Foxwell NT401 User Manual

NT401 Oil Service Tool Manual_English_V1.01

Trademarks

FOXWELL is trademark of Shenzhen Foxwell Technology Co., Ltd.

All other marks are trademarks or registered trademarks of their respective holders.

Copyright Information

© 2013 Shenzhen Foxwell Technology Co., Ltd.

All rights reserved.

Disclaimer

The information, specifications and illustrations in this manual are based on the latest information

available at the time of printing.

Foxwell reserves the right to make changes at any time without notice.

Visit our website at:

www.foxwelltech.com

For Technical Assistance, send us email at

support@foxwelltech.com

1

NT401 Oil Service Tool Manual_English_V1.01

One-Year Limited Warranty

Subject to the conditions of this limited warranty, Shenzhen Foxwell Technology Co., Ltd

(“FOXWELL”) warrants its customer that this product is free of defects in material and

workmanship at the time of its original purchase for a subsequent period of one (1) year.

In the event this product fails to operate under normal use, during the warranty period, due to

defects in materials and workmanship, FOXWELL will, at its sole option, either repair or replace

the product in accordance with the terms and conditions stipulated herein.

Terms and Conditions

1 If FOXWELL repairs or replaces the product, the repaired or replaced product shall be

warranted for the remaining time of the original warranty period. No charge will be made to the

customer for replacement parts or labor charges incurred by FOXWELL in repairing or replacing

the defective parts.

2 The customer shall have no coverage or benefits under this limited warranty if any of the

following conditions are applicable:

a) The product has been subjected to abnormal use, abnormal conditions, improper storage,

exposure to moisture or dampness, unauthorized modifications, unauthorized repair, misuse,

neglect, abuse, accident, alteration, improper installation, or other acts which are not the fault of

FOXWELL, including damage caused by shipping.

b) The Product has been damaged from external causes such as collision with an object, or from

fire, flooding, sand, dirt, windstorm, lightning, earthquake or damage from exposure to weather

conditions, an Act of God, or battery leakage, theft, blown fuse, improper use of any electrical

source, or the product was used in combination or connection with other product, attachments,

supplies or consumables not manufactured or distributed by FOXWELL.

3 The customer shall bear the cost of shipping the product to FOXWELL. And FOXWELL shall

bear the cost of shipping the product back to the customer after the completion of service under

this limited warranty.

4 FOXWELL does not warrant uninterrupted or error-free operation of the product. If a problem

develops during the limited warranty period, the consumer shall take the following step-by-step

procedure:

a) The customer shall return the product to the place of purchase for repair or replacement

processing, contact your local FOXWELL distributor or visit our website www.foxwelltech.com to

get further information.

b) The customer shall include a return address, daytime phone number and/or fax number,

complete description of the problem and original invoice specifying date of purchase and serial

number.

c) The customer will be billed for any parts or labor charges not covered by this limited warranty.

d) FOXWELL will repair the Product under the limited warranty within 30 days after receipt of the

product. If FOXWELL cannot perform repairs covered under this limited warranty within 30 days,

or after a reasonable number of attempts to repair the same defect, FOXWELL at its option, will

provide a replacement product or refund the purchase price of the product less a reasonable

amount for usage.

e) If the product is returned during the limited warranty period, but the problem with the product is

not covered under the terms and conditions of this limited warranty, the customer will be notified

and given an estimate of the charges the customer must pay to have the product repaired, with all

shipping charges billed to the customer. If the estimate is refused, the product will be returned

freight collect. If the product is returned after the expiration of the limited warranty period,

FOXWELL’ normal service policies shall apply and the customer will be responsible for all

shipping charges.

5 ANY IMPLIED WARRANTY OF MERCHANTABILITY, OR FITNESS FOR A PARTICULAR

PURPOSE OR USE, SHALL BE LIMITED TO THE DURATION OF THE FOREGOING LIMITED

2

NT401 Oil Service Tool Manual_English_V1.01

WRITTEN WARRANTY. OTHERWISE, THE FOREGOING LIMITED WARRANTY IS THE

CONSUMER’S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED. FOXWELL SHALL NOT BE LIABLE FOR SPECIAL,

INCIDENTAL, PUNITIVE OR CONSEQUENTIAL DAMAGES, INCLUDING BUT NOT LIMITED

TO LOSS OF ANTICIPATED BENEFITS OR PROFITS, LOSS OF SAVINGS OR REVENUE,

LOSS OF DATA, PUNITIVE DAMAGES, LOSS OF USE OF THE PRODUCT OR ANY

ASSOCIATED EQUIPMENT, COST OF CAPITAL, COST OF ANY SUBSTITUTE EQUIPMENT

OR FACILITIES, DOWNTIME, THE CLAIMS OF ANY THIRD PARTIES, INCLUDING

CUSTOMERS, AND INJURY TO PROPERTY, RESULTING FROM THE PURCHASE OR USE

OF THE PRODUCT OR ARISING FROM BREACH OF THE WARRANTY, BREACH OF

CONTRACT, NEGLIGENCE, STRICT TORT, OR ANY OTHER LEGAL OR EQUITABLE

THEORY, EVEN IF FOXWELL KNEW OF THE LIKELIHOOD OF SUCH DAMAGES. FOXWELL

SHALL NOT BE LIABLE FOR DELAY IN RENDERING SERVICE UNDER THE LIMITED

WARRANTY, OR LOSS OF USE DURING THE PERIOD THAT THE PRODUCT IS BEING

REPAIRED.

6 Some states do not allow limitation of how long an implied warranty lasts, so the one-year

warranty limitation may not apply to you (the Consumer). Some states do not allow the exclusion

or limitation of incidental and consequential damages, so certain of the above limitations or

exclusions may not apply to you (the Consumer). This limited warranty gives the Consumer

specific legal rights and the Consumer may also have other rights which vary from state to state.

3

NT401 Oil Service Tool Manual_English_V1.01

Safety Information

For your own safety and the safety of others, and to prevent damage to the equipment and

vehicles, read this manual thoroughly before operating your service tool. The safety messages

presented below and throughout this user’s manual are reminders to the operator to exercise

extreme care when using this device. Always refer to and follow safety messages and test

procedures provided by vehicle manufacturer. Read, understand and follow all safety messages

and instructions in this manual.

Safety Message Conventions Used

We provide safety messages to help prevent personal injury and equipment damage. Below are

signal words we used to indicate the hazard level in a condition.

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury to the operator or to bystanders.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious

injury to the operator or to bystanders.

Indicates a potentially hazardous situation which, if not avoided, may result in moderate or minor

injury to the operator or to bystanders.

Important Safety Instructions

And always use your service tool as described in the user’s manual, and follow all safety

messages.

● Do not route the test cable in a manner that would interfere with driving controls.

● Do not exceed voltage limits between inputs specified in this user’s manual.

● Always wear ANSI approved goggles to protect your eyes from propelled objects as well as hot

or caustic liquids.

● Fuel, oil vapors, hot steam, hot toxic exhaust gases, acid, refrigerant and other debris produced

by a malfunction engine can cause serious injury or death. Do not use the service tool in areas

where explosive vapor may collect, such as in below-ground pits, confined areas, or areas that

are less than 18 inches (45 cm) above the floor.

● Do not smoke, strike a match, or cause a spark near the vehicle while testing and keep all

sparks, heated items and open flames away from the battery and fuel / fuel vapors as they are

highly flammable.

● Keep a dry chemical fire extinguisher suitable for gasoline, chemical and electrical fires in work

area.

● Always be aware of rotating parts that move at high speed when an engine is running and keep

a safe distance from these parts as well as other potentially moving objects to avoid serious

injury.

● Do not touch engine components that get very hot when an engine is running to avoid severe

burns.

● Block drive wheels before testing with engine running. Put the transmission in park (for

automatic transmission) or neutral (for manual transmission). And never leave a running engine

unattended.

● Do not wear jewelry or loose fitting clothing when working on engine.

4

NT401 Oil Service Tool Manual_English_V1.01

Table of Contents

ONE-YEAR LIMITED WARRANTY

.....................................................................................................................

2

SAFETY INFORMATION

......................................................................................................................................

4

SAFETY MESSAGE CONVENTIONS USED

...........................................................................................................

4

IMPORTANT SAFETY INSTRUCTIONS

...................................................................................................................

4

1 USING THIS MANUAL

.......................................................................................................................................

7

1.1 BOLD TEXT

....................................................................................................................................................

7

1.2 SYMBOLS AND ICONS

....................................................................................................................................

7

1.2.1 Solid Spot

............................................................................................................................................

7

1.2.2 Arrow Icon

...........................................................................................................................................

7

1.2.3 Note and Important Message

...........................................................................................................

7

2 INTRODUCTION

.................................................................................................................................................

8

2.1 SCANNER DESCRIPTIONS

.............................................................................................................................

8

2.2 ACCESSORY DESCRIPTIONS

.........................................................................................................................

9

2.3 TECHNICAL SPECIFICATIONS

........................................................................................................................

9

3 GETTING STARTED

..........................................................................................................................................

9

3.1 PROVIDING POWER TO SCANNER

................................................................................................................

9

3.1.1 Connecting to Vehicle Power

...........................................................................................................

9

3.1.2 Connecting to Personal Computer with USB Cable

...................................................................

10

3.2 APPLICATION OVERVIEW

............................................................................................................................

10

3.3 INPUT DIALOG BOX

.....................................................................................................................................

10

4 INSTRUCTIONS

...............................................................................................................................................

11

4.1 VEHICLE IDENTIFICATION

............................................................................................................................

11

4.2 SERVICE RESET OPERATIONS

...................................................................................................................

13

4.2.1 Oil Reset With One Button

.............................................................................................................

13

4.2.2 Manual Reset

....................................................................................................................................

14

4.2.3 Auto Reset

.........................................................................................................................................

15

4.2.3.1 AUDI/SEAT/SKODA/VW Operations

....................................................................................

15

4.2.3.2 BMW Operations

......................................................................................................................

18

OBDII 16PIN Connector

..................................................................................................................

18

20PIN Connector

..............................................................................................................................

23

4.2.3.3 Fiat Operations

.........................................................................................................................

23

4.2.3.4 GM Operations

.........................................................................................................................

25

4.2.3.5 Mercedes Benz Operations

....................................................................................................

28

4.2.3.6 Land Rover Operations

...........................................................................................................

30

4.2.3.7 Saab Operations

......................................................................................................................

33

4.2.3.8 Vauxhall Operations

................................................................................................................

35

4.2.3.9 Volvo Operations

.....................................................................................................................

36

5 OBDII/EOBD OPERATIONS

..........................................................................................................................

38

5.1 SYSTEM STATUS

.........................................................................................................................................

38

5

NT401 Oil Service Tool Manual_English_V1.01

5.2 READ CODES

..............................................................................................................................................

39

5.3 ERASE CODES

............................................................................................................................................

41

5.4 LIVE DATA

...................................................................................................................................................

41

5.4.1 Complete Data List

..........................................................................................................................

42

5.4.2 Custom Data List

..............................................................................................................................

44

5.5 FREEZE FRAME

...........................................................................................................................................

45

5.6 READ I/M READINESS STATUS DATA

........................................................................................................

46

5.7 O2 MONITOR TEST

.....................................................................................................................................

48

5.8 ON-BOARD MONITOR TEST

.......................................................................................................................

49

5.9 COMPONENT TEST

......................................................................................................................................

51

5.10 REQUEST VEHICLE INFORMATION

...........................................................................................................

52

5.11 MODULES PRESENT

.................................................................................................................................

53

5.12 DTC LOOKUP

...........................................................................................................................................

54

6 PLAYBACK DATA

............................................................................................................................................

56

7 SYSTEM SETUP

..............................................................................................................................................

57

7.1 SELECT LANGUAGE

....................................................................................................................................

57

7.2 CHANGE UNITS

...........................................................................................................................................

58

7.3 CONFIGURE BEEPER

..................................................................................................................................

59

7.4 TEST KEYPAD

.............................................................................................................................................

59

7.5 LCD KEYPAD

..............................................................................................................................................

60

7.6 TOOL INFORMATION

....................................................................................................................................

61

7.7 CONFIGURE SHORTCUT KEYS

...................................................................................................................

61

8 UPDATE

.............................................................................................................................................................

62

8.1 REGISTER THE SCANNER

...........................................................................................................................

62

8.2 UPDATE THE SCANNER

..............................................................................................................................

67

6

1 Using This Manual

We provide tool usage instructions in this manual. Below is the conventions we used in the

manual.

1.1 Bold Text

Bold text is used to highlight selectable items such as buttons and menu options.

Example:

Press the ENTER button to select.

1.2 Symbols and Icons

1.2.1 Solid Spot

Operation tips and lists that apply to specific tool are introduced by a solid spot ●.

Example:

When System Setup is selected, a menu that lists all available options displays. Menu options

include:

● Languages

● Unit

● Beep

● Keypad Test

● LCD Test

● About

● Shortcuts

1.2.2 Arrow Icon

An arrow icon indicates a procedure.

Example:

To change menu language:

1. Scroll with the arrow keys to highlight Language on the menu.

2. Press the ENTER button to select.

1.2.3 Note and Important Message

Note

A NOTE provides helpful information such as additional explanations, tips, and comments.

Example:

NOTE

Test results do not necessarily indicate a faulty component or system.

Important

IMPORTANT indicates a situation which, if not avoided, may result in damage to the test

equipment or vehicle.

Example:

IMPORTANT

Do not soak keypad as water might find its way into the scanner.

NT401 Oil Service Tool Manual_English_V1.01

7

2 Introduction

Oil changes are the #1 service your shop will perform each year. Enhance your service with the

latest NT401 Oil Light Reset Tool from Foxwell and eliminate the need to take the vehicle to the

dealer or use an OEM service tool to reset oil service lights.

With the tool properly connected to the vehicle’s data link connector (DLC), you can use the

service tool to reset oil service light, oil inspection light, service mileage, service intervals and

more on 32 vehicles.

2.1 Scanner Descriptions

This section illustrates external features, ports and connectors of the service tool.

Figure 2-1 Front View

1 Diagnostic Port - provides connection between the service tool and vehicle.

2 LCD Display - shows menus, test results and operation tips.

3 Function Keys / Shortcut keys - three keys that correspond with “buttons” on some screens for

executing special commands or provide quick access to most frequently used applications or

functions.

4 Direction Keys - select an option or scroll through a screen of data or text.

5 BACK Key - exits a screen and generally returns to previous screen.

6 ENTER Key - executes a selected option and generally goes to the next screen.

7 HELP Key - displays helpful information.

NT401 Oil Service Tool Manual_English_V1.01

8

8 Power Switch - turns on/off the service tool and press and hold for 5 seconds for emergency

reboots.

9 SD Card Port - holds the SD memory card for data backup and software update.

10 USB Port - provides a USB connection between the Service tool and PC or laptop

IMPORTANT

Do not use solvents such as alcohol to clean keypad or display. Use a mild nonabrasive

detergent and a soft cotton cloth.

2.2 Accessory Descriptions

This section lists the accessories that go with the service tool. If you find any of the following

items missing from your package, contact your local dealer for assistance.

1 User’s Guide - provides operation instructions for the usage of the service tool.

2 USB Cable - provides connection between the service tool and a computer to upgrade the tool.

3 Memory Card - contains the service tool’s operating software and applications.

IMPORTANT

Do not remove the memory card unless performing updates to the card.

4 Diagnostic Cable - provides connection between the service tool and vehicle.

5 Nylon Carry Pouch - stores the service tool and its accessories.

2.3 Technical Specifications

Display: Backlit, 240*320 TFT color display

Working Temperature: 0 to 60 ℃ (32 to 140℉)

Storage Temperature: -20 to 70℃ (-4 to 158℉)

Power Supply: 8-18V powered by vehicle battery

Dimensions (L*W*H): 200*100*38mm

Gross Weight: 1.2Kg

Protocols: SAE J1850 (VPW and PWM), ISO 9141-2, ISO 14230-2 (KWP 2000), ISO 15765-4

(CAN)

3 Getting Started

This section describes how to provide power to the service tool, provides brief introductions of

applications loaded on the service tool and display screen layout and illustrates how to input text

and numbers with the service tool.

3.1 Providing Power to Scanner

Before using the service tool, make sure to provide power to the service tool.

The unit operates on any of the following sources:

● 12-volt vehicle power

● USB connection to personal computer

NT401 Oil Service Tool Manual_English_V1.01

9

NT401 Oil Service Tool Manual_English_V1.01

3.1.1 Connecting to Vehicle Power

The service tool normally powers on whenever it is connected to the data link connector (DLC).

To connect to vehicle power:

1. Locate the data link connector (DLC). The DLC is generally located under the dash on the

driver side of the vehicle.

2. Attached the diagnostic cable to the service tool and tighten the captive screws to ensure good

connection.

3. Connect a correct adapter to the data cable according to the vehicle being serviced and plug it

into the vehicle DLC.

4. Switch the ignition key to the ON position.

5. The service tool automatically boots up.

IMPORTANT

Never try to provide power for the service tool from USB connection when the service tool is

communicating with a vehicle.

3.1.2 Connecting to Personal Computer with USB Cable

The service tool also receives power through the USB port when it is connected to a PC for

updating software and transferring saved files.

To connect to PC:

1. Insert the small end of the USB cable to the USB port at the right side of the scanner and the

large end to a computer.

2. Press the power switch of the service tool to power it on.

3.2 Application Overview

When the service tool boots up, the Home screen opens. This screen shows all applications

loaded on the unit.

Following applications are preloaded into the service tool:

● OBDII/EOBD – leads to OBDII screens for all 9 generic OBD system tests.

● Oil Reset – leads to screens for resetting oil service light, oil inspection light, service mileage,

service intervals and more on 32 vehicle makes sold worldwide.

● Setup – leads to screens for adjusting default settings to meet your own preference and view

information about the scanner.

● Playback – leads to screens for access saved data files.

3.3 Input Dialog Box

This section illustrates how to use the service tool to input letters and numbers, such as channel

number, test values, service intervials, oil life values, service mileage, and DTC number.

Typically, you may be required to input letters or numbers when you are doing any of the

following operations.

● Input channel number

● look up DTCs

● service intervals

● oil life values

● service mileage

The service tool provides 3 different types of keyboard to meet your specific needs. Depending

on the needs of text entry, it automatically shows the most suitable keypad.

● classic QWERTY keyboad for input of texts that contain both letters and numbers

● numeric keyboard for input of numbers

● alphabet keyboard for input of letters

To input text with the service tool:

10

NT401 Oil Service Tool Manual_English_V1.01

1. When you are requested to input text, press the function key Keyboard, and the keyboard

displays.

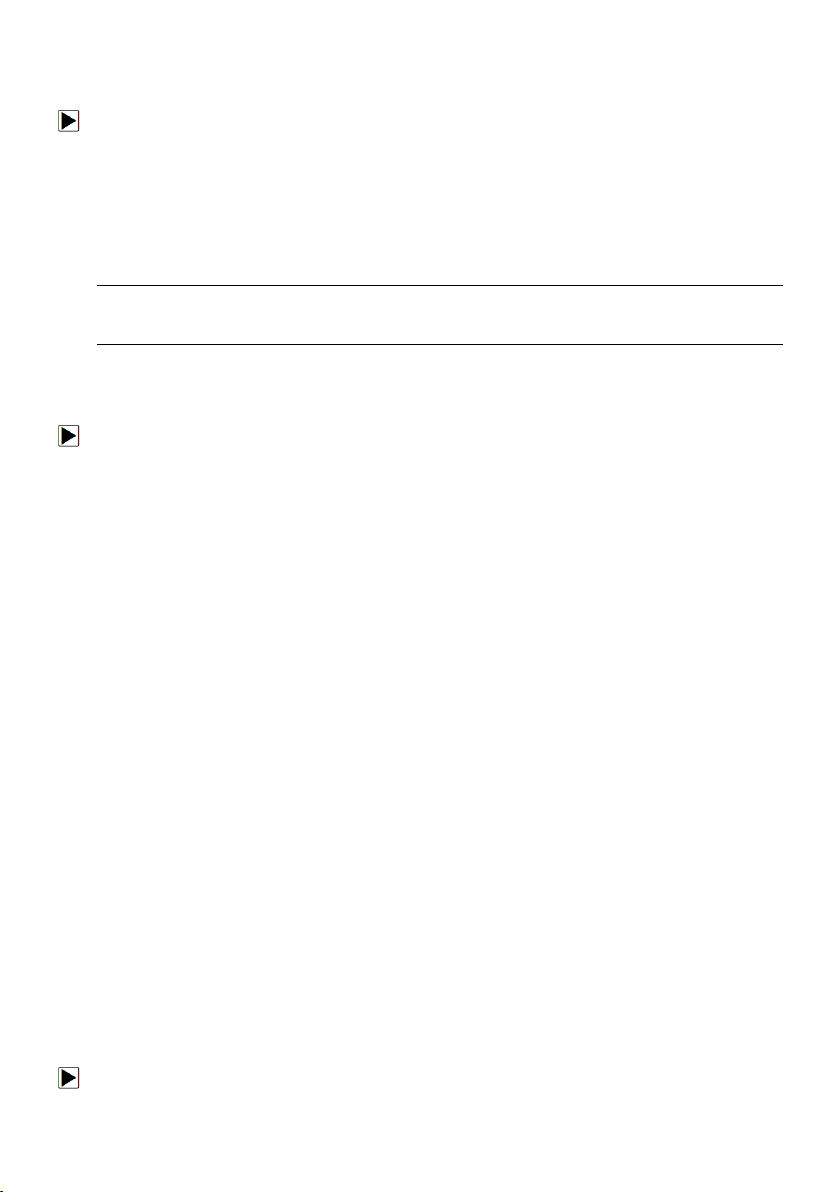

Figure 3-1 Sample Input Text Screen

2. Scroll with the arrow keys to highlight your desired letter or number and press the ENTER key

to confirm.

Figure 3-2 Sample QWERTY Keyboard Screen

3. To delete a letter or number, use the function key Previous to move the cursor to it and then

press the Backspace button.

4. When finished the entry, press Finish key to continue.

4 Instructions

This section illustrates how to use the service tool to reset oil service light, oil inspection light,

service mileage, service intervals and more on 32 vehicle manufacturers.

NOTE

All software screens shown in this manual are examples; actual test screens may vary by the

year, model, and makes of the test vehicle. Observe the menu titles and onscreen instructions to

make correct option selections.

11

NT401 Oil Service Tool Manual_English_V1.01

4.1 Vehicle Identification

The vehicle identification information presented is provided by the ECM of the vehicle being

tested. Therefore, certain attributes of the test vehicle must be entered into the service tool to

ensure the data displays correctly. The vehicle identification sequence is menu driven, you simply

follow the screen prompts and make a series of choices. Each selection you make advances you

to the next screen. Exact procedures may vary somewhat by vehicle.

To identify a vehicle:

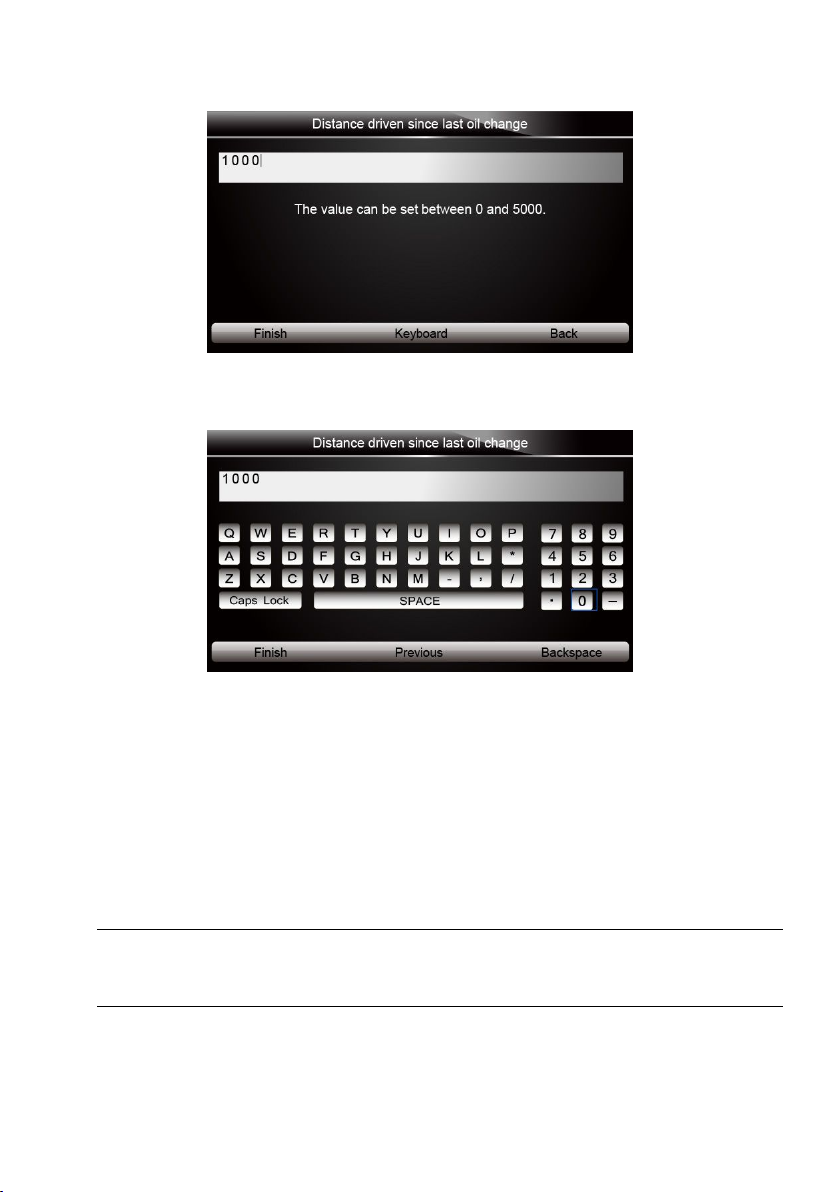

1. Scroll with the arrow keys to highlight Oil Reset from the Application menu and press the

ENTER key to start. If you have the application assigned to one of the function keys at the

bottom of the screen, you can alternatively press the function key to start the application.

Figure 4-1 Sample Application Menu Screen

2. A screen with a list of vehicles displays. Select the vehicle you wish to test and press the

ENTER key.

Figure 4-2 Sample Vehicle Manufacturer Selection Screen

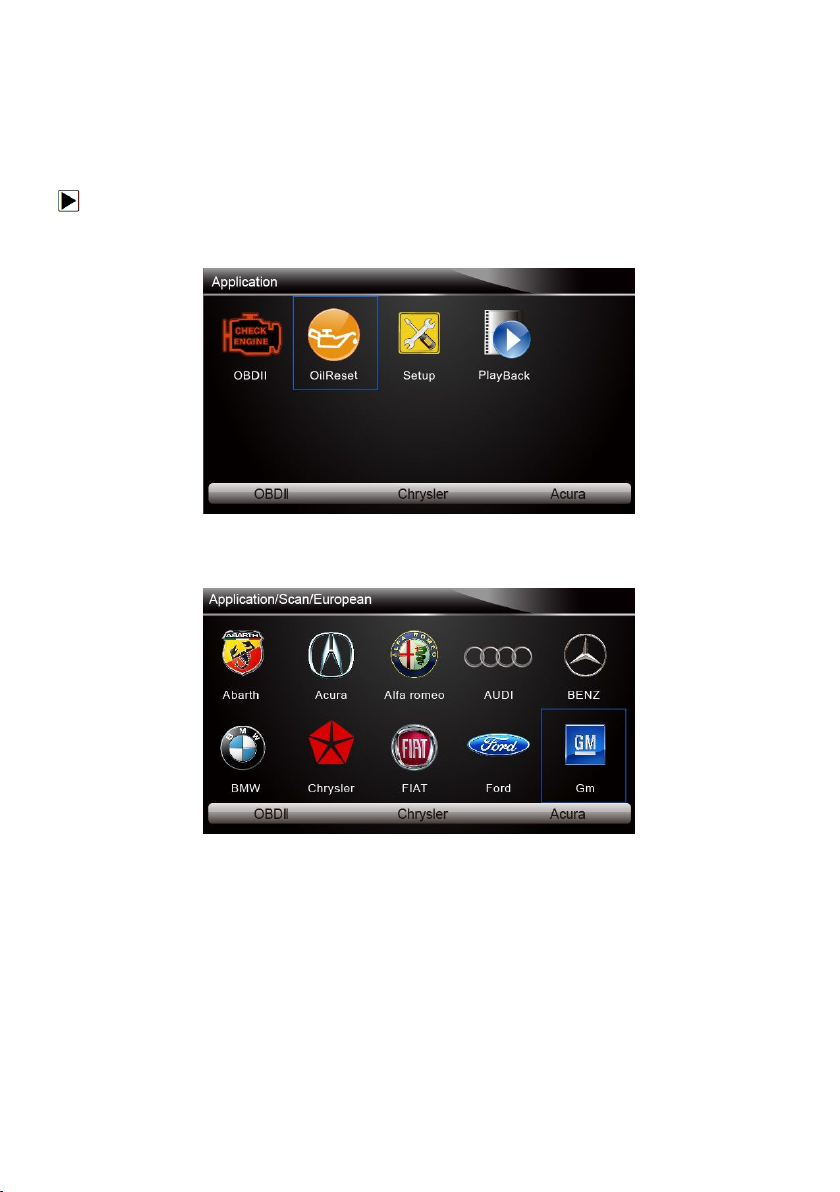

3. On each screen that appears, select the correct option and then press the ENTER key. Do this

until the complete vehicle information is entered and the menu of controller selection displays.

12

NT401 Oil Service Tool Manual_English_V1.01

Figure 4-3 Sample Vehicle Selection Screens

4.2 Service Reset Operations

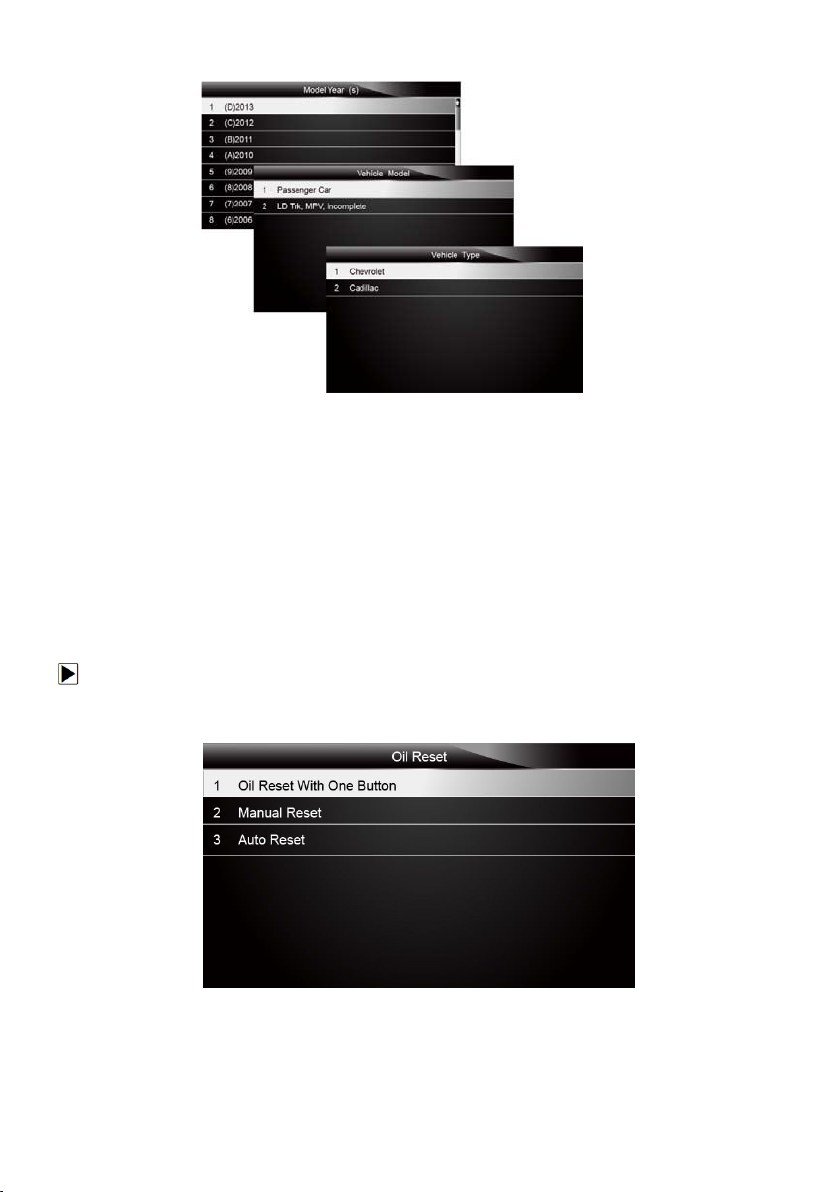

Oil service reset methods are determined by the vehicle being tested. Depending on the vehicle

being tested, any of the following means displays:

● Oil Reset With One Button

● Manual Reset

● Auto Reset

4.2.1 Oil Reset With One Button

Oil Reset With One Button is applicable to GM models only. It offers quick and simple oil service

reset with the click of one button.

To do Oil Reset With One Button:

1. Scroll with up and down arrow keys to highlight Oil Reset With One Button from the Oil Reset

menu. An Information screen displays. Press the function key OK to continue or Cancel key to

return to the Oil Reset menu.

Figure 4-4 Sample Oil Reset Menu Screen

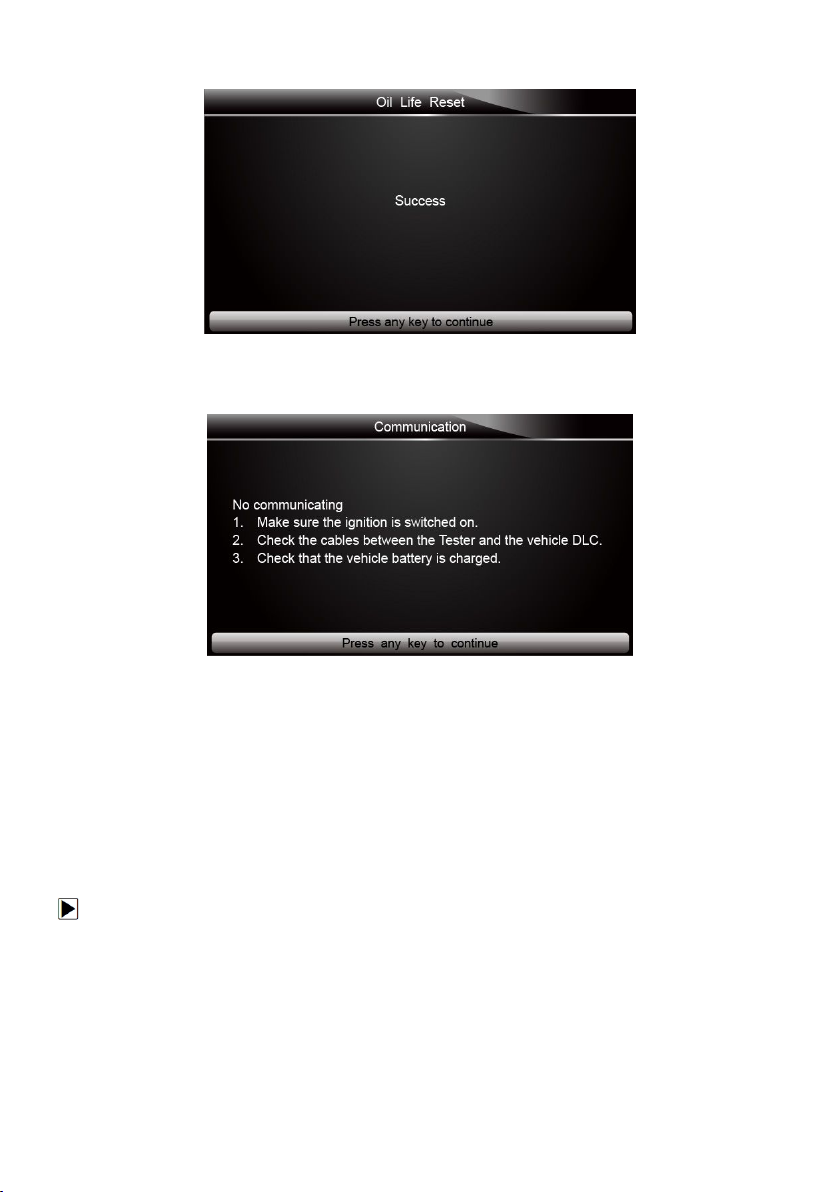

2. Follow on-screen instruction and send a command to reset oil service. A screen with

“Success” message displays once the lamp has been reset. Press any key to return.

13

NT401 Oil Service Tool Manual_English_V1.01

Figure 4-5 Sample Oil Reset With One Button Success Screen

3. If the oil service reset failed, the following screen displays. Please follow on-screen instructions

to troubleshoot it. If the problem still exists, please contact your local dealer for assistant.

Figure 4-6 Sample Oil Reset With One Button Failed Screen

4.2.2 Manual Reset

Almost all Asian vehicles and most American and European vehicles have mechanical oil service

indicator reset. The service tool does not have to communicate with the vehicle being tested, but

guides you to complete the service manually by providing step-by-step on-screen instructions.

When Manual Reset is selected and the vehicle being tested identified, a procedure opens on the

screen. Scroll with arrow keys to read the entire procedure and performing the necessary steps

as directed by the on-screen instructions. The exact order of the test operation steps may vary

depending on the test vehicle. Be sure to follow all on-screen instructions.

This manual reset procedure can be interrupted and aborted if the ignition key position is

changed.

To do oil reset manually:

1. Scroll with up and down arrow keys to highlight Manual Reset from the Oil Reset menu and

press ENTER to confirm.

14

NT401 Oil Service Tool Manual_English_V1.01

Figure 4-7 Sample Oil Reset Menu Screen

2. Enter vehicle information by certain VIN characters, such as model, and year to identify the

vehicle being tested and press ENTER key to confirm.

Figure 4-8 Sample Vehicle Identification Screens

3. When the vehicle is identified, a procedure screen displays.

Figure 4-9 Sample Manual Reset Instructions Screen

4. Follow all on-screen instructions to perform the manual mechanical reset.

5. Press function key OK to return.

15

NT401 Oil Service Tool Manual_English_V1.01

4.2.3 Auto Reset

Auto Reset is a bi-directional communication procedure directed by the service tool. The service

tool displays guides for you through the process. A number of instructions that require a response

to continue display, including an option to clear any stored codes once the interval has been reset.

Follow the on-screen instructions.

4.2.3.1 AUDI/SEAT/SKODA/VW Operations

Oil Service menu allows to reset the Service Reminder in vehicles so equipped. This function will

automatically access the Instrument Cluster and will retrieve SRI instructions as well as current

values stored in the cluster. It will also specify the total length in kilometers and or days between

the service intervals. In this case it only specifies the time or distance between intervals, it does

not reset the interval. When an inspection has been carried out prematurely (before the service

interval is required), it will read the kilometers or days since the last service set them to the

required value.

To do oil service reset on AUDI/SEAT/SKODA/VW vehicles:

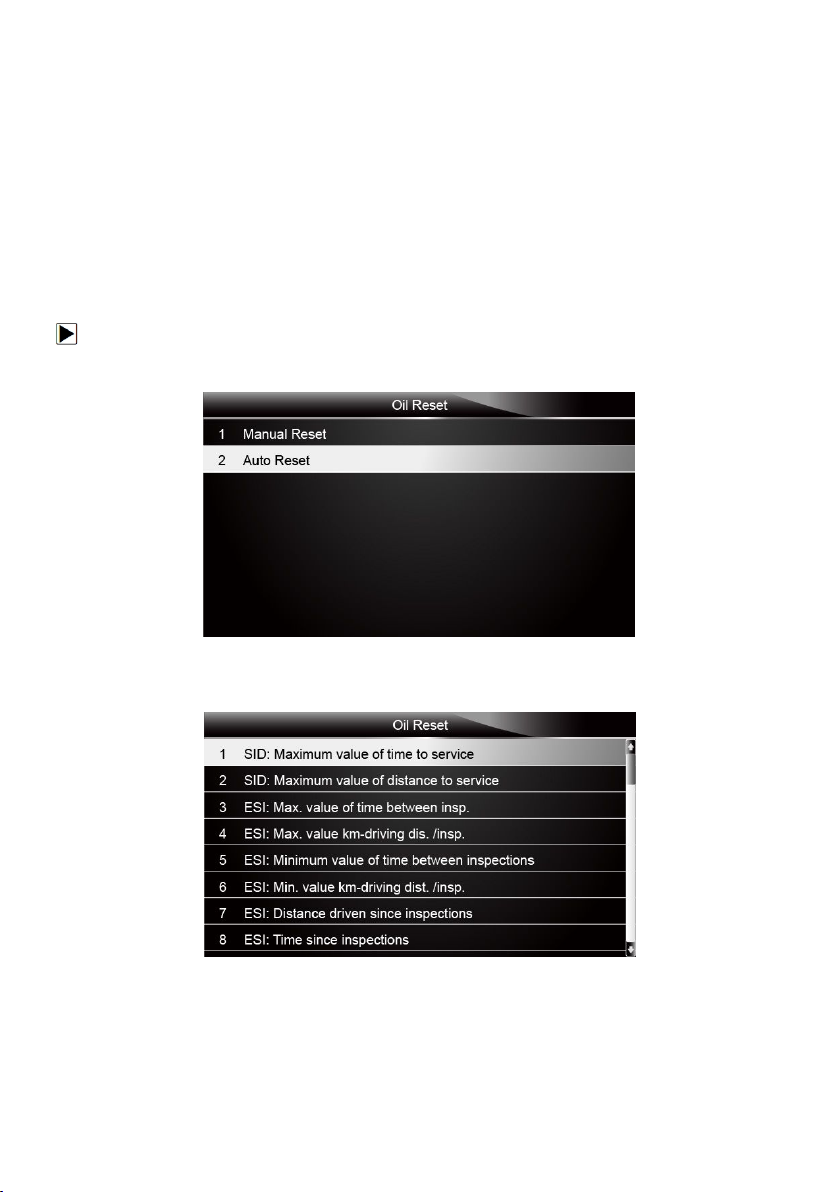

1. Scroll with up and down arrow keys to highlight Auto Reset from the Oil Reset menu and press

ENTER. A screen with a list of available service displays.

Figure 4-10 Sample Oil Reset Menu Screen

2. Scroll with the arrow keys to highlight a function you wish to test and press the ENTER key to

confirm.

Figure 4-11 Sample Oil Reset Function Screen

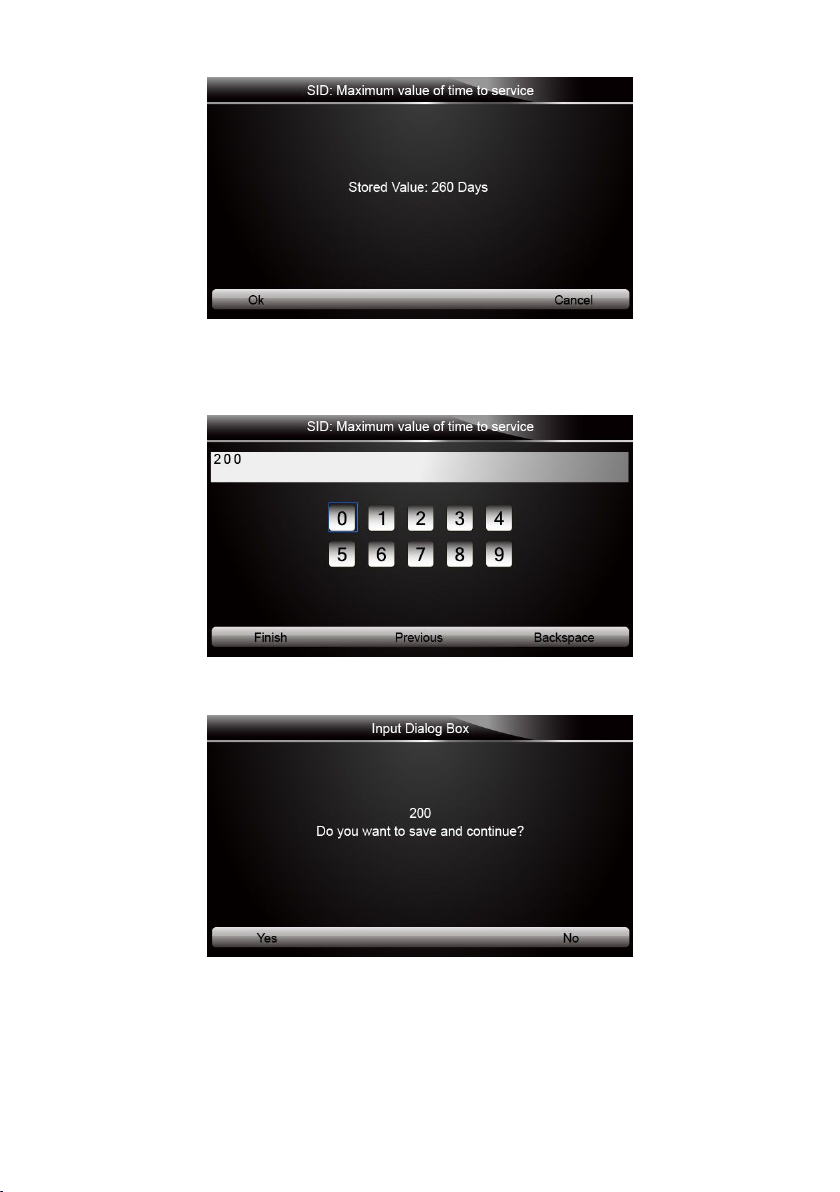

3. The stored value on the vehicle being tested displays. Press the function key OK to set the

service value you want or press the function key Cancel to quit service reset.

16

NT401 Oil Service Tool Manual_English_V1.01

Figure 4-12 Sample Vehicle Stored Value Screen

4. Enter a valid value and press Finish to continue.

Figure 4-13 Sample Service Time Value Entry Screen

5. Press the function key Yes to save and continue, or press the function key NO to quit.

Figure 4-14 Sample Input Dialog Box Screen

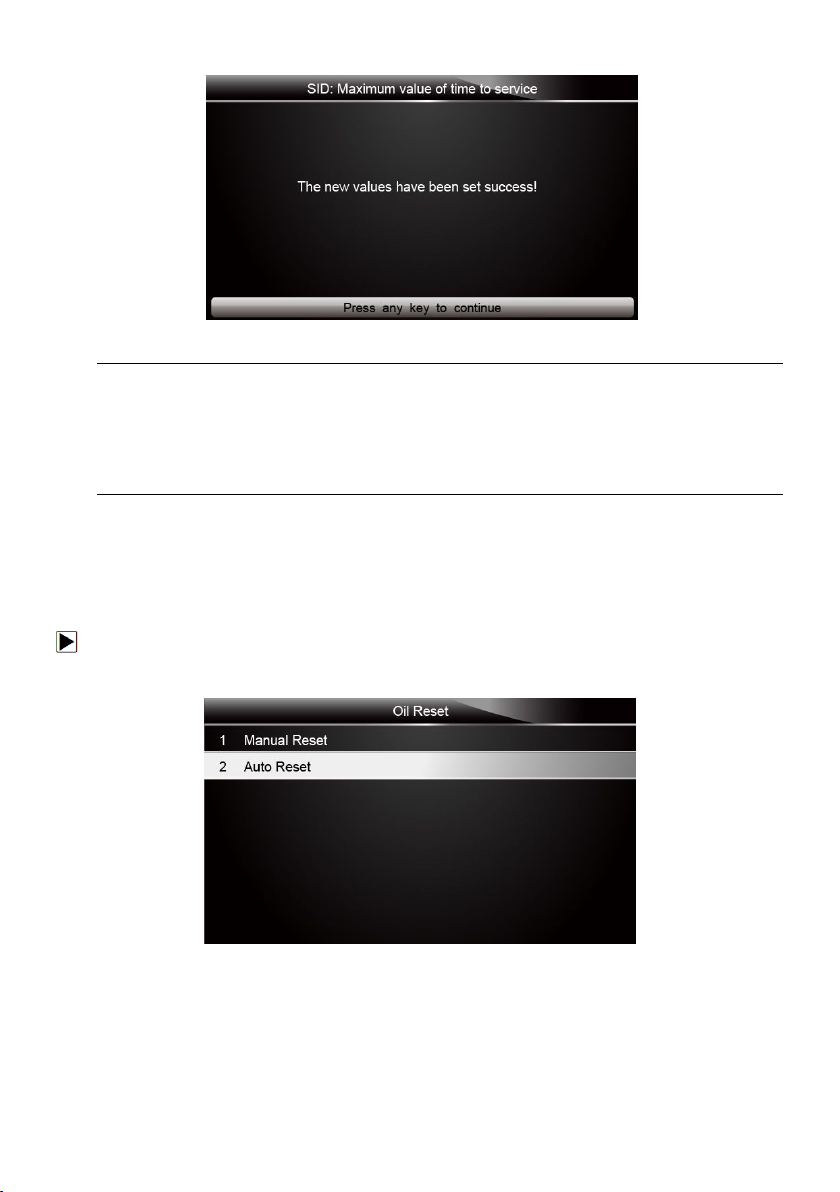

6. If the service reset has been completed, a confirmation message comes up. Press any key to

return.

17

NT401 Oil Service Tool Manual_English_V1.01

Figure 4-15 Sample Service Interval Reset Successful Screen

NOTE

●

“Stored Value” is the value of the most recent setup retrieved by NT401. If you change your

mind after making new setups, it can be used to reset all changed values to original ones. It is

advised to write down this value before making any changes.

●

If “No communicating” message comes up, it indicates the oil reset failed. Please follow

on-screen instructions to troubleshoot it. If the problem still exists, please contact your local

dealer for assistant.

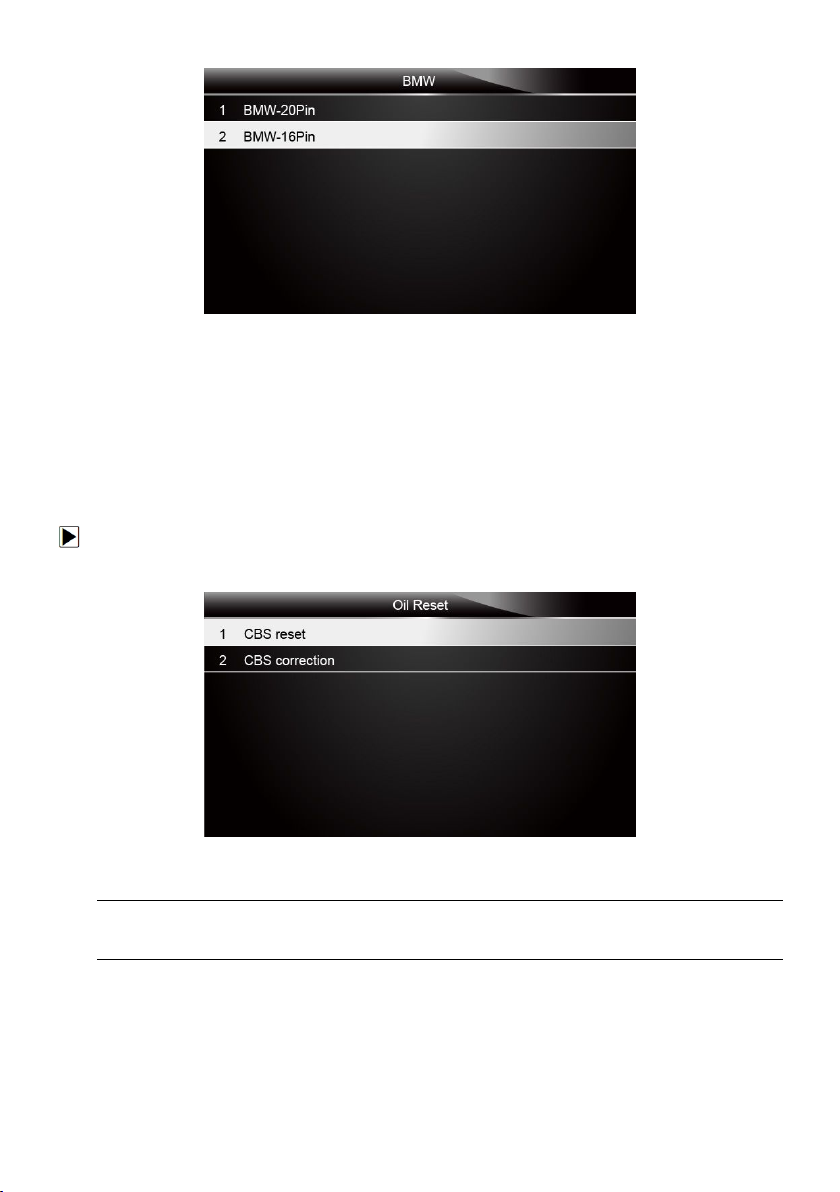

4.2.3.2 BMW Operations

This section illustrates how to reset the oil service lamps on the instrument cluster of BMW

vehicles. The Service Indicator System (SIA) is designed to alert the driver when the vehicle is

due for a service. The BMW Maintenance System includes the Engine Oil Service and

Inspections I (minor service) and II (major service). Different years and models have display

variations depending on the instrument cluster level type.

To perform oil service on BMW:

1. Scroll with up and down arrow keys to highlight Auto Reset from the Oil Reset menu and press

ENTER to start.

Figure 4-16 Sample Oil Reset Menu Screen

2. The connector type selection screen displays. Scroll with arrow keys to select the connector

type for the vehicle being tested.

18

NT401 Oil Service Tool Manual_English_V1.01

Figure 4-17 Sample BMW Vehicle Connector Screen

OBDII 16PIN Connector

BMW vehicles with OBDII connector have more service functions than those with 20-PIN

connector.

There are two ways to complete oil reset on 16 PIN Connector vehicles.

● CBS reset

● CBS correction

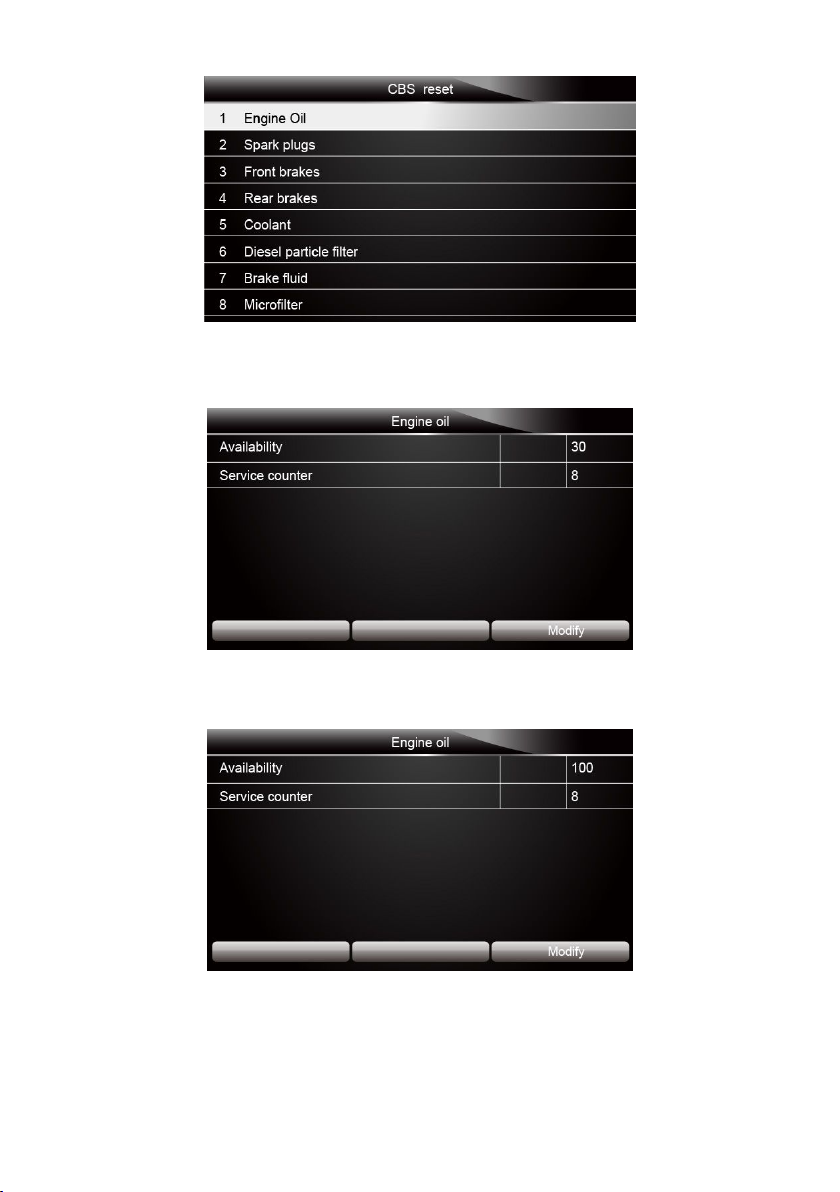

CBS reset

To perform oil service functions on BMW with OBDII connector:

1. To complete the service functions automatically, scroll with up and down arrow keys to select

CBS Reset from the Oil Reset menu and press ENTER key to confirm.

Figure 4-18 Sample Oil Reset Menu Screen

NOTE

Not all functions listed are applicable to all vehicles. Available options may very by the model

year of the vehicle being tested.

2. A screen with available services displays.

19

NT401 Oil Service Tool Manual_English_V1.01

Figure 4-19 Sample CBS Reset Menu Screen

3. Scroll with up and down arrow keys to highlight service you want to perform and press ENTER

key to confirm. Press Modify to perform the service.

Figure 4-20 Sample Engine Oil Reset Screen

4. A command to reset the engine oil is sent. A screen with ECU default value displays when the

lamp has been reset successfully. Press any key to return to the function menu.

Figure 4-21 Sample Engine Oil Reset Successful Screen

5. If it fails to reset engine oil, the following screen displays. Please follow the on-screen

instructions to troubleshoot it. If the problem still exists, please contact your local dealer for

assistant.

20

Loading...

Loading...