

get things working in 95% of installations. Please refer to the

installation instructions. This section and the subsequent User Interface is intended for more

advanced installations, problem solving and the general background of the product.

2.2 Standby Mode

The IA-200’s power switch is located on the back of the system.

Quick Start Guide for basic

A momentary contact Standby/Operate button is located at the extreme left of the front panel

(and is also implemented as a red button on the IR Remote.)

Standby mode is a low power mode which suspends the IA-200’s output to the projector. During

Standby mode, the IA-200’s front panel display is active and Remote Control are active, but in a

different context. In addition to provide an

setting, the Standby state enables the user to adjust parameters that would generally not be

adjusted during normal OSD operation. One benefit of this operation is that the user cannot

make a casual OSD keystroke error that, for example, resets the display resolution to something

that the display cannot support (causing the screen to go blank and depriving the user of the

visual feedback that he needs to fix the problem).

Instant On IR response from its low power output

2.3 Software Operating Environment

IA-200 comes with a CD with several different applications. Depending on your intended use,

you may require none, some or all of the applications. The Quick Start Guide describes how to

install the CD. This section briefly describes the software environment.

2.3.1 IA-200 Users (Keystone Correction Only)

No software is required (as long as you do not need to control anything over RS-232, USB or

Ethernet). All operation is achieved through the IR remote Control and OSD.

2.3.2 Router Manager

If you want to do anything else other than basic scaling and Keystone Correction, you need to run

Router Manager and install your specific IA-200. Router Manager is the common

© Flexible Picture Systems Page 17 of 49

Page 18

User’s Manual 0020D1.01 Image AnyPlace IA-200

communications and control layer that enables each IA-200 application to quickly identify that a

specific IA-200 is attached and ready to communicate. Basic details on how to quickly connect

are provided in the Quick Start Guide. In depth explanation is provided in the Router Manager

Manual.

2.3.3 IA-200 Control Tool

IA-200 Control is intended as Control Program Emulator and Control Script Development tool.

Use the IA-200 Control Tool to experiment with IA-200 Control Protocol, and develop scripts of

ASCII based protocol (described in the IA-200 Programmer’s Guide). These scripts can then be

imported into popular Pro AV controllers such as Crestron and AMX for control of the IA-200 in

a large installation. The IA-200 Control Utility does not require a software key for operation.

Installation with Router Manager is not required for IA-200 Control Tool.

2.3.4 eWarp Designer 200

eWarp Designer 200 is used to develop grid based Geometry Correction for the IA-200_EX and

IA-200_BEX versions. eWarp Designer 200 requires a serial number based Key for operation.

The key is installed during manufacturing or may be installed in the field (key installation is

accomplished with eWarp Designer 200 itself). Correct installation with Router Manager is

required for eWarp Designer 200operation.

2.3.5 Edge Blending Utility 200

Edge Blending Utility 200 is used to control Edge Blending in IA-200_BEX versions. Edge

Blending Utility 200 requires a serial number based Key for operation. The key is installed

during manufacturing or may be installed in the field (key installation is accomplished with Edge

Blending Utility 200 itself). Correct installation with Router Manager is required for Edge

Blending Utility 200 operation.

2.3.6 Updater

Update is used to provide firmware updates to all versions of IA-200. Updater connects directly

to the IA-200 in Service Mode. Please see the Updater manual for details on Service Mode and

the use of Updater. Updater does not require Router Manager.

Page 18 of 49 © Flexible Picture Systems

Page 19

Image AnyPlace User’s Manual 0020D1.01

3 User Interface

3.1 IR Remote Control

All IA-200 user interface controls are accessed via infrared (IR) remote control. The remote has

following groups of controls:

• OSD Navigation (including the On/Setup Key)

• Video Source Selection

• IA-200 Special Feature Selection

You may also select video sources and HQV processing features through the

controls; however, dedicated IR remote keys provide you with quick one-touch access to the most

frequently used commands.

Figure 5 illustrates the IA-200 remote control.

OSD navigation

© Flexible Picture Systems Page 19 of 49

Figure 5: Remote Control

Page 20

User’s Manual 0020D1.01 Image AnyPlace IA-200

3.1.1 OSD Navigation Buttons

These are the OSD navigation buttons on the IR remote.

• The On/Setup (indicated as Power) button toggles the IA-200 between On and Setup modes

of operation (as described in

• The Menu button is used to invoke the OSD main menu.

• The Up/Down/Left/Right arrow buttons are used to navigate the OSD.

• The Enter/Select button is used to activate an OSD menu selection.

Operational Modes).

3.1.2 Video Source Selection Buttons

Direct (one-touch) input selection is possible using the following buttons:

• The RGB button selects the VGA port as the active input.

• The DVI button selects the DVI port as the active input.

• The Video button selects the composite video port as the active input.

• The S-Video button selects the S-Video port as the active input.

• The YPbPr button selects component video as the active input.

• The HDMI button selects HDMI as the active input.

• The SDI button selects the SDI port as the active input

3.1.3 IA-200 Special Feature Selection Buttons

Additional buttons are available to directly access key video processing features and to cycle

through the available enhancements:

• The LUT button cycles through pre-loaded, and user programmed input LUT (Look Up

Tables, which can be used to brighten or darken the appearance of incoming video

• The TRNR button accesses the Temporal Recursive Noise Reduction feature, cycling

through the four available settings (Off, Low, Medium, and High).

• The CNR button accesses the Codec Noise Reduction feature, cycling through the four

available settings (Off, Low, Medium, and High).

• The eWarp button cycles through the available User defined Warp Maps (created by eWarp

Generator and stored in Index 1 through Index 8)

• The Split button activates/deactivates a split-screen mode for direct comparison of the image

with and without noise reduction activated.

• The Test cycles through a series of embedded Test Patterns which are instantly rendered at

the current output resolution

3.2 Operational Modes

The IA-200 has two operational modes, On and Setup (Stand-by). These modes are selected by

a dedicated key on the IR remote. The IA-200 also enables selection using the On Mode using

the ASCII control protocol with RS-232, USB, or Ethernet.

Page 20 of 49 © Flexible Picture Systems

Page 21

Image AnyPlace User’s Manual 0020D1.01

3.2.1.1 On Mode

On Mode is entered by toggling the On/Setup button on the IR remote. A brief transition of

about 3 seconds occurs when

On Mode is entered. During this transition period, the 24 x 2 LCD

Display indicates

IA-200

Please Wait

In On Mode, the video output signals are activated and you may control all of IA-200 parameters

with the remote control (except for

Setup restricted parameters, as noted below). The LCD front

panel display indicates the following information in its 24 x 2 character matrix:

Input=Connector Resolution

Output=Resolution

Depending on which IR remote key that you select, the operation of the OSD is slightly different:

• If you select the Menu key, the IA-200’s OSD appears on the screen.

The OSD remains on the screen until you press the Menu key once again or until 30 seconds

with no IR remote activity passes. Complete details on the OSD may be found in the

Screen Display

.

On

• If you select one of the dedicated IA-200 Special Feature keys, the IA-200 special feature is

immediately activated.

A brief message indicating the status of the selected IA-200 special feature appears

momentarily on the screen (e.g. TRNR = Medium or CNR = Off).

• If you select one of the Input Source keys, the selected source is chosen as the input.

The previously selected IA-200 Special Features, Scaling and Video Parameters are all

preserved for each input; each input appears exactly as you left it.

The IA-200 powers up in On Mode. All operational parameters are retained from the previous

session. A Factory Reset returns all parameters to the default state (defaults are described in the

On Screen Display), except for the input signal. The input signal most recently used is retained as

the power-up input signal.

3.2.1.2 Setup (Stand-by) Mode

Setup mode is entered by toggling the On/Setup button on the IR remote.

In Setup mode, the IA-200 is in a low-power state. The output signals are de-activated (no output

will appear on your display device). Setup mode enables you to power the unit down, but still

leaves the IR receiver circuitry energized so that you can re-start the system with the IR remote.

When the unit is in Setup Mode, you can also make adjustments to certain sensitive parameters,

such as Output Resolution. Visual feedback for the adjustments of Setup Mode is seen on the 24

x 2 LCD display, rather than on OSD of the main screen. Sensitive parameters are placed in the

Setup Menu so that an inadvertent key stroke with the IR remote does not cause a change in a

parameter from which that would be difficult to recover.

Table 2 lists the Setup parameters and Table 3 lists the output resolutions currently supported in

the unit.

© Flexible Picture Systems Page 21 of 49

Page 22

User’s Manual 0020D1.01 Image AnyPlace IA-200

Table 2: Setup Parameters

Parameter Description*

OUT = XXX ## Hz Cycles through all of the available IA-200 output modes

Table 3 for a list of Output Resolutions).

(see

LCD Brightness = On (Off)

Turns On (Off) the 24 x 2 LCD Display during On Mode

BAUD = ##### Lets you choose a baud rate of 1200, 9600, 19200, 57600,

or 115000.

OSD Location = Input (Output)

The OSD may be located pre (Input side) or post (Output

side) scaling and keystone correction

PC Control = Active (Inactive)

Turns On (Off) the computer control capability

DHCP = Enabled (Disabled)

Turns on Dynamic IP Address Selection

IP=aaa.bbb.ccc.ddd Select IP Address (selectable only if DHCP = Disabled)

DNS=aaa.bbb.ccc.ddd Select DNS Address (selectable only if DHCP = Disabled)

2nd DNS=aaa.bbb.ccc.ddd Select Alternate DNS Address

(selectable only if DHCP = Disabled)

Gateway=aaa.bbb.ccc.ddd Select Gateway Address (selectable only if DHCP =

Disabled)

SubMask=aaa.bbb.ccc.ddd Select SubNet Mask (selectable only if DHCP = Disabled)

MAC = ## ## ## ## ## ## Indicates the MAC Address of IA-200 unit

Serial No = ###### Indicates the Serial # of IA-200 unit

µProc Rev = #.## Indicates the Rev # of the Front Panel microprocessor.

* The default parameters configurations are highlighted in bold.

Table 3: Output Modes

Output Mode Comments

VGA 60 Hz (640 x 480) VESA Standard

VGA 50 Hz (640 x 480) VESA Standard

848 x 480 60 Hz Panel timing

SVGA 60 Hz (800 x 600) VESA Standard

SVGA 50 Hz (800 x 600) VESA Standard

720p 60 Hz (1280 x 720) SMPTE Standard

720p 50 Hz (1280 x 720) SMPTE Standard

XGA 60 Hz (1024 x 768) VESA Standard

XGA 72 Hz (1024 x 768) VESA Standard

XGA 50 Hz (1024 x 768) VESA Standard

1360 x 768 60 Hz NEC timing

1365 x 768 60 Hz NEC timing

1400 x 788 60 Hz Panel timing

SXGA 60 Hz (1280 x 1024) VESA Standard

Page 22 of 49 © Flexible Picture Systems

Page 23

Image AnyPlace User’s Manual 0020D1.01

Output Mode Comments

SXGA 50 Hz (1280 x 1024) VESA Standard

SXGA+ 60 Hz (1400 x 1050) VESA Standard

SXGA+ 50 Hz (1400 x 1050) VESA Standard

1080p 60 Hz (1920 x 1080) SMPTE Standard

1080p 50 Hz (1920 x 1080) SMPTE Standard

1080p 48 Hz (1920 x 1080) SMPTE Standard

QXGA 60 Hz (2048 x 1536) QXGA 50 Hz (2048 x 1536) QXGA 48 Hz (2048 x 1536) UXGA 60Hz (1600 x 1200) VESA Standard

1365 x 1024 50 Hz JVC timing

1365 x 1024 60 Hz JVC timing

1360 x 1024 60 Hz JVC timing

1280 x 768 60 Hz VESA Standard

Digital Cinema 60 Hz (2048 x

-

1080)

Digital Cinema 24 Hz (2048 x

-

1080)

WUXGA 60 Hz (1920 x 1200) VESA Standard

1366 x 768 Panasonic Timing

Reserved 9 Reserved for future use

Reserved 10 Reserved for future use

Reserved 11 Reserved for future use

Reserved 12 Reserved for future use

3.2.1.3 Setting Up the Unit

On entry to the Setup mode, the 24 x 2 LCD display indicates the following:

IA-200

Setup

Select the Menu key on your IR remote to bring up the Setup Menu on the 24 x 2 LCD display.

The LCD display indicates the following:

Parameter = Value

Setup Mode

Using the up/down navigation keys on the remote, you can select the next parameter in a circular

list of parameters. Using the left/right navigation keys on the remote, you can select the value of

the parameter. In some cases, the parameter is visible in the setup menu, but may not be altered

(such as Serial Number or MAC Address).

Selection of IP addresses is slightly different. IP addresses may only be selected if the DHCP

parameter has been set to "Off". In this case, you use the left/right navigation key to "enter" the

© Flexible Picture Systems Page 23 of 49

Page 24

User’s Manual 0020D1.01 Image AnyPlace IA-200

IP address. The left key will highlight the rightmost octet; the right key will select the leftmost

octet. The up/down keys may then be used to increase/decrease the value of the octet.

Subsequent presses of the left/right key highlight the octet immediately to the left/right. The

up/down keys may then be used to increase/decrease the value of the octet. When the

leftmost/rightmost octet is selected, an additional left/right key selection "exits" the IP address.

The up/down arrows may then be used to select the next parameter.

Table 2 lists the Setup

parameters.

Page 24 of 49 © Flexible Picture Systems

Page 25

Image AnyPlace User’s Manual 0020D1.01

4 On Screen Display

4.1 OSD Menu Structure

The OSD is the primary way of controlling and selecting functions in the IA-200 system. When

first powered up, the IA-200 is in a Factory Default configuration, with English as the OSD

language, Component Video as Video Input, and S/PDIF Audio as Audio input. All other Factory

Default parameters are indicated in

When you select the Factory Reset from the OSD menu, IA-200 reloads all of these default

parameters, replacing any adjustments previously made. As indicated in the

Setup Parameters are not affected by Factory Reset.

IA-200 preserves all the signal processing parameters on a selected input basis. When you power

down or select a different input, the processing parameters previously selected are automatically

re-established when returning to that input. An Input Reset sets the currently selected input to its

default parameters. (This allows you to reset a specific input channel without disturbing

selections that affect the entire IA-200 operation).

Table 5.

User Interface, the

A complete view of the OSD menu structure is shown in

Table 4: OSD Main Menu Structure

Icon On Icon Off

Description

Inputs

Picture

Setup

Language

Functionality

Enter this submenu to select the video or audio input.

Enter this menu to adjust the image brightness, contrast,

sharpness, gamma correction, black level, color

temperature, color, hue, tint, and aspect ratio.

Enter this submenu to review the video system, select the

background color, reset to default settings, and setup the

menu position.

Enter this submenu to select the language used by the OSD.

Table 4 and Table 5.

© Flexible Picture Systems Page 25 of 49

Page 26

User’s Manual 0020D1.01 Image AnyPlace IA-200

Icon On Icon Off

Description

Info

Functionality

Enter this submenu to view information about the system

(input resolution, horizontal and vertical frequency, output

resolution, horizontal and vertical frequency, firmware

revision, FPGA revision, serial number, and IP address).

Advanced Enter this submenu to access the advanced menu options.

Table 5: OSD Complete Menu Structure

OSD Menu Level

Level 1 Level 2 Level 3 Level 4 Level 5

Component - - HDTV or SDTV

VGA - - SDTV, HDTV, or Graphics

DVI - - Graphics, RGB HDTV

Inputs

Video

Audio

Audio Delay

S-Video - - SDTV

Composite - - SDTV

SDI - - SDI input selection

HDMI - - HDMI input selection

TosLink - - Selects TosLink as audio source

S/PDIF Selects S/PDIF as audio source

HDMI Selects HDMI as audio source

SDI - - Selects SDI as audio source

-100 - +100, 0

(default)

- -

Comments

Adjusts the Audio Delay through

IA-200. The Audio Delay is

calibrated in milliseconds. A delay

of ‘0’ selects a delay that is

automatically adjusted to the

number of frames of delay

introduced by IA-200 processing.

The Audio Delay adjustment allows

the user to compensate for Audio

or Video delay that is introduced by

other system components

Brightness

Picture

Picture

Settings

Page 26 of 49 © Flexible Picture Systems

Contrast

0 - 100,

50 (default)

0 - 100,

50 (default)

The higher the setting, the greater

-

-

the brightness.

The lower the setting, the lower the

brightness.

The higher the setting, the greater

the contrast.

The lower the setting, the lower the

contrast.

Page 27

Image AnyPlace User’s Manual 0020D1.01

OSD Menu Level

Level 1 Level 2 Level 3 Level 4 Level 5

Sharpness

Detail

Enhancement

0 - 100,

50 (default)

0 - 100,

0 (default)

-

-

Gamma 1.0

(default)

Gamma 1.5 Gamma LUT

Gamma 2.2

Input

Gamma

Gamma 2.4

Gamma 2.5

Comments

The higher the setting, the

sharper the image (edge

enhancement).

The lower the setting, the lower

the sharpness.

The higher the setting, the

better the image (detail

enhancement).

The lower the setting, the lower

the detail enhancement.

Gamma LUT for linear

processing response.

Gamma LUT

Gamma LUT

Gamma LUT

Picture

Picture

Settings

Gamma

Mode

Color Temp

Color

Gamma 2.8

Gamma 1.0

(default)

Gamma 2.2

Output

Gamma 2.4

Gamma

Gamma 2.5

Gamma 2.8

9300K 6500K

(default)

-

5500K -

0 - 100,

50 (default)

-

Gamma LUT

Gamma LUT for linear

processing response.

Gamma LUT

Gamma LUT

Gamma LUT

Gamma LUT

Gives a blue tint to the white

colors.

Gives a neutral tint to the white

colors.

Gives a red tint to the white

colors.

The higher the setting, the

greater the Color Saturation.

The lower the setting, the lower

the Color Saturation.

© Flexible Picture Systems Page 27 of 49

Page 28

User’s Manual 0020D1.01 Image AnyPlace IA-200

OSD Menu Level

Level 1 Level 2 Level 3 Level 4 Level 5

0 - 360,

Picture

Picture

Settings

Aspect

Ratio

Hue

Input Reset

Standard

(default)

Full Screen - -

180

(default)

Confirm

YES/NO

- -

-

-

Comments

The higher the setting, the

more greenish the picture. The

lower the setting, the more

purplish the picture.

Returns all of the adjustments

for a single input to the Factory

Default state. All the other

inputs and selections that affect

the IA-200 operation (such as

Keystone Correction) are

unaffected

Maintains the aspect ratio:

• 4:3 input and 16:9 output -

Output image would be

displayed with black pillar

bars (maintains input

aspect ratio)

• 4:3 input and 4:3 output -

No change

• 16:9 input and 16:9 output -

No change

• 16:9 input and 4:3 output -

Output image would be

displayed with black letter

box bars (maintains input

aspect ratio)

Fills the Output Screen by

stretching the image (distorting

the aspect ratio):

• 4:3 input and 4:3 output –

Grayed out, no action

• 4:3 input and 16:9 output –

Image is linearly stretched

horizontally to fill the output

screen

• 16:9 input and 4:3 output -

Image is linearly stretched

vertically to fill the output

screen

• 16:9 input and 16:9 output

– Grayed out, no action

See Aspect Ratio Treatments

for more information.

Page 28 of 49 © Flexible Picture Systems

Page 29

Image AnyPlace User’s Manual 0020D1.01

OSD Menu Level

Level 1 Level 2 Level 3 Level 4 Level 5

Crop - -

Picture

Aspect

Ratio

Anamorphic - -

Flexview - -

Comments

Fills the Output Screen by

cropping the image

(maintaining aspect ratio).

• 4:3 input and 4:3 output –

Grayed out, no action

• 4:3 input and 16:9 output –

Top and bottom portions of

the image are cropped

• 16:9 input and 4:3 output –

Left and right portions of

the image are cropped

• 16:9 input and 16:9 output

– Grayed out, no action

See Aspect Ratio Treatments

for more information.

This mode is used with DVDs

(Standard Definition) that are in

Widescreen [16:9] format:

• 4:3 input and 4:3 output –

The image is letter boxed

• 4:3 input and 16:9 output –

The image appears full

screen

• 16:9 input and 4:3 output –

Grayed out, no action

• 16:9 input and 16:9 output

– Grayed out, no action

See Aspect Ratio Treatments

for more information.

Fills the Output Screen by

stretching the image (distorting

the aspect ratio):

• 4:3 input and 4:3 output –

Grayed out, no action

• 4:3 input and 16:9 output –

Image is non-linearly

stretched horizontally to fill

the output screen

• 16:9 input and 4:3 output –

Grayed out, no action

• 16:9 input and 16:9 output

– Grayed out, no action

See Aspect Ratio Treatment for

more information.

© Flexible Picture Systems Page 29 of 49

Page 30

User’s Manual 0020D1.01 Image AnyPlace IA-200

OSD Menu Level

Level 1 Level 2 Level 3 Level 4 Level 5

Squeeze

Aspect

Ratio

Picture

Theater

Scope

- -

- -

Comments

Squeezes 16:9 pre-stretched

inputs to 4:3 presentation

• 4:3 input and 4:3 output –

grayed out, no action

• 4:3 input and 16:9 output –

grayed out, no action

• 16:9 input and 4:3 output –

full screen 16:9 input is

squeezed to full screen 4:3

(this aspect ratio treatment

assumes 16:9 input that

has been horizontally prestretched from a 4:3

source)

• 16:9 input and 16:9 output

– full screen 16:9 input is

squeezed to 4:3 and

presented in a pillar box

• (this aspect ratio

treatment assumes 16:9

input that has been

horizontally prestretched from a 4:3

source

Provides aspect ratio

treatments for a system that

includes an Anamorphic Lens.

• 4:3 input and 4:3 output –

the central 16:9 aspect

ratio strip is cropped and

scaled to full screen output.

• 4:3 input and 16:9 output -

the central 2.35 aspect

ratio strip is cropped, and

scaled to full screen output.

• 16:9 input and 4:3 output –

full screen 16:9 input is

squeezed to full screen

output

• 16:9 input and 16:9 output

– the central 2.35 aspect

ratio strip is cropped, and

scaled to full screen output.

Picture

Position

Page 30 of 49 © Flexible Picture Systems

Vertical 0 - 100 -

Adjusts the vertical position of

image (default setting depends

on the input video/graphics

source)

Page 31

Image AnyPlace User’s Manual 0020D1.01

OSD Menu Level

Level 1 Level 2 Level 3 Level 4 Level 5

Picture

Position

Horizontal 0 - 400 -

Autosync - - -

0 - 200,

Picture

Sync

Clock

Phase

100

(default)

0 - 100,

50 (default)

Off - -

- Adjusts clock sync

- Adjusts clock phase

Overscan Status

On - -

Left

Right

Overscan

Top

Bottom

0.0 – 10.0

0.0 (default)

0.0 – 10.0

0.0 (default)

0.0 – 10.0

0.0 (default)

0.0 – 10.0

0.0 (default)

-

-

-

-

Center - -

Top Left - -

Setup

Menu

Position

Top Right - -

Bottom Left - -

Bottom Right - -

Comments

Adjusts the horizontal position

of image (default setting

depends on the input

video/graphics source)

Automatically centers the

image for graphic inputs

Sets the percentage of

Overscan on the left edge

Sets the percentage of

Overscan on the right edge

Sets the percentage of

Overscan on the top edge

Sets the percentage of

Overscan on the bottom edge

Sets the OSD menu position in

the center of the display

Sets the OSD menu position in

the top left corner of the display

Sets the OSD menu position in

the top right corner of the

display

Sets the OSD menu position in

the bottom left corner of the

display

Sets the OSD menu position in

the bottom right corner of the

display

© Flexible Picture Systems Page 31 of 49

Page 32

User’s Manual 0020D1.01 Image AnyPlace IA-200

OSD Menu Level

Level 1 Level 2 Level 3 Level 4 Level 5

Test

Patterns

- - -

Setup

Off (default)

-

Trigger A

12 V

Triggers

On -

Off (default)

-

Trigger B

On -

Comments

Displays test pattern images on

screen, with OSD off. Up- and

down-arrows navigate user

through all 10 available test

patterns. Left-arrow key returns

user to Test Pattern menu. Test

patterns:

• Screen boundary with circle

• 100 % Color bars

• Full White

• Full Black

• White Adjustment (levels

253, 254, 255)

• Black Adjustment (levels 0,

1, 2)

• Gray Bars

• Resolution alignment

• RGB Bars

• Grid

Sets Trigger A off.

Sets Trigger A on.

Sets Trigger B off.

Sets Trigger B on.

Language

Info

Factory

Reset

Confirm

YES/NO

- - Resets to default settings

English - - French - - -

German - - -

Italian - - -

Spanish - - -

Portuguese - - -

Swedish - - -

Russian - - -

Japanese - - -

Chinese

Simplified

Chinese

Traditional

- - -

- - -

Korean - - -

Input

Resolution

- - - Shows the source resolution

Selects the language for the

OSD menus

Page 32 of 49 © Flexible Picture Systems

Page 33

Image AnyPlace User’s Manual 0020D1.01

OSD Menu Level

Level 1 Level 2 Level 3 Level 4 Level 5

Info

Input H

Frequency

Input V

Frequency

Output

Mode

Output

Resolution

Output H

Frequency

Output V

Frequency

Sync - - - Shows the synchronization type

Firmware

Revision

Serial

Number

- - - Shows the source H frequency

- - - Shows the source V frequency

- - - Shows the display mode

- - - Shows the display resolution

- - - Shows the display H frequency

- - - Shows the display V frequency

- - -

- - -

Comments

Shows the firmware revision

number

Shows the board serial

number.

IP Address - - -

FPGA

Revision

- - -

Standby

Micro

- - -

Rev. #

Shows the IP address only if

the Ethernet cable is connected

to the board and the IP address

has been assigned by DHCP

Shows the current revision

number for the FPGA code

Shows the firmware revision

number for the standby-mode

microcontroller

© Flexible Picture Systems Page 33 of 49

Page 34

User’s Manual 0020D1.01 Image AnyPlace IA-200

OSD Menu Level

Level 1 Level 2 Level 3 Level 4 Level 5

H

Top Left

V

Reset

H

Bottom Left

V

Reset

Projectio

n

Keystone

Top Right

H

V

Reset

H

Bottom Left

V

Reset

Reset -

Advanced

Low

Off - -

On - -

Latency

Extra Low - -

Video - -

Cinema - -

Vivid - -

BCE

Dark Scene - -

Bright Scene - -

Graphics - -

Comments

Top Left Corner H deviation

in + pixels

Top Left Corner V deviation in

+ pixels

Resets Top Left Corner

Bottom Left Corner H

deviation in + pixels

Bottom Left Corner V

deviation in - pixels

Resets Bottom Left Corner

Top Right Corner H deviation

in - pixels

Top Right Corner V deviation

in + pixels

Resets Top Right Corner

Bottom Right Corner H

deviation in - pixels

Bottom Right Corner V

deviation in - pixels

Resets Top Right Corner

Resets Entire Keystone

Projection

Low Latency Mode is Off;

HQV De-interlacing and

Noise Reduction is enabled

Low Latency Mode is On;

HQV De-Interlacing and

Noise Reduction is disabled

Extra Low Latency Mode is

On; HQV De-interlacing and

Noise Reduction is disabled;

VJam or VAdjust Sync Modes

are forced

Full range video is 16 - 235;

use for video sources

Film Enhancement for video

sources

High Color Saturation

Enhancement for video

sources

Dark Scene Enhancement for

video sources

Bright Scene Enhancement

for video sources

Full range video is 0 - 255;

use for computer graphics

sources

Page 34 of 49 © Flexible Picture Systems

Page 35

Image AnyPlace User’s Manual 0020D1.01

OSD Menu Level

Level 1 Level 2 Level 3 Level 4 Level 5

HQV

Processing

Auto -

TRNR -

CNR -

HQV

Processin

g

Auto Bias 0-4 -

Off -

TRNR Level

Low -

Mid -

High -

Off -

CNR Level

Advanced

Low -

Mid -

High -

Split - -

Bottom - -

Left - -

Edge

Blending

Right - -

Top - -

Enable - -

User Warp

Off - -

Map

Selection

Index 1 - 8 - -

Comments

Automatically sets up Noise

Reduction according to Auto

Bias

Enables specific adjustment

of Temporal Recursive Noise

Reduction

Enables specific adjustment

of Codec Noise Reduction

Selects amount of HQV

processing 0 - 4

No adjustment

Adjusts TRNR

Adjusts TRNR

Adjusts TRNR

No adjustment

Adjusts CNR

Adjusts CNR

Adjusts CNR

Enables/Disables Screen

Split

Enable Edge Blending on

Bottom Edge

Enable Edge Blending on Left

Edge

Enable Edge Blending on

Right Edge

Enable Edge Blending on Top

Edge

Overall Enable/Disable on

Edge Blending

No Custom Warp Map

Selection (Keystone is

enabled)

Selects user warp map by

index

© Flexible Picture Systems Page 35 of 49

Page 36

User’s Manual 0020D1.01 Image AnyPlace IA-200

5 Keystone and Geometry Correction

5.1 Operation of Keystone Control

Keystone Control is activated by selecting the Keystone sub-menu from the Projection sub-menu

in the Advanced main menu. Keystone Control operates significantly differently from the IA-100

predecessor product’s Keystone Control.

Keystone Control can only be operated from the OSD Menu and Control Protocol (i.e. there is no

4 point equivalent to the eWarp Designer program used with IA-100). To use Keystone Control,

take the following steps:

1. Ensure that the output resolution and aspect ratio of the IA-200 are the same as those of the

projector in use.

2. Select one of the IA-200’s source channels.

3. Play live content to the selected source channel (the best content is a complete white test

pattern; since the OSD of IA-200 is used to render the internal IA-200 test patterns, it is

unfortunately not possible to use the internal test patterns for this purpose) . Ensure that the

source content has sufficient contrast such that you can clearly see all of the corners of the

input.

4. Adjust the position of the display to match the screen’s corners using the Keystone controls.

5. The Keystone adjustment is adjustable in single pixel increments. Adjustments downwards

and to the left are taken as positive. Adjustments upwards and to the left are taken as

negative. Each control is active using only the Horizontal arrows (i.e. you cycle between H

and V adjustments using Up and Down Arrows only; you adjust the value of H and V

adjustments using the Left and Right Arrows only.

6. Each corner of the display is separately adjusted. The total amount of adjustment is

interdependent with other concurrent Keystone adjustments (i.e. on a 1080p output, you can

adjust the H range of a given corner to a maximum deviation, if there is no concurrently

selected V deviation. You can also adjust a corner’s V deviation to 350 pixels if there is no H

deviation. If you have a combination of both H and V, both parameters are reduced from

their independent maxima. In practice, there is enough range to cover all practical situations.

7. You can reset each corner independently or reset the entire display.

8. Keystone parameters remain in effect until reset, or until they are changed or until a User

Warp Map is selected.

9. Aspect ratio treatment remains in effect with Keystone Control.

5.2 User Warp Maps

If you have the IA-200_EX or IA-200_BEX version, then User Warp Maps (i.e. Geometry

Corrections for cylindrical, spherical or irregular surfaces ) created by the eWarp Designer 200

companion software program may be loaded into 8 locations, labeled Index 1 to Index 8. These

Page 36 of 49 © Flexible Picture Systems

Page 37

Image AnyPlace User’s Manual 0020D1.01

Warp Maps may be selected with the IR remote (using the dedicated eWarp button or by

navigating to the menu.) User Warp Maps may also be selected using the Control Protocol.

User Warp Maps are activated by selecting the User Warp Map Selection sub-menu from the

Projection sub-menu in the Advanced main menu. Up to 8 Warp Indices may be selected. User

Warp Maps Indices are grayed out if User Warp Maps have not been loaded into these locations.

Please note that aspect ratio treatments do not work with User Warp Maps. If you want to

configure different aspect ratio treatments in User Warp Map, you must create a specific User

Warp Map for each aspect ratio treatment that you wish to achieve.

Please refer to the

eWarp Designer 200 User’s Guide for complete detail on how to create and

download User Warp Maps.

© Flexible Picture Systems Page 37 of 49

Page 38

User’s Manual 0020D1.01 Image AnyPlace IA-200

6 Aspect Ratio Treatment

6.1 Aspect Ratio Treatments

The IA-200 provides several different aspect ratio treatments. The operation mode of these

treatments depends on the aspect ratio of the input channel and the output display.

Warning: Aspect ratio treatments are not functional when using custom warp

geometries. If you want to use custom warps with different aspect ratio treatments, you

will have to create a specific warp map for every aspect ratio treatment that you want to

view.

6.1.1 Supported Aspect Ratios

The IA-200 assumes that the aspect ratio of input and output is consistent with the industry

standard definition of the aspect ratio of the particular input signal and video mode. Output aspect

ratio is thus determined by the resolution selected by the user in Setup Mode. Input aspect ratio is

determined by the IA-200 video mode recognition circuitry.

Note: Only two output aspect ratios are supported, 4:3 and 16:92.

Inputs considered to have 4:3 aspect ratio are as follows:

• Computer Graphics signals with a 4:3 aspect ratio appearing on the DVI and Analog RGB

inputs

• SDTV signals (NTSC and PAL derived) appearing on the Composite, S-Video, and

Component inputs

• SDTV signals (NTSC and PAL derived) appearing on the SDI input

• SDTV signals (NTSC and PAL derived) appearing on the HDMI input

2

The special case of 1280 x 1024 SXGA (an aspect ratio of 5:4) on output is treated as if it were 4:3. The output of a 1280 x 1024

display will be slightly distorted; circles will appear to be vertically oriented ovals. Since the IA-200_EX is intended for wide

screen processing, the 1280 x 1024 SXGA is not a frequently encountered case. Input of 1280 x 1024 will be treated as a pillar

boxed 4:3 signal (i.e. it will have narrow black bars on the Right and Left); aspect ratio of the picture content will be undistorted.

Page 38 of 49 © Flexible Picture Systems

Page 39

Image AnyPlace User’s Manual 0020D1.01

Inputs considered to have 16:9 aspect ratio are as follows:

• Computer Graphics signals with a 16:9 aspect ratio appearing on the DVI and Analog RGB

inputs

• HDTV signals (480p, 720p, 1080i, 1080p) appearing on the Component input

• HDTV signals (480p, 720p, 1080i, 1080p) appearing on the SDI input

• HDTV signals (480p, 720p, 1080i, 1080p) appearing on the HDMI input

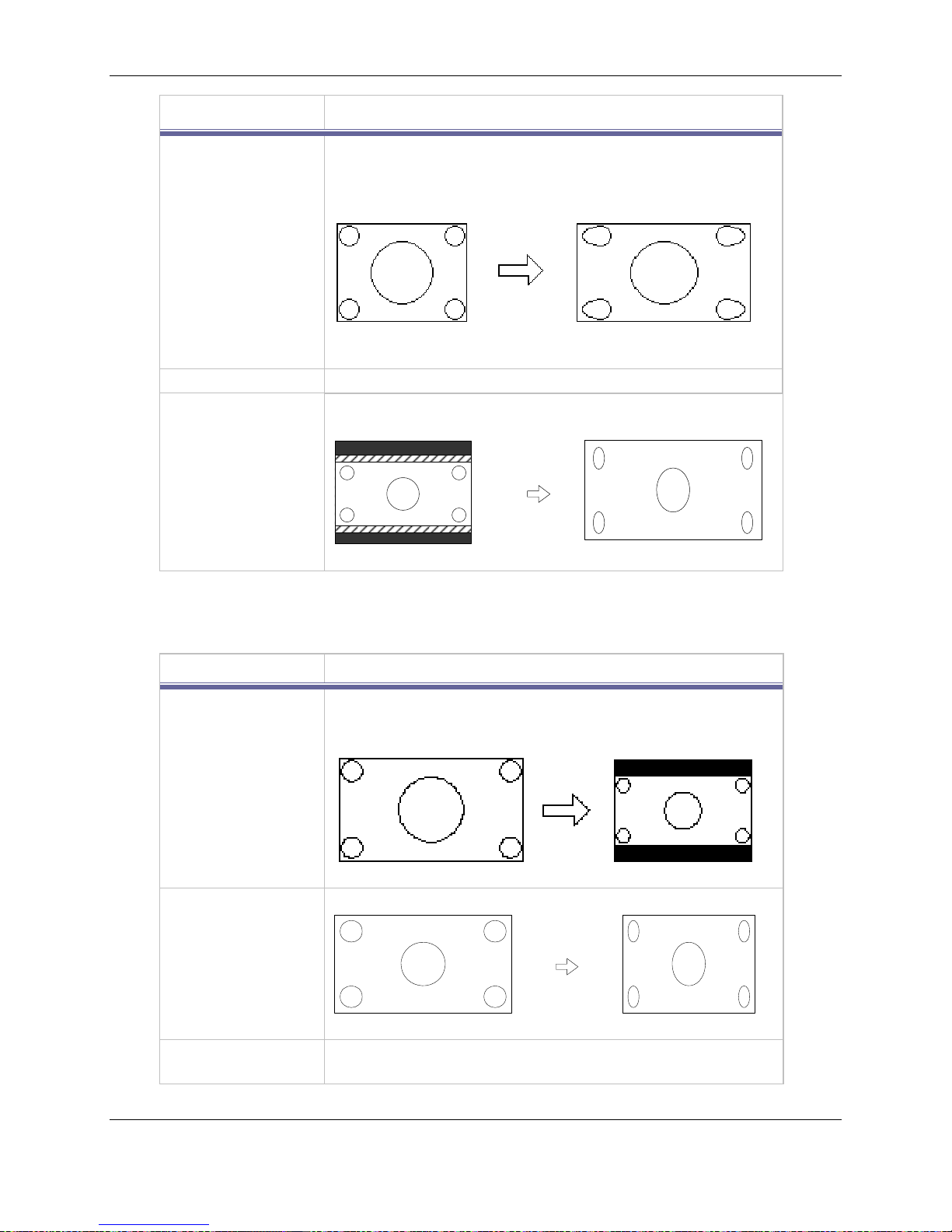

6.1.2 Aspect Ratio Treatments Objectives

The aspect ratio treatments achieve different aspect ratio objectives, and therefore behave

differently depending on which input and output aspect ratios are currently selected.

The Aspect Ratio objectives are the following:

Standard always displays the correct aspect ratio of the input picture; adds black bars at the

•

top and bottom or sides of the picture to achieve this objective.

Full Screen always fills the screen with the complete picture; linearly distorts the picture to

•

achieve this objective.

Crop always fills the screen with the correct aspect ratio of the input picture; crops the

•

picture's top and bottom or sides to achieve this objective.

Anamorphic handles the specific case of 16:9 aspect ratio anamorphically encoded into a 4:3

•

aspect ratio signal (e.g. an NTSC DVD encoded with a 16:9 picture).

• Flexview handles the specific case of a 4:3 input aspect ratio and 16:9 output aspect ratio,

stetching the 4:3 input to the 16:9 output in a non-linear fashion.

Squeeze compensates for signals that are incorrectly presented as 16:9. This often occurs in

•

cable TV situations, where a 4:3 aspect ratio signal is mistakenly stretched to 16:9.

Theater Scope prepares presentations for use with an Anamorphic lens, which optically

•

stretches images in the horizontal direction. With such a lens, a 4:3 projector fills a 16:9

screen, and a 16:9 projector fills a 2.35 aspect ratio screen. Viewed without the lens, the

treatment appears distorted (stretched vertically).

© Flexible Picture Systems Page 39 of 49

Page 40

User’s Manual 0020D1.01 Image AnyPlace IA-200

6.1.3 Input and Output Combinations

Table 6 to Table 9 present the five aspect ratio treatments over the four different combinations of

Input Aspect Ratio and Output Aspect Ratio.

Table 6: Aspect Ratio Treatments for 4:3 Input with 4:3 Output

OSD Menu Name Description

Standard 4:3 input signals shown full screen on 4:3 output display

Full Screen Grayed out. No action.

Crop Same as “Standard” mode above.

Anamorphic Anamorphic or widescreen encoded DVDs shown letterbox on

4:3 output display. These DVDs have 16:9 contents that has

been compressed and expanded vertically to fit the NTSC or

PAL signal.

Flexview Grayed out. No action.

Squeeze Grayed out. No action.

Theater Scope Vertically distorted 4:3 output image will be stretched

horizontally to 16:9 by Anamorphic lens.

Page 40 of 49 © Flexible Picture Systems

Page 41

Image AnyPlace User’s Manual 0020D1.01

Table 7: Aspect Ratio Treatments for 4:3 Input with 16:9 Output

OSD Menu Name Description

Standard 4:3 input signals are shown in a pillar box on the 16:9 output

display

Full Screen 4:3 input is linearly stretched horizontally to fill the 16:9 screen

Crop Top and bottom of image are cropped

Anamorphic SDTV input is displayed on a full screen 16:9 output display

© Flexible Picture Systems Page 41 of 49

Page 42

User’s Manual 0020D1.01 Image AnyPlace IA-200

OSD Menu Name Description

Flexview 4:3 input signals are non-linearly stretched in the horizontal

direction to fill 16:9 output displays. Horizontal and vertical

scaling is equal in the middle, more horizontal stretching

towards left and right sides to fill 16:9 outputs

Squeeze Grayed out. No action.

Theater Scope Vertically distorted 16:9 image will be stretched to 2.35 by

Anamorphic lens.

Table 8: Aspect Ratio Treatments for 16:9 Input with 4:3 Output

OSD Menu Name Description

Standard All HDTV inputs are assumed to be 16:9. HDTV input signals

(1080i and 720p) are shown in a letterbox on the 4:3 output

display

Full Screen Image stretched vertically to fill full screen.

Crop 16:9 HDTV input signals shown in 4:3 output display, cropped

Page 42 of 49 © Flexible Picture Systems

on left and right sides

Page 43

Image AnyPlace User’s Manual 0020D1.01

OSD Menu Name Description

Anamorphic Grayed out. No action.

Flexview Gray ed out. No action.

Squeeze 16:9 Input is squeezed to 4:3.

Theater Scope Vertically distorted 16:9 image will be stretched to 16:9 by

Anamorphic lens.

Table 9: Aspect Ratio Treatments for 16:9 Input with 16:9 Output

OSD Menu Name Description

Standard 16:9 input signals shown full screen on 16:9 output display

Full Screen Grayed out. No action.

Crop Grayed out. No action.

© Flexible Picture Systems Page 43 of 49

Page 44

User’s Manual 0020D1.01 Image AnyPlace IA-200

OSD Menu Name Description

Anamorphic Grayed out. No action.

Flexview Grayed out. No action.

Squeeze 16:9 Input will be squeezed and pillar boxed.

Theater Scope Vertically distorted 16:9 image will be stretched to 2.35 by

Anamorphic lens.

Page 44 of 49 © Flexible Picture Systems

Page 45

Image AnyPlace User’s Manual 0020D1.01

7 Input Modes Supported

Table 10: Input Modes Supported

Input Timing Format Input Video Source

Item No.

Mode

description

1 480i (NTSC) 720x485 60Hz NO - YES YES YES YES YES

2 576i (PAL) 720x576 50Hz NO - YES YES YES YES YES

3 576i (SECAM) 720x576 50Hz - - - YES YES - 4 480p 720x483 60Hz YES YES YES - - YES NO

5 576p 720x576 50Hz YES YES YES - - YES NO

6 HDTV 720 PROGRESSIVE 1280x720 60Hz YES YES YES - - YES YES

7 HDTV 720 PROGRESSIVE 1280x720 50Hz YES YES YES - - YES YES

8 HDTV 1080i @ 60Hz 1920x1080 60Hz YES YES YES - - YES YES

9 HDTV 1080i @ 50Hz 1920x1080 50Hz YES YES YES - - YES YES

10 1080p @ 24Hz 1920x1080 24Hz NO YES YES - - YES YES

11 1080p @ 25Hz 1920x1080 25Hz NO YES YES - - YES YES

12 1080p @ 30Hz 1920x1080 30Hz NO YES YES - - YES YES

13 1080p @ 24sF (1080i48) 1920x1080 48Hz NO YES YES - - - YES

14 1080p @ 25sF (1080i50) 1920x1080 50Hz NO YES YES - - YES YES

15 1080p @ 30sF (1080i60) 1920x1080 60Hz NO YES YES - - YES YES

16 1080p @ 50Hz 1920x1080 50Hz NO YES YES - - - 17 1080p @ 60Hz 1920x1080 60Hz NO YES YES - - - 18 DOS TEXT 640x400 70Hz YES YES YES - - - 19 VGA @ 60Hz 640x480 60Hz YES YES YES - - - 20 SVGA @ 75Hz 800x600 75Hz YES YES YES - - - 21 SVGA @ 60Hz 800x600 60Hz YES YES YES - - - 22 848 x 480 848 x 480 60Hz YES YES YES - - - 23 1024 x 576 1024 x 576 60Hz YES YES YES - - - 24 1400x788 1400x788 60Hz YES YES YES - - - 25 XGA @ 75Hz 1024x768 75Hz YES YES YES - - - 26 XGA @ 60Hz 1024x768 60Hz YES YES YES - - - 27 SXGA @ 75Hz 1280x1024 75Hz YES YES YES - - - 28 SXGA @ 60Hz 1280x1024 60Hz YES YES YES - - - 29 1360 x 768 1360x768 60Hz YES YES YES - - - 30 1365 x 768 1365x768 60Hz YES YES YES - - - 31 SXGA+ 1400x1050 60Hz YES YES YES - - - -

Resolution

Frequency

RGB

DVI

HDMI

Composite

S-video

Component

SDI

© Flexible Picture Systems Page 45 of 49

Page 46

User’s Manual 0020D1.01 Image AnyPlace IA-200

Input Timing Format Input Video Source

32 UXGA 1600x1200 60Hz - YES YES - - - 33 WUXGA 1920x1200 60Hz - YES - - - - 34 QXGA 2048x1536 60Hz - YES - - - - 35 MAC II Normal 13in 640x480 67Hz YES YES YES - - - 36 MAC II Normal 16in 832x624 75Hz YES YES YES - - - 37 MAC II Normal 19in 1024x768 75Hz YES YES - - - - 38 MAC II Normal 21in 1152x870 75Hz YES YES YES - - - 39 MAC 1440x960 96Hz - YES - - - - 40 MAC 20 1680x1050 88Hz - YES - - - - 41 MAC 23 1920x1200 76Hz - YES - - - - -

Page 46 of 49 © Flexible Picture Systems

Page 47

Image AnyPlace User’s Manual 0020D1.01

8 Latency Considerations

All IA-200 variations necessarily introduce some latency between the input and output. The

amount of latency varies greatly, depending on which features are selected. There are two factors

influencing the latency: 1) Choice of Latency mode and 2) Relative Frame rate between input and

output. The following table indicates the relationship between these items. A third item,

Synchronization Mode is affected by Latency and Frame Rate Difference.

8.1 Low Latency Mode Configuration

Input frame

rate (Hz)

Output frame

rate

(Hz)

Latency Mode Low Latency

mode

(ON/OFF)

Total Frame

delays

(# of frames)

50 50 ELL ON 2

60 60 ELL ON 2

50 50 LL OFF 2.5

60 60 LL OFF 2.5

50 60 ELL ON 5.5

60 50 ELL ON 5.5

50 60 LL OFF 6.1

60 50 LL OFF 6.1

50 50 ON OFF 7.6

60 60 ON OFF 7.6

50 60 ON OFF 9.2

60 50 ON OFF 9.2

Low Latency mode TVP processing

OFF TVP = ON

Low Latency TVP = OFF, All Sync Modes

Extra Low Latency TVP = OFF, Only Vjam and Vadjust

© Flexible Picture Systems Page 47 of 49

Page 48

User’s Manual 0020D1.01 Image AnyPlace IA-200

There are two latency modes, Low Latency and Extra Low Latency. Low Latency mode achieves

its effect by bypassing the HQV advanced video functions. This means that Noise Reduction,

Advanced De-interlacing and Cadence detection will not work in Low Latency mode. In