Operation, Maintenance &

Warranty Manual

Fountain Express Cruisers 2005-06

Operation, Maintenance &

Warranty Manual

Fountain Express Cruisers 2005-06

Record Your Boat Information Here:

Model Name:____________________________________

Serial Number:___________________________________

Date of Purchase:________________________________

Dealership:______________________________________

Record Your Engine & Drive Models Information Here:

Engine Model:___________________________________

Drive Model:____________________________________

Engine Serial Number(s):__________________________

__________________________

__________________________

Drive Serial Number(s):___________________________

___________________________

___________________________

OWNERS MANUAL 05-CRUISER MS-505 REV-0

Thank you for your purchase of what I

believe to be the finest high-performance express cruiser available. Our

racing heritage, and ongoing domination of both the offshore racing circuits

and the world speed record courses

make Fountain Powerboats the ultimate

choice for the performance boater.

Having captured Boating Magazine’s

Boat of the Year Award, our 48EC sets

the standard for performance an luxury with speeds in excess of 60

miles per hour. I take a great deal of personal pride in our boats,

and I would like to personally welcome you to the growing family of

Fountain Powerboat owners. This vessel has been delivered to you

with confidence, and it was produced using the latest techniques and

strict quality control using ISO 9001 standards.

This manual was prepared to help you understand the operation and

maintenance of your vessel so that you may enjoy many hours of

boating pleasure. Please read through this manual and view the

owner's video prior to operating your vessel.

I invite you to visit us on the web at www.fountainpowerboats.com for

parts, accessories and our award winning Fountain apparel.

Expressed Written Warranty (2005-2006 Models) 1

Specifications 10

Hull Support for Trailers & Hoists 16

Quick Reference Layout Drawings/Photos 17

Equipment, Tools, Safety Equipment and Spare Items 27

Pre-boating Checks 28

Fueling and Fuel Systems 31

Hull Technology 33

Starting and Driving, Gauges and Instruments, Controls 43

Electrical Systems and Optional Equipment 49

Appearance and Care 62

Storage 65

Maintenance and Do It Yourself 66

Accessories & Apparel 71

Refurbishment & Upgrades 72

Troubleshooting 74

Electrical Schematic Diagrams 76

Table of Contents

FOUNTAIN POWERBOATS EXPRESS LIMITED

TRANSFERABLE WARRANTY

TERM: As used in this Agreement, the term "customer" shall be

deemed to include and to mean, without limitation, "consumer" and

"purchaser," as the context may require. The consequences to, and

the obligations of, each of the parties hereto shall be the same regardless of which of the above terms is used.

Note: FAILURE BY THE CUSTOMER OR THE DEALER TO RETURN

TO FOUNTAIN AN ORIGINAL COPY OF THE WARRANTY REGISTRATION CARD, COMPLETED AND SIGNED BY THE CUSTOMER, WITHIN

THIRTY (30) DAYS FROM THE DATE OF PURCHASE BY THE CUSTOMER WILL VOID THIS WARRANTY. FOUNTAIN EXPRESSLY MAKES

THIS WARRANTY CONDITIONED ON THE RETURN OF THIS CARD TO

FOUNTAIN WITHIN THIRTY (30) DAYS OF PURCHASE. This warranty

gives the customer specific legal rights, and the customer may have other

rights. Rights varying from state to state shall be addressed by corresponding Supplemental Dealer Sales Agreements.

Fountain Powerboat Dealers are not the agents of Fountain

Powerboats, Inc. NO FOUNTAIN DEALER IS AUTHORIZED TO ALTER

THE TERMS OF THIS WARRANTY IN ANY MANNER, EXCEPT WITH

THE WRITTEN PERMISSION OF THE PRESIDENT OF FOUNTAIN

POWERBOATS, INC.. THE CUSTOMER IS ADVISED TO DEMAND A

COPY OF THIS WRITTEN CONSENT BEFORE RELYING ON ANY REPRESENTATIONS OR PROMISES THAT MAY VARY THE TERMS OF THIS

WARRANTY. Fountain Powerboats, Inc. does not authorize its dealers

or any other persons to assume for the company any liability in connection with this LIMITED EXPRESS WARRANTY or any liability or

expense incurred in the repairing or replacing of its products other

than those expressly authorized herein.

Fountain Powerboats warrants to the ORIGINAL RETAIL CUSTOMER each

new boat to be free from defects in materials and workmanship, provided

that the customer has maintained the same under normal, non-commercial

use and stored same in accordance with Fountain Powerboats' recommendations.

Except as expressly indicated below, this warranty is for a term of one (1)

year beginning with the delivery of the boat to the original retail customer.

With respect to the structural portions of the hull and deck only, this warranty is for a term of six (6) years beginning with the delivery of the boat to the

original retail customer. During this period, warranty repairs shall be made at

1

2

the selling dealer's store or service center or, at Fountain's discretion, at the

Fountain factory on Whichard's Beach Road in Washington, North Carolina.

This warranty may be transferred to a second or subsequent owner of the

boat provided that the second or subsequent owner notifies Fountain

Powerboats, Inc. in writing within thirty (30) days of the change of ownership, by way of a completed warranty registration card. A transferred warranty shall be limited in duration to the length of the original warranty period,

running from the date of delivery to the original retail customer, and the second or subsequent owners shall be required to use the boat in a non-commercial manner, and maintain and store the boat in accordance with

Fountain Powerboats' recommendations.

Transportation charges, if any, for Fountain Powerboats boats, to and from

the dealer's service center, or to and from the Fountain manufacturing plant

on Whichard's Beach Road in Washington, North Carolina, shall be the sole

responsibility of the customer. All repairs under the terms of this warranty

are subject to written authorization by factory-trained personnel whose decision shall be final.

The sales personnel or other employees of the selling Fountain dealer

are not authorized to make warranties concerning Fountain boats. No

other warranties are given beyond those set forth herein.

Please Note: In the event that a boat is on loan, has been leased, rented or continually used as a demo, the warranty will begin as soon as

one of these scenarios occurs. In the event that Fountain discovers

that this has occurred, the warranty will begin when Fountain, in its

sole discretion, has determined that the use began.

The warranty provided herein is in lieu of all other express warranties and

may not be extended or modified by anyone. Any implied warranties,

including any implied warranties of merchantability or fitness for a particular

purpose, are limited in duration to the period of the express warranty.

Repair and/or replacement is the exclusive remedy for all claims of breach

of warranty, both express and implied. Correction of non-conformities in the

manner and for the period of time as set forth above shall constitute fulfillment of all Fountain Powerboats liability to the customer whether based on

contract, negligence or otherwise. Fountain shall not be liable for incidental,

consequential or special damages, such as but not limited to, damage to or

loss of other property, equipment, loss of profits, cost of purchased or

replacement goods, or claims of persons against the original customer. The

remedies of the customer set forth herein are exclusive and the liability of

Fountain shall not, except as expressly provided herein, exceed the price of

the goods upon which such liability is based.

This warranty does not apply to the following:

1) Engines, out-drives, transmission and propellers or any other components of the powertrain or propulsion system. Custom-built Fountain

engines are also excluded from the warranty.

2) Equipment and accessories not manufactured by Fountain.

3) Cracking, crazing, discoloration or blistering of gel coat finishes, powder

coat finishes or paint finishes.

4) Carpet

5) Upholstery

6) Canvas

7) Windshield breakage, cracking or crazing.

8) Installation of engines by persons other than Fountain.

9) Costs for haul-out, launch, lift charges, towing, travel time charges, storage charges, dockage, insurance costs, and inconvenience for loss of

time or income, etc.

10) The achievement of any particular performance or fuel consumption.

11) The cost of removing or replacing defective parts.

The following voids Fountain's warranty:

1) Subjecting the boat to accident, misuse, abuse or negligence.

2) Use of the boat for racing or engaging in a contest of speed or

endurance of any type or modification of the boat in any way other than

upon express instruction by Fountain.

3) Failure to perform periodic maintenance in accordance with Fountain

recommendations.

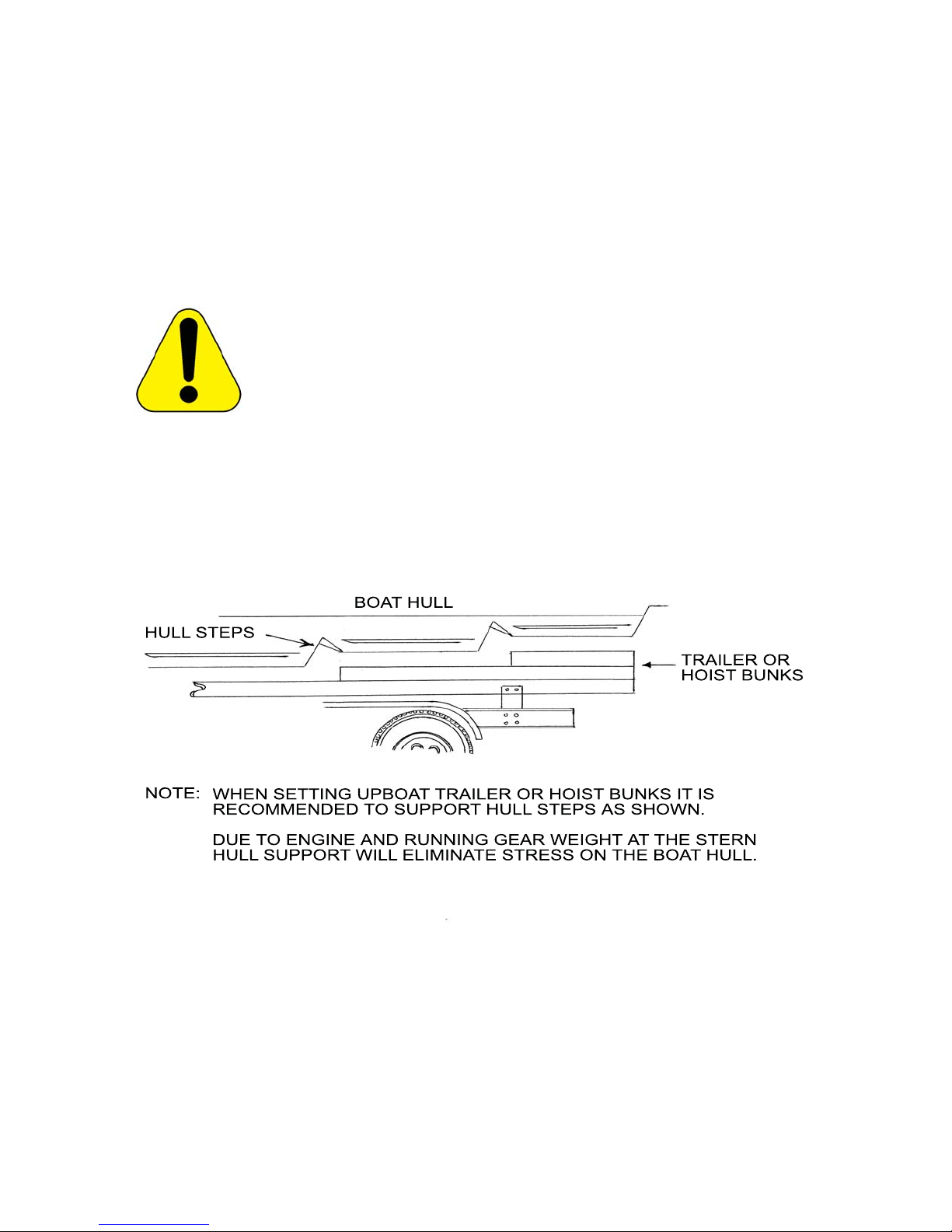

4) Damage caused by improper mating of the boat to the trailer. The

entire hull must be supported, which includes bunks that contour to

support the step hull on the entire running surface, especially directly

under the transom.

As an industry leader in research and development, Fountain Powerboats,

Inc. reserves the right to change specifications, features and prices of its

products without notification.

Warranty terms: Fountain's obligations under this express warranty and all

other implied warranties are limited solely to the repair and/or replacement

of any parts due to defective material or workmanship. The repair and/or

replacement work is to be done by an authorized Fountain dealer or by

Fountain within a reasonable time after the boat is delivered for repair. On

the day of sale, the customer and selling Fountain dealer must complete

and sign the warranty registration card, which is included with each boat.

The selling dealer must return the warranty registration card to Fountain

3

Powerboats within thirty (30) days of the date of sale. However, if the dealer fails to return the warranty registration card to Fountain within the time

period prescribed above, the customer's sole means of recovery shall be

against the Dealer.

The customer must bring the Fountain boat to the authorized servicing

Fountain dealer for such repair. No transportation charges will be paid by

Fountain to transport the boat to a dealer or the Fountain factory for repair.

Fountain is not responsible for engine removal and de-rigging. The customer must maintain the boat in accordance with commonly accepted practice and Fountain recommendations. Fountain boats are intended primarily

for normal recreational and leisure time purposes and have not been

designed or manufactured for heavy, commercial use. Therefore, Fountain

is not liable for any consequential economic or physical damage resulting

from any breach of any written or implied warranty.

Procedures for warranty repairs and replacements:

1. Upon receipt of the express limited transferable warranty card, a

Fountain representative will be contacting you to determine where your

boat shall be serviced, should the need arise.

2. You will then be assigned an authorized servicing center to perform

your warranty work.

3. Should you wish or need to take your Fountain boat to a different

authorized servicing center for warranty work, please contact the

Fountain Customer Service by the methods described below.

4. The Fountain boat must be returned to the authorized servicing dealer

who has the primary responsibility to perform warranty repairs. In the

event the servicing dealer has ceased to do business, or you are traveling or have moved to a different locale, work under the warranty may

be performed by any authorized Fountain dealer provided you have

pre-authorization from the factory. Except in the specific instances just

stated, your warranty work should be done by the authorized servicing

Fountain dealer. ANY AND ALL SERVICE QUESTIONS AND/OR

REQUESTS MUST BE MADE BY PHONE TO 252-975-2000 OR 252975-1132 OR BY MAIL TO FOUNTAIN'S PROPER MAILING

ADDRESS AS FOLLOWS:

Fountain Powerboats, Inc.

Attention: Customer Service

P.O. Box 457

Washington, NC 27889

4

5. The authorized servicing Fountain dealer will examine the boat to determine if, in its opinion, a warrantable defect exists. The servicing

Fountain dealer shall then report to Fountain whether a warrantable

defect appears to exist. Fountain, at its option and sole discretion, will

repair or authorize repair and/or replacement of all parts that are found

to be defective. For repairs performed other than at the Fountain factory in Washington, North Carolina, an authorization form will have to be

issued prior to any work performed. Prior written authorization from

Fountain is required. You will be asked to sign a warranty form to

assure Fountain that the warranty work has actually been performed to

your satisfaction.

Limitation on implied warranties:

ALL IMPLIED WARRANTIES, INCLUDING THE IMPLIED WARRANTIES

OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE,

ARE LIMITED TO THE DURATION OF THIS EXPRESS WRITTEN LIMITED WARRANTY AND, LIKE THE EXPRESS WRITTEN WARRANTY, ARE

LIMITED TO REPAIR AND/OR REPLACEMENT AS THE SOLE MEANS

OF RECOVERY IN THE CASE OF BREACH.

Exclusion or limitation of damages:

Fountain will not be liable (a) for personal injury or property damage except

personal injury or property damage caused by Fountain's negligence; (b)

FOR ANY CONSEQUENTIAL ECONOMIC DAMAGES, DAMAGES TO

PROPERTY, DAMAGES FOR LOSS OF USE, LOSS OF TIME, LOSS OF

PROFITS, OR INCOME, OR ANY OTHER INCIDENTAL DAMAGES, OR

FOR ANY DAMAGES REGARDLESS OF THEIR NATURE CAUSED BY

THE CUSTOMER'S AND OR DEALER'S FAILURE TO FULFILL THEIR

RESPONSIBILITIES AS SET FORTH HEREIN.

IT IS EXPRESSLY UNDERSTOOD AND AGREED TO BY FOUNTAIN, THE

SELLING DEALER AND THE CUSTOMER, THAT ANY DISPUTE ARISING UNDER THE TERMS OF THIS WARRANTY WILL BE GOVERNED

BY THE APPLICABLE LAWS OF THE STATE OF NORTH CAROLINA

AND, EXCEPT WHERE SPECIFICALLY PROHIBITED OR LIMITED BY

THE LAWS OF A PARTICULAR STATE, THAT FOR ANY DISPUTE ARISING UNDER THIS WARRANTY, THE PROPER FORUM WILL BE THE

COURTS OF BEAUFORT COUNTY, NORTH CAROLINA OR, WHERE

APPROPRIATE, THE FEDERAL DISTRICT COURT FOR THE EASTERN

DISTRICT OF NORTH CAROLINA.

Note: Some states do not allow limitations as to the court in which a dis-

pute may be resolved, so the foregoing provision may not apply in all cases.

5

This limited warranty, along with the Dealer Sales Contract, constitute the

entire agreement and understanding between the customer and Fountain

with respect to the purchase and sale of boats. No agreement or statement

not contained in these agreements shall be binding upon Fountain as warranty or otherwise, and neither this limited warranty nor the Sales Contract

shall be modified or amended unless it is in writing, executed by the

President of Fountain Powerboats and the customer. The foregoing terms

and conditions shall prevail notwithstanding any contrary terms and conditions of any other submitted by the customer for the boats. In the event that

any of the above provisions should be held void by a state's court, all other

warranty provisions shall remain intact.

IMPORTANT SAFETY INSTRUCTIONS

W

ARNING

1. Read the owners manual and watch the owner's video prior to operating the boat to understand and comply with systems and safety rules.

2. Always check your gas gauge before leaving the dock.

3. Consult your engine information packet for recommendations and specifications concerning fuels, lubrication, and boat & engine service intervals.

4. Do not smoke while refueling. Fuel is very flammable.

5. Always maintain proper safety equipment before leaving the dock,

including, but not limited to an anchor, anchor line, at least one life vest

per person on board, a throw cushion with a 20' rope attached, a ships

bell, fire extinguisher, first aid kit, signal kit, spare oil, spare transmission fluid, and an assortment of miscellaneous tools.

6. Always check fluid levels and do an overall general inspection of the

engine compartment prior to starting the engines.

7. Change the oil and filters after every 20-30 hours of operation to help

prevent engine damage.

6

8. Always monitor water pressure gauges. Loss of water pressure

increases engine temperature and can cause severe damage to the

engine(s).

9. Always monitor oil pressure gauges. If the oil pressure drops, severe

engine damage could occur.

10. Check all bilge pumps before each outing, and before leaving your boat

moored to be sure they are fully functional, both in automatic and manual modes.

11. Do not leave the boat unattended or uncovered for long periods of time,

or leave attached to mooring buoys in foul weather. Excess rain or

high winds may cause sinking. Once bilge pumps run down the battery, bilge pumps will no longer operate and the boat will sink if water

continues to enter the boat.

12. Review the performance report for proper trimming of the boat. Tests

are based on calm water operations. Rougher water requires substantially different trim as shown in the owner's video manual. Usually as

the water gets rougher, the tabs will need to go down and the drives will

need to go in.

13. Always operate the blowers for at least 5 minutes before starting the

engine(s) to insure that all gas fumes are removed. Gas fumes are

heavier than air, and must be forced out of the bilge area.

14. Check the warning buzzer for sound to insure proper working order of

this warning device.

15. Always start the boat with the drives and tabs in the down position.

16. Always start the boat with the shifters in the neutral position.

17. Always allow the engine to idle in the neutral position, and to attain normal operating temperature before shifting gears to prevent engine and

gear damage.

18. Do not launch the boat if the drain plug is not installed.

19. Always wear your safety lanyard while under way.

20. Never trim the outdrive(s) out past 5.5 while on plane, and never independently trim the outdrives to allow more than 2 marks of trim separa-

7

tion between the drives on the trim indicators.

21. Never trim the outdrive(s) in past 3 while on plane.

22. Always check forward visibility before getting on plane.

23. Always slow down before turning the boat.

24. Turning maneuvers are safer if done in calm water. Fast turns in any

conditions are dangerous.

25. Always look to the rear before turning. It is important to know what is

around you at all times.

26. Do not operate the boat so that it leaves the water. It may harm the

passengers. It will also cause over-rev related damage to the engine

and/or outdrives, as well as undue stress on the boat and it's internal

components.

27. Always be smooth, gentle and even with the throttles.

28. Never operate the boat at speeds that are beyond your capability, or the

capabilities of the boat.

29. Always check oil and fluids after use. See engine manual for fluids and

fluid levels.

30. Passenger safety is the boat owner/operators responsibility. Stop the

engines before using the transom area as a swim platform or when

swimmers are present in the area.

31. Do not operate this boat while under the influence of alcohol or drugs.

Alcohol and drugs severely reduce the ability to react, especially in several different situations at once. Alcohol and drugs lead to incorrect

judgments of speed, distance and direction. Alcohol and drugs reduce

vision and the ability to fully comprehend emergency situations.

32. Always wash and flush engine(s) after use to keep corrosion damage to

a minimum especially in using the boat in salt water.

33. Always be sure to support the bottom of the boat, including directly

under the transom, when storing and/or trailering to prevent damage to

the bottom of the boat.

8

34. Review the engine owner's manual for care and maintenance of your

engine(s).

35. THIS IS NOT AN EXHAUSTIVE LIST. Always use common sense

when operating your boat and seek proper guidance from qualified

mechanics when making repairs.

By signing this warranty card the customer acknowledges that he or she 1)

has viewed the Fountain Video Owner's Manual, 2) fully understands safe

boating operation and every aspect of his/her Fountain boat. The customer

also verifies that he/she has reviewed the Fountain performance report with

the dealer and understands the proper trim settings for tabs and drives for

all speeds, in all conditions, and while turning. The customer also verifies

that the dealer has fully demonstrated this boat to him/her on the water and

has demonstrated all systems and proper trimming of the drives and trim

tabs for all sea conditions. The customer acknowledges that he/she has

been informed of all potential hazards which can occur while boating. The

customer also acknowledges that this boat should not be operated if any of

the following are true: a) rough water, b) he/she is under the influence of

drugs or alcohol, c) in severe weather, darkness, fog or low visibility. The

customer acknowledges that he/she should wear their safety lanyard and

life vest at all times and never turn the boat at an unsafe speed. The customer also acknowledges that he/she has read, understands, and agrees to

abide by all of the important safety information on this warranty card.

This warranty registration must be completed and received by Fountain

Powerboats within 30 days of purchase. Failure to do so will result in the

warranty beginning on the date of delivery to the selling dealer. By signing,

customer acknowledged having read and understood Fountain's Boat

Warranty.

9

38 Express Cruiser

LOA: 37'11" / 11.55 m

Beam: 10'6" / 3.19 m

Weight, Dry: 13,500 lbs / 6179 kgs

Fuel Capacity: 270 gallons / 1021 L

Cabin Headroom: 6'4" / 1.98 m

Draft with drives down: 38" / .95m

Deadrise: 22 degrees

Sleeping Capacity: 4

Bridge clearance with arch 9' / 2.73m

Twin 496 Mag HO w/ Bravo One drive 60+ mph or

Twin 315 HP Yanmar Diesel w/ Bravo One drive 49 mph

Standard Equipment

Aft cabin w/twin bed & comforter

Anchor, custom polished stainless steel, integrated, w/windlass

Anchor locker

Automatic Fire Suppression System

Batteries, (2) w/switches, custom heavy duty mounting brackets and

battery charger (30 AMP)

Bilge Pumps (2) 1200 GPH

Bilge Blowers (2)

Bimini, w/front, side and aft enclosure

Bolster, Electric side-by-side at helm

Cabin Interior w/Dark Cherry Wood Trim

Cabin lighting

Cabin sofa

Carbon monoxide detector

Cleats, heavy duty 8"

Cockpit carpet

Cockpit table (removable)

Compass, electronic

Cooler storage area

Courtesy lights in cockpit

Cup holders in cockpit

Custom Fountain logo in red w/gold bolt

Dash w/Full instrumentation, depth gauge & Electronics area

Dockside pressure water hook-up

10

Specifications

Engine hatch, motorized

Engine room lights

Fender storage

Forward cabin w/V-berth w/comforter & pillows, dresser and hanging

closet

Fresh water, 50 gallon w/hot water heater

Fuel tanks, heavy duty, baffled, 3/16" thick aluminum; foamed,

glassed and bolted in position w/stainless steel pickups, 270 gallon

total capacity

Galley w/sink, microwave & refrigerator/freezer

Hanging locker, cedar lined

Head, enclosed fiberglass, vacu-flush, stand up w/shower

Horns, electric

Hot water heater, 6 gallons

Navigation lights

Positive lift hull, twin step, Generation III

Radar arch w/cockpit lighting

Reading lights in forward and aft cabins

Shore power

Steering, heavy duty hydraulic w/dual pumps

Stereo w/CD and remote

Swim platform w/transom shower, & swim ladder

TV/VCR combination

Table in cabin, removable

Throttle w/drive trim on handle

Trim tab indicators, mechanical

Trim tabs, heavy duty hydraulic, offshore hi-performance

Wet bar in cockpit w/Storage, pressurized sink & ice maker

Windlass

Windshield, wrap-around

11

Specifications

12

Specifications

48 Express Cruiser

LOA: 48'4" / 14.72 m

Beam: 12' / 3.66 m

Weight, Dry: 22,000 lbs / 9988 kgs

Fuel Capacity: 457 gallons / 1729 L

Draft with drives down: 46"

Deadrise: 22 degrees

Cabin Headroom: 6' 5"

Sleeping Capacity: 4

Fresh Water Capacity: 80 gal

Holding Tank Capacity: 36 gal

Recommended Power: Triple 440 HP Yanmar Diesel with Twin Disc

Surface Drives - 60+ mph

Standard Equipment

A/C & heat w/ shore power & battery charger

Aft cabin w/queen berth, comforter and closet

Air Vents, Integrated

Anchor locker

Anchor, custom polished stainless steel, integrated, w/windlass

Arch, Radar (forward facing)

Automatic fire suppression system

Batteries (4) w/switches

Battery Charger, 30 Amp

Battery boxes (4) w/custom heavy duty brackets

Bilge blowers (2)

Bilge pumps (2), 2000 GPH each

Bilge pumps, (2) water puppy style to totally dry bilge, 750 GPH each

Bimini, w/front, side and aft enclosure

Blower, exhaust in head, (2)

Bolster, electric side by side at helm

Cabin lighting

Cabin sofa, wrap around

Carbon Monoxide detector

Canvas enclosure, full rear (requires fuel vapor detector)

Cigarette lighter/Chart light

Cleats, (8) SS and (2) 8" pop up SS

Cockpit carpet

Cockpit table, (removable)

Compass, electronic

Cooler storage area under wet bar

Courtesy lights in cockpit

Cup holders in cockpit

Dash w/Full instrumentation, depth gauge & Electronics area

Depth gauge

Dockside pressure water hook-up

Engine hatch, motorized, hydraulic

Engine mounts, rubber isolated

Engine room lights

Fender storage

Forward cabin w/ king berth, comforter, pillows, w/dresser & cedar

lined hanging closet

Fresh water, 72 gallons

Fuel tanks, (3) heavy duty, baffled, 3/16" thick aluminum; foamed,

glassed and bolted in position w/stainless steel pickups, 457 gallons

total capacity

Fuel vapor detector

Galley sink

Gauges, Livorsi & GPS Speedometer

Generator 6.5 KW

Generator, diesel (7.6 KW)for diesel boats only

Head, enclosed fiberglass, vacu-flush, stand up shower

Holding tank, 36 gallons

Horns, electric

Hour meter

Ice maker in wet bar (cockpit)

Kiekhaefer throttles w/drive trim on throttles

Microwave oven

Navigation lights

Non-skid walk around

Positive lift hull, twin step generation 3

Propellers, (3) 5 or 6 blade stainless steel

Radar arch w/cockpit lighting

Rear lounge seating

Refrigerator w/freezer compartment

Rub rail w/ stainless steel insert

Seating, 12-14 in cockpit

Shore power, (2) 50 Amp

13

Specifications

Steering, heavy duty hydraulic w/dual pumps

Stereo w/CD and remote (3)

Stovetop w/two burners

Sun deck, expandable by raising power rear seating

Swim ladder

Swim platform

Table in cabin, removable

TV, plasma w/ DVD player (2)

Transom shower, hot/cold

Trim tabs, heavy duty

Trim indicators, mechanical, and trim switches on dash for both

drives and tabs

Vac-u-flush head, (2) w/dockside pumpout - (2) 18 gallon holding

tanks

Water heaters, (2) 11 gallon

Wet bar in cockpit w/storage, pressurized sink and ice maker

Windshield, wraparound

14

Specifications

15

Specifications

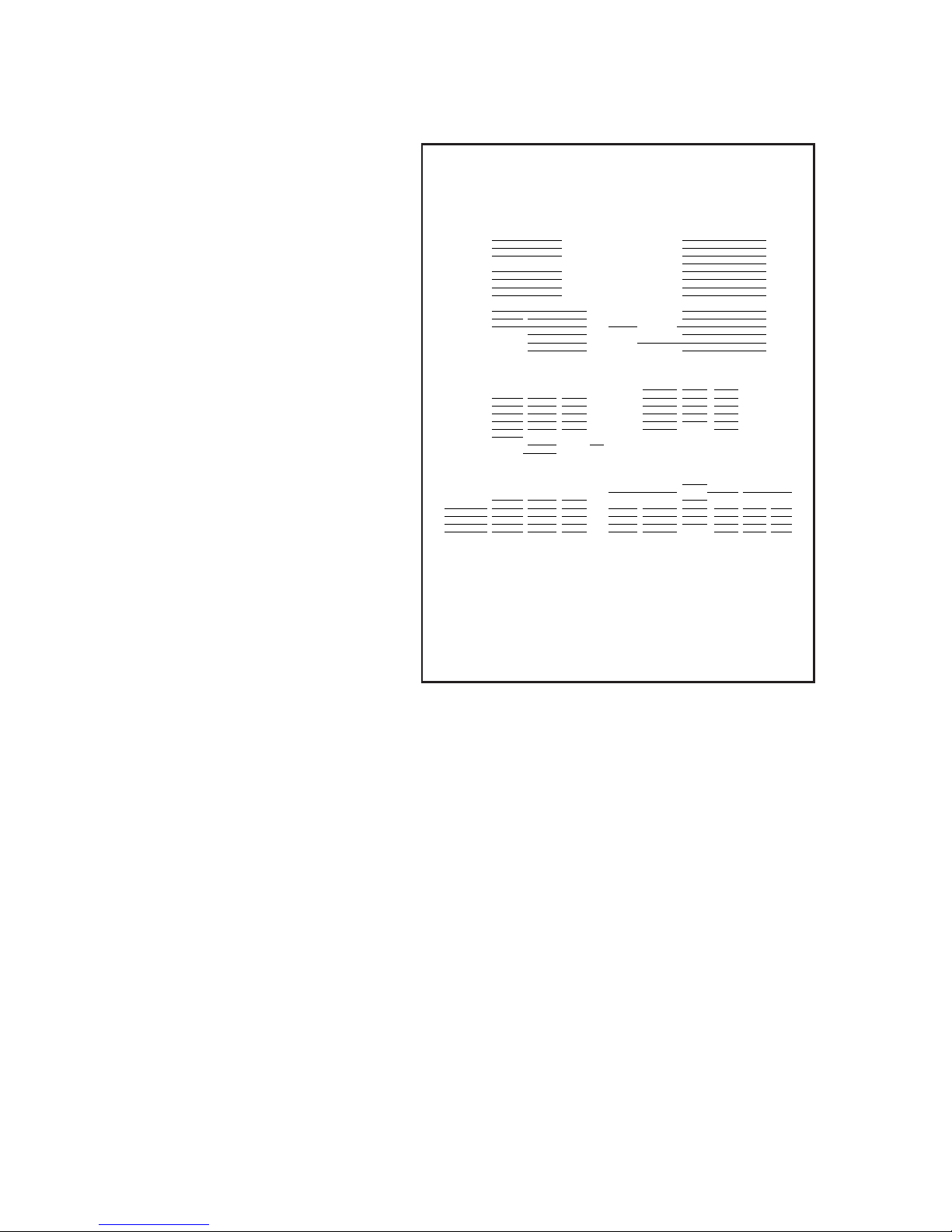

Performance Report:

Each Fountain Powerboat is

water tested prior to delivery.

This test information is

recorded on the

Performance Report, and

this report is provided with

every new boat purchase.

Use your performance report

to see the optimum performance obtained on your boat

at the factory, and as a reference for initial trim settings

at various engine RPM and

boat speeds.

BE ADVISED THAT THESE PERFORMANCE FIGURES ARE

MERELY AN ESTIMATE, NOT A GUARANTEE, OF WHAT YOU

MAY EXPECT BASED ON OUR FACTORY TESTING PROGRAM.

THE ABOVE LISTED SPEEDS ARE VERIFIED BY RADAR OR

GPS OR BOTH WITH ONE TEST DRIVER AND LESS THAN FIFTY

GALLONS FUEL LOAD. THIS BOAT SPEED CAN VARY

DEPENDING ON LOADED WEIGHT, FUEL LOAD, NUMBER OF

PASSENGERS, AIR, TEMPERATURE, ALTITUDE, HUMIDITY,

BAROMETRIC PRESSURE, WATER CONDITIONS, WIND, ENGINE

TUNING, HORSEPOWER VARIANCE FROM ENGINE TO ENGINE,

PROPELLERS, AND NUMEROUS OTHER FACTORS BEYOND

OUR CONTROL. THE SPEED VARIANCE CAN BE UP TO 4% OF

THE TOP SPEED.

S

D

FOUNTAIN POWERBOATS

PERFORMANCE REPORT

Date: 3/24/2004

Time: 3:15PM Wind: 5MPH

Test Driver: Water: CALM

Boat Dealer: Serial No.: 385XX

Address: Weight: 9007

City & Zip: Customer:

Phone: Phone:

ENGINES: 525 EFI MERCRUISER

Port Serial# 0M9059XX

OUTDRIVES: BRAVO 1 XR Ratio: 1.5:1 Prop: 2 32 MERC

TRANSOM PLATES: BRAVO 1 XR X Dimension 27 1/2 X 19 1/2

RPM: 850 700 5350 850 700 5350

Oil Pres: 50 30 40 50 30 40

Oil Temp: 140 220 195 140 # 220 195

Water Temp: 130 165 160 130 165 185

Volts: 13 14 14 13 14 14

Fuel Total: 100 Gal.

Vacuum in Gear at RPM: in Inches:

Depth Guage reads to 60 MPH

SPEEDO @WOT 90mph

0 to Plane Port Stbd Stbd. Port Stbd.

RPM: 3000 44 2 3 16 16 20 25

RPM: 4000 64 3 3 35 35 31 32

RPM: 3850 60 3 3 33 33 25 30

WOT:5350 90 4 2 45 45 45 50

WOT: Wide Open Throttle

WARNING--DO NOT TRIM DRIVE BEYOND 5 ABOVE 1200 RPM

*SUPERCHARGER ONLY

**BE ADVISED THAT THESE PERFORMANCE FIGURES ARE MERELY AN ESTIMATE, NOT A GUARANTEE, OF WHAT YOU MAY EXPECT BASE

ON OUR FACTORY TESTING PROGRAM. THE ABOVE LISTED SPEEDS ARE VERIFIED BY RADAR OR GPS OR BOTH WITH ONE TEST DRIVER

AND LESS THAN FIFTY GALLONS FUEL LOAD. THIS BOAT SPEED CAN VARY DEPENDING ON LOADED WEIGHT, FUEL LOAD, NUMBER

OF PASSENGERS, AIR, TEMPERATURE, ALTITUDE, HUMIDITY, BAROMETRIC PRESSURE, WATER CONDITIONS, WIND, ENGINE TUNING,

HORSEPOWER VARIANCE FROM ENGINE TO ENGINE, PROPELLERS, AND NUMEROUS OTHER FACTORS BEYOND OUR CONTROL.

THE SPEED VARIANCE CAN BE UP TO 4% OF THE TOP SPEED.

0W2151XX

Port Serial # 0W1500XX Stbd Serial # 0W1500XX

ENGINE GAUGE READINGS

Port Engine

Cold Hot WOT Cold Hot WOT

PERFORMANCE READING

MPH Drives Tabs Vacuum/Boost* Port Water Press.

Temperature: 65

Outboard Rotation

Stbd Serial # 0M9056XX

Stbd Serial # 0W2149XX

Starboard Engine

Fuel Press.*

Note: When setting up boat trailer or hoist bunks, it is recommended

to support hull steps as shown.

Hull support at the stern is essential due to the weight of the

engine(s) and running gear.

Incorrect hull support can have serious negative effects

on the running surface of the boat by introducing either

hook or rocker; damage to the strakes, steps or pad

areas; or in extreme instances can cause severe structural damage to the hull both externally and internally.

16

Hull Support

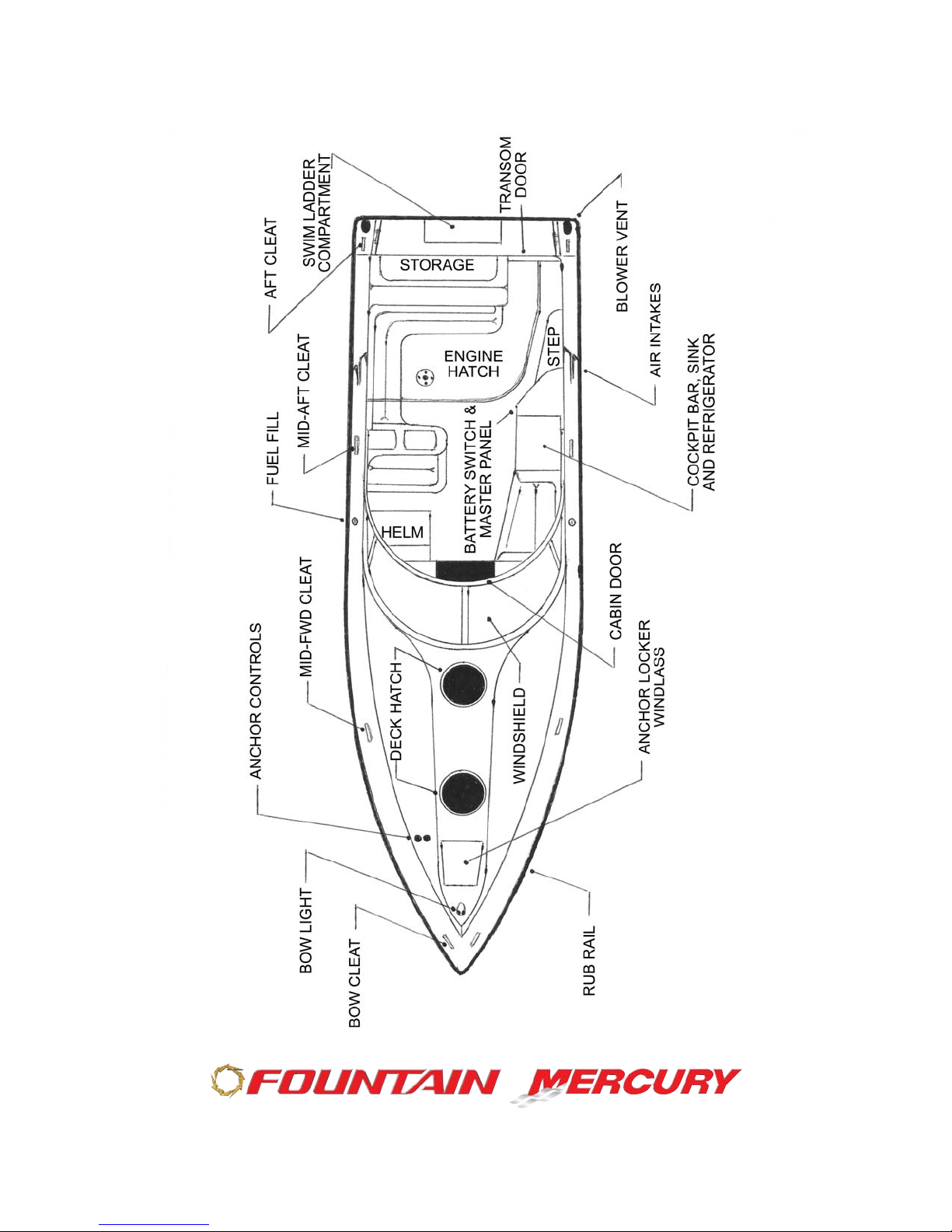

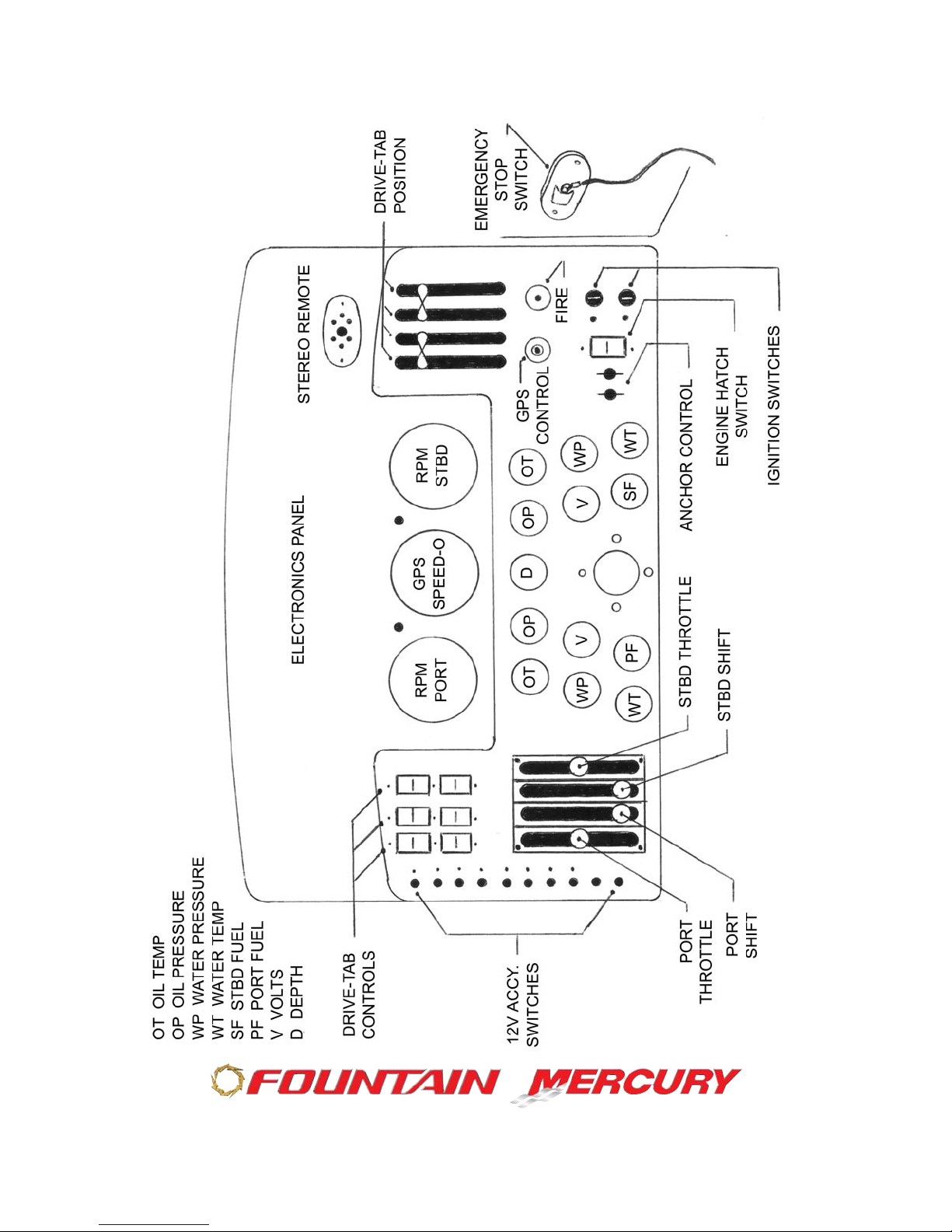

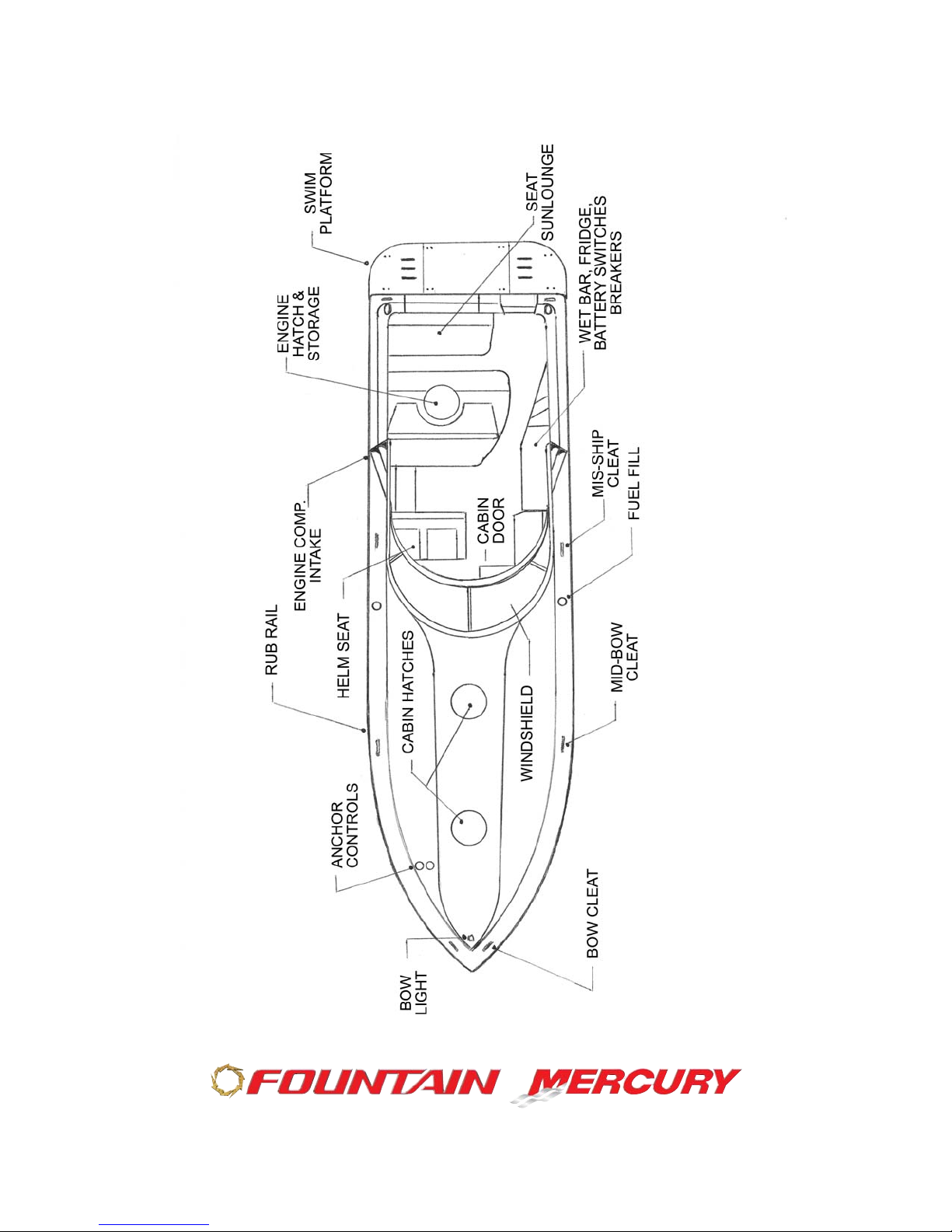

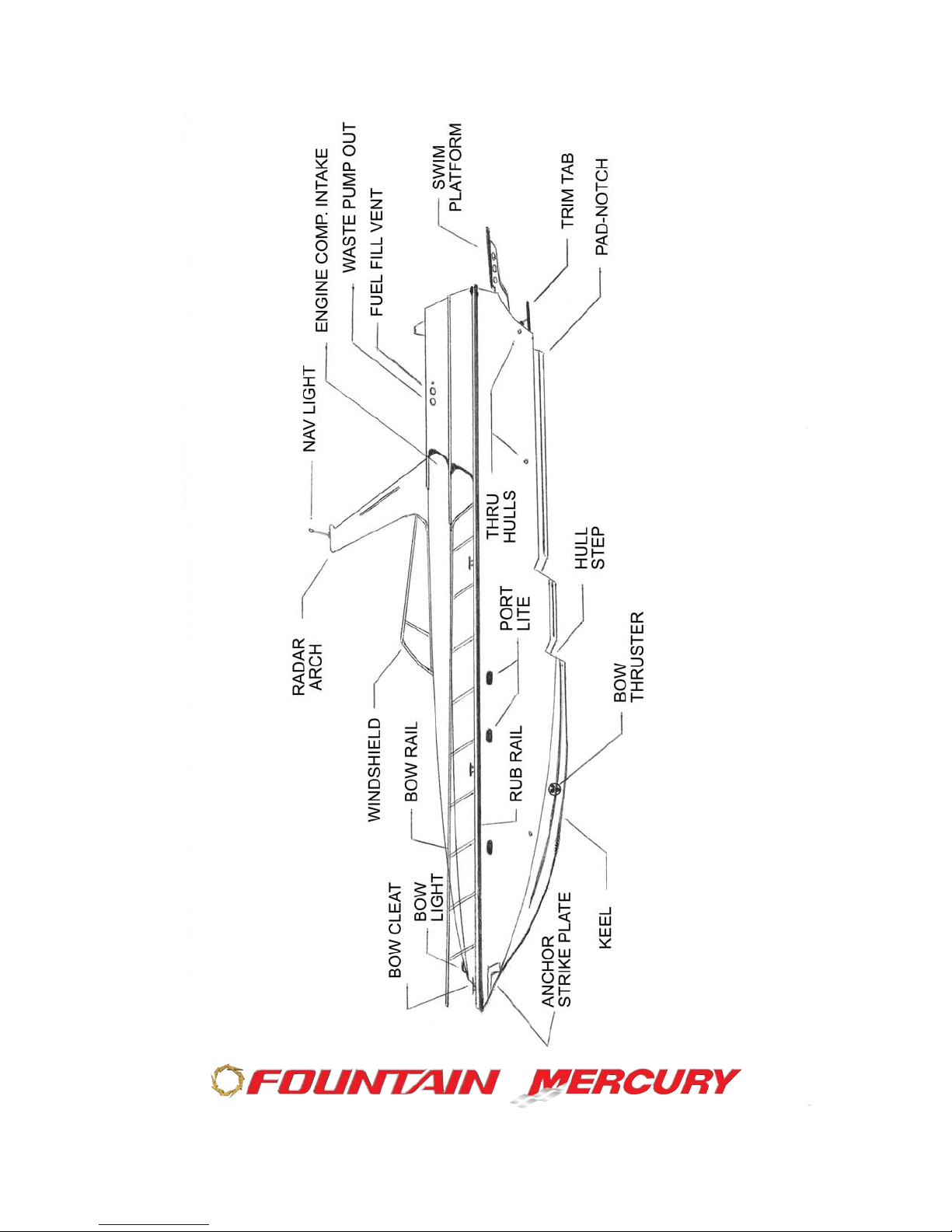

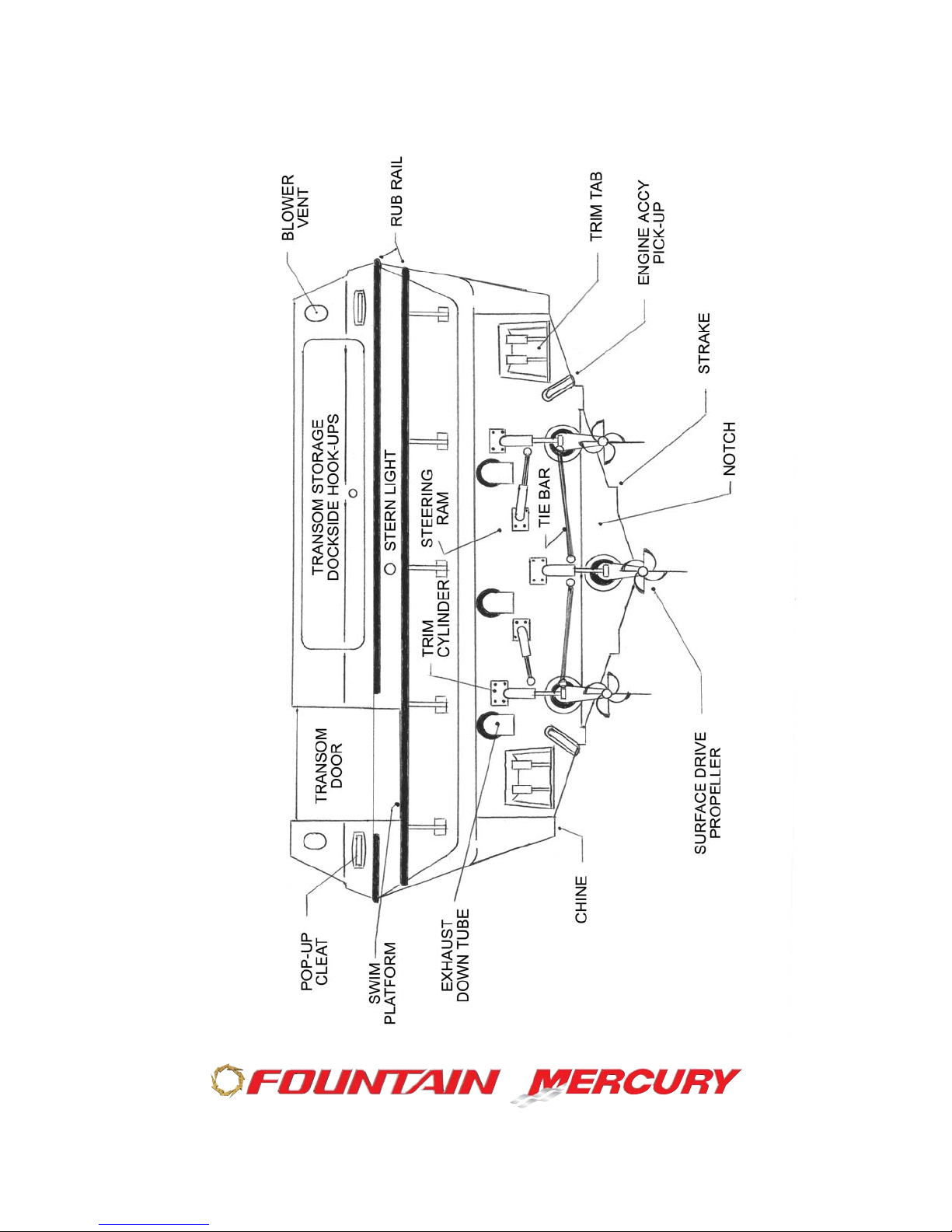

Quick Reference Drawing

17

38 Express Cruiser

Quick Reference Drawing

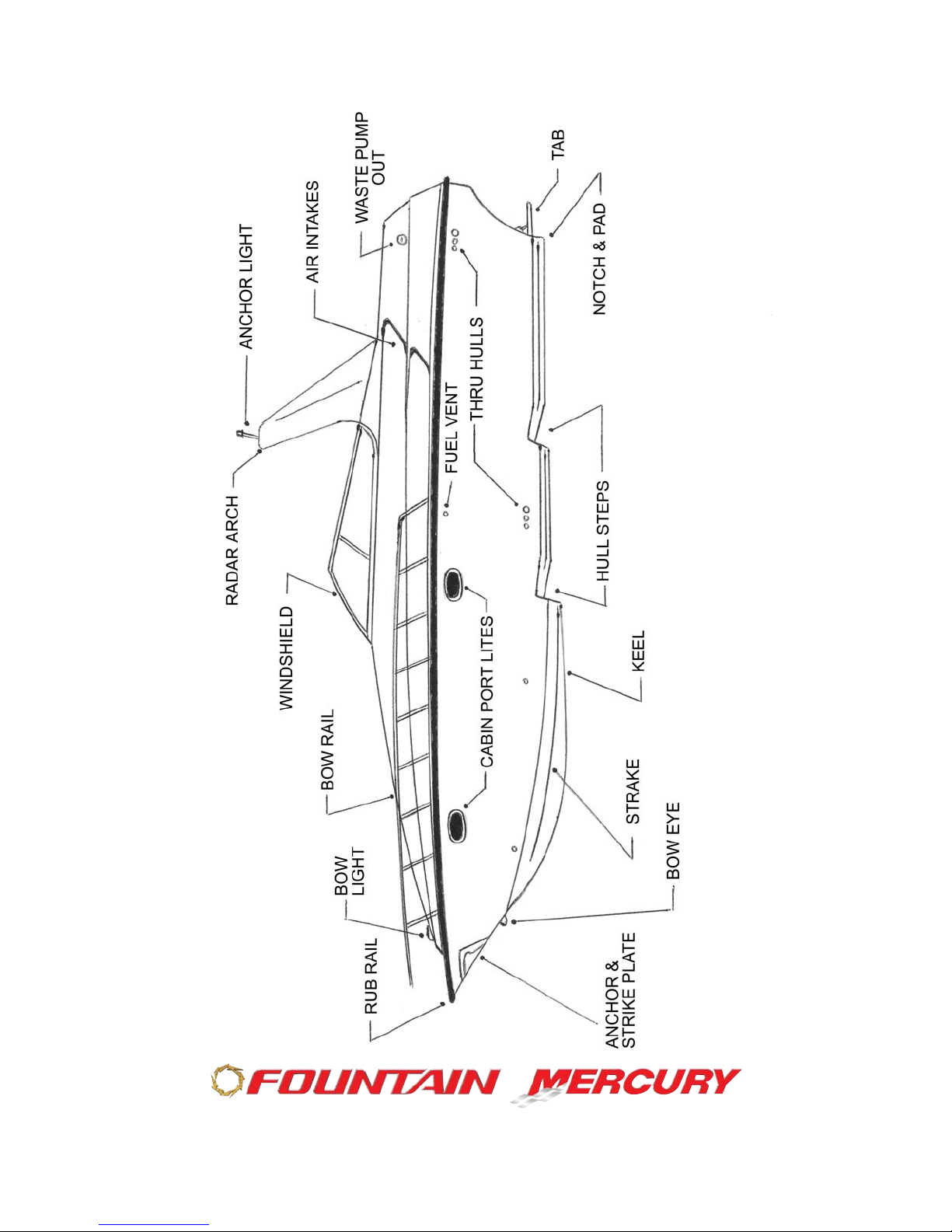

18

38 Express Cruiser

Quick Reference Drawing

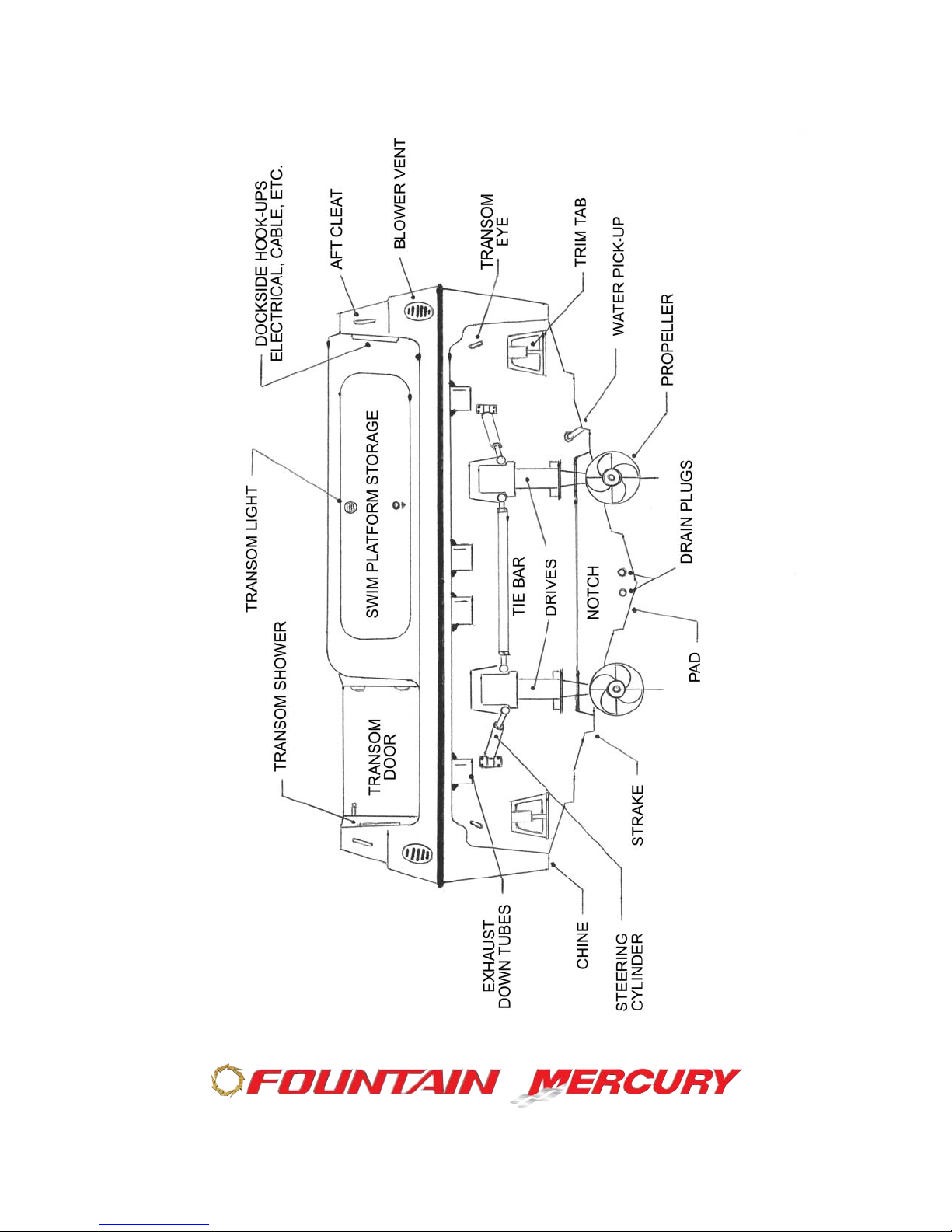

19

38 Express Cruiser

Quick Reference Drawing

20

38 Express Cruiser

Quick Reference Drawing

21

38 Express Cruiser

Quick Reference Drawing

22

48 Express Cruiser

Quick Reference Drawing

23

48 Express Cruiser

Quick Reference Drawing

24

48 Express Cruiser

Quick Reference Drawing

25

48 Express Cruiser

Quick Reference Drawing

26

48 Express Cruiser

27

Equipment, Tools, Safety Equipment and Spare Items

These items are recommended to carry on your vessel for maintenance or

minor trouble. Safety equipment for some items is required by law.

Tool Chest

Screwdriver (Phillips & Flat blade)

Pliers (Regular, Channel Loc, Vice Grip)

Wrench Set (Open End, Box, Allen, Adjustable, Propeller Wrench)

Socket Set (Metric & Standard)

Hammer

Jumper Cables (Standard Jumper plug cables provided with vessel)

Electrical Tape

Assorted Fasteners (Cable Ties, Electrical Connectors, Crimping tool,

Screws, Nuts, Etc.)

Grease Gun and Oils

Safety Equipment

Fire Extinguishers (Type ABC)

Personal Flotation Devices (Life jackets, 1 per person)

Throwable Flotation Device

Signaling Device (Ships Bell or Horn)

VHF Radio

First Aid Kit

Flashlight and Batteries

Anchor and Line

Dock Lines

Appropriate Charts for your Cruising Area

Miscellaneous Items

Spare Propellers (Thrust washers, Prop nuts and Lock washers)

Extra Engine Belts

Engine Oil (Recommended mfg weights)

Fuel and Oil Filters

Replacement Light Bulbs

Extra Spark Plugs

Assorted Fuses

We recommend that you strongly consider membership in a national

towing service. This can dramatically reduce your costs of any towing

service if it is ever needed on your vessel.

See Quick Reference Drawings for locating equipment and accessories

Before launching vessel, perform a visual inspection. Walk around,

check hull and deck for any damage from trailer or docking, from the

road or from your last trip. Check for damaged propellers and oil

leaks from lower units, steering hoses, steering rams and trim tabs.

Do not launch or run the vessel until questionable damage is

repaired.

If boating at night, check navigation lights for proper operation.

a Open engine hatch and visually check bilge floor for

leaking fluids, oil, and coolant or steering fluid. Find

the source of any leak and repair as necessary.

a Check drive and tab pump fluid levels, fill as neces-

sary.

a Check engine fluid levels (crankcase oil level,

coolant if the engine is closed-water cooled, power

steering fluid), and fill as necessary.

a Check for bad hoses or belts and replace as neces-

sary.

a Check blower and bilge pump operation.

a Check below water line. Check hoses at pickups

and thru hulls for looseness or damage.

Replace, repair or tighten as needed.

a Check below waterline, hose pick-ups and

through-hulls for looseness or damage. Replace,

repair or tighten as necessary.

Check water tanks (fill for trip). Empty holding tank for trip.

28

Pre-Boating Checks

29

Pre-Boating Checks

Make sure hull drain plug(s) are installed and tight,

(located at the bottom of boat hull under the notch at the

keel). FAILURE TO PROPERLY INSTALL THE DRAIN

PLUG(S) MAY RESULT IN THE BOAT SINKING.

Note: 48 Express Cruisers are not equipped with removable

drain plugs.

Now, you can safely launch your vessel and tie it to the dock.

Perform the following in-water checks prior to departure:

Engine hatch open, check for any water leaks. Locate source of

leak, repair or have repaired as necessary. (Note: bilge pumps will

handle some water automatically or manually.)

Fuel System

Everyone who owns or operates a boat must practice fire safety.

Each year, boat fires and explosions injure hundreds of individuals

and cause millions of dollars in property damage. Many of these

accidents can be prevented.

Be alert to your boat's fuel system. Over time, fuel fittings and hoses

wear out. Inspect these fittings and hoses regularly, especially near

the engine where heat and vibration can accelerate deterioration.

Schedule regular engine and exhaust system maintenance

inspections by experienced and trained technicians.

Inspect fuel systems annually, particularly hoses, connections

and tank surfaces. Use only USCG-approved fuel hoses.

Before fueling, shut down engines and auxiliary equipment and

all electrical equipment. Also, close hatches and doors on board.

Do not allow equipment or gear to contact fuel system compo-

nents. Monitor side storage areas where fill and vent hoses are

located.

Do not store portable fuel tanks in enclosed areas, including

engine room compartment (even though it may be "ventilated").

Ensure that all blowers and hoses are operational and intact.

Verify good airflow at the vent on the boat.

Take a boating safety course and learn the correct type and use

of a fire extinguisher aboard the boat. Have the appropriate fire

extinguisher on board at all times.

Make sure your passengers know the location of all fire extin-

guishers on board.

30

Pre-Boating Checks

Fueling Procedure as Follows:

Refer to the owner's manual for your engines to determine the appropriate fuel grade for use in your boat.

a Close all fuel valves and shut off battery

switches before fueling.

a Do not smoke.

a Fill fuel tanks desired through proper fills. Tanks are as full as

possible if fuel comes out of the vents. (Note, hose off boat of spilled

fuel, and let the boat air out as necessary to eliminate any fuel

vapors.)

a Open desired valve(s) for tank(s) you wish to run. Check bilge by

smell for leaks or fumes. Turn off valve(s) if any leaks are present,

repair or have repaired immediately. See engine compartment reference drawing for location.

a Operate the bilge blowers for at least 4 minutes before starting

your inboard or sterndrive engine.

31

Fueling

BE SURE TO CONFIRM DIESEL OR GASOLINE

PRIOR TO FILLING YOUR BOAT WITH FUEL.

CROSS-CONTAMINATION OF GASOLINE OR

DIESEL FUEL CAN DAMAGE YOUR ENGINE, AND

MAY VOID YOUR WARRANTY

Warning: Fuel is a dangerous explosion

and fire hazard. No smoking or sparks

during fueling operations.

Warning: Do not start engine(s); turn on

batteries, or electrical devices if fuel leaks

or fumes are present.

32

Fueling

33

Hull Technology

HULL STEP TECHNOLOGY HAS CHANGED THE WAY WE NEED

TO DRIVE!

WHILE SMOOTH OPERATION HAS ALWAYS BEEN THE KEY TO

SAFE HIGH SPEED OPERATION, BEING SMOOTH AND USING

COMMON SENSE IS EVEN MORE CRITICAL WITH TODAY’S

FASTER, MORE TECHNOLOGICALLY ADVANCED HULL

DESIGNS.

THE NEW TECHNOLOGY HAS ALLOWED LARGER, LONGER,

HEAVIER BOATS TO TRAVEL AT MUCH FASTER SPEEDS, WITH

STANDARD HORSEPOWER. THE SIMPLE FACT IS THAT

THINGS HAPPEN MUCH FASTER AT HIGHER RATES OF

SPEED, AND LARGER BOATS SIMPLY CARRY MORE ENERGY

ONCE IN MOTION.

INCORRECT TRIM SETTINGS OR IRRATIC TURNING MANEUVERS, WHILE STILL DANGEROUS AT SLOW SPEEDS, CAN BE

DISASTROUS AT HIGH SPEEDS.

AT HIGHER RATES OF SPEED, THERE IS LITTLE OR NO WARNING BEFORE THE BOAT REACTS TO RAPID TURNS OR INCORRECT AND/OR ABRUPT TRIM CHANGES.

COMMON SENSE IS YOUR BEST DEFENSE!

NONE OF US WOULD TAKE A NEW CORVETTE OUT, RUN IT UP

TO 60MPH, GRAB THE WHEEL AND MAKE AN ABRUPT 180

DEGREE TURN ON THE WHEEL. THE SAME CONCEPT

APPLIES TO BOATS.

KNOW YOUR LIMITATIONS, AS WELL AS THE LIMITATIONS OF

THE EQUIPMENT, AND DRIVE WITHIN THEM.

34

Hull Technology

IMPORTANT TERMINOLOGY

NEGATIVE TRIM

NEGATIVE TRIM

NEUTRAL TRIM

NEUTRAL TRIM

POSITIVE TRIM

POSITIVE TRIM

NEGATIVE TRIM

NEGATIVE TRIM

NEUTRAL TRIM

NEUTRAL TRIM

POSITIVE TRIM

POSITIVE TRIM

Thrust Angle

Negative Trim

CG

Thrust Angle

Negative Trim

CG

Thrust Angle

Negative Trim

CG

Neutral Trim

Thrust Angle

CG

Neutral Trim

Thrust Angle

CG

Neutral Trim

Thrust Angle

CG

Positive Tri m

CG

Thrust Angle

Positive Tri m

CG

Thrust Angle

Positive Tri m

CG

Thrust Angle

TABS OR DRIVES

TRAILING EDGE

BELOW THEORETICAL

RUNNING SURFACE

TRANSOM LIFT –

BOW DOWN

TABS OR DRIVES IN-

LINE WITH THE

THEORETICAL RUN-

NING SURFACE

NO LIFT

TABS OR DRIVES

TRAILING EDGE

ABOVE THEORETICAL

RUNNING SURFACE

BOW LIFT –

TRANSOM DOWN

KEY TECHNOLOGY POINTS

STEPS CHANGE THE ANGLE OF ATTACK, CHANGING PERCEIVED

NEUTRAL TRIM SETTINGS.

STEPS CONTROL PRESSURE.

STEPS ALLOW LOWER DRIVE ANGLES WHICH FOCUS 100% OF THE

THRUST AT PUSHING THE BOAT, RATHER THAN USING THRUST TO

CHANGE THE ANGLE OF ATTACK.

WATER PRESSURE MOVES FORWARD ALONG THE HULL, NOT

BACKWARD. THINK OF STEPS AS A HORIZONTAL STRAKE.

A NEGATIVE TRIM SETTING UPSETS THE PRESSURE ON THE HULL

CREATING A POTENTIALLY UNSTABLE SITUATION AT HIGHER SPEEDS.

THE PAD CREATES A STABLE PLATFORM FOR THE BOAT TO RIDE ON AT

SPEED, AND ACTS AS A WIDE STRAKE.

A NOTCH ALLOWS FOR HIGHER DRIVE PLACEMENT AND IMPROVED

PROPELLER EFFICIENCY FOR EXCEPTIONAL HIGH AND LOW SPEED

PERFORMANCE.

Perceived Angle of Attack

2.00°

THE “TRUE” BOTTOM OF A STEP

BOTTOM BOAT IS THE IMAGINARY

SURFACE CREATED BY RUNNING A

LINE FROM THE FORWARD STEP TO

THE TRANSOM AT THE KEEL.

STEPS EFFECTIVELY “LOWER” THE

TRANSOM THEREBY CHANGING THE

NATURAL ANGLE OF ATTACK.

STEP BOTTOM BOATS RUN BEST IN A

NEUTRAL TRIM POSITION DUE TO THE

NATURAL ANGLE OF ATTACK AND THE

REDUCED SUFRACE ADHESION

CREATED BY THE STEPS.

• TRADITIONAL BOTTOM KEEL LINE

• STEP BOTTOM KEEL LINE

• TRADITIONAL BOTTOM KEEL LINE

• STEP BOTTOM KEEL LINE

35

Hull Technology

CG

TRADITIONAL V-BOTTOM TECHNOLOGY

CG

TRADITIONAL V-BOTTOM TECHNOLOGY

STEP-BOTTOM TECHNOLOGY

A V-BOTTOM BOAT RUNS MAXIMUM SPEEDS WITH MINIMAL HULL CONTACT. HULL

CONTACT WITH WATER CREATES ADHESION.

A TRADITIONAL V-BOTTOM BOAT REQUIRES A GREAT DEAL OF POSITIVE TRIM TO

AFFECT A MODERATE RELEASE OF HULL CONTACT WITH THE WATER.

POSITIVE TRIM USES HORSEPOWER TO CARRY THE BOW OF THE BOAT AT THE

PROPER ANGLE OF ATTACK, AS WELL AS PROPEL IT THROUGH THE WATER.

A TRADITIONAL V-BOTTOM RUNNING AT MAXIMUM SPEEDS HAS VERY LITTLE HULL

CONTACT FORWARD OF THE BALANCE POINT, THEREFORE IN ORDER TO TURN THE

BOAT, IT MUST BE SET BACK INTO THE WATER, USUALLY BY MOVING THE TRIM

INTO A NEGATIVE POSITION.

THE “TRUE” BOTTOM OF A STEP

BOTTOM BOAT IS THE IMAGINARY

SURFACE CREATED BY RUNNING A

LINE FROM THE FORWARD STEP TO

THE TRANSOM AT THE KEEL.

STEPS EFFECTIVELY “LOWER” THE

TRANSOM THEREBY CHANGING THE

NATURAL ANGLE OF ATTACK.

STEP BOTTOM BOATS RUN BEST IN A

NEUTRAL TRIM POSITION DUE TO THE

NATURAL ANGLE OF ATTACK AND THE

REDUCED SURFACE ADHESION

CREATED BY THE STEPS.

A STRAKE IS A STEP THAT RUNS

PARALEL TO THE KEEL, WHICH BREAKS

THE SURFACE TENSION OF THE WATER

FLOWING OVER IT. AT SUFFICENT

SPEED, THIS BREAK CHANGES THE

RUNNING SURFACE ALLOWING THE

HULL TO RELEASE AND RIDE UP TO THE

LEVEL OF THE STRAKE.

36

Hull Technology

A STEP ACTS AS A HORIZONTALLY

POSITIONED STRAKE, WHICH BREAKS

THE SURFACE TENSION OF THE WATER

FLOWING OVER IT.

THIS BREAK ALLOWS THE BOAT TO

MAINTAIN MINIMUM SURFACE ADHESION

WHILE MAINTAING THE PROPER ANGLE

OF ATTACK AND DRIVE THRUST ANGLE.

A STRAKE IS A STEP THAT RUNS

PARALELL TO THE KEEL, WHICH

BREAKS THE SURFACE TENSION OF THE

WATER FLOWING OVER IT. AT

SUFFICENT SPEED, THIS BREAK

CHANGES THE RUNNING SURFACE

ALLOWING THE HULL TO RELEASE AND

RIDE UP TO THE LEVEL OF THE STRAKE.

PAD KEELPAD KEEL

A PAD KEEL IS A WIDE STRAKE,

THAT PROVIDES THE SAME BREAK

IN PRESSURE AND ADHESION AS

TRADITIONAL STRAKES.

THE TRADITIONAL V-BOTTOM

MAINTAINS THE SAME “HIGH” DEAD

RISE ANGLE FROM THE STRAKE TO

THE KEEL. THE PAD KEEL IS A 12”-

15” “PLATFORM” AT A LOWER DEAD

RISE ANGLE THAN THE HULL.

THE PAD KEEL PROVIDES THE

ULTIMATE RUNNING SURFACE FOR

THE KEEL AT EXTREEM SPEEDS,

PROVIDING INCREASED STABILITY

AND A REDUCED TENDANCY TO

“CHINE WALK”.

A STEP ACTS AS A HORIZONTALLY

POSITIONED STRAKE, WHICH BREAKS

THE SURFACE TENSION OF THE WATER

FLOWING OVER IT.

THIS BREAK ALLOWS THE BOAT TO

MAINTAIN MINIMUM SURFACE ADHESION

WHILE MAINTAINING THE PROPER

ANGLE OF ATTACK AND DRIVE THRUST

ANGLE.

A PAD KEEL IS A WIDE STRAKE,

THAT PROVIDES THE SAME BREAK

IN PRESSURE AND ADHESION AS

TRADITIONAL STRAKES.

THE TRADITIONAL V-BOTTOM

MAINTAINS THE SAME “HIGH” DEAD

RISE ANGLE FROM THE STRAKE TO

THE KEEL. THE PAD KEEL IS A 12”15” “PLATFORM” AT A LOWER DEAD

RISE ANGLE THAN THE HULL.

THE PAD KEEL PROVIDES THE

ULTIMATE RUNNING SURFACE FOR

THE KEEL AT EXTREME SPEEDS,

PROVIDING INCREASED STABILITY

AND A REDUCED TENDANCY TO

“CHINE WALK”.

A STRAKE IS A STEP THAT RUNS

PARALLEL TO THE KEEL, WHICH

BREAKS THE SURFACE TENSION OF THE

WATER FLOWING OVER IT. AT

SUFFICENT SPEED, THIS BREAK

CHANGES THE RUNNING SURFACE

ALLOWING THE HULL TO RELEASE AND

RIDE UP TO THE LEVEL OF THE STRAKE.

TRADITIONAL

TRANSOM

•

REPRESENTS FLOW OF WATER OVER PROPELLER

37

Hull Technology

NOTCHED TRANSOMNOTCHED TRANSOM

GENERALLY SPEAKING, A HIGHER XDIMENSION, UP TO A REASONABLE

LIMIT, REPRESENTS INCREASED TOP

END PERFORMANCE BY REDUCING

HYDRODYNAMIC DRAG CREATED BY

THE SUBMERGED GEAR CASE.

THE TRADE-OFF IS THAT WITH A

HIGHER X-DIMENSION COMES POOR

LOW SPEED PERFORMANCE CREATED

BY AIRIATION OF THE PROPELLER.

A NOTCHED TRANSOM HAS THE SAME

EFFECT AS A “STAND-OFF BOX” WHICH

ALLOWS A HIGHER X-DIMENSION

WHILE MAINTAINING NON-AIRIATED

WATER FLOW TO THE STERNDRIVES

AT LOWER OPERATIONAL SPEEDS.

AS THE BOAT MOVES FORWARD, THE DISPLACEMENT OF THE HULL CAUSES WATER

TO FLOW BACK AND UP FROM THE TRANSOM OVER THE STERNDRIVES. AS THE

BOAT SPEED INCREASES, THE UPWARD ANGLE OF THIS WATER FLOW DECREASES

AS THE BOAT PLANES OFF, APPROACHING ZERO DEFLECTION (NO UPWARD

TRAVEL).

THE NOTCHED TRANSOM HAS INCREASED WATER FLOW OVER THE STERNDRIVES

AT LOWER SPEEDS THAN THE TRADITIONAL TRANSOM, THEREBY INCREASING

PROPELLER EFFICENCY, ESPECIALLY IN HIGH X-DIMENSION APPLICATIONS.

THE INCREASED EFFICENCY RESULTS IN FASTER TIME ON PLANE, LITTLE OR NO

PROPELLER CAVITATION AT LOW SPEEDS, AND INCREASED THROTTLE RESPONSE.

NOTCHED TRANSOMNOTCHED TRANSOM

NOTCHED

TRANSOM

38

Hull Technology

TURNING SET-UP:

AVOID HIGH SPEED TURNS EXCEPT IN EMERGENCIES

REDUCE THROTTLES TO ALLOW FOR ACCELLERATION IF NEEDED

REDUCE DRIVES TO NO LESS

THAN NEUTRAL (TYPICALLY 3)

LOWER TABS TO 4 – 4 ½ DEPENDING ON WATER CONDITIONS

MAINTAIN MAXIMUM

RADIUS TURN FOR THE SITUATION. DO NOT TURN

MORE SHARPLY THAN NECESSARY

MAINTAIN SMOOTH, GRADUAL TURN – NO SHARP OR ABRUPT

MOVEMENTS OF THE WHEEL

FEEL CLOSELY FOR ANY INDICATION OF LOSS OF “TRACTION” IN TURN.

IMMEDIATELY REDUCE RATE OF TURN AND OR THROTTLE

ACCORDINGLY.

TURNING SET-UP:

AVOID HIGH SPEED TURNS EXCEPT IN EMERGENCIES

REDUCE THROTTLES TO ALLOW FOR ACCELLERATION IF NEEDED

REDUCE DRIVES TO NO LESS

THAN NEUTRAL (TYPICALLY 3)

LOWER TABS TO 4 – 4 ½ DEPENDING ON WATER CONDITIONS

MAINTAIN MAXIMUM

RADIUS TURN FOR THE SITUATION. DO NOT TURN

MORE SHARPLY THAN NECESSARY

MAINTAIN SMOOTH, GRADUAL TURN – NO SHARP OR ABRUPT

MOVEMENTS OF THE WHEEL

FEEL CLOSELY FOR ANY INDICATION OF LOSS OF “TRACTION” IN TURN.

IMMEDIATELY REDUCE RATE OF TURN AND OR THROTTLE

ACCORDINGLY.

HIGH-SPEED OPERATION

(Refer to the Performance Report)

DRIVES @ 4 ½ - 5 ½ TO WOT

TABS @ 2 ½ - 2 ¾ FOR SMOOTH CONDITIONS

MORE TAB FOR ROUGHER CONDITIONS UP TO 4 ½ TYPICAL MAXIMUM

TYPICAL ROUGH WATER SET UP: TABS @ 4 & DRIVES @ 4

Smooth WaterSmooth WaterSmooth Water

Rough WaterRough WaterRough Water

39

Hull Technology

Thrust Angle

CG

TURNING A STEP BOTTOM BOAT

“TRADITIONAL” TURNING TECHNIQUES ARE THE BASIS FOR

MOST INCIDENTS INVOLVING STEP BOTTOM BOATS.

TRADITIONAL V-BOTTOMS REQUIRE GREATER POSITIVE TRIM TO

ATTAIN TOP SPEEDS, AND TRADITIONALLY OPERATORS APPLY

NEGATIVE TRIM TO BRING THE BOAT BACK INTO CONTACT WITH

THE WATER PRIOR TO TURNING.

NEGATIVE TRIM WHILE TURNING A STEP BOTTOM BOAT CAN

CAUSE SEVERE AND VIOLENT SPIN-OUTS.

NEUTRAL TRIM

WHEN THE BOAT IS TRIMMED IN THE NEUTRAL POSITION,

PRESSURE, AND THEREFORE CONTACT, IS FOCUSED AROUND

THE CENTER OF GRAVITY AND TOWARD THE TRANSOM.

CONSISTANT HULL CONTACT IS MAINTAINED FROM THE

FORWARD STEP TO THE TRANSOM PROVIDING A STABLE

RUNNING PLATFORM.

THE TURNING FULCRUM WILL TYPICALLY BE LOCATED AROUND

THE HIGHEST AREA OF HULL CONTACT PRESSURE.

Thrust Angle

CG

+ ---+++++++-

FULCRUM

40

Hull Technology

NEGATIVE TRIM TRANSITION

AS THE TRIM ANGLE MOVES TO THE NEGATIVE POSITION

CREATING AN UPWARD THRUST ANGLE ON THE TRANSOM, HULL

PRESSURE IS MOVED FROM THE TRANSOM OF THE BOAT

TOWARD THE BOW.

HULL CONTACT PRESSURE BEGINS TO MOVE FORWARD OF THE

CENTER OF GRAVITY (CG).

AS THE PRESSURE MOVES FORWARD WITH CONTINUED

NEGATIVE TRIM, THE TURNING FULCRUM MOVES FORWARD OF

THE CG.

Thrust Angle

CG

+++++--- ---

FULCRUM

NEGATIVE TRIM EFFECT

CONTINUED NEGATIVE TRIM WILL ULTIMATELY MOVE THE

MAJORITY OF THE HULL CONTACT PRESSURE COMPLETELY

FORWARD OF STEPS.

HULL CONTACT PRESSURE IS NOW SIGNIFICANTLY FORWARD

OF THE CENTER OF GRAVITY (CG).

IN THE CASE OF A STEP BOTTOM BOAT, THE HULL OF THE

BOAT AFT OF THE CG NOW HAS LITTLE OR NO CONTACT

PRESSURE AND THE TURNING FULCRUM IS NOW

SIGNIFICANTLY FORWARD OF THE CG.

Thrust Angle

++++++------

CG

FULCRUM

41

Hull Technology

NEGATIVE TRIM EFFECT

Thrust Angle

++++++------

CG

FULCRUM

TURNS AT VARIOUS SPEEDS

ASIDE FROM LOW SPEED OPERATION, AND

PARTICULARLY IN BOATS WITH LARGER STEPS,

THERE IS NO REASON TO LOWER THE DRIVES TO LESS

THAN NEUTRAL WHEN TURNING.

REMEMBER, ON A STEP BOTTOM BOAT AT SPEED,

LOWERING THE DRIVES BELOW NEUTRAL CHANGES

THE THRUST ANGLE IN SUCH A WAY AS TO CHANGE

THE PRESSURE ON THE STERN SECTION OF THE BOAT,

CAUSING A LOSS OF ADHESION, AND CREATING AN

UNSTABLE CONDITION THAT IS EXAGGERATED

DRAMATICALLY WHEN TURNING.

WITH THE FULCRUM, OR PIVOT POINT FORWARD OF THE CG, A

VERY UNSTABLE SITUATION IS CREATED. THIS SITUATION

CAN BECOME DISASTEROUS IN A TURN AS THE LEVERAGE

CREATED BETWEEN THE TRANSOM OF THE BOAT AND THE

FULCRUM IS GREATEST.

THIS IS COMBINED WITH THE DECREASED HULL PRESSURE

AFT OF THE CG.

THE RESULT IS AN IMMEDIATE AND VIOLENT TENDANCY TO

SPIN-OUT.

42

Hull Technology

TRIM TO MAINTAIN DIRECT LINE OF THRUST (NEUTRAL

AS MINIMUM SETTING).

MAINTAIN CONTINUOUS HORIZON POSITIONING. IF YOU

LOOSE THE HORIZON, YOU ARE LIKELY TRIMMED TOO

HIGH.

USE COMMON SENSE & DISCRETION.

NEVER MAKE ABRUPT MANEUVERS OR TRIM CHANGES.

FEEL CLOSELY FOR ANY INDICATION OF LOSS OF

“TRACTION” IN A TURN. IMMEDIATELY REDUCE RATE OF

TURN AND/OR THROTTLE ACCORDINGLY.

DRIVE WITHIN YOUR ABILITIES, AND WITHIN SAFETY

PARAMETERS.

SUMMARY

Leave engine hatch door open before you begin starting procedures.

Familiarize yourself with the dashboard, side panel, gauges, switches

and controls.

Turn on your battery switches to the desired

positions. (Port, (Center), Starboard, 1-2 or All)

Battery Switches are located under the cockpit

sink unit. (“Both” & “Parallel” link all of the batteries in Parallel. This will utilize all of the batteries

for engine starting; however, a single “bad” battery could cause the others to drain.)

On gasoline powered boats, locate blower toggle switch on left hand

side of dashboard, above the throttle/shifter quadrant. Flip on blower

switch, red indicator light will illuminate. (Blowers are running) Run

blowers for at least five (5) minutes before starting engines. Diesel

powered boats may or may not have engine compartment blowers.

Note: Blowers should be run until vessel is under way.

Make sure shift handles on quadrant

(shifters are the shorter handles) are centered in the slot, as felt by a detente click.

Note: Engines will not start if the shifters

are not completely in the neutral position.

Make sure the throttle on quadrant (throttles are the taller handles)

are all the way down in the slot. Note: most modern marine engines

are fuel injected, and therefore do

not need to be pumped up and

down to start and idle the motors.

43

Starting, Driving Gauges, Controls

Blower Switch Throttle/Shifter

Quadrant

Make sure safety switch is armed

(Gasoline Engines Only). This switch

should have the lanyard on the toggle

and be attached to the driver for safety.

Note: The engines will not run unless

this switch is in the run position.

Trim drive(s) to the in position before

starting the engine(s).

Locate the ignition key switches at the lower dashboard. Insert keys into switches. Turn each to the

on position only (one click to the right-clockwise).

Indicator lights and audible alarms will sound for a

moment to indicate that systems are operational.

Note: Fire system light will stay on until key switch is

turned off. With the keys in this position (engines

cold) the only gauges that should indicate are the

fuel and volt gauges.

Turn key(s) to the full right start position until the engine starts, and

then release the key. It will spring back to the on-run position. Note:

Do not turn key to the start position with the engine running or

starter and/or engine damage may occur.

(Note: On diesel packages, push the key “IN” and turn left-counter

clockwise to shut off the engines.)

Confirm water flow through the engine by way of the water pressure

gauges, and flow of water from the exhaust tips located under the

swim platform.

Let the engine(s) warm up sufficiently before getting under way.

44

Starting, Driving Gauges, Controls

Check your bilge and engine compartment once more for any leaks

or unusual noise. Engine hatch may now be closed.

While at the dock, raise throttle slightly for throttle response. Bring

throttle back to idle and check shifters for forward and reverse operation.

Check operation of equipment for trip (VHF, GPS, Depth Gauge,

Horns, etc.) Inform passengers of location of all safety equipment,

seating and grab rails.

Untie dock lines and stow them away. Push vessel away from dock,

or utilize the bow thruster to push away (if so equipped), and shift

into desired gear. (The bow thruster is described in the “Electrical

System & Optional Equipment” section.)

Pilot (helm) bolster and passenger bolster have rocker switch activated drop out seat bottoms for stand-up or sit-down operation. Adjust

these as necessary for a comfortable position.

Warning: With the vessel in motion, pay close attention to

heading and water depth. Use caution in shallow water

operation.

With the shifter(s) forward, set up the drives and tabs as follows:

Using either the rocker switches located on the

dash above the quadrant, or the small rocker

switch located on the end of the throttle lever,

position the drives to the full “IN” position as

indicated on the drive indicators.

Using the rocker switches on the dashboard above the quadrant,

lower the trim tabs to the full down position, as indicated on the trim

tab indicators.

45

Starting, Driving Gauges, Controls

With one hand on the throttles and the other hand on the steering

wheel, move the throttles forward evenly and smoothly until the vessel comes on plane. (Plane is typically used to describe the vessels

transition from static depth in the water to riding on the water's surface.

As the boat planes off, use the rocker switches to bring the drives out

to the neutral position (defined as the propeller shaft parallel to the

running surface), typically indicated by the number 3 on the drive

indicator.

Using the rocker switches for the tabs, run them up until the desired

ride attitude is achieved.

46

Starting, Driving Gauges, Controls

Sterndrive (I/O)

Surface Drive

Sterndrive (I/O)

Surface Drive

Warning: Never run the vessel at higher speeds with

the tabs or drives at the extreme in/out - up/down positions. Never trim the drives to less than 3 on the drive

trim indicator while the boat is on plane.

You will learn to adjust your vessel for a comfortable ride attitude

depending upon loading and balance to achieve desired performance. Take note of your indicator positions to aid in your running setup.

Always monitor your gauges, warning lights and audible warning

alarms. Back off of the throttles, bring the boat to a complete stop,

put the shifters in the neutral position, and shut down the engine(s) at

the sign of any problem. Check the engine compartment for possible

repair. Note: Vessel can be run back to port on one engine if necessary (in a multi-engine configuration boat), as long as you do not

overwork the running engine. Call for help or tow-in if necessary.

While under way, it is necessary to frequently check the instrumenta-

tion for any possible sign of trouble.

Instrumentation:

Tachometer - The tachometer indicates the engine's revolutions per

minute (RPM). Use the tachometer to monitor engine speed to avoid

exceeding the maximum RPM rating for your engine.

Temperature Gauge - The temperature gauge indicates the engine

coolant temperature. If the gauge reads in the danger area, shut off

the engine, locate and repair the problem.

Oil Pressure Gauge - The oil pressure gauge indicates the engine

oil pressure. If the gauge reads low shut off the engine and repair

the problem before re-starting the engine.

Fuel Gauge - The fuel gauge indicates the approximate fuel level. At

times your gauge may provide an inaccurate reading because of the

water conditions and the level of the boat in the water. It is a good

idea to keep track of the fuel you have dispensed in the tank, running

47

Starting, Driving Gauges, Controls

time and fuel usage estimates to ensure you have an adequate fuel

supply for your trip.

Compass - The compass your boat is equipped with is an excellent

aid in navigation. Several factors can influence the operation of your

compass, such as the needle deflection caused by metal components or the use of electrical equipment on your boat.

Keep a log on engine hours for timely service and maintenance to

keep your Fountain running strong, and to prevent possible premature equipment failure. Refer to engine and accessory manufacturers manuals for service intervals. You engine hour meter is located

in the engine compartment on the starboard gunwale lip.

48

Starting, Driving Gauges, Controls

Electrical System:

Your Fountain Powerboat is equipped with standard 12VDC power.

All vessel power is operated by battery switch(s). Lights and accessories are protected by fuses or breakers. These are located under

the rear seat or under the dashboard wall. Note: See trouble-shooting section for fuse replacement or breaker reset procedures.

Do not use 12 volt power accessories for long periods

of time without engines or generator running to insure

that batteries will not run down

Stereo, VHF and GPS, whether standard or optional upgrades should

include manuals provided by the original equipment manufacturer.

Please refer to these manuals for proper usage and maintenance of

these electronics.

VHF and GPS options are very useful and are recommended for

easy navigation and trip plotting. VHF radio is the communication

used by marine and aircraft, and is very useful for emergency, ship to

ship, or ship to shore communications.

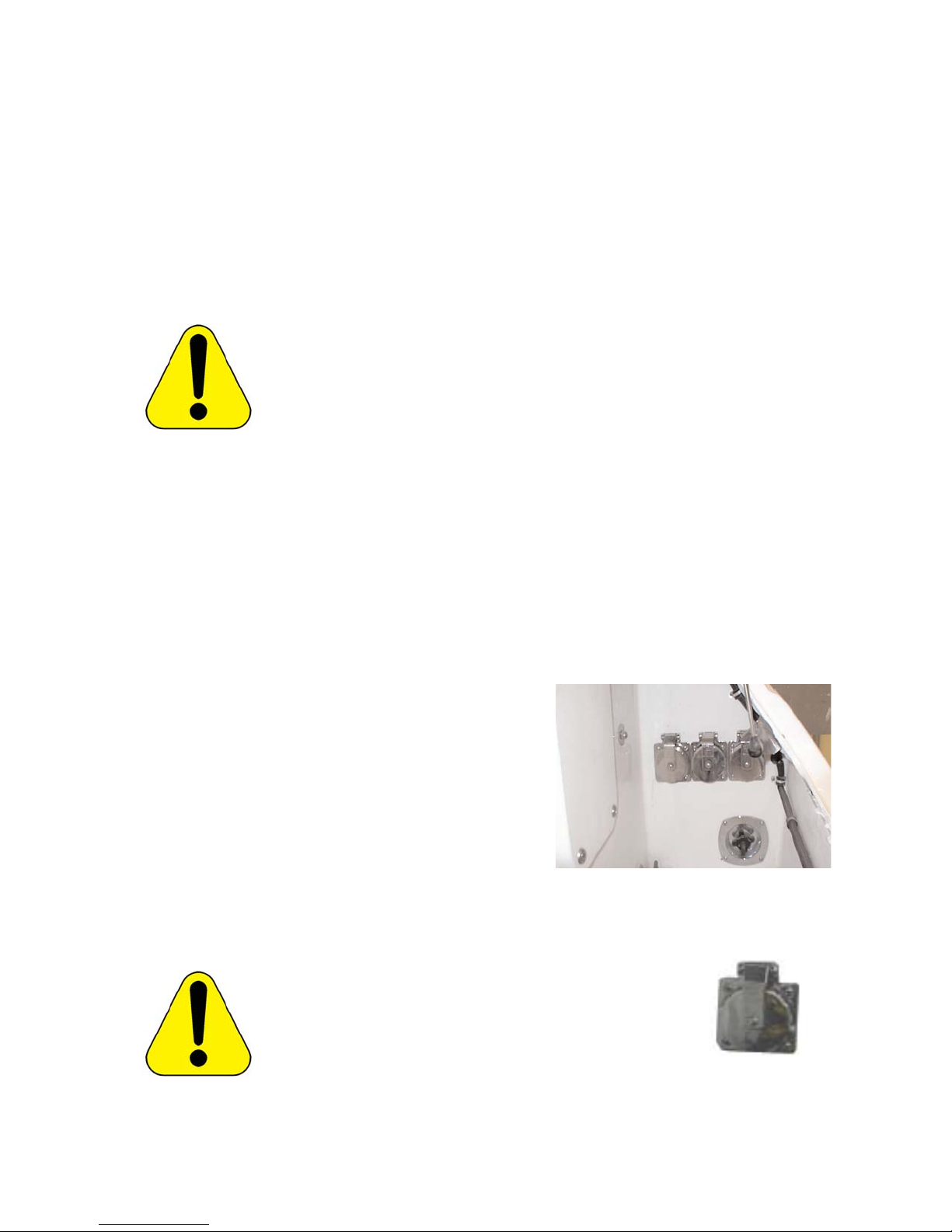

Shore power will provide 110-volt AC

power to outlets and optional appliances.

This option is for use at dockside only,

and requires the provided shore power

plug. All AC power is controlled by a

master AC panel in the cabin, with breakers and volt meters. Be sure to turn off

all breakers on the AC Main panel before connecting to the shore

power outlet at the dock. (For 240V systems, refer to 240V Section)

ALWAYS plug in the shore power cord with

the main breaker panel switched off, and

plug in the VESSEL END FIRST, then plug

into the dock side power to avoid dropping a

“hot” cord into the water. When disconnecting the

shore power, reverse the procedure. (Disconnect dockside first.)

49

Electrical System & Optional Equipment

On the AC panel, slide the cover up exposing the shore power breaker, and turn on the breaker to utilize shore power.

A safety cover is provided over the switches

that direct power to the panel to prevent both

shore power and generator power from being

used simultaneously. For shore power operation, plug the outlet into the boat receptacle

then plug into the dockside shore power outlet. On the boat AC panel, slide the cover

down exposing the shore power breaker, and

turn on the breaker to utilize shore power.

Generator Operation:

All Fountain cruisers are typically equipped with an AC generator.

This will provide 110-volt AC power to outlets and optional appliances

while away from the dock, or in locations that do not have dock-side

power available. Power is controlled by a master AC panel in the

cabin, with breakers and volt meters. It is important to understand

the operation of this system when switching from shore power to

generator power.

Before use, always make certain that

water control valves to the generator

are open, and the sea strainers are

clean, or severe damage may occur to

your generator. Always confirm water

flow from the generator by

visually checking for water

flow from the generator exhaust vent. If

water is not flowing from the exhaust, shut off

the generator immediately.

Read and familiarize yourself with the owner's manual provided by

your generator manufacturer for more specific details of operation.

Turn the generator battery switch on. The generator battery

switch is located in the wet bar cabinet in the cockpit.

50

Electrical System & Optional Equipment

Generator/Shore Power Select

The generator can be started (2) ways-either in the engine compartment or on the main panel in the salon.

It may be necessary (depending on the model of your generator)

to hold the "Pre-Heat" button, (particularly in diesel applications),

while starting the generator. Refer to the manufacturer owner's manual for specific details.

Once the generator has started, flip the main breaker on the

generator face to the on position, (if so equipped).

Note: The generator will shut itself down at sign of trouble, including

overheat, low oil, etc. The generator has it’s own battery and on-off

switch. There is also a cross-over switch to utilize engine batteries for

start-up.

On the AC panel, slide the cover up exposing the generator breaker,

and turn on the breaker to utilize generator power.

A safety cover is provided over the switches

that direct power to the panel to prevent both

shore power and generator power from being

used simultaneously. For shore power operation, plug the outlet into the boat receptacle

then plug into the dockside shore power outlet. On the boat AC panel, slide the cover

down exposing the shore power breaker, and

turn on the breaker to utilize shore power.

Most AC panels will have a "transfer" breaker which will allow both

sides of the breaker panel to be energized from either a single shore

power connection or the generator. If two shore power receptacles

are provided and utilized, both panels will be

powered without the use of the transfer

switch. (This is not applicable on 240V systems. See the 240V section below for more

details on the operation of the 240V system

panel.)

51

Electrical System & Optional Equipment

Transfer Switch

Generator/Shore Power Select

240V Shore Power Systems

48 Express Cruisers may be equipped with a 240V shore power system which is becoming more and more popular in marinas, especially

newer marinas. This systems works the same as a tandem 120V

system (2x 120V shore power hook-ups and a transfer switch) except

that it handles the transfer of power internally from 240V to 120V.

Additionally, since the system is 240V, there is no transfer switch to

power both banks of the AC panel.

The panel has an integrated master switch to determine ship or

shore power. It also includes the remote starter panel for the generator, as well as the fresh water level indicator.

Backlit labels indicate that a circuit is turned on, and has power from

the panel.

52

Electrical System & Optional Equipment

AC Controls

Source Selector

AC Master Breaker

Generator Remote

Start Panel

Fresh Water Level

Indicator Gauge

The center of the panel has a master AC breaker which must be

switched on for the panel to have power, weather from the generator

or from the shore power cord.

Connect the shore power cable in the same manner as described for

the 120V cable, making sure to hook up the boat side o the cable

first, then connect the cable to the dock side power outlet to prevent

to possibility of dropping a “hot” cord into the water.

After connecting the shore power cord, turn on the master AC breaker on the panel.

The DC side of the panel is illuminated the same as the AC side, and

has meters to display the available voltage to the panel.

53

Electrical System & Optional Equipment

DC Controls

AC Voltage DC VoltageAC Current

DC Current

Air Conditioning

Air conditioning and heat is another option operated by shore power

or optional generator. This unit is operated by its own control panel,

controlling on/off and temperature settings. See the manufacturers

owner manual for specific operating instructions of your air conditioning unit.

Before use, make sure that all valves

controlling water flow to the unit are in the

open position, and

the sea strainer is

clean.

Turn on the AIR COND PUMP breaker on the main panel in the

salon.

Turn on the breaker for the specific air conditioner you want to

use: AIR COND AFT or AIR COND FWD.

The air conditioner thermostat display will come on.

Press the up or down arrows to adjust the temperature.

Toilet and Sanitation

Fountain Cruisers are equipped with a Vacu-flush head, a macerator

pump and holding tank and may also be equipped with an overboard

discharge.

Consult your local laws regarding the overboard discharge of waste. Some areas prohibit the dumping of

any sewage, and may require that the overboard discharge valve (y-valve) be locked in the closed position to

prevent discharge. It is recommended that holding tanks be emptied out

after every trip if used. It is also recommended that the overboard dump be locked

in the closed position unless used in accordance with local laws regarding the dump-

54

Electrical System & Optional Equipment

Y-Valve (exposed)

ing of sewage. Overboard discharge requires the valve to be in the

“overboard” position, and switch activation to operate the pump.

The waste water system directs waste water from several locations

(head, sinks, etc.) to a sump that contains a float switch and pump to

pump the water to the waste holding tanks in the engine compartment. The tanks (one on the port side and one on the stbd side)

must be emptied when they become full.

Overboard Discharge Operation:

1. Turn the Y-valve to the overboard

position.

2. Open the waste thru-hull valve in

the engine compartment.

3. Flip the OVERBOARD DISCHARGE

switch in the wet bar cabinet for the

55

Electrical System & Optional Equipment

Port & Starboard Overboard

Waste Valves

Overboard Discharge

Pump Switch

Waste Tank Monitor

Y-Valve Location

(Port 48EC)

corresponding tank you want to empty.

4. When the tank is empty, release the OVERBOARD DISCHARGE switch. Turn the Y-valve to the original position and close

the waste thru-hull.

Dockside Pump-out:

The services of a dockside pump out station is

needed to empty the holding tank. Be sure the

hose is inserted in the deck plates labeled

WASTE.

Fresh Water Supply

Water for cabin galley and sink is supplied by an electrical pump and

water tank. Tank level is monitored by indicator lights for full or

empty. Tank is filled by a customer-supplied hose. Dock side pressurized water can be utilized to provide endless water while docked.

See quick reference for fitting location. Note: Use an approved hose

for filling a potable water tank in any vessel.

When using the water supply provided at the docks there is no need

to turn on the FRESHWATER PUMP breaker. The water supply is

already pressurized and will support all systems in the boat. The

dock side water WILL NOT fill the on board freshwater tanks. Attach

the dockside water hose to the water inlet.

Onboard Fresh Water System Operation:

Turn the FRESHWATER PUMP breaker on. The

freshwater gauge on the main panel will not operate

if the breaker is not on.

Fill the fresh water tanks as needed using the aft

“water” fill on the port side of the deck.

Warning: Water system must be purged of winterization

fluid used during shipping of the boat during the winter

months. Pink fluid should be run out of the water tap

and flushed out.

56

Electrical System & Optional Equipment

Engine Optional Equipment

Silent Choice Exhaust: This option allows vessel pilot to choose

straight out exhaust or quieter operation at the flip of a switch. This

is located at the pilot's right side helm switch panel, labeled "Exhaust

Open or Closed". Note: This system may not be legal for operation

in certain areas. It is the responsibility of the vessel owner to know

and understand the local noise laws, and outfit the vessel accordingly. It is strongly recommended that the vessel operator use common

sense and courtesy when operating the boat in marinas, around

homes, and in areas that excessive noise would be inconsiderate

and/or inappropriate.

Warning: Some waterway areas have noise level laws

that are very strictly enforced. Check with the local laws

in your area prior to operating your boat.

It is also recommended by many engine manufacturers to not use a

switchable exhaust system at higher speeds due to potential engine

damage that may occur.

Engine fresh water flush:

This option allows you to flush out your engine of saltwater and silt

after a trip. This system can be used at dockside, trailer or on a

hoist. It is also used to run the engine(s) while the boat is out of the

water for diagnostic and troubleshooting service. Use this step-bystep procedure as follows:

Engine flush valves are located inside the engine compartment on

the inner transom above each of the engine drive gimbals. The garden hose fitting for the flush system is located on the engine compartment lip.

Note: Diesel powered boats are flushed at the sea strainers, and do

not have separate flushing valves or water inlets on the deck.

57

Electrical System & Optional Equipment

Make sure that the boat attitude is NOT bow down. Raise the bow of

the boat to get the engine exhaust tips to angle downward so as to

insure that flush water does not flow back into the exhaust pipes, and

thus into the engine. Severe engine damage will occur is water is

ingested by the engine(s) through the exhaust pipes.

Remove the spin-off cap on

the garden hose fitting, and

let it hang on the chain.

Attach garden hose to the fitting.

Make sure that the garden hose is not kinked or turned off during the

flushing procedure. Failure to do so will result in engine overheating

and possible damage.

Run only one engine at a time using it's corresponding flush valve.

Do not run the engine until water is observed running out of the

exhaust pipes. Failure to do so will damage the water pumps and

overheat the engine(s).

On one valve only, throw the yellow handle ball valve up (in-line with

the valve body) to open the line from the garden hose inlet to the

engine. Close the gate valve to shut off water flow back through the

drive.

58

Electrical System & Optional Equipment

Turn on the garden hose all the way, and wait for water to come out

of the exhaust pipes.

Start the engine corresponding to the valve you just set up to flush,

and run the engine (at idle) the desired time to flush out the engine.

Continually monitor the engine gauges while flushing to verify engine

temperature.

When finished flushing, shut down the engine first, and then turn off

the garden hose. Return the engine flush valve to the run position

(turn the ball valve to the off position, perpendicular to the valve

body, open the gate valve by turning counterclockwise).

Repeat the procedure for each engine.

Make sure that you return the flush valve to the run

position as described above. Failure to do so will result

in damage to the water pump, and may cause severe

engine damage.

Remove the garden hose from the fitting, and re-cap the fitting.

Battery Charger:

A battery charger is used with shore power while docked, on the

trailer, or on your hoist. This unit will keep your batteries charged

and monitored while the vessel is shut down for a period of time.

This unit is located inside the mechanical access or in the engine

compartment of inboard powered boats. Refer to the quick reference

drawings for the location of the charger. The battery charger has

indicator lights to show low or full charge.

With the boat attached to shore power, or with the generator running,

turn on the BATTERY CHARGER breaker on the main AC/DC panel.

59

Electrical System & Optional Equipment

Dockside Communications or Television (Cruisers Only):