Page 1

OPERATOR MANUAL

ENGLISH

1

Page 2

2

Page 3

CONTENTS

Section Page Section Page

1 Precautions 1

1.1 Special national conditions 1

2 General 2

2.1 Understanding the system 2

2.2 Operating controls 3

2.3 Display 4

8.3 Cleaning the brushes 21

8.4 Cleaning the moistening felt 21

8.5 Cleaning the sensors 21

9 Options 21

10 Specifications 21

3 Operating the system 4

3.1 Switching on 4

3.2 The main menu 4

3.3 Main menu (1) 4

3.4 Job info 4

3.5 Other job 5

3.6 Main menu (2) 5

3.7 Reset count menu 5

3.8 Adjustments for document feeding 5

3.9 Adjustments for envelope feeding 8

3.10 Insert position 8

3.11 Fill & Start 9

4 Job programming 9

4.1 Job menu 9

4.2 Job menu (1) 9

4.3 Create job 9

4.4 Edit job 9

4.5 Job menu (2) 10

4.6 Copy job 10

4.7 Delete job 10

5 Job settings 10

5.1 Envelope settings 10

5.2 Document settings 10

5.3 Fold settings 11

5.4 Double Feed Control 12

5.5 OMR settings (Optional) 12

5.6 Job name 12

6 Optical Mark Reading

(Optional) 12

6.1 Adjustments 12

6.2 Feeding documents 14

6.3 OMR code 14

7 Fault finding 15

7.1 General 15

7.2 Clearing stoppages 16

7.3 Operator troubleshooting 17

7.4 OMR error codes 20

8 Maintenance 21

8.1 Servicing 21

8.2 General cleaning 21

ENGLISH

3

Page 4

4

Page 5

1. PRECAUTIONS

Before using this system, thoroughly read the

operating instructions. In the European Union

an operator manual printed in the national

language(s) is supplied with the system. If it is

not, contact your authorized distributor.

Warning

• Before connecting check if the system is

suitable for the local mains voltage; refer to

the type plate.

Safety precautions

• This system is only to be operated by fully

trained personnel. The manufacturer accepts

no responsibility for injuries caused by

unauthorized operation.

• The opening of covers must be carried out

only by a skilled and authorized person who is

aware of the hazard involved. The system will

not operate with the covers opened.

• Keep long hair, fingers, jewellery, etc. away

from turning parts of the system.

• The socket outlet shall be installed near the

equipment and shall be easily accessible.

• The mains plug shall be connected only to a

socket outlet provided with a protective earth

contact.

• Over-current protection in the equipment also

relies on the branch circuit protection (max.

20 A).

• The following part(s) is (are) considered the

equipment disconnect device(s):

- power supply cord plug.

1.1 Special national conditions

Denmark

appliances may be provided with a plug not

establishing earthing continuity when inserted

into Danish socket-outlets. Be sure the

equipment makes contact with the protective

earthing of the socket outlet.

(

Plug and socket outlet have to match!

Japan

the mains plug is connected to the mains. When

disconnecting the earthing connection, be sure

to disconnect after pulling out the mains plug

from the mains.

: In Denmark, certain types of Class 1

)

: Provide an earthing connection before

ENGLISH

Used symbols

Warning, this symbol indicates a

wrong action which can cause a

hazard to health or damage the

system.

This symbol also means: read your

operator instruction.

Warning, this symbol indicates a

hazard to life because of high voltage.

Note:

Additional information

5

Page 6

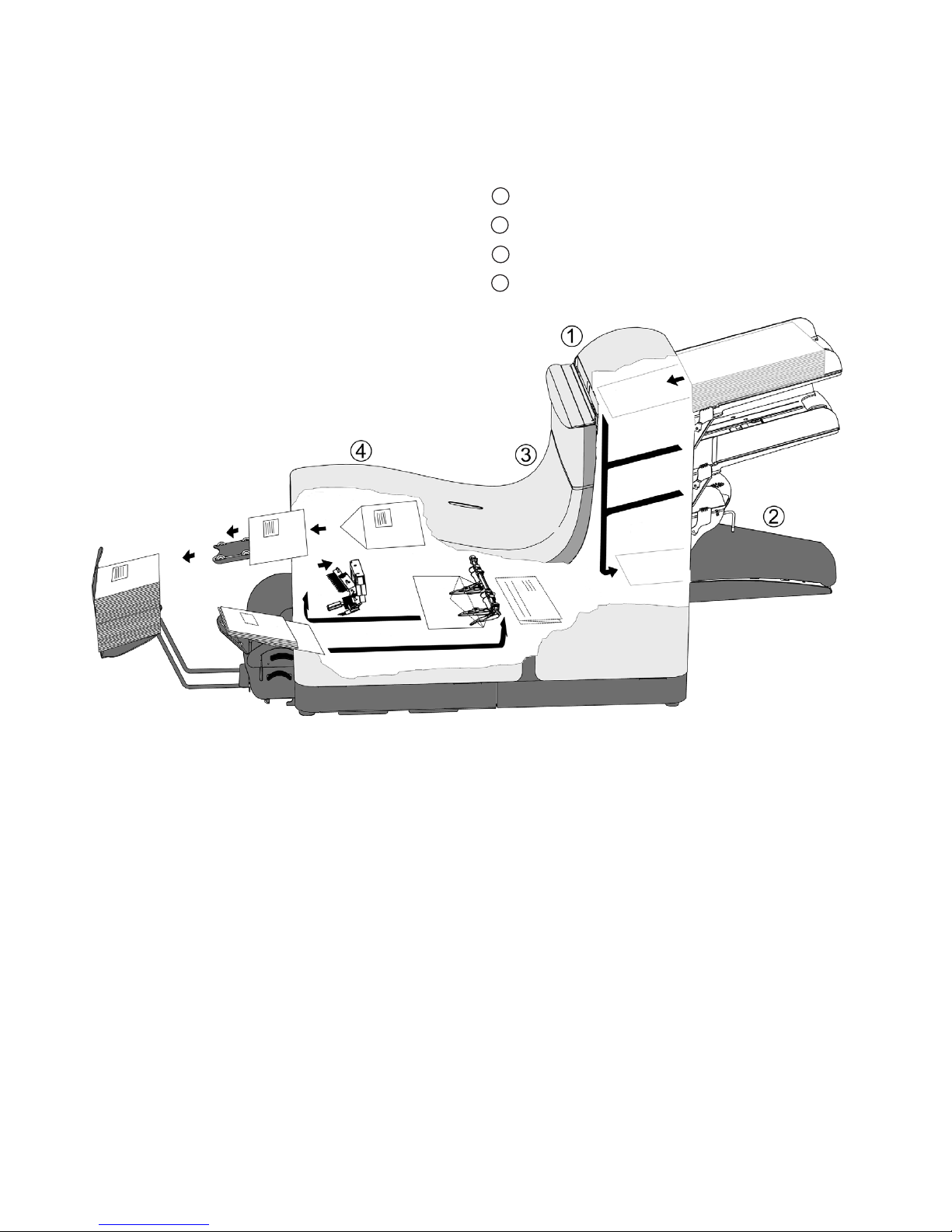

2. GENERAL

2.1 Understanding the system

This compact folding and inserting system can

process large quantities of mail rapidly and

easily.

The settings of the system are recorded in socalled jobs. These jobs can be programmed by

an authorized user.

As a special feature the system is equipped with

a Fill & Start function. The purpose of this

function is to start working as quickly as

possible.

The system consist of the following parts:

1

feeder

2

collating area

3

folder

4

inserter

6

Page 7

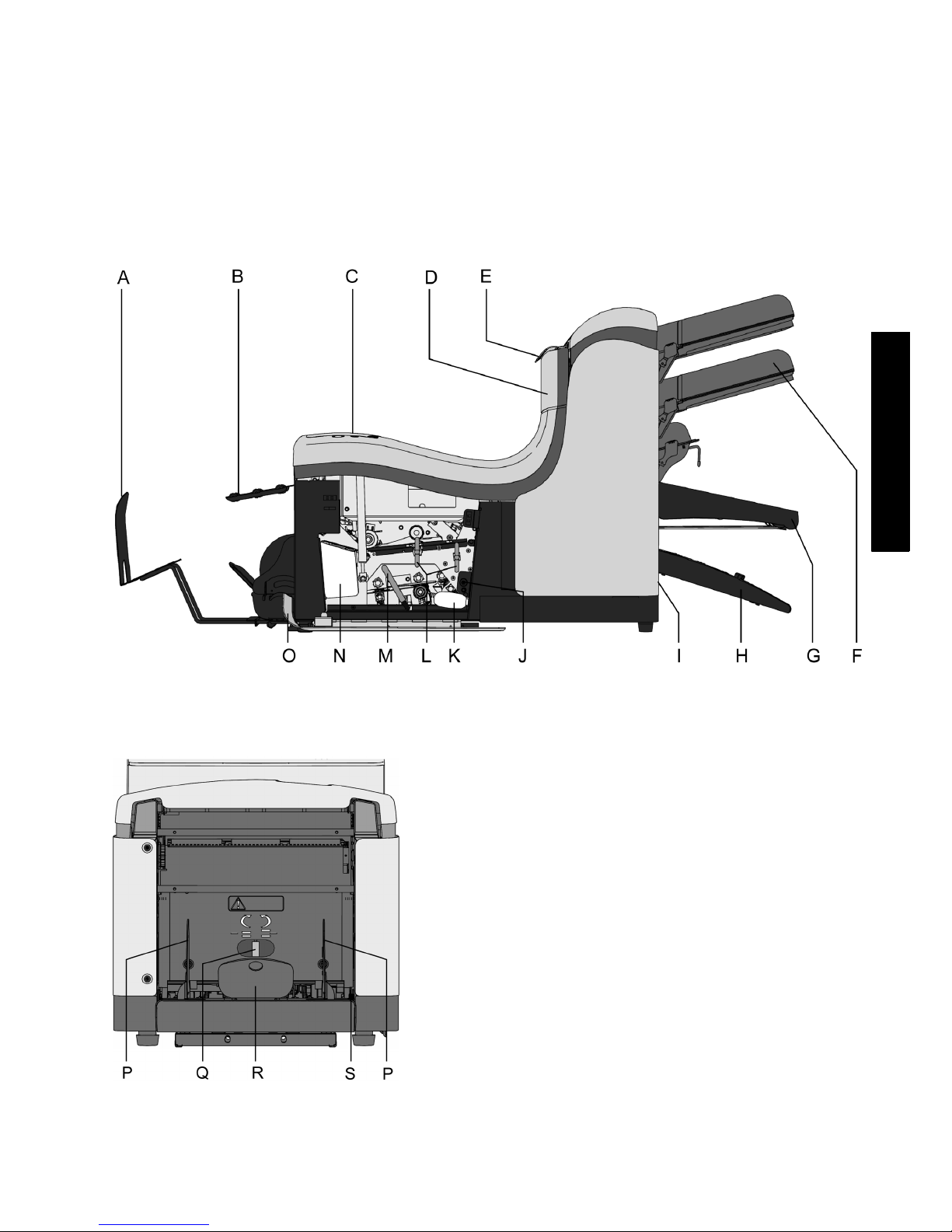

2.2 Operating controls

A : envelope receiving tray

B : envelope slide

C: display

D : upper unit

E : locking hand grip upper unit

F : document feeding tray

G : collator arm

H : collator area

I : power inlet, power switch

J : sensors

K : bellows

L : knobs for clearing stoppages

M : handle for clearing stoppages

N : water tray

O : side cover (opened)

ENGLISH

P : side guides envelope hopper

Q : knob for separation adjustment

R : envelopes support bracket

S : thumbwheel for side guide adjustment

7

Page 8

Moistening the brushes

The water tray must always be filled with a

special sealing liquid or water and the brushes

must be moistened. An extra set of brushes is

provided so that one set can be soaked in water.

For this a special section is available in the

water tray. Refer to chapter "Maintenance".

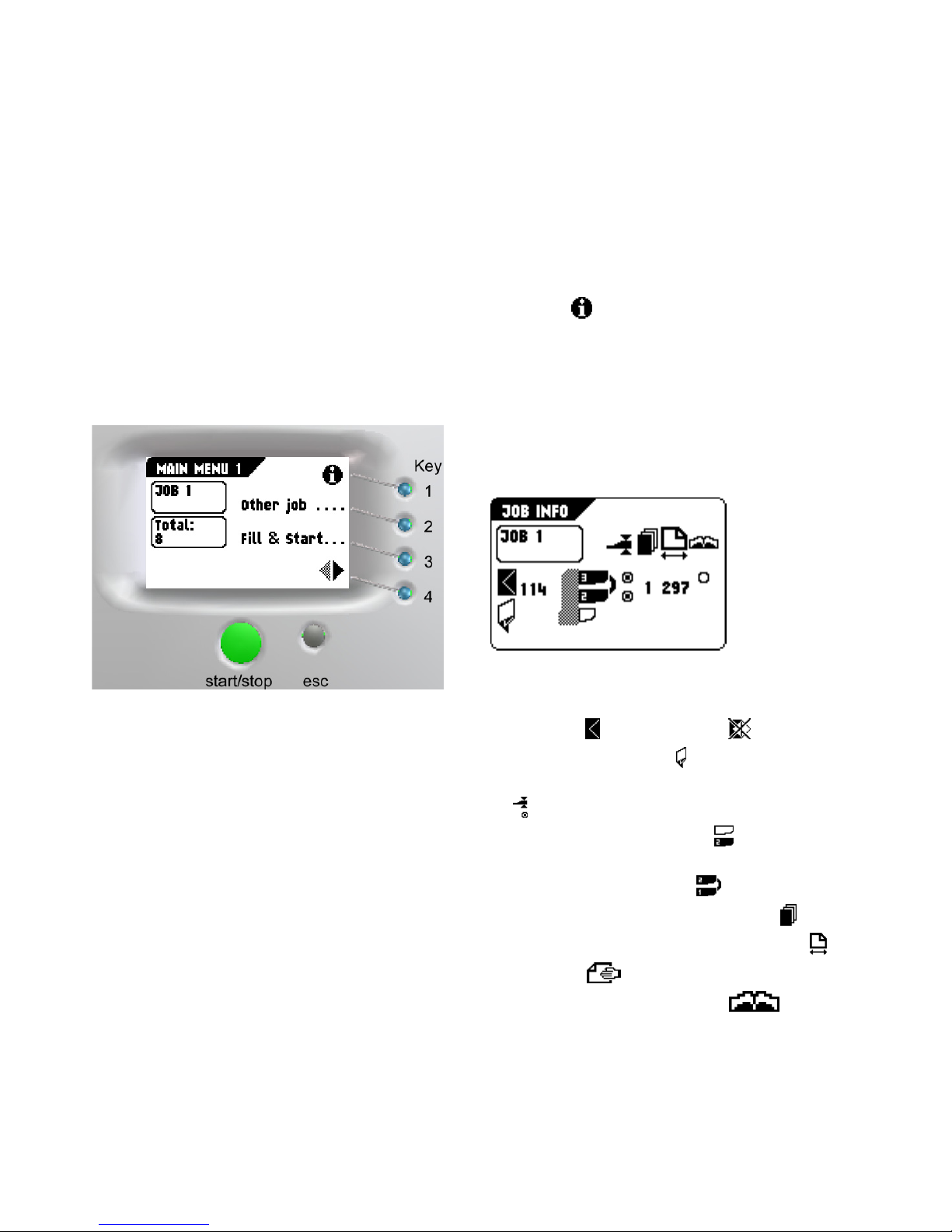

2.3 Display

The display shows the operating screens and

keys for operating the system (see figure

below). The keys below are used for the

functions: start/stop (combined key) and

escape. The four keys on the right of the display

are used for the corresponding functions shown

in the screens.

3.2 The main menu

The main menu consists of two menus, "main

menu (1)" and "main menu (2)". Press key 4 in

"main menu (1)", to go to "main menu (2)".

Press key 4 again to get back to "main menu

(1)".

3.3 Main menu (1)

Main menu (1) shows the following functions

(see figure above):

• job info ( ),

• other job,

• Fill & Start.

3.4 Job info

When key 1 is pressed in "main menu (1)", the

"job info" screen will be displayed (see figure

below). Press the escape key to go back to

"main menu (1)".

Press the start/stop key to start the machine.

When the start/stop key is pressed again the

machine stops feeding after completing the set.

It is possible that there are still documents left in

the document feeder (for example a small card).

Remove all these documents from the feeder

before restarting another job. There can also be

envelopes left in the envelope track. These

envelopes must be removed when another type

of envelopes is required.

The escape key can be used to exit a menu

without saving any settings.

3. OPERATING THE SYSTEM

3.1 Switching on

The system can be switched on or off with the

power switch on the back of the system. Refer

to section "Operating controls". After starting up,

the display shows "main menu (1)”.

The "job info" screen shows the following job

settings:

• envelope ( ) or no envelope ( ),

• type of document fold ( ),

• document double feed detection "on" or "off"

(),

• which feeders are selected ( black is

selected),

• which feeders are linked ( feeder swap),

• the number of documents per feeder( ),

• the length of the document in the feeder ( ),

• daily mail ( ) "on "or "off",

• OMR (Optical Mark Reading) ( ) "on" or

"off".

8

Page 9

3.5 Other job

Select the desired job in the "Other job" menu.

Confirm the job selection with "OK" which will

get you back to the "main menu (1)".

3.6 Main menu (2)

Main menu (2) shows the following functions

(see figure below):

• reset count,

• insert position,

• job menu.

3.7 Reset count menu

After pressing key 1 in "main menu (2)", the

counter is set to zero.

3.8 Adjustments for document

feeding

Document separation

The document separation for the feeders is set

automatically.

Side guides

To adjust the side guides it is best to remove the

document feeding tray as follows (see figure

below):

• push handle A downwards,

• lift the document feeding tray upwards to

unhook it and then pull it out from the feeder,

A

• loosen knob B half a turn (see figure below),

• grab the side guides C in the middle and push

them outwards,

• put a small stack of documents between the

side guides,

• grab the side guides in the middle and push

them towards the documents,

• The space between the side guides and the

documents should be such that the

documents have just enough play to move

freely,

• re-tighten knob B,

• remove the stack of documents.

ENGLISH

CCB

Replace the document feeding tray as follows

(see figure below):

• place the document feeding tray under guide

A,

9

Page 10

• push the document feeding tray up and then

lower it into position.

A

10

Page 11

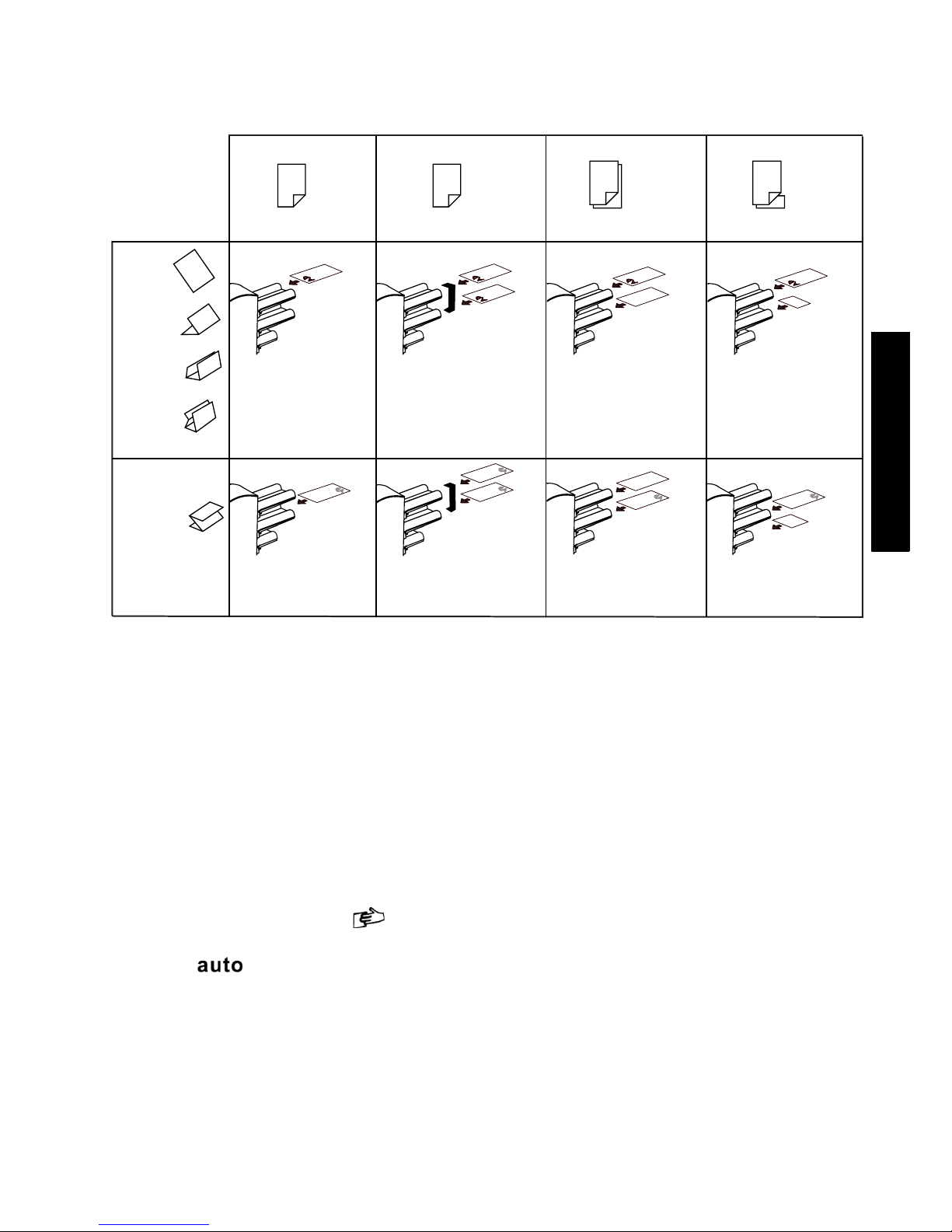

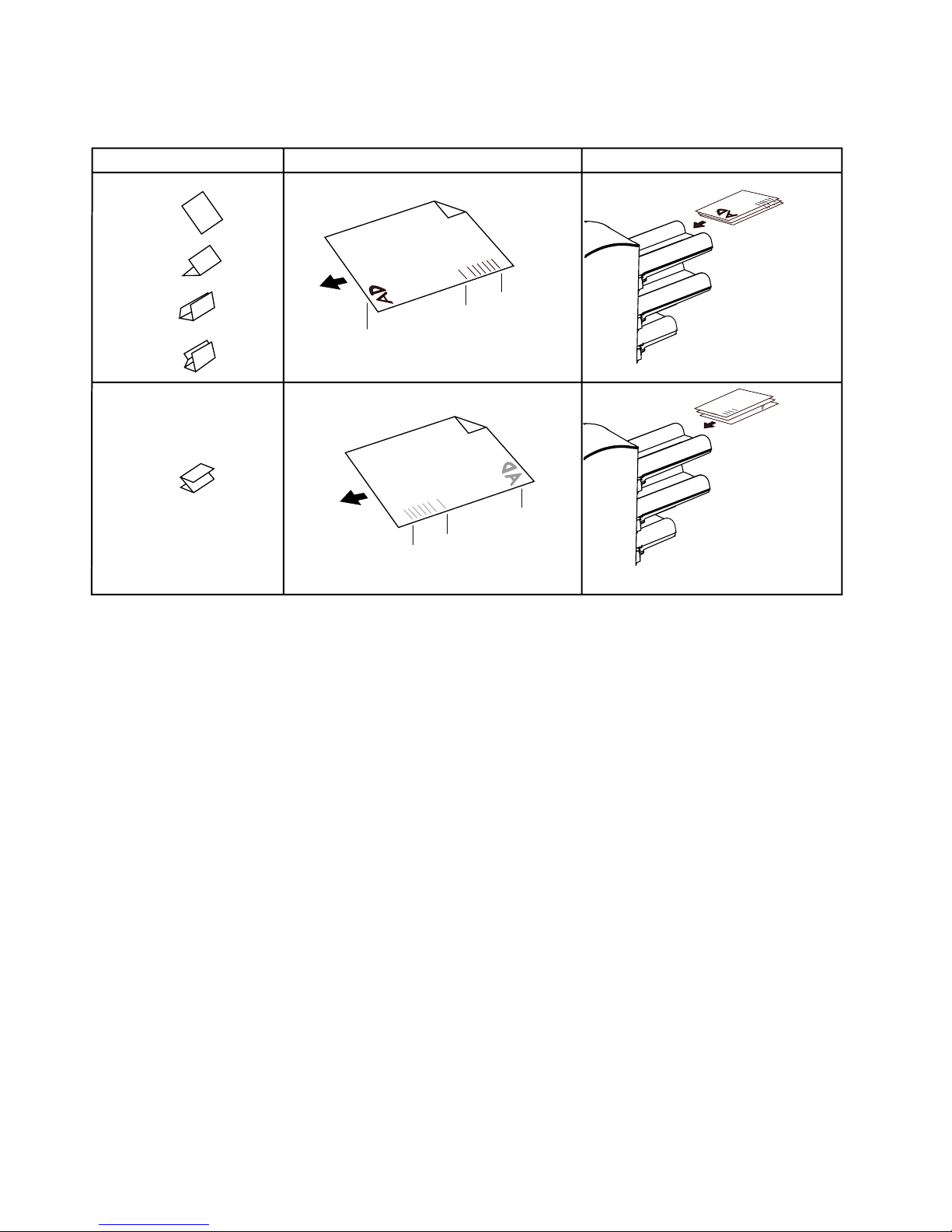

Feeding documents

The feeding of documents is shown in the figure below.

feeder swap

Address carrier in upper

linked pair feeders.

Face up and leading.

Address carrier in lower

linked pair feeders.

Face down and trailing.

no fold

single fold

letter fold

double

parallel fold

zig-zag fold

one document

Address carrier in

upper feeder.

Face up and leading.

Address carrier face

down and trailing.

Daily mail

The daily mail function can be used for

processing documents or sets which can not be

processed automatically.

The upper feeder is equipped with a daily mail

switch.

Switch to daily mail in the following way:

• select a job where the daily mail function has

been set to “on”,

• turn the left side guide of the upper feeder

downwards,

• the daily mail handle will be visible and can be

two documents

Address carrier in

upper feeder.

Face up and leading.

Address carrier in lower

feeder.

Face down and trailing.

document + enclosure

Address carrier in upper

feeder.

Face up and leading.

Address carrier in upper

feeder.

Face down and trailing.

Filling the document feeder

Open the left side guide by turning it downwards

(or the handle for the small feeder). The feed

rollers will automatically be lifted. Place a stack

of documents between the side guides. Turn the

left side guide upwards again (or the handle for

the small feeder).

ENGLISH

set. Push the handle towards ( ) to switch

to the daily mail function. Push the handle

towards ( ) to switch back to the

automatic function,

• turn the left side guide upwards again.

11

Page 12

3.9 Adjustments for envelope

feeding

Envelope separation

Adjust the envelope separation by turning knob

A (see figure below) counter clockwise until two

envelopes (flap down and "trailing"), one on top

of the other, can be moved backward and

forward between the rollers without resistance.

Turn knob A clockwise until one envelope will

just pass between the rollers.

Envelope sealing

Envelopes can be sealed or not sealed. To

switch sealing "on" or "off", pull the hand grip of

the upper cover upward and pull it into the

vertical position.

Shift the blue handle towards to switch

sealing off or towards to switch sealing on.

3.10 Insert position

Press key 2 in the "main menu (2)" to enter the

"Insert position" menu (see figure below).

Press key 1 in the "Insert position" menu to

bring one envelope onto the insert position.

Side guides

The bottom envelope must enter the separator

first. Adjust the side guides C (see figure above)

by turning the thumbwheel D to provide enough

space to move freely. Too much play causes

skewing.

Filling the envelope feeder

Fan the stack of envelopes a bit and place the

bottom envelope between the separation rollers

(flap down and trailing). Sometimes envelopes

may skew on the insert table. The envelope

support B (see figure above) can be rotated

slightly to compensate this. Shift the envelope

support B in or out so that the flap side of the

envelope is lifted about 20 mm (0.8 inch). Turn

the envelope support B so that the weight of the

envelopes is distributed evenly on both sides.

Open the upper cover. The flap folding line must

be positioned under the green indicator B (see

figure below). If necessary adjust the flap folding

line position by pressing key 2 or 3 in the "Insert

position" menu.

Each key stroke stops the next envelope 0,5

mm (0.02 inch) to the right (earlier) or to the left

(later). Check the settings by pressing key 1

again.

Save the insert position settings with "OK" which

will get you back to the "main menu (2)" again.

12

Page 13

Envelope insert fingers

To adjust the insert fingers A (see figure above)

loosen the knurled knob C on top of each finger.

Adjust each finger so that the tip enters about 5

mm (0.2 inch) into the envelope. Re-tighten the

knurled knob. The fingers can be moved

sideways to the desired position. Place the outer

fingers D about 5 to 10 mm (0.2 to 0.4 inch) from

the edges of the envelope.

Check the position of the insert fingers when

changing to a different type of envelope.

3.11 Fill & Start

Before starting the Fill & Start function (see

figure below) the adjustment of the side guides

and envelope separation must be made

manually to obtain correct operation.

4. JOB PROGRAMMING

4.1 Job menu

After pressing key 3 in the "main menu (2)", the

display shows the "job access" menu and asks

for a pin code (2324) to enter (see figure below).

4.2 Job menu (1)

The job menu (1) shows the following functions

(see figure below):

ENGLISH

The address carrier must be put into the upper

feeder.

Only the address position can be adjusted if

needed.

Testset

Press key 2 to start a testset in the Fill & Start

screen. The settings of the testset will be saved.

Only the feeders that feed successfully will be

selected.

If needed adjust the address position.

In the Fill & Start job the following options

cannot be used:

• feeder swap (the system switches

automatically to the upper feeder when the

lower feeder is empty and vice versa),

• multifeed (more sheets are fed from the same

feeder into the envelope),

• the use of the Fill & Start function is not

possible in the "no envelopes" mode.

Press and hold key 1 to show the job info.

To go back to the main menu (1) press "esc".

4.3 Create job

Only free jobs will be shown. The "create job"

menu shows the following functions.

• job information ( ),

• choose a higher job number,

• choose a lower job number,

• select the job to create and confirm with "OK"

which will get you to the "job settings" menu

(1).

If all jobs are used the display shows "no more

free jobs".

To get a free job one has to be deleted.

A new selected job number starts with default

settings.

4.4 Edit job

Only programmed jobs will be shown. This

menu shows the following functions:

• job information ( ),

13

Page 14

• choose a higher job number,

• choose a lower job number,

• select the job to edit and confirm with "OK"

which will get you to the "job settings" menu

(1).

4.5 Job menu (2)

The job menu (2) shows the following functions

(see figure below):

To go back to the main menu (1) press "esc".

4.6 Copy job

The "copy job" menu shows the following

functions:

• job information,

• choose a higher job number to copy from,

• choose a higher job number to copy to,

• copy the job with "OK" which will get you to

the job menu (2).

5. OMR menu (optional) ( ),

6. job name menu ( ).

Use key 1 or 2 to select a menu and key 3 to

edit the selection. Use key 4 to save the job.

5.1 Envelope settings

When the “envelope settings” menu is selected

the following choices are available (see figure

below):

1. envelope height ( ). The envelope height

can be set between 90 mm (3.5 inch) and

162 mm (6.38 inch).

2. no envelopes ( ). To process without

envelopes (fold only).

In the "copy job" menu it is possible to save a

job executed with the Fill & Start function.

4.7 Delete job

This menu shows the following functions:

• job information,

• select a higher job number to delete,

• select a lower job number to delete,

• delete job with "OK" which will get you to the

job menu (2).

5. JOB SETTINGS

To program a job use the following order (see

figure below):

1. envelope settings menu ( ),

2. document settings menu ( ),

3. fold settings menu ( ),

4. Double Feed Control (DFC) menu ( ),

5.2 Document settings

When the “document settings” menu is selected

the following choices are available (see figure

below):

14

Page 15

1. set number of documents per feeder ( ).

The number of sheets per feeder can be set

between 0 and 3. A feeder can be

deselected by setting the amount of

documents to zero. When a feeder is set to

daily mail the amount of documents is

always 1.

2. set document size ( ). The document size

can be set between 90 mm (3.54 inch) and

356 mm (14 inch) in steps of 1 mm (0.04

inch). For the upper station of a 2,5 station

system the minimum height is 115 mm (4.60

inch).

3. set feeder swap ( ). When feeder swap is

selected the following choices are available:

• select the pair of feeders that need to be

linked,

• select linked or unlinked for a pair of feeders,

• confirm the settings by pressing “OK” which

will get you back to the “job settings” menu.

When a pair of feeders is linked, the settings

of the lower feeder will be used and shown in

the display.

4. set daily mail on or off ( ). When daily

mail is selected the following choices are

available:

• set the daily mail function on or off,

• confirm the settings by pressing “OK” which

will get you back to the “job settings” menu.

When there are conflicting job parameters a

message will be shown.

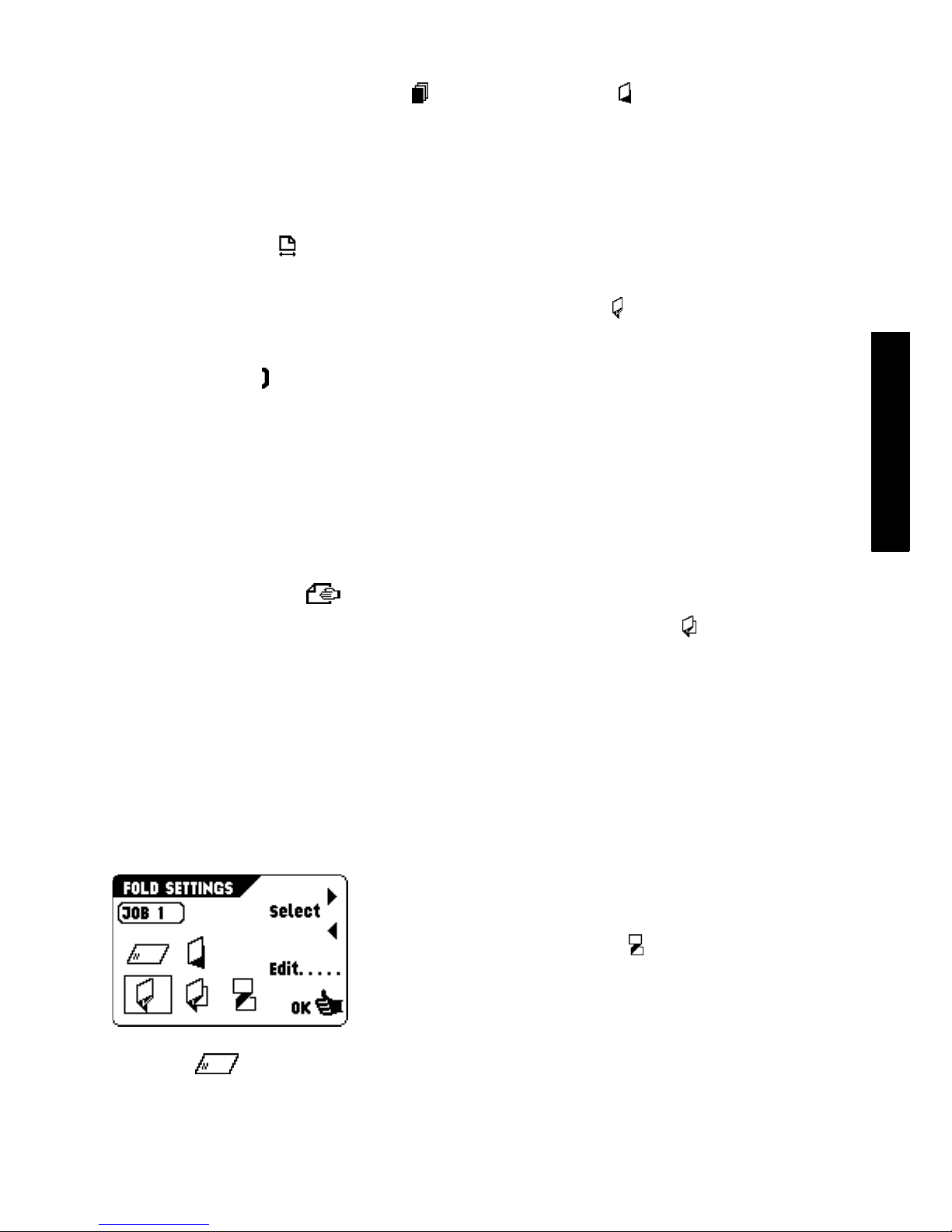

5.3 Fold settings

When the “fold settings” menu is selected the

following choices are available (see figure

below):

2. single fold ( ). When single fold is selected

and edit is pressed, the following choices are

available:

• move the fold position to the right,

• move the fold position to the left,

• confirm the settings by pressing “OK” which

will get you back to the “job settings” menu.

The fold length can be minimally 75 mm (2.95 inch)

and maximally the length of the longest document

used minus 25 mm (1.0 inch).

3. letter fold ( ). When letter fold is selected

and edit is pressed, the following choices are

available:

• select fold number,

• move the position of the fold to the right,

• move the position of the fold to the left,

• confirm the settings by pressing “OK” which

will get you back to the “job settings” menu.

The fold length of the first fold can be minimally 75

mm (2.95 inch) and maximally the length of the

longest document used minus 50 mm (2.0 inch).

The fold length of the second fold can be minimally

the length of the first fold plus 25 mm (1.0 inch)

and maximally the length of the longest document

used minus 25 mm (1.0 inch).

4. double parallel fold ( ). When double

parallel fold is selected and edit is pressed,

the following choices are available:

• select fold number,

• move the position of the fold to the right,

• move the position of the fold to the left,

• confirm the settings by pressing “OK” which

will get you back to the “job settings” menu.

The fold length of the first fold can be minimally 75

mm (2.95 inch) and maximally the length of the

longest document used minus 50 mm (2.0 inch).

The fold length of the second fold can be minimally

the length of the first fold plus 25 mm (1.0 inch)

and maximally the length of the longest document

used minus 25 mm (1.0 inch).

ENGLISH

1. no fold ( ). When no fold is selected

there are no settings required.

5. zig-zag fold ( ). When zig-zag fold is

selected and edit is pressed, the following

choices are available:

• select fold number,

• move the position of the fold to the right,

• move the position of the fold to the left,

15

Page 16

• confirm the settings by pressing “OK” which

will get you back to the “job settings” menu.

The fold length of the first fold can be minimally 75

mm (2.95 inch) and maximally the length of the

longest document used minus 100 mm (4.0 inch).

The fold length of the second fold can be minimally

the length of the first fold plus 25 mm (1.0 inch)

and maximally the length of the longest document

used minus 75 mm (3.0 inch).

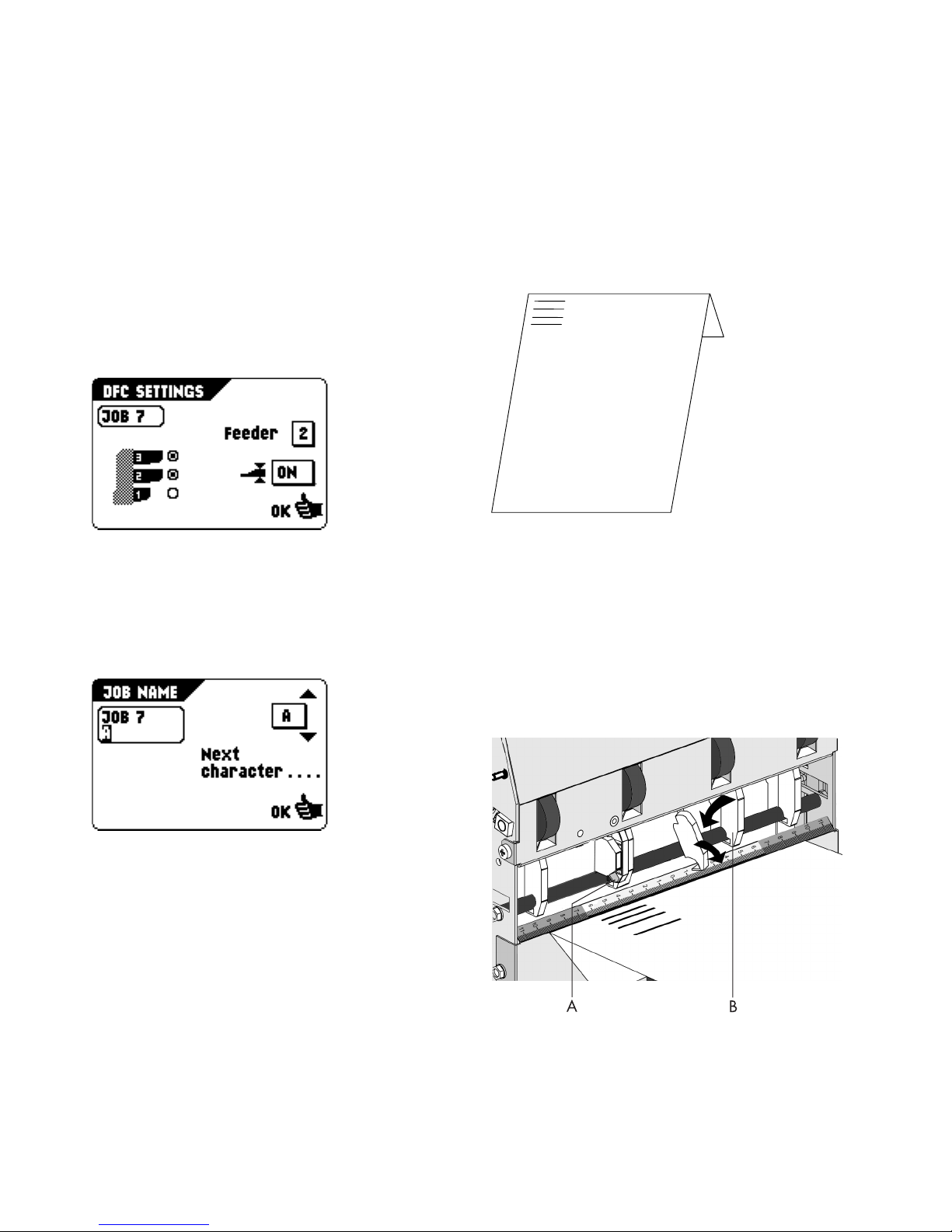

5.4 Double Feed Control

When the “DFC settings” menu is selected the

following functions are available (see figure

below):

5.5 OMR settings (Optional)

Refer to the chapter "Optical Mark Reading".

5.6 Job name

This menu shows the following functions (see

figure below):

6.1 Adjustments

Reading head position

The reading head must be placed according to

the (horizontal) position of the printed marks on

the documents. To adjust the reading head,

proceed as follows:

• take a document with a reading code,

• fold the document on the first mark (see next

figure).

• hold the document onto the ruler (see next

figure),

• adjust the reading head A according to the

middle of the marks,

• divide the paper guides B along the width of

the document.

When the reading head is adjusted it is possible

that some paper guides B have to be removed

and replaced on the other side of the reading

head.

6. OPTICAL MARK READING

(OPTIONAL)

The folding and inserting system can be

equipped with Optical Mark Reading. With this

option the system reads optical marks that have

been specially printed on the documents. This

code contains information about the processing

of the documents. A set can have a varying

number of sheets. The document with the

printed code is placed in the upper feeder.

16

The replacement procedure is the reversal of

the removal procedure.

Page 17

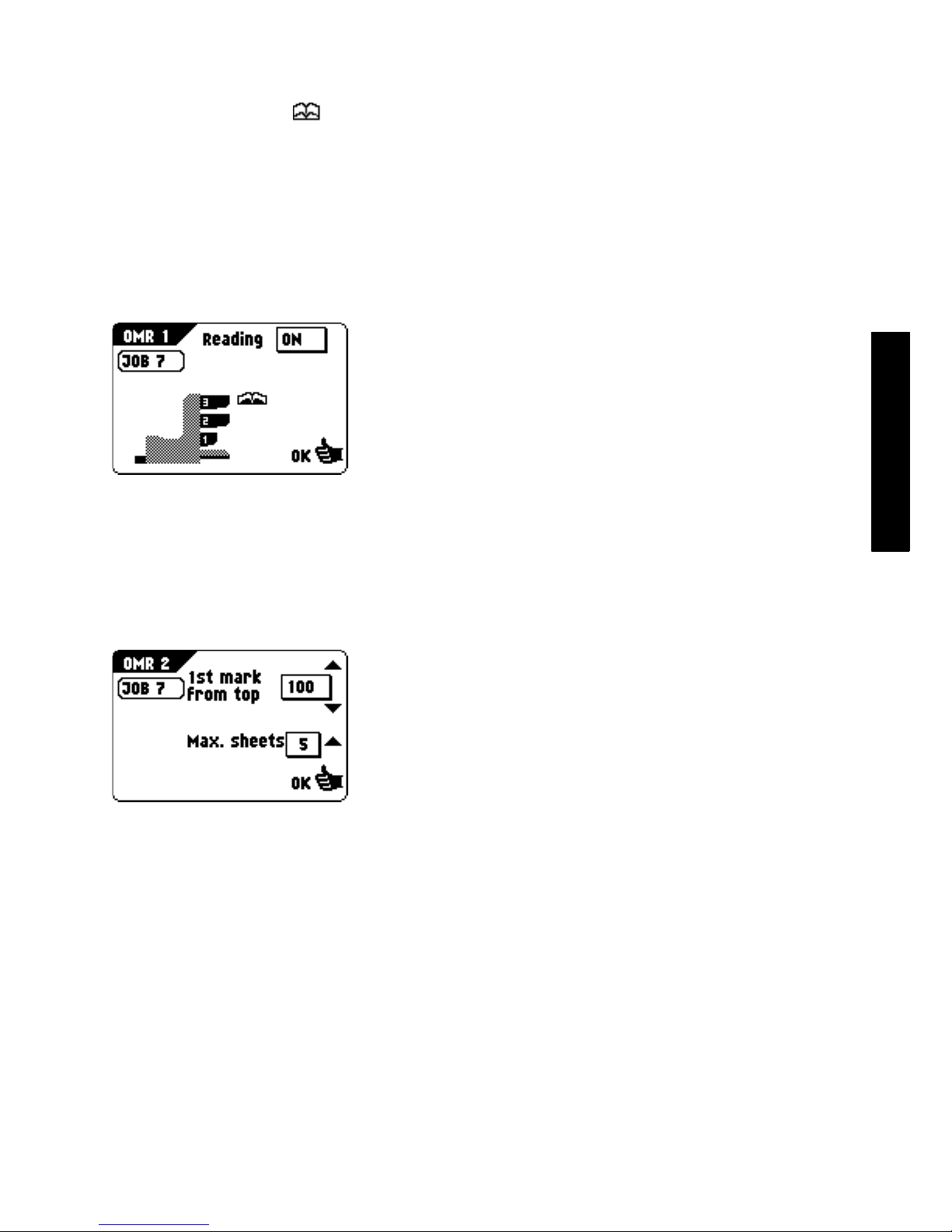

When OMR is selected in a job, the job info

screen shows the OMR symbol.

The OMR settings

Via the job settings the OMR 1 menu can be

selected (see figure below). The OMR function

can be activated by selecting "Reading on" or

"Reading off". The upper feeder is selected

automatically for reading. When "OK" is pressed

with "Reading off" the “job settings” menu is

shown again.

When "OK" is pressed with "Reading on" the

OMR 2 menu is shown (see figure below). In the

OMR 2 menu the distance from the top of the

page to the first mark can be set, and the

maximum amount of documents in a set can be

chosen. When "OK" is pressed the “job settings”

menu is shown again.

ENGLISH

It is not possible to put more than 5 sheets in

one set.

17

Page 18

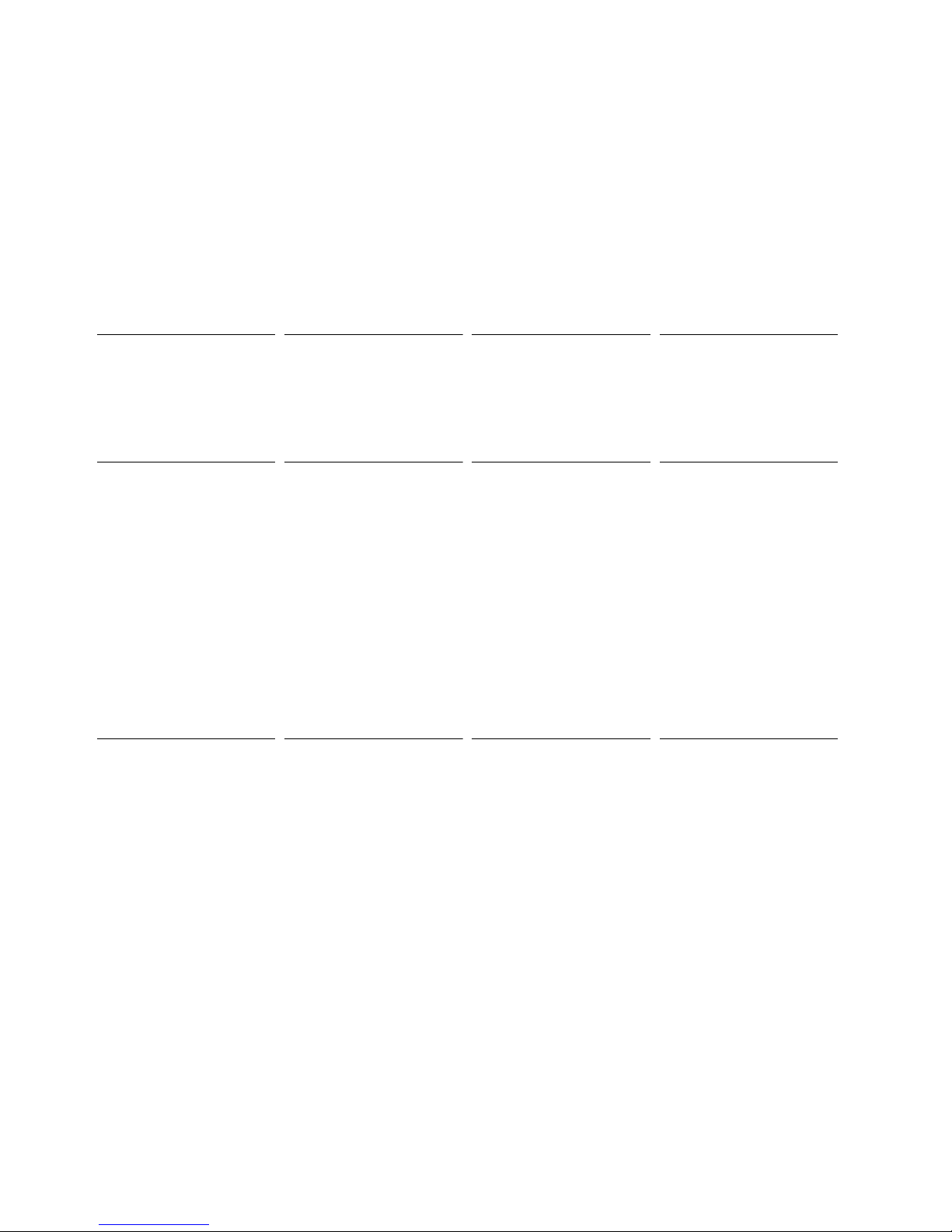

6.2 Feeding documents

The feeding of documents is shown in the figure below.

Fold type

no fold

single fold

letter fold

Double

parallel fold

zig-zag fold

Type of documents

first page

address

last page

(duplex printed)

OMR

stop

reading

OMR

start

reading

OMR

start

reading

OMR

stop

reading

address

Loading positions

1

2

Address carrier, face up and leading.

3

2

1

Address carrier, face down and trailing.

3

6.3 OMR code

Function

In order to handle computer printed documents

fully automatically, code marks are printed on

each document.

With the first four fold types (refer to section

"Feeding documents"), the first sheet of a set

always contains the address. In case of a zigzag fold the address has to be printed on the

last page of the set. A full length code is printed

on every sheet of a set.

The code on the last sheet of the set contains

the insert instruction. The other sheets carry the

accumulate instruction. If a parity check is used,

this is checked on each sheet. If the set contains

only one sheet, it is the “last” sheet. The code

must appear in the same location on every page

regardless of the actual code length.

Printing quality

Criteria:

• marks should be printed in black,

• marks on the same sheet must have equal

intensity,

• for matrix printers near letter quality (NLQ)

printed characters are preferred to obtain

maximum blackness (double strike),

• be aware of background “noise”. This can be

color changes on the form, background

design, a logo or copy on the opposite side of

the sheet that will bleed through and be read

by the reading head,

• the ribbon or toner quality must be checked,

• printing must be done on the same position

on every sheet.

Minimum code/basic commands

The minimum code is one mark in one line

(insert). However for reliability it is advised to

use at least 2 marks. The first line is the start

mark. A mark printed on the second line means

insert, no mark printed means accumulate (this

can be reversed on request).

18

Page 19

Code position and free area

The code must be printed minimally 15 mm

(0.59 inch) away from top and 30 mm (1,18

inch) from the bottom of the sheet. Default the

first mark from the top is set to 100 mm (3.9

inch). From the left hand and right hand side 7

mm (0.28 inch) must be kept clear. The code

must appear in the same location, and have a

consistent number of marks on every page.

Length

Above the first mark and below the last mark a

space of 8,5 mm (0.33 inch) must be kept

without printing. This means that the minimum

code area consists of 6 lines, 2 lines to print the

(basic) and 4 lines free space. Line distance

may be 2,54 mm (0.1 inch) to 6,35 mm (0.4

inch).

Code width, character space and pitch

The minimum width of the code area is 7

character spaces. From left to right: first 2

characters space unprinted (5 mm; 0.20 inch),

then the track mark (3 characters or 6,3 mm; 0.4

inch) and finally 2 character spaces unprinted.

Pitch 10 or 12 is accepted. The track mark can

be printed by using the “underline” sign (__),

which must have a thickness of at least 0,2 mm.

Parity mark

By adding a parity mark the reading code can be

checked. When the OMR-2 code is used the

sum of the marks has to be even.

Safety mark

The safety mark is used as an extra security.

With skewed paper the reading head can miss

part of the reading code. In these situations the

safety mark is not read, and the system will give

an error. The safety mark also indicates the end

of the reading code. This mark always has to be

printed on the document if it has been activated.

Criteria:

• the marks chosen are always used in the

above sequence,

• if a function is suppressed the following

function will move upwards one line,

• the chosen code is used on all material which

will be processed by the Optical Mark

Reading,

• the length of the code with it's mark definition

is a service setting.

7. FAULT FINDING

7.1 General

In the system the following error types are

possible:

• paperflow errors,

• reading errors (when the system is equipped

with Optical Mark Reading),

• technical errors.

If an error occurs the display shows a screen

with an error description and a suggested

solution.

When a paperflow error occurs the following

functions are available:

• show more information,

• reset the error after solving the problem (the

error screen will disappear).

The black arrow or a black feeder indicates

where the problem occurs.

When a reading or double feed control error

occurs, the document stops in the collator area.

The operator must remove the document(s) from

the collator area and must complete the set

manually!

When there is a technical problem the display

shows a message. The error cannot be solved

by operating personnel and assistance of the

service support is needed.

First write down the error code, then switch the

inserter off and on again, to verify system operation.

When the error still occurs contact your service

organization.

ENGLISH

19

Page 20

7.2 Clearing stoppages

For clearing stoppages the three sections of the

system can be opened (A, B and C).

Lower envelope track

Remove the envelopes as follows (see figure

below):

• open the side cover A,

• lower and hold the handle B to the left and

remove the envelope(s) from the lower

envelope track,

• release the handle B,

• close the side cover.

Folder

Remove the documents as follows:

• pull the hand grip up and pull the upper cover

into vertical position,

• remove the documents from the folder,

• close the upper cover until it clicks.

Reset the error after solving the problem with

key 4.

Reset the error after solving the problem with

(key 4).

If needed, envelopes and documents can be

transported manually by turning knob C

clockwise. To transport envelopes manually to

the insert table or to the lower envelope track,

turn knob D clockwise.

20

Page 21

7.3 Operator troubleshooting

Symptom Possible cause Remedy Section

The machine cannot be

started after switching

on.

Machine stops with

envelope at insert

position (flap not open).

Envelopes are double

fed.

Machine not connected

to mains.

Fuse is blown. Replace fuse below

A cover is opened. Close the covers -

Envelopes stacked

reversed in the hopper.

Envelope flap sticks. Store envelopes

Wrong envelope type

used (not according

specifications or job

settings).

Envelope separation not

correctly adjusted.

Connect the machine to

the mains.

power switch.

Check envelope feed

adjustments. Place

envelopes correctly in

hopper.

according to

specifications.

Change envelopes

according to

specifications.

Check separation

settings, adjust if

needed.

-

-

Adjustments for

envelope feeding.

Specifications.

Specifications.

Adjustments for

envelope feeding.

ENGLISH

Envelopes not placed

properly in the hopper.

Envelope stop skewed. Side guides of the

envelope hopper are set

too wide.

Envelopes are fed

irregularly.

Flap is wrinkled and

sometimes not opened.

Hopper almost empty. Refill hopper. Adjustments for

Separation set too

narrow.

Side guides set too

narrow.

Envelope support not

positioned correctly.

Envelope not within

specifications.

Check and replace if

needed.

Check side guides and

adjust if needed.

Check separation

settings, adjust if

needed.

Check side guides and

adjust if needed.

Reposition the envelope

support.

Check specifications

and change envelopes if

needed.

Adjustments for

envelope feeding.

Adjustments for

envelope feeding.

envelope feeding.

Adjustments for

envelope feeding.

Adjustments for

envelope feeding.

Adjustments for

envelope feeding.

Specifications.

21

Page 22

Symptom Possible cause Remedy Section

Fingers are placed on

top of the envelope.

Machine stops while

inserting (stoppage at

the inserting point).

Flap sticks. Store envelopes

according to

specifications.

Flap curled. Envelopes stored or

manufactured

improperly.

Separation set too

narrow.

Check separation

settings, adjust if

needed.

Fingers adjusted too

deep into the envelope.

Envelope stops too

early.

Check fingers position,

adjust if needed.

Check envelope stop

position, adjust if

needed.

Fingers not correctly

adjusted.

Inserted document too

Check fingers position,

adjust if needed.

Check fold settings. Fold settings menu.

long for used envelope.

Specifications.

Specifications.

Adjustments for

envelope feeding.

Envelope insert fingers.

Envelope insert fingers.

Envelope insert fingers.

Flap not sufficiently

moistened.

Envelope throat

incorrect.

Check envelope

specifications.

Envelope glued inside. Eliminate faulty

envelopes.

Window not glued

properly.

Eliminate faulty

envelopes.

Water level low. Check water level, refill

if needed.

Brushes dry. Check brushes, replace

if needed by the extra

soaked set.

Brushes dirty. Check brushes, clean if

needed.

Moistening felt dry. Check the moistening

felt, refill water tray if

needed.

Moistening felt dirty. Check the moistening

felt, clean if needed.

Moistening brushes

inactive.

Activate the moistening

brushes.

Specifications.

Specifications.

-

Moistening the brushes.

Moistening the brushes

or Maintenance.

Maintenance.

Moistening the brushes.

Maintenance.

Envelope sealing.

22

Page 23

Symptom Possible cause Remedy Section

Envelope not filled

properly or envelope

flap not closed properly.

No document fed. Feeder empty. Refill feeder. Filling the document

Skewed documents fed. Side guides set too

Inserted document too

big.

Document not inserted

deep enough.

Separation set too wide. Adjust the separation. Document separation.

Side guides set too

narrow.

wide.

Check fold settings,

adjust if needed.

Check adjustment of

envelope stop position

and fingers.

Adjust the side guides. Side guides.

Adjust side guides. Side guides.

Fold settings menu.

Envelope insert position.

hopper.

ENGLISH

23

Page 24

7.4 OMR error codes

error description suggested solution information Error code

Reading error. Remove the documents and

adjust the 1st mark from the

top position correctly.

Reading error. Remove the current

suspected set and check the

next set.

Reading error. Remove the documents and

adjust the reading head.

Adjust the1st mark from the

top position correctly. When

the error still occurs, contact

your service organization.

Reading error. Remove the documents and

check the used OMR code.

Reading error. Remove the documents and

check the used OMR code.

Adjust the reading head.

Reading error. Remove the documents and

check the used OMR code

(flex-dongle).

Wrong window position. 3 : 112

Suspected set after error. 3 : 114

Not enough marks. 3 : 120

No basic command. 3 : 122

Wrong parity in code. 3 : 126

Undefined mark found 3 : 127

Reading error. Remove the documents and

check the used OMR code’s

(mark line distance).

Reading error. Remove the documents and

check the used OMR code

(flex-dongle).

Too many sheets. Remove the documents.

Check the set and complete

the set manually.

Incomplete set. Remove the documents.

Check the set and complete

the set manually.

Service assistance is needed for the error codes with the message “technical failure”. First write down

the error code, then switch the inserter off and on again, to verify system operation. When the error still

occurs contact your service organization.

Wrong mark distance. 3 : 128

Too many marks. 3 : 129

Set size exceeded. 3 : 134

Part of previous set. 3 : 135

24

Page 25

8. MAINTENANCE

8.1 Servicing

Disconnect the mains supply before

performing any maintenance.

The user must not attempt to service

the appliance beyond that described in

this operator manual. All other

servicing must be carried out by

qualified service personnel only.

Please contact your authorized

distributor.

8.2 General cleaning

The system must be kept in proper condition by

regularly removing dust, paper remains, etc.

Clean the sealing table and rubber rollers when

dirty. This can be done by using a slightly wetted

cloth soaked in warm water.

Do not clean the display with water or a cleaning

liquid.

8.3 Cleaning the brushes

Clean the brushes when dirty or saturated with

glue. An extra set of brushes is provided. The

best procedure is to always soak one set of

brushes and use the other set. In that way there

is always a clean set of brushes ready for

usage.

The brushes can be removed one by one by

pulling them straight off the brush holder. When

replacing the brushes, align the studs on each

brush with the respective holes in the brush

holder.

The brushes should be cleaned once a week.

The sensors can be cleaned by using the bellow

located behind the side cover.

For cleaning the envelope track sensor, put the

bellow in the hole (refer to the section

"Operating controls"). Squeeze a few times

firmly to blow away the dust from the sensor.

Repeat this procedure for the other hole for

cleaning the flap sensor.

9. OPTIONS

Optical Mark Reading

The system can be equipped with optical mark

reading. With this reading the system reads

optical marks that have been specially printed

on the documents. This code contains

information about the processing of the

documents.

Side exit

ENGLISH

At the rear exit a side exit can be fitted by the

service organization. The side exit can be fitted

instead of the standard envelope receiving tray.

The side exit allows a conveyor, conveyor/

stacker or a franking machine to be fitted in line

with the machine.

When a side exit is ordered, a receiving tray will

be delivered with it. The side exit can be

mounted for exiting enveloppes to the left or to

the right.

10. SPECIFICATIONS

This operator manual refers to machines as

from machine number 04 DO-5001 or higher.

8.4 Cleaning the moistening felt

Clean the moistening felt and water tray when

dirty or saturated with glue.

8.5 Cleaning the sensors

When the display shows a message like “Track

sensor dusty”, the sensors on the envelope or

document path must be cleaned. The screen on

the display indicates which sensor(s) must be

cleaned.

25

Page 26

26

Loading...

Loading...