7410F Interfacility Link

Installation and User’s Guide

Copyright 2003

7410F IFL Installation and Users Guide

7410F Interfacility Link

Installation and User’s Guide

Foxcom Inc.

Princeton Forrestal Village

136 Main Street, Suite 300

Princeton NJ 08540

USA

Tel: 609-514-1800

Toll Free: 1-866-ONEPATH

Fax: 609-514-1881

Foxcom Ltd.

Beck Science Center

8 Hartom Street, Har-Hotzvim

P.O. Box 45092

Jerusalem 91450

Israel

Tel: +972-2-589-9888

Fax: +972-2-589-9898

Website: www.foxcom.com

e-mail: sales@foxcom.com

This manual contains PROPRIETARY and CONFIDENTIAL information of

Foxcom Inc. Reproduction, release to any third party, or any other unauthorized

use, of any information contained herein is expressly prohibited.

Foxcom Proprietary Information 2

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

Table of Contents

1. Front Chapter................................................................................................7

1.1 Warranty and Repair Policy .................................................................... 7

1.2 Reporting Defects.................................................................................... 9

1.3 Certification............................................................................................. 9

1.4 Conventions............................................................................................. 9

1.5 Precautions ............................................................................................ 10

2. Introduction to the 7410F IFL ................................................................... 11

2.1 Options .................................................................................................. 11

2.2 Product Drawings .................................................................................. 13

2.3 Panel Descriptions................................................................................. 14

2.4 Block Diagrams..................................................................................... 15

3. Installation ................................................................................................... 16

3.1 Setting Up the Transmitter .................................................................... 17

3.2 Connecting the Fiberoptic Cable........................................................... 18

3.3 Setting Up the Receiver......................................................................... 19

3.4 Powering the IFL................................................................................... 20

3.5 Connecting the Back Panel Jumpers ..................................................... 21

3.6 Monitoring the Input/Output Signal...................................................... 24

3.7 Aligning the Fiberoptic Link................................................................. 24

4. Product Technical Description...................................................................25

4.1 7410F IFL Specifications ...................................................................... 25

4.2 Model Dimensions ................................................................................ 27

4.3 7410F IFL Pinouts................................................................................. 28

4.4 7180M Chassis Pinouts ......................................................................... 32

5. Troubleshooting...........................................................................................36

6. Appendix I Cleaning Fiberoptic Connections........................................... 38

6.1 Cleaning Procedures for FC/APC Connectors ...................................... 39

6.2 Cleaning Procedure for FC/APC Bulkhead Ports ................................. 40

7. Appendix II Installing a Standalone Unit .................................................41

8. Appendix III The 2380 Relay Adaptor...................................................... 42

8.1 Installing the 2380 - Parts Needed ........................................................ 42

8.2 Installing the 2380 - Procedure ............................................................. 42

8.3 2380 Dimensions and Front Panel Label .............................................. 44

Foxcom Proprietary Information 3

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

8.4 2380 Pinouts .......................................................................................... 45

9. Appendix IV 7100M Chassis...................................................................... 47

9.1 Equipment Safety .................................................................................. 47

9.2 Installation ............................................................................................. 48

9.3 Model Dimensions ................................................................................ 54

9.4 7410F IFL Pinouts (7100M Chassis) .................................................... 55

9.5 7100M Pinouts ...................................................................................... 59

9.6 The 2300 Relay Adaptor ....................................................................... 63

9.7 Changing the Primary Power Setting .................................................... 69

10. Appendix V Pinouts, Detailed Information .......................................... 71

List of Figures

Figure 1 - Option Label ......................................................................................... 12

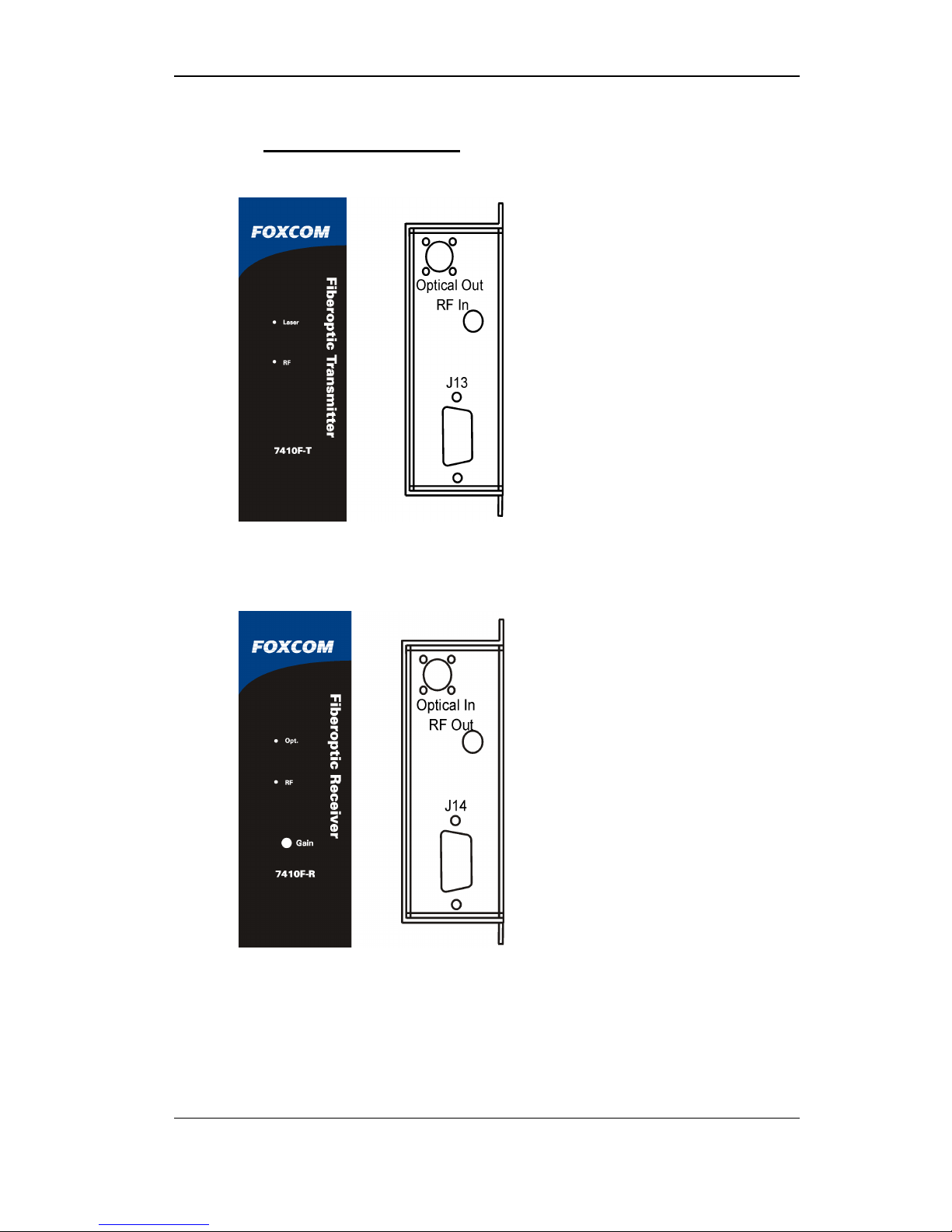

Figure 2 - 7410FT Transmitter Panels .................................................................. 13

Figure 3 - 7410FR Receiver Panels....................................................................... 13

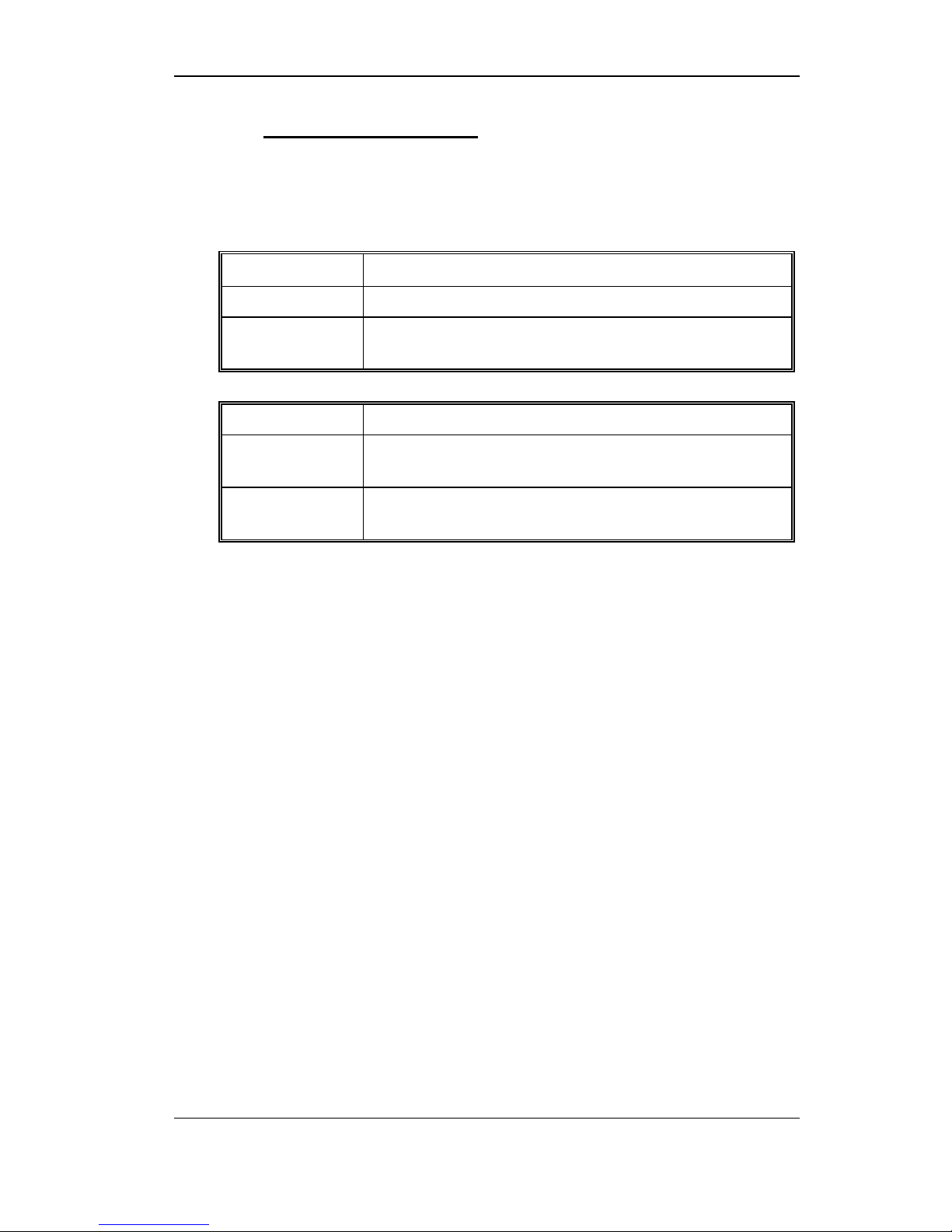

Figure 4 - 7410FT Transmitter Block Diagram .................................................... 15

Figure 5 - 7410FR Receiver Block Diagram......................................................... 15

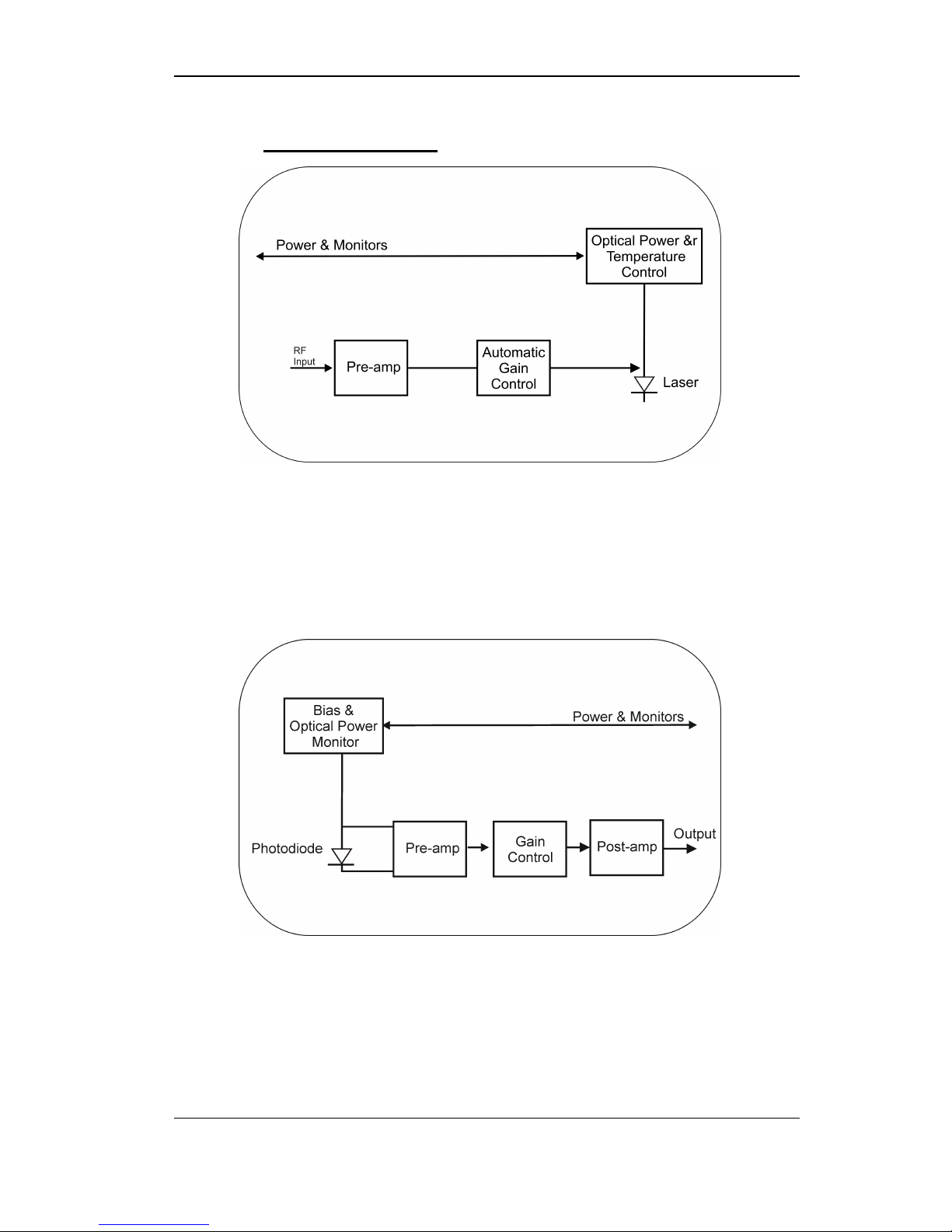

Figure 6 - Typical Application of a 7410F Link ................................................... 16

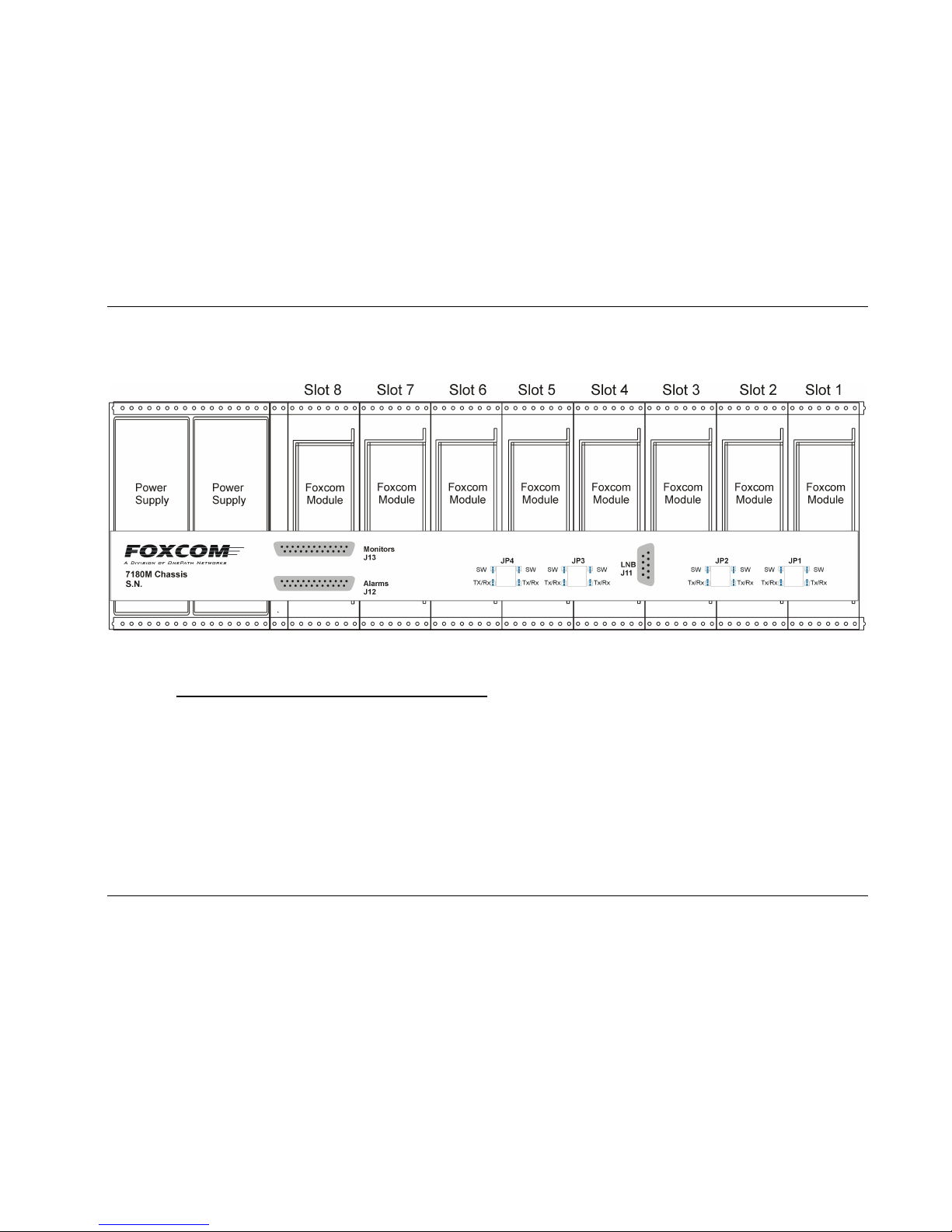

Figure 7 - 7180M Chassis Rear View ................................................................... 21

Figure 8 - Jumper Installation: Tx and Rx Only ................................................... 22

Figure 9 - Jumper Installation: 2000 Switch in Slot 2........................................... 22

Figure 10 - Jumper Installation: 2000 Switch in Slot 5......................................... 23

Figure 11 - Jumper Installation: 2000 Switch in Slots 2 and 5 ............................. 23

Figure 12 - Fiberoptic Alignment Setup................................................................ 24

Figure 13 - Unit Dimensions ................................................................................. 27

Figure 14 - 7180M Chassis Dimensions ............................................................... 27

Figure 15 - 7410FT Transmitter Pinout ................................................................ 29

Figure 16 - 7410FR Receiver Pinout..................................................................... 31

Figure 17 - 7180M Chassis Rear View ................................................................. 32

Figure 18 - 7180M Pin Numbers........................................................................... 35

Figure 19 - Wiping the Connector with a Kim Wipe ............................................ 39

Figure 20 - Wiping the Connector with a Kim Wipe (2) ...................................... 39

Figure 21 - Cleaning the Optical Port ................................................................... 40

Foxcom Proprietary Information 4

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

Figure 22 - Cleaning the Optical Port (2).............................................................. 40

Figure 23 - Mounting the Chassis and Adaptor - Detail ....................................... 42

Figure 24 - Mounting the Pins and Adaptor.......................................................... 43

Figure 25 - Mounting the Screws (1) .................................................................... 43

Figure 26 - Mounting the Screws (2) .................................................................... 44

Figure 27 - Mounted 2380..................................................................................... 44

Figure 28 - 2380 Dimensions ................................................................................ 44

Figure 29 - 2380 Front Label ................................................................................ 44

Figure 30 - 2380 Pin Numbers .............................................................................. 46

Figure 31 - 7100M Chassis Rear View ................................................................. 51

Figure 32 - Jumper Installation: Tx and Rx Only ................................................. 52

Figure 33 - Jumper Installation: 2000 Switch in Slot 2......................................... 52

Figure 34 - Jumper Installation: 2000 Switch in Slot 5......................................... 53

Figure 35 - Jumper Installation: 2000 Switch in Slots 2 and 5 ............................. 53

Figure 36 - Unit Dimensions ................................................................................. 54

Figure 37 - 7100M Chassis Dimensions ............................................................... 54

Figure 38 - 7410FT Transmitter Pinout ................................................................ 56

Figure 39 - 7410FR Receiver Pinout..................................................................... 58

Figure 40 - 7100M Chassis ................................................................................... 59

Figure 41 - 7100M Pin Numbers........................................................................... 62

Figure 42 - Mounting the Chassis and Adaptor - Detail ....................................... 63

Figure 43 - Mounting the Pins and Adaptor.......................................................... 64

Figure 44 - Mounting the Screws (1) .................................................................... 64

Figure 45 - Mounting the Screws (2) .................................................................... 65

Figure 46 - Mounted 2300..................................................................................... 65

Figure 47 - 2300 Dimensions ................................................................................ 66

Figure 48 - 2300 Front Label ................................................................................ 66

Figure 49 - 2300 Pin Numbers .............................................................................. 68

Figure 50 - Fuse Drawer........................................................................................ 69

Figure 51 - Voltage Selector (230 Side)................................................................ 69

Figure 52 - Voltage Selector (115 Side)................................................................ 70

Foxcom Proprietary Information 5

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

Figure 53 - Standard 7180M and 7180M with 2380 Relay Adaptor Pinout ......... 71

Figure 54 - 7180M with 2000 Switch Pinout ........................................................ 71

Figure 55 - Pinout of 7180M Jumper with 2000 Switch in Slot 2 and 5............... 71

Figure 56 - Pinout of 7180M Jumper with 2000 Switch in Slot 2 ........................ 71

Figure 57 - Pinout of 7180M Jumper with 2000 Switch in Slot 5 ........................ 71

Figure 58 - Pinout of 7180M Jumper with Tx or Rx only .................................... 71

List of Tables

Table 1 - 7410FT Transmitter LEDs..................................................................... 14

Table 2 - 7410FT Receiver LEDs ......................................................................... 14

Table 3 - 7410FT Transmitter Pinout.................................................................... 28

Table 4 - 7410FR Receiver Pinout ........................................................................ 30

Table 5 - 7180M Alarm Connector (J12) Pinout .................................................. 33

Table 6 - 7180M Monitor Connector (J13) Pinout................................................ 34

Table 7 - 7180M LNB Connector (J11) Pinout..................................................... 35

Table 8 - Troubleshooting ..................................................................................... 36

Table 9 - 2380 Alarms Pinout (J2) ........................................................................ 45

Table 10 - 2380 Monitor Connector Pinout (J4) ................................................... 46

Table 11 - 7410FT Transmitter Pinout.................................................................. 55

Table 12 - 7410FR Receiver Pinout ...................................................................... 57

Table 13 - 7100M Alarm Connector (J9) Pinout .................................................. 60

Table 14 - 7100M Monitor Connector (J10) Pinout.............................................. 61

Table 15 - 7100M LNB Connector (J11) Pinout................................................... 62

Table 16 - 2300 Alarms Pinout (J2) ...................................................................... 67

Table 17 - 2300 Monitor Connector Pinout (J4) ................................................... 68

Table 18 - AC Voltage Fuse Part Numbers........................................................... 70

Table 19 - DC Voltage Fuse Part Number ............................................................ 70

Foxcom Proprietary Information 6

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

1. Front Chapter

Front Chapter

1.1 Warranty and Repair Policy

Foxcom performs testing and inspection to verify the quality and reliability

of our products. Foxcom uses every reasonable precaution to ensure that

each unit meets specifications before shipment. Customers are asked to

advise their incoming inspection, assembly, and test personnel as to the

precautions required in handling and testing our products. Many of these

precautions are to be found in this manual.

Nullification of Warranty

The Warranty is null and void if the product casing is opened.

The products are covered by the following warranties:

A) General Warranty

Foxcom warrants to the original purchaser all standard products sold

by Foxcom to be free of defects in material and workmanship for one

(1) year from date of shipment from Foxcom. During the warranty

period, Foxcom will repair or replace any product that Foxcom proves

to be defective. This warranty does not apply to any product which

has been subject to alteration, abuse, improper installation or

application, accident, electrical or environmental over-stress,

negligence in use, storage, transportation or handling.

B) Specific Product Warranty Instructions

All Foxcom products are warranted against defects in workmanship,

materials and construction, and to no further extent. Any claim for

repair or replacement of units found to be defective on incoming

inspection by a customer must be made within 30 days of receipt of

shipment, or within 30 days of discovery of a defect within the

warranty period.

This warranty is the only warranty made by Foxcom and is in lieu of

all other warranties, expressed or implied. Foxcom sales agents or

representatives are not authorized to make commitments on warranty

returns.

C) Returns

In the event that it is necessary to return any product against above

warranty, the following procedure shall be followed:

1. Return authorization is to be received from Foxcom prior to

returning any unit. Advise Foxcom of the model, serial

Foxcom Proprietary Information 7

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

number, and discrepancy. The unit may then be forwarded to

Foxcom, transportation prepaid. Devices returned collect or

without authorization may not be accepted.

2. Prior to repair, Foxcom will advise the customer of our test

results and any charges for repairing customer-caused

problems or out-of-warranty conditions etc.

3. Repaired products are warranted for the balance of the original

warranty period, or at least 90 days from date of shipment.

D) Limitations of Liabilities

Foxcom's liability on any claim, of any kind, including negligence for

any loss or damage arising from, connected with, or resulting from the

purchase order, contract, quotation, or from the performance or breach

thereof, or from the design, manufacture, sale, delivery, installation,

inspection, operation or use of any equipment covered by or furnished

under this contact, shall in no case exceed the purchase price of the

device which gives rise to the claim.

Front Chapter

EXCEPT AS EXPRESSLY PROVIDED HEREIN, FOXCOM

MAKES NO WARRANTY, EXPRESSED OR IMPLIED, WITH

RESPECT TO ANY GOODS, PARTS AND SERVICES

PROVIDED IN CONNECTION WITH THIS AGREEMENT

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE. FOXCOM SHALL NOT BE

LIABLE FOR ANY OTHER DAMAGE INCLUDING, BUT NOT

LIMITED TO, INDIRECT, SPECIAL OR CONSEQUENTIAL

DAMAGES ARISING OUT OF OR IN CONNECTION WITH

FURNISHING OF GOODS, PARTS AND SERVICE

HEREUNDER, OR THE PERFORMANCE, USE OF, OR

INABILITY TO USE THE GOODS, PARTS AND SERVICE.

The Company's exclusive warranty and the remedy provided for

breach thereof shall not apply to (a) any Product used or operated other

than pursuant to the Company's written instructions, (b) damage or

deficiencies resulting from accident, alteration, modification, misuse,

tampering, negligence, improper maintenance, installation or abuse, (c)

use of any Product other than at the Installation Site, (d) use of any

Product that is defective or damaged due to misuse, accident, or

neglect, or due to external electrical stress, lightning or other acts of

nature, (e) use of any Product by a person who is not any authorized

employee of the Customer, or (f) used other than as explicitly

authorized in writing by the Company.

Foxcom Proprietary Information 8

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

1.2 Reporting Defects

The units were inspected before shipment and found to be free of mechanical

and electrical defects. Examine the units for any damage which may have

been caused in transit. If damage is discovered, file a claim with the freight

carrier immediately. Notify Foxcom as soon as possible.

Note

Keep all packing material until you have completed the inspection.

1.3 Certification

The 7410F IFL has CE, FCC, FDA, and UL certification.

1.4 Conventions

In this manual the following special formats are used:

Note

Front Chapter

Notes contain information detailing the current topic.

CAUTION

Cautions contain information regarding situations or materials which

could damage your product.

WARNING

WARNINGS CONTAIN INFORMATION REGARDING DANGEROUS

FUNCTIONS.

Foxcom Proprietary Information 9

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

1.5 Precautions

1.5.1. Personal Safety

WARNING

OPTICAL RADIATION

APPLYING POWER TO THE TRANSMITTER UNIT WILL

CREATE A LASER ENERGY SOURCE OPERATING IN CLASS I

AS DEFINED BY IEC 825-1. USE EITHER AN INFRARED

VIEWER, OPTICAL POWER METER OR FLUORESCENT

SCREEN FOR OPTICAL OUTPUT VERIFICATION.

AC POWER HAZARD

THE RACKMOUNT POWER SUPPLY LINE IS EMI FILTERED.

THE CHASSIS IS CONNECTED TO EARTH GROUND IN

COMPLIANCE WITH SAFETY REQUIREMENTS. ALWAYS USE

THE 3 PRONG AC PLUG WITH EARTH GROUND TO AVOID

POSSIBILITY OF ELECTRICAL SHOCK HAZARD TO

PERSONNEL.

Front Chapter

1.5.2. Equipment Safety

1. Fuses: The 7180M does not have fuses. If the unit fails, pull the

power supply out from the chassis and then push it back in.

2. The input of the transmitter has an optional built-in bias for

inserting DC power up the coax to the LNB. Make certain any

equipment or test equipment connected to the transmitter input can

withstand this bias.

3. The output of the receiver is AC coupled and can withstand the bias

from a satellite receiver. Do not exceed 25V DC bias.

4. Do not allow any dirt or foreign material to get into the optical

connector bulkheads. This may cause damage to the polished optical

connector end faces.

5. The optical fiber jumper cable bend radius is 3 cm. Smaller radii

can cause excessive optical loss and/or fiber breakage.

6. If multiple transmitters are installed in the chassis allow sufficient

room for adequate ventilation; otherwise the units may overheat

causing possible safety hazard or equipment damage.

7. When several units are installed on one 7180M chassis, ensure that

the total current consumption (including any LNB bias) does not

exceed 6A per chassis.

Foxcom Proprietary Information 10

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

Introduction to the 7410F IFL

2. Introduction to the 7410F IFL

The Sat-Light 7410F IFL transmits an L-Band RF signal over singlemode fiber

from a satellite antenna LNB to control room equipment up to two kilometers

away. The 7410F IFL consists of an optical transmitter (7410FT) which receives

the L-Band signal from the LNB and an optical receiver (7410FR) which connects

to a satellite receiver.

The 7410FT and 7410FR modules plug into the 7180M1, a 3U chassis/power

supply, which enables expansion of the system to accommodate any 8 Sat-Light

modules. Accessories include the Model 7001P Power Supply, the Model 2000

1:1 Redundant Switch, the Model 2100 Amplifier, the 2300 Relay Adaptor, and

the Model 7050 Serial Data Multiplexer, an asynchronous data link.

The 7410F IFL is a broadband transmission link; all standard satellite modulation

formulas can be transmitted (i.e. QPSK, FM, etc.). The RF signal is directly

modulated and adds virtually no phase noise to the original signal. The direct

modulation, coupled with the 7410F Links RF circuitry, guarantees superior signal

quality. The 7410F gives more than 30 dB carrier to noise performance in a full

multichannel environment.

Automatic Gain Control (AGC) at the transmit site provides for optimized signal

levels over various input power levels. Manual Gain Control (MGC) at the

receive site provides compensation of any signal loss caused by the link. LEDs,

and back panel monitors and alarms allow for complete system status monitoring

and for interfacing with monitor and control (M&C) systems.

2.1 Options

The 7410F IFL comes with a variety of options:

1. LNB powering; the transmitter unit can provide 14 VDC for optional

LNB powering.

2. 50 Ω Input/Output Impedance/BNC or SMA RF connector; standard

impedance is 75 Ω/F type, female connectors.

3. Standalone unit; the 7410F IFL can be installed as a standalone unit. If

the 7410F is used as a standalone, a separate power supply must be

used.

1

7100M in older models; refer to Appendix IV 7100M Chassis.

Foxcom Proprietary Information 11

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

Introduction to the 7410F IFL

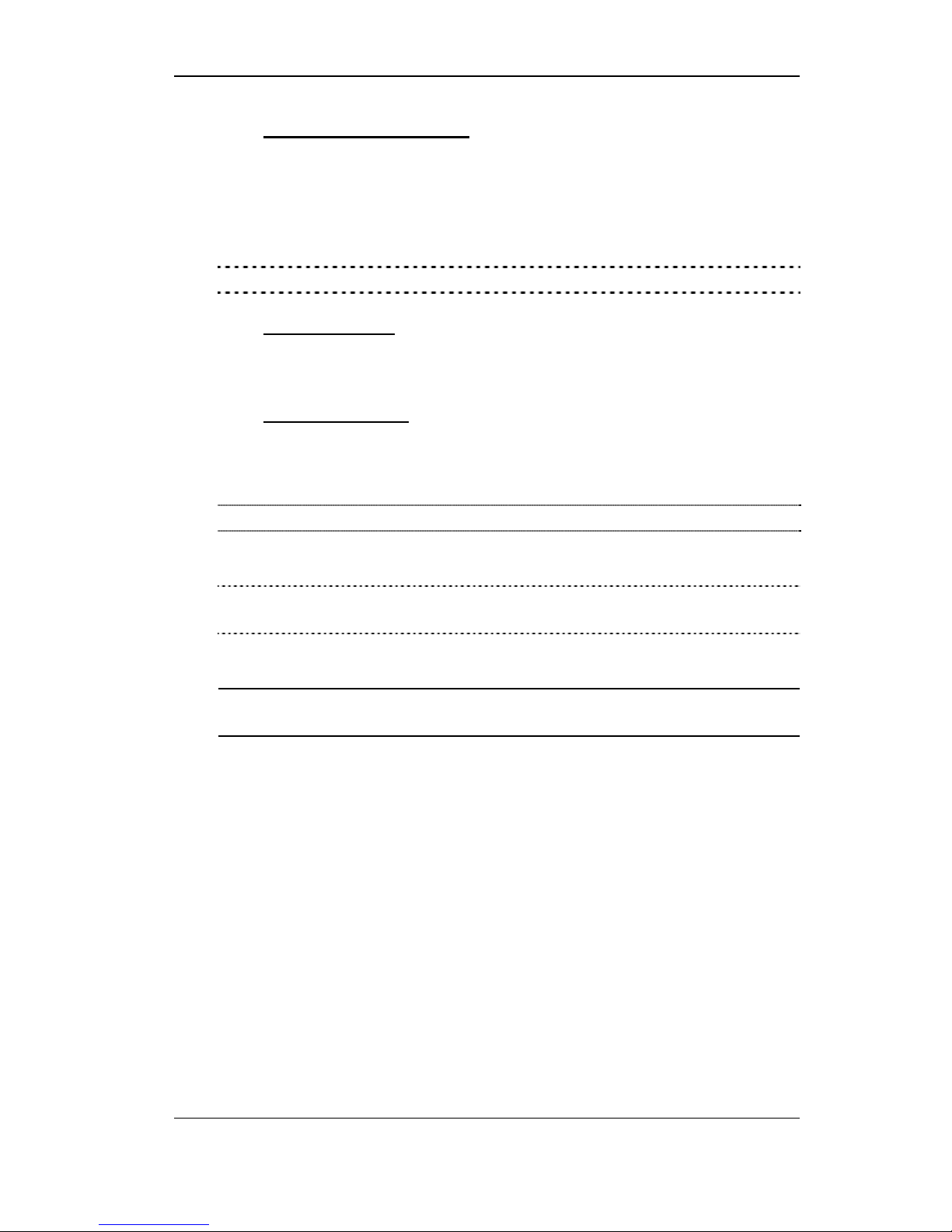

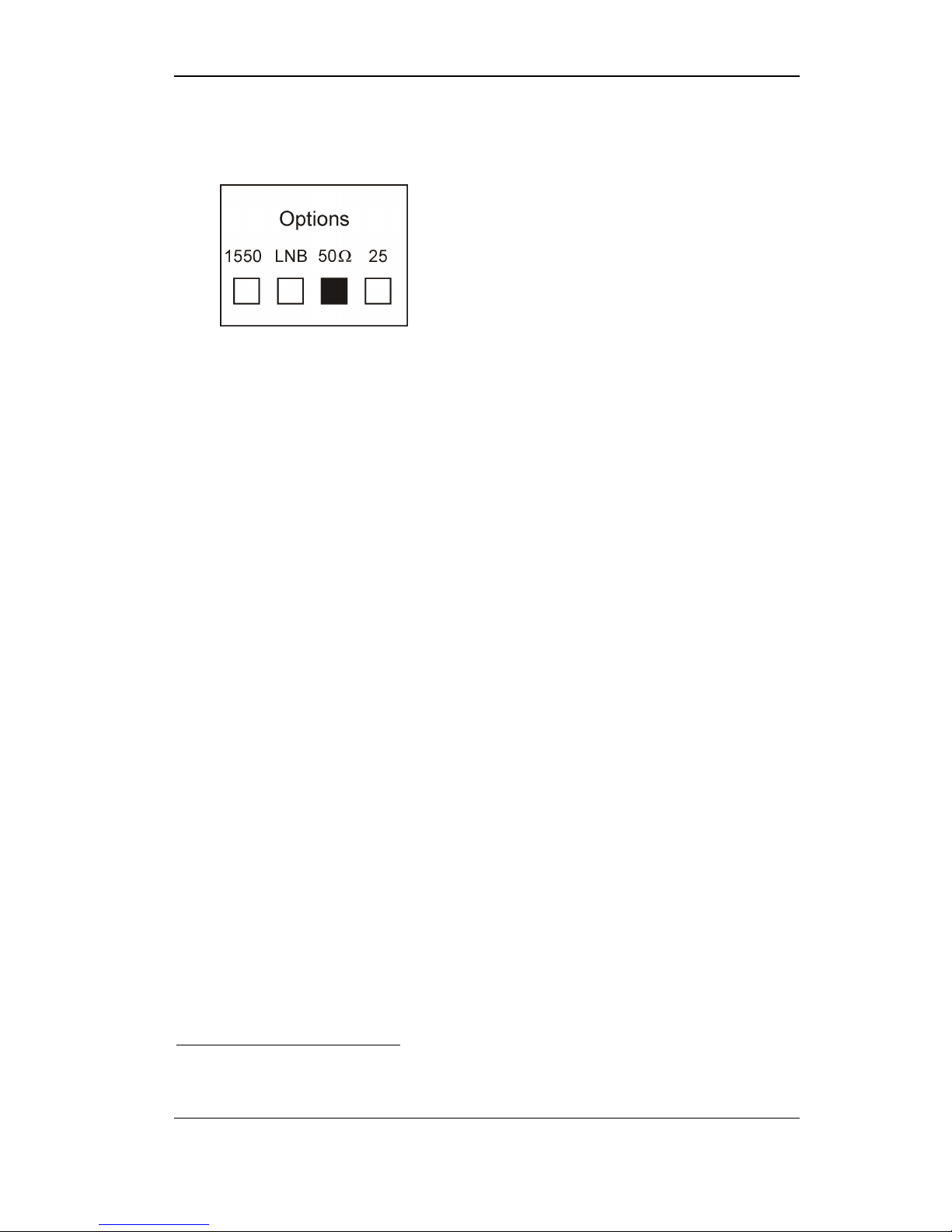

On the side of the 7410FT and the 7410FR units is a label which lists

options2. Under each option is a square. If the unit includes a particular

option the square under the option should be marked.

Figure 1 - Option Label

2

The label includes some options which are not relevant to the 7410F IFL.

Foxcom Proprietary Information 12

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

Introduction to the 7410F IFL

2.2 Product Drawings

Figure 2 shows the front and rear panels of the 7410FT Transmitter units.

Figure 2 - 7410FT Transmitter Panels

Figure 3 shows the front and rear panels of the 7410FR Receiver units.

Figure 3 - 7410FR Receiver Panels

Foxcom Proprietary Information 13

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

Introduction to the 7410F IFL

2.3 Panel Descriptions

On the Front Panel of the 7410F Transmitter and Receiver unit are two

LEDs. The following tables describe the LEDs.

Table 1 - 7410FT Transmitter LEDs

LED Name LED Function

Laser

RF

Indicates that the laser is functioning

Indicates if the Automatic Gain Control is within

operating limits (-40 to -20 dBm)

Table 2 - 7410FT Receiver LEDs

LED Name LED Function

Opt.

Indicates if the optical input power is above the

minimal level (≥-7 dBm)

RF

Indicates if the RF signal is above the minimal level

(≥-40 dBm)

Foxcom Proprietary Information 14

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

2.4 Block Diagrams

Figure 4 - 7410FT Transmitter Block Diagram

Introduction to the 7410F IFL

The 7410FT Transmitter accepts RF input signal levels ranging from

-40 to -20 dBm total power (i.e. at 10 channel loading this is equivalent to

-50 to -30 dBm per channel). The unit amplifies the signal, and feeds it to a

laser diode which linearly converts the broadband RF signal to light

intensity.

Figure 5 - 7410FR Receiver Block Diagram

The 7410FR Receiver receives the optical intensity signal, and linearly

converts the signal back to RF. The Receiver then amplifies and reproduces

the L-Band RF signal.

Foxcom Proprietary Information 15

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

Installation

3. Installation

The following section details how to setup the 7410F IFL units3.

Setting up the 7410F IFL Transmitters and Receivers consists of the following

steps:

1. Setting up the transmitter

2. Connecting the fiberoptic cable

3. Setting up the receiver

4. Powering the IFL

5. Connecting the back panel jumpers

6. Monitoring the input/output signal

7. Aligning the fiberoptic link

Observe all warnings and cautions mentioned at the beginning of this manual

(page 10). If after set-up you experience problems, refer to Troubleshooting on

page 36.

Figure 6 - Typical Application of a 7410F Link

3

This section gives instructions on installing the transmitter and receiver in a chassis rackmount.

For instructions on installing standalone units refer to Appendix II Installing a Standalone Unit.

Foxcom Proprietary Information 16

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

3.1 Setting Up the Transmitter

1. Place the 7410FT Transmitter in the 7180M Chassis. The operating base

plate temperature must be between -10° C to 55° C.

2. Apply AC power to the chassis. The Laser LED should be lit.

3. Using an optical power meter, measure the optical power. Insert the

meter’s cable into the Transmitter’s optical connector. Power levels should

be between 0.3 – 0.6 mW (-2 to -4 dBm).

Alternatively, use a DVM to measure the voltage at:

• pins J13-P17 through J13-P24 for the slot being measured (Refer to

Table 6 page 34 for details regarding J13 pinouts) (7180M

Rackmount)

• at pin #6 of the 9 pin connector (standalone)

The signal level should be -4.8 to -4.2 VDC.

4. On the rear panel, connect the coax cable to the RF Input Connector. The

RF LED should be lit.

Installation

5. On the rear panel, connect the fiberoptic cable to the Optical Connector.

6. The 7410FT Transmitter has AGC; no further adjustment is needed.

Note

If either LED is not lit, refer to Troubleshooting on page 36.

CAUTION

When monitoring the voltage outputs use a high resistance DVM only.

Foxcom Proprietary Information 17

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

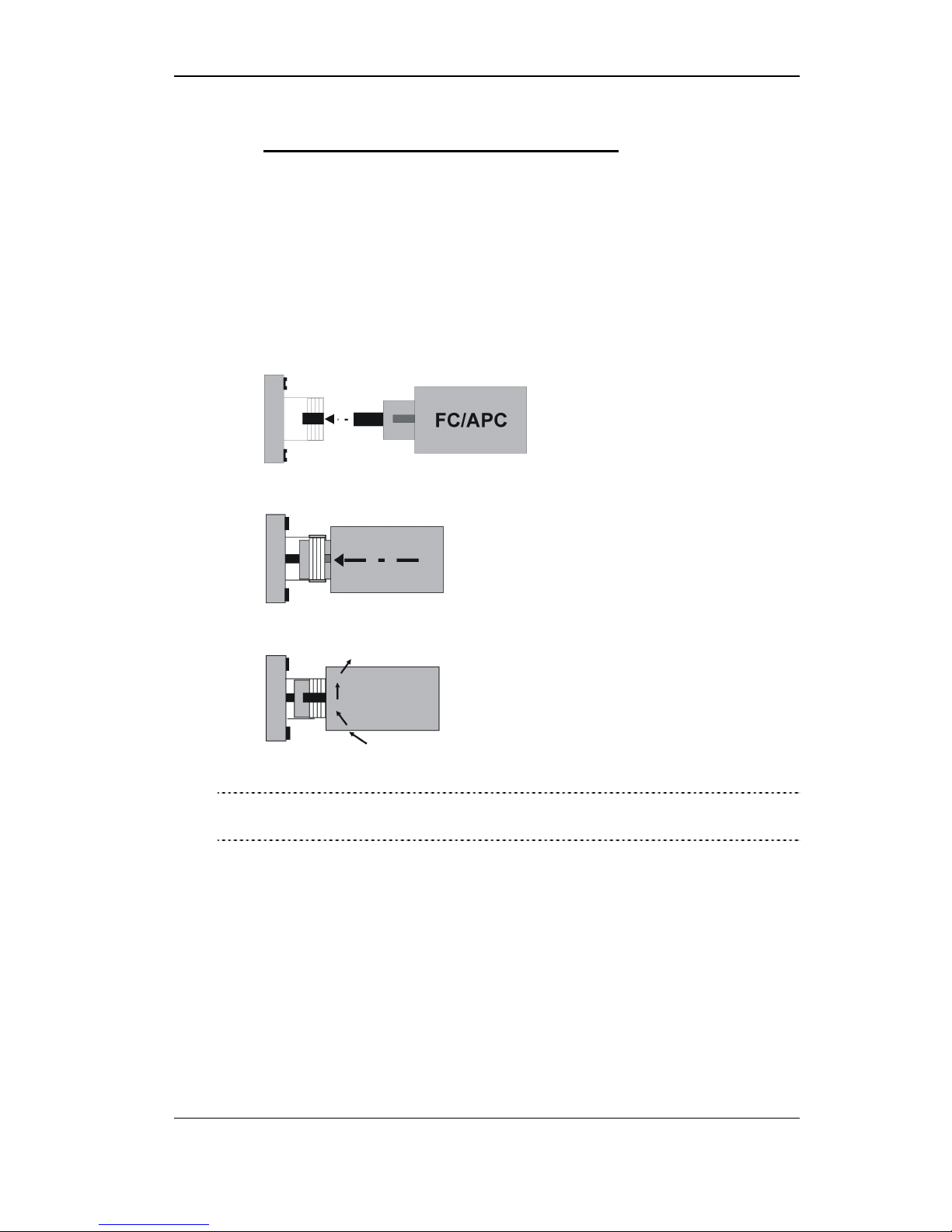

3.2 Connecting the Fiberoptic Cable

Before connecting the cable:

1. The fiberoptic cable must be either fusion spliced or connected via

FC/APC connectors.

2. Wipe the connector with a lint-free cotton cloth.

3. Note the polarity key of the optical connector before inserting.

To connect the cable:

1. Line Up the Polarity Key.

2. Insert the connector.

Installation

3. Tighten the connector.

CAUTION

Do not apply any glue, silicon adhesive, or any other material to the

fiberoptic connector!

Foxcom Proprietary Information 18

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

3.3 Setting Up the Receiver

1. Place the 7410FR Receiver in the 7180M Chassis, unless a 2000 RF

Switch is installed (refer to Figure 7, page 21). The operating base plate

temperature must be between -10° C to 55° C.

Note

If a 2000 RF Switch(s) is being installed, then slots 2 and/or 5 of the 7180M

are reserved for the switch(es).

2. Apply AC power to the chassis. The Power Supply’s LED should be lit.

3. Using an optical power meter, measure the optical power coming to the

Receiver from the fiberoptic cable. The power levels of the Receiver should

be the power level measured at the Transmitter minus the fiber loss

Alternatively, use a DVM to measure the voltage at:

• pins J13-P9 through J13-P16 for the slot being measured (Refer to

Table 6 page 34 for details regarding J13 pinouts) (7180M

Rackmount). The voltage level should be 1V for each 1 mW measured

at the Receiver input.

Installation

4

.

• at pin #5 of the 9 pin connector (standalone)

4. On the rear panel connect the fiberoptic cable to the Optical Connector.

The Opt. and RF LEDs should be lit.

5. On the rear panel, connect the coax cable to the RF Output Connector.

6. Adjust the Gain Control Potentiometer to give the desired output power.

Using a small screw driver, turn the potentiometer (located on the front

panel) to increase or decrease the gain.

Note

If either LED is not lit, refer to Troubleshooting on page 36.

Note

The potentiometer is 10 turns potentiometer.

• To increase the gain, turn the potentiometer clockwise.

• To decrease the gain, turn the potentiometer counterclockwise.

For more information refer to Aligning the Fiberoptic Link on page 24.

4

Fiber loss is defined as:

(0.4 dB/km x length (km) of the fiberoptic cable) + (0.5 dB x number of connectors).

For example if a link was 10 kilometers long and had two connectors the loss would be:

(0.4 dB/km x 10 km) + (0.5 dB x 2) = 5.0 dB.

Foxcom Proprietary Information 19

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

3.4 Powering the IFL

• Transmitter power requirement: +15VDC @ 300 mA

• Receiver power requirement: +15VDC @ 250 mA

• The Standalone Transmitter/Receiver can be powered by a

Foxcom-supplied external DC power supply.

• The Rackmount Transmitters/Receivers are plugged into the 7100M

rackmount chassis. The chassis can accept and power up to six units.

Note

At temperatures below 10° C, the Transmitter’s internal heater will require

an additional 100 mA. The Transmitter’s total power requirement will then

be 400 mA.

CAUTION

Ensure that there is a good airflow around the chassis rackmount.

There should be the space of a rackmount between chassis.

Installation

3.4.1. 7180M Chassis

The 7180M Chassis provides power to the plug in units. The power

supply is a switching type. Each plug-in regulates its own voltage.

The power supply provides:

• 14 VDC stable

• AC input; 100 - 240 VAC

• Units can be plugged in “hot standby”

Foxcom Proprietary Information 20

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

Installation

Foxcom Proprietary Information 21

Document No. 93-006-01-A

Figure 7 - 7180M Chassis Rear View

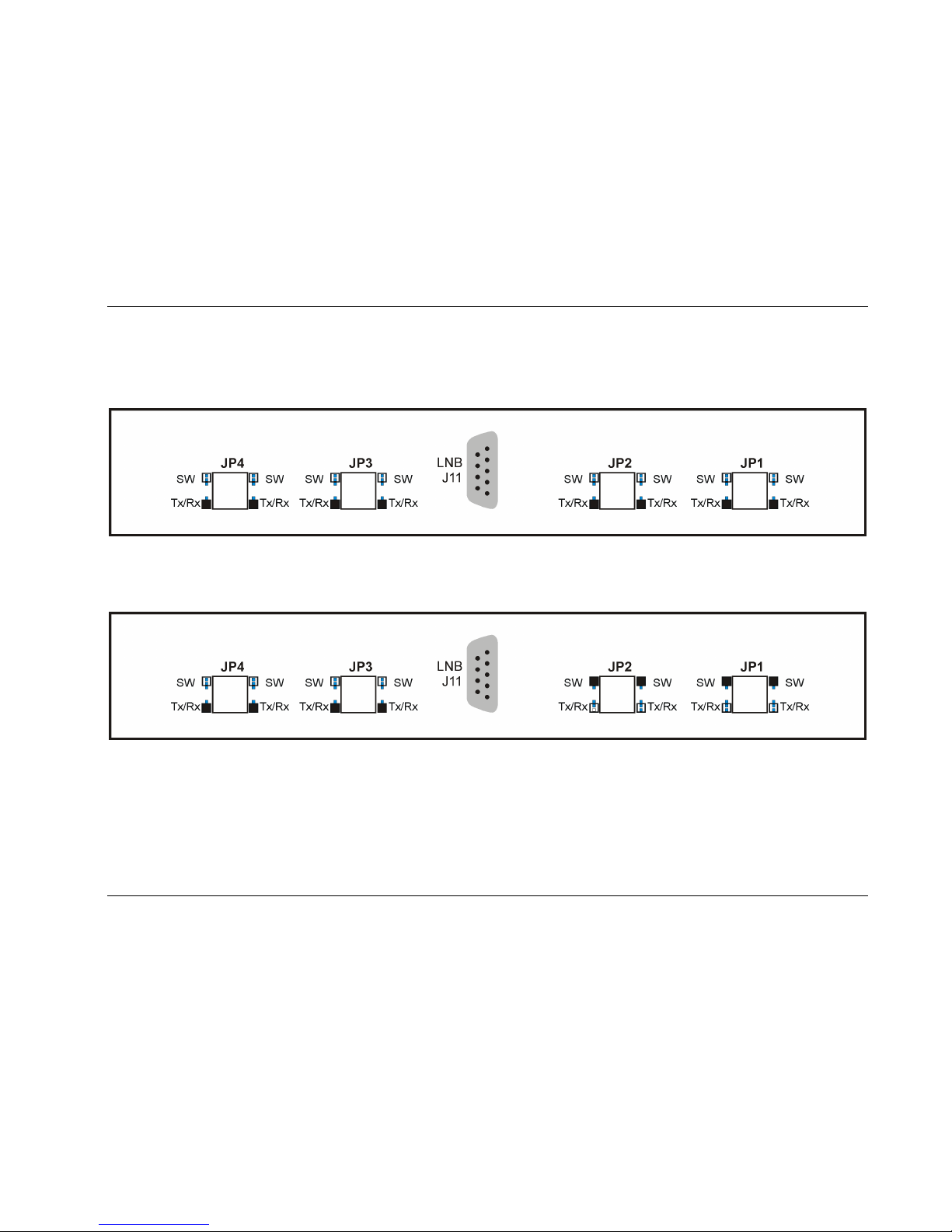

3.5 Connecting the Back Panel Jumpers

On the rear panel of the 7180M Back Panel are product selectors (JP1 to JP4). The 3 pin selectors (male) are the connecting

point between the slots and the back panel. One pin is for the transmitter/receiver (Tx/Rx), one is for the optional 2000 1:1

Redundant Switch, and one is for the 7180M. A 2 pin jumper (female) is placed on the relevant pins to complete the

connection between the 7180M and the units. For example, if a 2000 Switch is being used, the jumper is placed on the

Switch-7180M pins.

To connect the jumpers:

1. Each jumper has two sets of pins, upper and lower. The upper pins are labeled SW (Switch) and the lower pins Tx/Rx.

7410F IFL Installation and Users Guide

Installation

Foxcom Proprietary Information 22

Document No. 93-006-01-A

2. If the 7180M has Tx or Rx units only, place all jumpers on the lower two pins.

Figure 8 - Jumper Installation: Tx and Rx Only

3. If the 2000 Switch is installed in Slot 2, place the JP1 and JP2 jumpers on the higher two pins and the JP3 and JP4

jumpers on the lower two pins.

Figure 9 - Jumper Installation: 2000 Switch in Slot 2

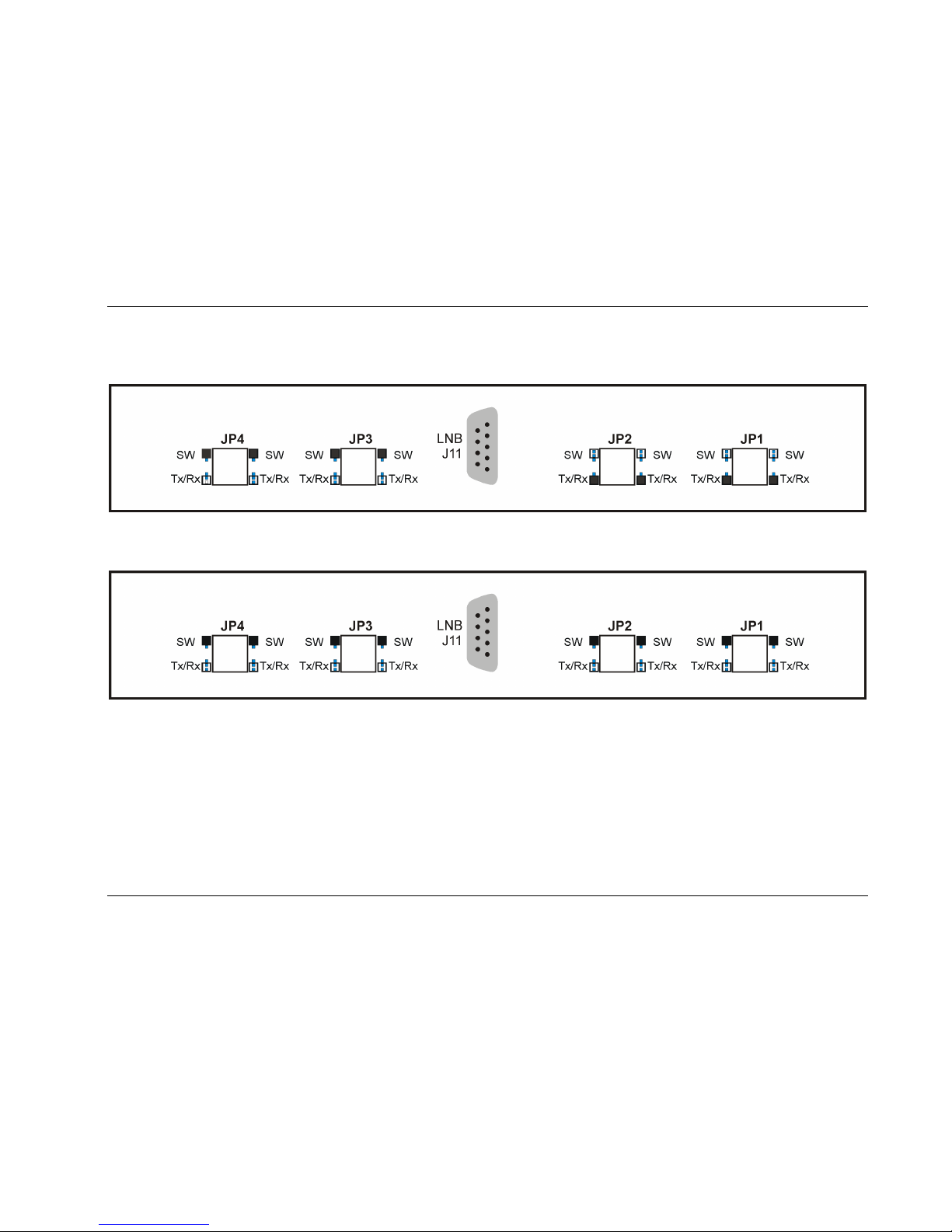

4. If the 2000 Switch is installed in Slot 5, place the JP1 and JP2 jumpers on the lower two pins and the JP3 and JP4

jumpers on the higher two pins.

7410F IFL Installation and Users Guide

Installation

Foxcom Proprietary Information 23

Document No. 93-006-01-A

Figure 10 - Jumper Installation: 2000 Switch in Slot 5

5. If the 2000 Switch is installed in Slots 2 and 5, place the JP1, JP2, JP3, and JP4 jumpers on the higher two pins.

Figure 11 - Jumper Installation: 2000 Switch in Slots 2 and 5

7410F IFL Installation and Users Guide

3.6 Monitoring the Input/Output Signal

The Receiver’s RF signal strength can be monitored during operation via a

DC RF signal-strength monitor. Maintenance personnel can perform a

simple verification process.

To measure the RF signal strength:

1. Using a Digital Volt Meter, measure the voltage at the connector pin #4

(both Rackmount and Standalone).

3.7 Aligning the Fiberoptic Link

The final step in installing the 7410F IFL is re-adjusting the Receiver Gain

Control for unity gain.

To set the unity gain:

1. Set the Signal Generator to -20 dBm on the S.A. at 1000 MHz

Installation

2. Set up the system as shown in Figure 12.

3. Adjust the Receiver Gain Control for unity gain.

Figure 12 - Fiberoptic Alignment Setup

Foxcom Proprietary Information 24

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

4. Product Technical Description

• 7410F IFL specifications

• Model Dimensions

• 7410F IFL Pinouts

• 7100M Pinouts

4.1 7410F IFL Specifications

Product Technical Description

RF Characteristics

Frequency Range

Flatness

Input/Output Impedance

Input/Output VSWR

@ 75ΩΩΩΩ

@ 50ΩΩΩΩ

Input Signal Range (Total Power)

Output Signal Range (Total Power)

Intermodulation Products5

CNR6

OIP3

Noise Figure7 (typical)

Link Gain8

Gain Control

Tx

Rx

RF Connector

SFDR9

950 - 2150 MHz

± 1.5 dB (typical)

75 Ω (50 Ω optional)

1.57:1 (max.)

1.5:1 (max.)

-40 to -20 dBm

-40 to -15 dBm

-40 dBc

>35 dB in 36 MHz BW

(single channel)

0 dBm

22 dB @ Max Input

adjustable ± 10 dB

Automatic

(input power ≤ -20 dBm)

Manual

F type female

(BNC or SMA - optional)

99 dB Hz

2/3

@ -25 dBm (typ)

5

With two equal carriers at -23 dBm per tone

6

Input power -40 dBm (min.). If the input power is less than -40 dBm the CNR will degrade at 1

dB per 1 dBm; e.g. @-43 dBm in put power the CNR will be 32 dB.

7

@ Maximum Input @ 1 dB Optical Loss @ Unity Gain

8

Within the operating range

9

@ Maximum Input Power

Foxcom Proprietary Information 25

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

Product Technical Description

Optical Characteristics

Optical Wavelength

Optical Power Output

Optical Connector

Optical Budget/Distance

Optical Return Loss

Miscellaneous

Chassis Capacity

Chassis Size

Plug-in Unit size

Power for Chassis

Power for Standalone

Transmitter

Receiver

Operating Temperature Range

Storage Temperature

1310 ± 10 nm

0.3 - 0.6 mW (-5.5 to -2.5 dBm)

FC/APC (or fusion splice)

3 dB/ 2 km (max.)

-55 dB (max.)

8 plug-ins

19” x 3U x 7”

5.1” x 4.9” x 1.6”

100 to 240 VAC 50/60 Hz

90 Watts (max.)

15 VDC @ 300 mA (max.)

(400 mA < 100 C)

15 VDC @ 210 mA (max.)

-10° C to 55° C

-20° C to 85° C

Foxcom Proprietary Information 26

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

4.2 Model Dimensions

Figure 13 - Unit Dimensions

Product Technical Description

Figure 14 - 7180M Chassis Dimensions

Foxcom Proprietary Information 27

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

4.3 7410F IFL Pinouts

Table 3 - 7410FT Transmitter Pinout

Product Technical Description

Standalone

9 Pin

Connector

(J13)

1 — — +15V

7180M

Chassis

Back Panel

Connector

2380 Relay

Adaptor

Connector

Name Description

200 mA (max.

Power

≥ 10° C )10

2 — — Spare Not Used

3 J11-P9

J4-P25 GND Chassis Ground

J12-P25

J13-P25

4 J13-P1 to

J13-P8

J4-P1 to

J4-P8

RSSI RF Signal Strength

Indicator; Range

3.5 to 4.5V

5 J13-P9 to

J13-P16

J4-P9 to

J4-P16

PDI Indicates Laser

Optical Power;

Range -4.2 to

-4.8V

6 J13-P17 to

J13-P24

7 J12-P1 to

J12-P8

J4-P17 to

J4-P24

J2: P1-P2

P3-P4, P5-P6

P7-P8, P9-P10

P11-P12,

P13-P14

LSRI Indicates Laser

Bias

RFA RF Alarm: Open

collector

interface.11 Sinks

current at low RF,

up to 30 mA

P15-P16

8 J12-P9 to

J12-P16

See Note

Below

OPTA Optical Alarm:

Open collector

interface12. Sinks

current at low

optical, up to 30

mA

9 J11-P1 to

J11-P8

LNB Bias

External LNB Bias

(optional)*

10

300 mA below 100 C

11

If the 2380 Relay Adapter is installed, the alarms are dry contact. Refer to section Appendix III

The 2380 Relay Adaptor.

12

If the 2380 Relay Adapter is installed, the alarms are dry contact. Refer to section Appendix III

The 2380 Relay Adaptor.

Foxcom Proprietary Information 28

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

Product Technical Description

Note

If a 2380 Relay Adaptor is installed RF and Optical Levels are measured together;

the alarm indicates a problem in either the RF or Optical Levels

Figure 15 - 7410FT Transmitter Pinout

Foxcom Proprietary Information 29

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

Table 4 - 7410FR Receiver Pinout

Product Technical Description

Standalone

9 Pin

Connector

(J14)

1 — — +15V

7180M

Chassis Back

Panel

Connector

2380 Relay

Adaptor

Connector

Name Description

250 mA

Power

2 — — Spare Not Used

3 J11-P9

J4-P25 GND Chassis Ground

J12-P25

J13-P25

4 J13-P1 to

J13-P8

J4-P1 to

J4-P8

RSSI RF Signal Strength

Indicator;

Range 0.2 - 10

VDC

5 J13-P9 to

J13-P16

J4-P9 to

J4-P16

PDI Indicates Received

Optical Power;

1V/1mW Optical

Power

6 — — Spare Not Used

7 J12-P1 to

J12-P8

J2: P1-P2

P3-P4,

P5-P6, P7-P8,

P9-P10

P11-P12,

P13-P14

RFA RF Alarm: Open

collector

interface13. Sinks

current at low

optical, up to 30

mA.

P15-P16

8 J12-P9 to

J12-P16

See Note

Below

OPTA Optical Alarm:

Open collector

interface14. Sinks

current at low

optical, up to

30 mA.

9 — — Spare Not Used

Note

If a 2380 Relay Adaptor is installed RF and Optical Levels are measured together;

the alarm indicates a problem in either the RF or Optical Levels.

13

If the 2380 Relay Adapter is installed, the alarms are dry contact. Refer to section Appendix III

The 2380 Relay Adaptor.

14

If the 2380 Relay Adapter is installed, the alarms are dry contact. Refer to section Appendix III

The 2380 Relay Adaptor.

Foxcom Proprietary Information 30

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

Figure 16 - 7410FR Receiver Pinout

CAUTION

Product Technical Description

When monitoring the voltage outputs use only a high resistance DVM.

Foxcom Proprietary Information 31

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

Product Technical Description

Foxcom Proprietary Information 32

Document No. 93-006-01-A

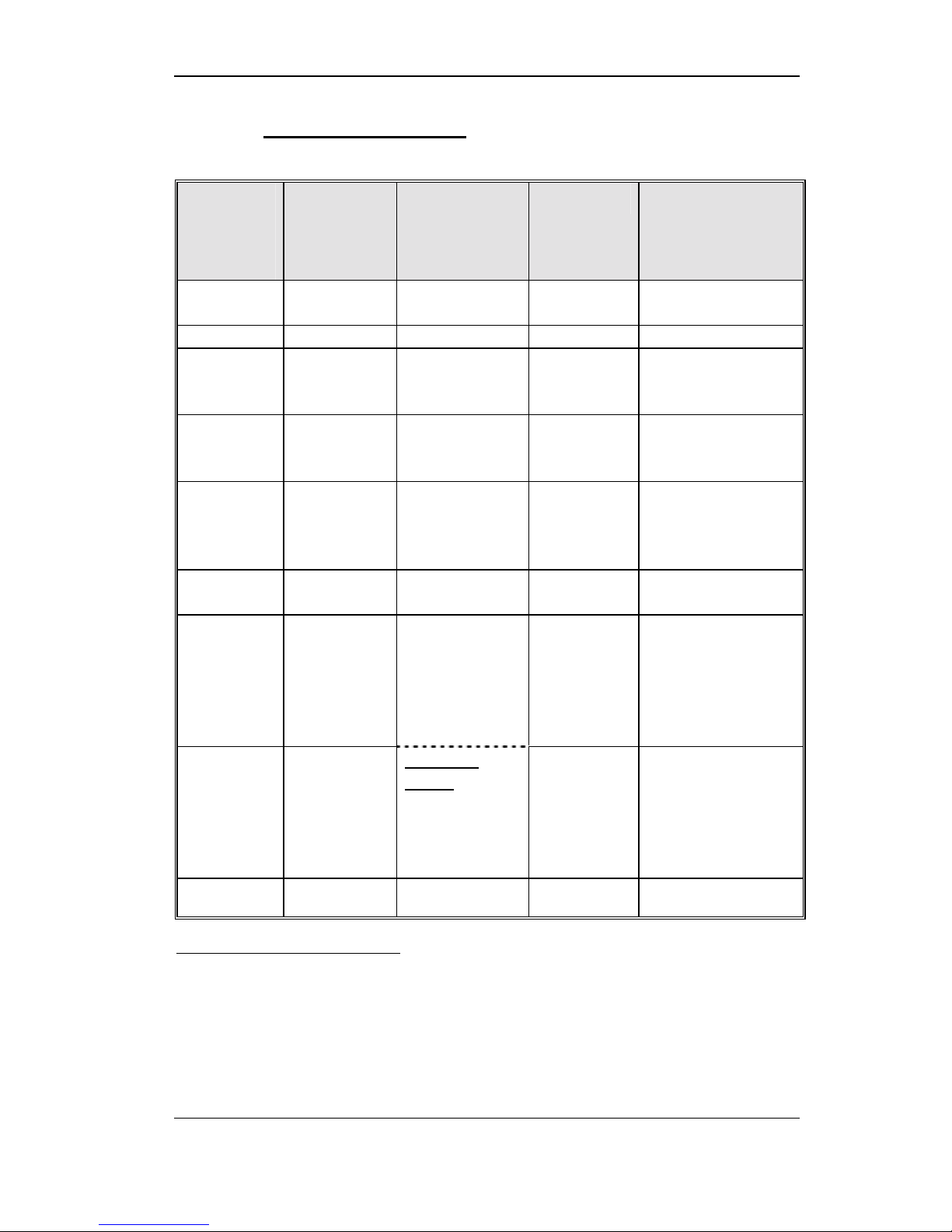

4.4 7180M Chassis Pinouts15

The unit’s pins are found at the backplane of the 7180M chassis. The 7180M chassis backplane incorporates eight

slots. Pinouts from the nine pin connector at each slot are sent through the backplane assembly to the two 25 pin

D connectors, J9 and J10, and one nine pin connector, J11. Any monitor voltages to be measured may be done

between the chassis ground and the required pin.

Figure 17 - 7180M Chassis Rear View

15

For further information refer to Appendix V Pinouts, Detailed Information.

7410F IFL Installation and User’s Guide

The pins are numbered as follows:

Table 5 - 7180M Alarm Connector (J12) Pinout

Pin No. Function Name Slot No.

Pin No. Function Name Slot No.

Product Technical Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

RF Alarm RfAlm1 1

RF Alarm RfAlm2 2

RF Alarm RfAlm3 3

RF Alarm RfAlm4 4

RF Alarm RfAlm5 5

RF Alarm RfAlm6 6

RF Alarm RfAlm7 7

RF Alarm RfAlm8 8

Optical Alarm OptAlm1 1

Optical Alarm OptAlm2 2

Optical Alarm OptAlm3 3

Optical Alarm OptAlm4 4

Optical Alarm OptAlm5 5

Optical Alarm OptAlm6 6

Optical Alarm OptAlm7 7

16

17

18

19

20

21

22

23

24

25

Foxcom Proprietary Information

Optical Alarm OptAlm8 8

Standby Power Supply SPSNOP

Standby Power Supply SPSCOM

Main Power Supply MPSNOP

Main Power Supply MPSCOM

Chassis Ground GND

Document No. 93-006-01-A

33

7410F IFL Installation and User’s Guide

Table 6 - 7180M Monitor Connector (J13) Pinout

Pin No. Function Name Slot No.

Product Technical Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

RSSI Monitor RSSI1 1

RSSI Monitor RSSI2 2

RSSI Monitor RSSI3 3

RSSI Monitor RSSI4 4

RSSI Monitor RSSI5 5

RSSI Monitor RSSI6 6

RSSI Monitor RSSI7 7

RSSI Monitor RSSI8 8

PDI Monitor PDI1 1

PDI Monitor PDI2 2

PDI Monitor PDI3 3

PDI Monitor PDI4 4

PDI Monitor PDI5 5

PDI Monitor PDI6 6

PDI Monitor PDI7 7

16

17

18

19

20

21

22

23

24

25

PDI Monitor PDI8 8

LSRI Monitor LSRI1 1

LSRI Monitor LSRI2 2

LSRI Monitor LSRI3 3

LSRI Monitor LSRI4 4

LSRI Monitor LSRI5 5

LSRI Monitor LSRI6 6

LSRI Monitor LSRI7 7

LSRI Monitor LSRI8 8

Chassis Ground GND

Foxcom Proprietary Information

Document No. 93-006-01-A

34

7410F IFL Installation and User’s Guide

Table 7 - 7180M LNB Connector (J11) Pinout

Pin No. Function Name Slot No.

Product Technical Description

1

2

3

4

5

6

7

8

9

LNB Powering LNB1 1

LNB Powering LNB2 2

LNB Powering LNB3 3

LNB Powering LNB4 4

LNB Powering LNB5 5

LNB Powering LNB6 6

LNB Powering LNB7 7

LNB Powering LNB8 8

Chassis Ground GND

Figure 18 - 7180M Pin Numbers

4.4.1. 7180M and Redundancy Switching

The 2000 Switch provides optional 1:1 redundancy switching for all

Foxcom Interfacility Links. If the customer chooses to add

redundancy switching to the link, the pin connector jumpers need to be

moved. Detailed instructions on moving the jumpers are provided in

the Model 2000 1:1 Redundant Switch Installation and User’s Guide

(Document Number 93-010-01).

Foxcom Proprietary Information

Document No. 93-006-01-A

35

7410F IFL Installation and User’s Guide

Troubleshooting

5. Troubleshooting

The 7410F IFL was tested before it left the factory. However if you are

experiencing difficulties consult the list below for possible solutions. If your

system is still experiencing problems attempt to isolate and identify the

malfunctioning unit.

Table 8 - Troubleshooting

PROBLEM POSSIBLE CAUSE

1. Laser LED not on 1. No DC power to the unit. Possible power

supply problem or AC power input problem.

Check the fuse.

2. Verify LSRI monitor is -4.8 to -4.2 VDC. If

not, laser may have overheated. Disconnect

power or remove plug in and allow cooling.

Try again with better airflow.

3. If an optical power meter is available,

measure the optical power out of the

transmitter. The power should be 0.3 to

0.6 mW (-5.5 to -2.5 dBm). If an optical

power meter is not available, then use another

receiver to determine if there is optical power

emerging from the transmitter (use the

5 meter jumper cable). If there is no optical

power, then the transmitter unit is

malfunctioning.

If any or all the above are not within the

guidelines, the transmitter unit is faulty.

2. Lack of RF signal

present at Receiver, yet

optical power is

functioning.

Foxcom Proprietary Information

1. If the unit has an LNB drive option, verify

that the correct LNB bias is coming down

the center of the RF connector at the

transmit site.

2. Verify that the dish is pointed and correctly

receiving satellite signals.

Conclusion: If signal still not present then

Transmitter input stage amplifier is defective.

Contact Foxcom.

Document No. 93-006-01-A

36

7410F IFL Installation and User’s Guide

PROBLEM POSSIBLE CAUSE

Troubleshooting

3. No optical power, LED

not illuminated.

4. Optical power light

illuminated with

disconnected optical

input.

1. There is a break or severe bend in the

fiberoptic cable. Use an optical power meter

or another functioning receiver unit to verify

optical power coming down the fiber.

2. Optical power too low, too many splits, too

long a distance (thus exceeding optical

budget). System may still function without

LED illuminated although at reduced

performance.

3. The transmitter is not functioning, see above.

Damaged (leaky) photodiode. Unit may still

function, otherwise contact Factory for service.

Foxcom Proprietary Information

Document No. 93-006-01-A

37

7410F IFL Installation and User’s Guide

Appendix I Cleaning Fiberoptic Connections

6. Appendix I Cleaning Fiberoptic Connections

The unit has an FC/APC angle polished optical connector for very high optical

return loss performance. The units are specified into singlemode fiber i.e. 9/125

micron core diameter. Full performance is specified only for low return loss

optical plant - meaning that the fiber must be fusion spliced and all connections or

splices must have a return loss greater than -60 dB. With these guidelines in mind,

link lengths beyond 40 kilometers (for DFB based products) can be achieved with

high performance. Specific performance and/or design assistance is available by

request from Foxcom.

If there is low/no signal or noisy signal at a Foxcom module, the connector should

be cleaned. Dirt on the inside connector tip can impair the flow of light causing

problems in signal transmission. Foxcom modules are sealed but dirt can

occasionally enter during installation and alignment.

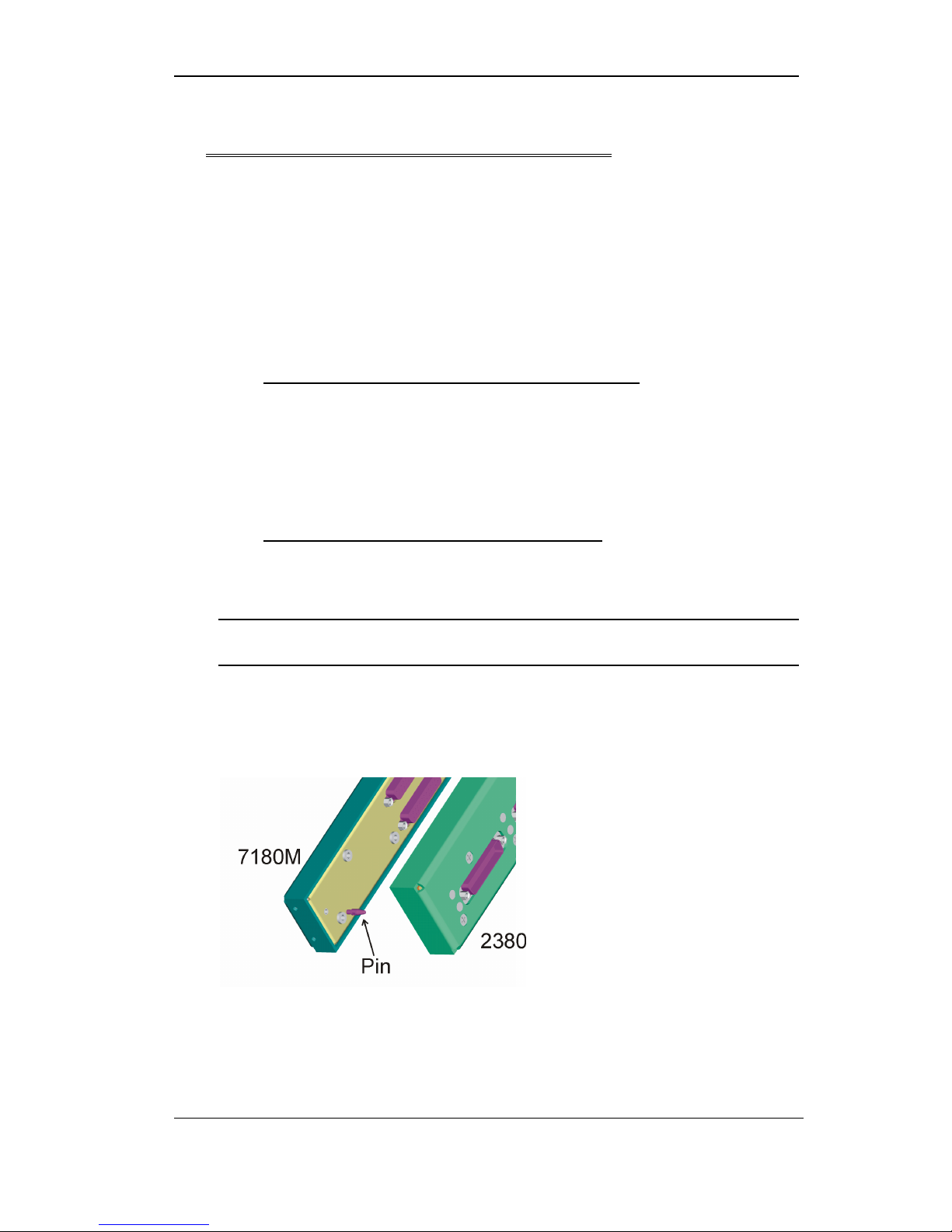

The input and output optical ports of all Foxcom equipment are known in the fiber

optic world as bulkhead ports. Foxcom uses FC/APC connectors.

The purpose of this document is to define the cleaning procedure for the FC/APC

bulkhead fiberoptic ports and for the fiberoptic connector which is connected to

the bulkhead port.

The following materials are representative of the types of cleaning materials that

should be used for cleaning the fiberoptic ports and connectors. They are available

from several suppliers.

Description Manufacturer

Kimwipes Kimberly Clark

Cletop Automatic Connector Cleaner Cletop

Fiberoptic Swab Cletop or FIS

Fiberoptic Compressed Air Chemtronics

Wiping clothes should be made of lint free alcohol free nonabrasive materials.

Swabs should have a tightly wrapped tip and be talcum free. For removing dust

from receptacles, a canned compressed gas is recommended. Do not use

commercial compressed air because of risk of contamination.

Foxcom Proprietary Information

Document No. 93-006-01-A

38

7410F IFL Installation and User’s Guide

Appendix I Cleaning Fiberoptic Connections

6.1 Cleaning Procedures for FC/APC Connectors

Use a Kim Wipe to gently wipe the end face surface of the connector.

Alternatively a Cletop automatic connector cleaner can be used.

Figure 19 - Wiping the Connector with a Kim Wipe

Figure 20 - Wiping the Connector with a Kim Wipe (2)

Foxcom Proprietary Information

Document No. 93-006-01-A

39

7410F IFL Installation and User’s Guide

Appendix I Cleaning Fiberoptic Connections

6.2 Cleaning Procedure for FC/APC Bulkhead Ports

CAUTION

Clean the transmitter and receiver optical ports only when there is

evidence of contamination or reduced performance.

6.2.1. Swab Method

Using a clean fiber optic cleaning swab, gently wipe out the optical

port. Discard the swab after use.

Figure 21 - Cleaning the Optical Port

Figure 22 - Cleaning the Optical Port (2)

Foxcom Proprietary Information

Document No. 93-006-01-A

40

7410F IFL Installation and User’s Guide

Appendix II Installing a Standalone Unit

6.2.2. Compressed Air Method

Using the extension tube of the compressed air, blow into the port to

remove any dust or debris. Do not allow the tube to touch the bottom

of the port. Do not use commercial compressed air due to potential oil

contamination.

Note

To prevent contamination, the optical ports should be connected or

covered with a dust cap at all times.

Use dry air or nitrogen only.

7. Appendix II Installing a Standalone Unit

To install the 7410FT or 7410FR Standalone:

1. Place the 7410F unit on the standalone flange, matching the holes.

2. Using four screws (#4 or #6) secure the unit and the flange to the wall.

3. Apply AC power to the standalone power supply unit.

4. Connect the 7410F unit to the power supply. The Laser LED should be lit.

5. All remaining steps are the same as in the product manual. Refer to Setting Up

the Transmitter on page 17, and Setting Up the Receiver on page 19.

Foxcom Proprietary Information

Document No. 93-006-01-A

41

7410F IFL Installation and User’s Guide

Appendix III The 2380 Relay Adaptor

8. Appendix III The 2380 Relay Adaptor

The following section describes how to install the 2380 Relay Adaptor onto the

7180M Chassis. The 2380 Relay Adaptor assembly provides dry contact output

signals as an option to the standard open collector signals available on the 7180M

chassis backplane.

If the 2380 Relay Adaptor is ordered separately from the 7180M chassis, it must

mounted by the user. The 2380 is easily mounted directly over the connectors on

the 7180M backplane, as shown below.

8.1 Installing the 2380 - Parts Needed

• 2380 Relay Adapter

• Two pin guides

• Four one inch screws

• Screw driver

8.2 Installing the 2380 - Procedure

To mount to the 2380 Relay Adapter:

WARNING

DO NOT PERFORM THIS PROCEDURE BEFORE DISCONNECTING

THE ELECTRICITY

1. Disconnect the electricity.

2. Make sure that you have all the needed equipment.

3. Install the pin guides.

Figure 23 - Mounting the Chassis and Adaptor - Detail

Foxcom Proprietary Information

Document No. 93-006-01-A

42

7410F IFL Installation and User’s Guide

4. Mount the unit onto the pin guides.

Appendix III The 2380 Relay Adaptor

Figure 24 - Mounting the Pins and Adaptor

5. Mount the four screws. The screws must be installed in the order shown

in Figure 25 and Figure 26.

Figure 25 - Mounting the Screws (1)

Foxcom Proprietary Information

Document No. 93-006-01-A

43

7410F IFL Installation and User’s Guide

Appendix III The 2380 Relay Adaptor

Figure 26 - Mounting the Screws (2)

CAUTION

Use only the mounting screws provided by Foxcom. Using other screws

can permanently damage the unit!

Figure 27 - Mounted 2380

6. Connect the cables.

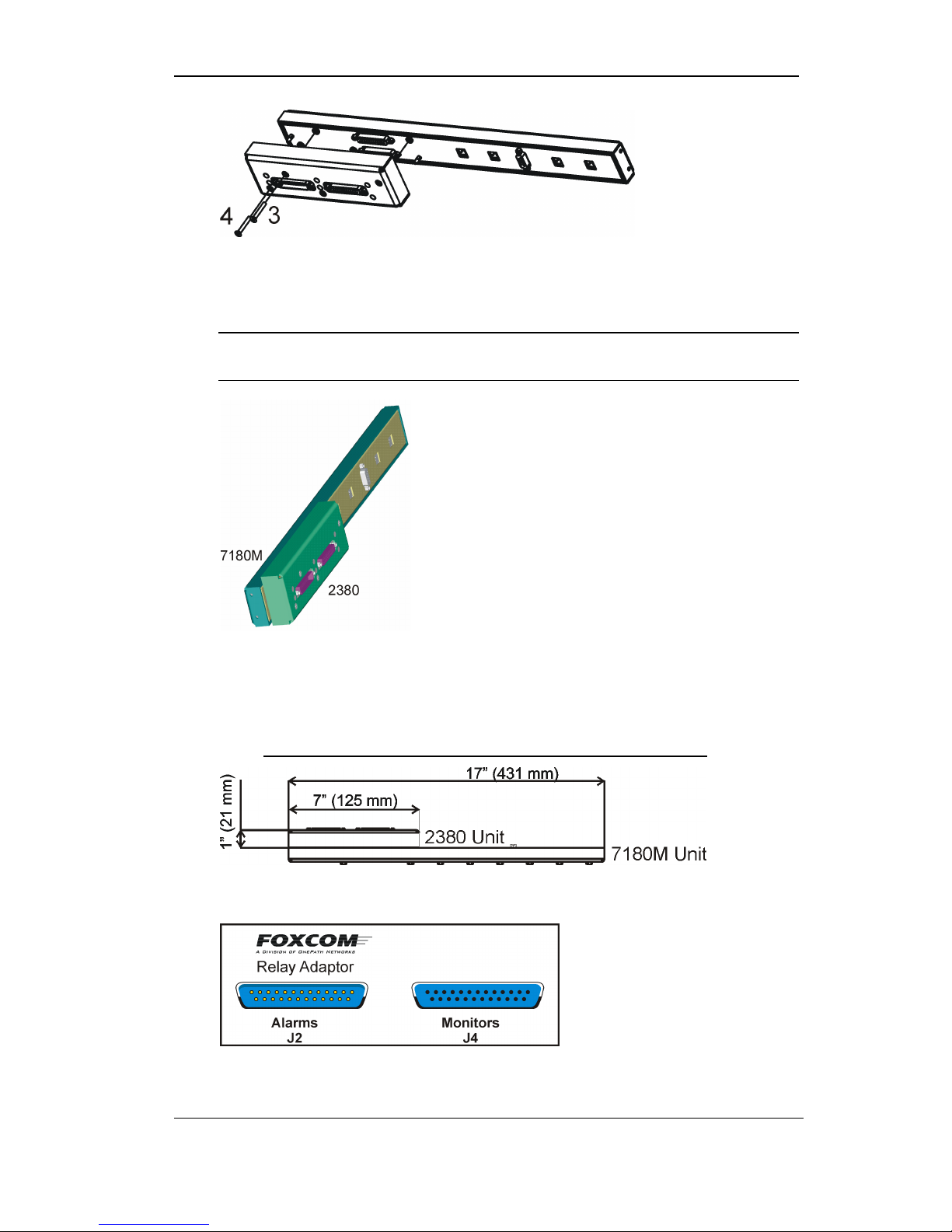

8.3 2380 Dimensions and Front Panel Label

Figure 28 - 2380 Dimensions

Figure 29 - 2380 Front Label

Foxcom Proprietary Information

Document No. 93-006-01-A

44

7410F IFL Installation and User’s Guide

8.4 2380 Pinouts

The following table details the 2380 Alarms pinouts.

Table 9 - 2380 Alarms Pinout (J2)

Pin Number Function Name Slot Number

1 Alarm NOP1 1

2 Alarm COM1 1

3 Alarm NOP2 2

4 Alarm COM2 2

5 Alarm NOP3 3

6 Alarm COM3 3

7 Alarm NOP4 4

8 Alarm COM4 4

9 Alarm NOP5 5

Appendix III The 2380 Relay Adaptor

10 Alarm COM5 5

11 Alarm NOP6 6

12 Alarm COM6 6

13 Alarm NOP7 7

14 Alarm COM7 7

15 Alarm NOP8 8

16 Alarm COM8 8

17

18

19

20

21

22

23 Main PS Alarm MPSA

24 Standby PS Alarm SPSA

25 Power Supply

PSCOM

Comm.

Note

Alarms in Pins 1 through 16 function if there is either a RF or Optical signals

failure.

Foxcom Proprietary Information

Document No. 93-006-01-A

45

7410F IFL Installation and User’s Guide

Table 10 - 2380 Monitor Connector Pinout (J4)

Pin No. Function Name Slot No.

Appendix III The 2380 Relay Adaptor

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

RSSI Monitor RSSI 1

RSSI Monitor RSSI 2

RSSI Monitor RSSI 3

RSSI Monitor RSSI 4

RSSI Monitor RSSI 5

RSSI Monitor RSSI 6

RSSI Monitor RSSI 7

RSSI Monitor RSSI 8

PDI Monitor PDI1 1

PDI Monitor PDI2 2

PDI Monitor PDI3 3

PDI Monitor PDI4 4

PDI Monitor PDI5 5

PDI Monitor PDI6 6

PDI Monitor PDI7 7

16

17

18

19

20

21

22

23

24

25

PDI Monitor PDI8 8

LSRI Monitor LSRI1 1

LSRI Monitor LSRI2 2

LSRI Monitor LSRI3 3

LSRI Monitor LSRI4 4

LSRI Monitor LSRI5 5

LSRI Monitor LSRI6 6

LSRI Monitor LSRI7 7

LSRI Monitor LSRI8 8

Chassis Ground GND

Figure 30 - 2380 Pin Numbers

Foxcom Proprietary Information

Document No. 93-006-01-A

46

7410F IFL Installation and User’s Guide

Appendix IV 7100M Chassis

9. Appendix IV 7100M Chassis

The 7100M Chassis is a standard Foxcom Chassis which holds up to 6 links.

If 7410F IFL is being installed into a 7100M the following information should be

used for installing and checking the unit.

9.1 Equipment Safety

To avoid damaging your product, please observe the following:

1. Fuses: To avoid possibility of fire hazard, always replace fuses with the

same type and rating of fuse as recommended on the power supply rear

label.

In the US/Canada 1A fuses must be used (refer to page 70).

In Europe/Asia/South America 0.5A fuses must be used.

2. The input of the transmitter has an optional built-in bias for inserting DC

power up the coax to the LNB. Make certain any equipment or test

equipment connected to the transmitter input can withstand this bias.

3. The transmitter and receiver output are DC coupled and can withstand the

bias from a satellite receiver. Do not exceed 25V DC bias.

4. Do not allow any dirt or foreign material to get into the optical connector

bulkheads. This may cause damage to the polished optical connector end

faces.

5. The optical fiber jumper cable bend radius is 3 cm. Smaller radii can

cause excessive optical loss and/or fiber breakage.

6. If multiple transmitters are installed in the chassis allow sufficient room

for adequate ventilation; otherwise the units may overheat causing possible

safety hazard or equipment damage.

7. When several units are installed on one 7100M chassis, ensure that the

total units’ current (including any LNB bias) does not exceed 2A per power

supply.

CAUTION

If several units in one chassis use the LNB option, the total current may

exceed 2A. Over current in this configuration and a failure of one

power supply may blow the fuse in the spare power supply.

Foxcom Proprietary Information

Document No. 93-006-01-A

47

7410F IFL Installation and User’s Guide

Appendix IV 7100M Chassis

9.2 Installation

The following section details the steps in the installation process which

differ from units installed in the 7180M Chassis. All other steps are the

same.

CAUTION

By default, an 7410F IFL installed in a 7100M is set to 230V. To change

the voltage to 115V, refer to page 69, Changing the Primary Power

Setting.

Observe all warnings and cautions mentioned at the beginning of this

manual (page 10). If after set-up you experience problems, refer to

Troubleshooting, page 36.

9.2.1. Setting Up the Transmitter

1. Place the 7410FT in the 7100M Chassis. The operating base plate

temperature must be between -10° C to 55° C.

2. Apply AC power to the chassis. The Power Supply’s LED should

be lit.

3. Mount the 7410FT into the chassis. The Laser LED should be lit.

4. Using an optical power meter, measure the optical power. Insert

the meter’s cable into the Transmitter’s optical connector. Power

levels should be between 0.3 – 0.6 mW (-5.5 to -2.5 dBm).

Alternatively, use a DVM to measure the voltage at:

• pins J10-P13 through J10-P18 for the slot being measured

(Refer to Table 14, page 61 for details regarding J10 pinouts)

(7100M Rackmount)

• at pin #6 of the 9 pin connector (standalone)

5. On the rear panel, connect the coax cable to the RF Input

Connector.

6. On the rear panel, connect the fiberoptic cable to the Optical

Connector.

7. The 7410FT Transmitter has AGC; no further adjustment is needed.

Note

If either LED is not lit, refer to Troubleshooting on page 36.

Foxcom Proprietary Information

Document No. 93-006-01-A

48

7410F IFL Installation and User’s Guide

9.2.2. Setting Up the Receiver

1. Place the 7410FR Receiver in the 7100M Chassis. The operating

base plate temperature must be between -10° C to 55° C.

2. Apply AC power to the chassis. The Power Supply’s LED should

be lit.

3. Mount the 7410FR into the chassis.

4. On the rear panel connect the fiberoptic cable to the Optical

Connector. The Opt. LED should be lit.

5. Using an optical power meter, measure the optical power coming to

the Receiver from the fiberoptic cable. The power levels of the

Receiver should be the power level measured at the Transmitter minus

the fiber loss

Alternatively, use a DVM to measure the voltage at:

• pins J10-P7 through J10-P12 for the slot being measured (Refer

to Table 14, page 61 for details regarding J10 pinouts) (7100M

Rackmount). The voltage level should be 1V for each 1 mW

measured at the Receiver input.

16

.

Appendix IV 7100M Chassis

• at pin #5 of the 9 pin connector (standalone)

6. On the rear panel, connect the coax cable to the RF Output

Connector.

Note

If either LED is not lit, refer to Troubleshooting on page 36.

16

Fiber loss is defined as:

(0.4 dB/km x length (km) of the fiberoptic cable) + (0.5 dB x number of connectors).

For example if a link was 10 kilometers long and had two connectors the loss would be:

(0.4 dB/km x 10 km) + (0.5 dB x 2) = 5.0 dB.

Foxcom Proprietary Information

Document No. 93-006-01-A

49

7410F IFL Installation and User’s Guide

9.2.3. Powering the IFL

• Transmitter power requirement: +15VDC @ 300 mA

• Receiver power requirement: +15VDC @ 250 mA

• The Standalone Transmitter/Receiver can be powered by a

Foxcom-supplied external DC power supply.

• The Rackmount Transmitters/Receivers are plugged into the

7100M rackmount chassis. The chassis can accept and power up

to six units.

Note

At temperatures below 10° C, the Transmitter’s internal heater will

require an additional 100 mA. The Transmitter’s total power

requirement will then be 400 mA.

CAUTION

Ensure that there is a good airflow around the chassis rackmount.

There should be the space of a rackmount between chassis.

Appendix IV 7100M Chassis

7100M Chassis

The 7100M Chassis provides power to the plug in units. The power

supply is a linear unregulated type. Each plug-in regulates its own

voltage. The power supply provides:

• 15 to 18 VDC (unregulated) @ 2.2 amps power

• AC input @ 110/220 VAC (user selected)

• Units can be plugged in “hot standby”

• An internal 5 amp fuse (refer to Table 18, page 70 for the fuse

part numbers)

Note

By default the power supply is set to 220V (0.5A).

7000S (Optional) Hot Standby Power Supply

For applications demanding the utmost in reliability and uptime, the

7000S standby power supply can be optionally plugged in to the

standard chassis. The 7000S features hot swapping - supplies may

be installed and removed even during operation. Each power supply

is fully redundant and can power a completely loaded chassis on its

own should its "partner" fail. During normal operation the two units

share the load by means of current steering diodes located on the

rear panell.

Foxcom Proprietary Information

Document No. 93-006-01-A

50

7410F IFL Installation and User’s Guide Appendix IV 7100M Chassis

Foxcom Proprietary Information 51

Document No. 93-006-01-A

Figure 31 - 7100M Chassis Rear View

9.2.4. Connecting the Back Panel Jumpers

On the rear panel of the 7100M Back Panel are product connectors (JP1 to JP4). The 3 pin connectors (male) are the

connecting point between the slots and the back panel. One pin is for the Tx/Rx, one is for the 2000 RF Switch, and one is

for the 7100M. A 2 pin jumper (female) is placed on the relevant pins to complete the connection between the 7100M and

the units. For example, if a 2000 RF Switch is being used, the jumper is placed on the Switch-7100M pins.

To connect the jumpers:

1. Each jumper has two sets of pins, upper and lower. The upper pins are labeled SW (Switch) and the lower pins Tx/Rx

(Transmitter/Receiver).

7410F IFL Installation and User’s Guide Appendix IV 7100M Chassis

Foxcom Proprietary Information 52

Document No. 93-006-01-A

2. If the 7100M has Tx or Rx units only, place all jumpers on the lower two pins.

Figure 32 - Jumper Installation: Tx and Rx Only

3. If the 2000 Switch is installed in Slot 2, place the JP1 and JP2 jumpers on the higher two pins and the JP3 and JP4 jumpers on

the lower two pins.

Figure 33 - Jumper Installation: 2000 Switch in Slot 2

4. If the 2000 Switch is installed in Slot 5, place the JP1 and JP2 jumpers on the lower two pins and the JP3 and JP4 jumpers on

the higher two pins.

7410F IFL Installation and User’s Guide Appendix IV 7100M Chassis

Foxcom Proprietary Information 53

Document No. 93-006-01-A

Figure 34 - Jumper Installation: 2000 Switch in Slot 5

5. If the 2000 Switch is installed in Slots 2 and 5, place the JP1, JP2, JP3, and JP4 jumpers on the higher two pins.

Figure 35 - Jumper Installation: 2000 Switch in Slots 2 and 5

7410F IFL Installation and User’s Guide

9.3 Model Dimensions

Figure 36 - Unit Dimensions

Appendix IV 7100M Chassis

Figure 37 - 7100M Chassis Dimensions

Foxcom Proprietary Information

Document No. 93-006-01-A

54

7410F IFL Installation and User’s Guide

9.4 7410F IFL Pinouts (7100M Chassis)

Table 11 - 7410FT Transmitter Pinout

Appendix IV 7100M Chassis

Standalone

9 Pin

Connector

7100M Chassis

Back Panel

Connector

2300 Relay

Adaptor

Connector

Name Description

(J14)

1 — — +15V Power 300 mA

17

(excluding

LNB Option)

2 — — Spare Not Used

3 J9-P25

J10-P25

J2-P25

J4-P25

GND Chassis Ground

J11-P9

4 J10-P1 to

J10-P6

J4-P1 to

J4-P6

RSSI RF Signal Strength

Indicator;

Range 3.5 ± 0.5V

5 J10-P7 to

J10-P12

J4-P7 to

J4-P12

PDI Indicates Laser

Optical Power;

Range -3 to -4V

6 J10-P13 to

J10-P18

7 J9-P1 to J9-P6 J2-P2, P5,

J4-P13 to

J4-P18

P8, P11, P14,

P17

LSRI Indicates Laser Bias;

Range -4.8 to -4.2V

AGC Alarm RF Alarm: Open

collector interface.18

Sinks current at low

RF up to 30 mA

8 J9-P14 to

J9-P19

J2-P1, P4,

P7, P10, P13,

P16

OPTA Optical Alarm: Open

collector interface.19

Sinks current at low

optical up to 30 mA

9 J11-P1 to

J11-P6

LNB Bias

(optional)

External LNB Bias

17

400 mA below 100 C

18

If the 2380 Relay Adapter is installed, the alarms are dry contact.

19

If the 2380 Relay Adapter is installed, the alarms are dry contact.

Foxcom Proprietary Information

Document No. 93-006-01-A

55

7410F IFL Installation and User’s Guide

Appendix IV 7100M Chassis

Figure 38 - 7410FT Transmitter Pinout

CAUTION

When monitoring the voltage outputs use only a high resistance DVM.

Foxcom Proprietary Information

Document No. 93-006-01-A

56

7410F IFL Installation and User’s Guide

Table 12 - 7410FR Receiver Pinout

Appendix IV 7100M Chassis

Standalone 9

Pin

Connector

7100M Chassis

Pin Back Panel

Connector

2300 Relay

Adaptor

Connector

(J14)

1

2

3 J9-P25

— —

— —

GND Chassis Ground

J10-P25

J11-P9

4 J10-P1 to

J10-P6

5 J10-P7 to

J10-P12

6

— —

J4-P1 to

J4-P6

J4-P7 to

J4-P12

7 J9-P1 to J9-P6 J2-P2, P5, P8,

P11, P14, P17

Name Description

+15V Power 280 mA

Spare Not Used

RSSI RF Signal

Strength Indicator;

Range 0.25 to 2V

PDI Indicates Received

Optical Power;

1V/1mW Optical

Power

Spare Not Used

RF Alarm RF Alarm: Open

collector

interface20. Sinks

current when RF

level is low.

8 J9-P14 to

J9-P19

9

— —

J2-P1, P4, P7,

P10, P13, P16

OPTA Optical Alarm:

Spare Not Used

20

If the 2300 Relay Adapter is installed, the alarms are dry contact. .

21

If the 2300 Relay Adapter is installed, the alarms are dry contact.

Foxcom Proprietary Information

Document No. 93-006-01-A

Open collector

interface21. Sinks

current when

optical level is

low.

57

7410F IFL Installation and User’s Guide

Appendix IV 7100M Chassis

Figure 39 - 7410FR Receiver Pinout

CAUTION

When monitoring the voltage outputs use a high resistance DVM only.

Foxcom Proprietary Information

Document No. 93-006-01-A

58

7410F IFL Installation and User’s Guide

Appendix IV 7100M Chassis

Foxcom Proprietary Information

59

Document No. 93-006-01-A

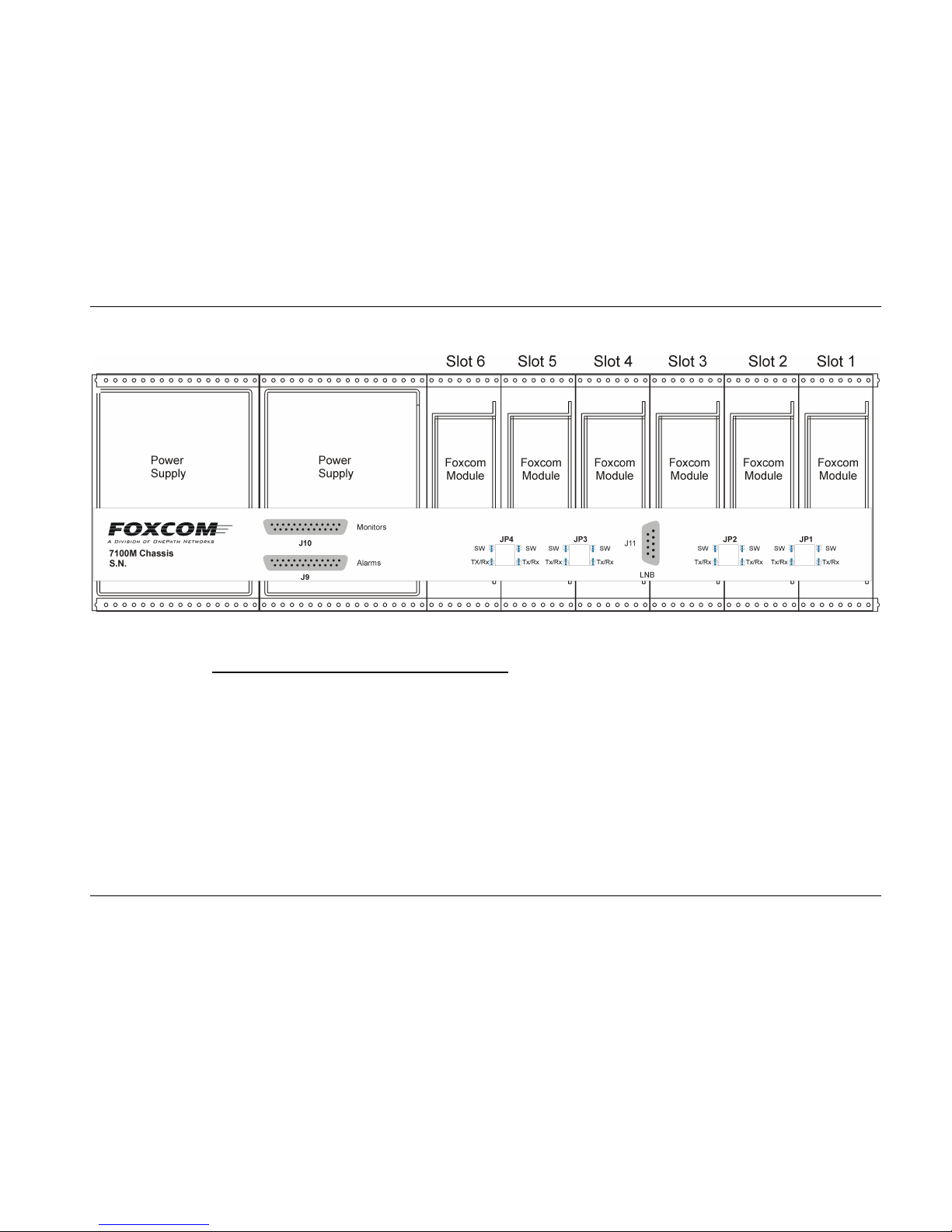

9.5 7100M Pinouts

The unit’s pins are found at the backplane of the 7100M chassis. The 7100M backplane incorporates 6 slots. Pinouts from the

nine pin connector at each slot are sent through the backplane assembly to the two 25 pin D connectors, J9 and J10, and one nine

pin connector, J11. Any monitor voltages to be measured may be done between the chassis ground and the required pin.

Figure 40 - 7100M Chassis

7410F IFL Installation and Users Guide

The pins are numbered as follows:

Table 13 - 7100M Alarm Connector (J9) Pinout

Pin No. Function Name Slot No.

Appendix IV 7100M Chassis

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

RF Alarm RfAlm1 1

RF Alarm RfAlm2 2

RF Alarm RfAlm3 3

RF Alarm RfAlm4 4

RF Alarm RfAlm5 5

RF Alarm RfAlm6 6

OPT/LSR Alarm OptAlm1 1

OPT/LSR Alarm OptAlm2 2

16

17

18

19

20

21

22

23

24

25

OPT/LSR Alarm OptAlm3 3

OPT/LSR Alarm OptAlm4 4

OPT/LSR Alarm OptAlm5 5

OPT/LSR Alarm OptAlm6 6

Relay Standby P.S NOP R2S

Relay Standby P.S Comm R1S

Relay Power P.S NOP R2M

Relay Power P.S Comm R1M

GND GND

Foxcom Proprietary Information 60

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

Table 14 - 7100M Monitor Connector (J10) Pinout

Pin No. Function Name Slot No.

Appendix IV 7100M Chassis

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

RSSI Monitor RSSI 1

RSSI Monitor RSSI 2

RSSI Monitor RSSI 3

RSSI Monitor RSSI 4

RSSI Monitor RSSI 5

RSSI Monitor RSSI 6

PDI Monitor PDi1 1

PDI Monitor PDi2 2

PDI Monitor PDi3 3

PDI Monitor PDi4 4

PDI Monitor PDi5 5

PDI Monitor PDi6 6

LSRI Monitor LsrM1 1

LSRI Monitor LsrM2 2

LSRI Monitor LsrM3 3

16

17

18

19

20

21

22

23

24

25

LSRI Monitor LsrM4 4

LSRI Monitor LsrM5 5

LSRI Monitor LsrM6 6

Ground GND

Foxcom Proprietary Information 61

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

Table 15 - 7100M LNB Connector (J11) Pinout

Pin No. Function Name Slot No.

Appendix IV 7100M Chassis

1

2

3

4

5

6

7

8

9

LNB Powering LNB1 1

LNB Powering LNB2 2

LNB Powering LNB3 3

LNB Powering LNB4 4

LNB Powering LNB5 5

LNB Powering LNB6 6

GND GND

Figure 41 - 7100M Pin Numbers

9.5.1. 7100M and Redundancy Switching

The 2000 Switch provides optional 1:1 redundancy switching for all

Foxcom Interfacility Links. If the customer chooses to add

redundancy switching to the link, the pin connector jumpers need to be

moved. Detailed instructions on moving the jumpers are provided in

the Model 2000 1:1 Redundant Switch Installation and User’s Guide

(Document Number 93-010-01).

Foxcom Proprietary Information 62

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

Appendix IV 7100M Chassis

9.6 The 2300 Relay Adaptor

The following section describes how to install the 2300 Relay Adaptor onto

the 7100M Chassis. The 2300 Relay Adaptor assembly provides dry contact

outputs as an option to the standard open collector signals available on the

7100M chassis backplane.

If the 2300 Relay Adaptor is ordered separately from the 7100M chassis, it

must mounted by the user. The 2300 is easily mounted directly over the

connectors on the 7100M backplane, as shown below.

9.6.1. Installing the 2300 - Parts Needed

• 2300 Relay Adapter

• Two pin guides

• Four one inch screws

• Screw driver

9.6.2. Installing the 2300 - Procedure

To mount to the 2300 Relay Adapter:

WARNING

DO NOT PERFORM THIS PROCEDURE BEFORE

DISCONNECTING THE ELECTRICITY

1. Disconnect the electricity.

2. Make sure that you have all the needed equipment.

3. Install the pin guides.

Figure 42 - Mounting the Chassis and Adaptor - Detail

4. Mount the unit onto the pin guides.

Foxcom Proprietary Information 63

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

Figure 43 - Mounting the Pins and Adaptor

5. Mount the four screws. The screws must be installed in the order

shown in Figure 44 and Figure 45.

Appendix IV 7100M Chassis

Figure 44 - Mounting the Screws (1)

Foxcom Proprietary Information 64

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

Figure 45 - Mounting the Screws (2)

CAUTION

Appendix IV 7100M Chassis

Use only the mounting screws provided by Foxcom. Using other

screws can permanently damage the unit!

Figure 46 - Mounted 2300

6. Connect the cables.

Foxcom Proprietary Information 65

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

9.6.3. 2300 Dimensions and Front Panel Label

Figure 47 - 2300 Dimensions

Figure 48 - 2300 Front Label

Appendix IV 7100M Chassis

Foxcom Proprietary Information 66

Document No. 93-006-01-A

7410F IFL Installation and Users Guide

9.6.4. 2300 Pinouts

The following table details the 2300 Alarms pinouts.

Table 16 - 2300 Alarms Pinout (J2)

Pin Number Function Name Slot Number

1 Opt. Alarm OPTA1 1

2 RF Alarm RFA1 1

3 Common COM1 1

4 Opt. Alarm OPTA2 2

5 RF Alarm RFA2 2

6 Common COM2 2

7 Opt. Alarm OPTA3 3

8 RF Alarm RFA3 3

9 Common COM3 3

Appendix IV 7100M Chassis

10 Opt. Alarm OPTA4 4

11 RF Alarm RFA4 4

12 Common COM4 4

13 Opt. Alarm OPTA5 5

14 RF Alarm RFA5 5

15 Common COM5 5

16 Opt. Alarm OPTA6 6

17 RF Alarm RFA6 6

18 Common COM6 6

19

20

21

22

23 Standby PS Alarm SPSA

24 Main PS Alarm MPSA

25 Power Supply

Table 17 - 2300 Monitor Connector Pinout (J4)

Foxcom Proprietary Information 67

PSCOM

Comm.

Document No. 93-006-01-A