Page 1

PRO PAK’R

USER MANUAL

www.fpintl.eu

FP International

Never stop

PROgressing

PRO PAK’R User Manual Version 1.0 Page -1-

Page 2

PRO PAK’R

Air Cushion Machine

FP International BV

HEERLEN

The Netherlands

PRO PAK’R User Manual Version 1.0 Page -2-

FP International

Page 3

About this mAnuAl

Edition : Version 1.0

ORIGINAL INSTRUCTION

Edition date : 04-03-2013

© Copyright : FP International BV, HEERLEN, THE NETHERLANDS 2013.

No part of this documentation may be reproduced in any form whatsoever without the prior

permission of FP International BV. Excepted are parts intended for reproduction for the purpose

of using the documentation, such as summary instructions and instructions (to be) afxed to the

machine.

mAchine identificAtion

This user manual forms part of the following machine:

Designation : PRO PAK’R

Model : MPRPK02MAC

Precise identication: see the data on the machine identication plate and/or the “EC Declaration of

Conformity” on page 30.

the mAnufActurer

The machine is produced by:

FP International B.V.

Nijverheidsweg 4

6422 PD Heerlen

The Netherlands

service centres

FP International B.V.

Nijverheidsweg 4

6422 PD Heerlen

The Netherlands

Tel. +31(0)45 566 7400

Fax. +31(0)45 566 7401

E-mail info@fpintl.eu

www.fpintl.eu

FP InternationalFP International

PRO PAK’R User Manual Version 1.0 Page -3-

Page 4

contents

ABOUT THIS MANUAL 3

MACHINE IDENTIFICATION 3

THE MANUFACTURER 3

SERVICE CENTRES 3

FOREWORD 5

USING THE MANUAL 5

TYPOGRAPHIC CONVENTIONS 6

SERVICE AND INFORMATION 6

WARRANTY AND LIABILITY 7

1 INTRODUCTION 8

1.1 Intention of Use 8

1.2 Glossary of Machine Terms and Jargon 8

1.3 Models and Accessories 8

1.3.1 Standard Machine and accessories 8

1.3.2 Not included with the machine 9

2 SAFETY 10

2.1 Introduction 10

2.2 Safety Features 10

2.3 Safety Rules 10

2.4 Unauthorized Use 10

2.5 Machine Users 11

2.5.1 Operators (level 1) 11

2.5.2 Maintenance Personnel (level 2) 11

2.6 Workplace 11

2.7 Personal Protective Equipment 11

2.8 Emergency switch 12

2.9 Cautions on the machine 12

2.10 Fire and other emergencies 12

3 OPERATING INSTRUCTIONS 13

3.1 Construction and operating controls 13

3.1.1 Conguration 13

3.1.2 Control panel keypad instructions 16

3.1.3 Control panel display symbols 16

3.2 Starting up the machine 17

3.3 Loading Film 18

3.3.1 General instructions to operate the machine 19

3.3.2 Changing Menu Setting 20

3.3.3 Display Errors 21

3.3.4 Moving 21

3.3.5 Setting up 21

3.4 Cleaning 22

3.5 Transport/storage 22

3.5.1 General 22

3.5.2 Storage 22

3.6 Commissioning 23

3.7 Repair and maintenance 23

3.7.1 Replacing blades / cone tip 23

3.7.1.1 Change cone tip 23

3.7.1.2 Replace blade / new cutting edge 23

3.7.2 Replacing wear strips 24

3.7.3 Cleaning backing wheel 24

3.7.4 Replacing backing wheel 24

3.7.5 Extention wide lm 24

3.8 Troubleshooting 25

4 SPECIFICATION 26

4.1 Machine specication 26

4.1.1 General 27

4.1.2 Product to be processed 26

4.2 Electrical specication 26

4.3 Machine environment 27

4.4 Directives and Standards applied 27

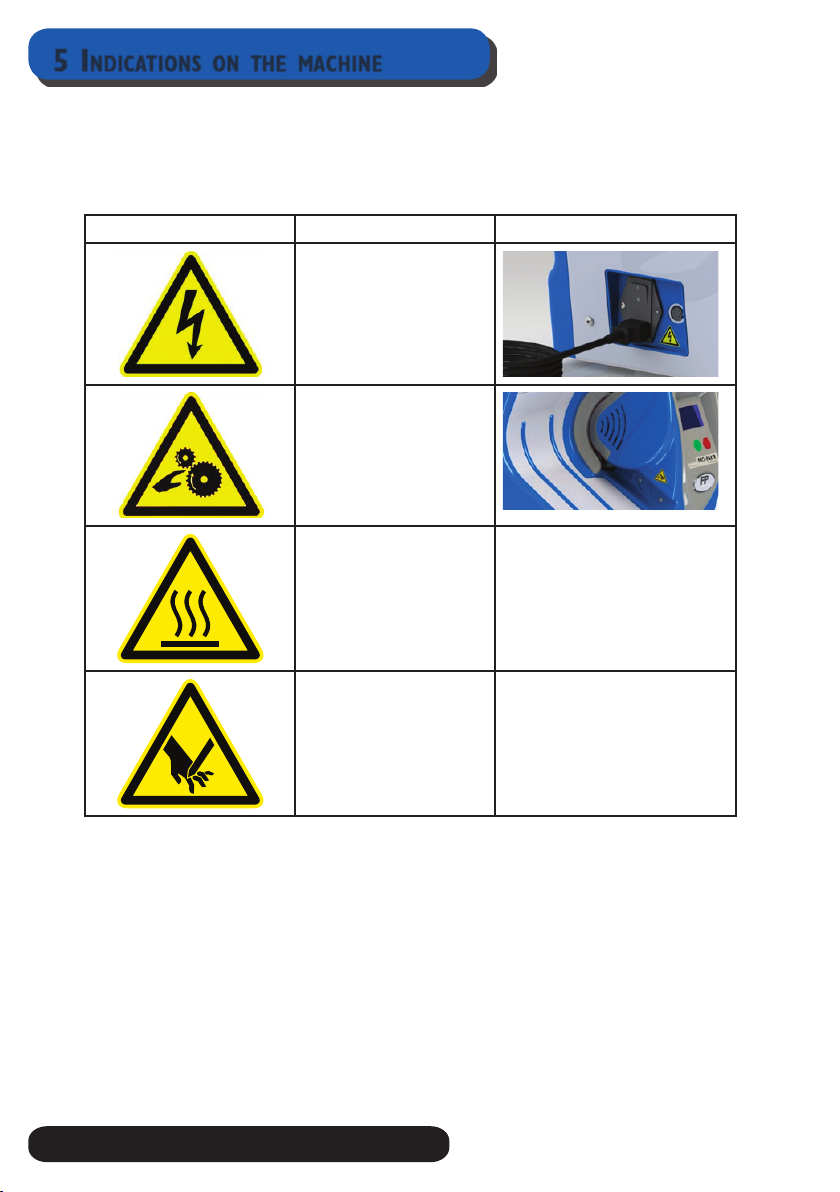

5 INDICATIONS ON THE MACHINE 28

5.1 Machine Identication Plate 28

5.2 Warnings 29

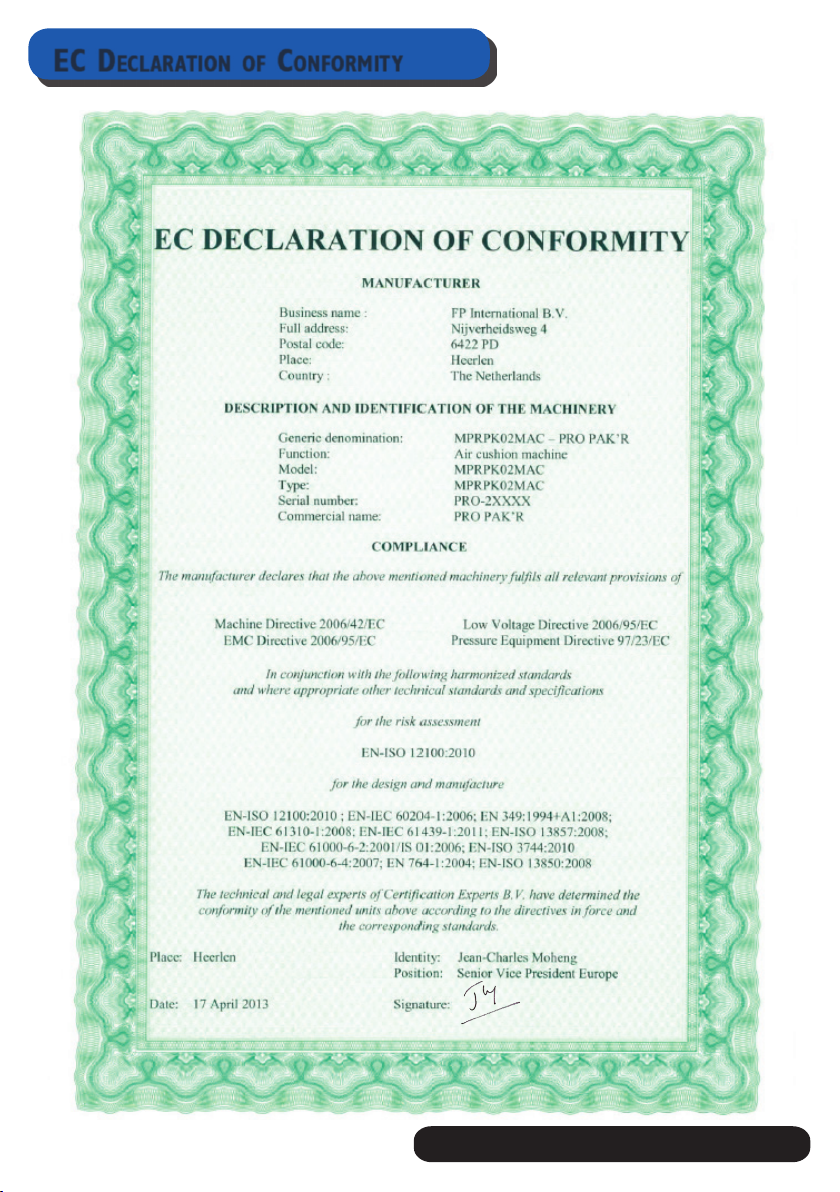

EC DECLARATION OF CONFORMITY 30

PRO PAK’R User Manual Version 1.0 Page -4-

FP International

Page 5

foreword

This user manual details the daily use and maintenance of the PRO PAK’R, an installation that is part

mechanical, part electrical.

Details of maintenance work to be carried out by the manufacturer’s personnel only are expressly

excluded.

This manual is an integral part of the machine and should be carefully looked after! It

contains information that may be useful or required at a later date, for example when

carrying out repairs and maintenance. It is recommended that you keep one copy

near the machine and that you le the other one, for example with the records of your

technical department. The manufacturer may be able to supply you with an additional

copy.

The manual is to accompany the machine, should its ownership be transferred to a third

party.

This PRO PAK’R is provided with a USB key (only FAT formatted USB Stick works)

This manual, also in different languages, is also available on the USB key in the machine.

using the mAnuAl

The instructions in this manual are listed according to the various classes of user of the machine. The

requirements for these different classes of user are given in chapter 2.

In this manual, the terms in the left hand column below are used as dened on the right.

User: The collective designation for everyone working on or with the machine.

Operator: Any person using the machine on a daily basis.

Maintenance personnel: Persons with qualications and experience in carrying out the work

Any work not described in this manual must be carried out by or in consultation with FP International

BV.

The term “product” is used in this manual to refer to the items to be processed by the machine and

therefore does not refer to the machine itself.

The gures included in the text of this manual serve the exclusive purpose of illustration. They are

intended only as text aids, for example to illustrate the location and function of controls or parts.

The actual layout and dimensions may vary. Technical drawings, if required, may be appended or

supplied separately.

Relevant chapters: Introduction, Safety and Operating Instructions.

described, and disposing of the means required to do so.

Relevant chapters: All

FP InternationalFP International

PRO PAK’R User Manual Version 1.0 Page -5-

Page 6

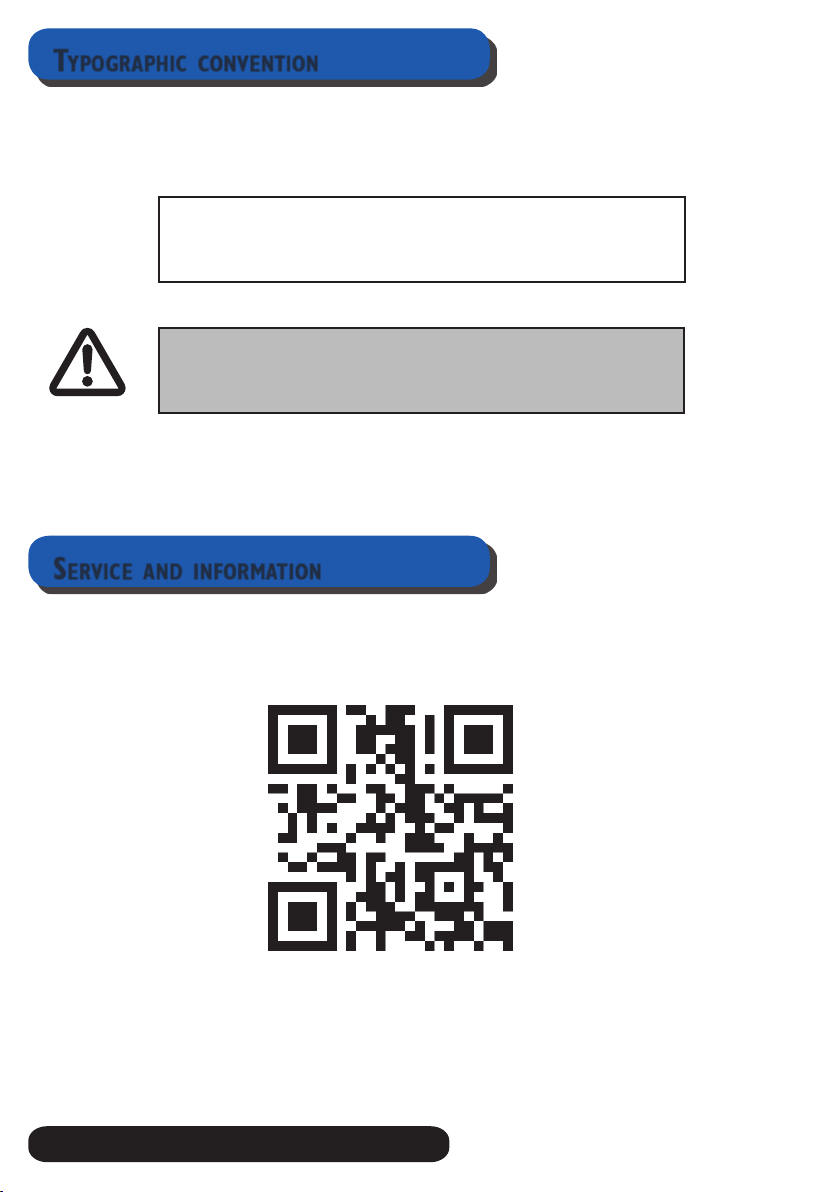

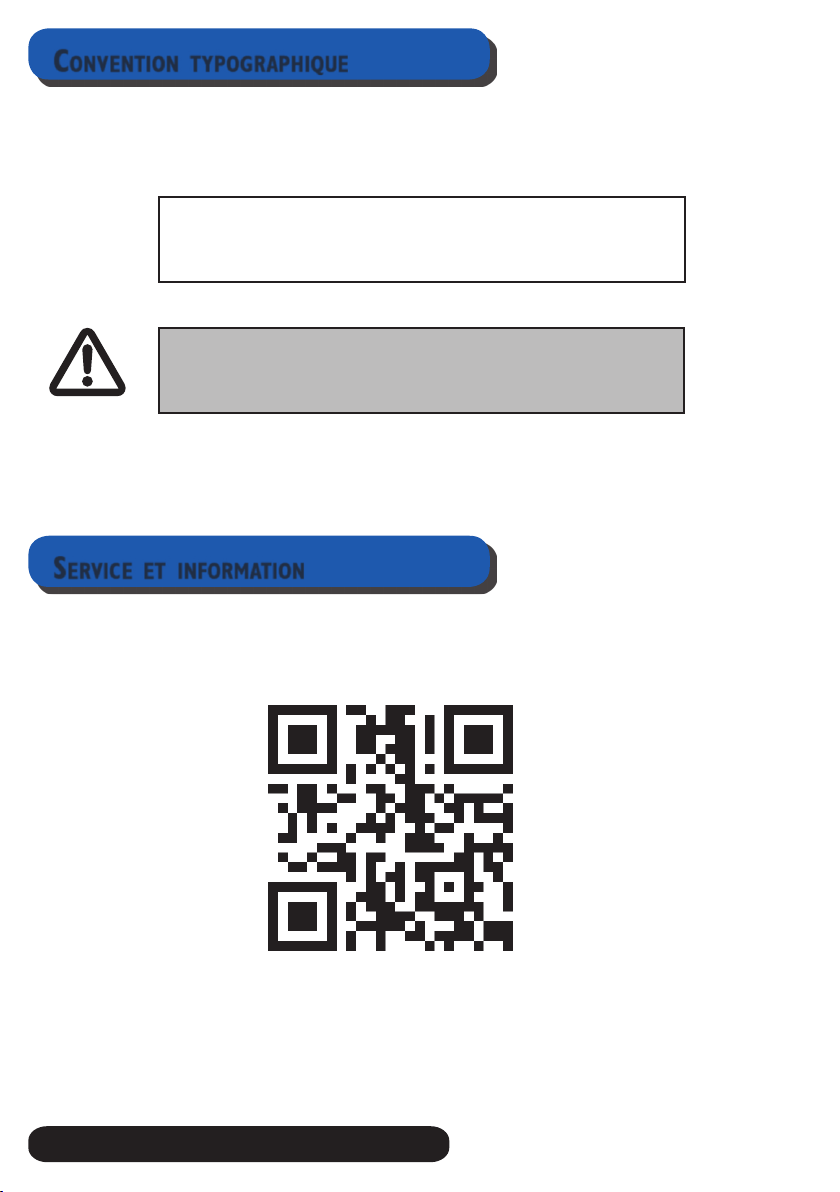

typogrAphic convention

Sections of text relating to personal health and safety are printed in bold, with the exception of the

Safety chapter itself. The following cautionary symbols may have been used:

Caution!

This pictogram draws attention to the possibility of damage to

the product or the machine.

Warning!

This pictogram draws attention to the risk of personal injury.

service And informAtion

For further details about the machine, please contact the manufacturer/your supplier

(see “About this Manual” on page 3).

By scanning this QR code, you will

access videos that show most of

the operations described in this

manual.

PRO PAK’R User Manual Version 1.0 Page -6-

FP International

Page 7

wArrAnty And liAbility

The warranty comprises the following terms and provisions, unless agreed otherwise in

writing:

• The manufacturer enters into this warranty with the original user for 12 months from the date of

delivery of the product.

• Defects must be reported to the manufacturer prior to expiry of the term of warranty.

- The warranty covers defects which:

- occur during normal operation of the machine/assembly;

- arise from defective construction or materials;

- arise from any lack of expertise on the part of the manufacturer;

• The warranty does not cover defects arising from:

- normal wear and tear;

- inexpert or inappropriate use;

- the use of consumables other than prescribed.

• Should any defects occur, the manufacturer will:

- replace the parts. Ownership of the parts replaced reverts to the manufacturer;

- correct the defects;

- opt to replace the equipment should repair, within reason, be ruled out. The customer must

provide the manufacturer with the opportunity to correct any defects;

• Integrated third party components are subject to the warranty of the manufacturer in question. The

applicable term of warranty may vary from the above.

• The manufacturer reserves the right to modify machines/assemblies without prior notice.

Please note that the following limitations apply to the manufacturer’s liability under the

terms of the warranty:

The manufacturer is not liable for potentially dangerous situations, not for incidents or damage

resulting from warnings or instructions supplied either on the machine/assembly or in this manual

having been ignored. No liability applies to, for example:

• inexpert or incorrect use or maintenance;

• use for purposes or under circumstances other than are indicated in this manual;

• the use of parts other than prescribed;

• repairs carried out without the manufacturer’s prior permission;

• modications to the machine/assembly, such as:

- modication of the control system;

- welding, mechanical alterations;

- additions to the machine/assembly or its control system.

Furthermore, the manufacturer is not liable:

• should the customer have failed to full any of his obligations (nancial or otherwise) in respect to

the manufacturer;

• for consequential damage resulting from any failure of or defects to the machine/assembly (such as

damage to products (to be processed), shut-down of operations, delayed production etc.).

FP InternationalFP International

PRO PAK’R User Manual Version 1.0 Page -7-

Page 8

1 introduction

1.1 intention of use

The machine is intended for the production of air lled cushions. The inated air cushions can be cut

at a desired quantity, then serves as void-ll for packaging purposes.

See “Product to be processed” on page 22 for precise details of suitable kinds of lm to be processed.

1.2 glossAry of mAchine terms And JArgon

Pedal: A control mechanism (transport and sealing of lm, starting up of presets) by

Display: Image shown on the screen.

Control panel: Screen operated by buttons, to access control functions.

RFID: We equip every PRO PAK’R roll with an RFID tag that holds information about

The controls are explained under “Operating Instructions ” on page 13.

1.3 models And Accessories

1.3.1 stAndArd mAchine And Accessories

The standard version consists of the assembled unit complete with:

• Machine (Inator), including power cord.

• >500mm wide lm (Optional)

• Stand (Optional)

• Pedal (Optional)

• Sensor (Optional)

means of a foot switch.

the optimal sealing temperature and ination levels.

Warning!

In case processing > 500mm wide lm, use the wide lm

kit.

If needed, read the instruction carefully.

PRO PAK’R User Manual Version 1.0 Page -8-

Use the >500mm wide lm kit for rolls;

• larger then 500mm (width).

• and heavier than 15 kg (weight).

FP International

Page 9

1 introduction

PRO PAK’R

machine

Wide lm kit (Optional)

Use the >500mm wide

lm kit for rolls

1.3.2 not included with the mAchine

Not included with the machine are:

• Work station for packing: conveyor belt, table etc.

Caution!

Any details in this manual about these parts are supplied for

information only. The current instructions or information given

by the supplier of whichever equipment may vary and

take precedence over ours.

FP InternationalFP International

PRO PAK’R on a stand

(optional)

PRO PAK’R User Manual Version 1.0 Page -9-

Page 10

2 sAfety

2.1 introduction

This machine has been designed and built with safety of use and maintenance in mind. The safety

applies provided the machine is used as set out in this manual, under the circumstances described

and in compliance with the instructions given. It is therefore crucially important that this manual is

read and the instructions are complied with, by everyone using or maintaining the machine. Used in

any business environment, the employer shall be responsible for ensuring that users are familiar and

comply with the instructions.

Additional safety regulations may apply within the organization or country in which the machine is put

to use. Most likely, these will concern the health and safety of the operators. This manual does not

describe how to comply with any such additional measures but does provide the information about

the machine that is necessary for this purpose. In cases of doubt, please consult your government or

Health and Safety Ofcer.

In this manual, a distinction is made between normal use (see “Operating Instructions” on page 15)

and other work to the machine. The reason is that maintenance work imposes different requirements

on personnel than machine operation, particularly in terms of safety.

The basic maintenance tasks described alongside the operating instructions, can be carried out by

qualied personnel of FP International. Any work not listed under “operating instructions” may

only be carried out by suitably qualied personnel. The items provided to restrict access to certain

machine parts or functions must not be kept with or near the machine. Only persons possessing the

know-how required may have access to such items.

2.2 sAfety feAtures

The machine is tted with the following safety features:

• Cover switch on the housing: the machine is disabled when the cover is open;

• Film feed button: the feed rollers only rotate when the button is pressed;

• Emergency stop (see “Emergency switch” on page 12);

2.3 sAfety rules

• Children and animals must be kept away from the machine!

• Do not reach into the machine while it is operating or has been switched on.

• Even when the machine is not operating, it may be “on”, meaning it may start to operate

automatically. Only in combination with sensor or pedal.

• Safety features may not be removed or disabled.

• Keep the workplace clean and free from obstacles.

• Ensure adequate lighting.

• The safety of the machine may deteriorate with prolonged use. Ensure frequent maintenance.

• Do not use the machine if the safety features are in any way damaged or malfunctioning. Make

sure the machine is repaired.

2.4 unAuthorized use

Please note that the machine is unsuitable for the following purposes:

• The processing of materials other than prescribed in this user manual.

PRO PAK’R User Manual Version 1.0 Page -10-

FP International

Page 11

2 sAfety

2.5 mAchine users

2.5.1 operAtors (level 1)

In the operating software, this class of user will handle the tasks in the menus “operator”

The machine may only be operated by adults who have familiarized themselves with the chapters

“Safety” and “Operating Instructions” of this manual and will comply with their content.

No special training is required.

Some previous experience in handling this type of equipment is required.

The operator’s duties will generally consist of:

• Fitting new rolls of lm

• Producing strips of lm

• Dening and applying the preset parameters (supervisor only)

• Cleaning the machine (exterior).

2.5.2 mAintenAnce personnel (level 2)

In the operating software, this class of user will handle the tasks in the menu “service”.

Maintenance staff should be aware of the added risk involved in the type of work they are to carry

out. In addition to the requirements listed under “Operators “ above, maintenance personnel

should therefore have:

• an HND in a relevant subject or know-how equivalent to that qualication;

• experience in maintaining machines;

• the necessary resources at their disposal (e.g. tools and measuring equipment).

2.6 workplAce

The denition of and requirements for the workplace are an area of 1 meter at both the front and

the rear of the machine. This provides sufcient room for all operating tasks to be carried out

and allows the machine to be placed over a roller conveyor belt, for example.

2.7 personAl protective equipment

No PPE is required to operate the machine.

FP InternationalFP International

PRO PAK’R User Manual Version 1.0 Page -11-

Page 12

2 sAfety

2.8 emergency switch

To allow the machine to be stopped as

quickly as possible in case of an emergency,

it has been tted with a clearly recognizable,

bright red emergency switch.

If the emergency switch is pressed in,

the machine will stop instantly.

The switch will remain mechanically disabled,

preventing the machine from restarting.

In case of personal injury, rst aid can then be provided without delay. Other emergency steps

should also be taken immediately.

Once the crisis has been resolved, the emergency switch can be re-enabled. The machine will not

restart automatically and should be started up in the normal manner.

The emergency switch may also be used in suddenly arising cases, for example when the machine

malfunctions or jams materials.

Recommendations:

• Allow novice operators to practise using the emergency switch;

• Regularly test the due functioning of the machine;

• Never re-enable the emergency switch until you are fully convinced that it is safe to do so. Find

out who used the emergency switch and why.

2.9 cAutions on the mAchine

The cautionary notices afxed onto the machine must remain clearly legible. Replace if worn.

The texts are included under “Warnings” on page 28

The risks in question are described more closely in the sections on operating and maintenance

instructions.

2.10 fire And other emergencies

No special instructions apply in case of re or other emergencies. Normally applicable

extinguishing media can be used.

PRO PAK’R User Manual Version 1.0 Page -12-

FP International

Page 13

3 operAting instructions

Before the machine is taken into use, operators must have familiarized themselves with the contents

of the chapter on safety.

This chapter is intended for operators, as dened in the section “Operators “ on page 11.

Any work not described in this chapter may only be carried out by maintenance personnel (as dened

in the section “Maintenance Personnel” on page 11).

Warning!

Before the machine can be taken into use, it must be

commissioned by maintenance personnel.

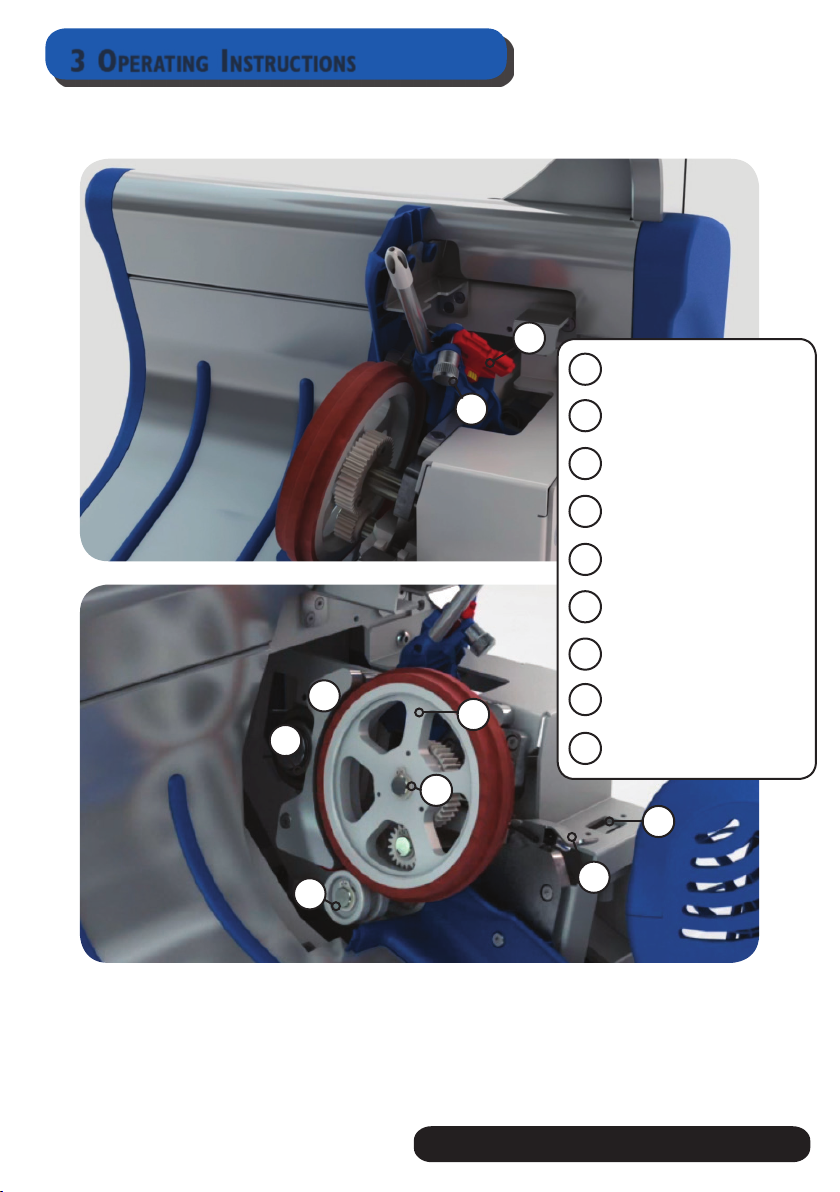

3.1 construction And operAting controls

3.1.1 configurAtion

The machine is congured as follows:

PRO PAK’R

machine

Switches /

Connectors

Wide lm kit

See page 8

FP InternationalFP International

PRO PAK’R on a stand

(optional)

PRO PAK’R User Manual Version 1.0 Page -13-

Page 14

3 operAting instructions

front view reAr view

1

7

2

1

Roll Holder

4

3

8

6

5

PRO PAK’R User Manual Version 1.0 Page -14-

Emergency stop

2

AC power inlet, on/off main

3

switch and fuse.

Accessoires Port

4

Control Panel

5

Fill Tube (Cone Tip)

6

Auto index sensor

7

Access screw display cover

8

FP International

Page 15

3 operAting instructions

1

Blade holder

1

2

8

4

7

Black knob

2

Circlip Backingwheel

3

Backingwheel

4

Lock / Lever

5

Drive roller

6

Sealwheel / heater

7

Film guides

8

USB connector

9

3

9

5

6

FP InternationalFP International

PRO PAK’R User Manual Version 1.0 Page -15-

Page 16

3 operAting instructions

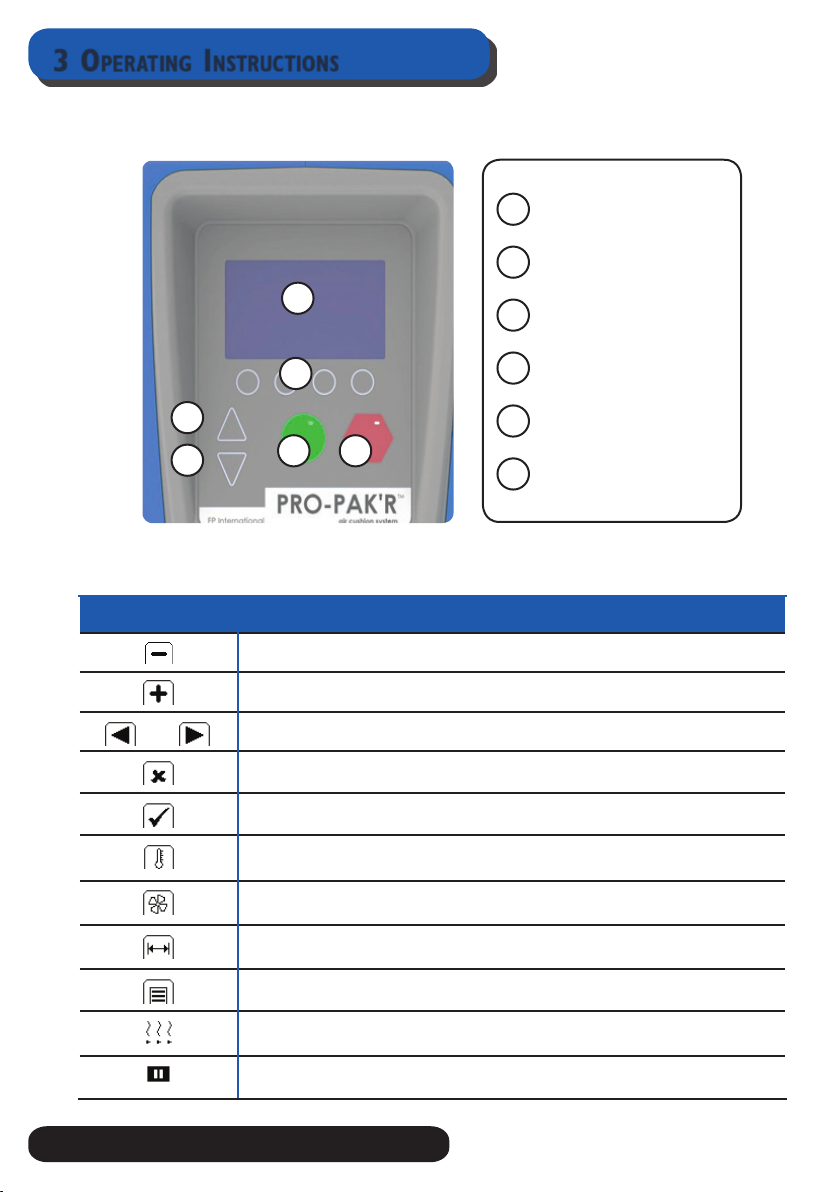

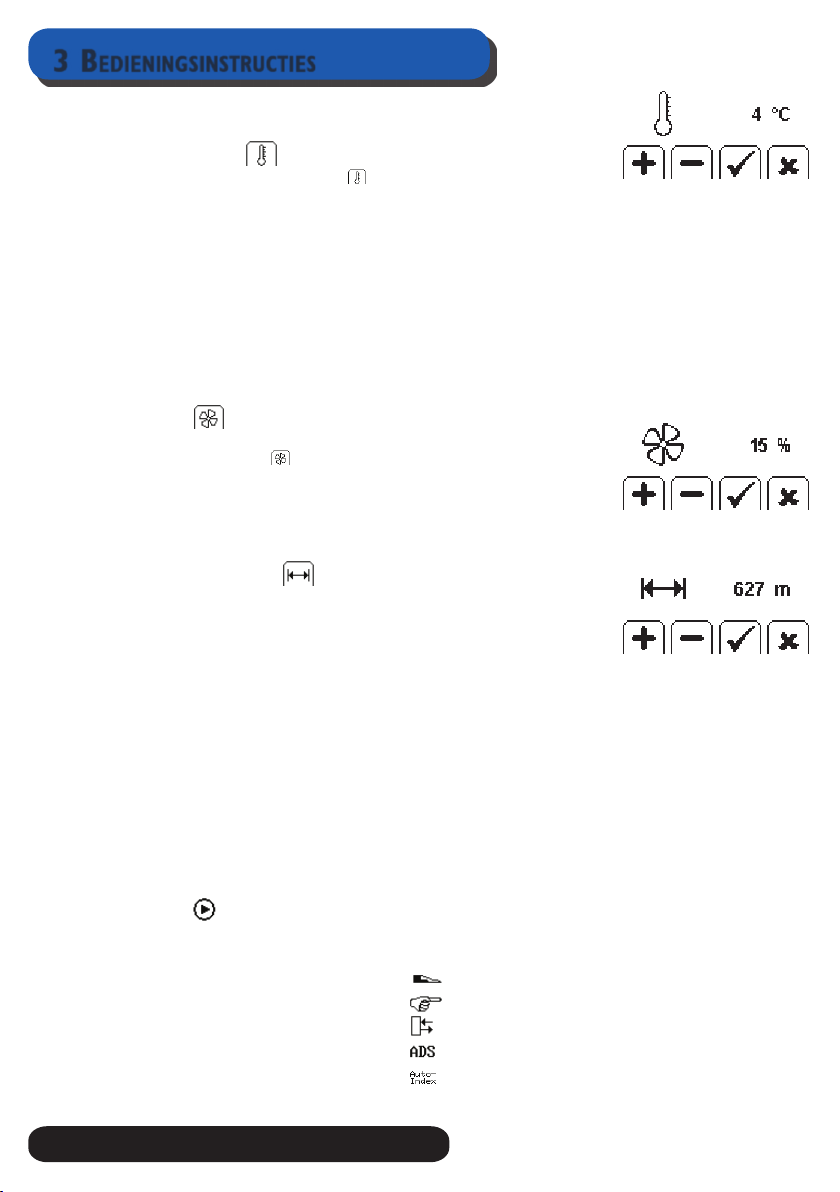

3.1.2 control pAnel keypAd instructions

Display Screen

1

4 Menu buttons

2

1

2

3

4

3.1.3 control pAnel displAy symbols

stAtus icon whAt it meAns

5 6

Shows the icon for decrease

Shows the icon for increase

Shows the way of sliding true the menu

Shows the cancel icon

Shows the conrm icon

Shows the temperature control of the seal wheel that fuses the front and back lm sheets

together. Press the menu button below the icon to access seal temperature.

Shows the ll level rate of the cushions. Press the menu button below the icon to access

ll level.

Shows the length of strings of the air cushions. Press the menu button below the icon to

adjust the cushion length

Shows the menu. Press the menu button below the icon to access the menu.

Forward feed button

3

Backward feed button

4

Start Button

5

Stop Button

6

Shows the machine is heating up or cooling down.

Shows the machine is in standby mode. If the PRO PAK’R is not used by “..” time it will go

in a “Standby” mode. To resume press “any” key.

PRO PAK’R User Manual Version 1.0 Page -16-

FP International

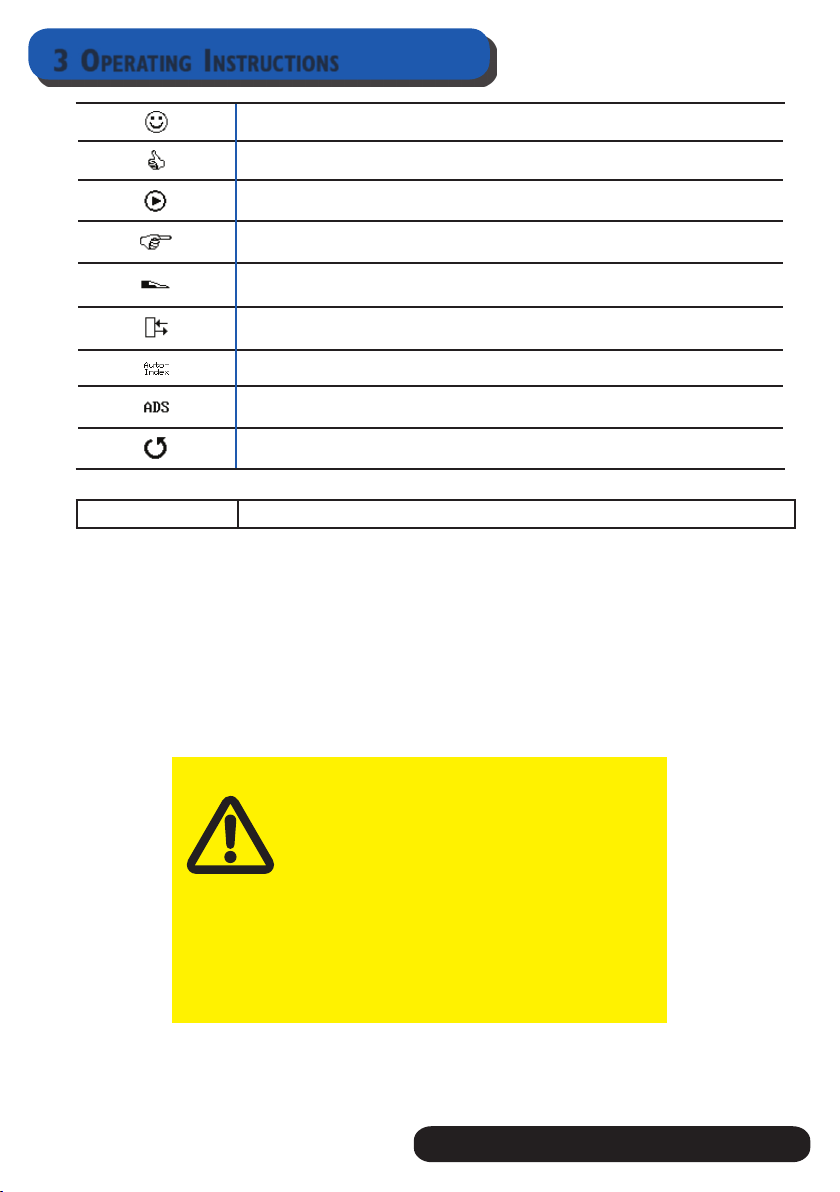

Page 17

3 operAting instructions

Shows the machine is ready to use

Shows the machine is running.

Shows the menu for switching to a operate mode

Shows that the machine is on manual mode

Shows that the machine is in foot pedal mode.

Shows that the machine is on bin / sensor mode

Shows that the machine is in Auto-Index mode .

Shows that the machine is in ADS mode.

Shows the restore. Press the restore button below the icon to access

NO TAG Press Start. This may clear the error. If not, turn the roll.

3.2 stArting up the mAchine

• Make sure the machine has been set up correctly.

• The machine can be xed on a stand (optional) or can be placed on a stable table.

• Insert provided power cord into the rear of the machine.

• Plug the power cord into a dedicated, grounded outlet.

• Switch on the machine with the main switch. The start-up screen will appear on the

display.

GB: Always remove the roll of lm before

changing the

position of the stand.

DE : Entfernen Sie immer zuerst die Folie

bevor Sie die Position des Standes änderen.

FR: Retirer impérativement la bobine de lm

avant de changer la position du stand.

NL: Verwijder altijd eerst de folie alvorens de

positie van de stand te veranderen.

FP InternationalFP International

PRO PAK’R User Manual Version 1.0 Page -17-

Page 18

3 operAting instructions

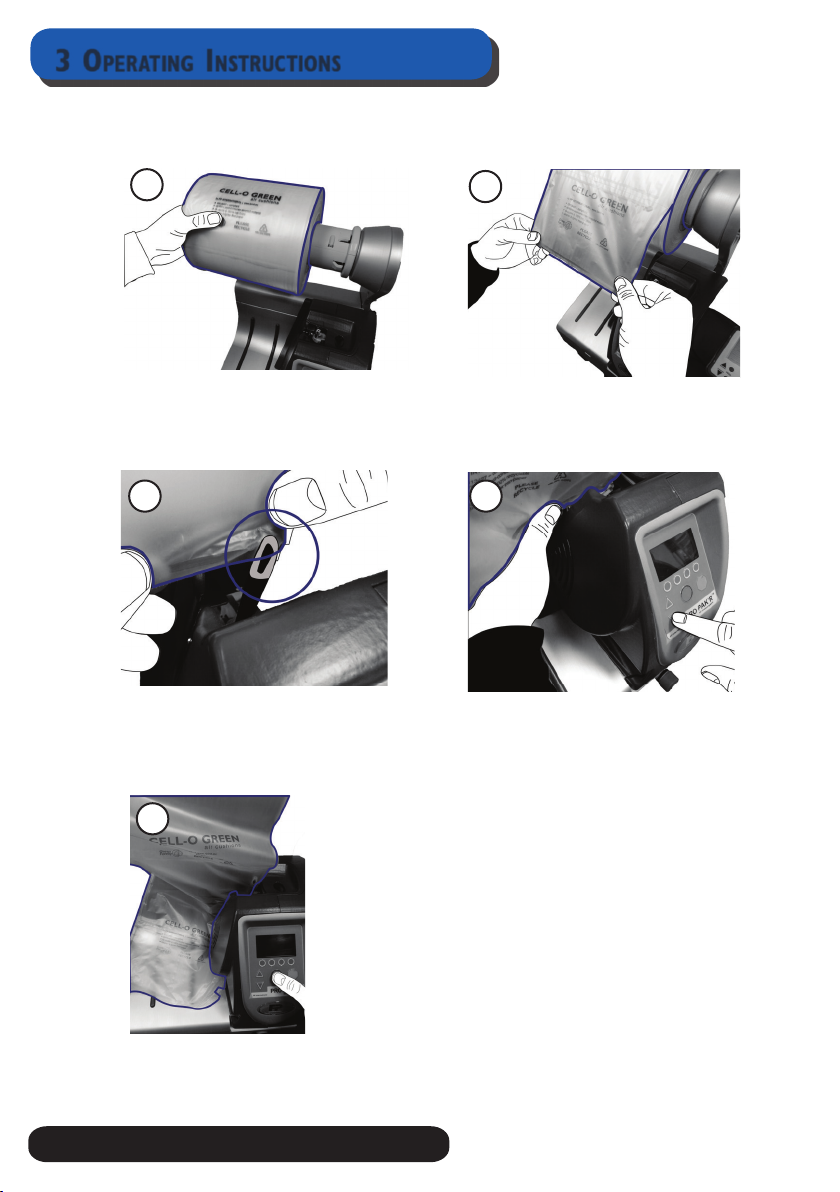

3.3 loAding film

1

Slide the lm roll on the roll holder.

3 4

Open the air channel of the lm-roll

and pull it over the ll-tube until you

feel resistance.

2

The lm unwind direction to be as

shown on the picture.

Pull the lm towards the ll-tube tip.

Use the feed down button on the

control panel to feed the lm all the

way through the machine.

5

Press the Start button as soon as the

machine is ready.

PRO PAK’R User Manual Version 1.0 Page -18-

FP International

Page 19

3 operAting instructions

3.3.1 generAl instructions to operAte the mAchine

• Make sure the E-stop is not activated. To deactivate twist the head of the E-stop to release.

• Power the machine on by turning the POWER TOGGLE SWITCH (AC power plug) on the

rear of the machine to ON.

• Press the button on the display panel to activate the machine when prompted on the screen

• Load the film onto the roll holder (Loading film figure 1)

• Open the air channel in the film and pull it over the air fill tube cone (Loading film figure 3)

• Pull the film down into the air tube (Loading film figure 4)

• Press the Forward Button and feed the film down the air tube until the feed rollers grab the

film. (Loading film figure 3)

The Machine is now ready to produce air cushions.

• The RFID technology will read the film installed and set the Pro Pak’r for optimal

performance.

o The fill level, sealing temperature and sealing pressure can be adjusted for specific

applications through the key pad display. (See 3.3.2.)

• The length of string of the air cushions can be set through the key pad display (see 3.3.2.)

o Holding the foot pedal down (if installed) will override the length control setting on the

equipment.

o Tapping the foot pedal will cause the machine to deliver a length of air cushions.

o The machine can be operated with the Start button.

FP InternationalFP International

PRO PAK’R User Manual Version 1.0 Page -19-

Page 20

3 operAting instructions

3.3.2 chAnging mAchine settings

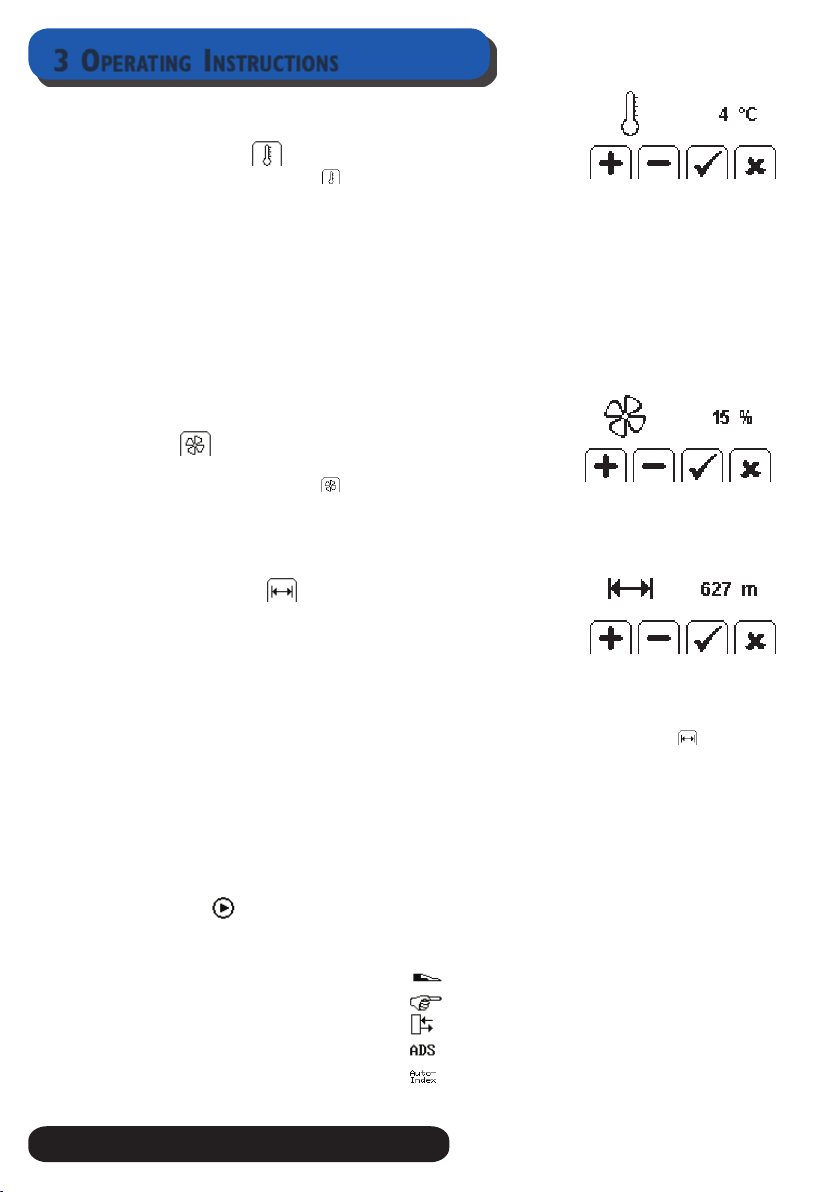

temperAture control

Press the button below the ( ) to adjust.

• If the air cushions become at, and upon inspection the heat seals are leaking air,

increase the Temperature Control by pressing the button below the “+” icon

• If the air cushions become at because the seals are burned through at the seal line as

evidenced by holes in the air cushions, decrease the temperature control by pressing

the button below the “-” icon

Press the button below P to accept

After changing the temperature control setting, the PRO PAK’R may take a few moments to

establish the new seal temperature.

During heat-up or cool down, RED LED will ash until the correct temperature has been

achieved.

If air cushions continue to show poor seals and produce at cushions, contact FPI for assistance.

Air control

Air Control regulates the amount of air in the Air Cushions.

Press the button below the ( ) to adjust

If you want to increase the ll level, press the button below the “+”icon

If you want to decrease the ll level, press the button below the “-” icon

Press the button below P to accept

AdJust length control

Length control sets the length of a string of air cushions to be produced each time you press the start button. You have 2 options:

continuous mode:

Length control at the factory is preset at continuous production. Press start button and the

machine will run the lm until the lm roll is empty or the stop button is pressed.

fixed length

If you want to produce a xed length of a string of air cushions, press below , press the +

Button until desired length is displayed. The machine will count down the length of air cushions produced.

Press P to accept

To change from Fixed to Continuous mode, press - button in the length control menu until

the display shows “0:”

Access menu

mode options

In this option you can select the operation mode, there are 5 option to select

Option 1 Foot Pedal

Option 2: Manually

Option 3: Sensor

Option 4: ADS

Option 5 Auto-Index

Select the desired Mode option. Accept press P.

PRO PAK’R User Manual Version 1.0 Page -20-

FP International

Page 21

3 operAting instructions

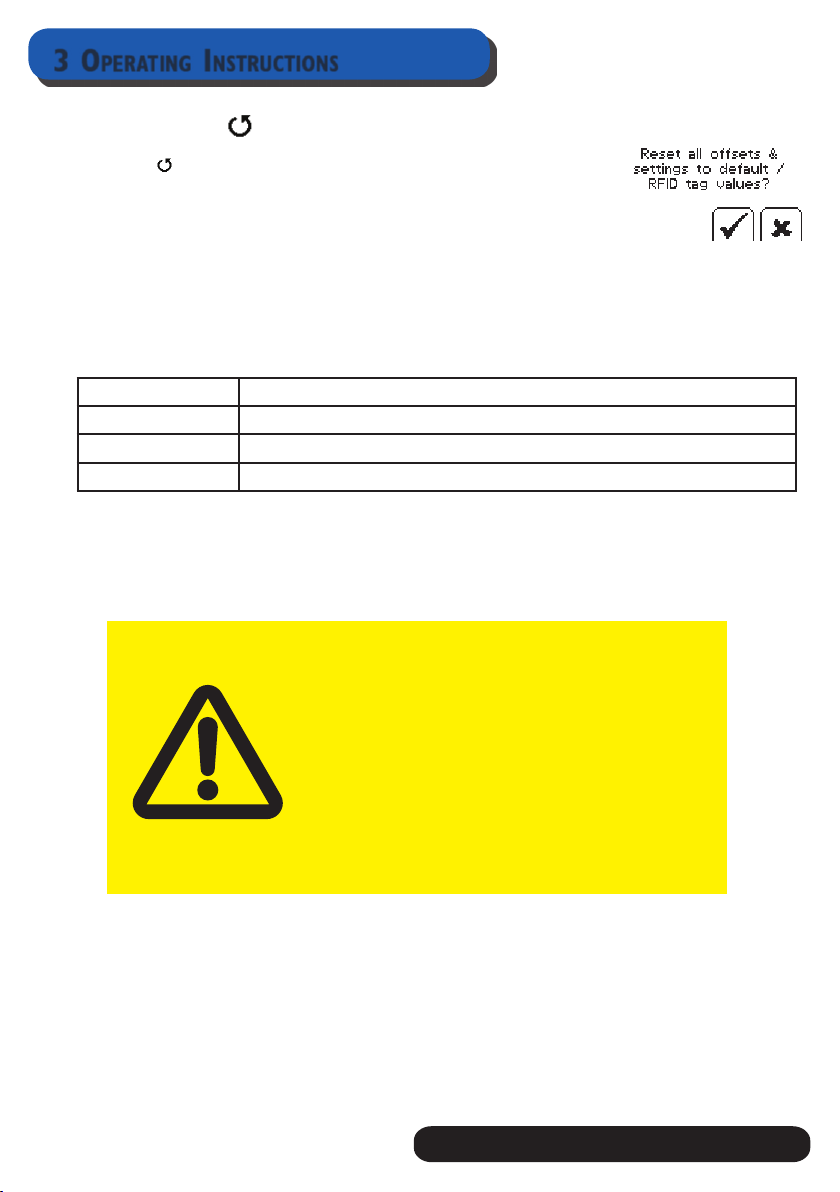

restore settings

Press in the Menu

In Display shows “Reset all offsets & settings to default / RFID tag

values”

Press P to accept

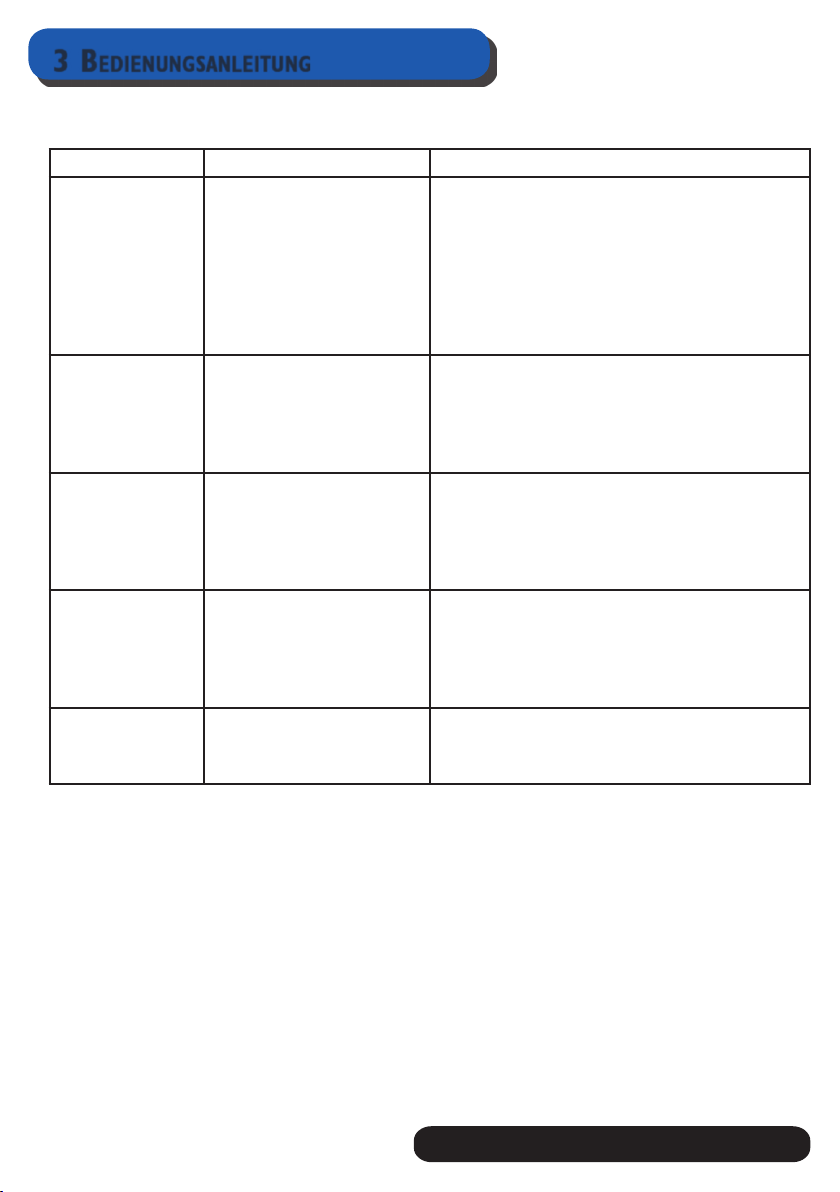

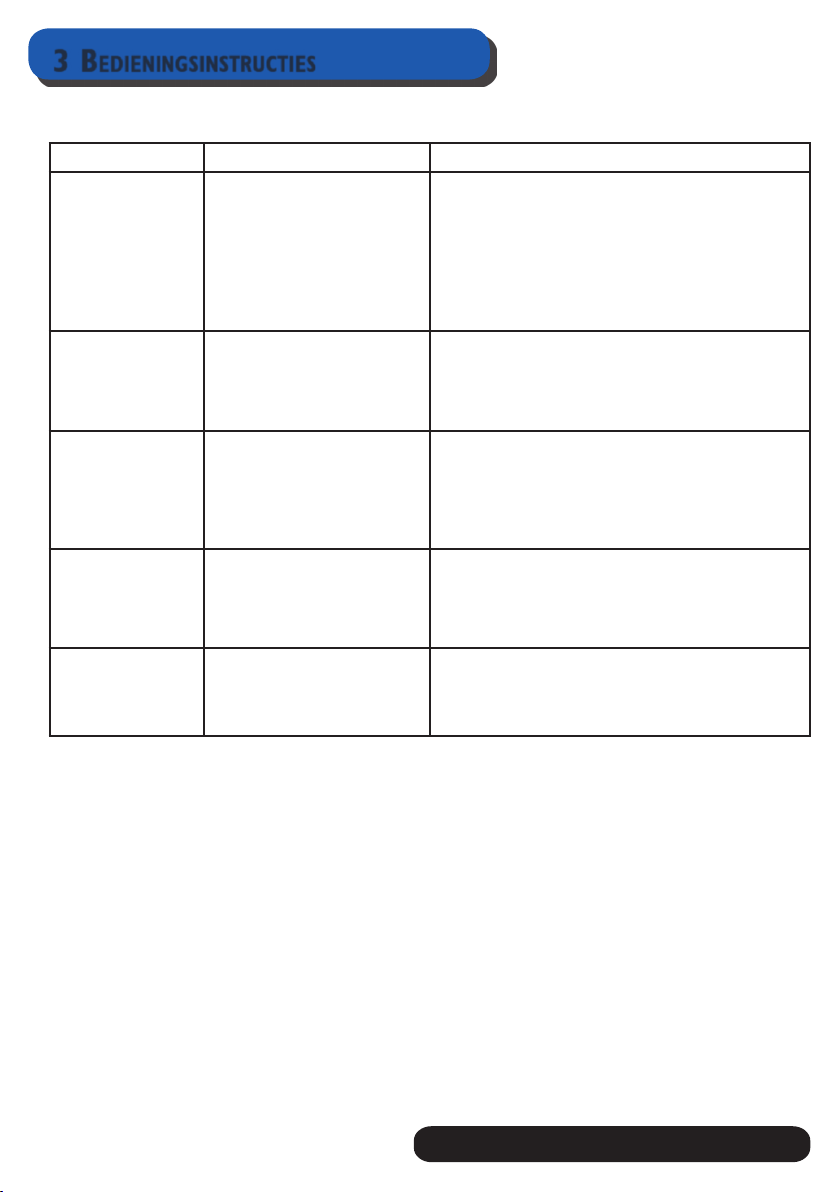

3.3.3 displAy error

If the display shows an error code / symbol, and the red LED ashes, consult the chart below to

determine the cause. Clear the problem as described below, then press START button to resume

normal operation. If the error persists, contact Service Centres at FP International B.v. (See page

3)

Error code Action

COVER Make sure covers are closed

DELTA T Contact your distributor or FPI for assistance

JAM / FILM END In case of jam, open display cover and remove jammed lm cafefully

3.3.4 moving

• Switch off the machine.

• Remove lm roll from machine

• Unlock the castors and move the machine to the desired place.

3.3.5 setting up

FP InternationalFP International

GB: Always remove the roll of lm before changing the

position of the stand.

DE : Entfernen Sie immer zuerst die Folie bevor Sie

die Position des Standes änderen.

FR: Retirer impérativement la bobine de lm avant de

changer la position du stand.

NL: Verwijder altijd eerst de folie alvorens de positie

van de stand te veranderen.

Bear in mind the requirements for a workplace. See “Workplace” on page 11.

• Set up the machine on a level surface.

• If the machine is on a stand lock all 4 casters with the integrated locking mechanisms

• Connect the machine to the mains.

PRO PAK’R User Manual Version 1.0 Page -21-

Page 22

3 operAting instructions

3.4 cleAning

Warning!

• During cleaning, the machine must be switched off.

• Electrical components should not come into contact with

water or other liquids.

As a rule, the machine does not need to be cleaned.

If required, the outside may be wiped down using a damp cloth and soapy water.

3.5 trAnsport/storAge

3.5.1 generAl

The machine is tted with castors to allow it to be moved rapidly from one workplace to

another. The castors are only suitable for short distances over level, hard factory oors.

3.5.2 storAge

No special instructions apply to storing the machine. A cool and dry area is the most suitable

environment for this purpose.

If the machine has been stored or idle for a length of time, it should be inspected by

maintenance personnel before being taken back into use.

3.6 commissioning

The machine is ready for use ex-factory and does not require any installation. Its rst use,

however, should be monitored by a technician, as should the rst operating session following

a major overhaul or long term storage.

Pay special attention to the following:

• Is there any damage (e.g. incurred during transport),

• Has the machine been set-up correctly (see page 16)

• Does the mains voltage conform to the rating on the identication plate (Page 27)?

• Are all moving parts (feed rollers) free?

Commissioning will generally be carried out by a specialist appointed by the manufacturer or

distributor

PRO PAK’R User Manual Version 1.0 Page -22-

FP International

Page 23

3 operAting instructions

3.7 repAir And mAintenAnce

Preventive maintenance.

The machine should be serviced every half year of particular importance are:

• Internal cleaning, external cleaning, visual check of wear parts.

Repairs may only be carried out by qualied service personnel of FP International. The

following parts can be carried out by maintenance personnel of the costumers:

Replacing blade, replacing cone tip, replacing wear strips, cleaning / replacing backing wheel.

3.7.1 replAcing blAdes / cone tip

3.7.1.1 Change Cone Tip. (See page 14)

Pull the cone off the blow pipe and replace a new cone tip.

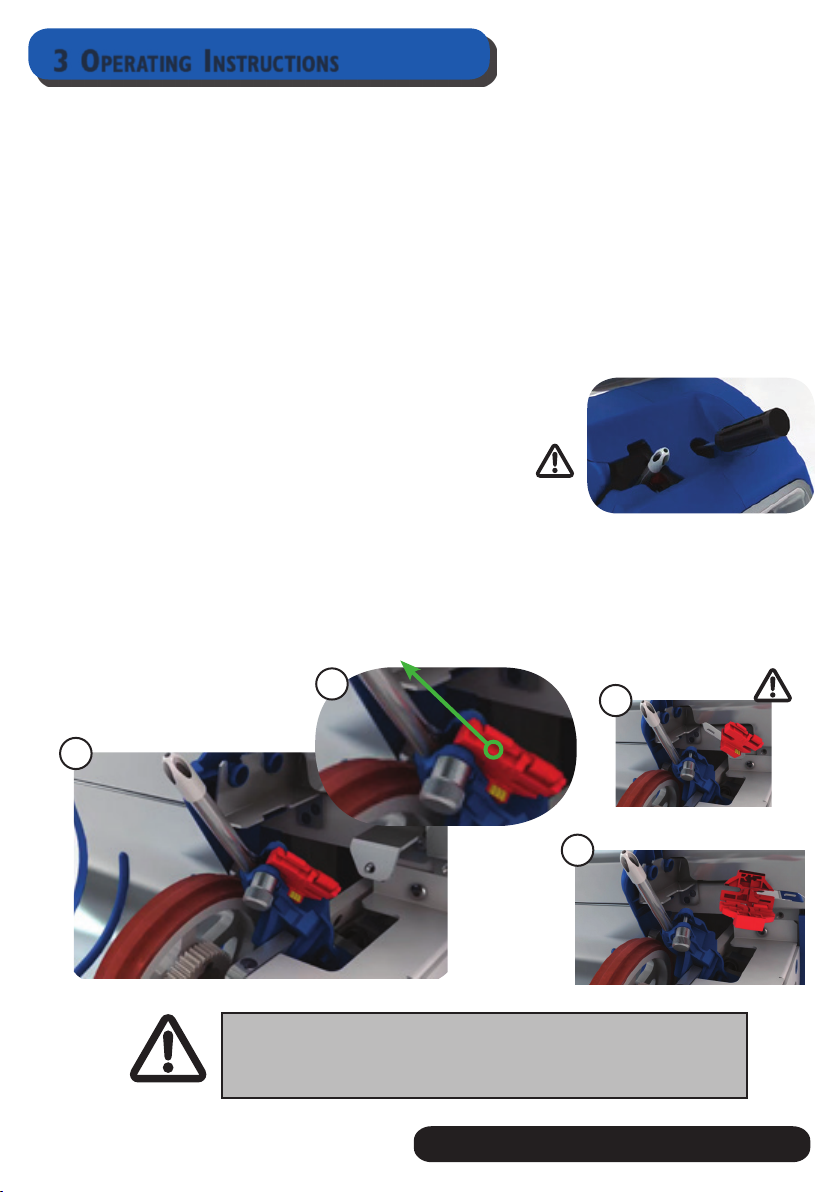

3.7.1.2 Replace blade or new cutting edge. (Be carefull, blade is

sharp.)

• If the lm jams frequently.

• After 100 lm rolls have been processed.

• If the blade is not cutting the lm properly or is making a

very rough cut.

Turn power OFF, unplug power cord, then wait 10 minutes for the machine to cool down.

Open display cover with slotted or Phillips screwdriver.

Unlock black screw. Slide the red bladeholder to the lltube (2), not possible to move the

bladeholder further, please rotate the blade (3 and 4). When the blade is dull on both sides,

please renew the blade.

2

3

1

4

RISK OF BURN

Before opening covers, turn power OFF, unplug power

cord, and wait 10 minutes for seal wheel to cool.

FP InternationalFP International

PRO PAK’R User Manual Version 1.0 Page -23-

Page 24

3 operAting instructions

3.7.3 replAcing weAr strips.

The Pro Pak’r has 2 wear strips, these strips transport the lm through the machine. These strip

can be removed when damaged / wear out.

3.7.4 cleAning bAcking wheel

Open Display Cover with Slotted or Phillips Screwdriver. Clean backing wheel with a soggy cloth

3.7.5 replAce bAcking wheel (pAge 15)

Open Display Cover with Slotted or Phillips

Screwdriver.

Remove the wearstrip guide, by pulling the guide

upwards.

Take a retaining plier to remove the circlip.

Remove backing wheel. Be carefull with the key.

remove the spurgear and place it on the new

backingwheel. Place backingwheel back on the

shaft.

3.7.6 extention wide film (optionAl)

If you use the wide rolls on a stand, please provide the machine with the extra extention.

Push the wide rill extention in the mandrel shaft (1). Lock it with the locking pin. (2)

1

2

PRO PAK’R User Manual Version 1.0 Page -24-

FP International

Page 25

3 operAting instructions

3.8 trouble shooting

Trouble Possible Problem Solution

No power to Pro

Pak’r machine

Film won’t run Film roll installed back-

Cushions are at,

do not hold air

Film jams frequently

Machine stops

automatically

Power cord unplugged

Power switch OFF

Toggle switch OFF

Fuse is blown

Display cover open

wards

Non-FPI lm installed

No RFID signal

Air ll tube not inside lm

Air pump not working

Seals leaking

Too much air ll

Blade is dull

Backing wheel are worn

Fill tube is worn

Cone tip is worn

Jam sensor not responding

Length Control set to

continuous

Plug power cord into Pro Pak’r and outlet

Turn power switch ON

Turn toggle switch ON

Replace Fuse on power inlet

Tighten display cover screw with screwdriver

Turn lm roll around

Install FPI lm roll

Turn roll, if not responding contact FPI for assistance

Reload lm onto ll tube

Contact FPI for assistance

Adjust seal temperature or clean backingwheel

Reduce air ll

Replace / reverse / or slide the blade.

Replace or clean backingwheel.

Replace ll tube.

Replace cone tip

Contact FPI for assistance

adjust length control. See page 20.

FP InternationalFP International

PRO PAK’R User Manual Version 1.0 Page -25-

Page 26

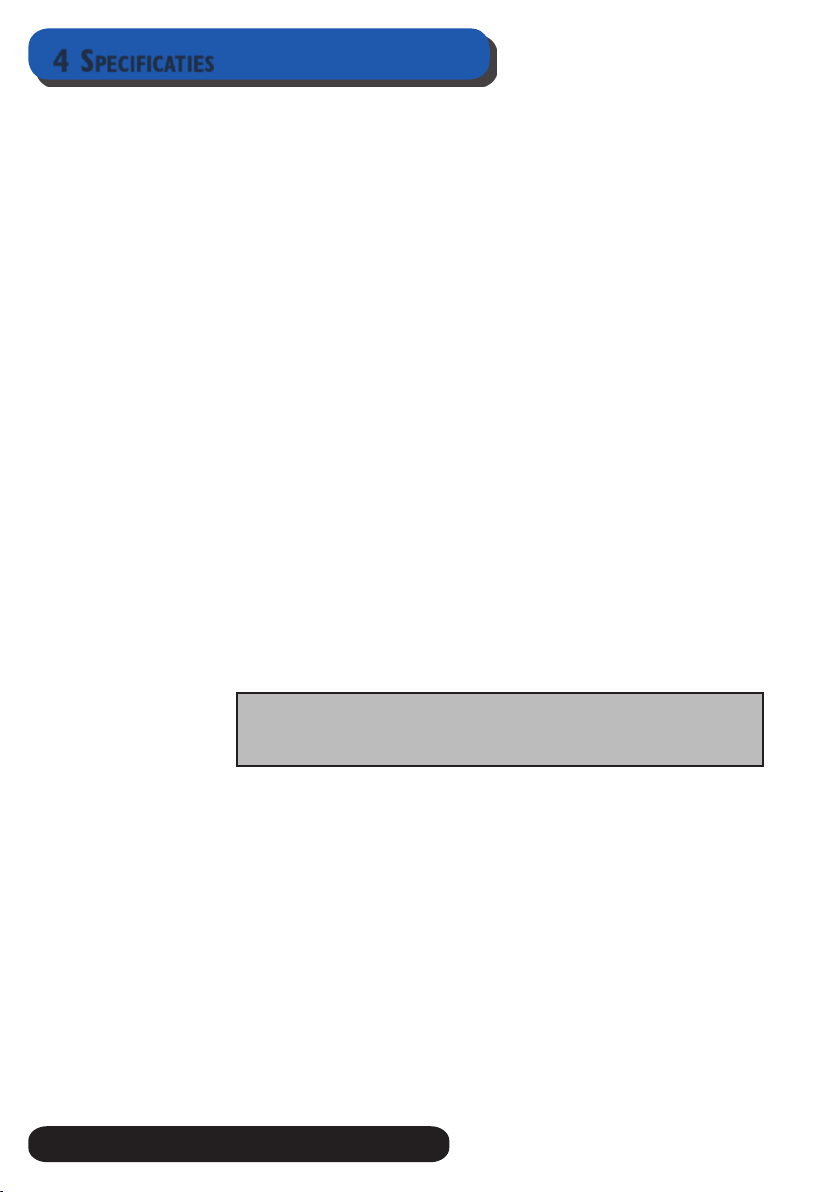

4 specificAtions

4.1 mAchine specificAtion

4.1.1 generAl

Speed: [m/min] Up to 23

Dimensions (length x width x

height): [mm] 350 x 330 x 350

Weight, approx.: [kg] 15

Maximum noise production: [dB(A)] < 70, as measured in the work place

Mains lead length: [m] 5

4.1.2 product to be processed

Contact the manufacturer or distributor for available film configurations exluded wide film kit:

Width: [mm] Max. 460

Core diameter: [mm] 77

Roll diameter: [mm] 280

Weight of roll: [kg] 7.7 – 15

Included wide lm kit (See page 8)

Width: [mm] Max. 750

Core diameter: [mm] 77

Roll diameter: [mm] 280

Weight of roll: [kg] 15.9-19

Recommended lm:

Brand: PRO PAK’R

Distributor: FP International (see “Service Centres” on page 3).

The machine was tested and functioned properly using the appropriate lm.

Caution!

Processing lm other than the recommended types may result

in problems.

4.2 electricAl specificAtion

Supply specication:

Voltage: [V] 230

Amperage fused: [A] 5 Type: Slow-blow

No. of conductors: 3 (1 phase, earth and neutral)

Earthing: required

Frequency: [Hz] 50 - 60

Other requirements: in conformity with EN 60204-1:1995 par 4.3.1.

The machine uses standard mains power

Machine rating:

Rated power: [kW] 0,48

Maximum current: [ A] 2

PRO PAK’R User Manual Version 1.0 Page -26-

FP International

Page 27

4 specificAtions

4.3 mAchine environment

Ambient temperature, operation: +5 to +40°C

During transport / storage: -25 to +55°C

Relative humidity (RH): 30% to 95%, non-condensing

Lighting: Normal room lighting.

The machine is not intended for outdoor use.

The machine is not intended for use in environments posing a risk of explosion.

4.4 directives And stAndArds Applied

This machine is marked with the CE-label, i.e. it is fully compliant with the requirements laid

down in the applicable European Directives on Health and Safety.

The “EC Declaration of Conformity” on page 30 states the Directives in question.

The “Declaration of Conformity” also lists the standards applied.

No lighting has been included with the machine.

FP InternationalFP International

PRO PAK’R User Manual Version 1.0 Page -27-

Page 28

5 indicAtions on the mAchine

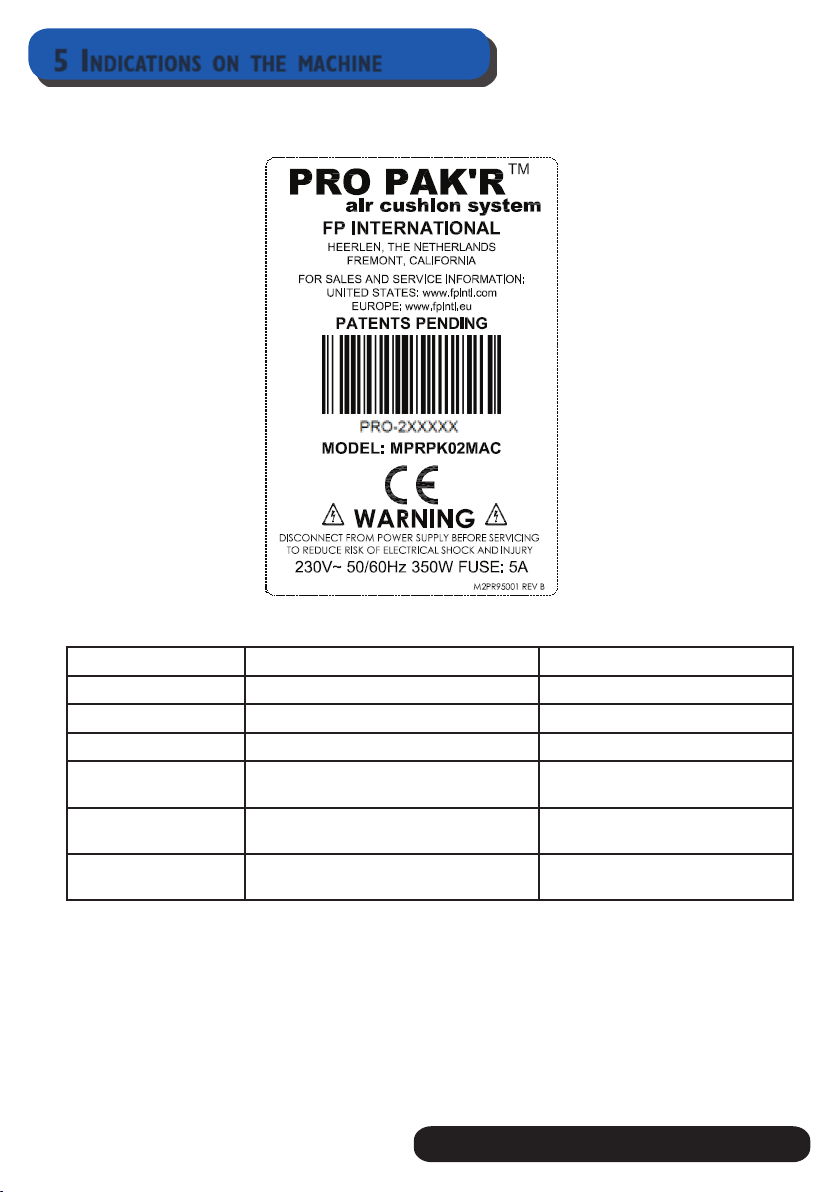

5.1 mAchine identificAtion plAte

explAnAtion of items:

Description : Data of this machine :

Type Model MPRPK02MAC

Serial nr. Serial number PRO-2XXXXX

Year Year of manufacture 2013

Voltage Voltage and frequency ratings 230 [V] / 50 [Hz]

Phases Number of supply phases 1

Full load Full load current 5 [A]

Some of the data on the Machine Identication Plate are specic to each machine and have therefore

been omitted from the above table. You can nd these data for your particular machine on its

identication plate.

230V / 50 Hz / 350 Watt / 5 Amp fuse

115V / 60Hz / 350 Watt / 5 Amp fuse (or closest higher available value)

FP International

PRO PAK’R User Manual Version 1.0 Page -28-

Page 29

5 indicAtions on the mAchine

5.2 wArnings

The following warning pictograms are present on the machine.

Pictogram Meaning Location

Dangerously high tension components inside

Danger of trapping-

hands and ngers

Beware hot surface

Beware your hands

PRO PAK’R User Manual Version 1.0 Page -29-

FP International

Page 30

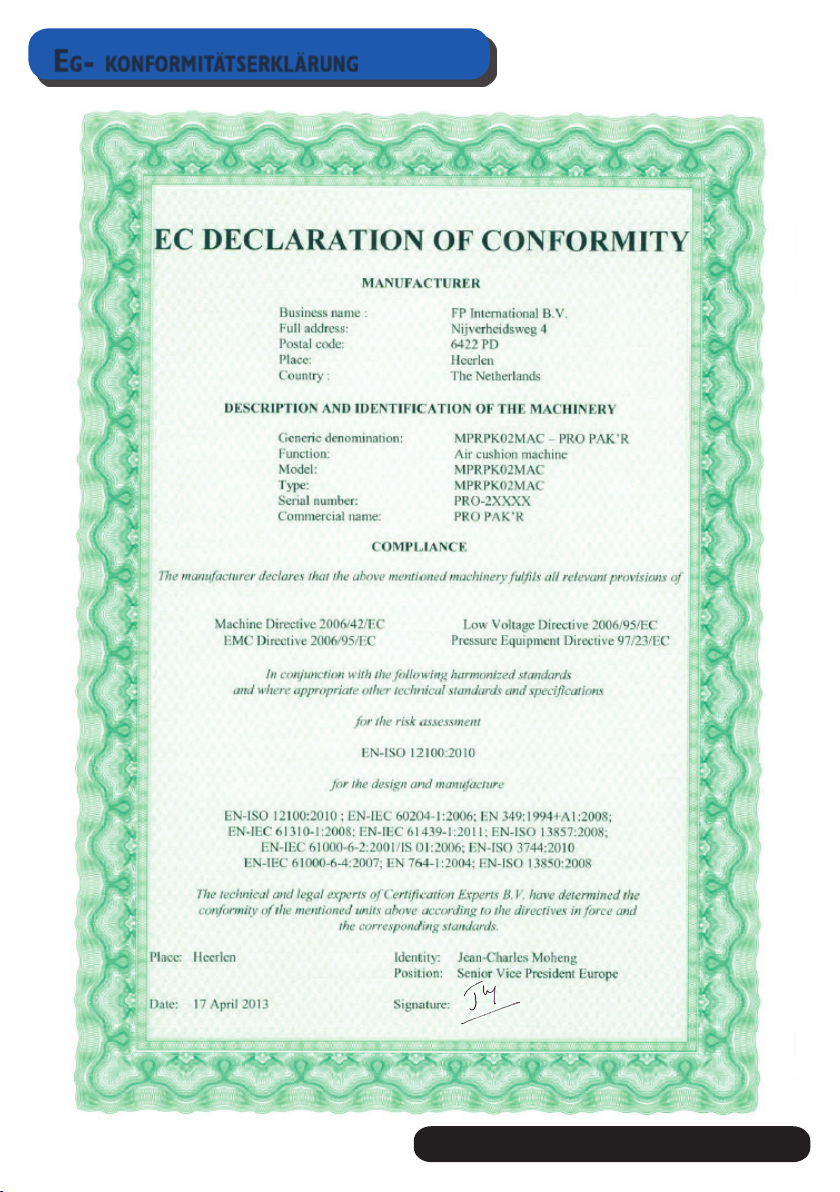

ec declArAtion of conformity

FP International

PRO PAK’R User Manual Version 1.0 Page -30-

Page 31

PRO PAK’R

BEDIENUNGSANLEITUNG

www.fpintl.eu

FP International

Never stop

PROgressing

Pro Pak´r bedienungsanleitun g version 1.0 Seite -1-

Page 32

PRO PAK’R

Luftkissenmaschine

FP International BV

HEERLEN

Niederlande

Pro Pak´r bedienungsanleitun g version 1.0 seite -2-

FP International

Page 33

Hinweise zu dieser Bedienungsanleitung

Ausgabe : Version 1.0

ORIGINAL-BEDIENUNGSANLEITUNG

Datum der Ausgabe : 04.03.2013

© Copyright : FP International BV, HEERLEN, THE NETHERLANDS 2013.

Ohne vorherige Zustimmung von FP International BV darf kein Teil dieser Publikation in irgendeiner

Form reproduziert werden. Davon ausgenommen sind Teile, die zum Zwecke der Vervielfältigung

oder Dokumentation gedacht sind, wie z.B. Kurzanleitungen und an der Maschine angebrachte oder

anzubringende Anleitungen.

MascHinenBezeicHnung

Diese Bedienungsanleitung gehört zu folgender Maschine:

Bezeichnung : PRO PAK’R

Modell : MPRPK02MAC

Die genaue Bezeichnung entnehmen Sie bitte den Angaben auf dem Typenschild der

Maschine und / oder der “EG- Konformitätserklärung” auf Seite 30.

der Hersteller

Diese Maschine wurde produziert von:

FP International B.V.

Nijverheidsweg 4

6422 PD Heerlen

Niederlande

service-zentrale

FP International B.V. (FPI)

Nijverheidsweg 4

6422 PD Heerlen

Niederlande

Tel. +31(0)45 566 7400

Fax. +31(0)45 566 7401

E-Mail info@fpintl.eu

www.fpintl.eu

FP InternationalFP International

Pro Pak´r bedienungsanleitun g version 1.0 Seite -3-

Page 34

inHalt

HINWEISE ZU DIESER BEDIENUNGSANLEITUNG 3

MASCHINENBEZEICHNUNG 3

HERSTELLER 3

SERVICE-ZENTRALE

VORWORT 5

BENUTZUNG DER BEDIENUNGSANLEITUNG 5

SCHREIBWEISEN 6

SERVICE UND INFORMATIONEN 6

GEWÄHRLEISTUNG UND HAFTUNG 7

1 EINLEITUNG 8

1.1 Verwendungszweck 8

1.2 Glossar: Begriffe und Terminologie 8

1.3 Modelle und Zubehör 8

1.3.1 Standardmodell und Zubehör 8

1.3.2 Nicht im Lieferumfang enthaltene Komponenten 9

2 SICHERHEIT 10

2.1 Einleitung 10

2.2 Sicherheitsmerkmale 10

2.3 Sicherheitsbestimmungen 10

2.4 Nicht bestimmungsgemäßer Gebrauch 10

2.5 Maschinenanwender 11

2.5.1 Bediener (Stufe 1) 11

2.5.2 Wartungspersonal (Stufe 2) 11

2.6 Arbeitsumgebung 11

2.7 Persönliche Schutzausrüstung 11

2.8 Notschalter 12

2.9 Warnhinweise an der Maschine 12

2.10 Brände und andere Notsituationen 12

3 BEDIENUNGSANLEITUNG 13

3.1 Aufbau und Bedienelemente 13

3.1.1 Konguration 13

3.1.2 Bedienung des Tastenfeldes 16

3.1.3 Tastenfeld-Symbole 16

3.2 Inbetriebnahme der Maschine 17

3.3 Einlegen der Folie 18

3.3.1 Allgemeine Hinweise zur Bedienung der Maschine 19

3.3.2 Ändern der Menü-Einstellungen 20

3.3.3 Fehlermeldungen 21

3.3.4 Versetzen der Maschine 21

3.3.5 Aufstellen und Anschließen 21

3.4 Reinigung 22

3.5 Transport/Lagerung 22

3.5.1 Allgemein 22

3.5.2 Lagerung 22

3.6 Inbetriebnahme 23

3.7 Reparatur und Wartung 23

3.7.1 Klingen / Kegelkopf austauschen 23

3.7.1.1 Kegelkopf wechseln 23

3.7.1.2 Klingen austauschen / neue Schneidkante 23

3.7.2 Verschleißleisten ersetzen 24

3.7.3 Führungsrad säubern 24

3.7.4 Führungsrad ersetzen 24

3.7.5 Verwendung von breiter Folie 24

3.8 Fehlersuche 25

4 TECHNISCHE DATEN 26

4.1 Maschinendaten 26

4.1.1 Allgemein 27

4.1.2 Zu verarbeitendes Produkt 26

4.2 Elektrische Daten 26

4.3 Maschinen-Umgebung 27

4.4 Anzuwendende Richtlinien und Normen 27

5 ANGABEN AUF DER MASCHINE 28

5.1 Typenschild 28

5.2 Warnhinweise 29

EG- KONFORMITÄTSERKLÄRUNG 30

Pro Pak´r bedienungsanleitun g version 1.0 seite -4 -

FP International

Page 35

vorwort

Diese Bedienungsanleitung beschreibt den täglichen Gebrauch und die Wartung von PRO PAK´R, einer

Maschine, die sowohl aus mechanischen als auch aus elektronischen Bauteilen besteht.

Details zu Wartungsarbeiten, die ausschließlich vom Wartungspersonal des Herstellers vorgenommen

werden dürfen, sind in dieser Anleitung bewusst ausgespart worden.

Diese Anleitung ist ein wesentlicher Bestandteil dieses Gerätes und sollte sorgfältig

aufbewahrt werden. Sie enthält Informationen, die zu einem späteren Zeitpunkt hilfreich

bzw. erforderlich sein könnten, zum Beispiel bei der Durchführung von Reparatur- und

Wartungsarbeiten. Es ist zu empfehlen, eine Ausfertigung dieser Anleitung in der Nähe

der Maschine aufzubewahren und eine andere abzuheften, z.B. zusammen mit anderen

technischen Unterlagen. Der Hersteller könnte Ihnen eine zusätzliche Ausfertigung zur

Verfügung stellen.

Sollte ein Dritter das Eigentum an dieser Maschine übertragen bekommen, muss dieser

die Bedienungsanleitung mit der Maschine zusammen erhalten.

PRO PAK´R ist mit einem USB-Key ausgestattet (ausschließlich mit FAT-formatiertem

USB-Stick kompatibel).

Auf dem USB-Key ist diese Bedienungsanleitung ebenfalls in verschiedenen Sprachen

gespeichert.

Benutzung der Bedienungsanleitung

Die Anleitungen in dieser Bedienungsanleitung sind nach unterschiedlichen Benutzergruppen

geordnet. Spezische Angaben zu diesen Benutzergruppen sind in Kapitel 2 aufgeführt.

Die Denition zu den in der linken Spalte aufgeführten Begriffen ist in der rechten Spalte zu nden.

Anwender: Sammelbegriff für alle Personen, die mit oder an der Maschine arbeiten.

Bediener: Jeder, der die Maschine täglich benutzt.

Relevante Kapitel: Einleitung, Sicherheit und Bedienungsanleitung.

Wartungspersonal: Qualizierte Personen, die Erfahrung mit den beschriebenen

Relevante Kapitel: alle

Alle nicht in dieser Anleitung enthaltenen Arbeitsschritte müssen durch FP International BV (FPI)

selbst ausgeführt werden oder dürfen erst nach Rücksprache mit FPI vorgenommen werden.

Der Begriff „Produkt“ wird in dieser Bedienungsanleitung im Hinblick auf die durch die Maschine zu

verarbeitenden Produkte verwendet und bezieht sich nicht auf die Maschine selbst.

Die in dieser Anleitung verwendeten Abbildungen dienen einzig und allein Illustrationszwecken.

Sie sollen die im Text enthaltenen Angaben spezizieren, also z.B. die Position und Funktion von

Steuerungseinrichtungen und anderen Komponenten verdeutlichen. Das tatsächliche Layout und die

Dimensionen können von den Abbildungen abweichen. Technische Zeichnungen können auf Wunsch

beigefügt oder gesondert zur Verfügung gestellt werden.

FP InternationalFP International

Arbeitsgängen haben und über die entsprechenden Mittel zur

Ausführung verfügen.

Pro Pak´r bedienungsanleitun g version 1.0 Seite -5-

Page 36

scHreiBweisen

Die Bereiche im Text, die sich auf die Gesundheit von Sicherheit von Personen beziehen, sind fett

gedruckt, mit Ausnahme des Kapitels SICHERHEIT. Die folgenden Warnsymbole werden verwendet:

Achtung!

Dieses Piktogramm weist auf mögliche Beschädigungen hin, die

an dem Produkt oder der Maschine entstehen könnten.

Warnung!

Dieses Piktogramm weist auf mögliche Verletzungsgefahren hin.

service und inforMationen

Für nähere Informationen zu dieser Maschine, wenden Sie sich bitte an den Hersteller oder Ihren

Händler (siehe “Hinweise zu dieser Bedienungsanleitung”, Seite 3).

Durch Scannen des QR-Codes

erhalten Sie Zugang zu Videos, die

die meisten in dieser Anleitung

beschriebenen Vorgänge zeigen.

Pro Pak´r bedienungsanleitun g version 1.0 seite -6-

FP International

Page 37

gewäHrleistung und Haftung

Die Gewährleistung ist an die folgenden Bedingungen geknüpft, sofern keine anders

lautende schriftliche Vereinbarung getroffen wurde:

• Der Hersteller übernimmt eine Gewährleistung im Hinblick auf den Originalbetreiber für einen

Zeitraum von 12 Monaten ab dem Lieferzeitpunkt des Produktes.

• Eventuelle Mängel müssen dem Hersteller vor Ablauf des Gewährleistungszeitraums mitgeteilt

werden.

- Die Gewährleistung deckt Mängel ab, die:

- während des normalen Betriebs der Maschine/Einheit auftreten

- aus Konstruktions- oder Materialfehlern resultieren

- aufgrund von mangelnder Fachkenntnis seitens des Herstellers entstehen

• Die Gewährleistung erstreckt sich nicht auf aus folgenden Gründen resultierende Mängel:

- normale Abnutzungserscheinungen

- unsachgemäße oder zweckwidrige Verwendung

- Verwendung von nicht ausdrücklich zugelassenen Verbrauchsmaterialien

• Sollten Mängel auftreten, wird der Hersteller:

- die betreffenden Teile ersetzen. Das Eigentum an den ersetzten Teilen geht wieder auf den Hersteller

über.

- die Mängel beheben

- sich für den Austausch des Gerätes entscheiden, falls eine Reparatur aus spezischen Gründen nicht in

Betracht kommt. Der Kunde muss dem Hersteller die Gelegenheit einräumen, die Mängel zu beheben.

• Von Dritten eingebaute Bauteile unterliegen der Gewährleistung bei den betreffenden Herstellern.

Die in diesem Fall anwendbaren Gewährleistungsbedingungen unterscheiden sich eventuell von den im

Vorfeld genannten.

• Der Hersteller behält sich das Recht vor, ohne vorherige Ankündigung Veränderungen an der

Maschine/Einheit vorzunehmen.

Bitte beachten Sie die folgenden Haftungsbeschränkungen des Herstellers im Rahmen der

Gewährleistungsbedingungen:

Der Hersteller übernimmt keinerlei Haftung für potenziell gefährliche Situationen, Unfälle oder

Schäden die aufgrund der Nichtbeachtung von Warnungen oder Anweisungen entstanden sind, die auf

der Maschine/Einheit angebracht oder in dieser Bedienungsanleitung enthalten sind.

Beispiele für Fälle, in denen der Hersteller keine Haftung übernimmt:

• unsachgemäße oder zweckwidrige Verwendung oder unprofessionelle Wartung

• Benutzung für Zwecke oder unter Umständen, die nicht in dieser Anleitung angegeben sind

• Verwendung von nicht zugelassenen Bauteilen

• ohne vorherige Genehmigung ausgeführte Reparaturarbeiten

• Umbauten an der Maschine/Einheit, z.B.:

- Umbauten am Steuerungssystem

- Schweißarbeiten, mechanische Veränderungen

- Anbauten an der Maschine/Einheit oder am Steuerungssystem

Außerdem übernimmt der Hersteller keine Haftung:

• falls der Kunde seinen Verpichtungen gegenüber dem Hersteller (nanzieller oder sonstiger Art)

nicht nachgekommen ist

• für Folgeschäden, die durch Mängel oder Ausfälle der Maschine/Einheit verursacht

wurden (z.B. Schäden an (zu verarbeitenden) Produkten, unbeabsichtigtes

Herunterfahren, Produktionsverzögerungen).

FP InternationalFP International

Pro Pak´r bedienungsanleitun g version 1.0 Seite -7-

Page 38

1 einleitung

1.1 verwendungszweck

Die Maschine wird zur Herstellung von Luftkissen verwendet. Die luftbefüllten Kissen können in der

jeweils gewünschten Anzahl abgetrennt und dann als Füllmaterial zu Verpackungszwecken verwendet

werden.

Siehe “Zu verarbeitendes Produkt” auf Seite 22 für detaillierte Angaben über die zur Verarbeitung

geeigneten Foliensorten.

1.2 glossar: Begriffe und terMinologie

Pedal: Ein Steuermechanismus (Transport und Versiegelung der Folie, Start der vorher

Display: Anzeige auf dem Bildschirm

Bedienfeld: Per Tastendruck einstellbare Anzeige, um Steuerfunktionen vorzunehmen.

RFID: Jede PRO PAK´R-Folienrolle ist mit einem RFID-Tag ausgerüstet, der

Erläuterungen zu den Steuerungselementen nden Sie im Abschnitt “Bedienungsanleitung” auf

Seite 13.

1.3 Modelle und zuBeHör

1.3.1 standardModell und zuBeHör

Die Standardversion besteht aus der komplett montierten Einheit inklusive:

• Maschine (zur Luftbefüllung) mit Netzkabel

• Folie mit >500mm Breite (optional)

• Gestell (optional)

• Pedal (optional)

• Sensor (optional)

eingestellten Programme) in Form eines Fußschalters

Informationen über die optimale Versiegelungstemperatur und Luftbefüllung

enthält.

Warnung!

Falls Folien > 500 mm Breite eingesetzt werden sollen,

muss das Set für breite Folien verwendet werden.

In diesem Fall lesen Sie bitte die Anleitung aufmerksam

Pro Pak´r bedienungsanleitun g version 1.0 seite -8 -

durch.

Set für Folienrollen mit:

• einer Breite von mehr als 500 mm

• einem Gewicht von mehr als 15 kg

FP International

Page 39

1 einleitung

PRO PAK’R

Maschine

Set für breite Folien

(optional)

Benutzen Sie das Set für

breite Folien (> 500 mm).

PRO PAK’R mit Gestell

1.3.2 nicHt iM lieferuMfang der MascHine entHaltene koMponenten:

Nicht im Lieferumfang enthalten:

• Arbeitsplatz zum Verpacken: Förderband, Tisch etc.

Achtung!

Alle in der Anleitung enthaltenen Angaben zu diesen

Komponenten dienen ausschließlich zu Informationszwecken.

Die aktuellen Informationen und Hinweise des Anbieters der

jeweiligen Komponenten können von den in dieser Anleitung

enthaltenen Informationen abweichen und haben diesbezüglich

Vorrang.

FP InternationalFP International

Pro Pak´r bedienungsanleitun g version 1.0 Seite -9-

(optional)

Page 40

2 sicHerHeit

2.1 einleitung

Bei der Entwicklung und Herstellung dieser Maschine wurde großer Wert auf

Gebrauchssicherheit und Wartungsfreundlichkeit gelegt. Gebrauchssicherheit besteht, wenn

die Maschine entsprechend dieser Anleitung genutzt wird, unter den beschriebenen Umständen

und unter Befolgung aller Hinweise zur Bedienung. Dementsprechend ist es unerlässlich, diese

Anleitung aufmerksam zu lesen und zu befolgen, und zwar von jeder Person, die das Gerät

verwenden oder warten wird. Wird die Maschine innerhalb eines Unternehmens mit mehreren

Angestellten verwendet, ist der Arbeitgeber dafür verantwortlich, dass alle Personen, die die

Maschine bedienen, die Bedienungsanleitung verinnerlicht haben und befolgen.

Zusätzliche Sicherheitsbestimmungen können innerhalb des Unternehmens oder in dem Land, in

dem die Maschine zum Einsatz kommt, bestehen. Meist beziehen sich diese auf die Erhaltung der

Gesundheit und Sicherheit des Bedienpersonals.

Diese Bedienungsanleitung geht nicht darauf ein, wie mit derartigen Bestimmungen umzugehen

ist, aber es sind alle relevanten Informationen enthalten, die zur Verwendung der Maschine

notwendig sind. Im Zweifelsfall wenden Sie sich bitte an die zuständigen Behörden Ihres Landes

oder an den Arbeitsschutzbeauftragten Ihres Unternehmens.

In dieser Anleitung wird unterschieden zwischen normalem Gebrauch (siehe

„Bedienungsanleitung“ auf Seite 15) und Wartungsarbeiten, die an dieser Maschine vorgenommen

werden. Der Grund dafür ist, dass Wartungstätigkeiten andere Anforderungen an das Personal

stellen als die normale Verwendung der Maschine, insbesondere hinsichtlich der Sicherheit.

Die grundlegenden Instandhaltungsmaßnahmen, die zusätzlich zu den normalen

Bedienungshinweisen beschrieben werden, können von qualizierten Mitarbeitern von FP

International durchgeführt werden. Sämtliche Maßnahmen, die nicht unter dem Abschnitt

„Bedienungsanleitung“ aufgeführt sind, dürfen nur von hinreichend qualiziertem Fachpersonal

vorgenommen werden.

Die Komponenten, mit denen man Zugang zu normalerweise bewusst nicht zugänglichen

Maschinenbauteilen oder Funktionen erhält, dürfen nicht zusammen mit der Maschine oder in

deren Nähe aufbewahrt werden. Nur Personen, die über die notwendige Fachkenntnis verfügen,

dürfen Zugang zu diesen Komponenten haben.

2.2 sicHerHeitsMerkMale

Die Maschine ist mit folgenden Sicherheitseinrichtungen ausgestattet:

• Gehäuseabdeckung: Die Maschine startet nicht, so lange die Abdeckung geöffnet ist.

• Folieneinzugstaste: Die Einzugsrollen drehen sich nur, wenn diese Taste gedrückt wird

• Notfall-Stopp (siehe “Notschalter” auf Seite 12)

2.3 sicHerHeitsBestiMMungen

• Kinder und Tiere von der Maschine fern halten!

• Nicht in die Maschine greifen, während sie in Betrieb bzw. angeschaltet ist.

• Auch wenn die Maschine gerade nicht verwendet wird, kann sie doch angeschaltet sein, d.h. es

besteht die Gefahr, dass sie automatisch startet. Nur in Kombination mit Sensor oder Pedal.

• Sicherheitseinrichtungen dürfen nicht entfernt oder deaktiviert werden.

• Sorgen Sie für eine saubere und frei zugängliche Arbeitsumgebung.

• Sorgen Sie für eine angemessene Beleuchtung.

• Die Gerätesicherheit könnte bei verlängerter Laufzeit beeinträchtigt werden. Sorgen Sie für

eine regelmäßige Wartung der Maschine.

• Die Maschine darf auf keinen Fall benutzt werden, wenn Sicherheitseinrichtungen beschädigt

sind oder Fehlfunktionen aufweisen. Stellen Sie sicher, dass die Maschine umgehend repariert

wird.

Pro Pak´r bedienungsanleitun g version 1.0 seite -10-

FP International

Page 41

2 sicHerHeit

2.4 Nicht bestimmungsgemäßer gebrauch

Bitte beachten Sie, dass die Maschine nicht für den folgenden Zweck verwendet werden kann:

• Verarbeitung von Materialien, die nicht ausdrücklich in dieser Anleitung zur Verarbeitung

zugelassen sind.

2.5 Maschinenanwender

2.5.1 Bediener (stufe 1)

Hinsichtlich der Betriebssoftware wird diese Benutzergruppe die Arbeitsschritte in den

“Operator”-Menübereichen ausführen.

Die Maschine darf nur von Erwachsenen bedient werden, die sich mit den Kapiteln „Sicherheit“

und „Bedienungsanleitung“ vertraut gemacht haben und ihre Tätigkeit nach diesen Vorgaben

ausrichten.

Eine spezielle Ausbildung ist nicht erforderlich.

Allerdings sollte das Bedienpersonal bereits im Vorfeld Erfahrungen im Umgang mit dieser Art

von Geräten gesammelt haben.

Im Allgemeinen wird der Bediener die folgenden Arbeitsschritte ausführen:

• neue Folienrollen einlegen

• Folienstreifen herstellen

• die voreingestellten Parameter auswählen und anwenden (Voreinstellungen sind nur vom

technischen Betreuer vorzunehmen.)

• die Maschine säubern (Außenächen)

2.5.2 wartungspersonal (stufe 2)

Hinsichtlich der Betriebssoftware wird diese Benutzergruppe die Tätigkeiten in den “Service”Menübereichen ausführen.

Das Wartungspersonal sollte sich der zusätzlichen Risiken bei dieser Art von Tätigkeiten bewusst

sein. Daher sollte das Wartungspersonal zusätzlich zu den o.g. Anforderungen an die „Operators“

auch noch die folgenden Voraussetzungen erfüllen:

• über ein HND-Diplom (Higher National Diploma) in einem relevanten Fachgebiet bzw.

gleichwertige Berufserfahrungen verfügen

• Erfahrung in der Wartung von Maschinen haben

• über die notwendigen technischen Mittel verfügen (z.B. Werkzeuge und andere Messgeräte).

2.6 arBeitsuMgeBung

Der Denition und den Anforderungen an die Arbeitsumgebung unterliegt ein Bereich von bis

zu einem Meter Entfernung von der Maschinenvorder- und Rückseite. Dieser Bereich bietet

genügend Platz für alle vorzunehmenden Arbeitsschritte. Außerdem kann die Maschine z.B. über

einem Förderband platziert werden.

2.7 persönlicHe scHutzausrüstung

Zur Bedienung dieser Maschine ist keine persönliche Schutzausrüstung erforderlich.

FP InternationalFP International

Pro Pak´r bedienungsanleitun g version 1.0 Seite -11-

Page 42

2 sicHerHeit

2.8 notscHalter

Um die Maschine in einer Notsituation so schnell wie

möglich anhalten zu können, wurde sie mit einem gut

sichtbaren, leuchtend roten Notschalter ausgerüstet.

Sobald dieser Notschalter gedrückt wird, hält die

Maschine an.

Der Schalter bleibt daraufhin mechanisch gesperrt,

um einen unbeabsichtigten Neustart der Maschine zu

verhindern.

Bei Personenschäden können somit unverzüglich

Erste-Hilfe-Maßnahmen eingeleitet werden.

Zusätzlich sollten umgehend die entsprechenden

sonstigen Notfallschritte ausgeführt werden.

Sobald die Notsituation unter Kontrolle ist, kann der

Notschalter entsperrt werden. Die Maschine wird nicht automatisch neu starten, sondern muss

auf die gewohnte Art und Weise wieder in Betrieb genommen werden.

Der Notschalter kann auch in anderen plötzlich auftretenden Situationen verwendet werden, z.B.

wenn die Maschine nicht ordnungsgemäß arbeitet oder es zu einem Folienstau kommt.

Empfehlungen:

• Neues Bedienpersonal sollte sich zunächst mit der Benutzung des Notschalters vertraut

machen.

• Die Maschine sollte regelmäßig im Hinblick auf ihre ordnungsgemäße Funktionsweise überprüft

werden.

• Der Notschalter darf niemals entsperrt werden, bevor die Maschine wieder absolut sicher

benutzt werden kann. Immer erst die Person ausndig machen, die den Notschalter betätigt hat

und den Grund dafür in Erfahrung bringen.

2.9 warnHinweise an der MascHine

Die Warnhinweise an der Maschine müssen immer deutlich lesbar sein. Sollte das Schild abgenutzt

sein, bitte ersetzen.

Die entsprechenden Warnhinweise sind unter „Warnhinweise“ auf Seite 29 aufgeführt.

Die in Frage kommenden Risiken werden in den Abschnitten zur Bedienung und Wartung näher

erläutert.

2.10 Brände und andere notsituationen

Für Brände und andere Notsituationen gelten keine besonderen Vorschriften. Alle

herkömmlichen Löschmittel können verwendet werden.

Pro Pak´r bedienungsanleitun g version 1.0 seite -12-

FP International

Page 43

3 Bedienungsanleitung

Bevor die Maschine in Betrieb genommen werden kann, muss sich das Bedienpersonal mit dem

Inhalt des Abschnitts über die Sicherheit vertraut machen. Dieses Kapitel ist für das Bedienpersonal

gedacht, d.h. den im Abschnitt „Bediener“ auf Seite 11 beschriebenen Personenkreis. Alle anderen

als die hier aufgeführten Tätigkeiten dürfen nur vom Wartungspersonal ausgeführt werden (siehe

“Wartungspersonal” auf Seite 11).

Warnung!

Bevor die Maschine in Betrieb genommen werden kann, muss

sie vom Wartungspersonal freigegeben werden.

3.1 aufBau und BedieneleMente

3.1.1 konfiguration

Die Maschine ist wie folgt konguriert:

PRO PAK’R

Maschine

Schalter /

Stecker

Set für breite Folien

Siehe Seite 8

FP InternationalFP International

PRO PAK’R mit Gestell

(optional)

Pro Pak´r bedienungsanleitun g version 1.0 Seite -13-

Page 44

3 Bedienungsanleitung

vorderansicHt rückansicHt

1

7

4

3

2

Rollenhalter

1

8

6

5

Pro Pak´r bedienungsanleitun g version 1.0 seite -14-

Notschalter

2

Netzkabel, Haupt-An-und-

3

Ausschalter und Sicherung

Zubehör-Anschlussbuchse

4

Bedienfeld

5

Befüllungsstutzen

6

(Kegelkopf)

Autoindex-Sensor

7

Schraubzugang

8

Display-Abdeckung

FP International

Page 45

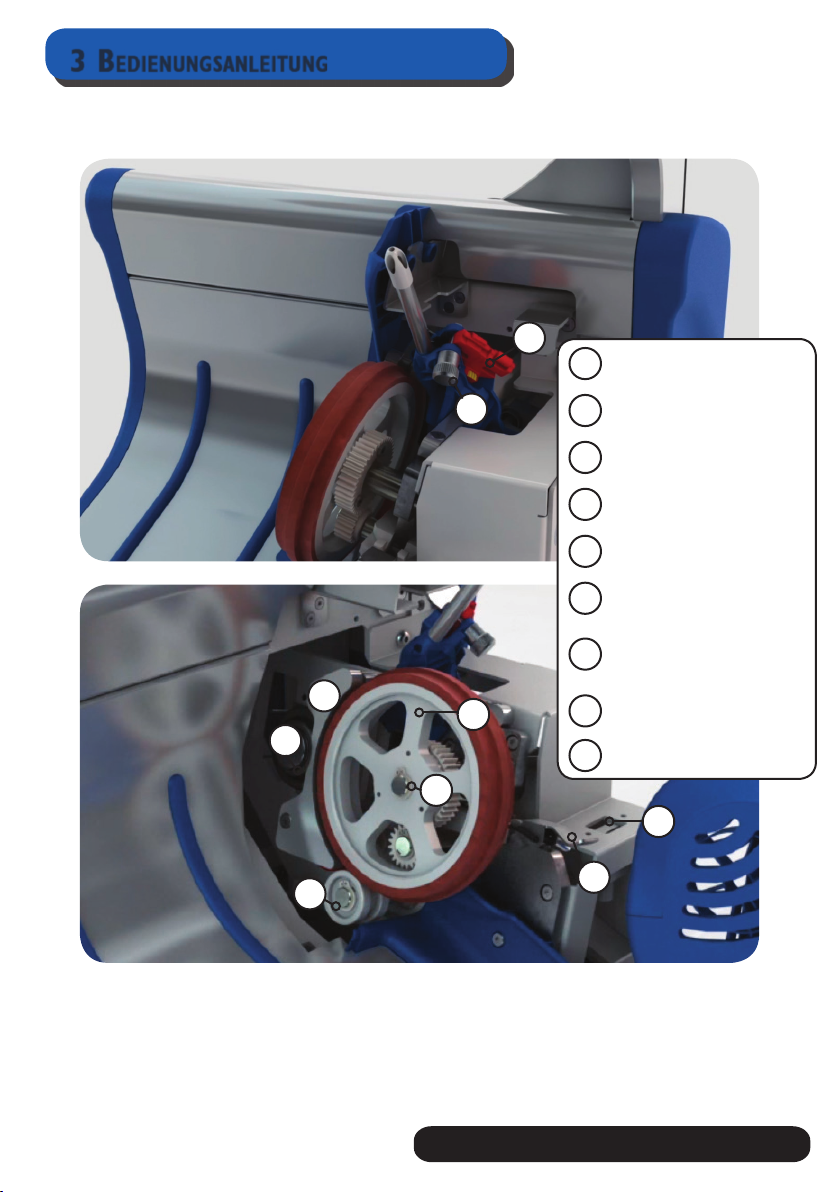

3 Bedienungsanleitung

1

Klingenhalter

1

2

8

4

7

Schwarzer Knopf

2

Sicherungsring Führungsrad

3

Führungsrad

4

Verriegelungshebel

5

Vorschubrolle

6

Versiegelungsrad /

7

Heizelement

Folienführung

8

USB-Anschluss

9

3

9

5

6

FP InternationalFP International

Pro Pak´r bedienungsanleitun g version 1.0 Seite -15-

Page 46

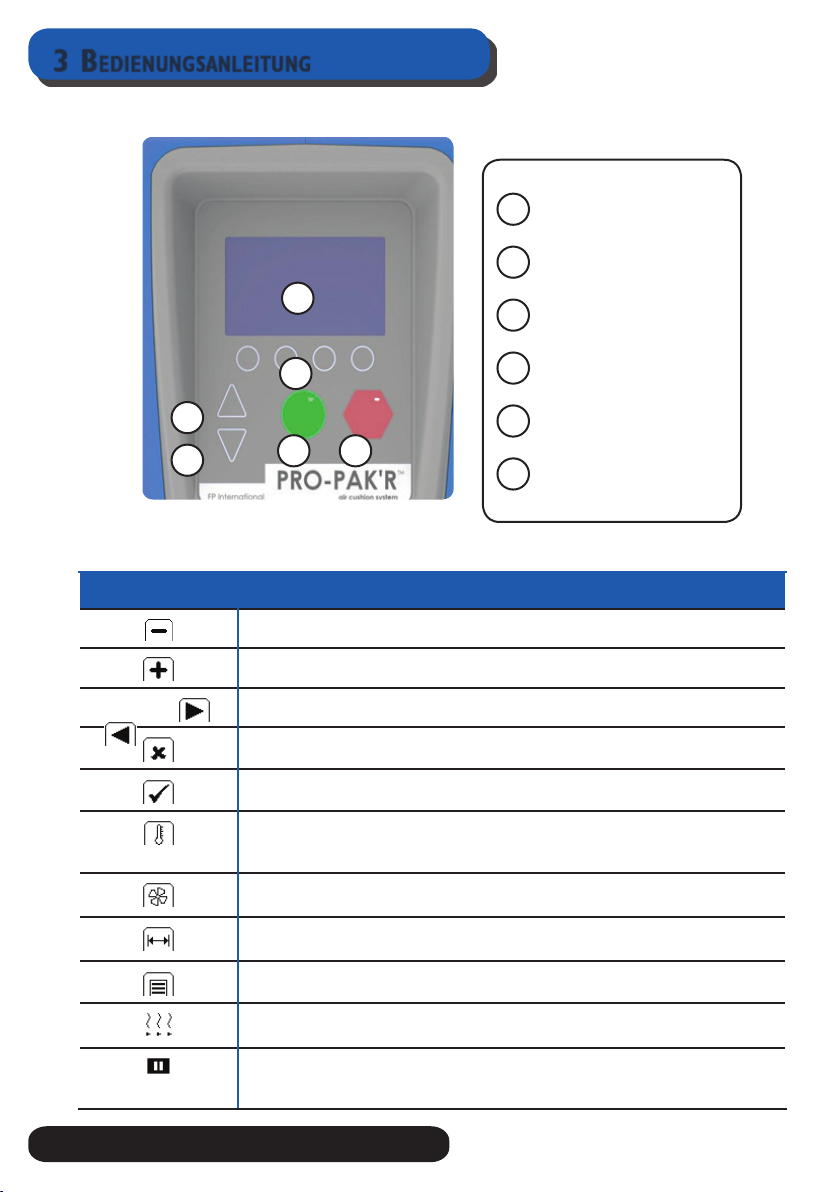

3 Bedienungsanleitung

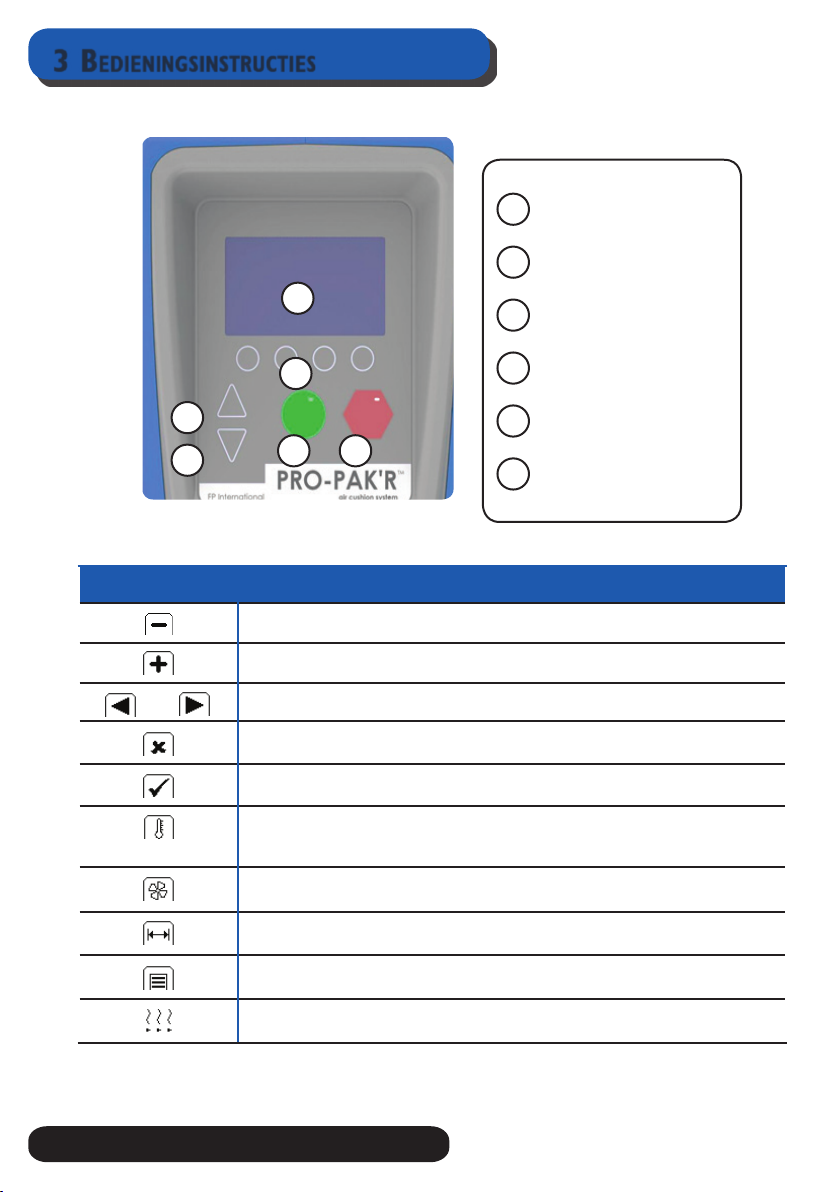

3.1.2 Bedienung des tastenfeldes

Displayanzeige

1

4 Menütasten

2

1

2

3

4

3.1.3 tastenfeld-syMBole

status-syMBol Bedeutung

5 6

Symbol für Verringerung

Symbol für Erhöhung

Bedienung der Menüanzeige

Symbol für Abbrechen / Löschen

Symbol für Bestätigung

Temperatursteuerung des Versiegelungsrades, welches die Vorder- und Rückseite

der Folienbahn verschweißt. Die Menütaste unterhalb des Symbols betätigen, um die

Versiegelungstemperatur zu steuern.

Anzeige des Befüllungsgrades der Luftkissen. Die Menütaste unterhalb des Symbols

betätigen, um den Befüllungsgrad zu steuern.

Anzeige der Länge der Luftkissenketten. Die Menütaste unterhalb des Symbols betätigen,

um die Länge der Luftkissen festzulegen.

Menüanzeige. Die Menütaste unterhalb des Symbols betätigen, um ins Menü zu gelangen.

Vorschubtaste

3

Rücklauftaste

4

Starttaste

5

Stopptaste

6

Anzeige des Heiz- bzw. Abkühlvorganges der Maschine.

Standby-Anzeige. Wenn PRO PAK´R in der angegebenen Zeit (“…”) nicht benutzt wird,

wechselt das Gerät in den Standby-Modus. Um ins Menü zurück zu gelangen, eine beliebige Taste betätigen.

Pro Pak´r bedienungsanleitun g version 1.0 seite -16-

FP International

Page 47

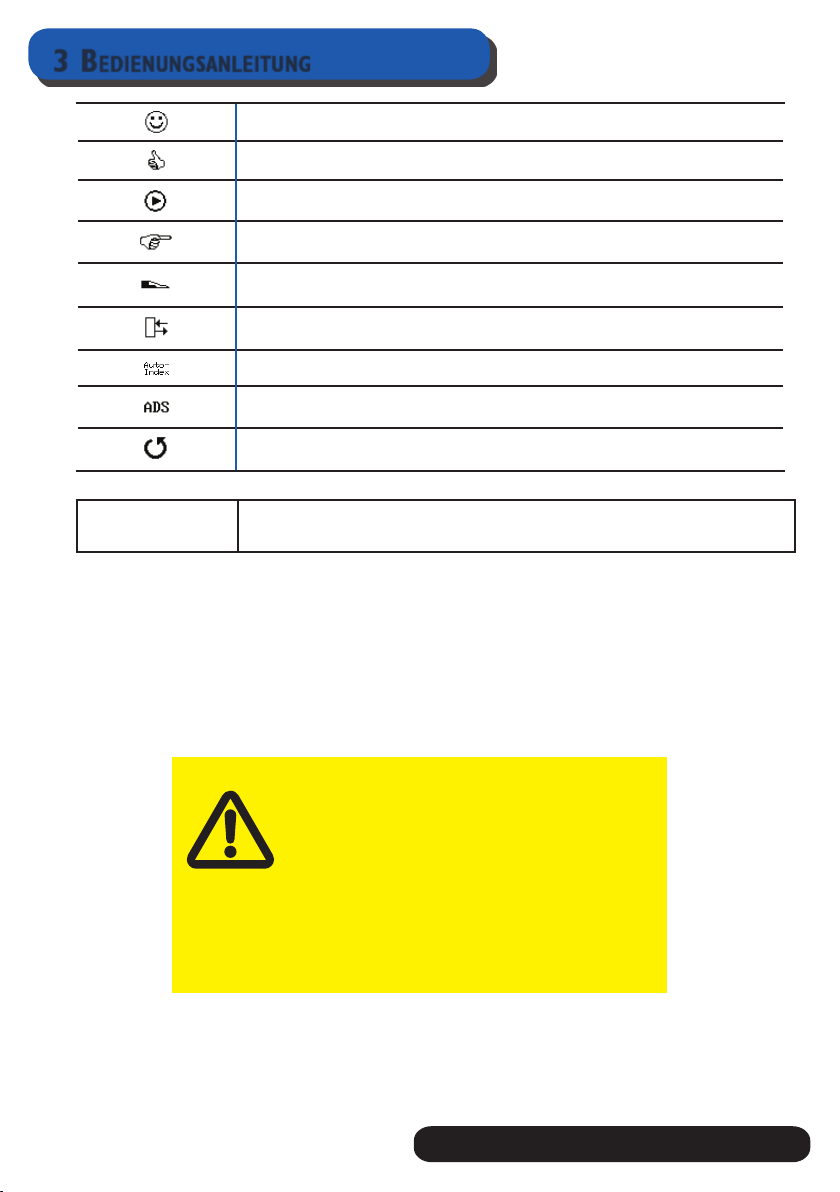

3 Bedienungsanleitung

Anzeige des Bereitschaftszustandes der Maschine

Symbol für laufenden Betrieb der Maschine

Menüanzeige für Wechsel des Betriebsmodus

Symbol für Handbetrieb

Symbol für Fußschalterbetrieb

Symbol für Binärmodus / Sensormodus

Symbol für Automatikmodus

Symbol für ADS-Modus

Symbol für Wiederherstellen. Die Taste unter dem Wiederherstellen-Symbol drücken,

um die Funktion anzusteuern.

NO TAG

(Kein TAG)

Durch Betätigung der Start-Taste kann der Fehler eventuell behoben

werden, ansonsten bitte die Folienrolle wenden.

3.2 inBetrieBnaHMe der MascHine

Stellen Sie sicher, dass die Maschine ordnungsgemäß aufgestellt wurde.

• Die Maschine kann auf einem Gestell angebracht (optional) oder auf einem stabilen Tisch platziert

werden.

• Schließen Sie das beigefügte Netzkabel auf der Rückseite der Maschine an.

• Verbinden Sie das Netzkabel mit einer ordnungsgemäß geerdeten Steckdose.

• Schalten Sie die Maschine mit Hilfe des Hauptschalters an. Das Startmenü wird auf der Anzeige

erscheinen.

GB: Always remove the roll of lm before

changing the position of the stand.

DE : Entfernen Sie immer zuerst die Folie,

bevor Sie den Aufstellungsort des Gerätes

verändern.

FR: Retirer impérativement la bobine de lm

avant de changer la position du stand.

NL: Verwijder altijd eerst de folie alvorens de

positie van de stand te veranderen.

FP InternationalFP International

Pro Pak´r bedienungsanleitun g version 1.0 Seite -17-

Page 48

3 Bedienungsanleitung

3.3 einlegen der folie

1

Schieben Sie die Folienrolle in die

Halterung.

3 4

Öffnen Sie den Luftkanal der

Folienrolle und ziehen Sie ihn über

den Befüllungsstutzen, bis Sie einen

Widerstand spüren.

2

Beim Abspulen der Folie muss

die Richtung entsprechend der

Abbildung eingehalten werden.

Ziehen Sie die Folie in Richtung des

Befüllungsstutzens.

Betätigen Sie die Vorschubtaste (Feed

down) auf dem Tastenfeld, um die

Folie komplett einziehen zu lassen.

5

Drücken Sie die Starttaste, sobald die

Maschine bereit ist.

Pro Pak´r bedienungsanleitun g version 1.0 seite -18-

FP International

Page 49

3 Bedienungsanleitung

3.3.1 allgeMeine Hinweise zur Bedienung der MascHine

• Vergewissern Sie sich, dass der Notstopp nicht aktiviert ist. Um ihn zu deaktivieren,

drehen sie den Notstoppknopf, bis er nicht mehr eingerastet ist.

• Schalten Sie die Stromversorgung des Gerätes ein, indem Sie den Kippschalter auf der

Rückseite des Gerätes auf ON stellen.

• Betätigen Sie die Taste auf dem Display, um die Maschine in Betrieb zu nehmen, wenn die

entsprechende Aufforderung erscheint.

• Schieben sie die Folienrolle in die Halterung (Einlegen der Folie, Abbildung 1).

• Öffnen Sie den Luftkanal der Folie und ziehen Sie ihn über den Befüllungsstutzen

(Einlegen der Folie, Abb.3).

• Ziehen Sie die Folie komplett in die Luftbefüllungseinheit (Einlegen der Folie, Abb. 4)

• Betätigen Sie die Vorschubtaste und lassen Sie die Folie einziehen, bis die

Vorschubwalzen die Folie erfassen (Einlegen der Folie, Abb. 3).

Jetzt ist die Maschine bereit für die Luftkissenproduktion.

• Das integrierte RFID-Lesegerät wird die eingelegte Folie erkennen und automatisch die

optimalen Einstellungen am PRO PAK´R vornehmen.

o Der Befüllungsgrad, die Versiegelungstemperatur und der Versiegelungsdruck können

für spezifische Anwendungen am Tastenfeld angepasst werden (siehe 3.3.2).

• Die Länge der Luftkissenketten kann am Tastenfeld eingestellt werden (siehe 3.3.2).

o Bei Dauerbetätigung des Fußschalters (falls installiert) werden die Voreinstellungen für

die Längensteuerung außer Kraft gesetzt.

o Beim Antippen des Fußschalters wird eine voreingestellte Länge von Luftkissen befüllt.

o Die Maschine kann mit der Starttaste in Betrieb genommen werden.

FP InternationalFP International

Pro Pak´r bedienungsanleitun g version 1.0 Seite -19-

Page 50

3 Bedienungsanleitung

3.3.2 änderung der geräteeinstellungen

teMperatursteuerung

Zur Anpassung die Taste unter ( ) betätigen.

• Falls die Luftkissen zu ach werden und Sie feststellen, dass

die Hitzeversiegelungen Luft lassen, erhöhen Sie die Temperatur durch Betätigung der Taste unter dem “+” – Symbol.

• Falls die Luftkissen zu ach werden, weil die Versiegelung-

sränder verbrannt sind, was man an Löchern in den Luftkissen erkennt, vermindern

Sie die Temperatur durch Betätigung der Taste unter dem “-” - Symbol.

Bestätigen Sie Ihre Eingabe durch Betätigung der Taste unter P

Nachdem Sie die Temperatureinstellungen verändert haben, könnte es einige Zeit dauern, bis

PRO PAK´R die neue Versiegelungstemperatur hergestellt hat.

Während des Aufheizens oder Abkühlens leuchtet eine ROTE LED-Anzeige, bis die korrekte

Temperatur erreicht ist.

Falls die Luftkissen trotzdem noch mangelhafte Versiegelungsnähte aufweisen und zu ache Luftkissen erzeugt werden, kontaktieren Sie bitte das FPI-Servicepersonal.

luftsteuerung

Die Luftsteuerung reguliert den Befüllungsgrad der Luftkissen.

Zur Anpassung die Taste unter ( ) betätigen.

Zur Erhöhung des Befüllungsgrades betätigen Sie bitte die Taste

unter dem “+” – Symbol.

Zur Verminderung des Befüllungsgrades betätigen Sie bitte die

Taste unter dem “-” – Symbol.

Bestätigen Sie Ihre Eingabe durch Betätigung der Taste unter P

längensteuerung

Die Längensteuerung legt die Länge der Luftkissenketten fest, die

grundsätzlich produziert werden, sobald die Starttaste gedrückt

wird. Sie haben 2 Optionen:

serienModus:

Die Längensteuerung wurde bei der Herstellung auf den Serienmodus voreingestellt. Bei

Betätigung der Starttaste lässt die Maschine die Folienrolle durchlaufen, bis die Rolle komplett

verbraucht ist oder die Stopptaste gedrückt wird.

festgelegte länge

Wenn Sie eine festgelegte Länge von Luftkissenketten herstellen wollen, betätigen Sie bitte

die Taste , …, drücken Sie dann die “+“-Taste, bis die gewünschte Länge angezeigt wird. Die

Maschine zählt dann die Länge der hergestellten Kissen rückwärts herunter.

Bestätigen Sie Ihre Eingabe durch Betätigung der Taste unter P .

Um wieder in den Serienmodus zu gelangen, betätigen Sie bitte die Taste “-”, bis im Display

die Zahl “0“ angezeigt wird.

Menü-zugriff

Modus-optionen

Bei dieser Option kann der Betriebsmodus ausgewählt werden, dabei haben Sie 5 Optionen:

Option 1: Fußschalter

Option 2: Manuell

Option 3: Sensor

Option 4: ADS

Option 5 Auto-Index

Wählen Sie den gewünschten Modus aus. Bestätigen Sie Ihre Eingabe durch Betätigung der

Taste unter P.

Pro Pak´r bedienungsanleitun g version 1.0 seite -20-

FP International

Page 51

3 Bedienungsanleitung

wiederHerstellen

Drücken Sie die Menütaste.

In der Anzeige erscheint”Wiederherstellen der

Standardeinstellungen / RFID-Tag-Werte“.

Bestätigung durch P .

3.3.3 feHlerMeldungen

Falls in der Anzeige ein Fehlercode oder –symbol erscheint, und die ROTE LED-Anzeige

aueuchtet, stellen Sie bitte anhand der folgenden Tabelle die Ursache für den Fehler fest.

Beheben Sie das Problem unter Beachtung der Hinweise. Im Anschluss betätigen Sie die

Starttaste, um den Normalbetrieb wieder aufzunehmen. Falls der Fehler dadurch nicht behoben

werden kann, kontaktieren Sie bitte die Service-Zentrale von FP International B.v. (siehe Seite 3).

Fehlercode Maßnahme

COVER /

ABDECKUNG

DELTA T Wenden Sie sich an Ihren Händler oder an FPI, um Hilfe zu erhalten.

STAU /

FOLIENENDE

3.3.4 versetzen der MascHine

• Schalten Sie die Maschine aus.

• Entfernen Sie die Folienrolle aus der Maschine.

• Lösen Sie die Laufrollen und bewegen Sie die Maschine zur gewünschten Position.

Vergewissern Sie sich, dass alle Abdeckungen geschlossen sind.

Bei einem Folienstau öffnen Sie bitte die Geräteabdeckung und entfernen vorsichtig die verklemmte Folie.

3.3.5 aufstellen und anscHließen

Beachten Sie die Anforderungen an die Arbeitsumgebung. Siehe “Arbeitsumgebung“ auf Seite 11.

• Stellen Sie die Maschine auf einer ebenen Fläche auf.

• Sollte die Maschine auf einem Gestell angebracht sein, verriegeln Sie alle 4 Laufrollen mit

dem eingebauten Verriegelungsmechanismus.

• Schließen Sie die Maschine an das Stromnetz an.

FP InternationalFP International

GB: Always remove the roll of lm before changing the

position of the stand.

DE : Entfernen Sie immer zuerst die Folie, bevor Sie

den Aufstellungsort des Gerätes verändern.

FR: Retirer impérativement la bobine de lm avant de

changer la position du stand.

NL: Verwijder altijd eerst de folie alvorens de positie

van de stand te veranderen.

Pro Pak´r bedienungsanleitun g version 1.0 Seite -21-

Page 52

3 Bedienungsanleitung

3.4 reinigung

Warnung!

• Während der Reinigung muss die Maschine ausgeschaltet sein.

• Elektrische Bauteile dürfen nicht in Kontakt mit Wasser oder

anderen Flüssigkeiten kommen.

Normalerweise braucht die Maschine nicht gereinigt zu werden. Falls nötig, kann sie mit einem

feuchten Lappen und Seifenlauge abgewischt werden.

3.5 transport/lagerung

3.5.1 allgeMein

Die Maschine ist mit Laufrollen ausgestattet, sodass sie schnell von einem Arbeitsplatz zum

anderen transportiert werden kann. Die Laufrollen sind nur für den Transport über kurze

Strecken auf ebenen, harten Fabrikböden geeignen.

3.5.2 lagerung

Es gibt keine spezischen Vorschriften für die Lagerung der Maschine. Eine kühle und

trockene Umgebung wäre aber für diesen Zweck am besten geeignet.

Sollte die Maschine lange gelagert oder nicht benutzt worden sein, muss sie vom

Wartungspersonal inspiziert werden, bevor sie wieder in Gebrauch genommen wird.

3.6 inBetrieBnaHMe

Die Maschine ist betriebsbereit, sobald wie den Produktionsstandort verlässt, und sie

benötigt keine spezielle Installation. Bei ihrem ersten Einsatz sollte sie dennoch von

einem Techniker überwacht werden. Das gilt auch für den erneuten Einsatz nach einer

Generalüberholung oder einer langen Lagerungsperiode.

Beachten Sie die folgenden Punkte:

• Ist ein Schaden entstanden (z.B. beim Transport)?

• Wurde die Maschine ordnungsgemäß aufgestellt (siehe Seite 16)?

• Entspricht die Netzspannung den Angaben auf dem Typenschild (siehe S. 27)?

• Können sich alle beweglichen Teile (Vorschubrollen) frei bewegen?

Die Inbetriebnahme wird für gewöhnlich von einem Spezialisten des Herstellers oder

Händlers vorgenommen.

Pro Pak´r bedienungsanleitun g version 1.0 seite -22-

FP International

Page 53

3 Bedienungsanleitung

3.7 reparatur und wartung

Vorbeugende Wartung.

Die Maschine sollte jedes halbe Jahr gewartet werden. Von besonderer Wichtigkeit hierbei

sind:

• interne und externe Reinigung, Sichtprobe auf Verschleiß

Reparaturen dürfen grundsätzlich nur vom qualizierten Servicepersonal von FP International

vorgenommen werden. Die folgenden Tätigkeiten können jedoch vom Wartungspersonal des

Kunden vorgenommen werden: Klinge / Kegelkopf / Verschleißleisten ersetzen, Führungsrad

säubern bzw. ersetzen.

3.7.1 klingen / kegelkopf austauscHen

3.7.1.1 Kegelkopf wechseln (siehe Seite 14)

Den Kegelkopf vom Gebläse entfernen und durch einen neuen

ersetzen.

3.7.1.2 Klingen austauschen / neue Schneidkante

(Seien Sie vorsichtig, die Klinge ist sehr scharf.)

• falls es oft zum Folienstau kommt

• nach der Verarbeitung von 100 Folienrollen

• falls die Klinge die Folie nicht ordentlich oder zu grob

abschneidet

Schalten Sie dazu das Gerät ab, ziehen Sie den Netzstecker und warten Sie 10 Minuten, bis

sich die Maschine abgekühlt hat.

Öffnen Sie die Displayabdeckung mit einem Schlitz- oder Kreuzschlitzschraubendreher. Lösen

Sie die schwarze Schraube. Schieben Sie den roten Klingenhalter zum Befüllungsstutzen (2).

Sollte es nicht möglich sein, den Klingenhalter weiter zu bewegen, drehen Sie bitte die Klinge

(3 und 4). Falls die Klinge auf beiden Seiten stumpf ist, muss sie erneuert werden.

2

3

1

4

VERBRENNUNGSGEFAHR

Bevor Sie eine Abdeckung öf fnen, schalten Sie das Gerät

bitte immer ab, ziehen den Netzstecker und warten 10

Minuten, bis sich das Versiegelungsrad abgekühlt hat.

FP InternationalFP International

Pro Pak´r bedienungsanleitun g version 1.0 Seite -23-

Page 54

3 Bedienungsanleitung

3.7.3 verscHleißleisten ersetzen

The Pro Pak’r has 2 wear strips, these strips transport the lm through the machine. These strip

can be removed when damaged / wear out.

PRO PAK´R ist mit 2 Verschleißleisten bestückt, die die Folie durch die Maschine transportieren.

Die Leisten können bei Beschädigung oder Abnutzung entfernt werden.

3.7.4 BackingwHeel säuBern

Öffnen Sie die Abdeckung mit einem Schlitz- oder Kreuzschlitzschraubendreher. Säubern Sie das

Backingwheel mit einem feuchten Tuch.

3.7.5 BackingwHeel ersetzen (seite 15)

Öffnen Sie die Anzeigeabdeckung mit einem

Schlitz- oder Kreuzschlitzschraubendreher.

Entfernen Sie die Verschleißstreifenführung,

indem sie diese nach oben ziehen. Benutzen

Sie eine Spitzzange, um den Sicherungsring zu

entfernen.

Entfernen Sie das Backingwheel. Gehen Sie