Refrigerated Cabinets

Part No.26107 Rev J August 2018 - 2 - Inline 5000 Series Cabinets

Copyright © August 2018 Future Products Group Limited.

All rights reserved.

No part of this publication may be reproduced, stored in a retrieval

system, or transmitted in any form or by any means, electronic,

mechanical, photocopying, recording or otherwise, without the prior

written permission of Future Products Group Ltd.

IN 5C08/12/15/18/24. - 3 - © Future Products Group

Table of Contents

INTRODUCTION ................................................................................................................. 7

Welcome ........................................................................................................................................................... 7

Future Products Group (FPG) .................................................................................................................... 7

Guidance and Help ..................................................................................................................................... 7

Warranty ........................................................................................................................................................... 7

Warranty Period .......................................................................................................................................... 7

Liability Exceptions ..................................................................................................................................... 8

Specific Exclusions ..................................................................................................................................... 8

Assessment ................................................................................................................................................ 8

Time Limit ................................................................................................................................................... 8

Caution ....................................................................................................................................................... 8

OPERATION ....................................................................................................................... 9

Cabinet Layout ................................................................................................................................................. 9

Tilt or Sliding Front Doors ........................................................................................................................... 9

Square Glass Cabinets .............................................................................................................................. 9

Lighting ....................................................................................................................................................... 9

Controls .......................................................................................................................................................... 10

Control Panel ............................................................................................................................................ 10

Power Switch ............................................................................................................................................ 10

Refrigeration ............................................................................................................................................. 10

Lights ........................................................................................................................................................ 10

Thermometer ............................................................................................................................................ 10

Temperature Controller ............................................................................................................................ 11

Temperature Controller Adjustment ......................................................................................................... 11

Preparation ..................................................................................................................................................... 11

Shelf Location and Ticketing .................................................................................................................... 11

Shelf Adjustment ...................................................................................................................................... 12

Caution ..................................................................................................................................................... 12

Power Supply ........................................................................................................................................... 12

Turn on Refrigeration................................................................................................................................ 12

Defrost Cycle ............................................................................................................................................ 12

Load Cabinet ............................................................................................................................................ 12

Loading Restrictions ................................................................................................................................. 13

Close all Doors ......................................................................................................................................... 13

Turn on Lights ........................................................................................................................................... 13

Routines ......................................................................................................................................................... 14

After Hours ............................................................................................................................................... 14

Cleaning ................................................................................................................................................... 14

De-frost Cycle ........................................................................................................................................... 14

Door Opening ........................................................................................................................................... 14

TROUBLE SHOOTING ..................................................................................................... 15

Part No.26107 Rev J August 2018 - 4 - Inline 5000 Series Cabinets

CLEANING ........................................................................................................................ 16

Cautions ......................................................................................................................................................... 16

Power ....................................................................................................................................................... 16

Water ........................................................................................................................................................ 16

Exterior ........................................................................................................................................................... 16

Louvers ..................................................................................................................................................... 16

Painted and Metal Surfaces ..................................................................................................................... 16

Glass ........................................................................................................................................................ 16

Sliding Doors ............................................................................................................................................ 17

Tilt Doors .................................................................................................................................................. 17

Interior............................................................................................................................................................. 17

Tilt Door Glass .......................................................................................................................................... 17

End Glass ................................................................................................................................................. 18

Trays, Shelves & Air Grills ........................................................................................................................ 18

Access to the Cabinet Base Cavity .......................................................................................................... 18

Caution ..................................................................................................................................................... 18

Cleaning the Base Cavity ......................................................................................................................... 19

Cooling Fins .............................................................................................................................................. 19

Temperature Probes................................................................................................................................. 19

Condensate Tray ...................................................................................................................................... 19

Routine............................................................................................................................................................ 20

Schedules ................................................................................................................................................. 20

Warning .................................................................................................................................................... 20

Condenser Radiator ................................................................................................................................. 20

Removable Filters (where fitted) .............................................................................................................. 20

Inspection ................................................................................................................................................. 20

Correction ................................................................................................................................................. 20

INSTALLATION ................................................................................................................ 21

Regulations .................................................................................................................................................... 21

Compliance with Local Requirements ...................................................................................................... 21

Setting Up ....................................................................................................................................................... 21

Unpacking ................................................................................................................................................. 21

Site Preparation ........................................................................................................................................ 21

Tilt Door Adjustment ................................................................................................................................. 21

Cabinet Preparation.................................................................................................................................. 22

Earthing .................................................................................................................................................... 22

Power Supply ........................................................................................................................................... 22

Isolation .................................................................................................................................................... 22

Location .......................................................................................................................................................... 22

Ventilation ................................................................................................................................................. 22

Access ...................................................................................................................................................... 22

IN 5C08/12/15/18/24. - 5 - © Future Products Group

SERVICING ....................................................................................................................... 23

Lighting ........................................................................................................................................................... 23

Caution ..................................................................................................................................................... 23

Circuit Breaker .......................................................................................................................................... 23

Test Lighting Components ....................................................................................................................... 23

Access to LED Strips ................................................................................................................................ 23

LED Strip Replacement ............................................................................................................................ 23

Mains Lead ..................................................................................................................................................... 24

Lead Replacement ................................................................................................................................... 24

Refrigeration .................................................................................................................................................. 24

Caution ..................................................................................................................................................... 24

Access to Compressor etc. ...................................................................................................................... 24

Remote Condensers................................................................................................................................. 24

Condensate Disposal ............................................................................................................................... 25

ACR Fault Finding Guide ......................................................................................................................... 25

Condenser Radiator ................................................................................................................................. 26

Louver Panels ........................................................................................................................................... 26

Temperature Regulator XR40CX ............................................................................................................. 27

XR40CX Connections .............................................................................................................................. 33

Gaskets ........................................................................................................................................................... 34

Qlon Gaskets ............................................................................................................................................ 34

Gasket Replacement ................................................................................................................................ 34

Rubber Gaskets ........................................................................................................................................ 34

SPECIFICATIONS ............................................................................................................. 35

Mechanical ..................................................................................................................................................... 35

Electrical ......................................................................................................................................................... 36

Controller Setting .......................................................................................................................................... 37

Dixell XR40CX Settings ............................................................................................................................ 37

Compliance .................................................................................................................................................... 38

Safety Aspects .......................................................................................................................................... 38

Operational Safety .................................................................................................................................... 38

Performance Aspects ............................................................................................................................... 38

Improvements ................................................................................................................................................ 38

Ongoing Development .............................................................................................................................. 38

Equipment Disposal ...................................................................................................................................... 39

Specialist Disposal ................................................................................................................................... 39

Hazardous Substances ............................................................................................................................ 39

Part No.26107 Rev J August 2018 - 6 - Inline 5000 Series Cabinets

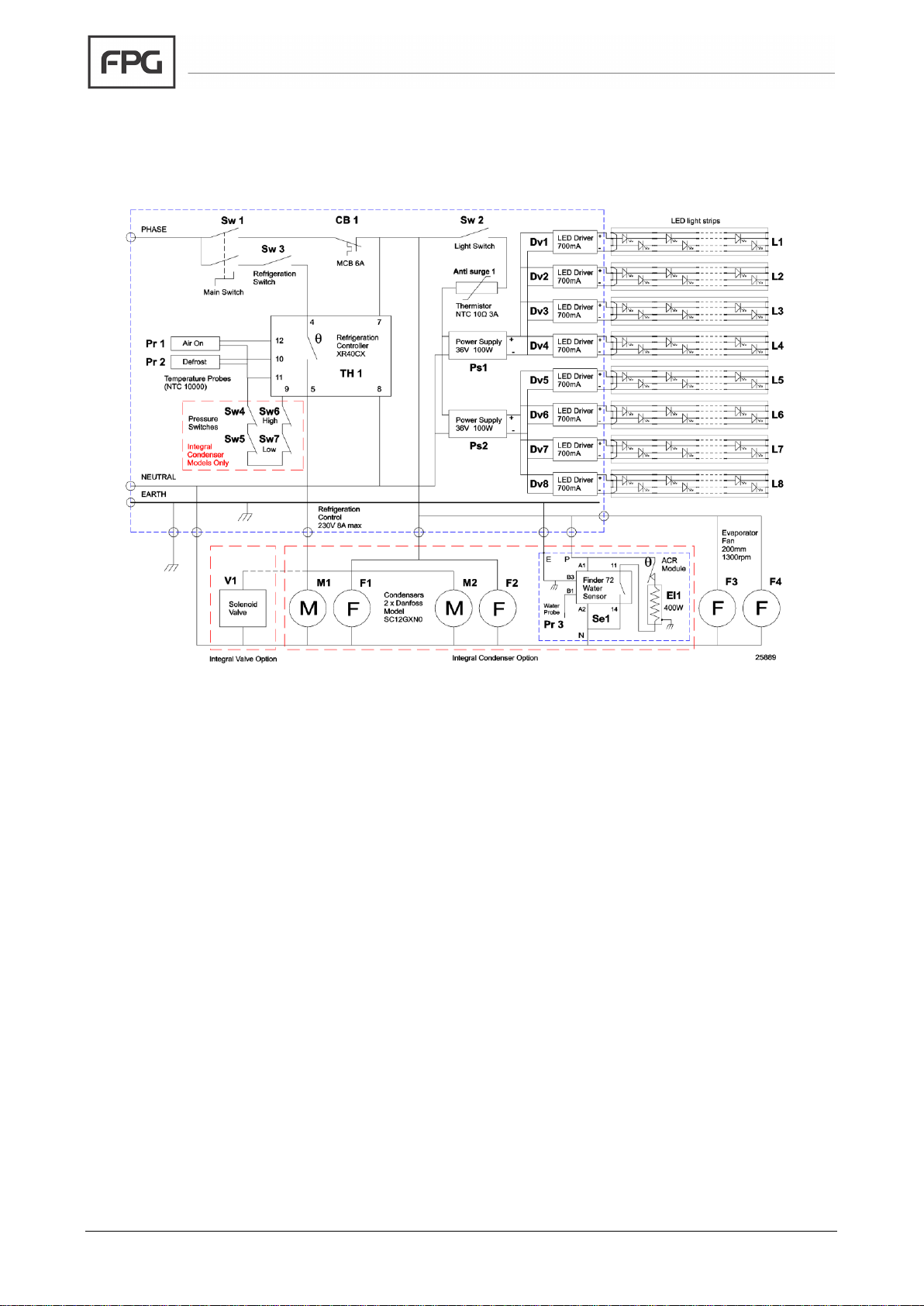

ELECTRICAL CIRCUIT DIAGRAMS ................................ ................................ ................ 40

Model: IN 5C08 ......................................................................................................................................... 40

Model: IN 5C12 ......................................................................................................................................... 40

Model: IN 5C15 ......................................................................................................................................... 41

Model: IN 5C18 ......................................................................................................................................... 41

Model: IN 5C24 ......................................................................................................................................... 42

SPARE PARTS ................................................................................................................. 43

Cabinet Serial Number ............................................................................................................................. 43

Location of Glass Parts ............................................................................................................................ 44

MECHANICAL DRAWINGS .............................................................................................. 45

Cabinet Feet ............................................................................................................................................. 45

Tilt Door Cabinets Types IN 5C08/12/15.................................................................................................. 45

Sliding Door Cabinets, Types IN 5C08/12/15 .......................................................................................... 46

Tilt Door Cabinets, Type IN 5C18 ............................................................................................................ 47

Sliding Door Cabinets, Type IN 5C18 ...................................................................................................... 48

Square Glass Cabinets Types IN 5C08/12/15/18 .................................................................................... 49

Cabinet Type IN 5C24 .............................................................................................................................. 50

Square Glass Cabinet Type IN 5C24 ....................................................................................................... 51

IN 5C08/12/15/18/24. - 7 - © Future Products Group

INTRODUCTION

Welcome

REFRIGERATED CABINETS

-

INTRODUCTION

Future

Products

Group (FPG)

Welcome to the world of FPG! Our products are designed and engineered to

give you the optimal performance that you deserve with innovative visual

merchandising appeal.

We are confident that you will be delighted with your state of the art inline food

service cabinet, and that it will become a valued appliance in your store.

Guidance and

Help

Any new appliance can seem very complex and confusing at first glance. To

ensure you receive the utmost benefit from your new inline cabinet, there are

two things you can do.

• Before operating the cabinet, please read the instruction book carefully and

follow its recommendations. The time taken will be well spent. These

instructions both general and technical tell you how to operate and look after

your inline food service cabinet so that you can receive the full benefits that

this cabinet has to offer.

• These instructions cannot, however, cover all eventualities. If you are

unsure of any aspect of the installation, instructions or performance of your

cabinet, contact your dealer promptly or contact us via email to

support@fpgworld.com.

Warranty

REFRIGERATED CABINETS

-

INTRODUCTION

Warranty

Period

Future Products Group Limited warrants, to the original purchaser of an FPG

manufactured food service cabinet that for ONE YEAR (12 months), from the

date of purchase, any defect in workmanship or material resulting in the product

malfunctioning while under correct use will be rectified.

The warranty is extended to THREE YEARS (36 months), for refrigeration

condenser units. Conditions apply, see Liability Exceptions.

Liability under this warranty is limited to replacing or repairing a part, without

charge.

Continued on next page

Part No.26107 Rev J August 2018 - 8 - Inline 5000 Series Cabinets

Warranty cont.

REFRIGERATED CABINETS - INTRODUCTION

Liability

Exceptions

Liability under this warranty does not include:

• Any loss, or damage or expenses directly or indirectly arising from use or

inability to use the product or from any other cause.

• Any part of the cabinet which has been subject to misuse, neglect,

alteration, incorrect installation, accident, or damage caused by

transportation, use of abrasive or caustic chemicals, flooding, fire or acts of

God.

• Damage, resulting from failure to have the cabinet regularly serviced every

three months by a refrigeration engineer. NB: You will be required to

provide copies of service records in the event of compressor failure.

• Damage resulting from maladjustment of the electronic refrigeration

controller, by an unqualified person.

• Any damage or malfunction resulting from the use of non-FPG supplied

spare parts.

Specific

Exclusions

The following are specifically excluded from warranty:

• Breakage of glass or plastic components or the replacement of LED lighting

strips or gaskets.

• Failure to re-assemble the cabinet correctly after cleaning.

• Fair wear and tear.

Assessment

The liability under this warranty is dependent on an assessment by FPG, to

determine the defect in workmanship or materials.

Time Limit

FPG does not guarantee that any service to be performed under this warranty

will be carried out within any particular time limit.

Caution

No warranty claim will be accepted unless authorised by FPG prior to

commencement of service.

IN 5C08/12/15/18/24. - 9 - © Future Products Group

OPERATION

Cabinet Layout

REFRIGERATED CABINETS

-

OPERATION

Tilt or Sliding

Front Doors

The tilt door cabinet has a single front door and two

sliding rear doors, (four on the

2400 cabinet).

The front door is hinged along

the bottom edge, and is opened

by pulling the top edge forward.

When opened, the door is

restrained from falling by wire

cables, which retract into “pull

boxes” when the door is closed.

The sliding door cabinet has two sliding doors on both

the front and rear of the cabinet, (four on the 2400 cabinet).

All the refrigeration and control equipment is housed in the base of the cabinet.

Square Glass

Cabinets

The square glass cabinet does not have front opening

doors. It has rear sliding doors, similar to the tilt and

sliding door models.

The front of the cabinet is formed entirely from fixed

glass panels, which are square and cemented together.

The shelf lights are the same as those used on the tilt

and sliding door models, but the top light is mounted on

brackets, similar to the shelf brackets.

The control equipment is housed in the base of the

cabinet, which may have either integral or remote

refrigeration equipment.

Lighting

As standard, all cabinets are

fitted with high efficiency LED

lighting strips in the ceiling of

the cabinet, and below each

shelf.

Part No.26107 Rev J August 2018 - 10 - Inline 5000 Series Cabinets

Controls

REFRIGERATED CABINETS

-

OPERATION

Control Panel

The control panel is mounted on the back of the

cabinet, and houses:

• The main power switch

• The refrigeration switch

• The Light switch

• The refrigeration controller

Power Switch

To turn the power on, rotate the switch in a clockwise

direction.

Note that the cabinet and condenser fans will operate as

soon as the power is turned on.

Refrigeration

To start refrigeration, rotate the refrigeration switch in a

clockwise direction.

Lights

To turn the lights on, rotate the light switch in a clockwise

direction.

Thermometer

The refrigeration controller, indicates the internal air

temperature of the cabinet. The sensor, located in the

base of the cabinet, measures the temperature of the

returned air, before it passes through the evaporator fins.

Continued on next page

IN 5C08/12/15/18/24. - 11 - © Future Products Group

Controls cont.

REFRIGERATED CABINETS - OPERATION

Temperature

Controller

The controller regulates the cabinet

temperature and controls the automatic

defrost cycles.

The display indicates the temperature of the

returned air, before it enters the cooling coil.

On integral condenser cabinets, the refrigeration gas pressure is also

monitored, to protect the compressor from damage resulting from a blocked

radiator or loss of gas.

Temperature

Controller

Adjustment

Caution:

This controller

should only be

adjusted by a

qualified service

technician.

The controller is set up during manufacture of the cabinet, and should not

require further adjustment.

The indicated temperature is sensed by a probe in the return air, entering the

cooling coil. This is used to control the refrigeration condenser operation, and

will be marginally higher than the internal cabinet temperature.

Incorrect adjustment can cause the fins to ice up, resulting in reduced airflow

and poor performance.

The controller also governs the de-frost cycles, and incorrect adjustment can

again lead to poor temperature control or possible overflow of condensate.

If you think an adjustment may be needed, call the service technician.

Preparation

REFRIGERATED CABINETS

-

OPERATION

Shelf Location

and Ticketing

All shelves are adjustable in height and can easily be

moved up or down, to match product size.

The movement is restricted to 50mm, because of the

electric cables to the lights. For greater movement

contact the manufacturer or supplier for advice, as

electrical modifications may be required.

The front and rear edges of the shelves

are profiled to carry ticketing/labels.

Continued on next page

Part No.26107 Rev J August 2018 - 12 - Inline 5000 Series Cabinets

Preparation cont.

REFRIGERATED CABINETS - OPERATION

Shelf

Adjustment

To move the shelf support

brackets, remove all the shelves

and then remove the rear sliding

doors. Using two people, one on

each bracket, slide the bracket

upwards and disengage it from

the support pillar. Insert the

bracket in the new position and

push it down firmly. Replace all

shelf trays and doors.

The brackets can be inserted in

two positions, allowing the

shelves to be either horizontal or

sloping downwards.

Caution

Make sure shelf brackets are pushed down as far as they can go. Failure

to do this may result in shelf collapse, when loaded with product.

Power Supply

Ensure that power is connected to the cabinet.

Turn on the main power switch, as shown above. The compressor and cabinet

fans will run.

Turn on

Refrigeration

Turn on refrigeration switch, as shown above. The compressor will run, and the

cabinet temperature will begin to fall.

The temperature controller is pre-set to maintain the cabinet temperature to 2 4 C, and should not need adjustment.

(Cabinets can also be supplied to operate at 15 - 17C)

Defrost Cycle

Note that the defrost times are set from when the cabinet is first turned on.

If they are required at a particular time, you must turn on the cabinet four hours

before the first defrost required.

The cycles will then occur every four hours, provided that the cabinet remains

on.

Load Cabinet

Load the cabinet with pre-chilled product, from the rear doors.

The cabinet is designed to maintain the temperature of pre-chilled product at

between 2 and 4C. It is not a refrigerator, and consequently, if warm

product is introduced, there could be some delay before the operating

temperature falls to the normal operating level.

Continued on next page

IN 5C08/12/15/18/24. - 13 - © Future Products Group

Preparation cont.

REFRIGERATED CABINETS - OPERATION

Loading

Restrictions

It is important to leave adequate free space for

the refrigerated air to circulate within the cabinet.

Product should be kept clear of the shaded

areas, shown in the picture.

A minimum clearance of 40 mm should be

maintained below the light fittings and air

deflectors.

The air grills at the front and rear of the cabinet

must not be covered at all.

Close all Doors

It is important to keep all cabinet doors closed. If doors are not fully closed, an

even temperature will not be maintained within the cabinet.

Turn on Lights

When ready for service, turn on the cabinet lights.

Part No.26107 Rev J August 2018 - 14 - Inline 5000 Series Cabinets

Routines

REFRIGERATED CABINETS

-

OPERATION

After Hours

Ideally, cabinets should not be turned off after hours or at night. Products can

either be left in the cabinet or placed in night storage. Shut the cabinet doors

and turn off the lights. The cabinet will then operate on minimum load, and stay

cold, ready for instant operation when next required.

If the cabinet is turned off, allow it to run for about half an hour before replacing

the pre-chilled products.

Cleaning

It is recommended that cabinets be cleaned at the end of the working day, since

they need to be shut down for this. See “Cleaning”.

Once the cleaning is finished, turn the cabinet on again, turn off the lights and

shut the doors. The cabinet will cool down under minimum load and be ready

for the next day’s use.

De-frost Cycle

The cabinet will de-frost automatically six times per day. The cabinet should

NOT be temperature tested within ½ hour of a de-frost programme being

completed.

The first defrost cycle will occur four hours after the cabinet is first switched on.

Door Opening

The cabinet is designed to maintain food at a temperature of 2 to 4C. The

refrigeration system is designed to maintain this temperature with the doors

being opened and closed up to sixty times per hour.

If the doors are left open for an extended period the temperature will rise. Once

the doors are shut the temperature will take some time to fall to the normal

operating level. The longer the doors are open the longer the time to restore

normal operating temperature.

IN 5C08/12/15/18/24. - 15 - © Future Products Group

TROUBLE SHOOTING

FAULT

POSSIBLE CAUSE

REMEDY

Cabinet does not operate/start

The mains isolating switch on

the wall, circuit breaker or

fuses are off at the power

board

Turn isolating switch circuit

breaker or fuses on

High pressure switch tripped

Clean condenser and radiator

Low pressure switch tripped

Switch cabinet off and on

Check gas pressure

The power switch on the

cabinet is OFF

Turn the power switch ON

The power switch on the unit is

faulty

Have the switch replaced

Cabinet does not reach

temperature

One or more doors is open

Close doors and re-test

temperature after 30 minutes

Ventilation grills are blocked

Vacuum or remove blockage

Product blocking air grill

Place product on shelves

Evaporator coil fins blocked

Clean coil fins of food etc.

Trays obstructing air flow

Re-position trays on shelves

Thermostat needs adjustment

Adjust controller

Ambient temperature > 25C

Adjust store air conditioning

Damaged or missing door seal

Replace door seal

Evaporator coil iced up

De-ice coil

Condenser radiator blocked

Remove dust and debris

Thermostat faulty

Replace controller

Temperature probe damaged

Replace temperature probe

Defrost cycle not suitable

Adjust to match

environment

Fans not operating

Have fans checked/replaced

Cabinet lights not working

The light switch is OFF

Turn light switch ON

A failed LED power supply

Replace the power supply

A failed LED Driver

Replace the LED driver

An LED strip has failed

Replace the LED assembly

Internal breaker tripped/failed

Have wiring checked and

reset or replace breaker

Doors are not sliding smoothly

Door not in track

Install door correctly in track

Debris in track

Clean door tracks (see cleaning)

Door glider damaged/missing

Have glider replaced

Lack of lubricant

Apply food grade lubricant to

door track

Aluminium parts corroded

Caustic detergent damage

Order replacement parts

Service

Personnel Only

The table entries in italics indicate actions to be taken only by qualified Service

Personnel.

Part No.26107 Rev J August 2018 - 16 - Inline 5000 Series Cabinets

CLEANING

Cautions

REFRIGERATED CABINETS

-

CLEANING

Power

ALWAYS TURN THE POWER SUPPLY OFF BEFORE CLEANING.

Water

THIS UNIT IS NOT WATERPROOF. DO NOT USE A WATER JET SPRAY TO

CLEAN THE INTERIOR OR EXTERIOR OF THIS CABINET.

Exterior

REFRIGERATED CABINETS

-

CLEANING

Louvers

Use a vacuum cleaner to remove dust and fluff from all of the ventilation

louvers.

This will maintain the refrigeration efficiency, and prevent overheating.

Painted and

Metal Surfaces

Painted, stainless steel or aluminium surfaces should be cleaned with hot soapy

water or a good quality metal cleaning compound. DO NOT clean surfaces with

abrasive pads or cleaners (e.g. Scotchbrite pads or Jif), as paint, stainless steel

and aluminium surfaces will be damaged.

Glass

All glass should be cleaned using a good quality glass cleaner and a clean

cloth.

DO NOT clean glass with abrasive pads or cleaners (e.g. Scotchbrite pads or

Jif), as the glass will be damaged.

Continued on next page

IN 5C08/12/15/18/24. - 17 - © Future Products Group

Exterior cont.

REFRIGERATED CABINETS - CLEANING

Sliding Doors

Sliding glass doors can be removed for cleaning

by sliding the door to central position, placing

hands either side of the door, lifting up and then

swinging out at the bottom.

When replacing doors, make sure that the top is

located in the correct slot, and the gliders are

properly located on the correct bottom track.

Sliding door tracks should be vacuumed out regularly to keep doors sliding

freely. Failure to do so will damage the gliders and track.

Tilt Doors

Tilt doors are not readily removable, so the outer glass should be cleaned with

the door closed.

Interior

REFRIGERATED CABINETS

-

CLEANING

Tilt Door Glass

Gently pull the top of the door forward, until it is

restrained in the open position.

The inside of the glass can now be carefully cleaned,

using a cloth and glass cleaner. Dry the glass off with

paper towels or a cloth.

DO NOT use abrasive pads or cleaners, because they

will damage the surface of the glass.

Continued on next page

Part No.26107 Rev J August 2018 - 18 - Inline 5000 Series Cabinets

Interior cont.

REFRIGERATED CABINETS - CLEANING

End Glass

The insides of the end glass panels can normally be cleaned after the shelf

trays have been removed.

Only remove the shelf lights and brackets etc. when carrying out longer term

maintenance/cleaning.

Trays, Shelves

& Air Grills

Stainless steel trays, shelves, grills etc. should be cleaned with hot soapy water.

Do not use abrasive pads or cleaners (e.g. Scotchbrite pads or Jif), as these

may damage surfaces.

Warning: Dishwasher detergents will damage any anodised aluminium parts.

Access to the

Cabinet Base

Cavity

Remove the front ticketing rail from the

deck trays, if fitted.

Lift out the deck trays and sweep out, or

use a vacuum cleaner, to remove any

loose debris.

Unscrew the two knobs,

which secure the base

plates.

Lift up the fan deck.

Lift the cover plate off the

evaporator coil, raising it

to the vertical position, to

disengage it from the

chassis.

Lift the air louvers out.

Caution

The whole of the cabinet interior is now accessible

for cleaning.

To avoid possible damage when replacing fan decks,

be sure that cables are not trapped by metal parts.

Continued on next page

IN 5C08/12/15/18/24. - 19 - © Future Products Group

Interior cont.

REFRIGERATED CABINETS - CLEANING

Cleaning the

Base Cavity

Sweep out, or use a vacuum cleaner, to remove any debris from the cabinet

base cavity.

A Wet-and-Dry vacuum cleaner should be used, since there is likely to be some

water in the bottom. Finally, wipe out the bottom with a damp sanitized cloth.

Do not pour water into the base, or the condensate tray will overflow.

Cooling Fins

If there is food wedged in the cooling fins, it is

best to use a wet and dry vacuum cleaner to

suck out the food. DO NOT attempt to hose food

parts from fins.

Caution: The fins are very sharp. Take extra

care when cleaning this area. Do not bend the

fins over, as this would restrict the air flow and

degrade cabinet performance.

Temperature

Probes

Take care not to damage or

move the temperature probes,

when cleaning the cooling fins.

One probe is inserted between

the fins of the cooling coil, on

the air-off side.

A second probe is located in the return air flow, on the other side of the cooling

coil.

Do NOT move the probes.

Condensate

Tray

The condensate boil off heater is only designed to handle cooling-coil defrosting

liquid that drains from the well.

DO NOT fill the well with liquid, or attempt to hose out as condensate tray will

overflow and leak onto floor.

Part No.26107 Rev J August 2018 - 20 - Inline 5000 Series Cabinets

Routine

REFRIGERATED CABINETS

-

CLEANING

Schedules

To maintain optimum performance, cleaning schedules must be regular and

thorough.

Warning

Failure to carry out routine cleaning/servicing schedules will void the

warranty on the refrigeration equipment.

Condenser

Radiator

For efficient refrigeration performance, the

condenser radiator must be kept clean, (see

Servicing, Condenser Radiator).

Accumulated dust and fluff.

Regular vacuuming will prevent a build-up of dust

and fluff, but periodic cleaning of the fins, by a

refrigeration engineer, is mandatory.

Removable

Filters

(where fitted)

These air filters must be kept clean,

to maintain efficient refrigeration

performance.

Slide the filters out, and use a

vacuum cleaner to remove dust and

fluff.

Additional periodic cleaning of

the actual radiator fins, by a

refrigeration engineer, is

mandatory. (see Servicing

section)

Inspection

As part of the cleaning routine, the controls, mechanical parts and electrical

wiring should be inspected for damage, deterioration or need of adjustment.

Correction

If any small faults are found, have them attended to promptly by a competent

serviceman. Don’t wait until they cause a complete breakdown.

IN 5C24

IN 5C08/12/15/18/24. - 21 - © Future Products Group

INSTALLATION

Regulations

REFRIGERATED CABINETS

-

INSTALLATION

Compliance

with Local

Requirements

It is very important that your inline food cabinet is installed correctly and that the

operation is correct before use. Installation must comply with local electrical,

health & safety and hygiene requirements.

Setting Up

REFRIGERATED CABINETS

-

INSTALLATION

Unpacking

Unpack and check unit for damage and report any damage to the carrier and

supplier. Report any deficiencies to your supplier.

The cabinet is supplied fully assembled, but the shelf trays are packed

separately.

Site

Preparation

Ensure the cabinet location and any bench cut outs are made to the precise

measurements shown in the specifications section. Position the cabinet in its

allocated working position. Use a spirit level to ensure the cabinet is level from

side to side and front to back. (If this is not carried out, water may accumulate in

the cabinet well, and uneven temperature distribution could also occur).

Tilt Door

Adjustment

If the tilt door glass fouls the frame, either the cabinet is not level, or the floor is

out of true.

The solution is to adjust the cabinet feet.

Continued on next page

Adjust

this foot

Door

fouls

here

Adjust

this foot

Door

fouls

here

Part No.26107 Rev J August 2018 - 22 - Inline 5000 Series Cabinets

Setting Up cont.

REFRIGERATED CABINETS - INSTALLATION

Cabinet

Preparation

Remove all tapes, ties and packers, used

to prevent movement during transit.

Lift out the deck trays and grills to gain

access to the cabinet well.

Earthing

WARNING-THIS APPLIANCE MUST BE EARTHED/GROUNDED

The cabinet should be earthed via the earth lead in the mains

cable.

In addition, an equipotential earth bonding terminal is provided,

to allow the cabinet to be bonded to a building surge earth or

adjacent equipment.

Power Supply

Before connecting to the power supply, check that the local supply is correct to

that shown on the rating plate, located on the rear of the cabinet.

Isolation

If the cabinet is not connected by a plug and socket, but is hard wired to the

mains supply, a means of isolation must be provided.

If a plug and socket are used, they should still be accessible after the cabinet is

installed.

Location

REFRIGERATED CABINETS

-

INSTALLATION

Ventilation

The vent located on the rear of the cabinet must never be obstructed. If

obstructed the cabinet may overheat and cause an electrical malfunction.

Before use, operate the cabinet for 1-2 hours to remove any fumes or odours,

which may be present.

Access

The cabinet should also be positioned so the operating panel and shelves are

easily reachable for loading and unloading.

IN 5C08/12/15/18/24. - 23 - © Future Products Group

SERVICING

Lighting

REFRIGERATED CABINETS

-

SERVICING

Caution

DO NOT service lights without isolating the cabinet at the main switch or

unplugging it from the wall.

Circuit Breaker

All lighting circuits are protected by a circuit

breaker, MCB.

On IN C08/12/15&18 cabinets the circuit

breaker and LED power supplies are located

behind the control panel.

The MCB can be operated via a cut-out in the

top of the chassis.

On the IN 5C24 cabinet, the circuit breaker and

power supplies are located on a separate

chassis, in the base of the cabinet.

Test Lighting

Components

Before replacing an LED strip, check that the power supply is working.

If there is no dc voltage at the output, the power supply should be replaced.

Access to LED

Strips

The LED strips are protected with

plastic covers. These clip into grooves

in the aluminium extrusion.

Remove the plastic cover to access

the LED strip.

The top light assembly is similar to

the shelf lights, but the correct

replacement unit must be used.

LED Strip

Replacement

Individual LED modules cannot be

replaced. A complete light unit must

be used.

Connection is made with a plug and

socket. Disconnect the faulty unit,

and re-connect the replacement unit.

Replace the plastic covers.

Part No.26107 Rev J August 2018 - 24 - Inline 5000 Series Cabinets

Mains Lead

REFRIGERATED CABINETS

-

SERVICING

Lead

Replacement

If damaged, the mains lead must ONLY be replaced by a qualified service

person.

Refrigeration

REFRIGERATED CABINETS

-

SERVICING

Caution

DO NOT attempt to service the refrigeration equipment without isolating

the cabinet at the main switch or unplugging it from the wall.

Access to

Compressor

etc.

To gain access to the

refrigeration condenser, radiator

and ACR module etc., the rear

panels should be removed.

The control panel chassis may

also be removed for greater

access.

The IN 5C24 cabinet has two condenser assemblies,

located at either end of the cabinet.

Remote

Condensers

Some cabinets can be supplied for operation from remote refrigeration

condenser units. These versions must have the condensate piped to a drain.

Continued on next page

IN 5C08/12/15/18/24. - 25 - © Future Products Group

Refrigeration cont.

REFRIGERATED CABINETS - SERVICING

Condensate

Disposal

The automatic condensate removal,

ACR system consists of a water tray, a

water level detector and a boil-off

element with an over temperature cutout.

If the element fails, it may be replaced

by springing it from the mounting

bracket. Cut and splice the leads and

protect with heat-shrink sleeves.

ACR Fault

Finding Guide

First check if the condensate water level probe in the ACR tank is dirty and

needs cleaning (a dirty probe may either fail to detect water, or give a false

indication of water) clean if required.

Check the Finder Level Control unit sensitivity range adjustment is set to 75k.

If the sensitivity is set too low, the Finder Level Control unit may not detect the

condensate water and won’t switch on the ACR element. If the sensitivity is set

too high, the Finder Level Control unit may get a false indication of the

condensate water and switch on the ACR element without water present.

Fault: ACR element is on continuously when no condensate water is present.

Test: Check if the Finder Level Control unit is faulty by disconnecting the probe

wire from terminal B1 on the Finder Level Control unit. With the cabinet power

turned on and after waiting 10 seconds, check for 230V across terminals 11 and

14. If 230v is not present across terminals 11 & 14, replace the Finder Level

Control unit.

Fault: ACR element does not heat even though condensate water is present

and touching the water level probe.

Test: First check the ACR unit has a 230V power supply.

Next, check the Finder Level Control unit water sensing circuit by short-

circuiting the level sensor terminals B1 & B3. Turn the cabinet power on and

wait 10 seconds and then check if the ACR element heats. If the element heats,

check for an open circuit in the water sensing probe circuit and clean the probe.

If the element does not heat, turn the cabinet power off and take the element

wire out of terminal 11 and wire into terminal 14 on the Finder Level Control

unit. Turn the cabinet power on and wait 10 seconds and then check if the ACR

element heats. If the element heats, replace the Finder Level Control Unit. If the

element does not heat replace the element and Therm-O-Disc assembly.

Note: The element and Therm-O-Disc are supplied as a complete assembly.

Continued on next page

Part No.26107 Rev J August 2018 - 26 - Inline 5000 Series Cabinets

Refrigeration cont.

REFRIGERATED CABINETS - SERVICING

Condenser

Radiator

For efficient refrigeration

performance, the condenser

radiator must be kept clean.

Failure to do this will lead to

a build-up of dust, and

restricted airflow will

prevent the unit from

working properly. The compressor may overheat

and the cabinet temperature may rise.

Regular vacuuming will prevent a build-up of dust

and fluff, however, three monthly service checks,

which include cleaning of the condenser using C02

by a refrigeration engineer, are mandatory.

Be very careful not to bend or damage the soft

aluminium fins when vacuuming the radiator. If the fins are flattened, airflow will

be restricted and overheating will result.

Louver Panels

All louvered panels should be kept free of dust by regular vacuuming, so that air

flow is not restricted.

Continued on next page

IN 5C08

Cabinets

IN 5C12/15/18

Cabinets

IN 5C24

Cabinet

IN 5C08/12/15/18/24. - 27 - © Future Products Group

ON

Time

Refrigeration cont.

REFRIGERATED CABINETS - SERVICING

Temperature

Regulator

XR40CX

Model XR40CX is a microprocessor based

controller.

It uses two NTC temperature probes, the

first one, for temperature control, is

located in the return air (air on), and the

second one, located between the fins of

the cooling coil, measures the defrost

termination temperature.

Pressure switches, monitoring the condenser gas pressure, are connected to

the digital input terminals.

Since the temperature control probe is located on the return air side of the coil,

(Air On), the measured temperature will be higher than the average air

temperature inside the cabinet.

The instrument is fully configurable through special parameters that can be

easily programmed through the keyboard, or by use of a “hot key”.

XR40CX

Compressor

Control

The regulation is performed according to the

temperature measured by the thermostat probe

with a positive differential from the set point: if the

temperature increases and reaches set point plus

differential the compressor is started and then

turned off when the temperature reaches the set

point value again.

In case of a fault in the thermostat probe the start and stop of the compressor

are timed through parameters COn and COF.

XR40CX

Defrost Control

Parameters are used to control the interval between defrost cycles (IdF), its

maximum length (MdF) and two defrost modes: timed or controlled by the

evaporator’s probe (P2P).

In this cabinet, the start of the defrost cycle is timed, but the cycle will be

terminated as soon as the defrost probe reaches the pre-determined

temperature.

At the end of defrost dripping time is started, its length is set in the FSt

parameter. With FSt =0 the dripping time is disabled

Continued on next page

Part No.26107 Rev J August 2018 - 28 - Inline 5000 Series Cabinets

Refrigeration cont.

REFRIGERATED CABINETS - SERVICING

XR40CX Key

Functions

KEY

FUNCTION

To display target set point; in programming mode it selects

a parameter or confirm an operation

(DEF) To start a manual defrost

(UP): To see the max. stored temperature; in

programming mode it browses the parameter codes or

increases the displayed value

(DOWN): To see the min stored temperature; in

programming mode it browses the parameter codes or

decreases the displayed value

To switch the instrument off, if onF = oFF. Not enabled

To lock & unlock the keyboard

To enter into programming mode

To return to the temperature display mode

XR40CX LED

Functions

LED

MODE

FUNCTION

ON

Compressor enabled

Flashing

Anti-short cycle delay enabled

ON

Defrost enabled

Flashing

Drip time in progress

ON

An alarm is occurring

ON

Continuous cycle is running

ON

Energy saving enabled

ON

Measurement unit

Flashing

Programming phase

Continued on next page

IN 5C08/12/15/18/24. - 29 - © Future Products Group

Refrigeration cont.

REFRIGERATED CABINETS - SERVICING

XR40CX

Min & Max

Recorded

Temperature

Press and release the key.

Lo will be displayed followed by the minimum temperature recorded.

Press the key again or wait 5s to restore the normal display.

Press and release the key.

Hi will be displayed followed by the maximum temperature recorded.

Press the key again or wait 5s to restore the normal display.

XR40CX

Reset Max/Min

Temperature

Memory

Press the SET key for more than 3s, while the max. or min. temperature is

displayed. (rSt message will be displayed)

To confirm the operation the rSt message starts blinking and the normal

temperature will be displayed.

XR40CX

Display the Setpoint

To show the set-point value, press and immediately release the SET key.

Press and immediately release the SET key or wait for 5 seconds to display the

probe temperature again.

XR40CX

Change the

Set-point

To change the set-point value, press the SET key for more than 2 seconds;

The value of the set-point will be displayed and the °C or °F LED starts blinking;

To change the set value push the or arrows within 10s.

To memorise the new set-point value push the SET key again or wait 10s.

XR40CX

Start a Manual

Defrost

To start a manual defrost, press the (DEF) key for more than 2 seconds.

XR40CX

Programming

Mode

Enter the Programming mode by pressing the keys for 3s

(the °C or °F LED starts blinking).

• Use the or keys to select the required parameter.

• Press the key to display its value.

• Use the or keys to change its value.

• Press to store the new value and move to the following parameter.

To exit Programming mode, press or wait 15s without pressing a key.

NOTE: the set value is stored even when the procedure is exited by waiting for

the time-out to expire.

Continued on next page

Part No.26107 Rev J August 2018 - 30 - Inline 5000 Series Cabinets

Refrigeration cont.

REFRIGERATED CABINETS - SERVICING

XR40CX The

Hidden Menu

The hidden menu includes all the parameters of the instrument.

TO ENTER THE HIDDEN MENU

• Enter the Programming mode by pressing the keys for 3s, (the °C

or °F LED starts blinking).

• Release the keys, then press the keys again, for more than 7s.

The Pr2 label will be displayed immediately followed from the Hy parameter.

NOW YOU ARE IN THE HIDDEN MENU.

• Select the required parameter.

• Press the key to display its value

• Use or to change its value.

• Press to store the new value and move to the following parameter.

• To exit: Press or wait 15s without pressing a key.

NOTE 1: If no parameter is present in Pr1, after 3s the noP message is

displayed. Keep the keys pushed till the Pr2 message is displayed.

NOTE 2: The set value is stored even when the procedure is exited by waiting

for the time-out period to expire.

TO MOVE A PARAMETER FROM THE HIDDEN MENU TO THE FIRST LEVEL

AND VICEVERSA.

Each parameter present in the HIDDEN MENU can be removed or put into

“THE FIRST LEVEL” (user level) by pressing

In HIDDEN MENU when a parameter is present in the First Level the decimal

point is shown.

XR40CX

Locking and

Unlocking the

Keyboard

To lock the keyboard, press the keys for more than 3 s.

The POF message will be displayed, followed by the previous temperature

display.

If a key is pressed more than 3s the POF message will be displayed.

To unlock the keyboard, press the keys for more than 3s, till the Pon

message is displayed.

Continued on next page

IN 5C08/12/15/18/24. - 31 - © Future Products Group

Refrigeration cont.

REFRIGERATED CABINETS - SERVICING

FPG Settings

Note that the following settings are Dixell factory defaults. Refer to the

Specification section for the correct FPG settings for your cabinet.

Dixell Default

Settings

Label

Name

Range

Default Setting

Set

Set point

LS÷ US

-5.0

Hy

Differential

0,1÷25.5°C/ 1÷ 255°F

2.0

LS

Minimum set point

-50°C÷SET/-58°F÷SET

-50.0

US

Maximum set point

SET÷110°C/ SET ÷ 230°F

110

Ot

Thermostat probe calibration

-12÷12°C /-120÷120°F

0.0

P2P

Evaporator probe presence

n=not present; Y=pres.

Y

OE

Evaporator probe calibration

-12÷12°C /-120÷120°F

0.0

P3P

Third probe presence

n=not present; Y=pres.

n

O3

Third probe calibration

-12÷12°C /-120÷120°F

0

P4P

Fourth probe presence

n=not present; Y=pres.

n

O4

Fourth probe calibration

-12÷12°C /-120÷120°F

0

OdS

Outputs delay at start up

0÷255 min

0

AC

Anti-short cycle delay

0 ÷ 50 min

1

rtr

P1-P2 percentage for regulation

0 ÷ 100 (100=P1 , 0=P2)

100

CCt

Continuous cycle duration

0.0÷24.0h

0.0

CCS

Set point for continuous cycle

(-55.0÷150,0°C) (-67÷302°F)

-5

COn

Compressor ON time with faulty probe

0 ÷ 255 min

15

COF

Compressor OFF time with faulty probe

0 ÷ 255 min

30

CF

Temperature measurement unit

°C ÷ °F

°C

rES

Resolution

in=integer; dE= dec.point

dE

Lod

Probe displayed

P1;P2

P1

rEd2

X-REP display

P1 - P2 - P3 - P4 - SEt - dtr

P1

dLy

Display temperature delay

0 ÷ 20.0 min (10 sec.)

0

dtr

P1-P2 percentage for display

1 ÷ 99

50

tdF

Defrost type

EL=el. heater; in= hot gas

EL

dFP

Probe selection for defrost termination

nP; P1; P2; P3; P4

P2

dtE

Defrost termination temperature

-50 ÷ 50 °C

8

IdF

Interval between defrost cycles

1 ÷ 120 ore

6

MdF

(Maximum) length for defrost

0 ÷ 255 min

30

dSd

Start defrost delay

0÷99min

0

dFd

Displaying during defrost

rt, it, SEt, DEF

it

dAd

MAX display delay after defrost

0 ÷ 255 min

30

Fdt

Draining time

0÷120 min

0

dPo

First defrost after start-up

n=after IdF; y=immed.

n

dAF

Defrost delay after fast freezing

0 ÷ 23h e 50’

0.0

ALc

Temperature alarms configuration

rE= related to set; Ab = absolute

Ab

ALU

MAXIMUM temperature alarm

Set÷110.0°C; Set÷230°F

110

ALL

Minimum temperature alarm

-50.0°C÷Set/ -58°F÷Set

-50.0

Continued on next page

Part No.26107 Rev J August 2018 - 32 - Inline 5000 Series Cabinets

Refrigeration cont.

REFRIGERATED CABINETS - SERVICING

Dixell Default

Settings cont.

Label

Name

Range

Default Setting

AFH

Differential for temperat. alarm recovery

(0,1 °C÷25,5°C) (1 °F÷45°F)

1

ALd

Temperature alarm delay

0 ÷ 255 min

15

dAO

Delay of temperature alarm at start up

0 ÷ 23h e 50’

1.3

AP2

Probe for temperat. alarm of condenser

nP; P1; P2; P3; P4

P4

AL2

Condenser for low temperat. alarm

(-55 ÷ 150°C) (-67÷ 302°F)

-40

AU2

Condenser for high temperat. alarm

(-55 ÷ 150°C) (-67÷ 302°F)

110

AH2

Differ. for condenser temp. alar. recovery

[0,1 °C ÷ 25,5°C] [1 °F ÷ 45°F]

5

Ad2

Condenser temperature alarm delay

0 ÷ 254 (min.) , 255=nU

15

dA2

Delay of cond. temper. alarm at start up

0.0 ÷ 23h 50’

1,3

bLL

Compressor OFF for condenser low temperature alarm

n(0) - Y(1)

n

AC2

Compressor OFF for condenser high temperature alarm

n(0) - Y(1)

n

i1P

Digital input polarity

oP=opening; CL=closing

cL

i1F

Digital input configuration

EAL, bAL, PAL, dor; dEF; Htr, AUS

EAL

did

Digital input alarm delay

0÷255min

5

Nps

Number of activation of pressure switch

0 ÷15

15

odc

Compress status when open door

no; Fan; CPr; F_C

no

rrd

Regulation restart with door open alarm

n – Y

y

HES

Differential for Energy Saving

(-30°C÷ 30°C) (-54°F÷ 54°F)

0

Adr

Serial address

0÷247

1

PbC

Kind of probe

Ptc; ntc

ntc

onF

on/off key enabling

nu, oFF; ES

nu

dP1

Room probe display

--

--

dP2

Evaporator probe display

--

--

dP3

Third probe display

--

--

dP4

Fourth probe display

--

--

rSE

Set operating value

actual set

--

rEL

Software release

--

--

Ptb

Map code

--

--

XR40CX

Hot Key

To program the controller from a Hot Key:

• Turn OFF the instrument, and disconnect probe Pr4.

• Insert a programmed Hot Key into the 5 PIN socket and then turn the

Controller ON.

• The parameter list of the Hot Key is automatically downloaded into the

Controller memory, the doL will blink, followed a by a flashing End.

• After 10 seconds the instrument will restart working with the new

parameters.

• Remove the Hot Key, and reconnect probe Pr4.

NOTE the message Err is displayed if programming fails. In this case turn the

unit off and then on again, if you want to restart the download again, or remove

the Hot Key to abort the operation.

Continued on next page

IN 5C08/12/15/18/24. - 33 - © Future Products Group

Refrigeration cont.

REFRIGERATED CABINETS - SERVICING

XR40CX

Alarm Signals

Message

Cause

Outputs

P1

Room probe failure

Compressor output acc. to par. Con and COF

P2

Evaporator probe failure

Defrost end is timed

P3

Third probe failure

Outputs unchanged

P4

Fourth probe failure

Outputs unchanged

HA

Maximum temperature alarm

Outputs unchanged.

LA

Minimum temperature alarm

Outputs unchanged.

HA2

Condenser high temperature

It depends on the Ac2 parameter

LA2

Condenser low temperature

It depends on the bLL parameter

dA

Door open

Compressor according to rrd

EA

External alarm

Output unchanged.

CA

Serious external alarm (i1 F=bAL)

All outputs OFF.

CA

Pressure switch alarm (i1 F=PAL)

All outputs OFF

XR40CX Alarm

Recovery

Probe alarms P1, P2, P3 and P4 start some seconds after the fault in the

related probe; they automatically stop some seconds after the probe restarts

normal operation. Check connections before replacing the probe.

Temperature alarms HA, LA, HA2 and LA2 automatically stop as soon as the

temperature returns to normal values.

Alarms EA and CA (with i1 F=bAL) recover as soon as the digital input is

disabled. Alarm CA (with i1 F=PAL) recovers only by switching off and on the

instrument.

XR40CX Other

Messages

Message

Cause

Pon

Keyboard unlocked.

PoF

Keyboard locked

noP

In programming mode: none parameter is present in Pr1

On the display or in dP2, dP3, dP4: the selected probe is not enabled

noA

No alarm is recorded.

XR40CX

Connections

Part No.26107 Rev J August 2018 - 34 - Inline 5000 Series Cabinets

Gaskets

REFRIGERATED CABINETS

-

SERVICING

Qlon Gaskets

The front door aperture is fitted with Qlon gaskets

along the top, bottom and on either side.

The gaskets are foam filled, and have T section

bases, which slide into aluminium extrusions.

Gasket

Replacement

The top aluminium extrusion is in two halves,

with a 20mm gap at the centre.

The bottom

extrusion

has a gap at

one side.

To replace

the gasket,

pull the old one out of the extrusion. Cut the

replacement gasket to length, and feed it in

through the gap.

The side gaskets can be removed and replaced via gaps, at the

tops of the aluminium extrusions.

Rubber

Gaskets

The rubber gaskets on sliding doors fit into T section slots in the door frames,

and can also be replaced if damaged.

IN 5C08/12/15/18/24. - 35 - © Future Products Group

SPECIFICATIONS

Mechanical

REFRIGERATED CABINETS

-

SPECIFICATIONS

CABINET MODEL

IN 5C08

IN 5C12

IN 5C15

IN 5C15

Remote

IN 5C18

IN 5C18

Remote

IN 5C24

IN 5C24

Remote

Height (150mm Feet)

1443 mm

1443 mm

1443 mm

1443 mm

1443 mm

1443 mm

1443 mm

1443 mm

Height (100mm Feet)

1393 mm

1393 mm

1393 mm

1393 mm

1393 mm

1393 mm

1393 mm

1393 mm

Width

807 mm

1207 mm

1507 mm

1507 mm

1807 mm

1807 mm

2407 mm

2407 mm

Depth

789 mm

789 mm

789 mm

789 mm

789 mm

789 mm

789 mm

789 mm

Dry Weight

125 kg

183 kg

213 kg

183 kg

275 kg

240 kg

323 kg

285 kg

Height Adjustment

(150mm Feet)

- 0 + 30

mm

- 0 + 30

mm

- 0 + 30

mm

- 0 + 30

mm

- 0 + 30

mm

- 0 + 30

mm

- 0 + 30

mm

- 0 + 30

mm

Height Adjustment

(100mm Feet)

- 0 + 25

mm

- 0 + 25

mm

- 0 + 25

mm

- 0 + 25

mm

- 0 + 25

mm

- 0 + 25

mm

- 0 + 25

mm

- 0 + 25

mm

Front Doors

Slide, Tilt

or Fixed

Glass

Slide, Tilt

or Fixed

Glass

Slide, Tilt

or Fixed

Glass

Slide, Tilt

or Fixed

Glass

Slide, Tilt

or Fixed

Glass

Slide, Tilt

or Fixed

Glass

Slide, Tilt

or Fixed

Glass

Slide, Tilt

or Fixed

Glass

Cabinet Well Material

Stainless

steel

Stainless

steel

Stainless

steel

Stainless

steel

Stainless

steel

Stainless

steel

Stainless

steel

Stainless

steel

Number of Shelves

3 plus

base

3 plus

base

3 plus

base

3 plus

base

3 plus

base

3 plus

base

3 plus

base

3 plus base

Display Area *

1.2 m2

1.8 m2

2.3 m2

2.3 m2

2.7 m2

2.7 m2

3.6 m2

3.6 m2

Refrigerant

R134A

R134A

R134A

N/A

R134A

N/A

R134A

N/A

Refrigerant Charge

Refer to the Product ID/Rating Label for details.

Condensate capacity

2.5 litres

2.5 litres

2.5 litres

N/A

2.5 litres

N/A

2.5 litres

N/A

Climatic Class & IP

Cabinets are tested under Climate Class 3 conditions and have IP 22 ratings

* Because the front face of Square glass cabinets is vertical, deeper shelves can be

fitted in the upper two levels. This will increase the display area by about 10%.

Part No.26107 Rev J August 2018 - 36 - Inline 5000 Series Cabinets

Electrical

REFRIGERATED CABINETS

-

SPECIFICATIONS

CABINET MODEL

IN 5C08

IN 5C12

IN 5C15

IN 5C15

Remote

IN 5C18

IN 5C18

Remote

IN 5C24

IN 5C24

Remote

Voltage

220-240 V 50 Hz 1

Power

1.01 kW

1.21 kW

1.54 kW

230 W

excl.

condenser

1.42 kW

300W

excl.

condenser

1.93 kW

360W

excl.

condenser

Current

4.4 A

5.3 A

6.7 A

1A excl.

condenser

6.2 A

1.3 A excl.

condenser

8.4 A

1.5 A excl.

condenser

Connection

Three core cable with 10A, 3 pin plug

Temperature Range1

2 - 4 C

2 - 4 C

2 - 4 C

2 - 4 C

2 - 4 C

2 - 4 C

2 - 4 C

2 - 4 C

Lighting

4 x LED

strips

4 x LED

strips

4 x LED

strips

4 x LED

strips

4 x LED

strips

4 x LED

strips

8 x LED

strips

8 x LED

strips

1

Controlled Ambient cabinets, designated IN-CA---, have a temperature range of 16 - 18C

IN 5C08/12/15/18/24. - 37 - © Future Products Group

Controller Setting

REFRIGERATED CABINETS

-

SPECIFICATIONS

Dixell XR40CX Settings

Parameter

Integral

Condenser

Models

Remote

Condenser

Models

Integral

Controlled

Ambient

Remote

Controlled

Ambient

Units/Range

Set Point

Set 2 2

16

16

degC

Differential

Hy 2 2 2 2

degC

Anti Short Cycle Delay

AC 0 0 0 0

Min

Comp On Time - Faulty Probe

C0n 4 4 4 4

Min

Comp Off Time - Faulty Probe

C0F 6 6 6 6

Min

Defrost Terminate Temp

dtE 3 3 3 3

degC

Interval Between Defrosts

idF 4 4 4 4

Hrs

Display During Defrost

dFd

DEF

DEF

DEF

DEF

rt, it, Set, DEF

Maximum Temperature Alarm

ALU

12

12

110

110

degC

Differential For Temp Alarm

AFH 8 8 1 1

degC

Temperature Alarm Delay

Ald

60

60

15

15

Min

Probe For High Temp Alarm

AP2

nP

nP

nP

nP

nP, P1, P2, P3, P4

Digital input polarity

i1P

oP

cL

oP

cL

cL, oP

Digital input configuration

i1F

PAL

EAL

PAL

EAL

EAL, bAL, PAL,

dor, dEF, AUS, Htr,

ES

Digital input alarm delay

did 0 5 0 5

Min

Activations of pressure switch

Nps 1 15 1 15

0-15

Parameters shown thus are Dixell default settings

Part No.26107 Rev J August 2018 - 38 - Inline 5000 Series Cabinets

Compliance

REFRIGERATED CABINETS

-

SPECIFICATIONS

Safety Aspects

These cabinets have been designed to comply with the relevant requirements of the

following specifications:

• AS/NZS 3100 General Requirements for Electrical Equipment

• AS/NZS 3182 Refrigerated Food Commercial Cabinets

• AS/NZS 3820 Essential Safety Requirements

• AS/NZS 4417 Marking of Electrical Products

IEC 60335 Household and Similar Electrical Appliances – Safety

Part 1: General Requirements

Part 2-24: Particular Requirements for Refrigerating Appliances / Ice Cream Appliances and Ice Makers

EN 55014 Electromagnetic Compatibility Requirements for Household Appliances,

Electric Tools and Similar Apparatus

Part 1: Emissions

Part 2: Immunity - Product Family Standard

EN 61000 Electromagnetic compatibility (EMC)

Part 3-2: Limits - Limits for harmonic current emissions (equipment input current up to and including 16A per phase)

Part 3: Limits - Section 3: Limitations of voltage changes, voltage fluctuations and flicker in public low-voltage supply

systems, for equipment with rated current ≤ 16A per phase and not subject to conditional connection

Operational

Safety

This appliance is not intended for use by young children or infirm persons,

unless they have been adequately supervised by a responsible person, to

ensure that they can use the appliance safely.

Young children should be supervised, to ensure that they do not play with the

appliance.

Performance

Aspects