Foxjet Marksman MATRIX, Marksman ELITE User Manual

User

Manual

Marksman

MATRIX & ELITE

High Resolution Printing

for the Real World

2465-623

Revision E

1 Missouri Research Park Drive • St. Charles, MO 63304

Tel: 800-369-5384 • Fax: 636-300-2188

Illinois Tool Works Inc © 2018

www.foxjet.com

Marksman

MATRIX & ELITE

Ink Jet System

User Manual

2465-623

The information contained in this manual

is correct and accurate at the time of its

publication. ITW reserves the right to

change or alter any information or

technical specifications at any time and

without notice.

©2018 Illinois Tool Works Inc.

All rights reserved

Warranty:

The Marksman© Matrix & Elite Ink Jet system, including all components unless other

wise specified, carries a limited warranty.

The inks and conditioners used with the Marksman© Matrix & Elite Ink Jet system

carry a limited warranty.

For all warranty terms and conditions, contact the Distributor for a complete copy of the

Limited Warranty Statement.

Marksman Matrix & Elite

Section 1: Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Section 2: Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Section 3: System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Integrated Print Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Bracketry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Photosensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Inks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Waste Bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Section 4: Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Materials Required for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

System Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installing Bracketry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Mounting the Print System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Setting Up the Print Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Mounting the Photosensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Ship Caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

The Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Electrical Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Priming the Print Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Section 5: Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Counts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

User Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

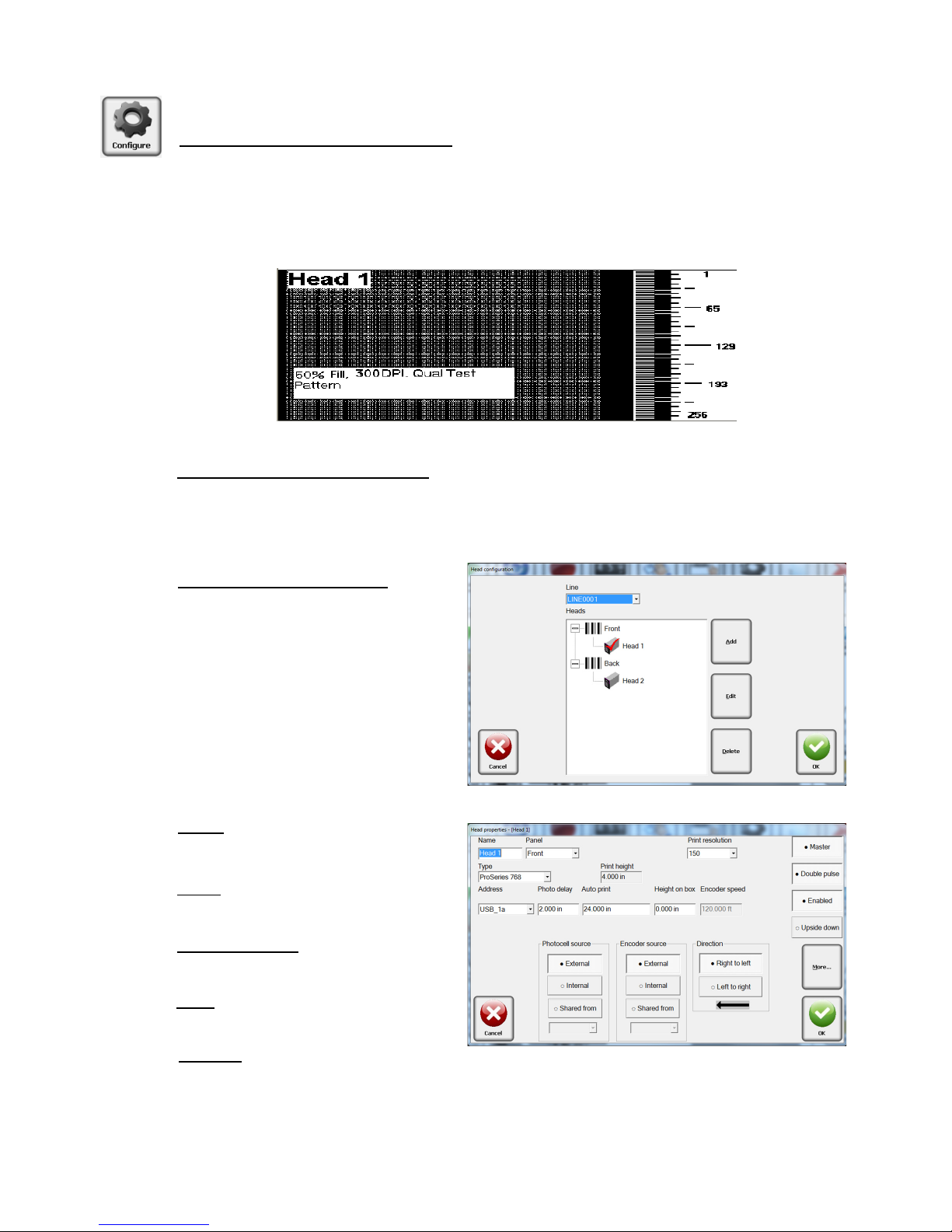

Configure, Print Head: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Configure, System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Delays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Section 6: BoxWriter© Matrix & Elite Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Define . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

ToolBar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Perspective . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Section 7: Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

APS - Automatic Priming System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Shutdown Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Ink Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Section 8: Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Troubleshooting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Troubleshooting Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Print Quality Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

2465-623 User Manual Rev E

Marksman Matrix & Elite

Appendix A: Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Matrix Controller Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Elite Controller Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Print Head Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Appendix B: Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

The Marksman© Matrix & Elite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Print Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Photosensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Matrix Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Elite Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Appendix C: Parts and Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Matrix Spare Parts Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Elite Spare Parts Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

384e and 768e Print System Service Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Appendix D: Testing the Electrical Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Electrical Line Transients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Appendix E: Database Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Database Start Task Routine Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Database Lookup Definition - Global Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Database Start Task . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Serial Port Modification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Printer Report Modification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Appendix F: Hand Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Scan and Shoot Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Appendix G: Fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Font List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Font Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Appendix H: Standard Operating Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

FJSOP1 - Removal of FoxJet High Resolution Printheads . . . . . . . . . . . . . . . . . . . . . . . . . . 113

FJSOP2 - Daily Maintenance for AMS/APS Printheads . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

FJSOP4 - Installation of FoxJet High Resolution AMS/APS Printheads . . . . . . . . . . . . . . .117

2465-623 User Manual Rev E

Marksman Matrix & Elite

Section 1: Introduction

The Marksman© Matrix & Elite are advanced high-resolution ink jet controllers that runs on

a Microsoft Windows 7® platform. It includes a built-in keypad with a TFT display with

touch-screen control. The Marksman© Matrix & Elite can control up to 4 Pro Series highresolution print heads for printing industry compliant barcodes, graphics or alphanumeric

text on porous materials and cases.

This manual covers the operation of the Marksman© Matrix & Elite Ink Jet Printing System,

Marksman© Matrix & Elite Controller and Print Heads.

Section 1: Introduction

2465-623 User Manual Rev E Page 1

Marksman Matrix & Elite

Section 2: Safety

Following is a list of safety symbols and their meanings, which will be found throughout this

manual. Pay attention to these symbols where they appear in the manual.

Wear safety goggles when performing the procedure described!

Caution or Warning! Denotes possible personal injury and/or damage to the equip-

!

ment.

Caution or Warning! Denotes possible personal injury and/or equipment damage

due to electrical hazard.

NOTE: (Will be followed by a brief comment or explanation.)

Section 2: Safety

Only trained personnel should operate and service the equipment.

NOTE: It is extremely important to:

• Clean up all ink spills with the appropriate conditioners immediately and dispose of all

waste according to local and state regulations.

• Wear safety glasses and protective clothing, including gloves, when handling all inks

and conditioners.

• Store inks and conditioners under the recommended conditions found on the MSDS

(Material Safety Data Sheet).

PRODUCT COMPLIANCE DISCLAIMER NOTE:

This product meets the requirements of CAN/CSA-22.2 NO.60950-00 * UL 60950 using

FoxJet an ITW Company approved items. Units are only tested and qualified with FoxJet

an ITW Company approved inks, parts and accessories. Use of other inks, parts or accessories may introduce potential risks that FoxJet an ITW Company can assume no liability

for.

2465-623 User Manual Rev E Page 2

Marksman Matrix & Elite

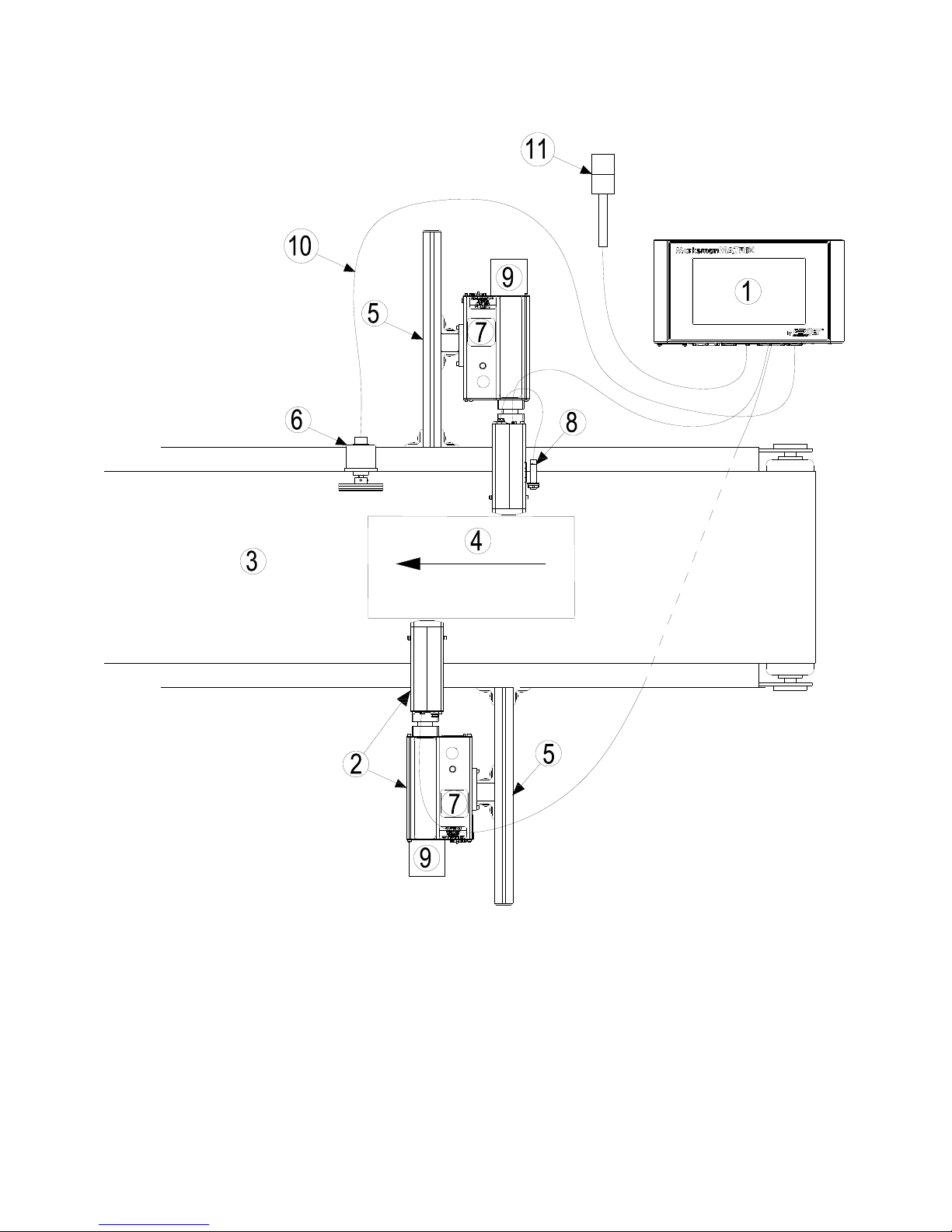

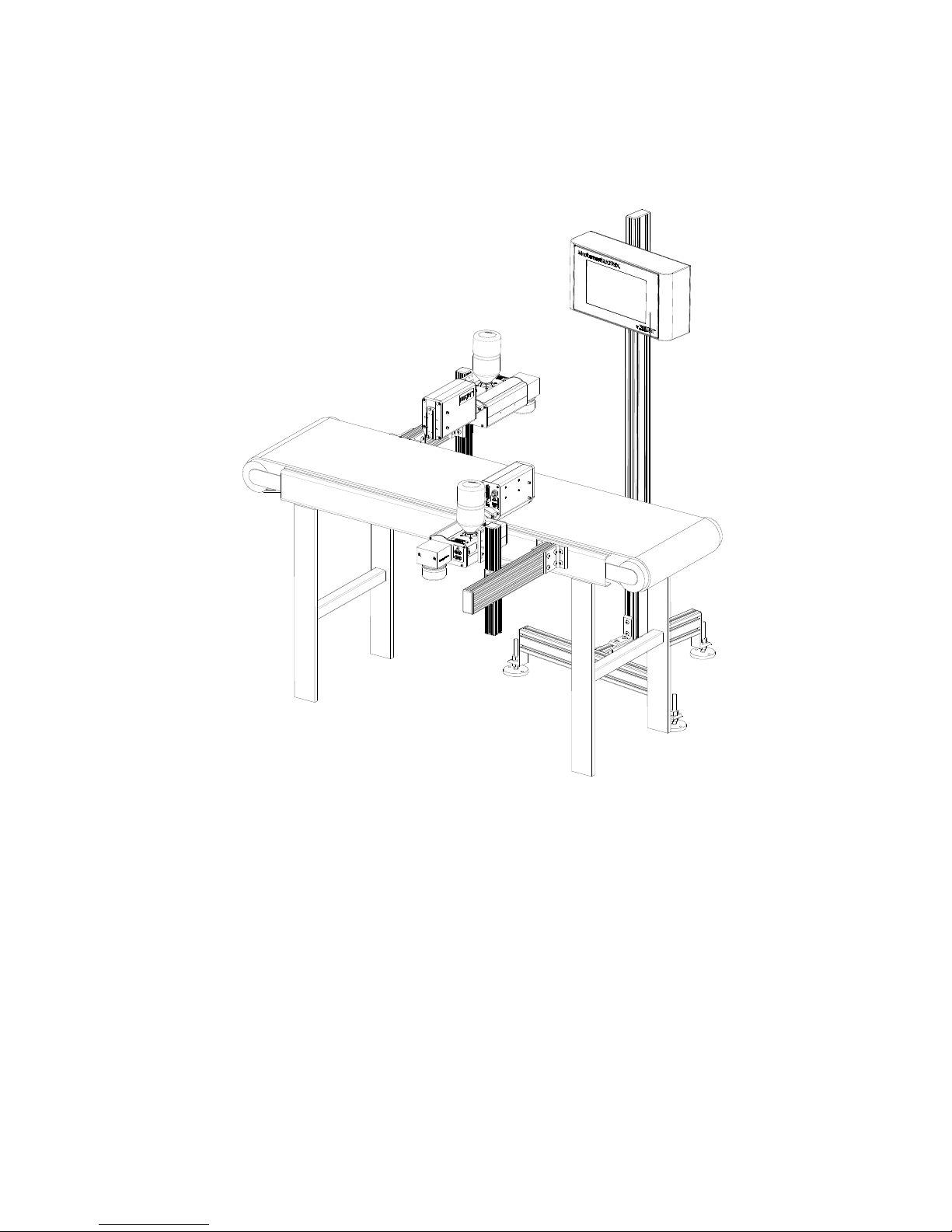

Section 3: System Components

1 Controller, Matrix or Elite

2 Proseries Print Head

3 Conveyor

4 Product

5 Print System Bracketry

6 Encoder

7 Ink Supply

8 Photo Sensor

9 Vacuum Waste Collector Bottle

10 Encoder Cable

11 Alarm Beacon (Strobe)

Section 3: System Components

2465-623 User Manual Rev E Page 3

Section 3: System Components

Marksman Matrix & Elite

The Marksman© Ink Jet System is available with the following components, options and

service kits:

Part Number

2464076 ProSeries 384e

2464076F ProSeries 384e, Flushed

2464078 ProSeries 384e, 90°

2464078F ProSeries 384e, 90°, Flushed

2464079 ProSeries 384e, Modular

2464079F ProSeries 384e, Modular, Flushed

2464082 ProSeries 768e

2464082F ProSeries 768e, Flushed

2464083 ProSeries 768e, Modular

2464083F ProSeries 768e, Modular, Flushed

2464084 ProSeries 768e, 90 Degree

2464084F ProSeries 768e, 90 Degree, Flushed

2465006D2 Controller Assembly, Marksman© Matrix, 2 Head, Domestic

2465006E2 Controller Assembly, Marksman© Matrix, 2 Head, European

2465006D4 Controller Assembly, Marksman© Matrix, 4 Head, Domestic

2465006E4 Controller Assembly, Marksman© Matrix, 4 Head, European

2465004D2 Controller Assembly, Marksman© Elite, 2 Head, Domestic

2465004E2 Controller Assembly, Marksman© Elite, 2 Head, European

Description

Print Head

Matrix Controller Assembly

Elite Controller Assembly

Remote PHC Board & Elite board kit

2465321 Assembly, Marksman remote PHC Board

2465246 Elite PHC Board Kit

Print Head/Controller Bracketry

2464550 Print Head Conveyor Mount Bracket

2464553 Print Head Pivot Bracket

2464561 X-Y Axis Linear Adjustment, Tool-Less Bracket

2464562 Conveyor Mount/Roller Bracket for 768 Print Head

2464563 Print Head Floor Mount Bracket Kit

2464564 Conveyor Mount/Roller Bracket for 384/352 Print Head

2464565 Conveyor Mounting Bracket with Integrated Guide Rails for 384/768 Print Head

2465243 Kit, T-Stand, Matrix & Elite

2465244 Kit, Conveyor Mounting, Matrix & Elite

2465254 Kit, Pivot Bracket, Matrix & Elite

Encoder, Photosensor, Alarm Beacon

2465224 Photosensor, ProSeries

2465253 Alarm Beacon (Strobe), 3-Color

2465525 Photosensor, Auxiliary, APS Controller

2465-623 User Manual Rev E Page 4

Section 3: System Components

Marksman Matrix & Elite

INK SYSTEM

WASTE BOTTLE

PRINT HEAD

INK BOTTLE

Cabling

2464182-010 Cable, Straight Thru, DB9, 10 Ft.

2464182-025 Cable, Straight Thru, DB9, 25Ft.

2464182-050 Cable, Straight Thru, DB9, 50 Ft.

2465155-002 Cable Kit, Print Head, DB25, 2 Ft.

2465155-010 Cable Kit, Print Head, DB25, 10 Ft.

2465155-025 Cable Kit, Print Head, DB25, 25 Ft.

2464312 Cable, APS Photocell Network ("Y" Cable for sharing Auxiliary Photocell)

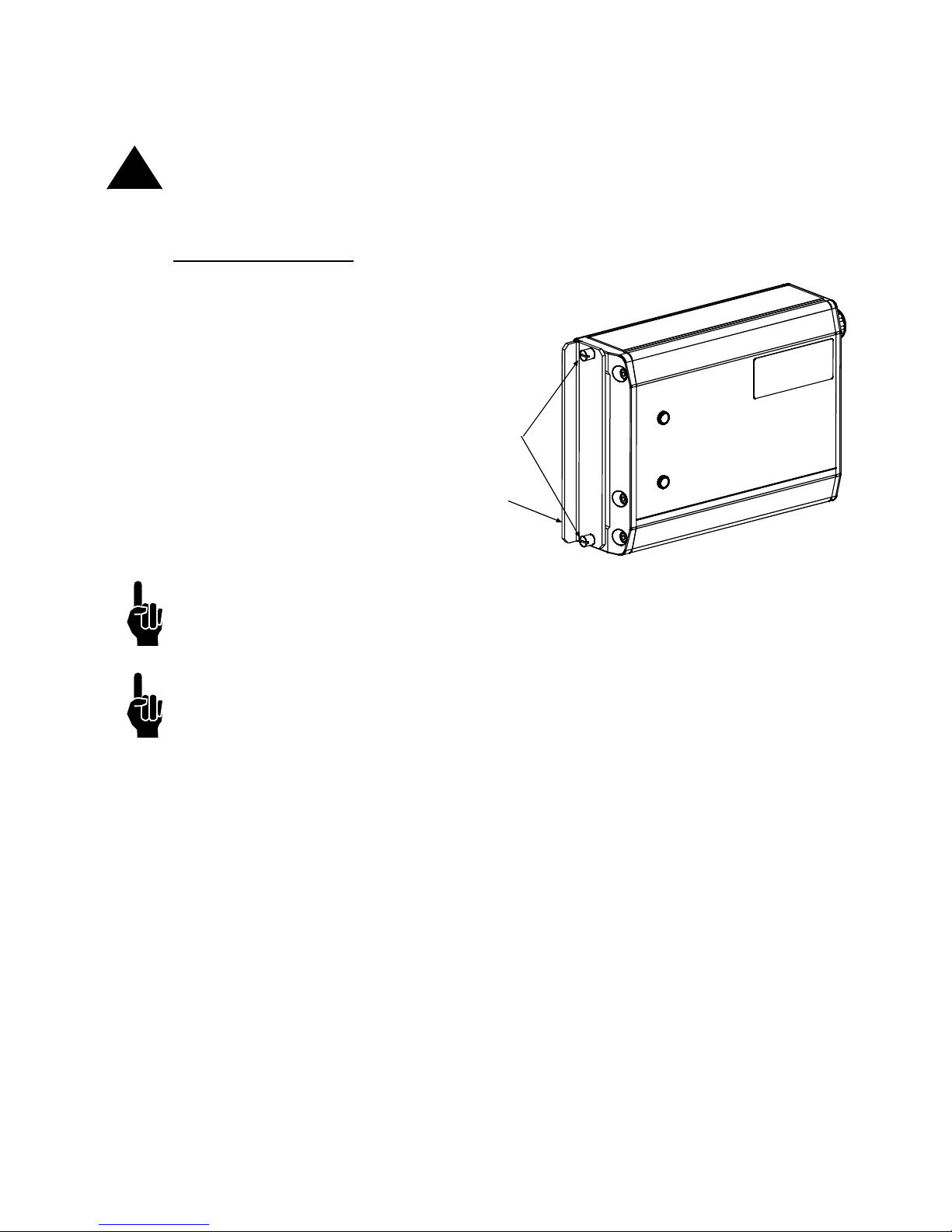

Integrated Print Head

2465-623 User Manual Rev E Page 5

Section 3: System Components

Marksman Matrix & Elite

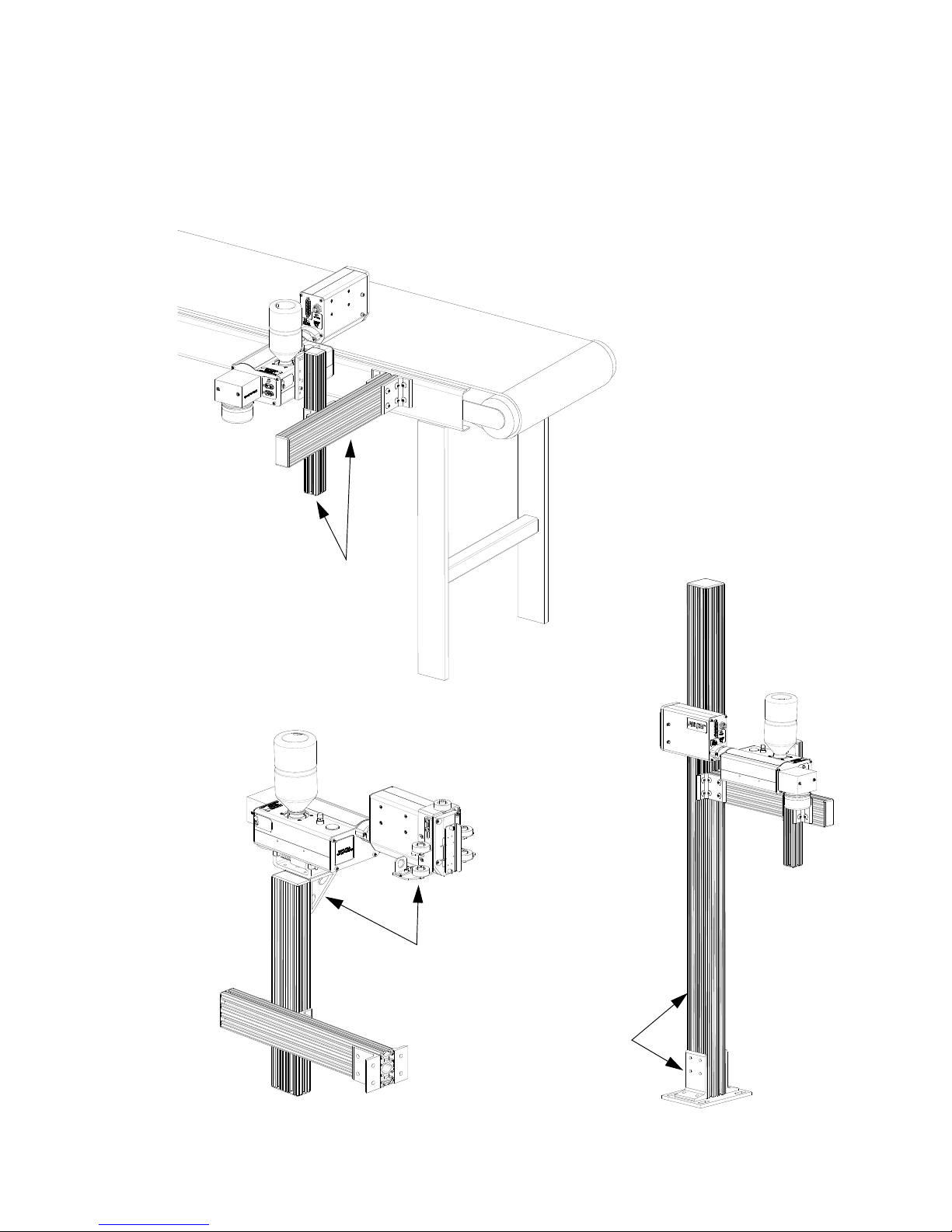

Retracting Bracket

Floor Mount

Conveyor Mount

Bracketry

Bracketry is the structure that supports the controller, print system and other accessories.

This manual details instructions for mounting all system components to a conveyor. Other

mounting options for the controller and print system include the floor mount and the retracting bracket. Assembly instructions are included with parts kits.

2465-623 User Manual Rev E Page 6

Section 3: System Components

Marksman Matrix & Elite

ENCODER ASSEMBLY

Photosensor

The photosensor is both a light source and a sensor. It emits light and detects the arrival of

a product when the product reflects the light source back to the sensor. The sensor then

sends a signal to the controller to start the printing cycle.

Encoder

The encoder assembly provides conveyor line

speed information to the controller. It also allows

automatic disabling of printing when the line

stops.

The Marksman© Matrix & Elite System uses a

5000 ppr open collector output encoder. The

wheel is sized to provide the correct timing

inputs to allow the print heads to print from 150

to 300 dpi.

Inks

Ink is supplied via 500 mL plastic containers. ScanTrue® II PLUS is a pigmented ink formulated for use on porous substrates.

NOTE: Check the label on the Print Head for correct ink type.

NOTE: Inks are not miscible. Do NOT

mix the inks.

Waste Bottle

The APS includes a Waste Collection Bottle mounted on the rear of the Print Head assembly. This bottle must be changed when full to prevent improper operation of the system.

Instructions for waste disposal are on the collection bottle.

2465-623 User Manual Rev E Page 7

Marksman Matrix & Elite

Section 4: Installation

The figure below illustrates a typical conveyor-mounted installation. (Cables are not

shown.)

Section 4: Installation

Materials Required for Installation

You will need the following items:

• Lint-free wipes

• Safety goggles

•Level

• Tape measure

Use appropriate safety equipment and procedures. Leave print heads in their shipping cartons until all bracketry is in place and tightened down.

2465-623 User Manual Rev E Page 8

Section 4: Installation

Marksman Matrix & Elite

ATTACH ING

CORNER

BRACKET

Single T-nut

Corner Bracket

System Installation Overview

NOTE: The following steps give an overview of the procedure to properly install the Marks-

man© Matrix or Elite print system. Refer to the appropriate section for details.

1. Carefully plan the mounting location of the equipment. Keep in mind bracketry hardware location and printer equipment size.

2. Remove equipment from packaging.

3. Assemble all bracketry to the floor, conveyor, or other bracketry per bracketry installation section.

4. Mount the print system to its appropriate bracketry. Do not connect to power outlet.

5. Assemble the optional retracting bracket to each print head, if applicable.

6. Mount the print head(s) to their appropriate bracketry and in the approximate location

relative to the carton.

7. Mount the photosensor, optional bracketry, and optional encoder per procedure.

CAUTION: Remove the print head Ship Cap prior to operating the Print Heads.

!

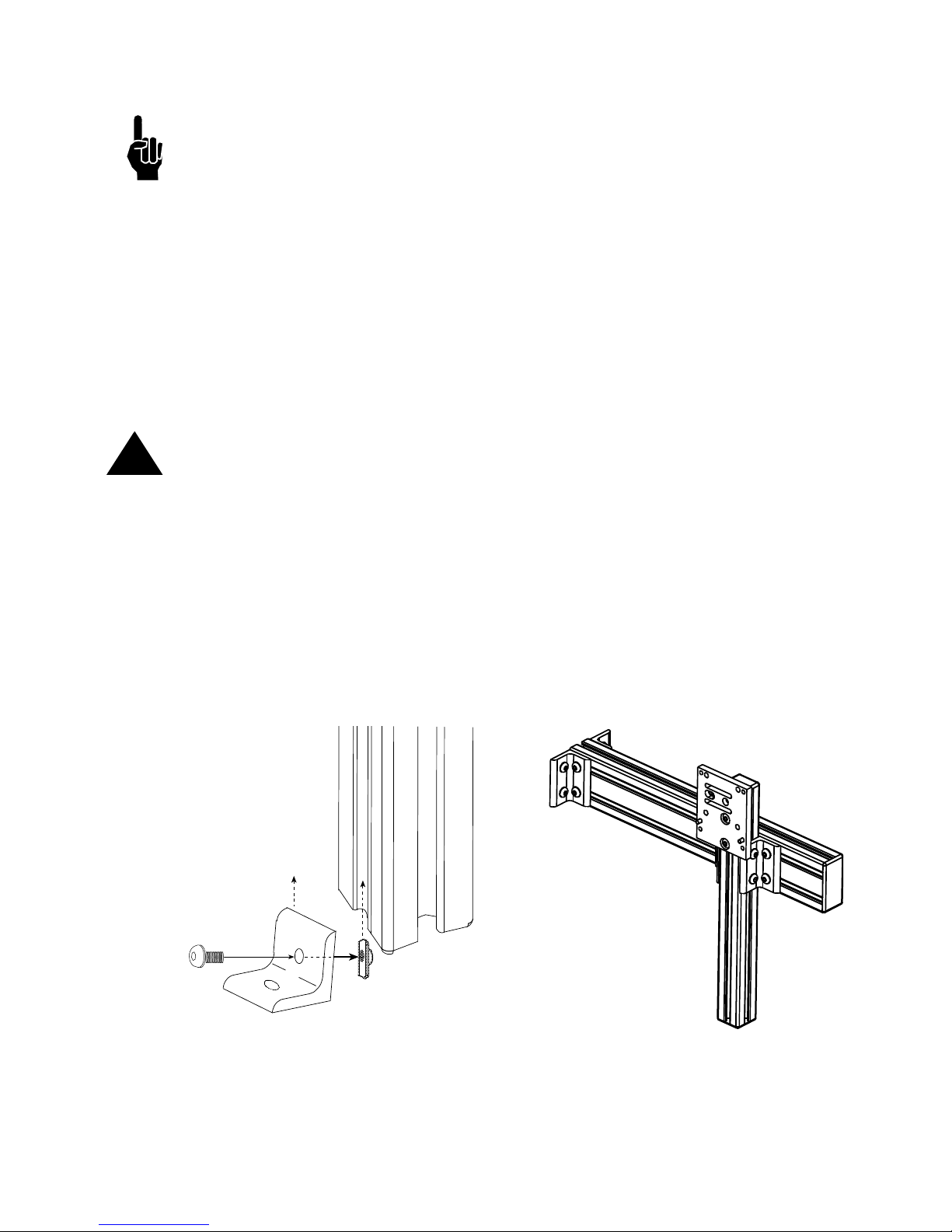

Installing Bracketry

This section shows controller bracketry mounted to a conveyor. This is the most common

mounting method, and the most stable, as all bracketry is bolted directly to the conveyor.

Detailed assembly instructions are included with the parts kit.

Other mounting options, including parts kit numbers, are listed in

ponents.

Corner brackets are attached to aluminum bars as shown.

Section 3, System Com-

2465-623 User Manual Rev E Page 9

Section 4: Installation

Marksman Matrix & Elite

Mounting the Print System

Unpack the print head just before mounting to the bracketry.

Attach the print head to the bracketry with a print head mounting bracket.

The print head must be mounted in close proximity to the product. To maintain consistent

print, the head should be mounted no more than 1/8" from the substrate. An optional

retracting bracket is available to mount the head and control the distance from the head to

the substrate. The retracting bracket allows the head to bump the product and retract as

required to maintain a consistent throw distance. (See

bracketry options.)

NOTE: Install optional retracting bracket kit on the print head prior to mounting the print

head to the conveyor bracket.

It may be necessary to vertically adjust each bracket's horizontal bar later to fine-tune message placement. This is especially true when using multiple print heads, as message lines

will need to be synchronized with each other.

NOTE: When adjusting the horizontal bar or print head mounting bracket, always support

the print head with your hand to keep it from falling forward onto the conveyor.

Section 3, System Components for

NOTE: The ProSeries print heads work on gravity and capillary ink feed, internal in the

print head. The head must be mounted in a level position from front to back to prevent leakage.

2465-623 User Manual Rev E Page 10

Section 4: Installation

Marksman Matrix & Elite

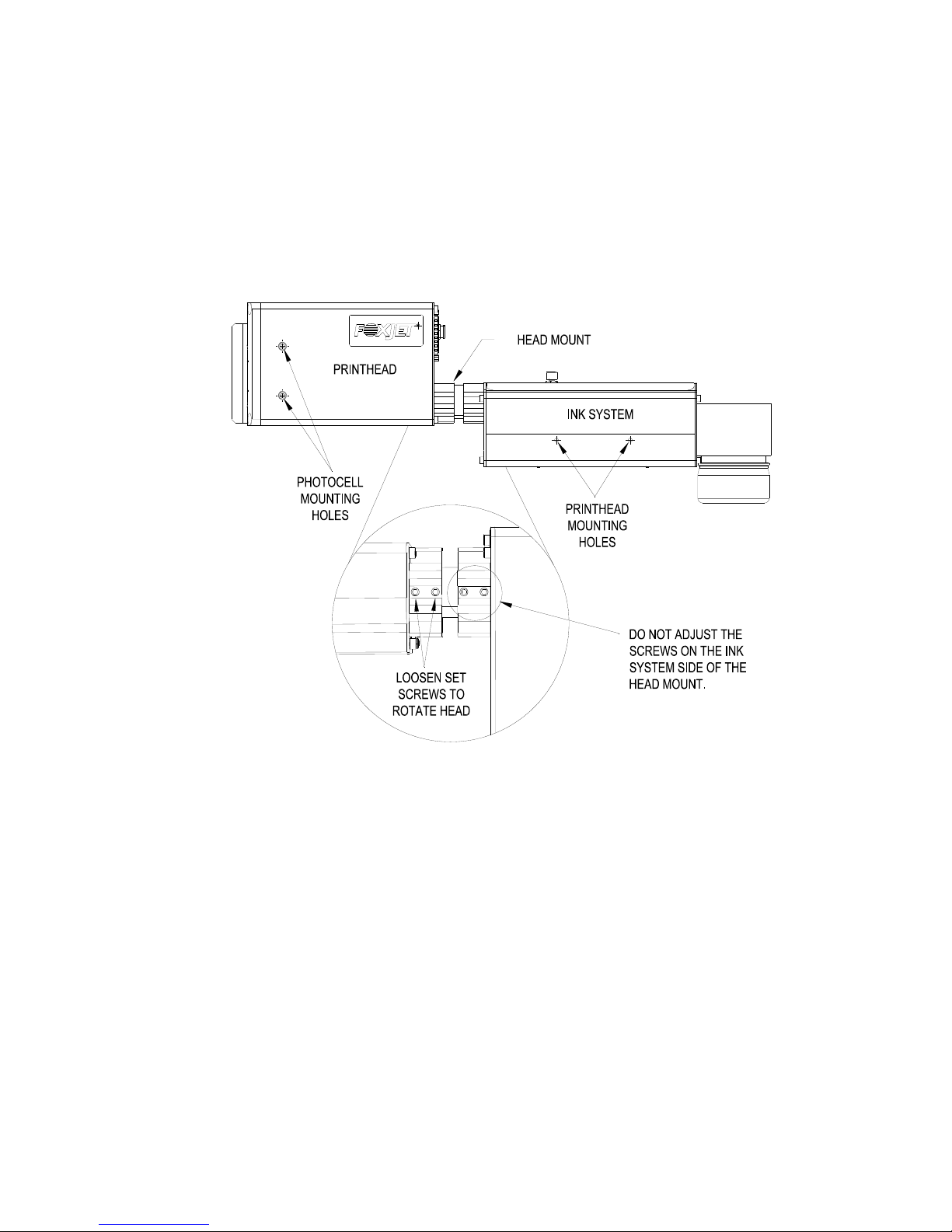

Setting Up the Print Head

The Matrix/Classic Series print heads are mounted using the 10-32 tapped holes on the

right or left side of the Ink System bottom case. The print head angle can be set between 0°

and 90°.

To adjust the head to its correct angle:

1. Loosen the two set screws (1/8" hex head) on the print head side of the head mount.

2. Rotate the head to the desired angle.

3. Secure the set screws.

Mounting the Photosensor

The product detect Photocell can be mounted on either side of the print head, depending

on the direction of print. Remove the plugs or set screws (3/32" hex head) in the photocell

mounting holes, then attach the Photocell Mounting Bracket with the 10-32 x 1/2" screws

provided with the bracket.

2465-623 User Manual Rev E Page 11

Section 4: Installation

Marksman Matrix & Elite

THUMBSCREWS

SHIP CAP

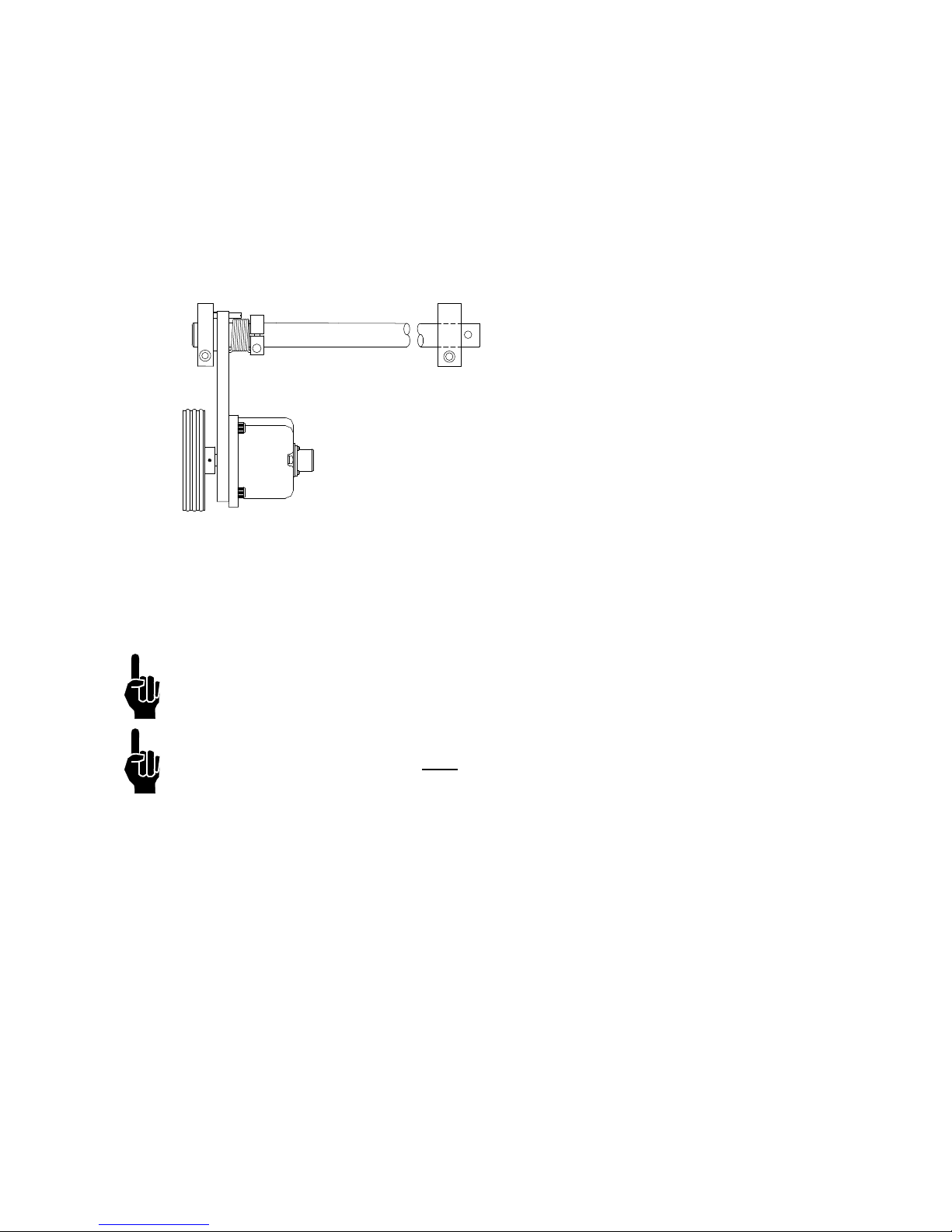

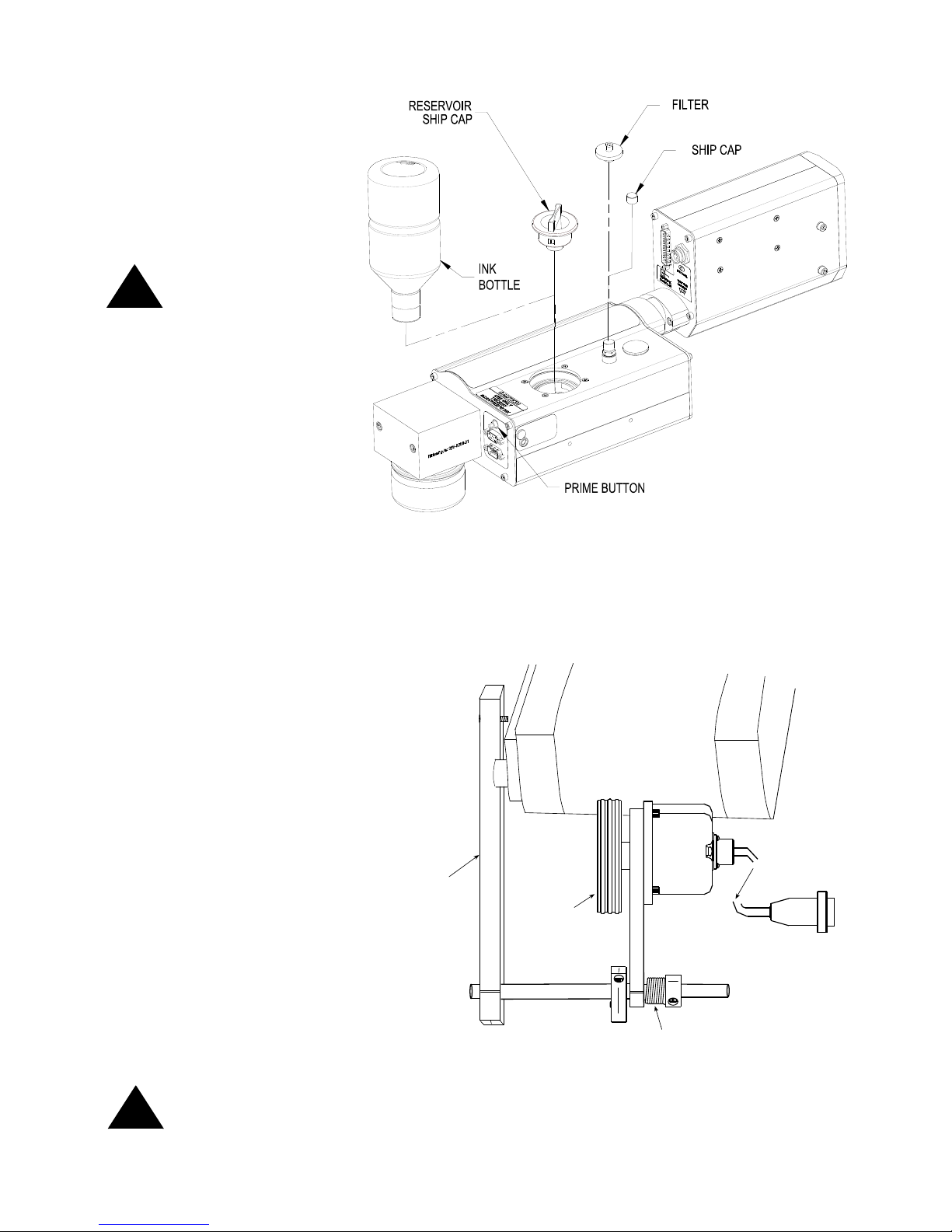

Ship Caps

CAUTION: Do not operate APS Print Heads with the Print Head Ship Cap installed! Oper-

!

ating a closed system can cause a siphoning effect which can drain the ink supply.

384e/768e Print Heads

Loosen the two thumbscrews

and remove the Ship Cap.

(See illustration at right.)

NOTE: If you place the Print Head Ship Cap on a hot print head and do not fasten it

securely, the print head will weep ink until the head has cooled down.

NOTE: Ink may accumulate behind the ship cap during shipping.

2465-623 User Manual Rev E Page 12

Marksman Matrix & Elite

Remove the Ship Cap

Spring

Mounting

Bracket

Encoder

Wheel

Conveyor

Out to Controller

Mounting Bracket

Shaft

Encoder

ENCODER

ASSEMBLY

and Install the Filter.

Remove the Reservoir

Ship Cap and Install

the Ink Bottle. Save

caps in a zip-lock bag

for future use.

CAUTION: Do not

over-tighten the ink

!

bottle when screwing

into the Reservoir.

Over-tightening will

damage the Reservoir.

Section 4: Installation

!

The Encoder

The encoder uses a wheel

that rolls against the conveyor line to track the speed.

It sends a signal to the controller, which makes adjustments for reported changes in

the line speed.

It is not necessary to install

the encoder immediately adjacent to the print heads. It is

more important to place it

where it will accurately measure the speed of the conveyor. Install it in contact with

the conveyor, or with a wheel

or roller moving the same

speed as the conveyor.

The encoder's mounting

bracket is spring-loaded.

Adjust the spring collar to

ensure that the encoder maintains stable contact with the

conveyor.

CAUTION: Do not jam the encoder wheel against the surface of the conveyor. A radial

force of over 40 lbs. will reduce the life of the bearings.

2465-623 User Manual Rev E Page 13

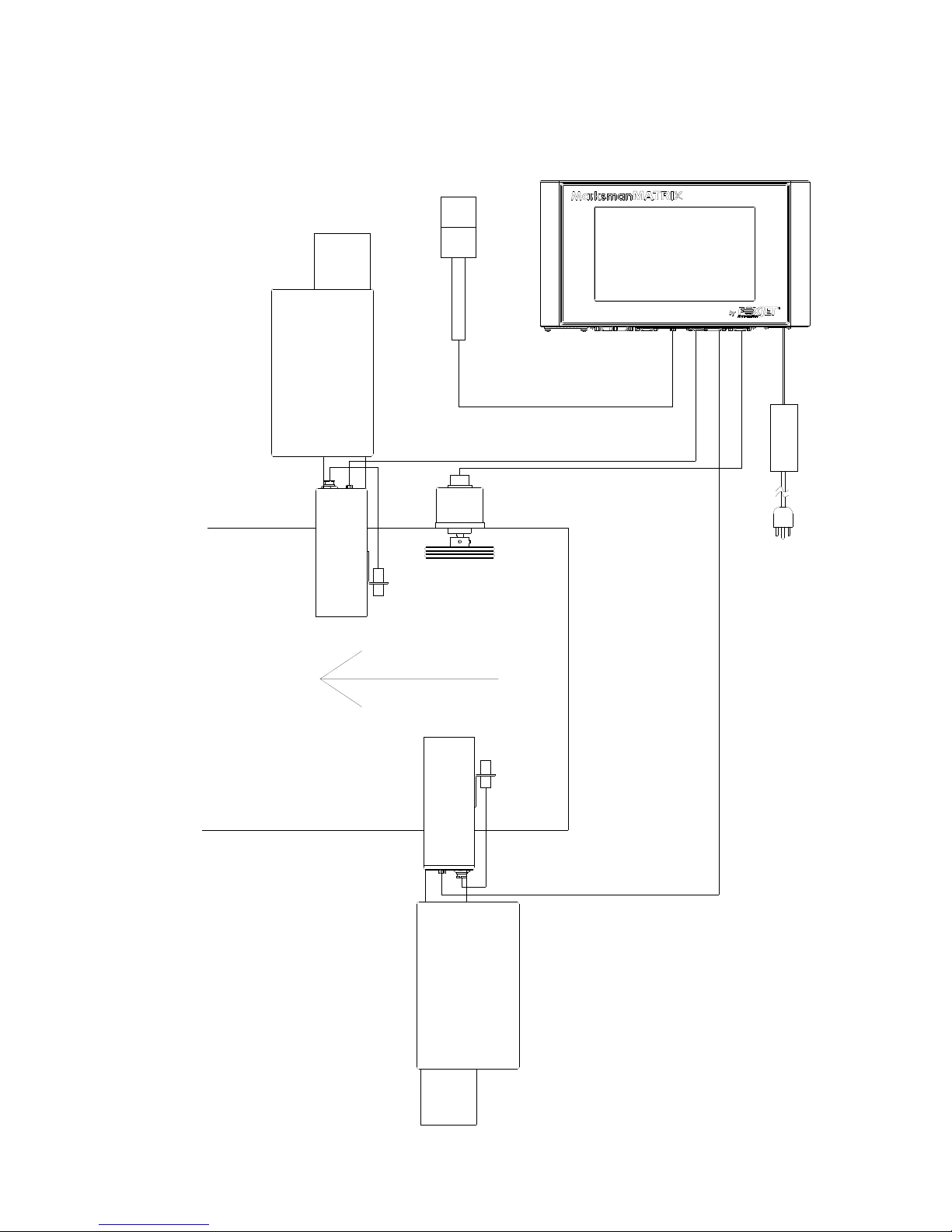

Marksman Matrix & Elite

PRINT

SYSTEM

PRINT HEAD CABLE

PHOTO

SENSOR

ENCODER

SYSTEM

PRINT

ALARM

BEACON

(STROBE)

MARKSMAN MATRIX OR ELITE CONTROLLER

24V

Section 4: Installation

Electrical Cable Connections

2465-623 User Manual Rev E Page 14

Marksman Matrix & Elite

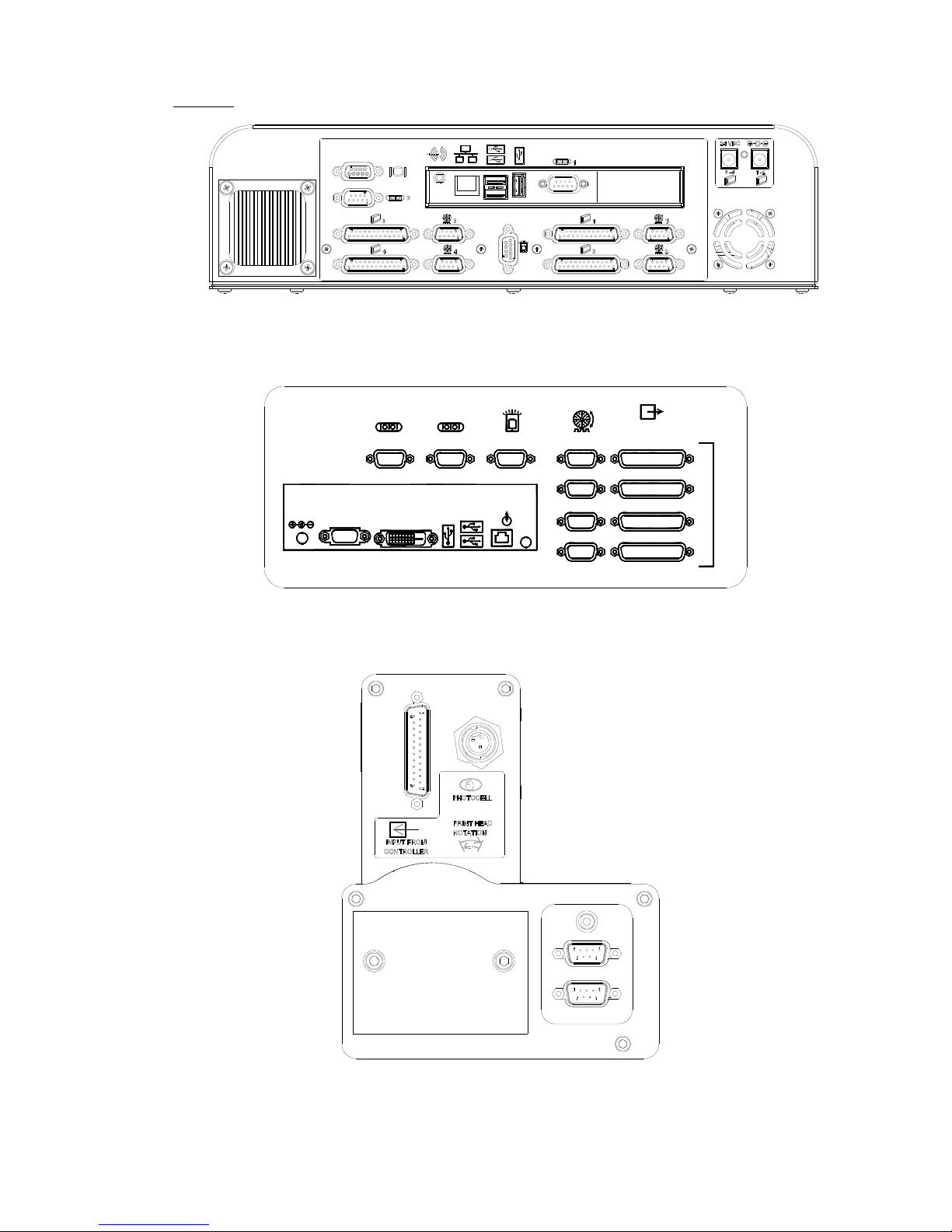

Views

Bottom view of Matrix Controller

(With Optional second PHC Board

ETHERNET

LINE OUT

12 VDC

USB

VGA

DVI-D

COM 1 STROBECOM 2 ENCODER

1

2

OUTPUT TO

PRINTHEAD

4

3

PRINT HEAD CARDS

Bottom view of Elite Controller

Back view of Print System

Section 4: Installation

2465-623 User Manual Rev E Page 15

Section 4: Installation

Marksman Matrix & Elite

Priming the Print Heads

NOTE: The system will not prime either manually or automatically if there is a low ink indi-

cation. Low ink indication is caused by either low ink in the reservoir or full ink in the waste

collection bottle.

Manual Prime

NOTE: Place a wipe in front of the maintenance plate to catch excessive ink.

A manual prime can be accomplished by depressing the push-button switch on the rear of

the ink system housing. Pressing and holding the button for longer than one second will

start the pump for a manual prime. It will continue to run as long as the button is depressed,

or up to five seconds. If additional priming is required, release and press the button again.

Pressing for less than 0.5 seconds will initiate a maintenance cycle. If the system has

started a maintenance cycle and the button is pressed, the manual prime will not operate.

(The Priming Sequence and the Vacuum Cycle are less than 10 seconds long.)

APS Cycle

The APS (Automatic Priming System) cycle is a means for re-priming channels in the head

if some are missing. The APS system does this by using a priming pump to force ink out of

the channels and a vacuum pump and collection bottle to collect the ink waste. The APS

cycle can be manually started by momentarily pressing the prime button.

NOTE: The system may not print during an APS cycle or manual prime.

2465-623 User Manual Rev E Page 16

Section 4: Installation

Marksman Matrix & Elite

0= No APS

UJII Heads Graphics Heads

Switch

Setting

0 1 2 3 4 5 6 7 8 9 A B C D E F

Interval

(Hours)

0 2 4 6 8 10 12 14 16 18 1 2 4 6 8 12

Timing Interval Settings

0

1

2

3

4

5

6

7

8

9

A

B

C

F

E

D

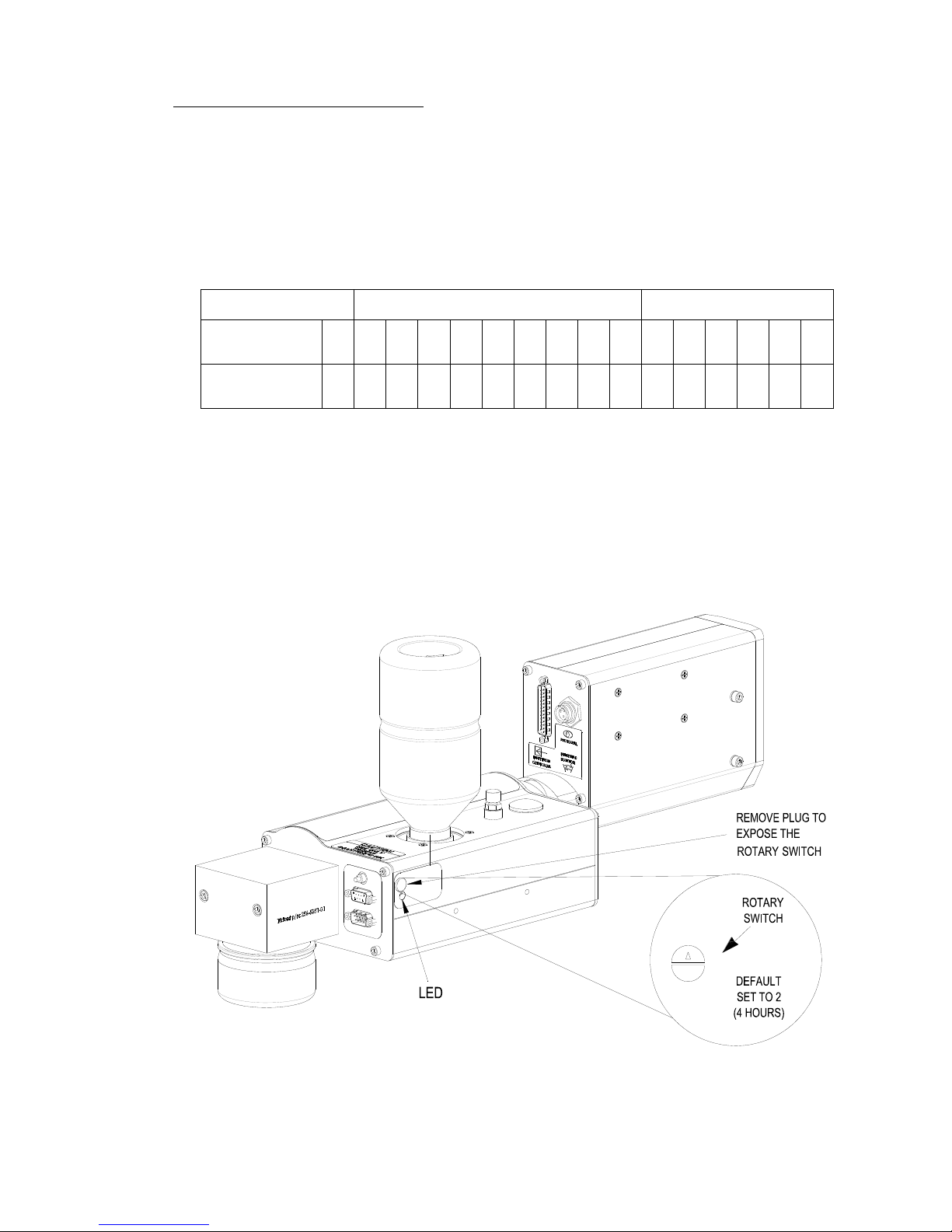

APS View for Printheads

Print Head Control of APS

Print Head control of the APS (Automatic Priming System) cycle is accomplished by a programmed timing interval set by the user at the print head (each head, if more then one is

used). It can be set to run as often as necessary, from once every 2 hours to once every 18

hours for the UJII heads; or from once every hour to once every 12 hours for the graphic

heads. The default setting is once every 4 hours (Switch Setting 2 for a UJII head or Switch

Setting C for a graphics head). The interval can be adjusted by means of a rotary switch

(Programmable Timer) mounted on the APS Controller PCB. (See the illustration below.)

See the following Table for the hour interval for each setting of programmable timer.

The priming sequence will perform three separate consecutive primes of approximately

four milliseconds each. The required time for the priming sequence is less than five seconds, with an additional 20 seconds for the vacuum cycle. As with pervious Trident printheads, printing cannot occur during the priming sequence.

2465-623 User Manual Rev E Page 17

Section 4: Installation

Marksman Matrix & Elite

Auxiliary Photocell Input

NOTE: The APS Control Cable and Auxiliary Photocell cannot be used together.

An Auxiliary Photocell input is available to insure a print cycle is not missed during the

automatic priming sequence. Connecting the Auxiliary Photocell will retard a prime

sequence until there is enough time to complete the sequence without missing a print

cycle. The default delay setting is three (3) seconds after the product passes the photocell.

Multiple heads can share the Auxiliary Photocell by using the Photocell "Y" Cable. To

change the default setting, perform the following steps:

1. Insure that the rotary switch is not in the "0" position.

2. Place a box in front of the photocell.

3. While the photocell is on, set the rotary switch to 0.

4. When the LED stays illuminated continuously, set the rotary switch to a new number (1

through F) representing the number of seconds (1 through 15) you want to delay.

"0" is not an available user setting.

5. Press and hold the Prime button until the LED starts flashing.

6. Release the Prime button.

7. Remove the box from in front of the photocell.

8. Set the rotary switch back to the desired hour setting.

Note:

2465-623 User Manual Rev E Page 18

Marksman Matrix & Elite

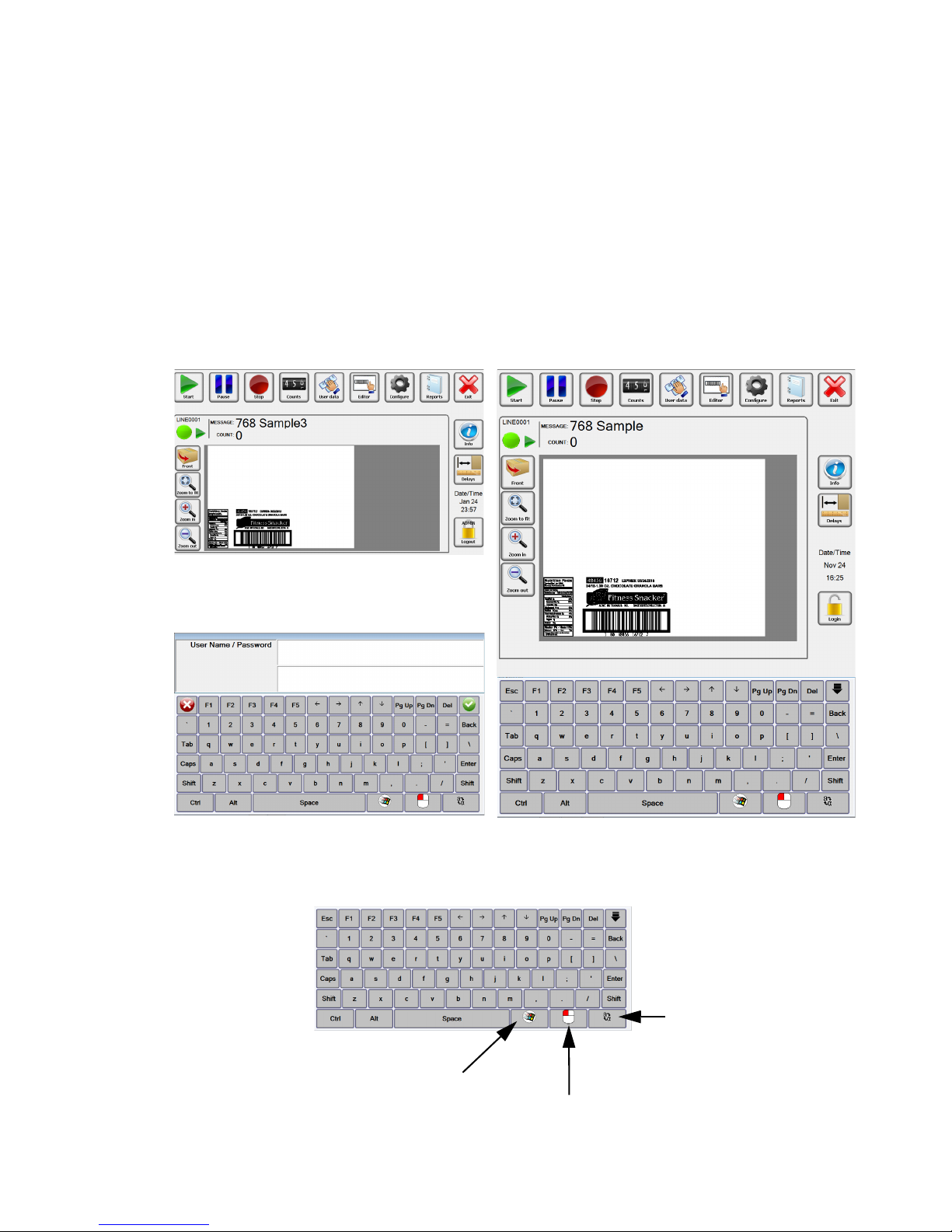

Section 5: Getting Started

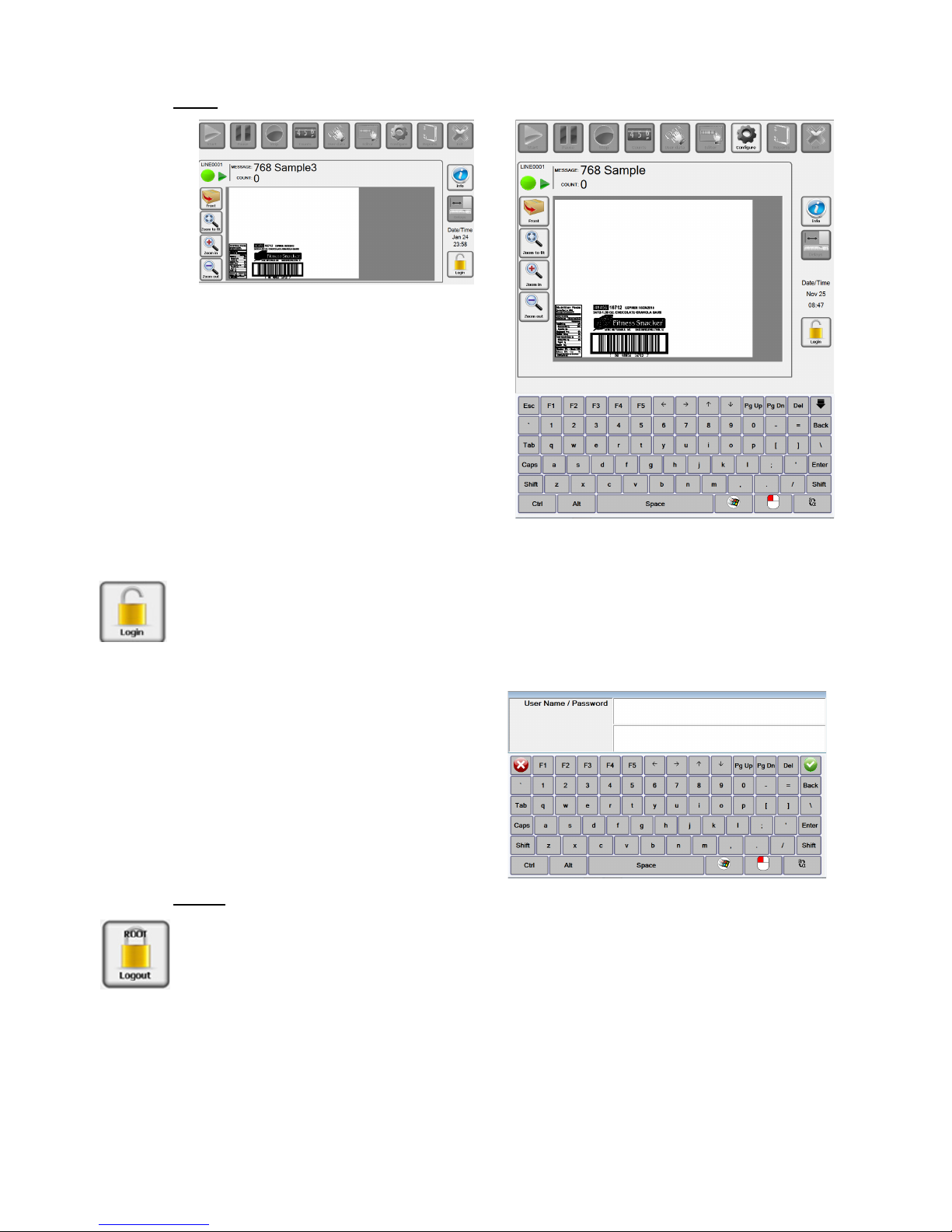

Matrix Version

Elite Version

Matrix keyboard: The keyboard is

called when an input field is selected or

used data is required.

To Windows

Special Function

To change the

key-board language.

Matrix Keyboard

The Marksman Matrix and Elite controllers are standalone units capable of operating one to four printheads, with the addition of an optional controller card. The software has an ICON user interface for is message selection. The main difference

between the two controllers is the size and the resolution of the displays. The resolutions are 1024 x 1280 for the Elite and 1024 x 600 for the Matrix. The extra room

on the Elite display allows for the software keyboard to be accessible at all time.

To get to the keyboard on the Matrix, simply select a field that requires keyboard

input and it will appear. The main dialogs for the print control application (BoxWriter) is shown below:

Section 5: Getting Started

2465-623 User Manual Rev E Page 19

Marksman Matrix & Elite

Login

Before Login, Matrix

Before Login, Elite

Default Username and Password:

Username: Admin

Password: FOXJET

(not case sensitive)

Section 5: Getting Started

Select the Login ICON. The following screen will appear for the Matrix. Enter a username

then tab to the next field, enter a password then select the Enter button or the green check

mark. Once logged in the users account will display on the lock.

Note: User names and passwords are not case sensitive.

Logout

Each user should log out of the Marksman© Elite application to enforce the security restrictions. The user may log by selecting the closed padlock icon from the main display. The

system will continue operating in its current state. All menu options are disabled after the

user logs out, with the exception of the Login, Preview options and Info.

2465-623 User Manual Rev E Page 20

Section 5: Getting Started

Marksman Matrix & Elite

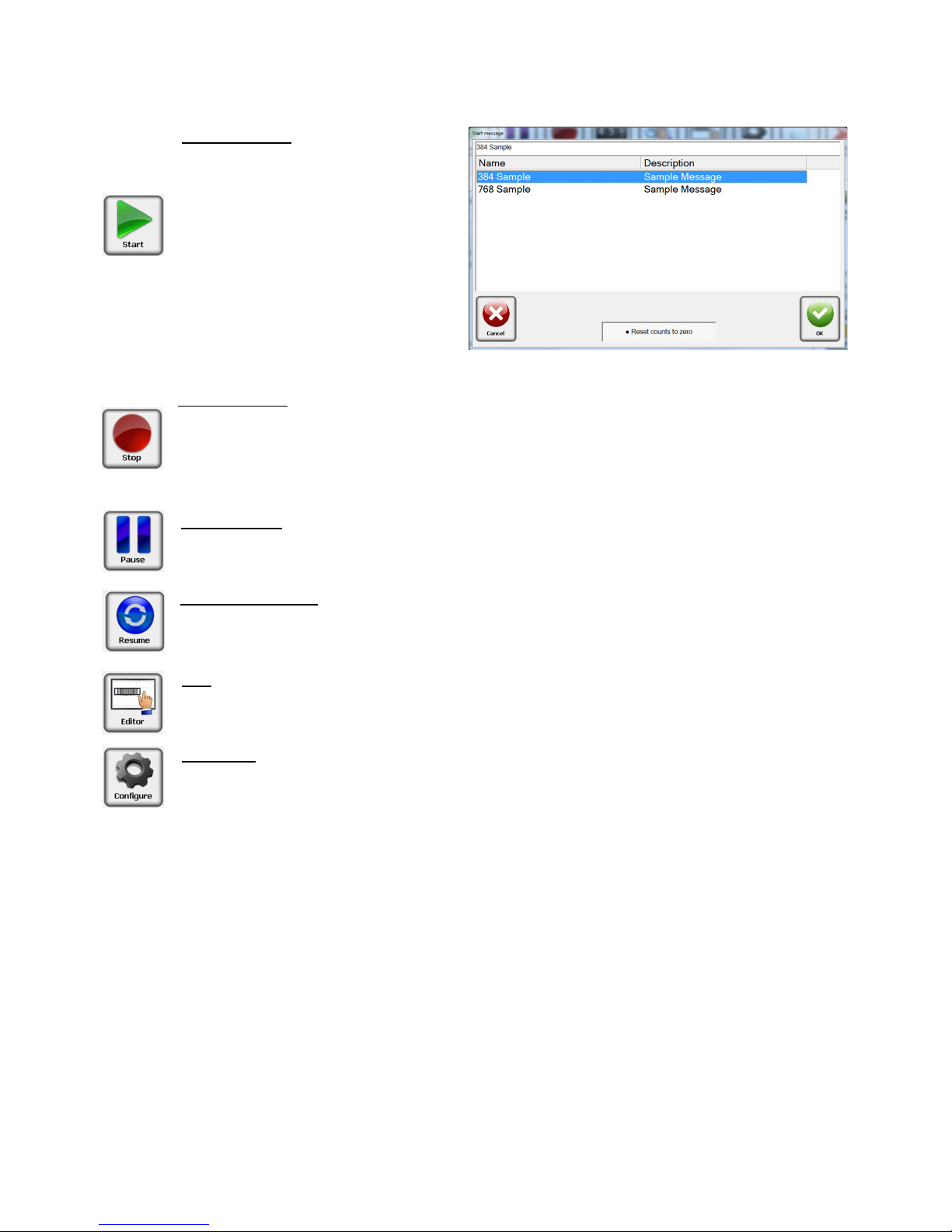

Start or Stop Message.

Pause or Resume message being printed.

Change the variable data that is being printed.

Start the Editor that can be used to create or change

messages.

Access to configure the system. See Configure section.

Change the count being printed, if the message contains a count element.

Access to the Printer report and Scan report.

Close BoxWriter to enter Windows desk top.

ICON’s to toggle between info window and Preview

window.

Easy access to the print head’s photocell delay.

Control of preview window and update preview data.

2465-623 User Manual Rev E Page 21

Section 5: Getting Started

Marksman Matrix & Elite

Start Message

The start message is used to ready

the system to print a label or image

that was created with the BoxWriter

Editor.

Select the desired message from the

list, or enter the message name, and

press the OK button.

Reset counts to zero: This allows the

count value to accumulate if needed

or to be reset with the start of the

message.

Stop Message

Stopping a message halts all printing related to the selected production line. The product

count is reset to zero.

The Stop message icon may be selected from the tool bar to stop the task on the

selected production line.

Idle Message

The Idle message option causes the printing to pause on the selected production line.

The product counts are halted until the current message is Resumed

Resume Message

The Resume message option causes the printing to resume on the selected production

line. The product counts are restored from the previously idled message.

Edit

The Edit menu option launches the Marksman BoxWriter Editor application. The user

must have the required rights to use this feature.

Configure

The Configure icon allows access to other options, Print Test Pattern, Database Start,

Print Heads, Production line, System, Security, Help.

See the Configure section in the manual for additional information.

2465-623 User Manual Rev E Page 22

Marksman Matrix & Elite

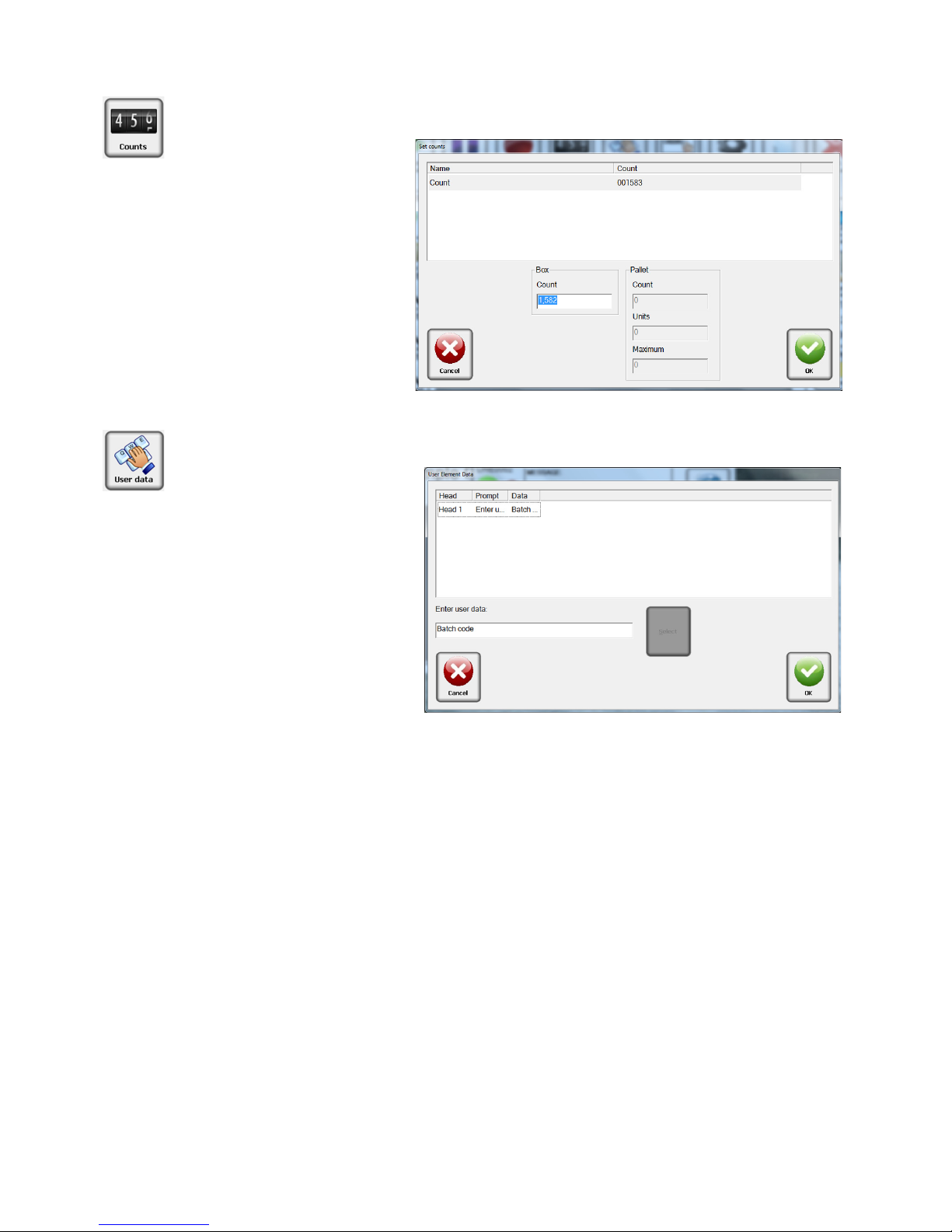

Counts

Count is the current number

of the box in the pallet

series. It is always listed as

the "last printed" box. To

change the Count value,

enter the current box count

value. Enter a

0 to print a

count of 1 on the next box.

User data or User elements

may only be changed if the

message is loaded. The message must contain user elements and be "Running" or

"Idle" in order to modify the

user data.

Select the

User data ICON.

Edit the data in the lower edit

box and press

OK to save

changes. For multiple elements, make all data changes

before pressing

OK to save

changes. Press

Cancel to exit

without saving changes.

User Data

Section 5: Getting Started

2465-623 User Manual Rev E Page 23

Section 5: Getting Started

Marksman Matrix & Elite

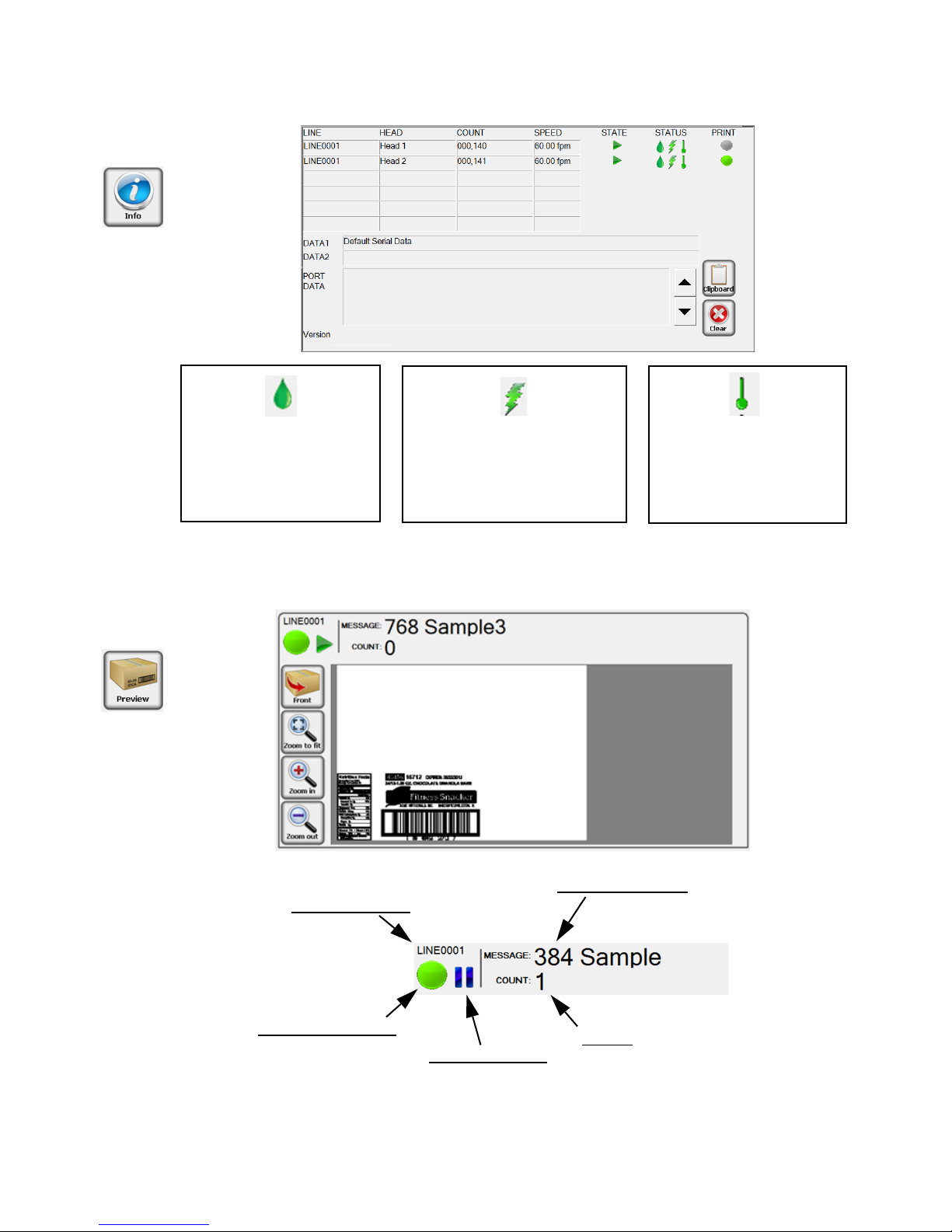

Print Head Ink level or

Ink Collection bottle

Green = Good

Yellow = Low

Red = Out

Print Head High Voltage

Green = Good

Red = Low

Print Head Temperature

Green = Good

Red = Low

NOTE: The system will not print if the controller is reporting a Low Voltage Error, Out of

Ink condition or Low Temperature condition. If a strobe is connected to the system, this

is represented by a flashing red light.

Current Message

Count:

Next count to be printed

Production Line

Print Head Status:

Green: Ok

Yellow: Low Ink

Red: System Printing Error

Message State:

Printing

Stopped

2465-623 User Manual Rev E Page 24

Marksman Matrix & Elite

Configure, Print Head:

Configure, Print Test Pattern

This function is designed to exercise every channel of the print head to verify all are

printing properly.

When the user clicks the “Test Pattern” button, a test image is generated. Each head on

the currently selected line will print this pattern (along with the print head’s name). In the

example below, the Test Pattern is from Head 1.

Configure, Database Start

Set a message based on data that is located in a database. The database must be setup

before the option is available.

Refer to Appendix F: Database Start

Configure, Print Head

Select Configure, then select Print

Heads from the menu. Select a

panel and click on a head. A head

may be added or removed by

clicking the appropriate Add/

Remove button. To edit a head,

select it and click Edit; or double

click it.

Name: The head’s

user-defined name.

Panel

: The panel which the head

will print on.

Print Resolution

: 150, 200 and 300

dots per inch (dpi).

Type

: Select a head type from the

drop-down menu list.

Address

:

Each card is assigned two heads: 1a and 1b, or 2a and 2b. The cards have jumpers

to determine which card it is. The bottom connector of the card is always the designated as “a”.

Section 5: Getting Started

2465-623 User Manual Rev E Page 25

Loading...

Loading...