User

Manual

Marksman

MATRIX & ELITE

High Resolution Printing

for the Real World

2465-623

Revision E

1 Missouri Research Park Drive • St. Charles, MO 63304

Tel: 800-369-5384 • Fax: 636-300-2188

Illinois Tool Works Inc © 2018

www.foxjet.com

Marksman

MATRIX & ELITE

Ink Jet System

User Manual

2465-623

The information contained in this manual

is correct and accurate at the time of its

publication. ITW reserves the right to

change or alter any information or

technical specifications at any time and

without notice.

©2018 Illinois Tool Works Inc.

All rights reserved

Warranty:

The Marksman© Matrix & Elite Ink Jet system, including all components unless other

wise specified, carries a limited warranty.

The inks and conditioners used with the Marksman© Matrix & Elite Ink Jet system

carry a limited warranty.

For all warranty terms and conditions, contact the Distributor for a complete copy of the

Limited Warranty Statement.

Marksman Matrix & Elite

Section 1: Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Section 2: Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Section 3: System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Integrated Print Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Bracketry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Photosensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Inks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Waste Bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Section 4: Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Materials Required for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

System Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installing Bracketry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Mounting the Print System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Setting Up the Print Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Mounting the Photosensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Ship Caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

The Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Electrical Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Priming the Print Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Section 5: Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Counts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

User Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Configure, Print Head: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Configure, System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Delays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Section 6: BoxWriter© Matrix & Elite Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Define . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

ToolBar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Perspective . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Section 7: Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

APS - Automatic Priming System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Shutdown Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Ink Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Section 8: Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Troubleshooting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Troubleshooting Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Print Quality Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

2465-623 User Manual Rev E

Marksman Matrix & Elite

Appendix A: Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Matrix Controller Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Elite Controller Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Print Head Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Appendix B: Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

The Marksman© Matrix & Elite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Print Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Photosensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Matrix Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Elite Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Appendix C: Parts and Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Matrix Spare Parts Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Elite Spare Parts Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

384e and 768e Print System Service Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Appendix D: Testing the Electrical Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Electrical Line Transients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Appendix E: Database Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Database Start Task Routine Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Database Lookup Definition - Global Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Database Start Task . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Serial Port Modification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Printer Report Modification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Appendix F: Hand Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Scan and Shoot Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Appendix G: Fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Font List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Font Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Appendix H: Standard Operating Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

FJSOP1 - Removal of FoxJet High Resolution Printheads . . . . . . . . . . . . . . . . . . . . . . . . . . 113

FJSOP2 - Daily Maintenance for AMS/APS Printheads . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

FJSOP4 - Installation of FoxJet High Resolution AMS/APS Printheads . . . . . . . . . . . . . . .117

2465-623 User Manual Rev E

Marksman Matrix & Elite

Section 1: Introduction

The Marksman© Matrix & Elite are advanced high-resolution ink jet controllers that runs on

a Microsoft Windows 7® platform. It includes a built-in keypad with a TFT display with

touch-screen control. The Marksman© Matrix & Elite can control up to 4 Pro Series highresolution print heads for printing industry compliant barcodes, graphics or alphanumeric

text on porous materials and cases.

This manual covers the operation of the Marksman© Matrix & Elite Ink Jet Printing System,

Marksman© Matrix & Elite Controller and Print Heads.

Section 1: Introduction

2465-623 User Manual Rev E Page 1

Marksman Matrix & Elite

Section 2: Safety

Following is a list of safety symbols and their meanings, which will be found throughout this

manual. Pay attention to these symbols where they appear in the manual.

Wear safety goggles when performing the procedure described!

Caution or Warning! Denotes possible personal injury and/or damage to the equip-

!

ment.

Caution or Warning! Denotes possible personal injury and/or equipment damage

due to electrical hazard.

NOTE: (Will be followed by a brief comment or explanation.)

Section 2: Safety

Only trained personnel should operate and service the equipment.

NOTE: It is extremely important to:

• Clean up all ink spills with the appropriate conditioners immediately and dispose of all

waste according to local and state regulations.

• Wear safety glasses and protective clothing, including gloves, when handling all inks

and conditioners.

• Store inks and conditioners under the recommended conditions found on the MSDS

(Material Safety Data Sheet).

PRODUCT COMPLIANCE DISCLAIMER NOTE:

This product meets the requirements of CAN/CSA-22.2 NO.60950-00 * UL 60950 using

FoxJet an ITW Company approved items. Units are only tested and qualified with FoxJet

an ITW Company approved inks, parts and accessories. Use of other inks, parts or accessories may introduce potential risks that FoxJet an ITW Company can assume no liability

for.

2465-623 User Manual Rev E Page 2

Marksman Matrix & Elite

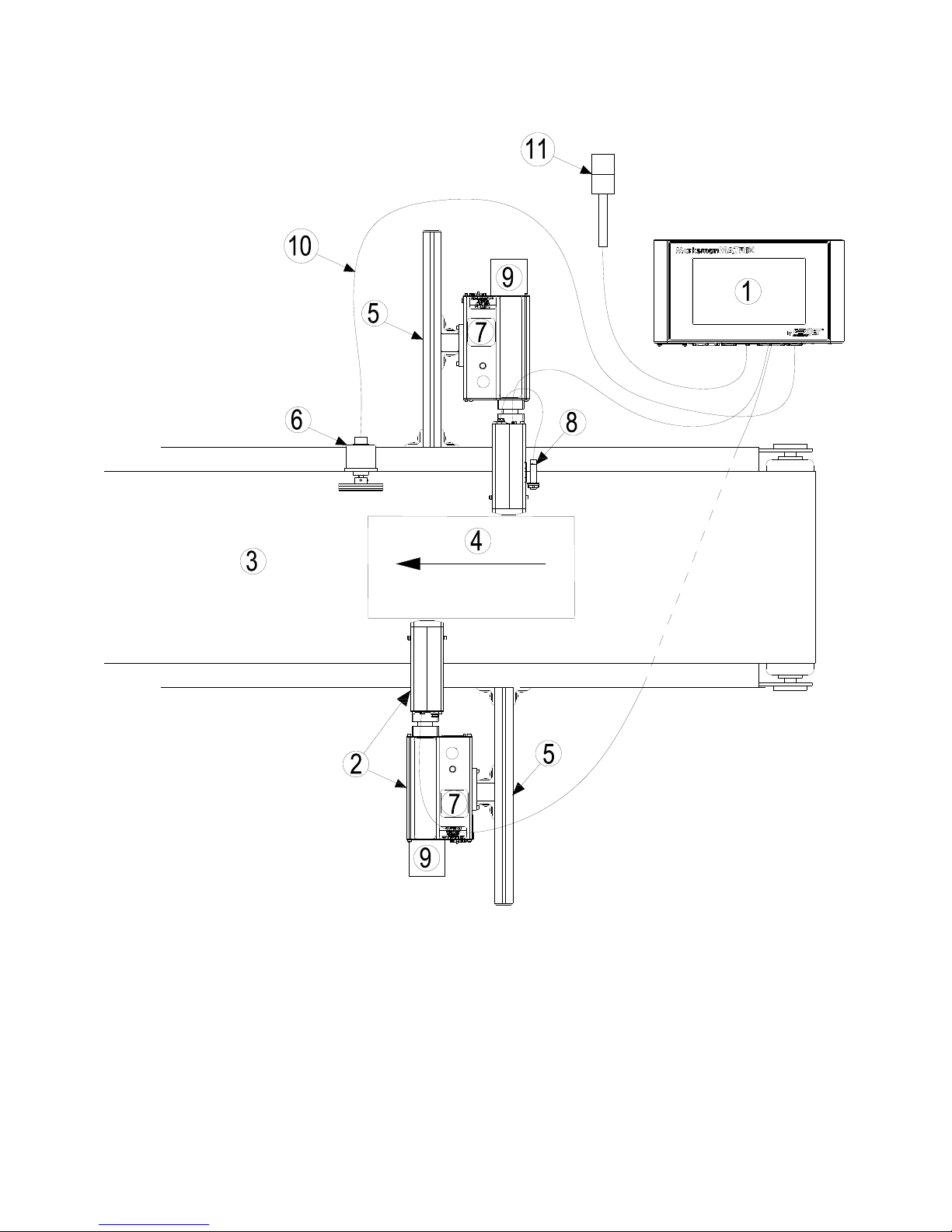

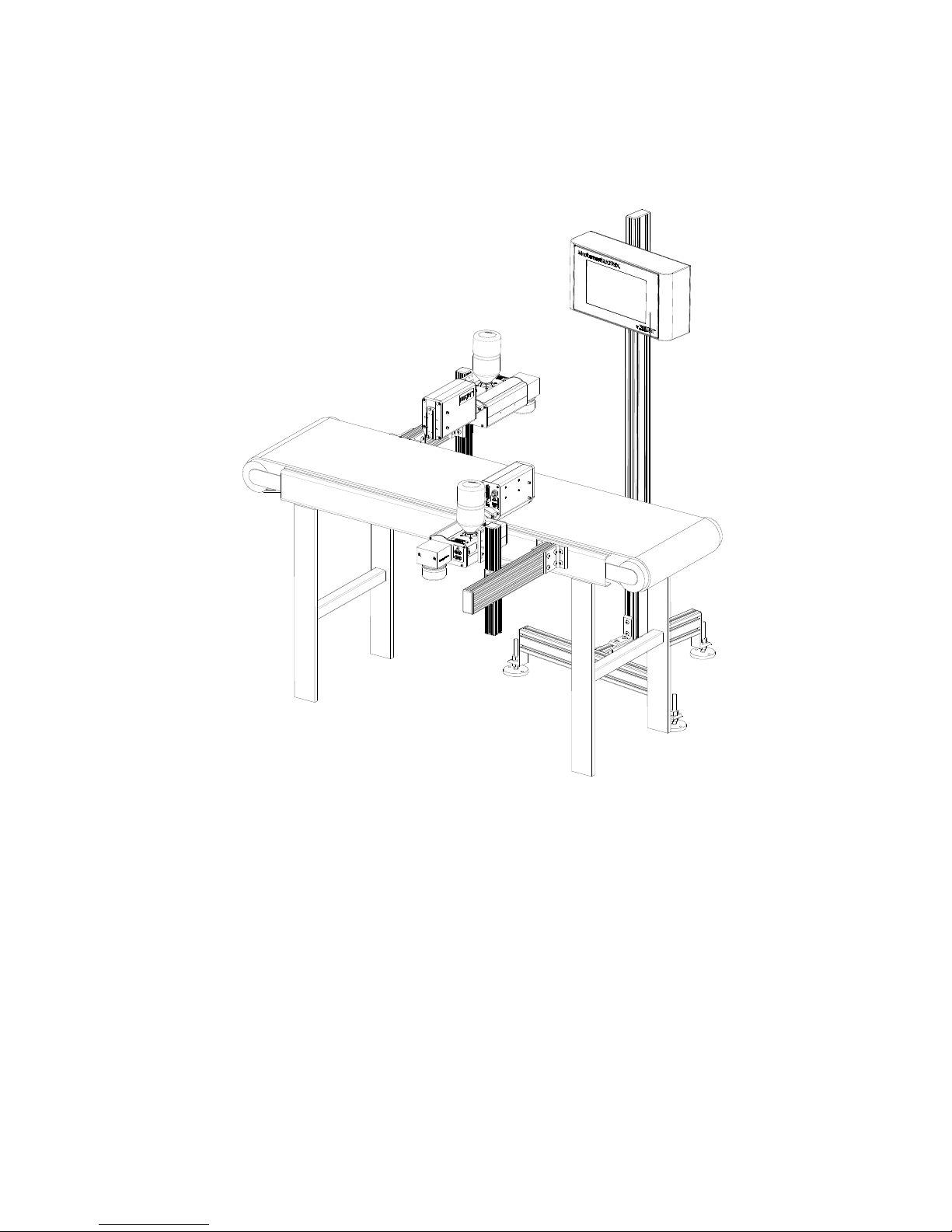

Section 3: System Components

1 Controller, Matrix or Elite

2 Proseries Print Head

3 Conveyor

4 Product

5 Print System Bracketry

6 Encoder

7 Ink Supply

8 Photo Sensor

9 Vacuum Waste Collector Bottle

10 Encoder Cable

11 Alarm Beacon (Strobe)

Section 3: System Components

2465-623 User Manual Rev E Page 3

Section 3: System Components

Marksman Matrix & Elite

The Marksman© Ink Jet System is available with the following components, options and

service kits:

Part Number

2464076 ProSeries 384e

2464076F ProSeries 384e, Flushed

2464078 ProSeries 384e, 90°

2464078F ProSeries 384e, 90°, Flushed

2464079 ProSeries 384e, Modular

2464079F ProSeries 384e, Modular, Flushed

2464082 ProSeries 768e

2464082F ProSeries 768e, Flushed

2464083 ProSeries 768e, Modular

2464083F ProSeries 768e, Modular, Flushed

2464084 ProSeries 768e, 90 Degree

2464084F ProSeries 768e, 90 Degree, Flushed

2465006D2 Controller Assembly, Marksman© Matrix, 2 Head, Domestic

2465006E2 Controller Assembly, Marksman© Matrix, 2 Head, European

2465006D4 Controller Assembly, Marksman© Matrix, 4 Head, Domestic

2465006E4 Controller Assembly, Marksman© Matrix, 4 Head, European

2465004D2 Controller Assembly, Marksman© Elite, 2 Head, Domestic

2465004E2 Controller Assembly, Marksman© Elite, 2 Head, European

Description

Print Head

Matrix Controller Assembly

Elite Controller Assembly

Remote PHC Board & Elite board kit

2465321 Assembly, Marksman remote PHC Board

2465246 Elite PHC Board Kit

Print Head/Controller Bracketry

2464550 Print Head Conveyor Mount Bracket

2464553 Print Head Pivot Bracket

2464561 X-Y Axis Linear Adjustment, Tool-Less Bracket

2464562 Conveyor Mount/Roller Bracket for 768 Print Head

2464563 Print Head Floor Mount Bracket Kit

2464564 Conveyor Mount/Roller Bracket for 384/352 Print Head

2464565 Conveyor Mounting Bracket with Integrated Guide Rails for 384/768 Print Head

2465243 Kit, T-Stand, Matrix & Elite

2465244 Kit, Conveyor Mounting, Matrix & Elite

2465254 Kit, Pivot Bracket, Matrix & Elite

Encoder, Photosensor, Alarm Beacon

2465224 Photosensor, ProSeries

2465253 Alarm Beacon (Strobe), 3-Color

2465525 Photosensor, Auxiliary, APS Controller

2465-623 User Manual Rev E Page 4

Section 3: System Components

Marksman Matrix & Elite

INK SYSTEM

WASTE BOTTLE

PRINT HEAD

INK BOTTLE

Cabling

2464182-010 Cable, Straight Thru, DB9, 10 Ft.

2464182-025 Cable, Straight Thru, DB9, 25Ft.

2464182-050 Cable, Straight Thru, DB9, 50 Ft.

2465155-002 Cable Kit, Print Head, DB25, 2 Ft.

2465155-010 Cable Kit, Print Head, DB25, 10 Ft.

2465155-025 Cable Kit, Print Head, DB25, 25 Ft.

2464312 Cable, APS Photocell Network ("Y" Cable for sharing Auxiliary Photocell)

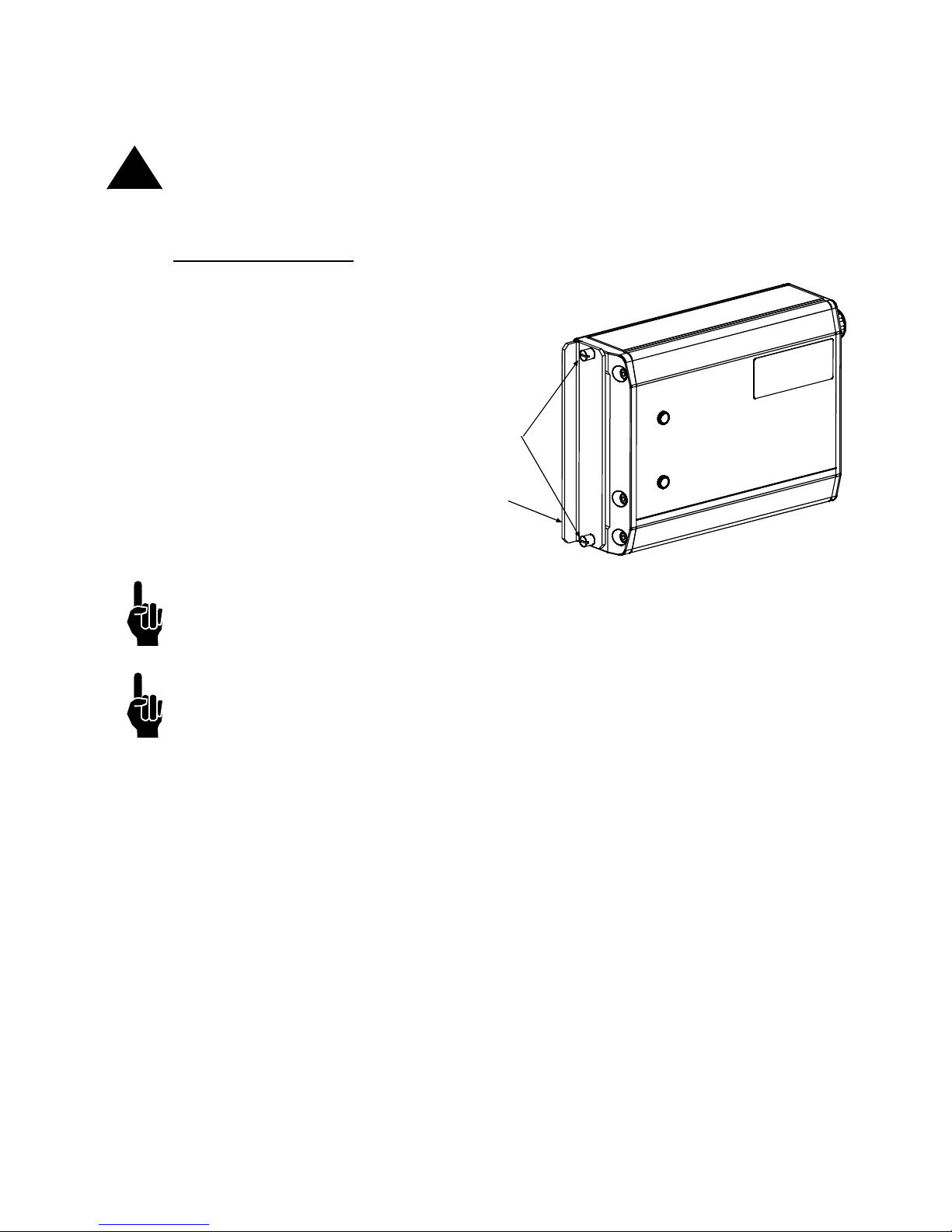

Integrated Print Head

2465-623 User Manual Rev E Page 5

Section 3: System Components

Marksman Matrix & Elite

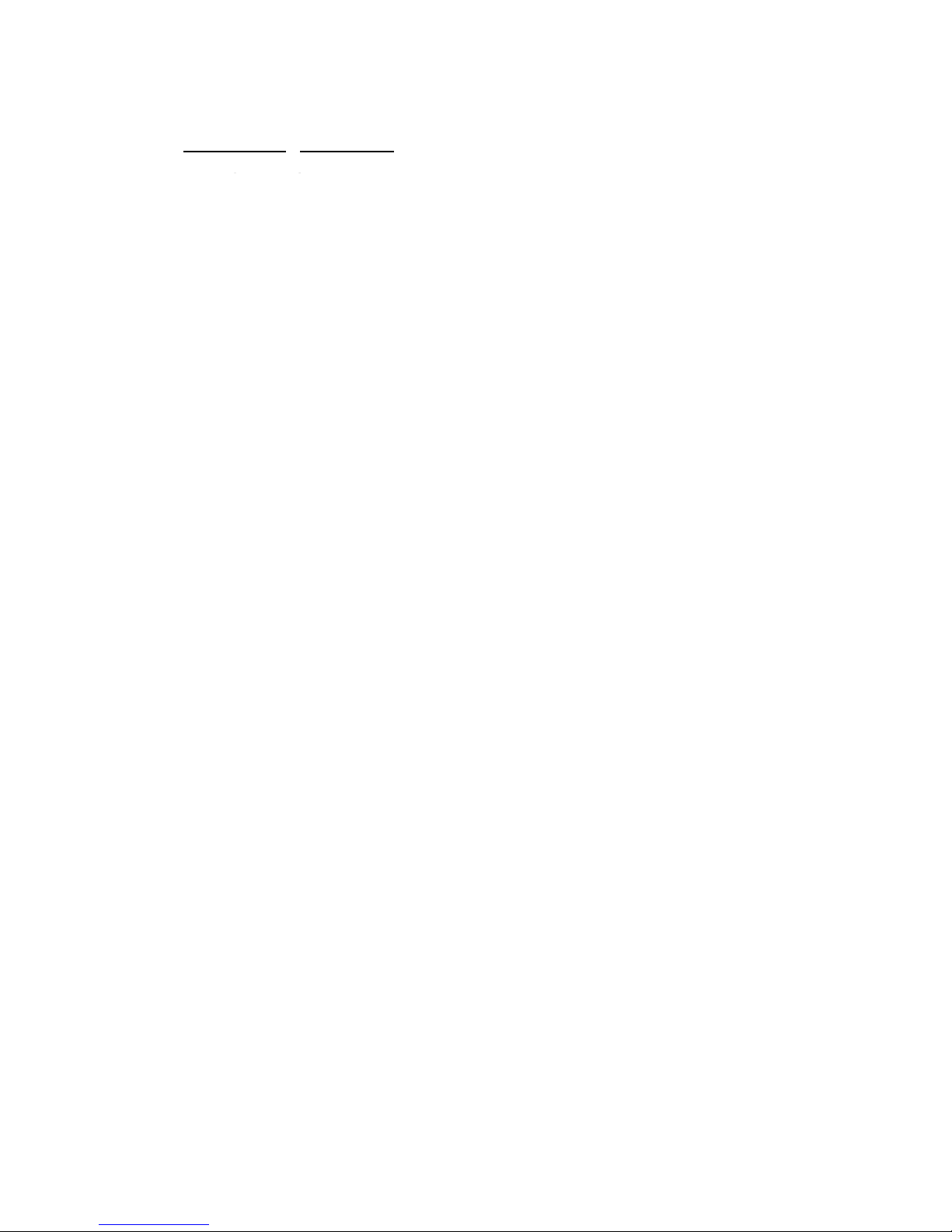

Retracting Bracket

Floor Mount

Conveyor Mount

Bracketry

Bracketry is the structure that supports the controller, print system and other accessories.

This manual details instructions for mounting all system components to a conveyor. Other

mounting options for the controller and print system include the floor mount and the retracting bracket. Assembly instructions are included with parts kits.

2465-623 User Manual Rev E Page 6

Section 3: System Components

Marksman Matrix & Elite

ENCODER ASSEMBLY

Photosensor

The photosensor is both a light source and a sensor. It emits light and detects the arrival of

a product when the product reflects the light source back to the sensor. The sensor then

sends a signal to the controller to start the printing cycle.

Encoder

The encoder assembly provides conveyor line

speed information to the controller. It also allows

automatic disabling of printing when the line

stops.

The Marksman© Matrix & Elite System uses a

5000 ppr open collector output encoder. The

wheel is sized to provide the correct timing

inputs to allow the print heads to print from 150

to 300 dpi.

Inks

Ink is supplied via 500 mL plastic containers. ScanTrue® II PLUS is a pigmented ink formulated for use on porous substrates.

NOTE: Check the label on the Print Head for correct ink type.

NOTE: Inks are not miscible. Do NOT

mix the inks.

Waste Bottle

The APS includes a Waste Collection Bottle mounted on the rear of the Print Head assembly. This bottle must be changed when full to prevent improper operation of the system.

Instructions for waste disposal are on the collection bottle.

2465-623 User Manual Rev E Page 7

Marksman Matrix & Elite

Section 4: Installation

The figure below illustrates a typical conveyor-mounted installation. (Cables are not

shown.)

Section 4: Installation

Materials Required for Installation

You will need the following items:

• Lint-free wipes

• Safety goggles

•Level

• Tape measure

Use appropriate safety equipment and procedures. Leave print heads in their shipping cartons until all bracketry is in place and tightened down.

2465-623 User Manual Rev E Page 8

Section 4: Installation

Marksman Matrix & Elite

ATTACH ING

CORNER

BRACKET

Single T-nut

Corner Bracket

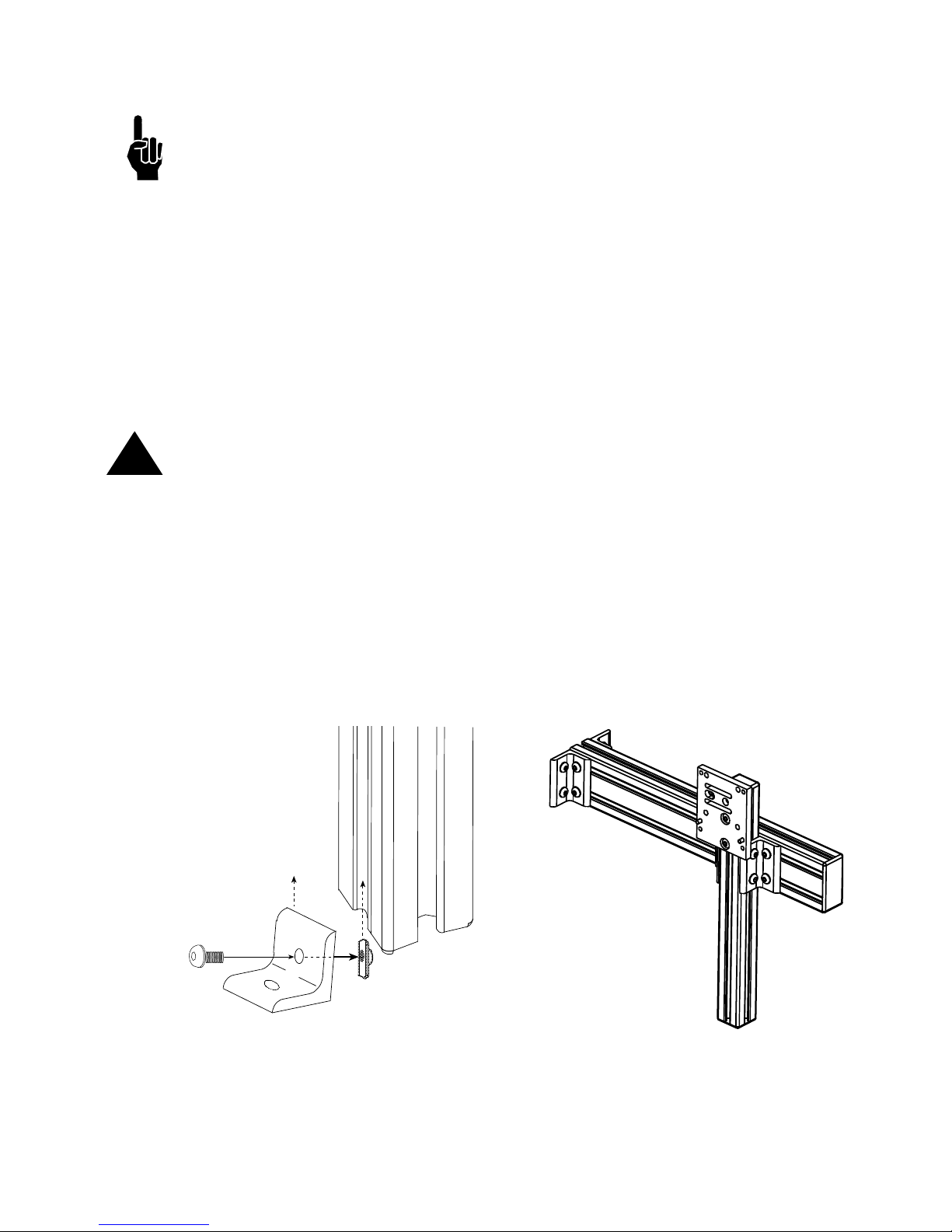

System Installation Overview

NOTE: The following steps give an overview of the procedure to properly install the Marks-

man© Matrix or Elite print system. Refer to the appropriate section for details.

1. Carefully plan the mounting location of the equipment. Keep in mind bracketry hardware location and printer equipment size.

2. Remove equipment from packaging.

3. Assemble all bracketry to the floor, conveyor, or other bracketry per bracketry installation section.

4. Mount the print system to its appropriate bracketry. Do not connect to power outlet.

5. Assemble the optional retracting bracket to each print head, if applicable.

6. Mount the print head(s) to their appropriate bracketry and in the approximate location

relative to the carton.

7. Mount the photosensor, optional bracketry, and optional encoder per procedure.

CAUTION: Remove the print head Ship Cap prior to operating the Print Heads.

!

Installing Bracketry

This section shows controller bracketry mounted to a conveyor. This is the most common

mounting method, and the most stable, as all bracketry is bolted directly to the conveyor.

Detailed assembly instructions are included with the parts kit.

Other mounting options, including parts kit numbers, are listed in

ponents.

Corner brackets are attached to aluminum bars as shown.

Section 3, System Com-

2465-623 User Manual Rev E Page 9

Section 4: Installation

Marksman Matrix & Elite

Mounting the Print System

Unpack the print head just before mounting to the bracketry.

Attach the print head to the bracketry with a print head mounting bracket.

The print head must be mounted in close proximity to the product. To maintain consistent

print, the head should be mounted no more than 1/8" from the substrate. An optional

retracting bracket is available to mount the head and control the distance from the head to

the substrate. The retracting bracket allows the head to bump the product and retract as

required to maintain a consistent throw distance. (See

bracketry options.)

NOTE: Install optional retracting bracket kit on the print head prior to mounting the print

head to the conveyor bracket.

It may be necessary to vertically adjust each bracket's horizontal bar later to fine-tune message placement. This is especially true when using multiple print heads, as message lines

will need to be synchronized with each other.

NOTE: When adjusting the horizontal bar or print head mounting bracket, always support

the print head with your hand to keep it from falling forward onto the conveyor.

Section 3, System Components for

NOTE: The ProSeries print heads work on gravity and capillary ink feed, internal in the

print head. The head must be mounted in a level position from front to back to prevent leakage.

2465-623 User Manual Rev E Page 10

Section 4: Installation

Marksman Matrix & Elite

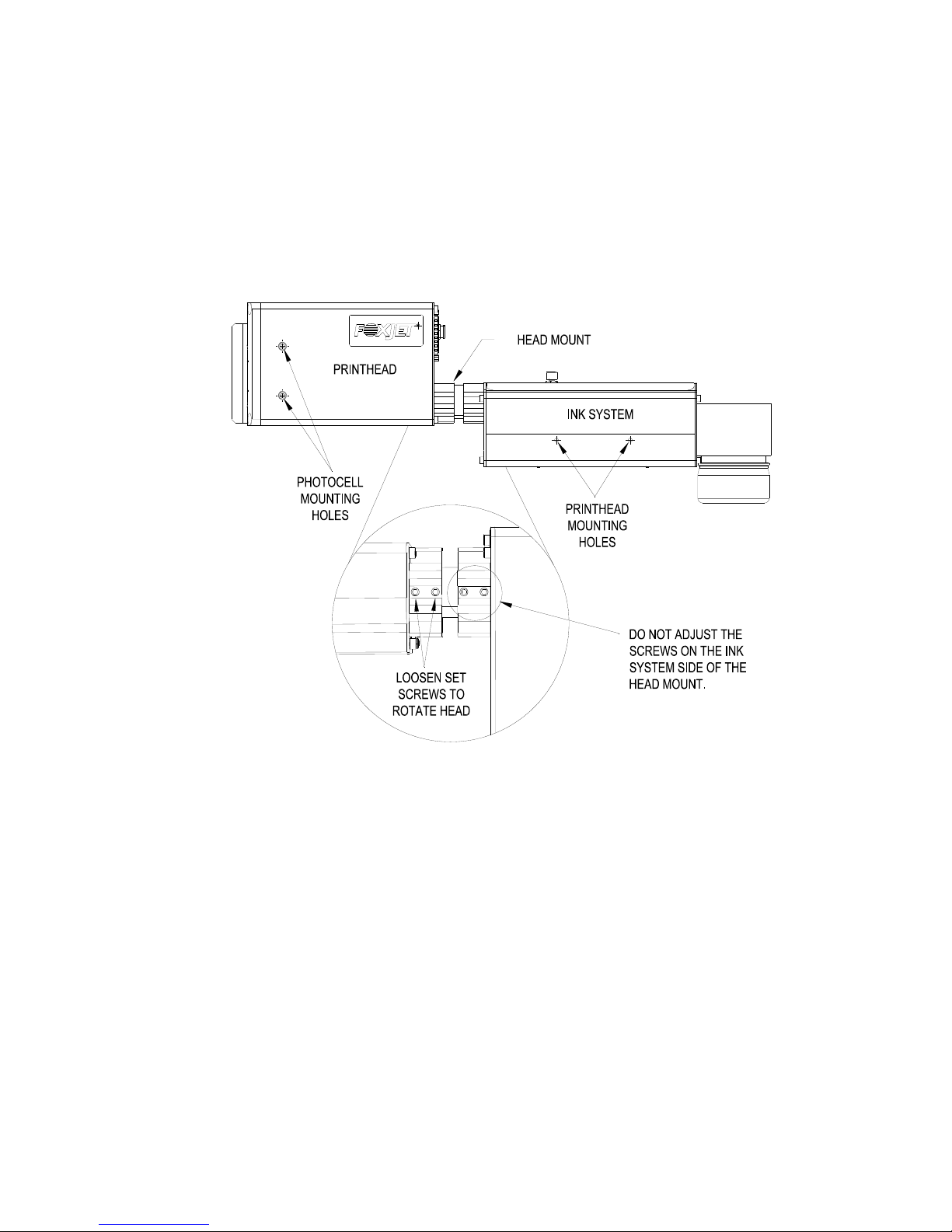

Setting Up the Print Head

The Matrix/Classic Series print heads are mounted using the 10-32 tapped holes on the

right or left side of the Ink System bottom case. The print head angle can be set between 0°

and 90°.

To adjust the head to its correct angle:

1. Loosen the two set screws (1/8" hex head) on the print head side of the head mount.

2. Rotate the head to the desired angle.

3. Secure the set screws.

Mounting the Photosensor

The product detect Photocell can be mounted on either side of the print head, depending

on the direction of print. Remove the plugs or set screws (3/32" hex head) in the photocell

mounting holes, then attach the Photocell Mounting Bracket with the 10-32 x 1/2" screws

provided with the bracket.

2465-623 User Manual Rev E Page 11

Section 4: Installation

Marksman Matrix & Elite

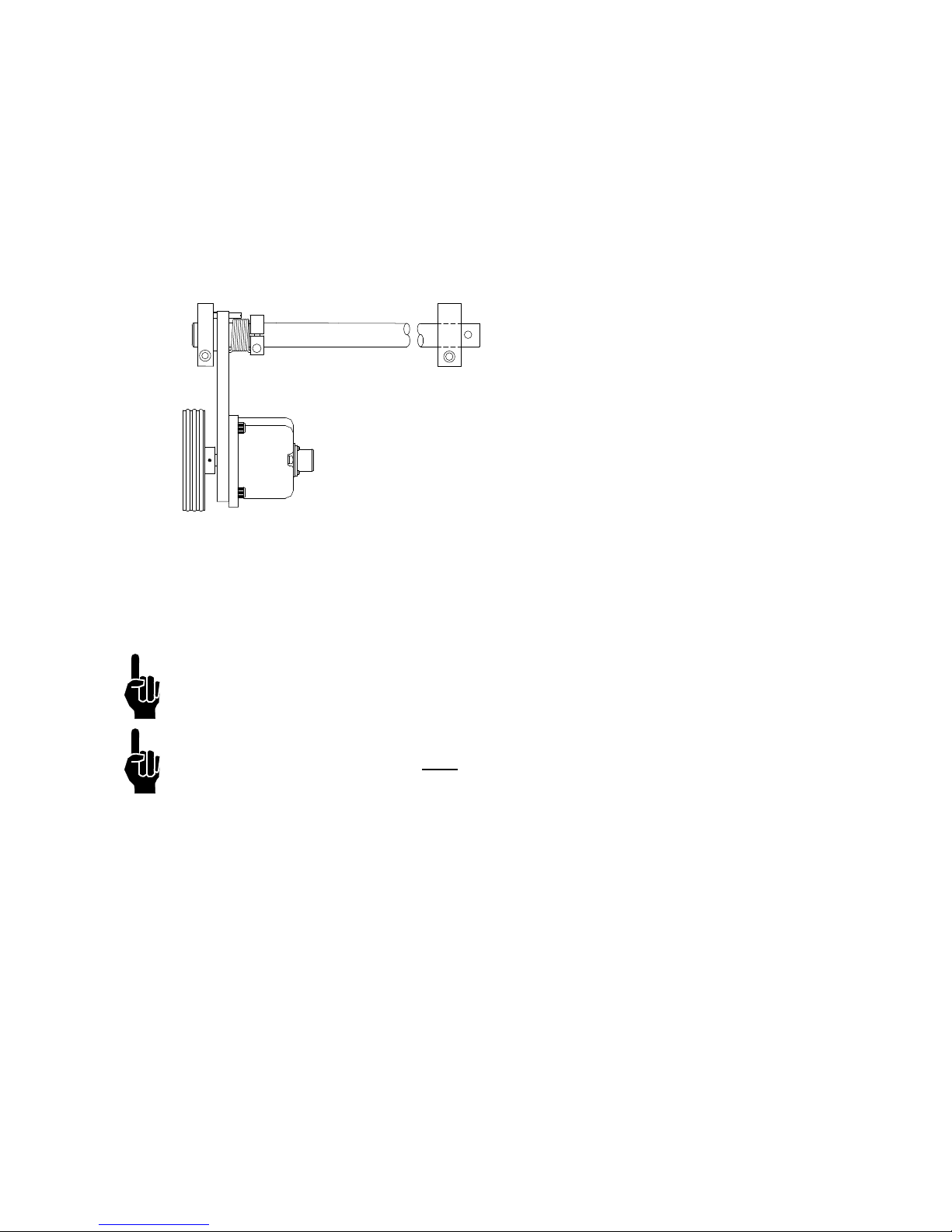

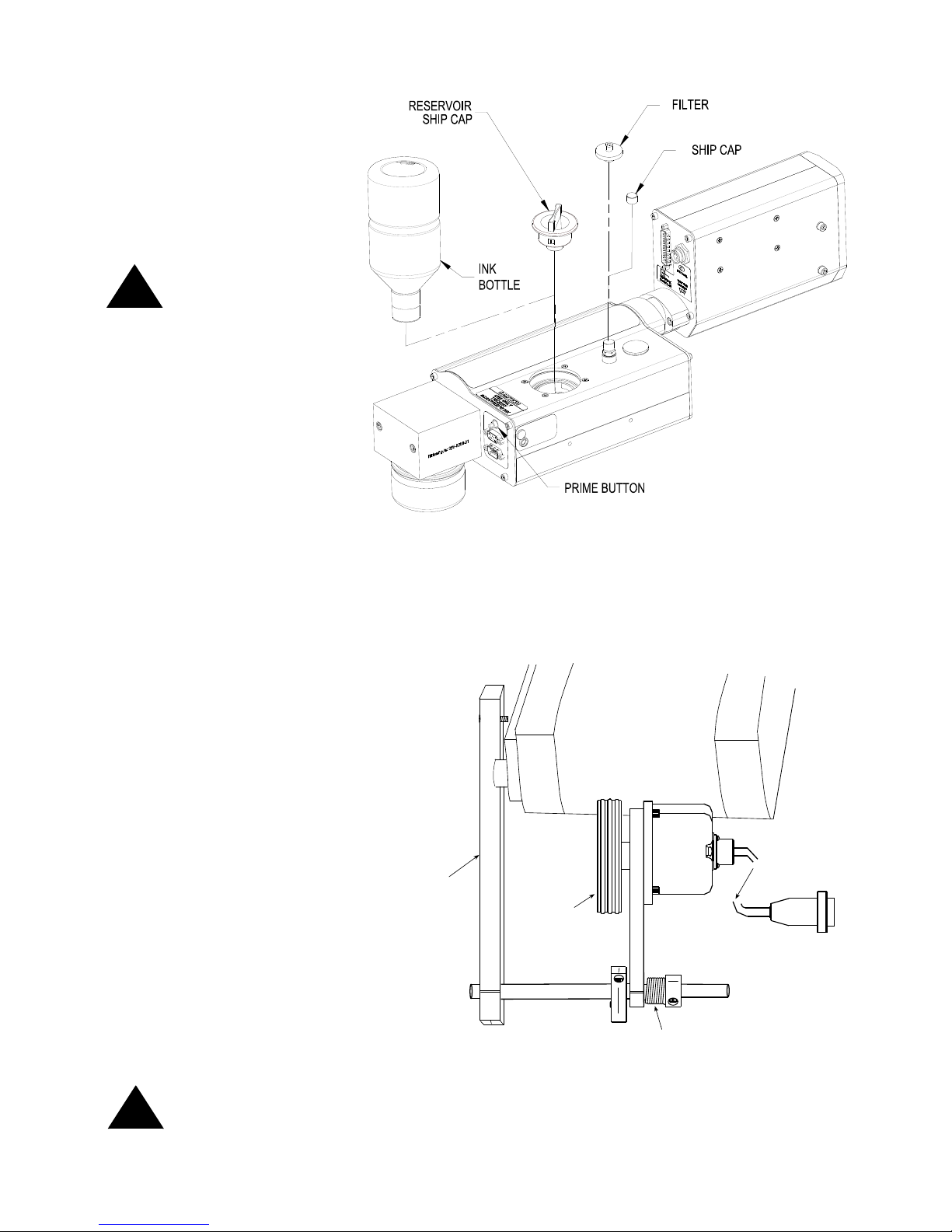

THUMBSCREWS

SHIP CAP

Ship Caps

CAUTION: Do not operate APS Print Heads with the Print Head Ship Cap installed! Oper-

!

ating a closed system can cause a siphoning effect which can drain the ink supply.

384e/768e Print Heads

Loosen the two thumbscrews

and remove the Ship Cap.

(See illustration at right.)

NOTE: If you place the Print Head Ship Cap on a hot print head and do not fasten it

securely, the print head will weep ink until the head has cooled down.

NOTE: Ink may accumulate behind the ship cap during shipping.

2465-623 User Manual Rev E Page 12

Marksman Matrix & Elite

Remove the Ship Cap

Spring

Mounting

Bracket

Encoder

Wheel

Conveyor

Out to Controller

Mounting Bracket

Shaft

Encoder

ENCODER

ASSEMBLY

and Install the Filter.

Remove the Reservoir

Ship Cap and Install

the Ink Bottle. Save

caps in a zip-lock bag

for future use.

CAUTION: Do not

over-tighten the ink

!

bottle when screwing

into the Reservoir.

Over-tightening will

damage the Reservoir.

Section 4: Installation

!

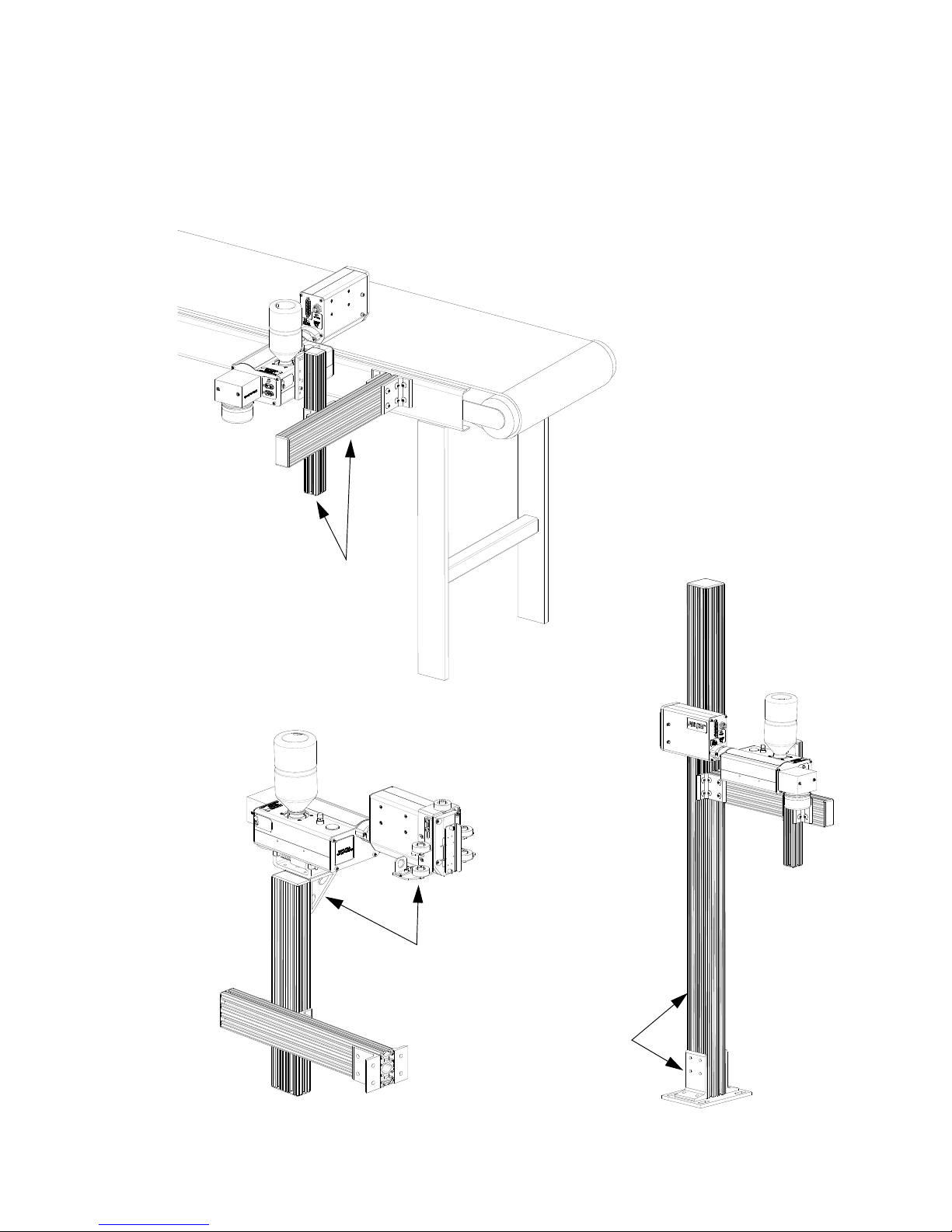

The Encoder

The encoder uses a wheel

that rolls against the conveyor line to track the speed.

It sends a signal to the controller, which makes adjustments for reported changes in

the line speed.

It is not necessary to install

the encoder immediately adjacent to the print heads. It is

more important to place it

where it will accurately measure the speed of the conveyor. Install it in contact with

the conveyor, or with a wheel

or roller moving the same

speed as the conveyor.

The encoder's mounting

bracket is spring-loaded.

Adjust the spring collar to

ensure that the encoder maintains stable contact with the

conveyor.

CAUTION: Do not jam the encoder wheel against the surface of the conveyor. A radial

force of over 40 lbs. will reduce the life of the bearings.

2465-623 User Manual Rev E Page 13

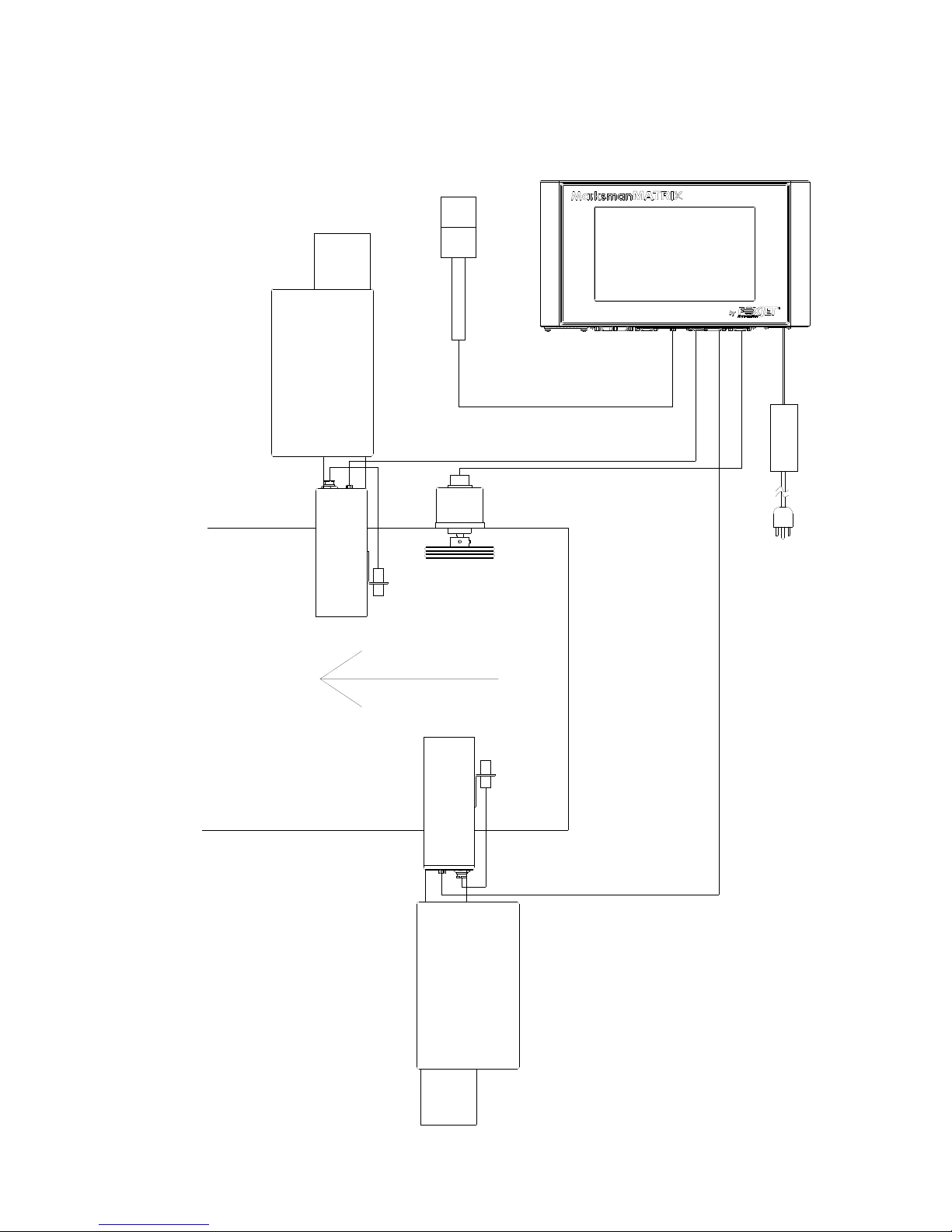

Marksman Matrix & Elite

PRINT

SYSTEM

PRINT HEAD CABLE

PHOTO

SENSOR

ENCODER

SYSTEM

PRINT

ALARM

BEACON

(STROBE)

MARKSMAN MATRIX OR ELITE CONTROLLER

24V

Section 4: Installation

Electrical Cable Connections

2465-623 User Manual Rev E Page 14

Marksman Matrix & Elite

Views

Bottom view of Matrix Controller

(With Optional second PHC Board

ETHERNET

LINE OUT

12 VDC

USB

VGA

DVI-D

COM 1 STROBECOM 2 ENCODER

1

2

OUTPUT TO

PRINTHEAD

4

3

PRINT HEAD CARDS

Bottom view of Elite Controller

Back view of Print System

Section 4: Installation

2465-623 User Manual Rev E Page 15

Section 4: Installation

Marksman Matrix & Elite

Priming the Print Heads

NOTE: The system will not prime either manually or automatically if there is a low ink indi-

cation. Low ink indication is caused by either low ink in the reservoir or full ink in the waste

collection bottle.

Manual Prime

NOTE: Place a wipe in front of the maintenance plate to catch excessive ink.

A manual prime can be accomplished by depressing the push-button switch on the rear of

the ink system housing. Pressing and holding the button for longer than one second will

start the pump for a manual prime. It will continue to run as long as the button is depressed,

or up to five seconds. If additional priming is required, release and press the button again.

Pressing for less than 0.5 seconds will initiate a maintenance cycle. If the system has

started a maintenance cycle and the button is pressed, the manual prime will not operate.

(The Priming Sequence and the Vacuum Cycle are less than 10 seconds long.)

APS Cycle

The APS (Automatic Priming System) cycle is a means for re-priming channels in the head

if some are missing. The APS system does this by using a priming pump to force ink out of

the channels and a vacuum pump and collection bottle to collect the ink waste. The APS

cycle can be manually started by momentarily pressing the prime button.

NOTE: The system may not print during an APS cycle or manual prime.

2465-623 User Manual Rev E Page 16

Section 4: Installation

Marksman Matrix & Elite

0= No APS

UJII Heads Graphics Heads

Switch

Setting

0 1 2 3 4 5 6 7 8 9 A B C D E F

Interval

(Hours)

0 2 4 6 8 10 12 14 16 18 1 2 4 6 8 12

Timing Interval Settings

0

1

2

3

4

5

6

7

8

9

A

B

C

F

E

D

APS View for Printheads

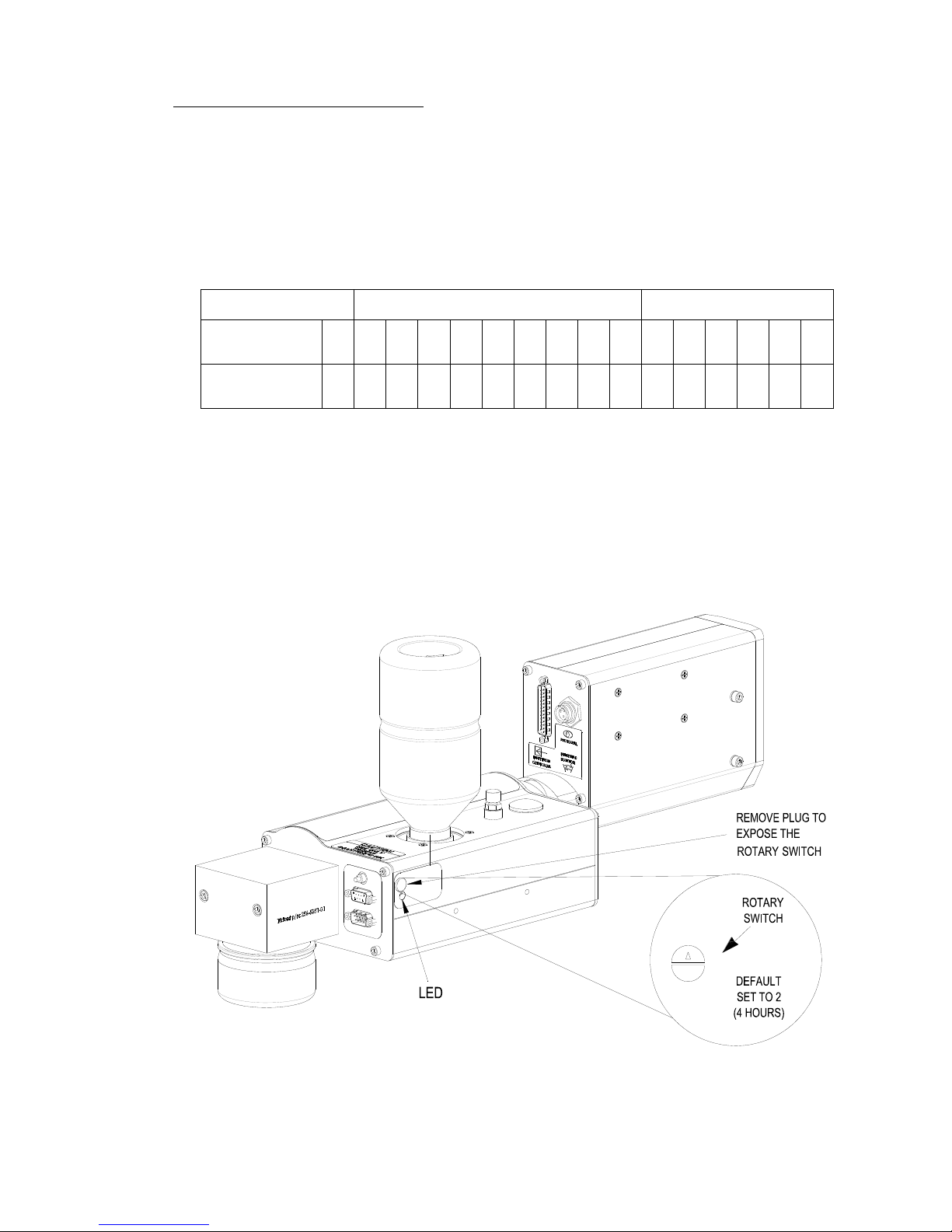

Print Head Control of APS

Print Head control of the APS (Automatic Priming System) cycle is accomplished by a programmed timing interval set by the user at the print head (each head, if more then one is

used). It can be set to run as often as necessary, from once every 2 hours to once every 18

hours for the UJII heads; or from once every hour to once every 12 hours for the graphic

heads. The default setting is once every 4 hours (Switch Setting 2 for a UJII head or Switch

Setting C for a graphics head). The interval can be adjusted by means of a rotary switch

(Programmable Timer) mounted on the APS Controller PCB. (See the illustration below.)

See the following Table for the hour interval for each setting of programmable timer.

The priming sequence will perform three separate consecutive primes of approximately

four milliseconds each. The required time for the priming sequence is less than five seconds, with an additional 20 seconds for the vacuum cycle. As with pervious Trident printheads, printing cannot occur during the priming sequence.

2465-623 User Manual Rev E Page 17

Section 4: Installation

Marksman Matrix & Elite

Auxiliary Photocell Input

NOTE: The APS Control Cable and Auxiliary Photocell cannot be used together.

An Auxiliary Photocell input is available to insure a print cycle is not missed during the

automatic priming sequence. Connecting the Auxiliary Photocell will retard a prime

sequence until there is enough time to complete the sequence without missing a print

cycle. The default delay setting is three (3) seconds after the product passes the photocell.

Multiple heads can share the Auxiliary Photocell by using the Photocell "Y" Cable. To

change the default setting, perform the following steps:

1. Insure that the rotary switch is not in the "0" position.

2. Place a box in front of the photocell.

3. While the photocell is on, set the rotary switch to 0.

4. When the LED stays illuminated continuously, set the rotary switch to a new number (1

through F) representing the number of seconds (1 through 15) you want to delay.

"0" is not an available user setting.

5. Press and hold the Prime button until the LED starts flashing.

6. Release the Prime button.

7. Remove the box from in front of the photocell.

8. Set the rotary switch back to the desired hour setting.

Note:

2465-623 User Manual Rev E Page 18

Marksman Matrix & Elite

Section 5: Getting Started

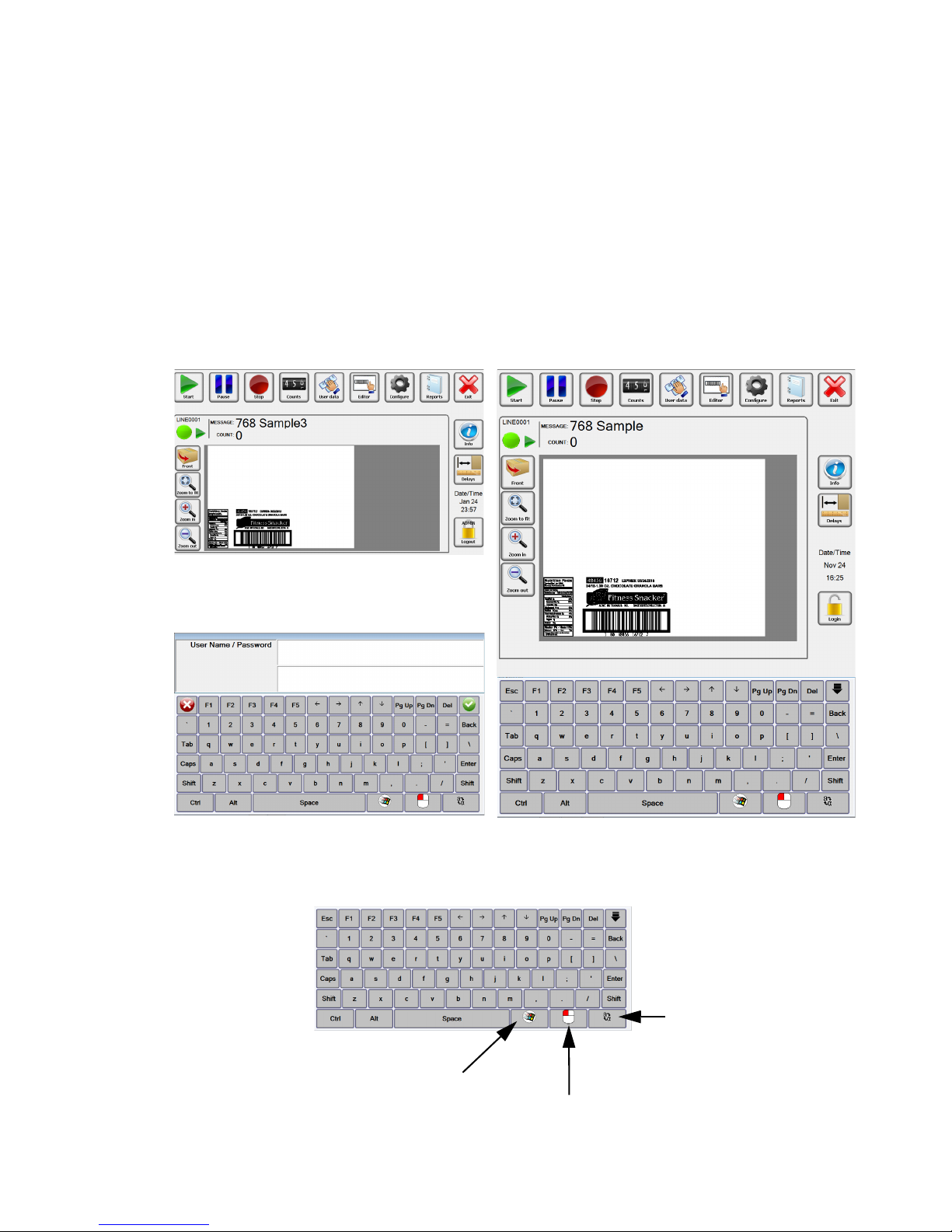

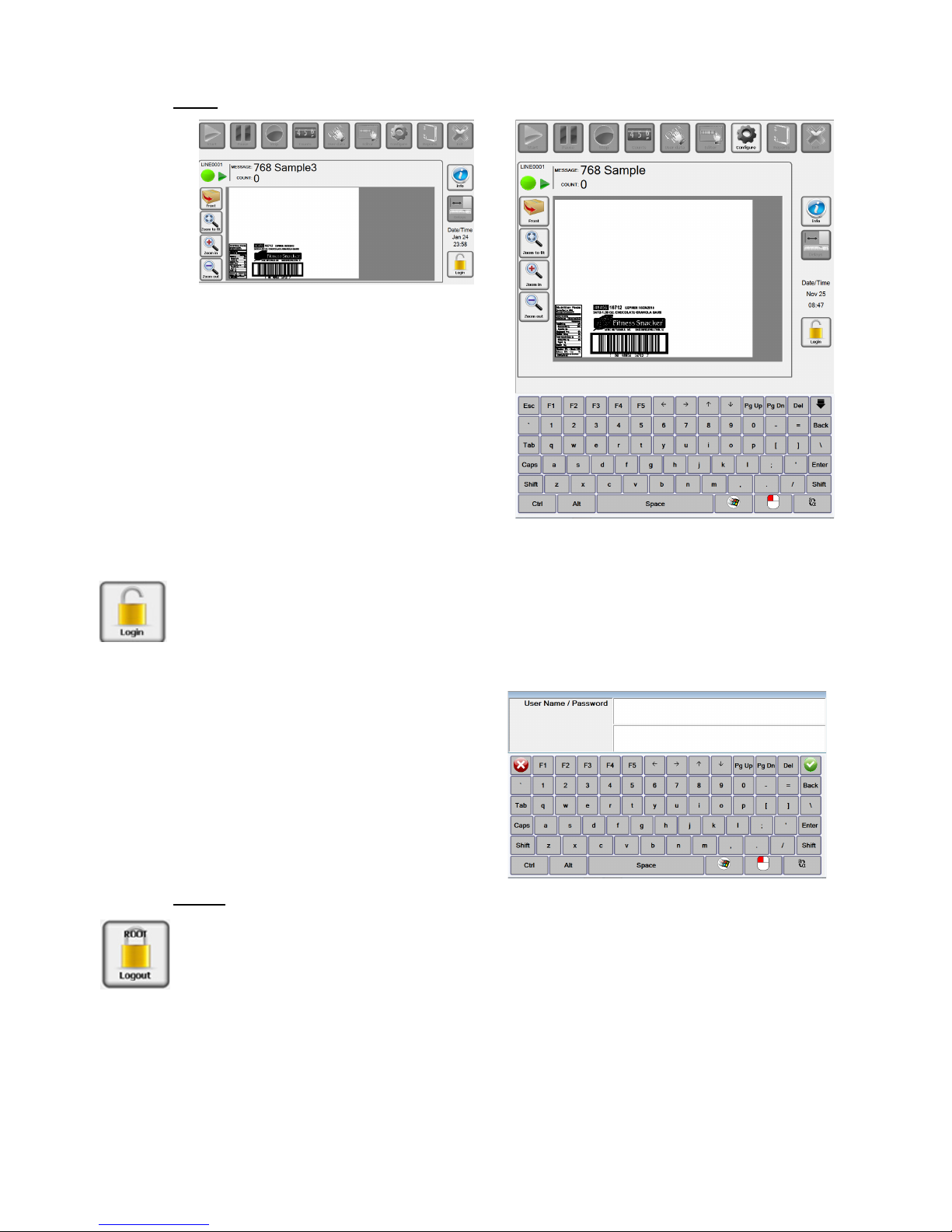

Matrix Version

Elite Version

Matrix keyboard: The keyboard is

called when an input field is selected or

used data is required.

To Windows

Special Function

To change the

key-board language.

Matrix Keyboard

The Marksman Matrix and Elite controllers are standalone units capable of operating one to four printheads, with the addition of an optional controller card. The software has an ICON user interface for is message selection. The main difference

between the two controllers is the size and the resolution of the displays. The resolutions are 1024 x 1280 for the Elite and 1024 x 600 for the Matrix. The extra room

on the Elite display allows for the software keyboard to be accessible at all time.

To get to the keyboard on the Matrix, simply select a field that requires keyboard

input and it will appear. The main dialogs for the print control application (BoxWriter) is shown below:

Section 5: Getting Started

2465-623 User Manual Rev E Page 19

Marksman Matrix & Elite

Login

Before Login, Matrix

Before Login, Elite

Default Username and Password:

Username: Admin

Password: FOXJET

(not case sensitive)

Section 5: Getting Started

Select the Login ICON. The following screen will appear for the Matrix. Enter a username

then tab to the next field, enter a password then select the Enter button or the green check

mark. Once logged in the users account will display on the lock.

Note: User names and passwords are not case sensitive.

Logout

Each user should log out of the Marksman© Elite application to enforce the security restrictions. The user may log by selecting the closed padlock icon from the main display. The

system will continue operating in its current state. All menu options are disabled after the

user logs out, with the exception of the Login, Preview options and Info.

2465-623 User Manual Rev E Page 20

Section 5: Getting Started

Marksman Matrix & Elite

Start or Stop Message.

Pause or Resume message being printed.

Change the variable data that is being printed.

Start the Editor that can be used to create or change

messages.

Access to configure the system. See Configure section.

Change the count being printed, if the message contains a count element.

Access to the Printer report and Scan report.

Close BoxWriter to enter Windows desk top.

ICON’s to toggle between info window and Preview

window.

Easy access to the print head’s photocell delay.

Control of preview window and update preview data.

2465-623 User Manual Rev E Page 21

Section 5: Getting Started

Marksman Matrix & Elite

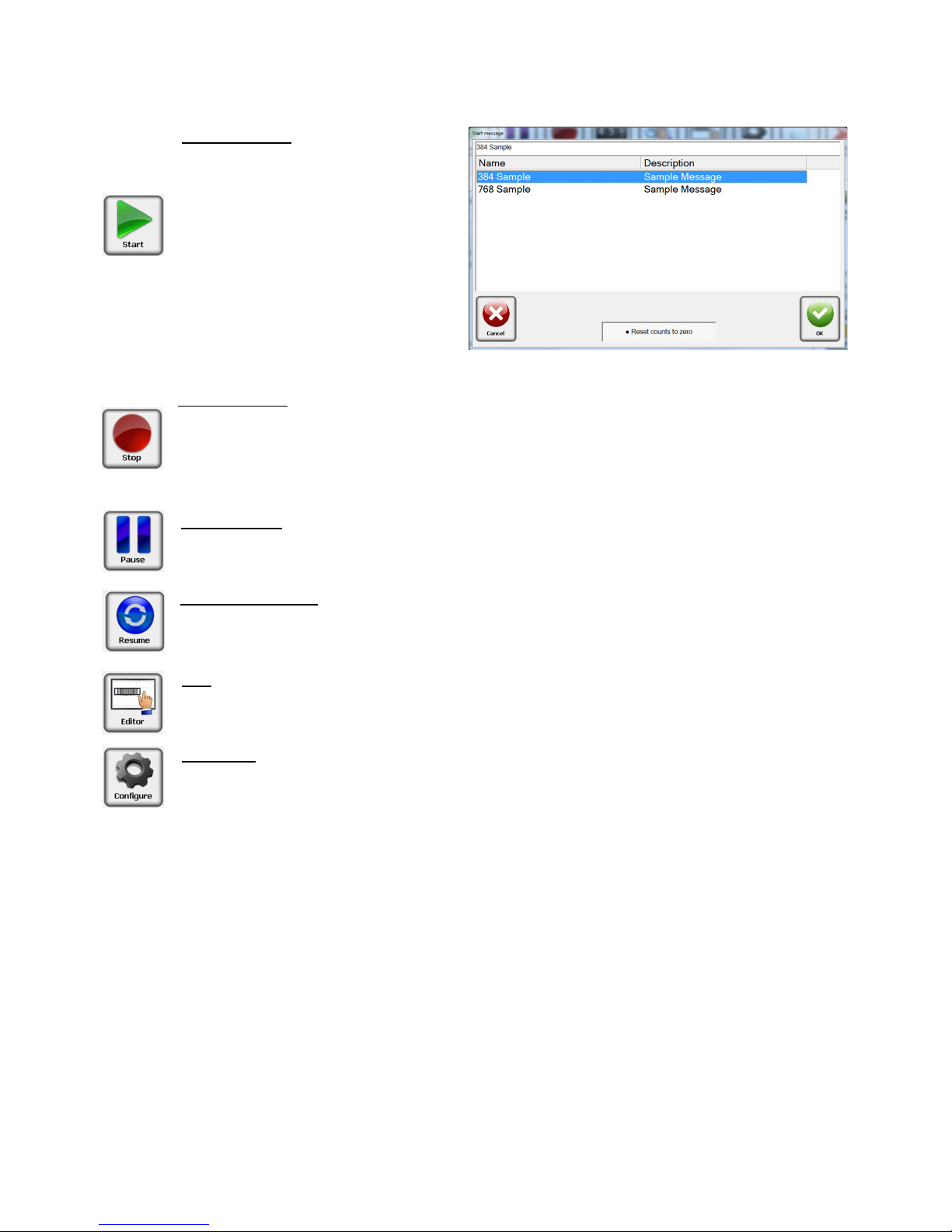

Start Message

The start message is used to ready

the system to print a label or image

that was created with the BoxWriter

Editor.

Select the desired message from the

list, or enter the message name, and

press the OK button.

Reset counts to zero: This allows the

count value to accumulate if needed

or to be reset with the start of the

message.

Stop Message

Stopping a message halts all printing related to the selected production line. The product

count is reset to zero.

The Stop message icon may be selected from the tool bar to stop the task on the

selected production line.

Idle Message

The Idle message option causes the printing to pause on the selected production line.

The product counts are halted until the current message is Resumed

Resume Message

The Resume message option causes the printing to resume on the selected production

line. The product counts are restored from the previously idled message.

Edit

The Edit menu option launches the Marksman BoxWriter Editor application. The user

must have the required rights to use this feature.

Configure

The Configure icon allows access to other options, Print Test Pattern, Database Start,

Print Heads, Production line, System, Security, Help.

See the Configure section in the manual for additional information.

2465-623 User Manual Rev E Page 22

Marksman Matrix & Elite

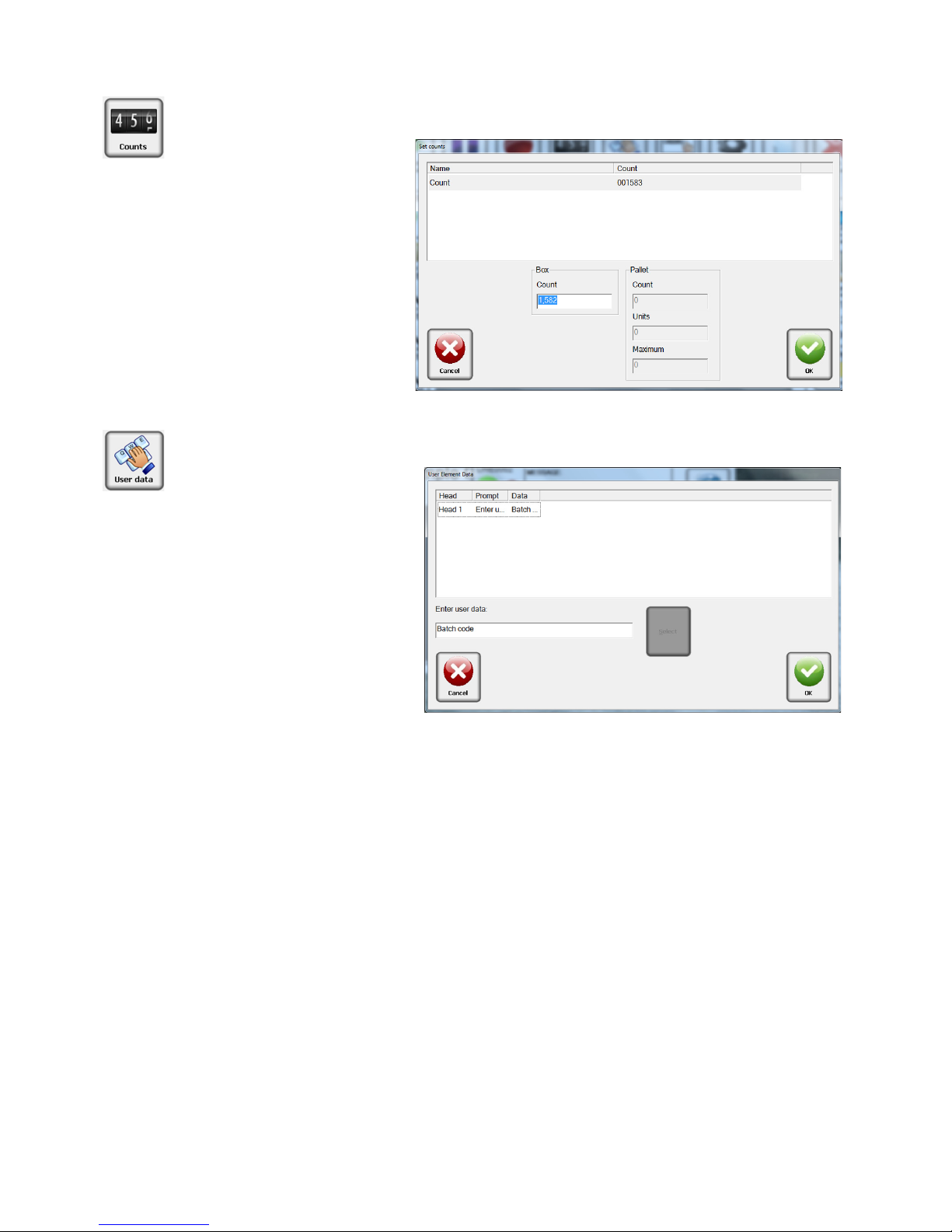

Counts

Count is the current number

of the box in the pallet

series. It is always listed as

the "last printed" box. To

change the Count value,

enter the current box count

value. Enter a

0 to print a

count of 1 on the next box.

User data or User elements

may only be changed if the

message is loaded. The message must contain user elements and be "Running" or

"Idle" in order to modify the

user data.

Select the

User data ICON.

Edit the data in the lower edit

box and press

OK to save

changes. For multiple elements, make all data changes

before pressing

OK to save

changes. Press

Cancel to exit

without saving changes.

User Data

Section 5: Getting Started

2465-623 User Manual Rev E Page 23

Section 5: Getting Started

Marksman Matrix & Elite

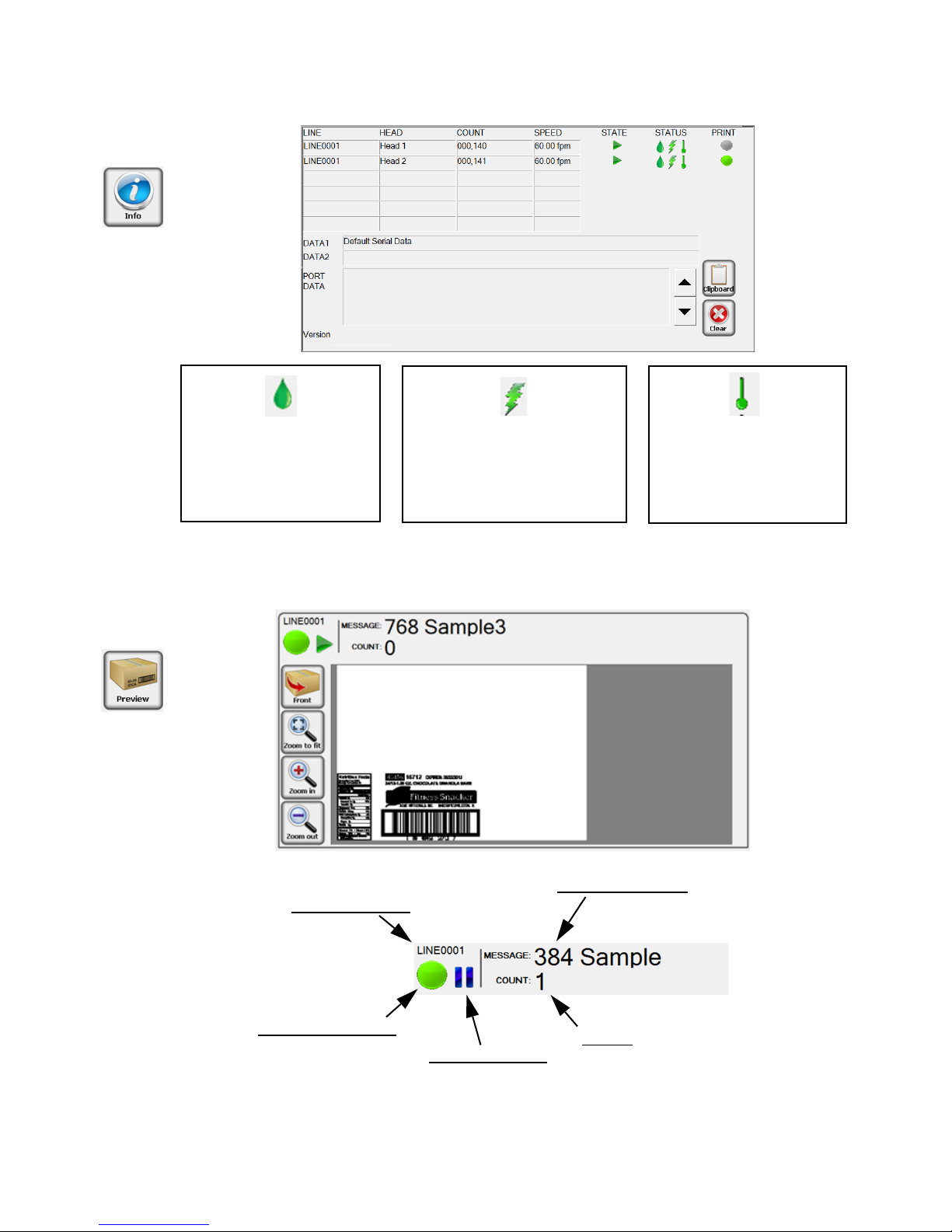

Print Head Ink level or

Ink Collection bottle

Green = Good

Yellow = Low

Red = Out

Print Head High Voltage

Green = Good

Red = Low

Print Head Temperature

Green = Good

Red = Low

NOTE: The system will not print if the controller is reporting a Low Voltage Error, Out of

Ink condition or Low Temperature condition. If a strobe is connected to the system, this

is represented by a flashing red light.

Current Message

Count:

Next count to be printed

Production Line

Print Head Status:

Green: Ok

Yellow: Low Ink

Red: System Printing Error

Message State:

Printing

Stopped

2465-623 User Manual Rev E Page 24

Marksman Matrix & Elite

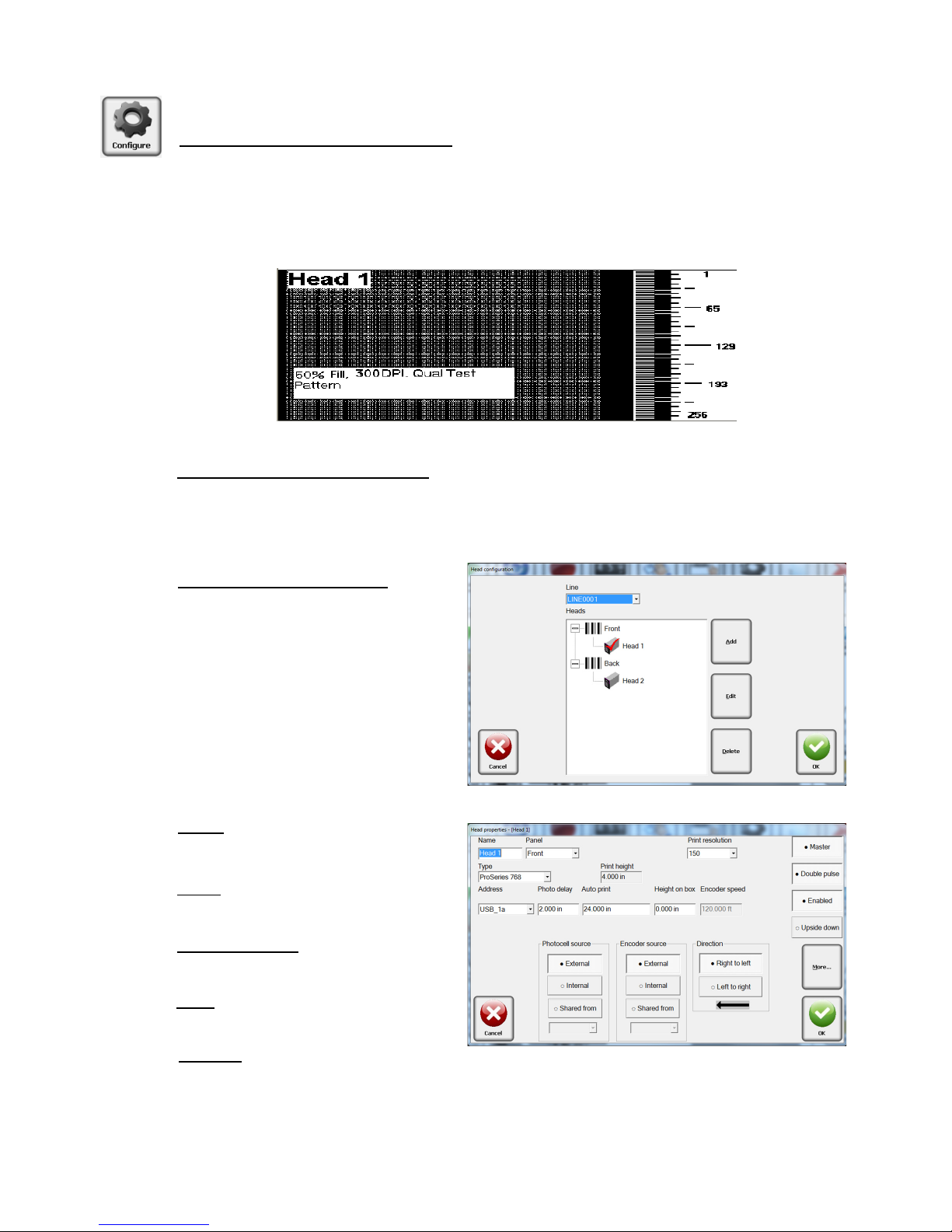

Configure, Print Head:

Configure, Print Test Pattern

This function is designed to exercise every channel of the print head to verify all are

printing properly.

When the user clicks the “Test Pattern” button, a test image is generated. Each head on

the currently selected line will print this pattern (along with the print head’s name). In the

example below, the Test Pattern is from Head 1.

Configure, Database Start

Set a message based on data that is located in a database. The database must be setup

before the option is available.

Refer to Appendix F: Database Start

Configure, Print Head

Select Configure, then select Print

Heads from the menu. Select a

panel and click on a head. A head

may be added or removed by

clicking the appropriate Add/

Remove button. To edit a head,

select it and click Edit; or double

click it.

Name: The head’s

user-defined name.

Panel

: The panel which the head

will print on.

Print Resolution

: 150, 200 and 300

dots per inch (dpi).

Type

: Select a head type from the

drop-down menu list.

Address

:

Each card is assigned two heads: 1a and 1b, or 2a and 2b. The cards have jumpers

to determine which card it is. The bottom connector of the card is always the designated as “a”.

Section 5: Getting Started

2465-623 User Manual Rev E Page 25

Section 5: Getting Started

Marksman Matrix & Elite

Photo delay: Photo delay is the horizontal distance (in inches) measured from the photocell to the head.

Auto print inches

: If internal photocell is selected, this number indicates the length of the

message to be printed. For example, if it is set to 36, the internal photocell will fire once

for every 36 inches of travel of the conveyor, as indicated by the encoder. The accrual

photocell must be tripped for this to work.

Height on box

: The vertical distance in inches measured form the lower part of the prod-

uct or conveyor to the print head nozzle zero.

Encoder Speed

: The desired internal encoder speed measured in feet per minute. The

default is 60 feet/min

Photocell source

: Indicates whether the photocell is external or internal. The photocell

signal from another head may also be used (shared).

Encoder source:

Indicates whether the encoder is external or internal. The encoder sig-

nal from another head may also be used (shared).

Direction

: The direction of travel of the product may be right-to-left or left-to-right, as

viewed from behind the print head.

Master

: Each line must have a master head. The master print head receives/distributes

the signals for the photocell and encoder to the remaining heads. The master head is

also used to determine count values.

Double pulse

: Creates a darker print generally needed for the ProSeries 768e and 384e.

Enable

: Activates the card and errors

Upside Down

: Used to print the entire image upside down.

More

Linked to: Ties the information to be printed to additional heads. If the information is the

same on multiple sides of the box, link the heads together and the image is automatically

placed on the other head.

2465-623 User Manual Rev E Page 26

Marksman Matrix & Elite

Configure, Production Line

The production line configuration

allows for grouping of settings that

relate to a particular setup. Select

Configure, then Production Line

form the menu. To edit a line, select

it and click

Edit; or double click the

line.

Add

: The Add button allows for the

addition of another production line,

for a maximum of two production

lines.

Delete

: The Delete button allows for the removal of a production line form the

configuration. All messages created for the production line will be deleted.

Description

: The description field is used to help define the production line.

Coupled

: If this field is checked, starting a message on one line will also start in on the

other. The same is true for Stop, Idle and Resume. Note that you must have a two lines

configured to use this feature.

This group defines the parameters

for a fixed scanner that may be

connected to the Controller, The

data is stored under the Scan

Report (see

Reports, Scan Report).

No Read String

: The No Read

String must match the No Read

string that is transmitted by a fixed

scanner. The printing will be

stopped upon reaching the maximum value.

Consecutive No Reads

: The consecutive No Reads field is used to preform a quality

check on barcodes that are printed, This value determines the maximum number of

consecutive No Reads that may be transmitted by a fixed scanner. The printing will be

stropped upon reaching the maximum value.

Serial Download Port:

Please select the port to be used to send the data out if it is

required to be transmitted to a device at the start of each task. The data is entered

through the Editor Task properties.

Reset on Task Start

: The Reset on Task start check box determines that the current

number of consecutive No Reads will be reset to zero upon a message start.

Buffer Offset

: The Buffer Offset value determines the number of characters to offset into

the buffer as transmitted by the hand scanner.

Data Length

: The Data Length value determines the number of characters to extract from

the data buffer that will form a task name.

Section 5: Getting Started

Configure, Fixed Scanner

2465-623 User Manual Rev E Page 27

Marksman Matrix & Elite

Configure, System

General Setting– Windows

Ports

Used to configure the system

COM ports, that may be used for

variable data or stating a message.

Serial Port

: Select the appropriate

button to edit the setup

parameters for a serial port on the

Matrix or Elite.

Each of the properties may be

selected using the corresponding

drop-down menu choices. When

selections are complete, click

Apply. The default selections are

shown in the screen at the right.

Baud

: The Baud option

determines the speed of the

transferred data and may be set

to 9600, 19200, 38400, 57600 or

115200.

Parity

: Parity determines the type

of parity bit to be used. It may be

set to None, Odd, or Even.

Data Bits: Data Bits determines

the number of data bits used. It may be set to 7 or 8.

Stop Bits

: Stop Bits determines the number of stop bits to be used. It may be set to 1, 1.5

or 2.

Device Type:

Task Start- Serial device used to select/start a message, generally a hand scanner.

Database task start

– Serial device used to search s database for message start.

Barcode Verification

– Fixed scanner used to read each barcode after it is printed.

Varia ble Data

– Data to be printed imported through the serial port

Host interface

– Remote control of the Controller through the serial port.

General Setting– Startup

To restart the message that was running if power is lost or the system was shut down,

check the “Automatically restart last task” box. (This box is checked by default.)

Remember user data: The data will be retained until new data is entered even if the

software is reset.

Remember serial data: The data will be retained until new data is sent even if the software is reset.

General Setting– Counts

Continuous Count: Select this feature to cause the Count on the main screen never reset

to zero at the start of a new message.

Section 5: Getting Started

2465-623 User Manual Rev E Page 28

Marksman Matrix & Elite

General Setting - Time:

The main screen Time and Date

field format is defined in this window.

There are three user controlled date

and time fields that can be

formatted.

Suppress time change warnings:

Used to disable software warnings of

any Windows time changes.

Current time: Windows system time

Users

The security feature of the

Marksman Matrix & Elite

Series allows the system

administrator to configure

users and access rights.

Add

: Select the Add button

to create a user account.

Remove

: Select the

Remove button to delete a

user account.

Properties

: Select the

Properties button to modify

or view the user account

information.

Firstname

: Enter the user’s

first name in this edit box.

Lastname

: Enter the user’s

last name in this edit box.

Username

: Enter the user’s

first name in this edit box.

Configure, Security:

Section 5: Getting Started

2465-623 User Manual Rev E Page 29

Section 5: Getting Started

Marksman Matrix & Elite

Security groups allow the administrator to assign similar users with a specific set of

access rights. Select Security, then Group Options from the menu. Ten configurable

security groups are available. A user must be assigned to one group. Group names may

be modified to better describe the access level. Select a Group, then select or unselect

Options. Click OK to accept changes and close the screen.

The default access rights for each security group are shown in the following table:

Security Group/Option Access

Table

Operator

Manager

Level 3

Graphics Dept.

Supervisor

Level 6

Level 7

Level 8

Level 9

Administrator

Output Table X

Configure Print Head Settings X X X X X

Start Message

X

X X

Stop Message

X

X X X X

Place System in Test Mode X

Run Editor X

Configure Pr oduction Lines X X X X

Configure Users X

Configure Security Options X

View/Clear Scanne r Report X

View/Clear Scanne r Report X

Translate the software X

Configure general Windows X

Exit Application X

Configure task start database X

Configure serial data format X

Configure the strobe X

Import X

Export X

Group Options:

2465-623 User Manual Rev E Page 30

Section 5: Getting Started

Marksman Matrix & Elite

To import all tasks that

were previously exported,

choose

File, then Import.

In the “filename” field, input

the name of the file (full

path) the exported tasks

were saved to; or browse

for the file by clicking the

Browse button.

If there is data on the controller that the user wants

to back-up, click

Yes on

the Export option.

To export all existing tasks,

choose

File, then Export.

Input the name of the file to

export to, or browse for an

existing file by clicking the

Browse button. Click the

Export button. If the file

already exists, the user will

be prompted to overwrite

the file or cancel the

request.

If successful, a confirmation

message will appear.

About

Components

A list of the .dll that are installed and the version number.

Cmd line args

A list of the software options that are turned on.

Firmware

A list of the Gate Array version number of the Print Head controller cards.

Translate

Select the desired language to be converted to. When the files have been translated, the

application will be re-started in the desired language.

Configure, Import:

NOTE: It is recommended that all printing tasks be stopped until the Import function has

been successfully completed; and that the current database be exported for backup purposes.

Configure, Export:

NOTE: It is recommended that all printing tasks be stopped until the Export function

has been successfully completed.

Configure, Help:

2465-623 User Manual Rev E Page 31

Section 5: Getting Started

Marksman Matrix & Elite

Scan reports

The Scan Report contains information relating to the current task and scan results of a

printed barcode. The scan results are received through the RS232 port from a barcode

scanner properly. configured and connected to the Marksman© controller.

Date:

Date is the date the scan event occurred.

Line:

Line is the production line that the scan event occurred on.

Message:

Message is the name of the message operating while the scan event occurred.

Barcode:

Barcode is the barcode data scanned and received. The contents of this field

may contain the words NO READ if the barcode could not be decoded.

Total:

Total number of decode attempts, including successful and failed decodes.

Good:

Good indicates the number of successful decodes of the scanned barcode.

Export:

Export allows the information to be saved in a comma delimiter format so it can

be used in other software applications.

Enabled:

Allows for the collection of data.

Auto Export at Task Start:

Exports an entry to text file defined by export path.

Print reports

The Print Report contains historical information regarding the printing operation. The print

report is a table named

reports within a Microsoft® Access® Database named Marks-

man Elite. Click on

Reports then select Printer Report from the menu.

Time:

Date and time that the

action occurred.

Action:

The event such as Start or

Stop Message.

User:

The User who was logged

in at the time the action

occurred.

Counts:

Counts is the product count

of the task for which the

action applies.

Line:

The production line that the information is for.

Message:

The name of the message for which the action applies.

Export:

Export allows the information to be saved in a comma delimiter format so it can be used

in other software applications.

Auto Export at Task Start:

Exports an entry to text file defined by export path.

Enabled:

Allows for the collection of data.

Reports

2465-623 User Manual Rev E Page 32

Marksman Matrix & Elite

Delays

This feature allows the operator to make changes to

where the print starts, or

change the photocell delay.

These changes are not permanent and only last until

another message is selected.

This may be useful do to variations in the location of preprinted information on the

box.

NOTE:

Changes made using the Delay ICON are only temporary or until another message is

started. Permanent changes to the photocell delays must be done thru the Configuration.

To make changes, Select the

desired head, use the arrow

buttons to decrease or increase

the delay value.

Use the

Apply button to

implement the changes.

The incremental value can be

changed by selecting the field.

Select

OK when complete.

To Decrease

delay

To Increase

Delay

Incremental Value

Section 5: Getting Started

Exit

This will close down the all printing operation and exit out of BoxWriter software. Only operators with proper security rights can Exit the software.

2465-623 User Manual Rev E Page 33

Section 6: BoxWriter© Matrix & Elite Editor

Marksman Matrix & Elite

Section 6: BoxWriter© Matrix & Elite Editor

Define

Boxes

To define boxes, select Define

> Boxes

.

To add a new box, click

Enter the length, width, height

and name. The length, width

and height fields must be

between 1 and 40 inches. The

description field is optional.

To edit an existing box, select it

and click

the item.

To delete an existing box,

select it and click

ple boxes can be selected by

using the shift and/or control

keys. Boxes that are currently

in use in a task cannot be

deleted. The task’s box property must be changed before

the box can be deleted here.

Edit, or double-click

Delete. Multi-

Add.

Pre-printed information can be

added to the box to give the

operator a true representation

of how the box will look as it is

being printed on.

Add: Allows the operator to

assign a .bmp or .jpg file to a

panel on the box.

Edit: Allows the operator to

change which .bmp or .jpg file

is assigned to a panel of the

box.

Delete: Will remove the file

from the panel.

2465-623 User Manual Rev E Page 34

Marksman Matrix & Elite

Box Usage

To define box usage, select

Define > Box usage.

If it is desirable to restrict a

box from a given line, it can

be done here. By default, all

new boxes are available on

all lines. To restrict it, select

the line, then select the box.

It can then be moved to the

"restricted" list by clicking

the "<" key. Clicking the

"<<" moves all boxes for a

given line to the restricted

list, regardless of selection.

Conversely, the ">" and

">>" keys move boxes to

the "available" list.

Section 6: BoxWriter© Matrix & Elite Editor

Editor Defaults

To define editor defaults, select Define > Editor

defaults

This dialog controls the editor's display units.

The "Resize handle size" field is used by re-sizable elements (such as a Bitmap element). Valid

values range from 5 to 15. Larger values make it

easier to perform a resize operation on a touch

screen.

In the example at right, the eight squares

around the perimeter are the resize handles.

.

Checking the "Warn if elements overlap" box will warn

the user when element fields overlap in a message.

2465-623 User Manual Rev E Page 35

Marksman Matrix & Elite

Element Defaults

To define element defaults, select

Define > Element defaults. To

change the defaults, select an element type and click

double-click the item.

The elements listed here define

how new elements are created.

(For a description of the individual

elements, refer to the

section of this manual.)

Properties, or

Elements

Section 6: BoxWriter© Matrix & Elite Editor

To change the font, click

Change button. The

the

dialog at right is used to

change the default font

parameters.

The Font drop-down box

will display a list of all

TrueType fonts installed

on the system.

The Size field refers to

the height of the font in

pixels.

Average width defines

the average character

width (in pixels). A value

of 0 means that the system will use the font's

default widths.

Backup Path

A backup of the Marksman Matrix & Elite database is stored in a backup location every

time the application is closed. The path directs where the file is saved.

2465-623 User Manual Rev E Page 36

Marksman Matrix & Elite

Custom Date/Time Formats

To define date/time settings, select

tom date/time formats

The date/time settings

shown here are used by

Date/time and Expiration

date elements.

To create a new custom

format, click

To delete an existing custom format, select it and

click

Delete. Multiple codes

can be selected by using

the shift and/or control

keys.

Define > Cus-

.

Add.

Section 6: BoxWriter© Matrix & Elite Editor

To edit an existing custom code, select it and click

time format dialog is shown below.

The "Format string" contains a user-defined string consisting of format specifiers.

Edit, or double-click it. The Build date/

The "Sample" field shows a sample of the current Format string.

Valid format specifiers are listed at the bottom of the dialog. To insert them in the current

string, select them and click

2465-623 User Manual Rev E Page 37

Insert (or double-click).

Section 6: BoxWriter© Matrix & Elite Editor

Marksman Matrix & Elite

Possible format specifiers are listed in the following table:

Specifier Meaning

%a Abbreviated weekday name

%A Full weekday name

%b Abbreviated month name

%B Full month name

%c Date and time representation appropriate for locale

%d Day of month as decimal number (01 - 31)

%%D Day of month as decimal number (arbitrary length)

%%-D Day of month as decimal number, left justified (arbitrary length)

%#d Day of month as decimal number; no leading zero (1-31)

%H Hour in 24-hour format, with leading zero (00 - 23)

%#H Hour in 24-hour format; no leading zero (0-23)

%H:%M:%S Hour: Minute: Second in 24-hour format, with leading zero on the hour

(00-23)

%#H:%M:%S Hour: Minute: Second in 24-hour format, no leading zero on the hour (0-

23)

%I Hour in 12-hour format (01 - 12)

%#I Hour in 12-hour format; no leading zero (1-12)

%I:%M:%S Hour: Minute: Second in 12-hour format; with leading zero on the hour

(1-12)

%#I:%M:%S Hour: Minute: Second in 12-hour format; no leading zero on the hour (1-

12)

%j Day of year as decimal number (001 - 366)

%m Month as decimal number (01 - 12)

%M Minute as decimal number (00 - 59)

%%M Month as decimal number (arbitrary length)

%%-M Month as decimal number, left justified (arbitrary length)

%p Current locale’s AM/PM indicator for 12-hour clock

%S Second as decimal number (00 - 59)

%U Week of year as decimal number, with Sunday as first day of week (00 -

53)

%w Weekday as decimal number (0 - 6; Sunday is 0)

2465-623 User Manual Rev E Page 38

Section 6: BoxWriter© Matrix & Elite Editor

Marksman Matrix & Elite

%W Week of year as decimal number, with Monday as first day of week (00 -

53)

%x Date representation for current locale

%X Time representation for current locale

%y Year without century, as decimal number (00 - 99)

%Y Year with century, as decimal number

%%Y Year as decimal number (arbitrary length)

Examples:

"%%YYYY" is formatted as "2004"

"%%YY" is formatted as "04"

"%%Y" is formatted as "4"

%%-Y Year as decimal number, left justified (arbitrary length)

%z; %Z Time zone name or abbreviation; no characters if time zone is unknown

%% Percent sign

%%0H Hour Code

%%0M Month Code

%%0A Day Code

%%0Q Quarter Hour Code

NOTE: The # flag may prefix any format specifier. In that case the meaning of the format

code is changed as follows:

%#a, %#A,

%#b, %#B,

%#p, %#X,

%#z, %#Z,

%#%

%#c Long date and time representation, appropriate for current locale. For

%#x Long date representation, appropriate to current locale. For example:

%#d, %#H,

%#I, %#j,

%#m, %#M,

%#S, %#U,

%#w, %#W,

%#y, %#Y

# flag is ignored

example: "Tuesday, March 14, 1995, 12:41:29"

"Tuesday, March 14, 1995"

Remove leading zeroes (if any)

2465-623 User Manual Rev E Page 39

Section 6: BoxWriter© Matrix & Elite Editor

Marksman Matrix & Elite

Date/Time Codes

Select Configure, System, then Date/Time Codes from the menu.

Line indicates the production

Line:

line selected.

Click on the folder tabs to access

the date/time code tables. Select an

entry in the table by clicking on the

desired row. Click on

the data for the selected table entry.

Click

OK to exit and save changes

Cancel to exit without saving

or

changes.

Edit to modify

Months:

string values that are used in date

codes for the standard months of

the year.

Hours:

twenty-four codes for the hours of

the day. The codes may be customized for special coding.

Quarter Hours

Days:

Rollover:

expiration and date codes will

change to a new value. The default

rollover value is midnight.

"Hold"

tion Date until the Roll over time.

Months represents the

The Hours table stores the

: The Quarter Hours’ table stores codes for 15 minute intervals.

The day table holds the value to be used for the appropriate day.

The time at which the

: Holds the Date or Expira-

2465-623 User Manual Rev E Page 40

Marksman Matrix & Elite

Bitmap Editor

To define bitmap settings, select

Bitmap settings

The "Bitmap editor"

field defines the program used to edit bitmaps. By default, it is

Microsoft® Paint. To

change it, browse

and select the program to be used.

Define >

.

Section 6: BoxWriter© Matrix & Elite Editor

Label Editor

Used to configure software when the Marksman Matrix or Elite is used with a Label Applicator.

Shift Codes

To define shift codes, select

Define > Shift codes. Shift

codes are used by Shift elements.

The shift code’s length must be

from 1 to 15 characters. The

code’s times must be in order

from least to greatest (i.e., code

1 cannot be later than code 2 or

3).

This determines the pro-

Line:

duction line for the shift code

definitions.

Select the appropriate production line. Enter the shift start times and any user-defined

codes. The shift start times must be entered in 24-hour format. The shift code may contain

a maximum of 15 alphanumeric characters.

The sample dialog shows shift 1 starting at 7:00 AM, shift 2 starting at 3:00 PM and shift 3

starting at 11:00 PM.

2465-623 User Manual Rev E Page 41

Section 6: BoxWriter© Matrix & Elite Editor

Marksman Matrix & Elite

Sub-Elements

To define fonts, select Define > Sub-elements.

Sub-elements can be used by certain barcodes (see the

usage). The Sub-elements dialog is shown below.

To create a new sub-element, click the "

To delete an existing sub-element, select it and click the "

+" button.

Barcode section of the manual for

X" button.

To edit an existing sub-element, select it and click the

most button). The Sub-element properties dialog is shown below.

The "ID" field identifies the sub-element.

Properties button (the bottom, left-

2465-623 User Manual Rev E Page 42

Section 6: BoxWriter© Matrix & Elite Editor

Marksman Matrix & Elite

The "Element type" field defines the type of element. The following types are supported by

sub-elements:

•Text

• Count

• Date / time

• Expiration date

•Shift

•User

• Serial data

To change the element's default values, click the

tion of the manual for examples of property dialogs for element types.

The "Description" field is used for a long-hand description of the sub-element.

The "Data" field contains the default data for the sub-element. Note that the Data must satisfy the Input mask.

The Input mask defines what kind of

data the sub-element can accept.

To change it, click the

The Build mask dialog is shown at

right.

In this example, the mask is set up

for data consisting of two digits and

up to 10 alpha-numeric characters.

Build button.

Properties button. See the Elements sec-

The buttons along the right side of the dialog are as follows, from top to bottom:

• Move up - moves the selected mask up.

• Move down - moves the selected mask down.

• Properties - displays the mask properties for editing.

• Add - creates a new mask.

• Delete - deletes the selected mask.

2465-623 User Manual Rev E Page 43

Marksman Matrix & Elite

The following is an example of the Mask

properties dialog:

• Alpha allows uppercase A to Z.

• Numeric allows 0 to 9.

• Alphanumeric allows uppercase A to Z

or 0 to 9.

• Punctuation allows characters such as

"," or ":".

• Any allows any character.

Application Identifiers

To define fonts,

select

Application

identifiers

Define >

.

Section 6: BoxWriter© Matrix & Elite Editor

Application

identifiers can

also be used by

certain barcodes. They

work in the

same manner

as sub-elements.

An example of the

Application identifier properties dialog is shown at right.

Only the "Element

type" and "Data"

fields can be

changed. See the

Sub-elements sec-

tion for descriptions

of these fields.

2465-623 User Manual Rev E Page 44

Section 6: BoxWriter© Matrix & Elite Editor

Marksman Matrix & Elite

Global Barcode Parameters

To define barcode parameters, select Define > Global Barcode Parameters.

Select the line, then select the head type. Heads with 32 channels have their own set of

barcode parameters, as do 256 channel heads.

To view or edit a set of barcode parameters, select it then click

item.

NOTES:

Only the custom bar and space parameters can be changed; and only a person having

advanced knowledge of barcode and inkjet printing systems should change these parameters. An unusable barcode may be printed using improper settings.

C128, C39, C93 & I 2of5

height and Ratio cannot be changed. Only custom parameters allow these fields to be

changed.

: On standard barcode parameters, the Magnification, Bar width and Space width can-

UPC

not be changed. Only custom parameters allow these fields to be changed.

: On standard barcode parameters, the Magnification, Width, Total

Edit, or double-click the

2465-623 User Manual Rev E Page 45

Marksman Matrix & Elite

An example of UPCA barcode parameters is shown at right.

The "Magnification" field is the value displayed in the Magnification field on the

Barcode element dialog.

The "Bar height" is the total height of the

symbol in pixels.

The "Bar width" and "Space width" fields

define the width, in pixels, of the symbol's

bar/space modules.

The "Font name" control will display a list

of all TrueType fonts installed on the system.

The "Font size" field refers to the height

of the font in pixels.

Section 6: BoxWriter© Matrix & Elite Editor

"Average width" defines the

average character width (in

pixels). A value of 0 means

that Windows will use the

font's default widths.

The "Magnification" field is

the value displayed in the

Magnification field on the

Barcode element dialog.

The "Total height" is the total

height of the symbol in pixels.

The "Horz. bearer" field specifies the width of the symbol's

horizontal bearer, in thousandths of an inch.

The "Vert. bearer" field specifies the width of the symbol's

vertical bearer, in thousandths of an inch.

The "Quiet zone" field specifies the width of the symbol's

quiet zone, in thousandths of an inch.

The "Font name" control will display a list of all TrueType fonts installed on the system.

The "Font" size field refers to the height of the font in pixels.

2465-623 User Manual Rev E Page 46

Section 6: BoxWriter© Matrix & Elite Editor

Marksman Matrix & Elite

Tools

Ink Usage

The ink usage generator will calculate the cost of each print and how many prints you will

get from each bottle.

Files

New

To create a new task,

choose

The user will be presented

with the dialog at right. Pick

which production line the

task is to be created for, give

it a name (and description, if

desired) and select the box it

will be printed on.

The "Task name" field must

contain only letters and numbers; no spaces or special

characters are allowed. The

maximum number of characters is 32.

File > New.

2465-623 User Manual Rev E Page 47

Section 6: BoxWriter© Matrix & Elite Editor

Marksman Matrix & Elite

Creating a Task

The next step is to insert elements into the label to be printed. The box is shown with highlighted areas showing where heads have been placed on the box. The printing areas cannot be changed from the editor because the information about the heads and their

relationship to the box comes from the system configuration, which is limited by physical

devices installed. Different panels can be selected to add elements to the task. Once a

head has been chosen, select an element to be placed on the box. The process is

repeated until all the desired information needed on all sides of the box are completed. The

next step would be to save the task. (Refer to appropriate sections in this manual relating

to Elements and Saving Files.)

NOTE: If two elements overlap each other they both will show up in red. This is to let the

operator know that a problem may occur. The operator will also be told before saving the

task.

To disable the element overlap warnings, see

2465-623 User Manual Rev E Page 48

Define, Editor Defaults earlier in this section.

Marksman Matrix & Elite

Open

To open an existing task,

choose

Select the task to be opened,

and click

the task to be opened.

Checking the "Open read

only" box will open the task in

read-only mode (i.e., the user

will not be able to modify the

task).

Checking the "Show preview"

box will show a preview of the

selected task. For large

tasks, it may take several

seconds to generate the preview.

File > Open.

OK; or double-click

Section 6: BoxWriter© Matrix & Elite Editor

2465-623 User Manual Rev E Page 49

Section 6: BoxWriter© Matrix & Elite Editor

Marksman Matrix & Elite

Copy

To copy tasks from one line to another, choose File > Copy.

Select the line to copy from, then select the tasks to be copied. Checking the "All" box will

automatically select all existing tasks for the given line.

When the desired tasks are selected, click

Copy.

If successful, you will see a confirmation message similar to the one at right.

The user may change both the "To" and "From"

lines and perform the copy function multiple

times.

OK after to save the changes.

Click

2465-623 User Manual Rev E Page 50

Section 6: BoxWriter© Matrix & Elite Editor

Marksman Matrix & Elite

This function works best when both the "To" and "From" lines have identical head configurations. However, if they do not, the user may elect to configure the head mapping. To do

this, select the head to be mapped and click

The user will be presented with

the dialog at right. Select the head

to map to in the "To" field and click

OK.

Edit (or double-click).

Clicking

bring up the Head properties dialog. Note that head

properties are read-only in

the Editor.

Properties will

2465-623 User Manual Rev E Page 51

Section 6: BoxWriter© Matrix & Elite Editor

Marksman Matrix & Elite

Import

NOTE: It is recommended that all printing tasks be stopped until the Import function has

been successfully completed; and that the current database be exported for backup purposes.

To import all tasks that were previously exported, choose

Import.

then

In the "filename" field, input the

name of the file (full path) the

exported tasks were saved to; or

browse for the file by clicking the

Browse button.

File,

If there is data on the controller that the user does not want to lose, click

ing screen.

The screen at right will appear at the

completion of the Import function.

Yes on the follow-

2465-623 User Manual Rev E Page 52

Section 6: BoxWriter© Matrix & Elite Editor

Marksman Matrix & Elite

Export

NOTE: It is recommended that all printing tasks be stopped until the Export function has

been successfully completed.

To export all existing tasks,

choose

Input the name of the file to

export to, or browse for an existing file by clicking the

button. Click the Export button.

If the file already exists, the user

will be prompted to overwrite the

file or cancel the request.

If successful, a confirmation message will appear.

File, then Export.

Browse

Delete

To delete existing tasks,

choose

Select the task to be

deleted. Multiple tasks may

be selected by using the

control and/or shift keys.

When the selection has

been made, click

The delete function may be

used several times without

closing the window. Tasks

on other lines may also be

deleted.

Click

changes.

Checking the "Show preview" box will show a preview of the selected task.

For large tasks, it may take

several seconds to generate the preview.

File > Delete.

Delete.

OK to save the

2465-623 User Manual Rev E Page 53

Marksman Matrix & Elite

Save As

To save an open task under a

different name, choose

Save as

The "File" field must contain

only letters and numbers; no

spaces or special characters

are allowed. The maximum

number of characters is 32.

If the name entered

matches a task already in

the database, the user will

be prompted with a confirmation dialog, like the one

at right.

.

File >

Section 6: BoxWriter© Matrix & Elite Editor

Properties

To change an open task's properties, choose File > Properties. The task's description,

download string, box and/or expiration data may be changed using this dialog.

2465-623 User Manual Rev E Page 54

Section 6: BoxWriter© Matrix & Elite Editor

Marksman Matrix & Elite

The following table lists special ASCII characters that can be entered in the "Download

String" field. (For example, to send 0012345 terminated by a carriage return, enter

"0012345<CR>" in the Download String.)

Character Description

<NULL> Null

<SOH> Start of heading

<STX> Start of text

<ETX> End of text

<EOT> End of transmission

<ENQ> Enquiry

<ACK> Acknowledge

<BEL> Bell

<BS> Backspace

<HT> Horizontal tab

<LF> NL Line feed, New line

<VT> Vertical tab

<FF> NP Form feed, New page

<CR> Carriage return

<SO> Shift out

<SI> Shift in

<SLE>

<DC1> Device control 1

<DC2> Device control 2

<DC3> Device control 3

<DC4> Device control 4

<NAK> Negative acknowledge

<SYN> Synchronous idle

<ETB> End of transmission block

<CAN> Cancel

<EM> End of medium

<SIB> Substitute

<ESC> Escape

<FS> File separator

<GS> Group separator

<RS> Record separator

<US> Unit separator

Exit

To exit the Editor, choose File > Exit.

2465-623 User Manual Rev E Page 55

Section 6: BoxWriter© Matrix & Elite Editor

Marksman Matrix & Elite

Elements

Element Bar

Using the element bar, the user can add new elements to a task. Element types, from left to

right, are as follows:

•Text

•Bitmap

• Count

• Date / time

• Expiration date

•User

•Shift

• Barcode

• Database

•Serial

New elements can be created by clicking one of the buttons on the element bar, by rightclicking on the printable area of the box, or by using the