Page 1

THEA-130 / 160

Sprayer Drone

User Manual

V1.0

2019.04

Page 2

Contents

THEA-130 / 160 Sprayer Drone User Manual

Disclaimer

Flight Operation

Environmental Requirements

Pre-ight Check

Compass Clibration

Work in Manual Stabilization Mode

Work in Manual Plus (AB point) Mode

Repair and Maintenance

Replace the Propeller

Replace the Motor

Replace the ESC

Replace Nozzles

Replace the Pump

3

5

5

5

5

6

7

11

11

11

11

11

11

Cleaning After Use

System Introduction

System Characteristic

Introduction to Flight Mode

Installation and Connection

System Supporting List

Flight Controller System Connection Diagram

Interface Denition

Status Indicator Description

Remote Control Equipment

Receiver

Remote Control Conguration

Unlocking and Locking for Flight Control

12

13

13

14

15

15

15

16

18

20

20

20

21

ESC Calibration (Electronic Speed Controller)

22

©

2019 FOXTECH All Rights Reserved

1

Page 3

THEA-130 / 160 Sprayer Drone User Manual

Remote Control Protection

Protect Content

Return Logic

Remote Control Security

Data Link Loss of Control

Voltage Detection and Protection

Area Limited Protection

Ground Station Setting

Equipment Connection

Function Introduction

Route Planning

Ready to Take Off

RTK Use Instructions

23

23

24

24

25

25

25

26

26

27

32

36

37

Concise Operation Process

Precautions

Failure Analysis

After-sales Service

Installation of Ground Station and Drivers

Installation

40

41

42

43

44

44

©

2019 FOXTECH All Rights Reserved

2

Page 4

THEA-130 / 160 Sprayer Drone User Manual

Disclaimer

1. To protect the legitimate rights and interests of users, please read the instructions, disclaimers and safety

instructions provided with this product before using this product. Know your legal rights, responsibilities,

and safety instructions; otherwise you may incur property damage, safety incidents, and personal safety

hazards. The company reserves the right to update the above documents. Please be sure to operate this

product in accordance with the instructions and safety instructions.

2. The company will not be responsible for any violation of the law that occurs directly or indirectly by the

user.

3. This product is not suitable for people under the age of 18 and other people who do not have full civil

capacity. Please avoid the above-mentioned people from contacting this product. In the case where the

above-mentioned persons appear, please pay special attention to the operation.

4. Once you start using this product, you are deemed to have read, understood, approved and accepted all

terms and conditions of the product's instructions, disclaimers and safety instructions. The user is committed

to being responsible for his or her actions and all consequences arising by this. The User undertakes to use

the Product solely for legitimate purposes and agrees to these Terms and any relevant policies or guidelines

that may be established by the Company.

5. In the process of using this product, please strictly observe and implement the requirements including but

not limited to the instructions and safety instructions. All personal injury, accident, property damage, legal

disputes, and other adverse events that cause conflicts of interest caused by breach of safety instructions

or force majeure factors shall be borne by the user and the company shall not bear any responsibility.

6. We do not provide any technical support and security commitments in the following situations:

1) Units or individuals who obtain this product through informal agents or irregular channels;

2) Products that are not authorized to be modified, commissioned or replaced;

3) Warranty card, serial number or flight data are lost;

4) Personal injury and property damage due to personal operation errors.

©

2019 FOXTECH All Rights Reserved

3

Page 5

THEA-130 / 160 Sprayer Drone User Manual

1. To protect the legitimate rights and interests of users, please read the instructions, disclaimers and safety

instructions provided with this product before using this product. Know your legal rights, responsibilities,

and safety instructions; otherwise you may incur property damage, safety incidents, and personal safety

hazards. The company reserves the right to update the above documents. Please be sure to operate this

product in accordance with the instructions and safety instructions.

2. The company will not be responsible for any violation of the law that occurs directly or indirectly by the

user.

3. This product is not suitable for people under the age of 18 and other people who do not have full civil

capacity. Please avoid the above-mentioned people from contacting this product. In the case where the

above-mentioned persons appear, please pay special attention to the operation.

4. Once you start using this product, you are deemed to have read, understood, approved and accepted all

terms and conditions of the product's instructions, disclaimers and safety instructions. The user is committed

to being responsible for his or her actions and all consequences arising by this. The User undertakes to use

the Product solely for legitimate purposes and agrees to these Terms and any relevant policies or guidelines

that may be established by the Company.

5. In the process of using this product, please strictly observe and implement the requirements including but

not limited to the instructions and safety instructions. All personal injury, accident, property damage, legal

disputes, and other adverse events that cause conflicts of interest caused by breach of safety instructions

or force majeure factors shall be borne by the user and the company shall not bear any responsibility.

6. We do not provide any technical support and security commitments in the following situations:

1) Units or individuals who obtain this product through informal agents or irregular channels;

2) Products that are not authorized to be modified, commissioned or replaced;

3) Warranty card, serial number or flight data are lost;

4) Personal injury and property damage due to personal operation errors.

©

2019 FOXTECH All Rights Reserved

4

Page 6

THEA-130 / 160 Sprayer Drone User Manual

Flight Operation

Environmental Requirements

-In an open environment, there is no occlusion, so as not to affect the search for satellite signals.

-The wind is less than 5 (≤8m/s).

-There is no strong magnetic field around, such as high-voltage lines, magnetite, etc., so as not to affect the

normal operation of the magnetic compass.

Pre-ight Check

-Make sure that the drone battery, remote control battery, and ground station (Android phone) are fully

charged.

-Make sure the drone battery is fixed.

-Ensure that the components are tightly fastened and that all screws are not loose.

-Make sure all connections are correct.

-Make sure that the propellers are not damaged, securely mounted, in the right direction, and that it works

correctly. All arms and propellers are fully deployed and the arm sleeve is locked.

-Make sure the spray system is free of impurities and can work properly.

Compass Clibration

Compass calibration must be performed before first use, otherwise the system may not work properly, which

may affect flight safety.

Do not calibrate in areas with strong magnetic or large blocks of metal, such as high voltage lines,

magnetic mines, parking lots, and buildings near steels.

Do not carry magnetic substances with your body during calibration, such as mobile phones

If the compass is calibrated indoors, remember to recalibrate when using it outdoors to prevent the

magnetic field difference between the two areas and cause abnormal flight data.

The position of the Earth's magnetic field is different. Please recalibrate the compass when replacing

a remote area.

Calibration Steps:

The remote control E switch continuously dials 7-8 times or clicks the magnetic calibration command in

the ground station software. The LED indicator turns green and enters the horizontal calibration phase, as

shown below:

©

2019 FOXTECH All Rights Reserved

5

Page 7

THEA-130 / 160 Sprayer Drone User Manual

Rotate the drone horizontally until the LED turns blue and enter the vertical calibration phase, as shown

below:

Then the drone head vertically upwards and rotates. When the LED indicator turns off, then it flashes,

and the calibration is successful. When the LED indicator turns red, the calibration fails and needs to be

recalibrated.

After the calibration is completed, you need to unplug the power to restart the aircraft.

Recalibration is required in the following case:

- The compass data is abnormal: the LED status indicator of the drone indicates that the yellow-green light

flashes alternately.

- The flight field is far from the site where the last calibration of compass was made.

- The mechanical mechanism or the body circuit of the drone has changed.

- Drifting during flight is more serious, or can not fly in a straight line

Work in Manual Stabilization Mode

Unlock, Start the Motor

Before performing the unlocking operation, keep away from the

drone to avoid danger and injury. The motor can be started by

performing the following operations on the remote control.

Unlock

After unlocking, push the throttle stick above the middle position

and the drone can take off.

©

Push the throttle slowly.

2019 FOXTECH All Rights Reserved

6

Page 8

THEA-130 / 160 Sprayer Drone User Manual

If the throttle is not pushed to more than 10% after unlocking, the motor will automatically stop and lock after

3 seconds.

Immediately after the motor starts, release the rocker and take off as soon as possible.

If does not calibrate the range the remote control, the motor cannot be started by performing an unlock

operation.

If the fine adjustment of the joystick is not 0, the motor may not start when the unlocking operation is

performed!

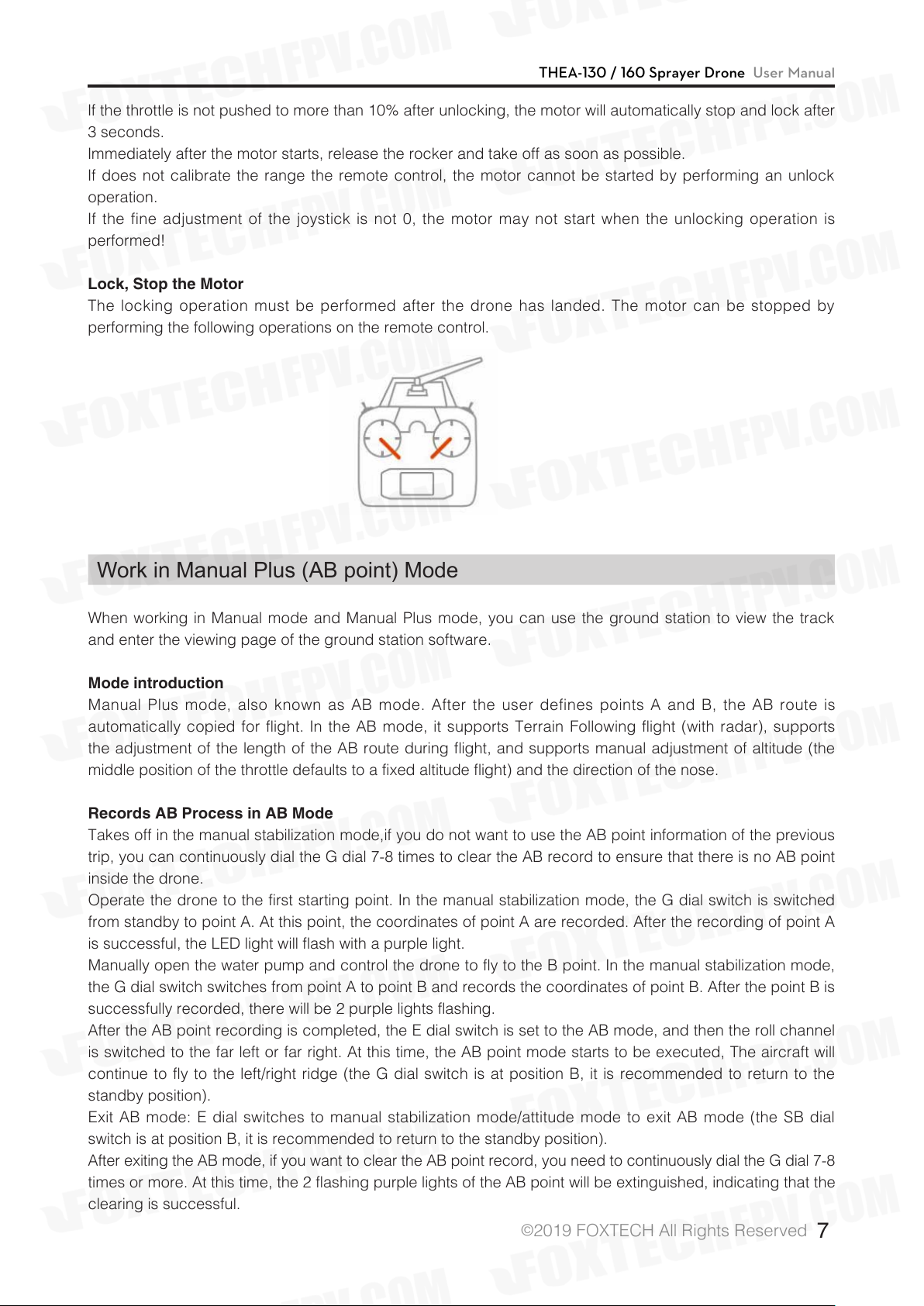

Lock, Stop the Motor

The locking operation must be performed after the drone has landed. The motor can be stopped by

performing the following operations on the remote control.

Lock

Work in Manual Plus (AB point) Mode

When working in Manual mode and Manual Plus mode, you can use the ground station to view the track

and enter the viewing page of the ground station software.

Mode introduction

Manual Plus mode, also known as AB mode. After the user defines points A and B, the AB route is

automatically copied for flight. In the AB mode, it supports Terrain Following flight (with radar), supports

the adjustment of the length of the AB route during flight, and supports manual adjustment of altitude (the

middle position of the throttle defaults to a fixed altitude flight) and the direction of the nose.

Records AB Process in AB Mode

Takes off in the manual stabilization mode,if you do not want to use the AB point information of the previous

trip, you can continuously dial the G dial 7-8 times to clear the AB record to ensure that there is no AB point

inside the drone.

Operate the drone to the first starting point. In the manual stabilization mode, the G dial switch is switched

from standby to point A. At this point, the coordinates of point A are recorded. After the recording of point A

is successful, the LED light will flash with a purple light.

Manually open the water pump and control the drone to fly to the B point. In the manual stabilization mode,

the G dial switch switches from point A to point B and records the coordinates of point B. After the point B is

successfully recorded, there will be 2 purple lights flashing.

After the AB point recording is completed, the E dial switch is set to the AB mode, and then the roll channel

is switched to the far left or far right. At this time, the AB point mode starts to be executed, The aircraft will

continue to fly to the left/right ridge (the G dial switch is at position B, it is recommended to return to the

standby position).

Exit AB mode: E dial switches to manual stabilization mode/attitude mode to exit AB mode (the SB dial

switch is at position B, it is recommended to return to the standby position).

After exiting the AB mode, if you want to clear the AB point record, you need to continuously dial the G dial 7-8

times or more. At this time, the 2 flashing purple lights of the AB point will be extinguished, indicating that the

clearing is successful.

©

2019 FOXTECH All Rights Reserved

7

Page 9

THEA-130 / 160 Sprayer Drone User Manual

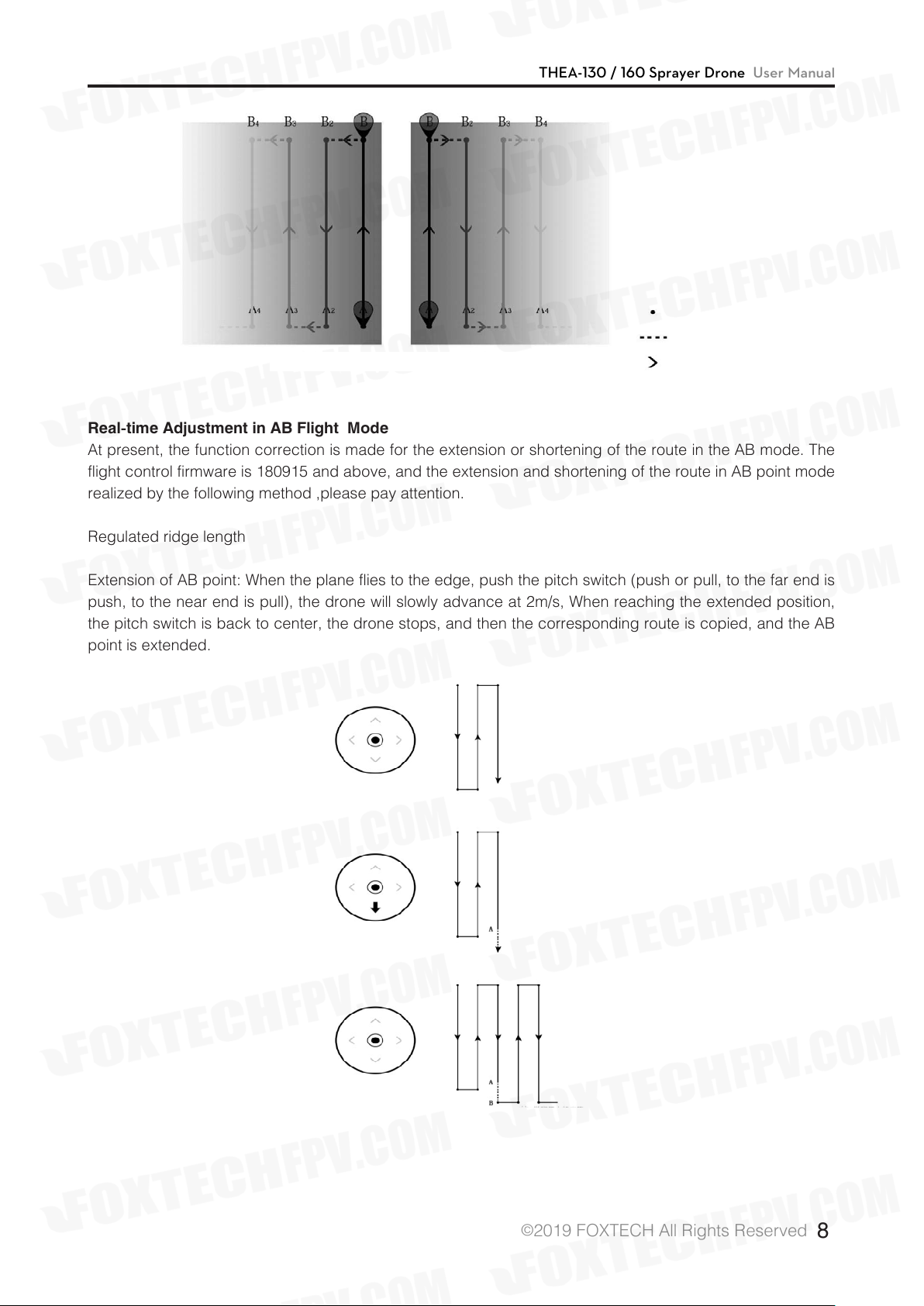

Route Node

Route Spacing

Left Right

Real-time Adjustment in AB Flight Mode

At present, the function correction is made for the extension or shortening of the route in the AB mode. The

flight control firmware is 180915 and above, and the extension and shortening of the route in AB point mode

realized by the following method ,please pay attention.

Flying Direction

Regulated ridge length

Extension of AB point: When the plane flies to the edge, push the pitch switch (push or pull, to the far end is

push, to the near end is pull), the drone will slowly advance at 2m/s, When reaching the extended position,

the pitch switch is back to center, the drone stops, and then the corresponding route is copied, and the AB

point is extended.

©

2019 FOXTECH All Rights Reserved

8

Page 10

THEA-130 / 160 Sprayer Drone User Manual

Shorten the route of the AB point: When the drone flies to a position close to the shortened position, push

the pitch switch (push or pull, to the far end is pull, to the near end is push), and the drone will slowly

advance at 2m/s. When the shortened position is reached, the pitching switch is back to center and the

drone stops, and then the corresponding route is copied, and the AB point route is shortened.

- Adjust the altitude

During the flight, when the throttle stick is in the middle position, it will fly in a fixed-height status(with a

radar,can realize terrain following flight), when the throttle is pushed up, the height rises and the throttle is

pulled down, the height drops.

- Adjust the direction of the nose

During the flight, when the yaw joystick is in the middle position, the nose is locked, the yaw joystick is

pushed to the left, the drone turns to left, when the yaw joystick is pushed to right, the drone turns to right.

Continue to fly at breakpoints in AB Point Mode

When exiting from AB point mode, the drone saves the current spray breakpoint, AB point definition, and

task direction. If you want to use the original AB point record and continue to perform the AB point mode,

you can follow the following steps:

- In the manual stabilization mode, the remote controller E dial switch is set to the AB mode, and the drone

is hovering at a certain position.

- The pitch channel is fully pushed forward, and the drone enters the breakpoint-flying mode, flying to the

place where the drone exited the AB mode last time. Then continue to perform in AB point mode.

©

2019 FOXTECH All Rights Reserved

9

Page 11

THEA-130 / 160 Sprayer Drone User Manual

Route node::::

Route spacing

Flying direction

Route breakpoint

Complete Route

Not executed route

Avoids obstacles and continue to fly in AB Mode.

At present, the manual intervention for obstacle avoidance is added for AB mode. The flight control firmware

is 180915 and above. Please pay attention:

Manual intervention for obstacle avoidance at AB point mode: When the drone is performing AB point

task, after encountering obstacles in front, first dail the roll joystick, the drone will stop, then will move to

the direction to which the roll joystick is dial, then could start operating the pitch joystick after moving to an

secure position, then all the joysticks are back to center, the drone will automatically turn to AB point mode,

then perform the subsequent task.

©

2019 FOXTECH All Rights Reserved

10

Page 12

THEA-130 / 160 Sprayer Drone User Manual

Repair and Maintenance

Replace the Propeller

- Insert the propeller into the motor column (note the direction of the propeller).

- Turn the propeller, align the mounting holes, and tighten the four M3x6 screws.

Replace the Motor

- Place the motor on the lower cover of the motor base and align it with the mounting hole (note the direction

of the motor)

- Secure the motor and motor base lower cover with four M4X16 screws.

- Pass the motor wire through the hole in the lower cover of the motor base and connect it to the ESC.

Secure the motor cover and lower cover with four M3X10 screws.

Replace the ESC

- After the wire and signal wire at one end of the ESC pass through the arm, the wire is connected to

the distribution board, the signal line is connected to the flight controller, and the wire at the other end is

connected to the motor.

- In the motor check setting, check if the motor is turning correctly and the speed is the same as other

motors.

- The ESC is placed in the motor base, and the motor upper cover and lower cover are fixed with four

M3X10 screws.

Replace Nozzles

- Insert the nozzle into the nozzle fixed rod (Note: the connection part of nozzle and hose need to be

inserted into the fixing rod gap)

- Place the nozzle clamp into the nozzle and fix it with the M3 locknut and M3X14 screw.

- Prepare auxiliary tools such as pliers and pipe clamps, connect the hose from the pump to the nozzle.

:* Pass the hose through the pipe clamp and then onto the nozzle joint.

:* Use an auxiliary tool such as pliers to clamp the upper part of the pipe clamp to open it, move it to the

connection part of hose and joint, and then loosen it to clamp the connection part between the hose and

the joint.

Replace the Pump

-:Place the pump on the pump mounting plate (note: the arrow on the pump is facing up), align the

mounting holes, and secure with four M4X6 screws and four 4-flat washers.

-:Prepare auxiliary tools and pipe clamps such as pliers, and connect the nozzle and the hose exported

from the flowmeter to the water pump.

*:Pass the hose through the pipe clamp and connect it to the pump coupling.

: * Use an auxiliary tool such as pliers to clamp the upper part of the pipe clamp to open it, move it to the

connection part of hose and joint, and then loosen it to clamp the connection part between the hose and

the joint.

- Align the projections on the pump wire with the grooves on the pump connection and insert the pump

motor.

©

2019 FOXTECH All Rights Reserved

11

Page 13

THEA-130 / 160 Sprayer Drone User Manual

Cleaning After Use

The spray system needs to be cleaned after each use:

:Step1: Remove the filter from the nozzle and wash off the attachment.

:Step2: Wash the aircraft pesticide tank with soapy water.

:Step3: Clean the aircraft pesticide tank with clean water.

:Step4: Install the filter in the nozzle and then clean with water, and the degree of atomization of the nozzle

is used to judge whether it is cleaned.

©

2019 FOXTECH All Rights Reserved

12

Page 14

THEA-130 / 160 Sprayer Drone User Manual

System Introduction

System Characteristic

Main features:

· With the comprehensive flight status monitoring alarm function (including the state of power supply voltage,

state of inertial navigation, GPS, link-state, etc.) and perfect emergency protection mechanisms (including

return, hover, autonomous landing, etc.), and Paladin system can realize the control law of restructuring in

some failure cases of sensors or attitude algorithm, thus the maximum guarantee the safe operation of the

user's system;

· Provide highly integrated ground station software BY- GCS, which has the functions of flight data

monitoring, dashboard status display, abnormal status alarm, flying remote control, electronic map, route

planning, etc;

· The attitude algorithm of Paladin system adopts KALMAN filtering technology, which has high

measurement accuracy, and reduces the probability of attitude divergence, thus ensuring the reliability and

safety of the system work;

· Combined with the remote control device, the Paladin system can be controlled by the remote control

mode to control the operation, thus ensuring that multi-rotor UAV can step in and ensure flight safety during

take-off and landing.

· It provides a strong route planning capability and flexible task control function, and users can use ground

station software to make a variety of flight tasks conveniently service;

· The Paladin system integrates high precision inertial and satellite navigation sensors, and the sensor data

is covered by the pretreatment and the whole temperature range compensation and data fusion can obtain

flight attitude, position coordinate and working status in real time, and complete the high-precision attitude

and route control of the multi-rotor UAV platform;

· The Paladin system integrates dual degree CPU and sensor, which can automatically detect and switch

independently to ensure flight safety.

Navigation task:

· Offer up to 170 user routes, or 340 navigable points.

· Automatically generate return routes Protection configuration:

· Low voltage protection of battery;

· Exceed the maximum flying range protection (isolation regional security protection);

· Remote control protection;

· Radio interrupt protection;

· GPS fault protection;

Protection measures to switch to high maintenance mode;

· Flight overrun protection: when the aircraft pitch and roll attitude angle more than 60 °, the plane

automatically lock blade.

Remote control equipment:

· Compatible the commonly used remote control;

· Manually mode or autonomous control mode can be switched through the remote controller;

· Failsafe (protection when it’s out of control) status of the remote control can be monitored;

Airborne data record:

· Flight data is stored on dedicated storage devices for flight control;

©

2019 FOXTECH All Rights Reserved

13

Page 15

THEA-130 / 160 Sprayer Drone User Manual

Ground station software:

:

· Strong ability of route planning;

· A powerful digital map;

· A clear, intuitive flight instrument;

· Convenient operation and anti-error operation of key instructions;

· Integrated sensor calibration, protection configuration and other functions;

· The display, alarm and recording of telemetry data;

Communication interface:

:

· Physical interface: USB, digital radio;

Introduction to Flight Mode

Flight Control Mode

High maintenance mode.

Position maintenance mode.

Return mode .

Fully autonomous flight mode

(point mode formula).

AB point mode.

The Control Mode

Remote control.

Remote control.

Remote control.

Fully autonomous

can be divided

into 5 kinds of

flight modes:

1.autonomous takeoff

2.autonomous landing

3.waypoint flight

4. return

5. hover

Semi-autonomous

flight

Features

In the return of the remote rod, the

aircraft will maintain its own posture,

the position of the throttle can be

fixed, but the precise fixed point

suspension cannot be realized, and

manual correction is required.

When the satellite signal is good:

Hovering can be done with high

precision and the limit can be

achieved speed, but the RC remote

control aircraft still control, speed

can pass over ground station

settings.

Depends on the satellite, flew home

from the current point and hovered

over.

According to the ground station set

a good mission route, autonomous

flight, due to independent mode the

type depends on the satellite, so the

satellite should be located before

unlocking and taking off.

According to the set point A,

B, to achieve semi-autonomous

flight, this mode depends on the

satellite, so before the unlock and

take off the satellite to locate.

Remark

1. The route up to 170 article, that

way to do more 340.

2. The throttle can still control

height, throttle setting middle

will maintain the current height.

1. By the roll channel to provide

wrap instructions

2. By the pitch channel to provide

fine-tuning instructions.

3. The throttle can still control the

height and when it is set middle, it

will maintain the current height.

©

2019 FOXTECH All Rights Reserved

14

Page 16

THEA-130 / 160 Sprayer Drone User Manual

Installation and Connection

System Supporting List

Master control

High-precision and high-sensitivity GPS with positioning and orientation module using

external compass

Power conversion and monitoring module, allowing 6S~12S

Flight indicator

Data transmission radio on 2.4Ghz loaded on aerial vehicle, which is applicable for

ground station users

Data transmission radio on 2.4Ghz on the ground, which is applicable for ground station

users

Ultrasonic sensor, which is used for imitate-terrain flight and fixing height at low attitude

Data transmission checkpoint based on Bluetooth, which is applicable for ground station

on mobile phone users

Water pump governor, which is suitable for agriculture and plant protection unmanned

aerial vehicle users

Level sensor, which is suitable for agriculture and plant protection unmanned aerial

vehicle users

Flight Controller System Connection Diagram

This is the schematic of flight controller and peripheral equipment during installation:you must pay attention

to the direction of interface and install the interface firmly to avoid virtual connection. Diagram 2.2 is the

schematic.

©

2019 FOXTECH All Rights Reserved

15

Page 17

THEA-130 / 160 Sprayer Drone User Manual

Power System Description

Power supply range of Version 2 flight controller power module: DC 24V(6S)~50V(12S);

Power supply range of RTK base station: DC 24V (6S)~50V(12S)

Power supply range of RTK board: DC 12V (3S)~50V(12S)

Power supply range of water pump module: Input DC 24V (6S), Output DC 12V

Interface Denition

The panel layout of Paladin interface is as the picture shows.

©

2019 FOXTECH All Rights Reserved

16

Page 18

Interface definition picture on the front panel

Chart 2.1 interface board description

THEA-130 / 160 Sprayer Drone User Manual

Name

BY-RTK

LEVEL1

LEVEL2

RADAR

RADIO

LED

POWER

Use Instructions

Difference airborne terminal.

Contactless level gauge.

Reserved

Radar

Data transmission radio

External indicator.

Power interface.

Remarks

It should be pasted at the bottom of

medicine box with free nail glue.

There should be nothing blocked in the

range of 15 below the radar, and it needs

to be far away from the satellite navigation

module.

It needs to be far away from the satellite

navigation module.

If the external indicator is accessed,

indicators on motherboard of the flight

controller won’t work.

Input: 6S~12S, Output: DC 5V

©

2019 FOXTECH All Rights Reserved

17

Page 19

Interface definition picture on the back panel.

THEA-130 / 160 Sprayer Drone User Manual

Interface name

S.BUS

CH1~CH8

PUMP/NOZ

BUP-POW

Use instructions

Receiver interface.

Output Port of motor signal.

Pump/Centrifugal nozzle

signal port.

Backup power

Status Indicator Description

Here is Paladin’s status indicator,

Remarks

CH1~CH8 correspond to NO.1~8 motor. The signal

line splits into two, the shorter part links motors with

odd numbers and the longer part links motors with

even numbers.

The longer wire links the pump and the shorter links

the centrifugal nozzle.

©

2019 FOXTECH All Rights Reserved

18

Page 20

THEA-130 / 160 Sprayer Drone User Manual

Number

1

2

3

4

5

6

7

8

9

10

Status of RGB

Light is not on.

Lights of all colors are always on, and

it cannot connect with the ground

station.

The red light and the white light flash

alternately.

The red light, the yellow light, the

blue light and the green light flash

alternately. (in low brightness)

The red light, the blue light and the

green light flash alternately.

Only the yellow light flashes once.

Only the yellow light flashes twice.

Only the fuchsia light flashes once.

Only the fuchsia light flashes twice.

The fuchsia light flashes quickly.

Malfunction status

It’s crashed.

The flight controller

is initializing.

The equipment is

not calibrated.

The equipment is being

calibrated or tested.

Remote control failure.

Low power.

Magnetic compass failure.

Accelerometer failure.

Other failure before unlocking.

Instructions

Line fault or light fault

Remote control, compass and

accelerometer.

Motor test or ESC test

The gyro is not working properly.

11

12

13

14

15

16

17

The red light is always on.

The red light and the yellow light flash

alternately.

Only the blue light flashes once.

The blue light is always on.

Only the green light flashes once.

The green light is always on.

The green light flashes quickly.

The log storage evice failure.

GPS failure.

Cannot find GPS and

being locked.

Cannot find GPS and

being unlocked.

Can find GPS and

being locked.

Can find GPS, and

being unlocked.

GPS is working with

high precision.

If the blue light is on, it means

that there is no problem with the

equipment.

If the green light is on, it means

that there is no problem with the

equipment.

Paladin has three kinds of working status: one is the normal status, one is the calibration status and

the other is the protect status. Among them, the calibration status and the protect status mean that

the equipment is not working properly, you must pay attention to it!

©

2019 FOXTECH All Rights Reserved

19

Page 21

THEA-130 / 160 Sprayer Drone User Manual

Remote Control Equipment

Receiver

Paladin System could communicate with the receiver (like Futaba) which supports S.BUS through S.BUS

protocol. If S.BUS function doesn’t supported by the remote control, an optional PPM encoder is required.

The definition of each channel is shown in Table 3.1. The frequency should be adjusted before the use of

receiver. For detailed operation, please refer to the corresponding remote control manual.

Table 3.1 Definition of RCreceiver channel(take Japanese hand as example)

Receiver channel

number

1

2

3

4

5

6

7

8

Definition

Rollover

Tilt

Accelerator

Course

Flight mode.

Task load switch.

RTL Return and land.

Add breakpoint.

Remarks

For channel 5, except the flight mode, when rapid

repeated dial more than 6 times, flight control will

enter the magnetic compass calibration state. So do

not quickly and repeatedly dial channel 5 when not

necessary.

Two switches—Triggered in high level.

Return—Triggered in high level.

Two switches—Triggered by dial back and forth

once in auto/AB point mode.

The RC remote control's channel definition should be configured according to Table 3.1.

Remote Control Conguration

FUTABA remote controller is recommended for flight control operations (The remote requires at least 8

channels to achieve basic flight control functions). Specific remote control settings include the

following steps (take FUTABA 14SG, receiver R7008SB for example):

1. Double-click the LNK button to enter LINKAGRE MENU;

2. Enter the MODE SEL directory;

3. Choose NEW. Long press RTN to create a new control model(Fixed wing or quadrotor);

4. Click RTN twice to confirm;

5. If the remote accelerator is in the middle, please turn the ON of THR POS to OFF in the WARNING menu;

6. Enter the REVERSE menu, turn Channel 3 and Channel 6 NORM to REV;

©

2019 FOXTECH All Rights Reserved

20

Page 22

THEA-130 / 160 Sprayer Drone User Manual

7. Enter the FUNCTION menu, set AIL, ELE, THR, ROU to J1, J3, J2, J4 (Japanese Hand). Set AIL, ELE,

THR, ROU to J1, J2, J3, J4 (American Hand).Please map Channel 5 to 9 to the appropriate switch or knob.

The recommended settings are as follows: Channel 5 mapping is SE, Channel 6 mapping is SG, Channel

7 mapping is SC, Channel 8 mapping is SD, and Channel 9 mapping is SB. So far the basic settings of the

remote control are completed.

After configuring, please connect Paladin for verification. In manual (fixed high / fixed point) state,

the remote can control the motor. (without propeller).

Unlocking and Locking for Flight Control

The aircraft can take off only after unlocking (take Japanese Hand as example).

Unlockable mode: Altitude Hold / GNSS Assist / Position Hold Mode

Lockable mode: Altitude Hold / GNSS Assist / Position Hold Mode

Waysto Unlock:

· Unlock requirements:

1) Altitude Hold Mode: available after self-test passed;

2) GNSS Assist/Position Hold Mode: available after positioned by satellite and indicator flashes green light;

·Unlock action: Maximum tilting degree with lowest accelerator degree, push the course-control stick to

the far right and the rolling-control stick to the far left. Indicator light changes from blinking to steady means

unlock successful, as shown in figure 3.3a

Waysto Lock:

· To lock immediately, maximum tilting degree while with lowest accelerator degree, push the course-control

stick to the far left and the rolling-control stick to the far right.

· If the light starts flashing, the lock is successful.

©

2019 FOXTECH All Rights Reserved

21

Page 23

THEA-130 / 160 Sprayer Drone User Manual

ESC Calibration (Electronic Speed Controller)

The purpose of ESC calibration is to match the PWM value output by the flight control with the range of

PWM values that the ESC can receive.

The Paladin system provides two ESC calibration methods(take HOBBYWING ESC for example):

·General steps of ESC calibration(ESC signal line disconnected to flight control):

a. Connect a single ESC signal line to the receiver Channel 3(Accelerator Channel);

b. Power on the remote control, push the accelerator to the highest position, power on the ESC, hear "Di -

Di" twice, pull the accelerator to the lowest position, hear "Di - Di - Di" three times, then push the

accelerator, motor rotates, calibration completed;.

c. Repeat the above steps for other ESC calibration;

· Flight control ESC calibration steps(ESC signal lines and receivers have access to flight control):

d. Power on the remote control, push the accelerator to the highest position;

e. Power on the flight control, indicator lights flashing red and blue, flight control enter the ESC calibration

mode, turn off the power of flight control, the remote control maintains the highest position;

f. Re-power the flight control, turn on power system, when hear the ESC "beep - beep" sound, pull the

accelerator to the lowest position immediately, at this point will hear "Di - Di - Di" three times, then push the

accelerator again, motor rotates, calibration completed.

ESC calibration must be propeller-free, the audible tones of ESC calibration may be different by

different manufacturers, please refer to the manual of ESC .

©

2019 FOXTECH All Rights Reserved

22

Page 24

THEA-130 / 160 Sprayer Drone User Manual

Remote Control Protection

Protect Content

Paladin has perfect protection mechanism, the specific content and measures of protection are hown in

table 4.1

TABLE 4.1 Paladincontent and Measures of Protection

Protect Content

Low battery voltage.

Remote control signal lost.

Data link is interrupted.

GPS is abnormal.

No medicine.

Protect Measures

1. Return

2. Landing

3. Continue to perform the task.

1. Return

2. Landing

Return

1. Set High

2. Landing

1. Return

Description

-Protective measures: valid or

invalid.

-Protection mode optional.

-Protective measures: valid or

invalid.

-Protection mode optional.

Protective measures: valid or

invalid.

When GPS is abnormal, it will be

switched to fixed high mode. If high

modulus fails to switch, it will carry

out landing.

-Protective measures: valid or

invalid.

-Autonomous mode trigger

protection.

Regional restrictions.

Angle protection.

1. Not Open

2. Hovering

1. The maximum angle of flight

35 °.

2.Out of control protection

angle of 60 °.

©

Exceeded maximum radius: hover

Above maximum height: height

cannot climb, but can drop.

When the plane is in normal flight,

the angle will not exceed 35°;when

the pitch and roll angle more than

60 ° at the same time, fly machine

will turn off the motor output, lock

the paddle.

2019 FOXTECH All Rights Reserved

23

Page 25

THEA-130 / 160 Sprayer Drone User Manual

Return Logic

The trigger conditions of aircraft into the return status are: remote control channel 7 (return mode) to high,

the ground station control, the emergence of flight breakpoints, the phenomenon of runaway protection, etc.

The return process is: the aircraft climbed 2 meters in the current location (to ensure return safety, climbing

value can be set by the ground station), then fly to safety point (return back to the point if no automatic

mode has been taken off or return to nearest ascending point if there is a near standby point) and hovering

waiting for the operation, if the remote control signal is lost during the return process, the aircraft will hover

for 2 seconds to perform autonomous landing. The returning logic execution diagram is:

Remote Control Security

Remote control is the most direct means of control the aircraft, from a security point of view, the current

remote control for UAV plant protection operations are still irreplaceable. In order to ensure the safety of

UAV flight, taking into account the actual needs of large areas of independent spraying, PALADIN designed

a more complete remote control security strategy. The out-of-control protection action can be set by the

ground station software. It should be pointed out that the out-of-control protection setting of the remote

controller is only for the "fully autonomous mode"; the manual mode (constant height / positioning mode)

and the AB point mode are both open by default and cannot be closed, the remote control out of control

logic diagram (for details, please refer to "5.4.3 Security Settings"):

©

2019 FOXTECH All Rights Reserved

24

Page 26

THEA-130 / 160 Sprayer Drone User Manual

Data Link Loss of Control

Data link for aircraft and ground station connectivity, in order to improve ease of use, PALADIN the ground

station is set to asynchronous equipment required that the actual flight plane can observe the state of the

aircraft through the ground station, you can also disconnect the data link , only to observe the status of

aircraft and lights to determine the aircraft work. In order to prevent the instability of the digital link from

affecting the actual operation, the data link failsafe protection is set to be valid only in the fully autonomous

mode and the remote controller signal loss. The manual mode (fixed height, positioning) and the AB point

mode cannot be triggered, Autonomous mode remote control signal cannot be triggered normally, please

refer to the details according to "5.4.3 Security Settings."

Voltage Detection and Protection

PALADIN offers a voltage protection function based on a modifiable voltage value, that the user can correct

the voltage value of the flight control via the ground station (if the difference between the actual value and

the measured value can be used to correct the measured value), flight control detection monolithic voltage

and implement protection. The voltage fail-safe protection action can be set to "Off", "Return" or "Landing".

For details, please refer to "5.4.3 Security Settings".

Area Limited Protection

For details, refer to "5.4.3 Security Settings".

©

2019 FOXTECH All Rights Reserved

25

Page 27

THEA-130 / 160 Sprayer Drone User Manual

Ground Station Setting

Equipment Connection

1.Click “Not connected”:will pop up the following dialog box, select “Connect” to connect the drone,

“Connect handheld mapping device” to connect the handheld mapping device, “Connect RTK mapping

device” to connect RTK mapping device, “Connect RTK onboard” to connect RTK air unit.

2.Select the corresponding address based on the paired Bluetooth device.

©

2019 FOXTECH All Rights Reserved

26

Page 28

3.Waiting for the drone to be connected (voice prompt).

THEA-130 / 160 Sprayer Drone User Manual

Function Introduction

1.Main interface function.

©

2019 FOXTECH All Rights Reserved

27

Page 29

THEA-130 / 160 Sprayer Drone User Manual

2.Click “Display Seetings”, the user can select the parameter item you need (up to 6 items).

Click ”Setting”, then will pop up the dialog box.

Task Statistics: the cumulative number of working acres(Mu) ,Dosage (L) and time.

©

2019 FOXTECH All Rights Reserved

28

Page 30

THEA-130 / 160 Sprayer Drone User Manual

Frame Type Setting:Select the drone type (it has been set at the factory, please do not change it:

Motor test: Input duration (recommended 3s-5s), throttle (recommended 10%-15%), then according to

the diagram, check whether the propellers of the multi-rotor motors are normal (please test away from the

crowd to prevent accidents).

Remote Control Calibration

Check if the remote control joystick is in the position shown below, check the status of each channel in turn

(do not check multiple channels at the same time). If the position of the remote control joystick develop

offsets, please click the “remote control” button, then successively dial the channels of the remote control in

the maximum to the minimum range.

Please click” SAVE MODE” after modifying the fifth channel mode.

©

2019 FOXTECH All Rights Reserved

29

Page 31

THEA-130 / 160 Sprayer Drone User Manual

Calibration Setting

Calibrate accelerometer, horizontal calibration, dynamic balance correction.

3.Control Sensitivity Setting

©

2019 FOXTECH All Rights Reserved

30

Page 32

4.Safety Setting

THEA-130 / 160 Sprayer Drone User Manual

5.Agriculture Plant Protection Setting:

©

2019 FOXTECH All Rights Reserved

31

Page 33

6.System Setting(including system version etc.)

THEA-130 / 160 Sprayer Drone User Manual

Route Planning

1.Click :enter the route planning interface.

©

2019 FOXTECH All Rights Reserved

32

Page 34

THEA-130 / 160 Sprayer Drone User Manual

2.Click :Enter the mark mode, then select 1. work (working area), select the mark mode on the right

side, from top to bottom there are 3 modes: the mobile phone GPS positioning mark, mobile map manual

mark, aircraft GPS mark. Click the , start to mark. Use green lines and green markers as the edge

of the work area in the map. (at least three points form an area).

3.Mark the obstacle area in the work zone. Click :enter the marker mode, then select 2 Obstacle

obstacle area select to create new obstacle area (multiple obstacle areas can be created), select the mark

mode on the right side, from top to bottom there are 3 modes: the mobile phone GPS positioning mark,

mobile map manual mark, aircraft GPS mark. Click the start to mark, the red line and blue icons in the

map represent the obstacle area:at least three points form an area).

©

2019 FOXTECH All Rights Reserved

33

Page 35

THEA-130 / 160 Sprayer Drone User Manual

4.Click the on the left:to generate the route:the top parameters can be edited separately. From left

to right: the route interval, flight speed, start position of the route, route angle, obstacle avoidance scheme,

overall retraction of the work area (m), Expansion of obstacle area (m).

©

2019 FOXTECH All Rights Reserved

34

Page 36

THEA-130 / 160 Sprayer Drone User Manual

5. After the route planning is completed, click on the left side, upload the route to the aircraft.

6.After the upload is completed, you need to click :to download the route and ensure that the route is

transmitted to the aircraft accurately.

©

2019 FOXTECH All Rights Reserved

35

Page 37

THEA-130 / 160 Sprayer Drone User Manual

Ready to Take Off

1.Click to exit the route editing interface.

2.Click , the aircraft takes off automatically, the height is 2m.

3.Click , the aircraft enters the autonomous operation mode and will fly following the route that has

already been uploaded.

4.After the flight is completed, the aircraft will return to home automatically and hover:or click to

control the aircraft to return according to the actual situation.

©

2019 FOXTECH All Rights Reserved

36

Page 38

RTK Use Instructions

THEA-130 / 160 Sprayer Drone User Manual

©

2019 FOXTECH All Rights Reserved

37

Page 39

THEA-130 / 160 Sprayer Drone User Manual

©

2019 FOXTECH All Rights Reserved

38

Page 40

THEA-130 / 160 Sprayer Drone User Manual

Software terminal connection method

RTK work flow

Turn on your mobile phone Bluetooth:then match the devices with the default password 1234.

1. First work:

Connect your mobile phone and the base station:and save the position of the base station.

·Purpose of saving the position of the base station: In order to fix the position of the base station when

working in the same area the next time. It can ensure accuracy of navigation if the base station is in the

same position(less than 5m) in the same region using the same route. If the situation doesn’t match, the

accuracy of navigation will be reduced, but it won’t affect the work. So you should select whether it needs to

fix the position of the base station, if not, you don’t need to save the position.

Specific methods of operation:

Switch the “route planning” interface on your mobile phone, and click “connect RTK base station”

·When prompted “connection XXX success”, it means that Bluetooth connection is successful.

When prompted “connection XXX failed”, it means that Bluetooth connection is failed.

·When prompted “receive RTK base station data successfully”, it means that the data we received is right.

·If it’s prompted “receiving data” for a long time, it means that Bluetooth connection is successful, but it

hasn’t received effective data, please wait.

If RTK base station data is right, the position of RTK base station will be displayed on map at real time (blue

point).

If you click the , as shown below will appear:

Select the type of area point to be added.

RTK Base station position.

Cancel Mapping Model In the Field

Click “mapping model in the field”, then click , the position of RTK base station will be displayed on

map . at the same time, the ground station will save the position as file (in Boying-GCS/RTK/ , the suffix

name is .rtkbase). You can mark many points on map, every point you mark will be saved as file separately.

After marking points of position of the base station, click “disconnect RTK base station” in the upper right

corner.

©

2019 FOXTECH All Rights Reserved

39

Page 41

THEA-130 / 160 Sprayer Drone User Manual

Concise Operation Process

1) check power cable and cable between peripherals and flight control;

2) launch ground station, and launch BY-GCS ground station;

3) switch on RC remote control equipment;

4) switch on the aircraft system and connect to the ground station;

5) calibrate the remote control, if it has been calibrated, skip;

6) calibrate the electronic governor(Do not install propellers.), if it has been calibrated, skip;

7) start the function of motor test on the ground station, and make sure the whirling and the serial number of

motors match;

8) calibrate the accelerometer, if it has been calibrated, skip;

9) calibrate the magnetic compass, if it has been calibrated, skip;

10) set flight model;

11) set protection of being out of control;

12) check if there is any warning from the ground station, analyze the reasons and solve it;

13) check if key data is normal such as attitude data, course data and GPS data, and move the aircraft to

observe whether change of data is normal;

14) check installation of external GPS and compass;

15) check installation direction of the flight control and damping;

16) check whirling direction of motors and propellers and check if they are installed firmly;

17) toggle switches of flight models and observe whether the displayed area in flight model on the ground

station switches normally;

18) set route tasks and upload, then download them and make sure the route has been planned right; If you

have any question, don’t force it to fly, please contact the technician.

Only when the position has been decided by GPS can you unlock it in the fixed-point model.

©

2019 FOXTECH All Rights Reserved

40

Page 42

THEA-130 / 160 Sprayer Drone User Manual

Precautions

Due to safety concerns, here is what you should pay attention to before using:

Environmental factor precautions:

1) Try to be familiar with the flight environment and be far away from the obstacle and the crowd when flying

2) Don’t fly when in low spirits.

3) Don’t fly after drinking wine or taking psychotropic drugs to avoid causing accidents because of human

factors.

4) Don’t fly in thunderstorm or windy weather to avoid the damage of equipment and the danger of flying.

5) If you need to use it in glare, please use sunglasses.

6) Be far away from high-temperature heat source to avoid damage to the electronics.

7) Beginner should be taught by experienced pilots before using.

8) You should prepare necessary tools before using, such as wrenches, screwdrivers, spare propellers,

telescopes, walkie-talkies, sunglasses, first aid kit and so on.

9) Don’t overload, or it will cause damage to the aircraft structure and fly dangers.

10) Be far away from propellers rotating at high speed,

11) Check every device before flying, if the key devices don’t work normally, and don’t force it to fly, or it will

cause accidents.

Equipment factors precautions:

1) We suggest that you had better debug the aircraft when propellers are not installed, check if the remote

control and motors work normally, and then install propellers if everything is ok.

2) Keep the accelerator the lowest before flying.

3) Check if there is any interference on the same frequency among devices.

4) The 2.4G antenna has weak ability of avoidance, please keep a good visibility between antenna on the

aircraft and on the ground station while flying. Put the ground station at a height and keep the antenna up

when using, and keep the antenna on the aircraft down as possible so that it can increase the distance of

transmission.

5) Check if every device works normally.

6) Make sure the life time of your battery matches your needs, such as the battery in your remote control

and your aircraft.

7) Check if whirling direction of propellers is right.

8) Follow the instructions strictly.

©

2019 FOXTECH All Rights Reserved

41

Page 43

THEA-130 / 160 Sprayer Drone User Manual

Failure Analysis

1) Cannot unlock

a. The accelerator is not set the lowest.

b. The tilt angle of the aircraft is too large.

c. The signal line of the receiver doesn’t connect well, or it has connected to the wrong interface.

d. Observe the warning from the ground station and check if sensors and the remote control have been

calibrated.

2) When do you need to calibrate the magnetic compass

a. If you have moved or disassemble the flight control or GPS,

or it’s far away from the region where you calibrated last time,

or the magnetic field has changed a lot.

b. You can check if the data from the magnetic compass is right, for example, if the aircraft turns around,

the course will change 360 degrees, and observe if the course data from the ground station is with the

actual match.

3) Rotating speed of motors doesn’t match when you increase the throttle.

a. If the throttle is too low, rotating speed of motors doesn’t match, but it matches after you increase the

throttle, it’s a normal phenomenon. If motors still don’t match after you increase the throttle, you need to

calibrate the ESC again.

4) rotate after taking off or flip

a. Check if propellers are installed correctly.

b. Check if the whirling direction of motors is right.

c. Check if the dynamic equilibrium of the aircraft is well. You can reference the “troubleshooting center” on

our official website to get more failure analysis, or you can contact us for technical support, we will answer

timely.

©

2019 FOXTECH All Rights Reserved

42

Page 44

THEA-130 / 160 Sprayer Drone User Manual

After-sales Service

Warranty regulation

·If the malfunction is caused by products quality, BOYING will offer limited quality assurance in the circuit

part.

·Since the date of purchase, six months is the shelf life based on the proof of purchase.

·If it’s within the warranty period and within the warranty, BOYING will offer free replacement or maintenance

service.

Not covered by the warranty

·Not follow instructions provided by BOYING when installing or operating.

· Performance problems caused by man-made improper operation or chemical agents.

·Performance problems caused by the unofficial part.

· Electronic equipment performance problems caused by water.

·Performance problems caused by private modification.

·Performance problems caused by electronic interference.

·Performance problems caused by using poor quality power or using nonstandard input voltage.

· Damage caused by human factors (such as handling, operating error, collision and so on).

·Damage caused by irresistible factors outside world (such as earthquake, typhoon, thunderstorm, fire and

so on).

©

2019 FOXTECH All Rights Reserved

43

Page 45

THEA-130 / 160 Sprayer Drone User Manual

Installation of Ground Station and Drivers

Installation

Operating environment: WIN2000, WINXP, WIN Vista, WIN7, WIN8, WIN10

First, if you want to install it in Win10 system, it needs digital certificate authentication; the specific operation

is as follows:

1) Click “settings” ”update and safety”

2) Click ”recover”->” advanced startup” -> ”restart immediately”

3) After restart, click “troubleshooting”-> ->”advanced options”->”startup settings”->”restart” follow the

prompts to enter 7 to forbid drivers to force signatures Then, install the ground station software:

1) Click “ByAero.exe”

2) Choose the installation path

3) Follow the prompts

4) Finish

Finally, if you need to connect the flight control to the ground station using USB cable, please make sure

that you have chosen the right driver, as shown below:

Install data transmission driver:

The first method: If your computer is in a networked state, access the data transmission radio, drivers will be

loaded automatically.

The second method: If your computer hasn’t link to the network, unzip “BOYING data transmission drivers”

to the root directory of C, then access the data transmission devices on the ground station, it will prompt

that it could not find drivers.

Specific steps of loading drivers are as shown below:

a. Right-click “my computer”->”management”->”devices management”->”port”

b. Choose the driver with yellow exclamation point, right-click “update drivers”->”browse the computer…”

choose the folder where to unzip the driver, click “next”. If installation fails, repeat it twice or more.

©

2019 FOXTECH All Rights Reserved

44

Page 46

THEA-130 / 160 Sprayer Drone User Manual

This content is subject to change.

Download the latest version from

https://www.foxtechfpv.com/thea-130-agriculture-spraying-drone.html

https://www.foxtechfpv.com/thea-160-agriculture-sprayer.html

For everyday updates, please follow

Foxtech Facebook page: Foxtechhobby

YouTube Channel: Foxtech

©

2019 FOXTECH All Rights Reserved

45

Loading...

Loading...