Four winns Vista (1994-2000 models), 238 Vista, 258 Vista, 278 Vista Owner's Manual

PREF ACE

This manual will acquaint you with the use and maintenance of your new Four Winns boat. The manual also

provides special information critical to the safety of the passengers, and longevity of the equipment. The information on the following page lists the conventions used to increase the visibility of these important messages. Also

included with this manual is the “Boating Basics, A Guide to Responsible Boating”. This publication covers all the

boating basics and should be read along with the Four Winns manual before operating your boat. Review this

information in detail.

Four Winns continually strives to improve its products. Unit specifications, including standard and optional

equipment are constantly being modified. Equipment availability is also subject to change. The most current and

accurate information available at the time of publication is included in this manual. Some variation in equipment,

description, location, and details can result.

The information in this manual focuses upon the equipment designed and manufactured by Four Winns on Vista

models. Utilize the information pertinent to your specific boat model. Equipment such as engines, and other

accessories are manufactured by others. The information provided in this manual is intended to be used in

conjunction with the information provided by the manufacturers. All information available at the time of manufacture has been included with this manual.

Read this manual carefully before operating your new boat. Many instructions may require direct performance of

the activity to fully understand the correct method. If you choose to read this manual at home, remember to take

it to the boat with you.

Y our Four Winns dealer knows your boat best and is interested in your complete satisfaction. Return to him for

service or other assistance. If you find it necessary to contact Four Winns directly , please write the office listed

below. Be sure to include the boat model, serial number , your daytime telephone number, and specifics of the

information desired.

This manual has been specifically developed for the 238, 258 & 278 Vista models. Please record the model and

serial number information below.

Model Serial Number

________________________ __________________________

This manual should be considered part of the boat. Should you sell the boat, pass this manual on to the new

owner. T ake special care of this manual. Certain information in this manual may not be available in a replacement

manual.

Thank you for joining the Four Winns family. We appreciate your purchase and welcome the opportunity to

demonstrate our commitment to you.

Four Winns Customer Service Department

925 Frisbie Street

Cadillac, Michigan 49601

616-775-1343

© Four Winns Boats 1995. All Rights Reserved.

Vista Owners Manual

10/93

Preface

Page 1

WARNING CONVENTIONS

This manual contains instructions critical to the safety of those aboard or the longevity of the equipment.

The conventions below have been adopted to increase the visibility of this information throughout the

manual.

This is used to indicate the presence of a hazard which WILL cause SEVERE injury or death if the

warning is ignored.

This is used to indicate the presence of a hazard which CAN cause SEVERE injury or death if the

warning is ignored.

This is used to indicate the presence of a hazard which WILL or CAN cause MINOR personal injury

or property damage if the warning is ignORED

NOTICE

This is used to notify people of installation, operation, or maintenance information which is important

but not hazard-related.

Vista Owners Manual

10/93

Preface

Page 2

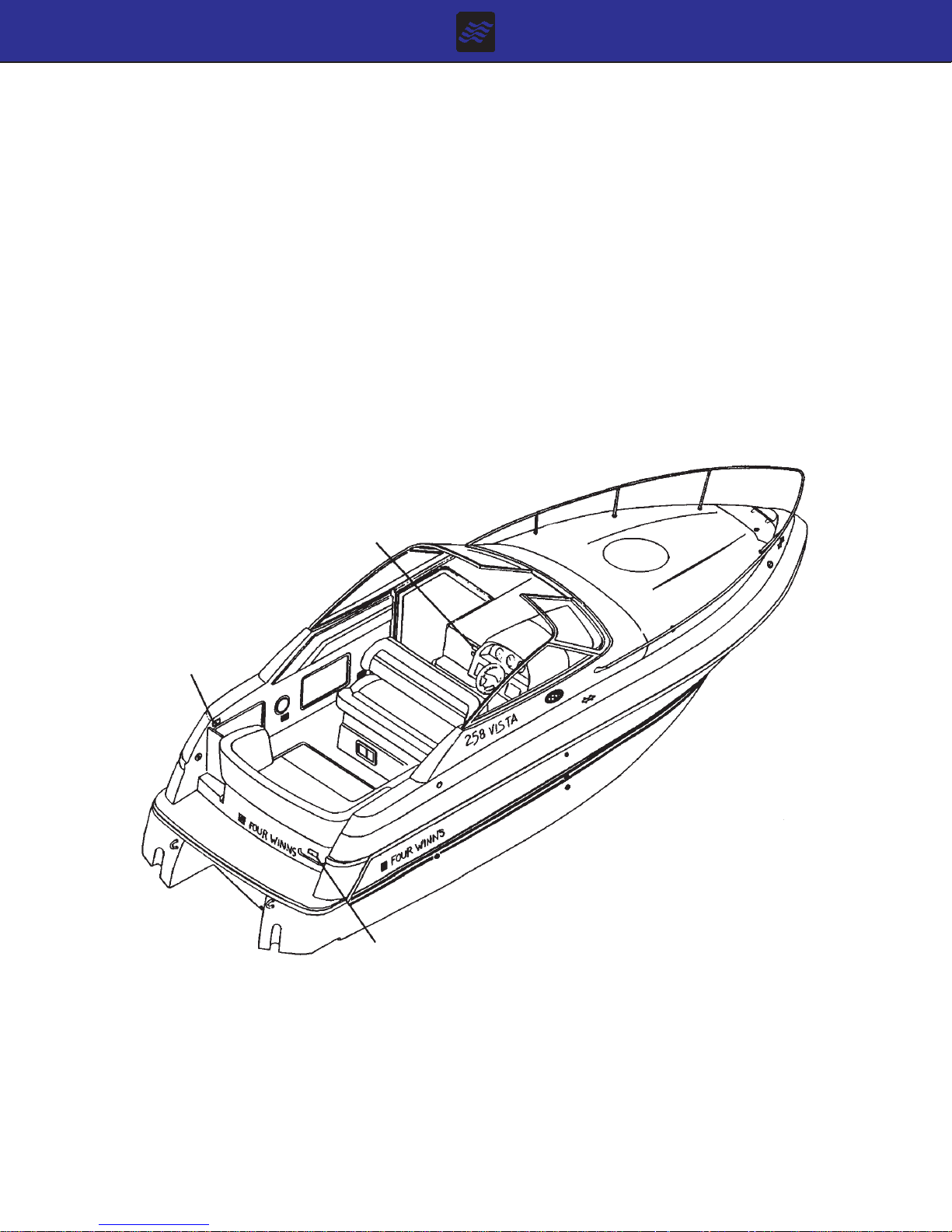

LABEL AND STICKER LOCA TIONS

The NMMA Capacity label, checklists and various warning stickers are placed at different locations on each

model for your safety . Additional warnings for fuel leakage, operating the blower , and other important

information will be imprinted or located on the dash. Many of these stickers and labels are not required by

the U.S. Coast Guard but are important to ensure the safe operation of your Four Winns boat. In addition,

the Hull Identification Number is molded into the gelcoat below the deck-hull joint in the starboard aft corner .

Below is a list corresponding to the various letters in Figure 1.

A. Transom Door Danger Label C. Procedure Checklist

B. Ladder Danger Label D. Equipment Checklist

DC,

A

B

Figure 1: Vista Models

Vista Owners Manual

10/93

Preface

Page 3

TABLE OF CONTENTS

WARRANTY AND SERVICE...................................................................................................................... 1

A - 1 FOUR WINNS WARRANTY POLICY ...................................................................................... 1

A - 2 HULL STRUCTURE WARRANTY ........................................................................................... 1

A - 3 WARRANTY REGISTRATION................................................................................................. 1

A - 4 TRANSFER OF WARRANTY ................................................................................................. 1

A - 5 PRE-OWNED UNIT REGISTRA TION ...................................................................................... 1

A - 6 INSURANCE COVERAGE ..................................................................................................... 2

A - 7 SERIAL NUMBER RECORD .................................................................................................. 2

A - 8 PRE-DELIVERY SERVICE..................................................................................................... 2

A - 9 REPLACEMENT P ARTS ........................................................................................................ 2

A - 10 CUSTOMER SA TISF ACTION SURVEY................................................................................... 2

A - 1 1 WINN GEAR .......................................................................................................................... 3

ENGINES AND INSTRUMENTA TION......................................................................................................... 1

B - 1 GENERAL.............................................................................................................................. 2

B - 2 ENGINE EXHAUST ................................................................................................................ 2

A. Carbon Monoxide ............................................................................................................. 2

B. Carbon Monoxide Monitor................................................................................................. 3

B - 3 ENGINE & DRIVE SYSTEM................................................................................................... 3

A. Engine ............................................................................................................................. 3

B. Stern Drive ....................................................................................................................... 3

B - 4 ENGINE FLUSHING ............................................................................................................... 4

B - 5 PROPELLERS....................................................................................................................... 4

A. Diameter .......................................................................................................................... 4

B. Pitch................................................................................................................................ 4

C. Prop Slip ......................................................................................................................... 4

B - 6 RUNNING ANGLE & POWER TRIM/TILT................................................................................. 5

A. Power Trim ...................................................................................................................... 5

B. Power Tilt ........................................................................................................................ 6

B - 7 TRIM TABS ............................................................................................................................ 6

A. Control Listing.................................................................................................................. 6

B. Induce Planing & Control Trim Angle................................................................................. 6

C. T rim T ab Maintenance ...................................................................................................... 7

B - 8 ENGINE INSTRUMENT ATION ................................................................................................. 7

A. T achometer...................................................................................................................... 8

B. Speedometer ................................................................................................................... 8

C. T emperature Gauge.......................................................................................................... 8

D. Oil Pressure Gauge ......................................................................................................... 9

E. Voltmeter ......................................................................................................................... 9

F. Fuel Gauge...................................................................................................................... 9

G. Power Trim Gauge ........................................................................................................... 9

H. Depth Gauge ................................................................................................................... 9

I. Gas Vapor Detector ......................................................................................................... 9

Vista Owners Manual

10/93

Section A

Page PB

J. Engine Hour Meter ........................................................................................................... 9

K. Ignition Switch ................................................................................................................. 9

L. Emergency Ignition Shut-Off ............................................................................................. 9

M. Alarm Systems .............................................................................................................. 10

N. Instrument Maintenance .................................................................................................. 10

CONTROL SYSTEMS ............................................................................................................................... 1

C - 1 GENERAL.............................................................................................................................. 1

C - 2 CONTROL OPERATION ......................................................................................................... 1

A. Standard Engines............................................................................................................. 1

B. Multi-port Fuel Injected Engines (EFI) ............................................................................... 1

C - 3 NEUTRAL SAFETY SWITCH.................................................................................................. 1

C - 4 CONTROL SYSTEM MAINTENANCE..................................................................................... 1

STEERING SYSTEMS............................................................................................................................... 1

D - 1 GENERAL.............................................................................................................................. 1

A. Rotary Steering ................................................................................................................ 1

B. Tilt S teering...................................................................................................................... 1

C. Power Steering................................................................................................................. 1

D - 2 PROPELLER TORQUE .......................................................................................................... 2

D - 3 STEERING SYSTEM MAINTENANCE.................................................................................... 2

ELECTRICAL SYSTEMS........................................................................................................................... 1

E - 1 GENERAL.............................................................................................................................. 1

E - 2 SINGLE BATTERY SYSTEM.................................................................................................. 1

E - 3 SINGLE ENGINE - DUAL BATTER Y SYSTEM........................................................................ 2

A. Installation ....................................................................................................................... 2

B. Operation ......................................................................................................................... 2

C. Battery Charger................................................................................................................ 3

E - 4 DUAL ENGINE - DUAL BA TTERY SYSTEM ........................................................................... 3

A. Installation ....................................................................................................................... 3

B. Operation ......................................................................................................................... 3

C. Battery Charger................................................................................................................ 4

E - 5 VOLTMETER ......................................................................................................................... 4

E - 6 12 VOLT ELECTRICAL EQUIPMENT ...................................................................................... 4

A. Helm Equipment .............................................................................................................. 4

B. Installation of Additional 12 Volt Equipment ....................................................................... 5

C. Interior Equipment ............................................................................................................ 6

E - 7 120 (220) VOLT ELECTRICAL SYSTEM ................................................................................. 6

E - 8 DOCKSIDE OPERATION........................................................................................................ 7

A. Shore Power Connections ................................................................................................ 7

B. 120 Volt AC Equipment .................................................................................................... 7

C. Reverse Polarity Indicator ................................................................................................. 8

D. Ground Fault Current Interrupters (GFCI)........................................................................... 9

E - 9 GENERA TOR OPTION ........................................................................................................... 9

E - 10 ELECTRICAL SYSTEM MAINTENANCE................................................................................ 10

A. Battery Maintenance....................................................................................................... 10

B. Electrical Wiring Maintenance ......................................................................................... 10

Vista Owners Manual

10/93

Section A

Page 2

E - 11 STRAY CURRENT CORROSION ........................................................................................... 10

A. General.......................................................................................................................... 10

B. Galvanic Corrosion ........................................................................................................... 11

C. Corrosion Prevention ........................................................................................................ 11

FUEL SYSTEMS ....................................................................................................................................... 1

F - 1 GASOLINE FUEL SYSTEMS ................................................................................................. 1

A. System T esting................................................................................................................ 1

B. Fuel Fills ......................................................................................................................... 1

C. Fuel Vents ....................................................................................................................... 1

D. Anti-Syphon Valves .......................................................................................................... 2

E. Fuel Gauge ...................................................................................................................... 2

F. Fuel Sender ..................................................................................................................... 2

G . Fuel Filters ...................................................................................................................... 2

H. Gas Vapor Detector ......................................................................................................... 2

I. Use and Maintenance ...................................................................................................... 3

F - 2 FUEL ST ANDARDS................................................................................................................ 3

A. Problems With Alcohol In Gasoline................................................................................... 3

B. Recommendations ........................................................................................................... 3

F - 3 FUELING INSTRUCTIONS...................................................................................................... 4

WA TER AND WASTE SYSTEMS............................................................................................................... 1

G - 1 GENERAL.............................................................................................................................. 1

G - 2 PRESSURIZED W A TER SYSTEM ......................................................................................... 2

A. Priming the System ......................................................................................................... 2

B. System Operation............................................................................................................ 2

C. Water Heating Systems ................................................................................................... 2

D. Using the Shower............................................................................................................. 3

G - 3 GREY WA TER SYSTEM........................................................................................................ 3

G - 4 SHORE WA TER CONNECTION ............................................................................................. 4

G - 5 TRANSOM WASHDOWN ...................................................................................................... 4

G - 6 H EA D S .................................................................................................................................. 4

A. Portable Head .................................................................................................................. 4

B. Porcelain Head ................................................................................................................ 4

C. Overboard Discharge ........................................................................................................ 5

D. Dockside Pumpout .......................................................................................................... 6

G - 7 SYSTEM MAINTENANCE ....................................................................................................... 6

A. Clean Vent s and Screens .................................................................................................. 6

B. Winterizing the Water System........................................................................................... 7

C. Winterizing the Waste System .......................................................................................... 7

VENTILA TION AND DRAINAGE SYSTEMS .............................................................................................. 1

H - 1 ENGINE COMP AR TMENT VENTILATION ............................................................................... 1

A. Gravity V entilation System ............................................................................................... 1

B. Forced Air Ventilation ....................................................................................................... 1

C. Engine Ventilation System Maintenance........................................................................... 1

H - 2 CABIN VENTILA TION ............................................................................................................. 1

Vista Owners Manual

10/93

Section A

Page PB

H - 3 HULL DRAINAGE SYSTEMS ................................................................................................. 2

A. Transom Drain ................................................................................................................. 2

B. Bilge Pumps.................................................................................................................... 2

C. Liner Drains ..................................................................................................................... 2

D. Bilge Compartment Drainage ............................................................................................ 2

E. Cockpit Drainage ............................................................................................................. 3

H - 4 CARBON MONOXIDE ............................................................................................................ 3

A. Definition of Carbon Monoxide .......................................................................................... 3

B. Properties and Characteristics of Carbon Monoxide .......................................................... 3

C. What Makes Carbon Monoxide ........................................................................................ 3

D. How a Person is Affected by Carbon Monoxide................................................................. 3

E. Effects of Carbon Monoxide.............................................................................................. 4

F. Symptoms ....................................................................................................................... 4

G. Treatment (Evacuate, V entilate, Investigate, T ake Corrective Action) .................................. 4

H. Inspection ........................................................................................................................ 4

I. Operation......................................................................................................................... 4

J. Boathouses, Sea Walls and Other Boats.......................................................................... 5

K. Backdrafting (S tation Wagon Effect) ................................................................................. 5

L. Cabin Appliances ............................................................................................................. 6

M. Ventilation of Accomodation S paces ................................................................................. 6

N. Altitude and Sea Conditions ............................................................................................. 6

O. Portable Generator Sets ................................................................................................... 6

P . Maintenance - Engine Performance .................................................................................. 6

Q. Maintenance - External Conditions ................................................................................... 6

R. CO Detection Systems .................................................................................................... 7

INTERIOR EQUIPMENT ............................................................................................................................ 1

I - 1 GALLEY EQUIPMENT.................................................................................................................. 1

A. Alcohol Stove ................................................................................................................... 1

B. Alcohol/Electric Stove ...................................................................................................... 1

C. Microwave Oven ............................................................................................................... 1

D. Ice Box ............................................................................................................................ 1

E. Refrigerator ...................................................................................................................... 1

I - 2 STEREO SYSTEM ....................................................................................................................... 1

I - 3 AIR CONDITIONING...................................................................................................................... 2

A. General............................................................................................................................ 2

B. Operation ......................................................................................................................... 2

C. Maintenance .................................................................................................................... 2

EXTERIOR AND SAFETY EQUIPMENT..................................................................................................... 1

J - 1 RAILS & DECK HARDWARE ................................................................................................. 1

J - 2 TRANSOM DOOR.................................................................................................................. 1

J - 3 COMP ANIONWA Y DOOR ...................................................................................................... 2

J - 4 WINDSHIELDS ...................................................................................................................... 2

A. Windshields and Cabin Windows...................................................................................... 2

B. Plexiglass........................................................................................................................ 3

J - 5 FOREDECK HATCH............................................................................................................... 3

J - 6 SWIM PLA TFORM ................................................................................................................. 3

J - 7 COCKPIT STORAGE ............................................................................................................. 3

Vista Owners Manual

10/93

Section A

Page 4

J - 8 ANCHOR STORAGE & OPTIONS .......................................................................................... 4

A. Anchor Storage ................................................................................................................ 4

B. Bow Roller Assembly ...................................................................................................... 4

C. Windlass ......................................................................................................................... 4

J - 9 NAVIGA TIONAL EQUIPMENT................................................................................................. 5

A. Compass ......................................................................................................................... 5

B. Depth Sounder ................................................................................................................ 5

C. Ship to Shore VHF Radio ................................................................................................. 5

D. Navigational Package ...................................................................................................... 5

E. Radar Arch....................................................................................................................... 5

J - 10 SPOTLIGHT ........................................................................................................................... 5

UPHOLSTERY .......................................................................................................................................... 1

K - 1 INTERIOR SEATING ............................................................................................................... 1

A. Cabin T ables .................................................................................................................... 1

B. V-berth Compartment....................................................................................................... 1

C. Dinette ............................................................................................................................. 1

D. Aft Cabin ......................................................................................................................... 1

K - 2 EXTERIOR SEATING.............................................................................................................. 2

A. Companion Helm Seat ..................................................................................................... 2

B. Stern Seat ....................................................................................................................... 3

C. Cockpit T ables ................................................................................................................. 4

K - 3 INTERIOR UPHOLSTERY CARE............................................................................................ 4

A. Cleaning Interior Fabric..................................................................................................... 4

B. Draperies ......................................................................................................................... 4

K - 4 EXTERIOR UPHOLSTERY CARE........................................................................................... 5

K - 5 REPLACEMENT UPHOLSTERY ............................................................................................ 6

K - 6 CARPET CARE ..................................................................................................................... 6

A. Interior and Exterior Carpet ............................................................................................... 6

B. Cleaning and Maintenance ............................................................................................... 6

C. Stain Removal .................................................................................................................. 6

WEA THER COVERS ................................................................................................................................. 1

L - 1 GENERAL INFORMA TION ..................................................................................................... 1

A. Bimini Top & Camper ....................................................................................................... 1

B. Cockpit Cover................................................................................................................... 2

L - 2 TRAILERING .......................................................................................................................... 2

L - 3 WINTER STORAGE ............................................................................................................... 2

L - 4 MAINTENANCE ..................................................................................................................... 2

L - 5 CARBON MONOXIDE ............................................................................................................ 3

FIBERGLASS AND HULL INFORMATION ................................................................................................ 1

M - 1 HULL DESIGN INFORMATION................................................................................................ 1

M - 2 FIBERGLASS CONSTRUCTION............................................................................................. 1

M - 3 EQUIPMENT INST ALLATION .................................................................................................. 1

M - 4 FIBERGLASS CARE & MAINTENANCE................................................................................. 2

A. General Maintenance ....................................................................................................... 2

B. Weathering Effects on Gel Coat ....................................................................................... 2

C. Stains .............................................................................................................................. 3

Vista Owners Manual

10/93

Section A

Page PB

M - 5 FIBERGLASS REPAIRS ........................................................................................................ 3

A. Scratches........................................................................................................................ 4

B. Gouges, Cracks, & Blisters.............................................................................................. 4

C. Osmotic Blistering ........................................................................................................... 5

M - 6 ANTI-FOULING PAINT ............................................................................................................ 5

M - 7 HULL SUPPORT.................................................................................................................... 6

WOODWORK AND COMPOSITES ........................................................................................................... 1

N - 1 TEAK ..................................................................................................................................... 1

N - 2 HIGH-PRESSURE LAMINATE CARE ..................................................................................... 1

N - 3 ASH....................................................................................................................................... 1

N - 4 BI R C H.................................................................................................................................... 1

N - 5 STAR BOARD ........................................................................................................................ 1

N - 6 FOUNTAINHEAD.................................................................................................................... 2

GENERAL MAINTENANCE ....................................................................................................................... 1

O - 1 WINTERIZA TION .................................................................................................................... 1

A. Prior to Lifting for Winter Layup......................................................................................... 1

B. After Lifting....................................................................................................................... 1

C. Prior to Winter Storage..................................................................................................... 2

O - 2 ENGINE FLUSH OUT............................................................................................................. 2

O - 3 GENERAL MAINTENANCE SCHEDULE................................................................................. 3

TRAILERS ................................................................................................................................................ 1

P - 1 GENERAL TRAILER INFORMATION ...................................................................................... 1

A. Regulations ...................................................................................................................... 1

B. Load Carrying Capacity ..................................................................................................... 1

C. Hitches ............................................................................................................................. 1

P - 2 TRAILER COMPONENTS ....................................................................................................... 2

A. Bunk Sup ports.................................................................................................................. 2

B. T ongue.............................................................................................................................. 2

C. Swivel Jack ....................................................................................................................... 2

D. Surge Brakes.................................................................................................................... 3

E. Winch............................................................................................................................... 4

F. Wheels ............................................................................................................................. 4

G. Spare T ire Carrier .............................................................................................................. 5

H. Lights .............................................................................................................................. 5

I. Tie-downs ........................................................................................................................ 5

P - 3 OPERATION .......................................................................................................................... 6

A. Hitching Trailer ................................................................................................................. 6

B. Backing Up....................................................................................................................... 7

P - 4 TRAILERING .......................................................................................................................... 7

A. Checklist ......................................................................................................................... 7

B. Tactics............................................................................................................................. 8

P - 5 MAINTENANCE ..................................................................................................................... 9

A. Care of Exterior Finish..................................................................................................... 9

B. Bunks............................................................................................................................. 9

C. Swivel Jack ..................................................................................................................... 9

D. Brake Actuator & Coupling Assembly .............................................................................. 9

Vista Owners Manual

10/93

Section A

Page 6

E. Winch............................................................................................................................. 9

F. Lights ............................................................................................................................. 9

G. Tie-downs ........................................................................................................................ 9

H. Wheels ............................................................................................................................ 9

I. Brakes............................................................................................................................ 10

J. Bearings ......................................................................................................................... 10

P - 6 AXLE INSPECTION & REP AIRS ............................................................................................ 10

A. Removal of Hub .............................................................................................................. 10

B. Bearing/Seal Inspection and Replacement ....................................................................... 1 1

C. Hub Reinstallation ........................................................................................................... 1 1

OPERATION ............................................................................................................................................. 1

Q - 1 GENERAL.............................................................................................................................. 1

Q - 2 COMPONENT SYSTEMS ...................................................................................................... 1

Q - 3 SAFETY EQUIPMENT ........................................................................................................... 1

Q - 4 PASSENGER SAFETY .......................................................................................................... 1

Q - 5 RULES OF THE ROAD .......................................................................................................... 1

Q - 6 LIGHTNING ............................................................................................................................ 1

Q - 7 DRINKING AND DRIVING ....................................................................................................... 2

Q - 8 PRE-CRUISE SYSTEM CHECK ............................................................................................. 2

A. Before Starting The Engines ............................................................................................. 2

B. After S tarting The Engine.................................................................................................. 2

Q - 9 ENGINE OPERA TIONAL PROCEDURES ............................................................................... 3

A. Before Starting ................................................................................................................. 3

B. Cold Engine Start............................................................................................................. 3

C. Warm Engine St arting ...................................................................................................... 3

D. Shifting ............................................................................................................................ 3

Q - 10 GROUNDING AND TOWING .................................................................................................. 4

Q - 11 BOATING EDUCA TION........................................................................................................... 5

A. Boating Courses .............................................................................................................. 5

B. Boating Manuals or Literature ........................................................................................... 5

C. Charts and Maps ............................................................................................................. 5

Q - 12 GLOSSARY........................................................................................................................... 5

FUEL LOG ................................................................................................................................................ 1

SERVICE LOG .......................................................................................................................................... 1

SERVICE INFORMA TION ......................................................................................................................... 1

ELECTRICAL SCHEMA TICS ..................................................................................................................... 1

Vista Owners Manual

10/93

Section A

Page PB

WARRANTY AND SERVICE

A - 1 FOUR WINNS W ARRANTY POLICY

The Four Winns Winning EdgeÔ Owner Protection Plan,

provides the new Four Winns purchaser with one of the

most comprehensive corporate commitments in the marine industry today. The Four Winns Owner Protection

Plan, defines the warranty coverage on all units manufactured by Four Winns. It thoroughly describes the warranty policies and those procedures to be followed to obtain

warranty coverage. Review the Four Winns Owner Protection Plan and limited warranty statements carefully .

All engines utilized in the Four Winns product are warranted by the engine manufacturer. Your Four Winns

dealer is authorized to repair your engines and will work

closely with the manufacturer to resolve any problems

you have.

A - 2 HULL STRUCTURE W ARRANTY

Each unit manufactured by Four Winns is encompassed

by a separate warranty providing specific coverage on the

hull structure. The Four Winns Owner Protection Plan

thoroughly describes this coverage.

A - 4 TRANSFER OF W ARRANTY

Four Winns confidence in the product and our warranty

commitments can extend long after the original purchaser

may choose to move on to a new boat. Four Winns

Limited Warranty coverage and Extended Protection Plan,

when applicable, are transferable to successive owners

of the boat. Registration of the second or successive

owners is required. The Four Winns Owner Protection

Plan thoroughly describes the action required to transfer

warranty coverage.

A - 5 PRE-OWNED UNIT REGISTRA TION

Section A-4 T ransfer of W arranty discussed the need to

properly register the purchase of a pre-owned boat with

Four Winns to transfer applicable warranty coverage.

Purchasers of all Pre-Owned Four Winns models are

encouraged to register ownership with Four Winns. To

register ownership of a “Pre-Owned Four Winns boat,”

provide Four Winns with your name, address, daytime

phone number, purchase date, and hull serial number of

the boat purchased.

A - 3 WARRANTY REGISTRA TION

A Four Winns Warranty Registration Card is attached to

the Four Winns Owner Protection Plan statement. Y our

Four Winns Dealer is responsible for completing and

mailing the warranty card at the time of purchase. This is

the sole basis for establishing proof of ownership of the

boat and trailer and corresponding warranty validation.

Registration of the boat and engines with the manufacturer is required by the Federal Boat Safety Act of 1971.

Other equipment manufacturers also require that their

products be registered with the respective companies.

These warranty registration cards are provided with this

manual.

If you wish to transfer warranty or an extended service

plan coverage, be sure to include a check to cover the

necessary fees.

The hull serial number is embossed into the starboard

side of the transom. The trailer serial number is imprinted

on an identification plate affixed to the trailer frame.

Registration of a Pre-Owned Four Winns boat does not

extend or in any way affect or modify the specific terms of

the Four Winns Owner Protection Plan or Limited Warranties.

We provide this service to the purchasers of Pre-Owned

Four Winns boats in the interest of better boating. Four

Winns welcomes every purchaser of a Four Winns boat,

new or used, to our family .

Vista Owners Manual

10/93

Section A

Page 1

A - 6 INSURANCE COVERAGE

A - 9 REPLACEMENT P ARTS

One of your responsibilities as a new boat owner is to

acquire proper insurance protection. Insurance should

include comprehensive and general liability coverage appropriate to your financial needs. Please contact your

local agent for assistance on insurance coverage.

A - 7 SERIAL NUMBER RECORD

The manufacturer, model, and serial number of major components are recorded during the assembly of each Four

Winns boat. Two copies of this completed form are included at the end of this section. One copy should be

removed and kept by the dealer in his records. This can

assist the dealer in processing warranty claims, or obtaining necessary information. The second copy should be

kept in this owners manual.

A - 8 PRE-DELIVERY SERVICE

Four Winns makes every effort to deliver your boat in ‘turn

key’ condition to the dealer . The process of transporting

and handling the boat necessitates certain inspections

and adjustments prior to delivery to you. Also, various

aspects of operation must be checked and adjusted

immediately prior to final delivery and use.

The selling Four Winns dealer must perform this thorough review of the boat and its numerous systems during

the commissioning or “dealer pre-delivery service” of the

craft.

Four Winns dealers are equipped with a Four Winns Parts

Manual that details the components of each model and

their appropriate part numbers. Many Four Winns dealers inventory common replacement components.

In addition, Four Winns maintains specific records on

the components used in the manufacture of each unit

and makes a concerted effort to maintain components

specifically to fill replacement part needs.

The Four Winns dealer from whom you purchased your

boat is in the best position to meet your needs. If he

does not have the needed item, he has the capability,

through direct facsimile contact with the Four Winns Customer Service Department, to obtain it quickly . Four Winns

will only sell replacement parts to established Four Winns

dealers. If you relocate and cannot find a Four Winns

dealer close to you, contact the Four Winns Customer

Service Department for information on the nearest dealer

in your area.

A - 10 CUSTOMER SA TISF ACTION SURVEY

Four Winns, in association with Outboard Marine Corporation, participate in an on-going market study of the purchasers of our products. Our concern and desire for your

complete satisfaction is genuine. Should you receive such

a survey , we would appreciate your comments and any

suggestions you may have. Each dealer, the product,

and our customer support services are rated based upon

the responses received.

A Four Winns Pre-Delivery Service Record form is provided with this manual. This form lists the many items

encompassed by the pre-delivery service previously described. The Four Winns Pre-Delivery Service Record is

a four-part form. The dealer is to check off the items as

they are completed, and complete the form as indicated

providing specific performance related information appropriately .

Y our Four Winns dealer will sign the Pre-Delivery Service

Record upon completion of the work. You will be asked

to sign this form upon accepting delivery of the boat. Both

you and your dealer are to retain one copy of the completed Four Winns Pre-Delivery Service Record. The other

two copies are to be mailed to the Four Winns Customer

Service Department.

Vista Owners Manual

10/93

A - 11 WINNGEAR

™

Show your colors! Four Winns offers a complete line of

sports clothing designed to complement your new boat.

Y our Four Winns dealer has a complete catalog and pricing.

Section A

Page 2

IMPORT ANT OPERATING INSTRUCTIONS

FOR GENERA TOR OPTION ONL Y

Caution is needed when operating or starting a generator on Four Winns 278 Vistas equipped with

hydro-lift mufflers. W ater can accumulate in the muffler if engine fails to start. Prolonged cranking

of the starter will pump water into the muffler system. Each additional attempt to start (that fails)

places more water into the exhaust, and will back up into the manifold and flow into the cylinders.

If the starter does not crank over the engine (after continued attempts have failed), there may be

water backed into a cylinder. This condition may be mistaken as a dead battery and immediate

action is necessary to prevent engine damage.

If the generator is hard starting, Four Winns recommends removing the drain plug in the muffler to

allow water to drain and have engine tuned up or repaired as soon as possible. Once the engine is

started, reinstall the drain plug.

DO NOT leave boat unattended with plug removed. Water may enter boat from

overboard.

T o locate the drain plug or muffler , refer to the generator manufacturer’s literature supplied with this

manual. If the generator does take on water , it is very important that immediate action is taken

to prevent engine damage. Contact your Four Winns or OMC dealer for assistance.

Vista Owners Manual

10/93

Section B

Page 1

ENGINE AND DRIVE SYSTEMS

B - 1 GENERAL

DO NOT attempt to service any engine or drive

component without being totally familiar with the

safe and proper service procedures. Certain moving parts are exposed and can prove dangerous

to one unfamiliar with the operation and function

of the equipment.

Four Winns does not manufacture engines or drives.

Because of the technical nature of the engine and drive

systems, all manufacturers of these items require that

warranty and service problems be taken directly to an

authorized dealer for resolution. The Four Winns dealer

from whom you purchased your boat, will handle all warranty and service matters with the engine manufacturer

for you.

In compliance with the Federal Boat Safety Act of 1971

all engine manufacturers require their products to be registered. A registration card is furnished with each new engine. When selling a Four Winns boat, the dealer, along

with the purchaser, should complete the information requested on these cards and return them to the respective

engine manufacturers. Engine registration cards are provided with the engine and will usually be found with the

boat literature.

Each manufacturer of the various marine power components provides an owners information manual with their

product. This publication is included with this manual. It

is important that you read the manual(s) carefully and

become completely familiar with proper care and operation of the engine and drive system. Be sure to read the

section on winterization. Replacement costs associated

with frozen engine blocks, drive systems and other components are quite substantial.

Also review the other sections in this manual, especially

Sections F on Fuel Systems, and Section C on Control

Systems.

B - 2 ENGINE EXHAUST

A. Carbon Monoxide

The carbon monoxide in exhaust fumes can be hazardous. It is important for you and your passengers to be

aware of the potential safety hazard created by exhaust

fumes. Familiarize yourself with the symptoms of individuals overcome by carbon monoxide, and most importantly , ways you can protect yourself and your guest s.

DO NOT inhale exhaust fumes! Exhaust contains carbon monoxide which is colorless and

odorless. Carbon monoxide is a dangerous gas

that is potentially lethal.

Persons overcome by carbon monoxide may

exhibit the following symptoms:

a. Watering and itchy eyes

b. Flushed appearance

c. Throbbing temples

d. Inattentiveness

e. Inability to think coherently

f. Ringing in the ears

g. Tightness across the chest

h. Headache

i. Drowsiness

j. Incoherence

k. Nausea

l. Dizziness

m. Fatigue

n. Vomiting

o. Collapse

p. Convulsion

IF YOU THINK EXHAUST FUMES ARE ENTERING

YOUR BOA T , DETERMINE THE CAUSE AND HA VE

IT CORRECTED IMMEDIA TEL Y!

Vista Owners Manual

10/93

Section B

Page 2

The following suggestions can help prevent exhaust fumes

from entering the boat:

1. DO NOT allow the boat to remain stationary with the

engines running for an extended period of time.

2. Use extreme caution while operating the engines in

confined areas such as enclosed slips, congested

piers, or in any area where the exhaust outlets are

facing or near a bulkhead or wall structure of any

kind. Operation under such conditions could easily

lead to exhaust gasses (carbon monoxide) entering

even though you may have all the hatches, windows,

doors and portholes closed.

3. Never operate your generator while the boat is moored

against any other boat, dock or wall structure that is

against or near the exhaust outlet. Again, operation

under such conditions could easily lead to exhaust

gasses (carbon monoxide) entering your boat or the

boat to which you are moored, even though you may

have all the hatches, windows, doors, and portholes

closed.

6. If possible, ventilate your cabin while under way.

Open a forward hatch or window to allow air to travel

through the cabin. Be very careful of operating the

boat with the cabin door or windows that face aft,

open. The natural vacuum created during operation

may allow exhaust gasses to be drawn into the cabin.

NOTICE

Current deck hatches are designed to allow ventilation when

locked in a partially open position.

7. Inspect the engine exhaust system frequently for water

and exhaust gas leakage, hose deterioration, and

loose hose clamps. See Section O General Maintenance for additional information.

8. Have a competent marine engine service technician

inspect your exhaust system whenever your boat is

in for service, or if you notice a change in the sound

of your engines.

For additional information, refer to Section H-4 Carbon

Monoxide.

4. Under certain conditions, exhaust gases can enter

the boat through the sink drains. Each sink drain

has a water trap installed to help prevent this. To be

effective, the sink drains must have water in them.

Normal use of the sinks will provide the water needed

for this to occur.

5. Persons sleeping can be easily overcome by carbon

monoxide because they are unaware of its presence.

Sleeping while the engines or generator are running

is not recommended. If persons are sleeping aboard

while underway, or while the generator is running,

those awake should monitor for carbon monoxide

accumulation in the cabin; especially the sleeping

areas. Open forward facing windows or deck hatches

to provide fresh air ventilation. Keep hatches, windows, and doorways that face aft or towards the exhaust discharge closed.

NEVER operate the propulsion engine(s) or generator while everyone on-board is sleeping. Fatal

carbon monoxide poisoning can occur.

B. Carbon Monoxide Monitor

A carbon monoxide (CO) monitor will sound an alert should

carbon monoxide reach an unsafe level in the cabin of

your Four Winns boat. The CO Monitor is optional equipment on all Vista models and is usually located on the aft

cabin wall. If a CO monitor is installed, refer to the manufacturer’s literature included with this manual.

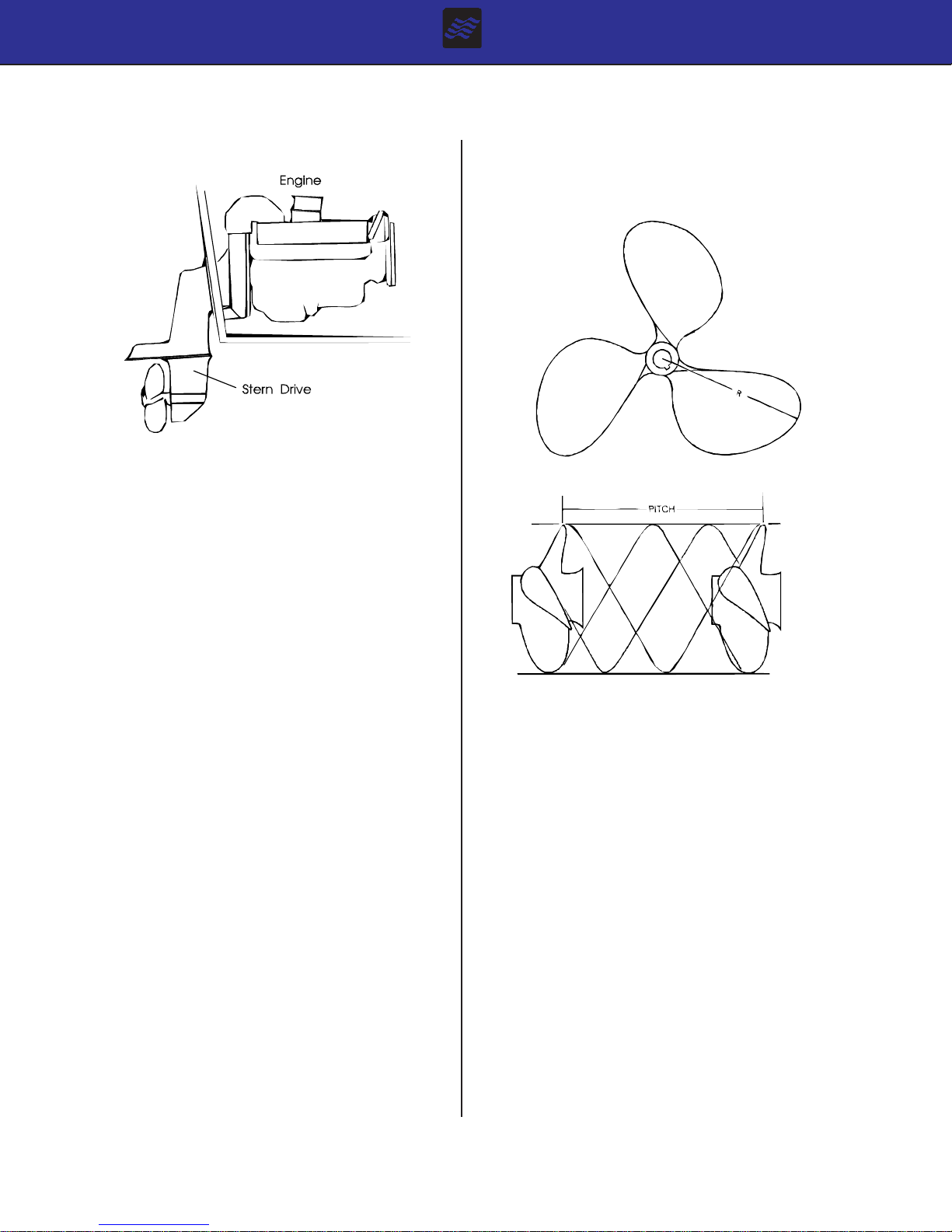

B - 3 ENGINE & DRIVE SYSTEM

A. Engine

Consult the Engine Owners manual provided with this

manual for operation and maintenance information.

B. Stern Drive

A stern drive or inboard/outboard propulsion system has

a piston engine equipped with special marine components

mounted near the transom and coupled to an external

outdrive-type transmission unit. Shifting is performed

within the outdrive gear case. This type of system is

depicted in Figure B1.

Vista Owners Manual

10/93

Section B

Page 3

Figure B1: Stern Drive

Consult the Engine Owners manual for additional information on stern drives.

B - 4 ENGINE FLUSHING

The engine flush out option is offered on all Vista models.

The engine flushing kits attach permanently to the engine. A fresh water supply can be connected to the engine with the boat in the water. It is not intended for use

with the boat out of the water. This option is useful to

flush the engine cooling system of unwanted salt residue.

The flush out kit should only be used with the boat in the

water and the engine OFF . See Section O General Maintenance for flushing procedures.

B - 5 PROPELLERS

Knowledge of the propeller is most easily gained through

better understanding of the terminology used to refer to

the aspects of propeller size and performance.

A. Diameter

Diameter is twice the distance from the center of the prop

shaft to the extreme tip of a propeller blade. Increasing or

decreasing propeller size will have a direct bearing on the

RPM’s an engine will develop. This is due to the greater

amount of propeller blade surface in contact with the water. See Figure B2.

Figure B2: Propeller Pitch & Diameter

B. Pitch

Pitch is a measure of helix angle, or angle of attack, of

the rotating blade. Pitch is easily understood if one imagines the propeller rotating through a semi-solid such as

butter or gelatin. The distance the propeller will travel in

one revolution is called “Pitch.” Increasing or decreasing

pitch will also have a direct bearing on engine RPM’s

because of the greater bite taken by the blade with each

rotation. See Figure B2.

C. Prop Slip

When traveling through water a propeller is unable to get

a complete bite because of the fluidity of water. “Prop

Slip” is usually expressed as a percent of the computed

theoretical speed. T wentyfive to thirty-five percent prop

Vista Owners Manual

10/93

Section B

Page 4

slip is common for a cruiser-type boat operating at cruising speed.

Therefore the deduction can be made that a propeller, of a

certain diameter, with a 10 inch pitch, rotating at 3600

revolutions per minute, with a prop slip of 30%, would move

the boat at a rate of 24 miles per hour.

Changing either diameter or pitch will have an effect on

engine speed and prop slip, and in turn, directly effect the

performance of a boat. The propeller(s) included with each

Four Winns boat provide the best general performance

based on data obtained from on-the-water testing of that

model. V ariations in load, operating conditions,

environment, the individual engine and hull performance

may necessitate the purchase and use of another

propeller(s).

Under your normal load conditions, the engine(s) should

turn within the maximum RPM range when at full throttle.

If the engine(s) exceeds the recommended RPM, an increase in pitch or diameter is required. If the engine RPM

is too low, a decrease in pitch or diameter is required.

An engine that is not developing full power and the load

carried in a boat will directly affect performance of the

engine. Always be sure the engine is properly tuned and

load conditions are those normally experienced, before

changing propellers.

The running angle can be controlled through the use of

power trim and trim tabs. See Section B-6 Trim Tabs,

for information on the use of trim tabs.

NOTICE

For twin engine installations, always check drive

shaft rotation before propeller installation. A right

hand rotation propeller must be installed on the

stern drive to the starboard engine. Similarly , a

left hand prop must be installed on the port stern

drive.

For additional information on factors affecting performance,

please consult your Four Winns dealer .

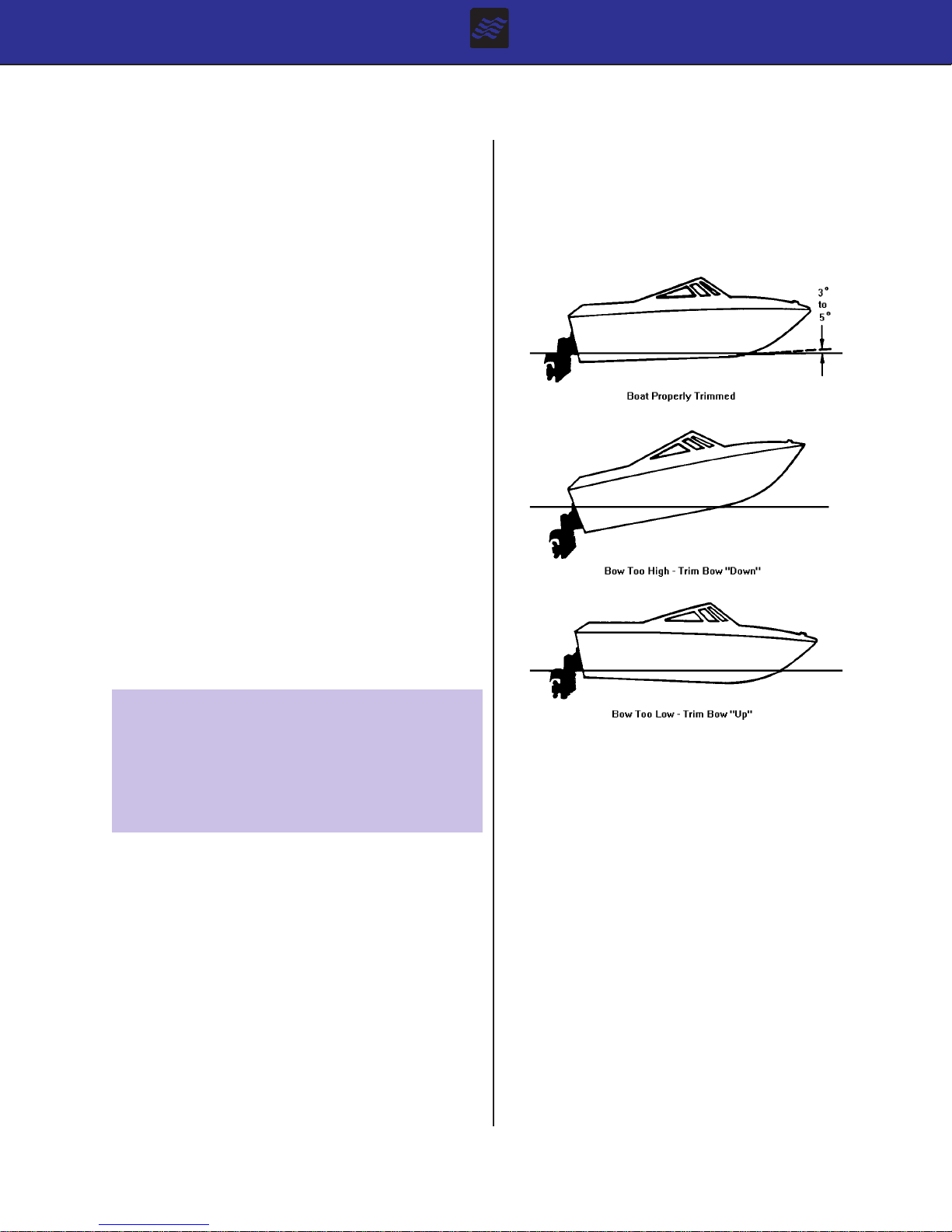

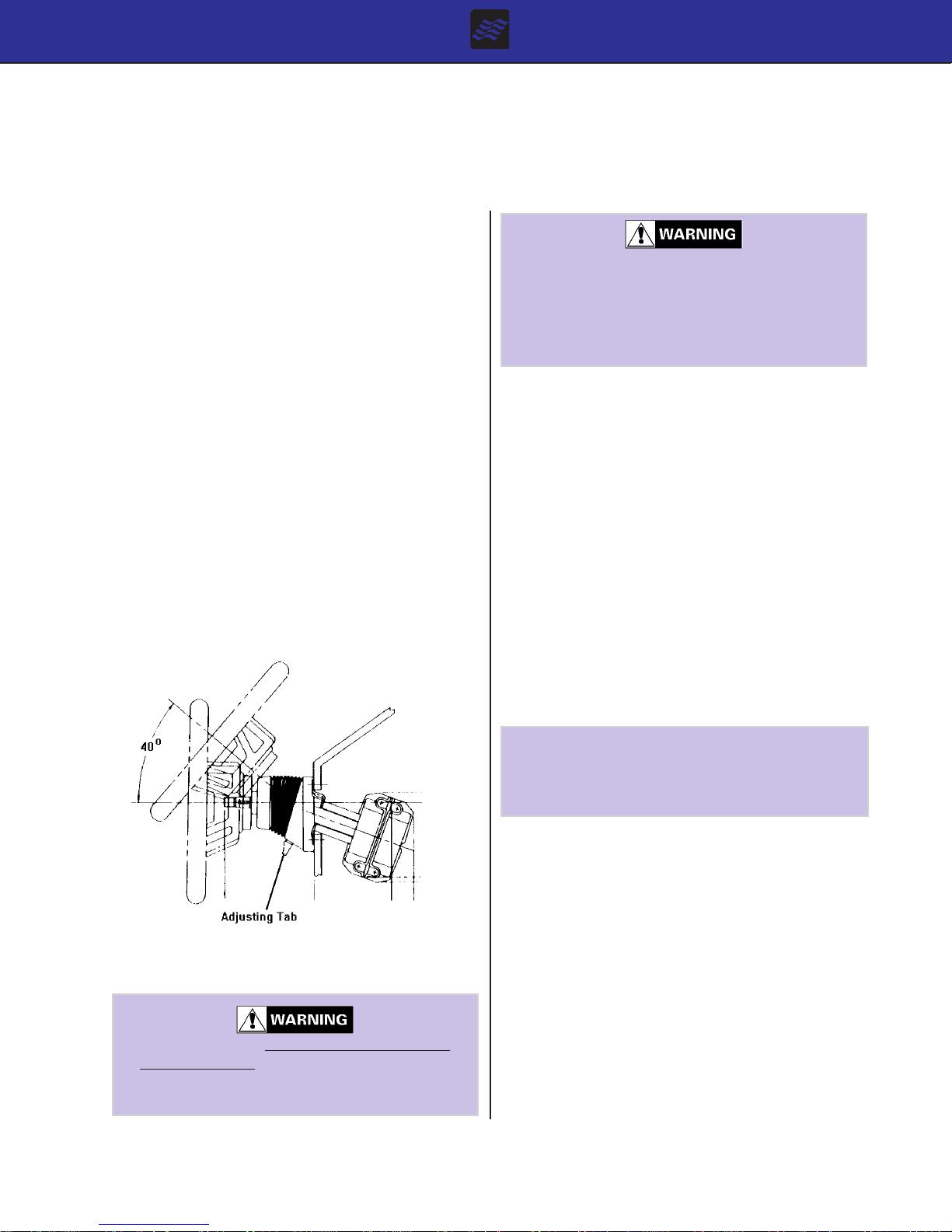

B - 6 RUNNING ANGLE & POWER TRIM/TIL T

Hull planing surfaces have the least amount of drag at a

three to five degree angle with the water. This is the preferred running angle when boating. The running angle has

a significant impact on top speed and handling. Heavy

load or certain water conditions may make it difficult to

achieve the optimum running angle. See Figure B3.

Figure B3: Running Angle

A. Power Trim

Trim angle is how far in or out, the lower unit is positioned in relation to the bottom of the boat. The trim

angle of the lower unit has a distinct affect on the running

angle of the boat.

The power trim system permits control of the trim angle

of the drive unit relative to the boat, at the touch of a

button.

It allows the drive unit to be raised (trimmed out) for shallow water operation. Power trim also allows the operator

to adjust the drive unit while underway to provide the

ideal running angle for a given load and water condition.

Additional information can be found in the Engine Owners manual.

Vista Owners Manual

10/93

Section B

Page 5

B. Power Tilt

Power tilt allows the operator to raise and lower the drive

unit for trailering, launching, and beaching. Additional

information on power tilt can be found in the engine

manufacturer’s manual included with this manual.

NOTICE

DO NOT operate the engine with the stern drive

tilted up. Severe damage to the engine drive

system can result. Consult the Engine Owners

manual for specific information.

B - 7 TRIM T ABS

Electric/hydraulic trim tabs are optional and help provide

maximum control of the hull in all water and load conditions. If used properly , trim tabs can

a. Compensate for wind and load listing (level the boat

side to side).

b. Induce faster planing and help achieve optimum run-

ning angle (see Section B-6 Running Angle & Power

Trim/Tilt)

Pressing the lower starboard trim tab switch will cause

the starboard trim tab to move upward and will result in

the port bow being allowed to rise.

Depressing the upper port trim tab switch will cause the

port trim tab to move downward and will force the starboard bow downward.

Depressing the upper starboard trim tab switch will cause

the starboard trim tab to move downward and will force

the port bow downward.

Always establish your intended heading and attain desired cruising speed before trying to adjust running attitude (using the trim tabs).

Always press the trim tab switches in short 1/2

second bursts. If depressed too long, you can

overcompensate, and potentially lose control. DO

NOT try to correct the situation by depressing

the other upper trim tab switch. Instead, raise

the tab slightly by depressing the appropriate

lower half of the trim tab switch.

The proper use of electric/hydraulic trim tabs requires a

basic understanding of trim tab operation and some practice in calm water.

The trim tab control uses two (2) momentary-type rocker

switches. The trim tab switches control the attitude or

position of the boat. The trim tab switches are labeled by

position such as “Bow Up” and “Bow Down”. They are

also labeled for “Port” and “Stbd”. When depressed, the

label indicates what happens to the bow of the boat.

Before leaving the dock and utilizing the trim tabs, ensure the trim tabs are in the full up position. Depress

both lower halves of the trim tab switches and hold (for

approximately 10 seconds) until the tabs are full up.

A. Control Listing

Wind, loading and many other factors can result in the

boat tilting or leaning towards one side while running.

This is called listing and can be negated using trim tabs.

Pressing the lower port trim tab switch will move he port

trim tab upward. This will result in the starboard bow of

the boat being allowed to rise.

After stabilization of speed and direction, depress the upper

half of the appropriate trim tab switch to achieve a level

side to side running attitude. Be sure to press the correct

trim tab switch to obtain the desired result.

After depressing a trim tab switch, always wait and allow

time for the change in trim tab position to take effect. DO

NOT continue to depress the trim tab switch while awaiting

trim tab reaction. By the time the effect is noted, the trim

tab will move too far and thus overcompensate.

B. Induce Planing & Controlling Trim Angle

Trim tabs can also be used to facilitate faster planing and

allow better control of the running angle.

Before accelerating and trying to gain plane, depress both

upper trim tab switches. This will cause both trim tabs to

move downward and force the bow down when running.

This can also be used when running the boat with a heavy

load aboard.

Vista Owners Manual

10/93

Section B

Page 6

C. Trim Tab Maintenance

The use of trim tabs to attain quicker planing

should not be used by inexperienced boaters. The

combination of extreme inward drive position and

extended trim tabs can dangerously affect the

boats handling under certain sea conditions.

Moving the trim tabs downward will increase the lift and

the boat will achieve plane faster, or stay on plane at a

lower engine and boat speed.

After gaining plane and establishing cruising speed, depressing both lower trim tab switches will cause both trim

tabs to move upward and will allow the bow to rise. This

should be used to adjust the running attitude of the boat

to decrease the drag at cruising speed or above, or when

running in a following sea.

When running at an engine speed that results in the boat

falling off plane or causes the boat to plane inefficiently,

lowering both tabs slightly (bow down) will improve the

running angle and improve operating efficiency .

Optimum efficiency is obtained when operating at a 3 to 5

degree running angle. Utilizing too much “Bow Down”

trim tab can reduce operating efficiency and cause

substantial steering and hand-ling difficulties. Be extremely

careful when running in a following sea. The effect of trim

tabs is amplified under such conditions. Steering and

handling difficulties can result from improper trim tab usage, especially in a following sea. If unsure of proper trim

tab positioning, raise the trim tabs to the full-up position.

Check the fluid level of the trim tab reservoir often. Always keep the fluid level between the designated marks

on the trim tab pump-reservoir . Refer to the manufacturers information for specifications on the type of fluid to be

used and other operation and maintenance information.

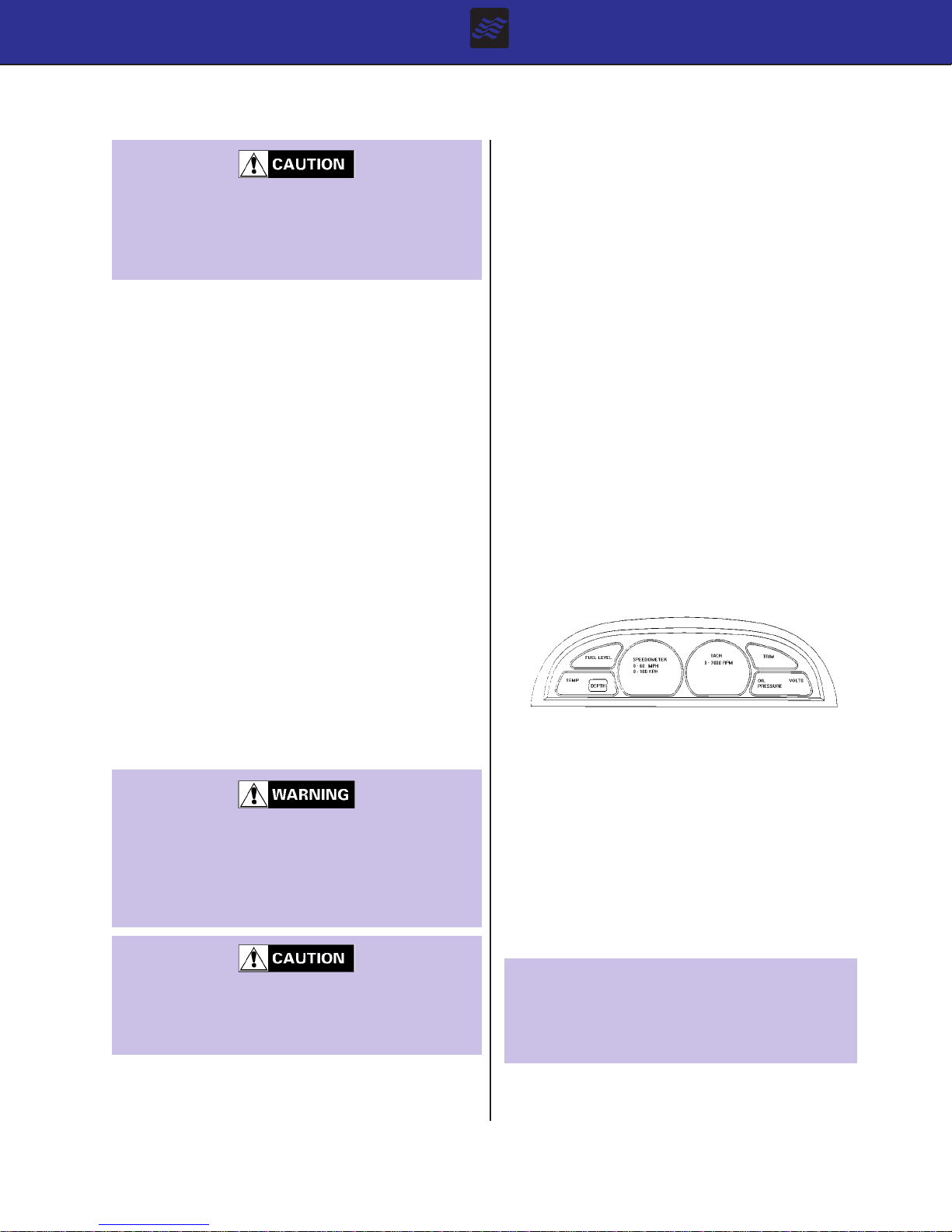

B - 8 ENGINE INSTRUMENT ATION

The helm station is equipped with a complete set of engine instruments. These instruments allow the pilot to

constantly monitor the operational condition of the engine. Close observation of these instruments could save

the engine from damage.

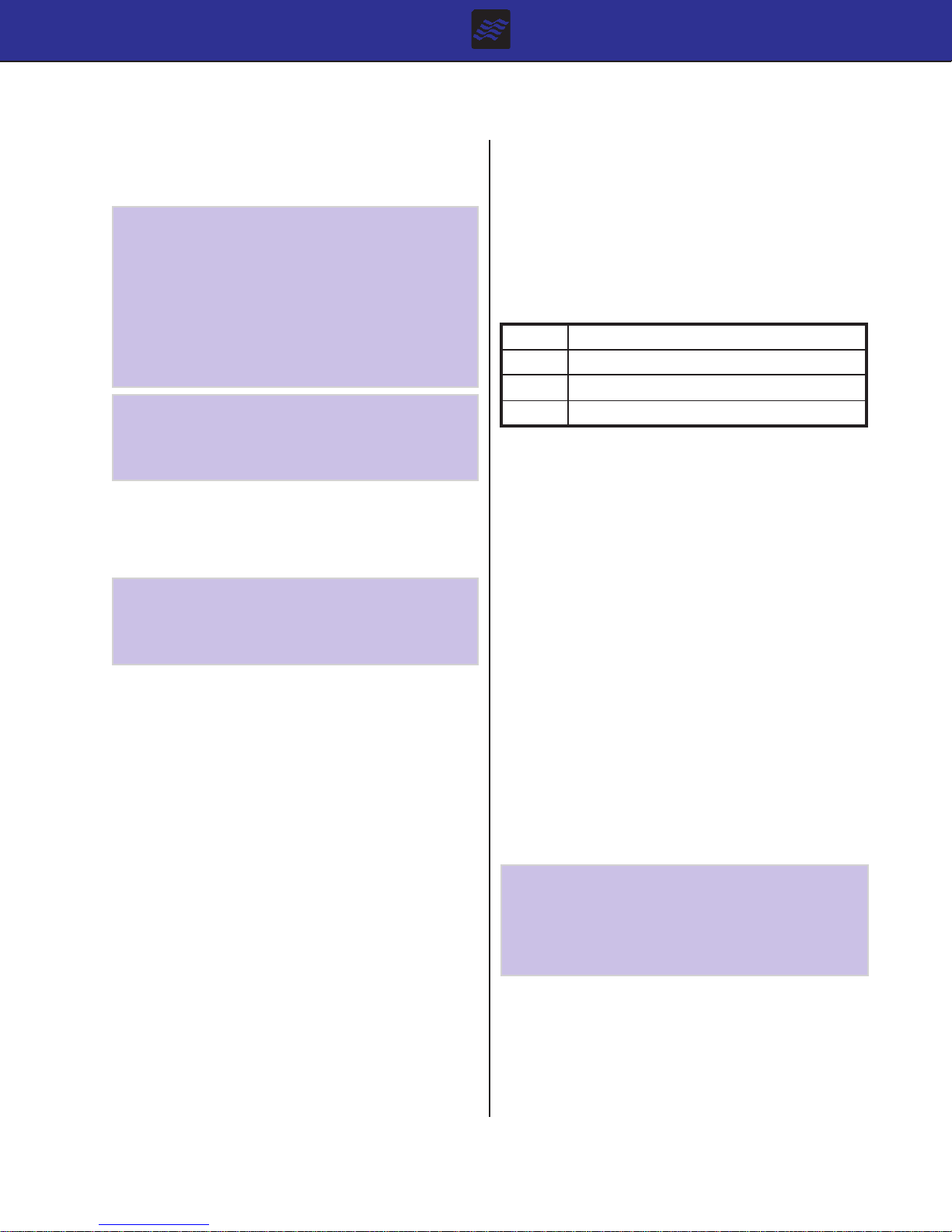

Four Winns is using a new style of instrumentation package which consists of a module similar to units used in

the automobile industry . See Figure B4. This is limited

to the 238 and 258 Vista models. The 278 Vista will

have standard instrumentation with gauges in the shroud

or dash panel.

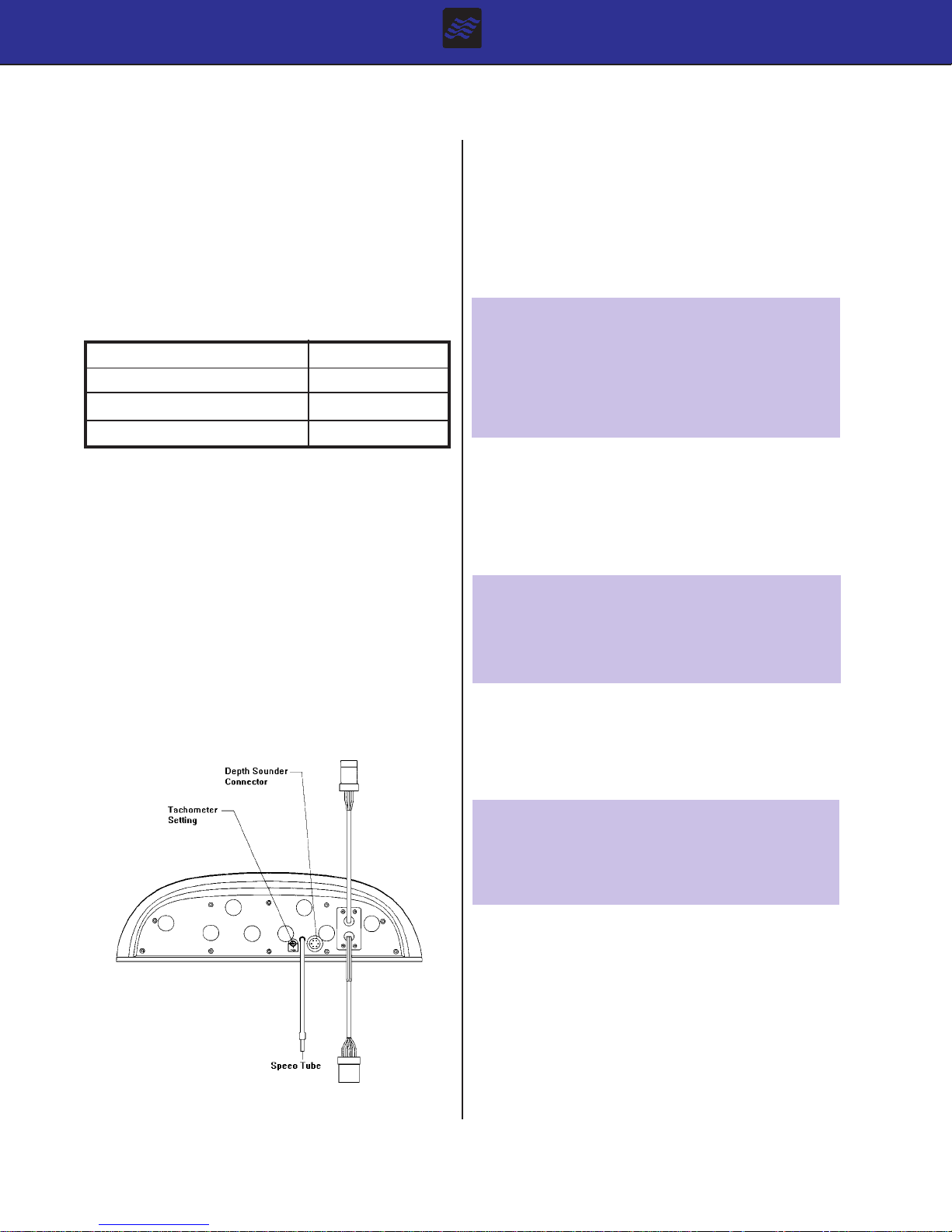

Figure B4: 238 & 258 Vista Dash Module

The following general information on gauges applies to

all Vista models.

When running at high engine speeds, be sure

the trim tabs are in the full up position. Trim tab

action should be only enough to compensate for

any listing. Trim tab adjustments at high speeds

are extremely critical. Be prepared to slow down

should handling difficulties arise.

The combination of extreme inward drive position

and extended trim tabs will cause a severe bow

down running angle. In certain sea conditions,

this will limit the operator’s control over the boat.

When running in a displacement (very slow speed) mode,

better efficiency will be obtained with the trim tabs in the

full-up position.

Vista Owners Manual

10/93

A. Tachometer

The tachometer indicates the speed of the engine in revolutions per minute (rpm). This speed is not the boat

speed or necessarily the speed of the propeller. The

tachometer may not register zero with the Ignition Key in

the OFF position.

NOTICE

Never exceed the maximum recommended

operating RPM of your engine. Maintaining maximum, or close to maximum RPM for extended

periods can reduce the life of the engine.

Section B

Page 7

Some engines are equipped with devices that limit engine rpm in accordance with the oil pressure or engine

temperature. Refer to the Engine Owners manual for

additional information.

When winterizing the boat, the speedometer tubing must

be drained of water. Disconnect the speedometer hose

at the pick-up assembly and at the gauge and blow

through the tubing to remove the water.

The tachometer must be set for different engines installed.

The tachometer setting screw or knob is located on the

backside of the gauge. See Figure B5. The tachometer

should be set according to the information in Table I.

Table I: Tachometer Adjustments

Engine Size T ach Setting

4 Cylinder 2

6 Cylinder 3

8 Cylinder 4

B. Speedometer

The speedometer is a water pressure sensitive unit. It

has a pick-up (pitot tube) assembly mounted on the transom and a small plastic hose that connects it to speedometer gauge on the dash. The pitot tube extends below

the hull. Water strikes the tube inlet and creates positive

pressure. The faster the boat speed, the greater the pressure, and the higher the speed indication on the speedometer.

If the pick-up becomes clogged, the speedometer will not

register. Clean the opening with a piece of wire or disconnect the tubing and blow out the pick-up with compressed

air

Speedometers are not precision instruments. The indications are relative and should never be used for navigational purposes or similar critical situations

NOTICE

DO NOT rely on the speedometer when trying to

achieve a “NO WAKE” condition in a harbor or

other enclosed waterway. ALWAYS reduce

throttle! Speedometers are not effective at measuring low operational speeds. Y ou are responsible for damage caused by the wake of your boat.

C. Temperature Gauge

The temperature gauge monitors the cooling system of

the engine. A sudden increase in the temperature could

be a signal of a blocked cooling passage or a water pump

malfunction.

NOTICE

Operation of an overheated engine can result in

engine seizure. If an unusually high temperature reading occurs, shut the engine off immediately.

D. Oil Pressure Gauge

The Oil Pressure Gauge indicates the pressure in the

engine lubrication system. A drop in oil pressure is a

possible indication of oil pump or leakage problems.

Figure B5: Rear View of 238 & 258 Vista Module

Vista Owners Manual

10/93

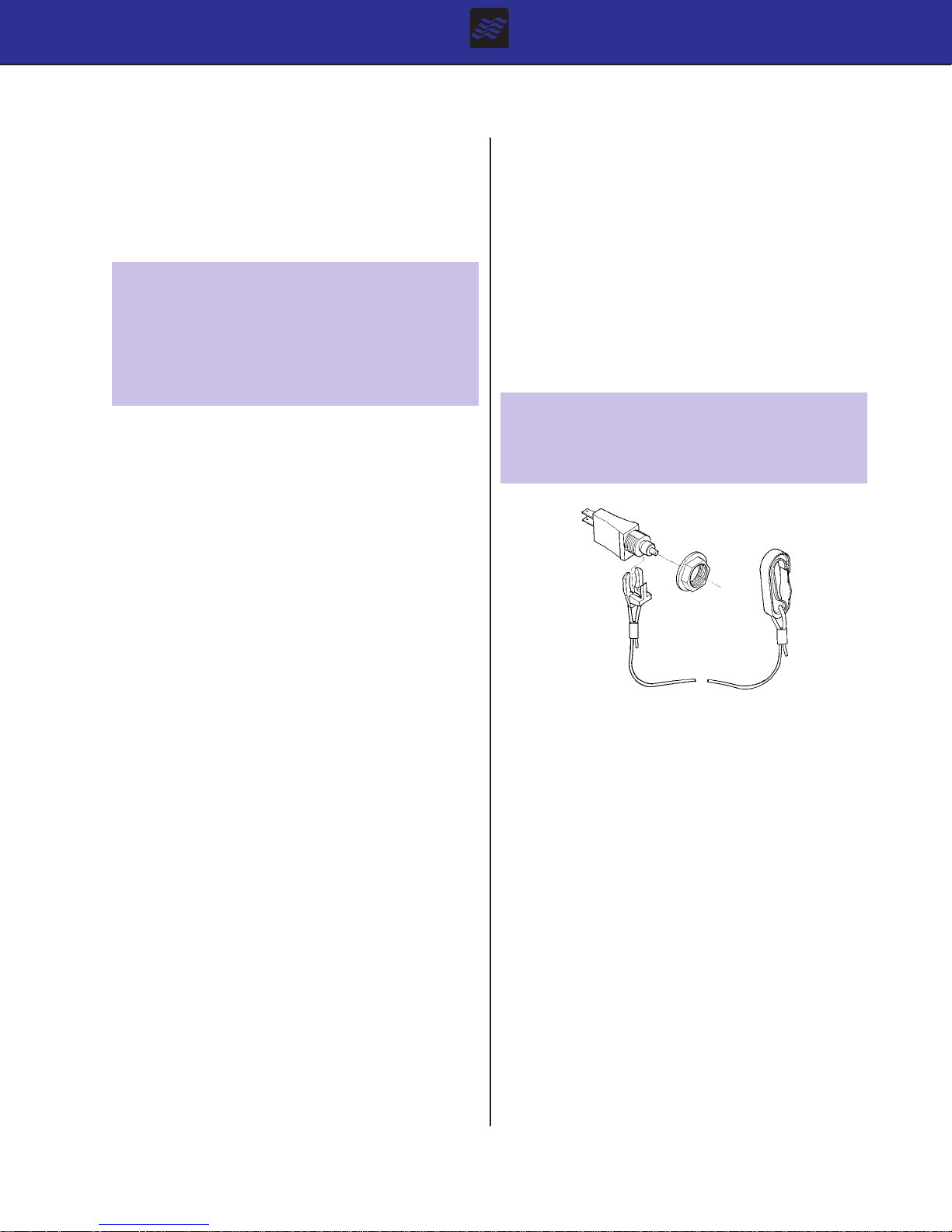

NOTICE