Fountainhead OMLB-2, OMLP-2, RMLB-2, RMLP-2 Owner's Manual

BARB

CONNECTION

SHU T-OFF

EXTENSION

BARB

CONNECTION

TANK

NOZZLE

PUMP HANDLE

SHU T-OFF

LOCK

ASSEMBLY INSTRUCTIONS

Owner’s Manual

The Fountainhead Group

Compressed Air Sprayer

1-800-3 11-9903

Owner’s Manual

OMLB-2, OMLP-2, RMLB-2, RMLP-2

WARNING! The sprayer is operated with liquid under pressure. Failure to observe CAUTION and to follow instructions for operating and cleaning

can cause tank, hose and other parts to be weakened and/or rupture under pressure. This can result in SERIOUS INJURY from high pressure discharge of liquids

or forcible ejection of parts. DO NOT USE FLAMMABLE MATERIALS IN THIS SPRAYER. Material could ignite or explode, causing serious injury. FOR SAFE USE

OF THIS PRODUCT - YOU MUST READ AND FOLLOW ALL INSTRUCTIONS BEFORE USE. TEST SPRAYER WITH WATER BEFORE USING ANY CHEMICALS .

SAFETY PRECAUTIONS:

1. Rea d ow ner ’s m anu al comp lete ly befo re

operating this sprayer.

2. This sprayer is designed for light duty lawn and

garden use only.

3. Always u se g og gles, gl oves a nd pro te ctive

clothing when using spraye r.

4. Read and follow all instructions and cautions on

label of products used in this sprayer.

5. Spray when air is calm to prevent drift of

chemical.

6. Do not leave sprayer in the sun when not in

use.

7. Never use flammable liquids, caustics, acids

or hot water in this tank.

8. Never store chemicals in this tank.

9. Always release pressure when sprayer is not in

use and before removing pump from tank.

10. Never stand with face or body over sprayer when

pressurizing tank or releasing pressure.

11. Clean and rinse sprayer thoroughly after each use.

12. Never attempt to alter sprayer from original

condition.

13. Always use replacement parts fr om original

manufacture r.

1-800-3 11-9903

If you have any problems with, or have any questions about your sprayer,

BEFORE YOU

RETURN IT TO THE STORE, CALL OUR TOLL FREE CUSTOMER SERVICE CENTER AT:

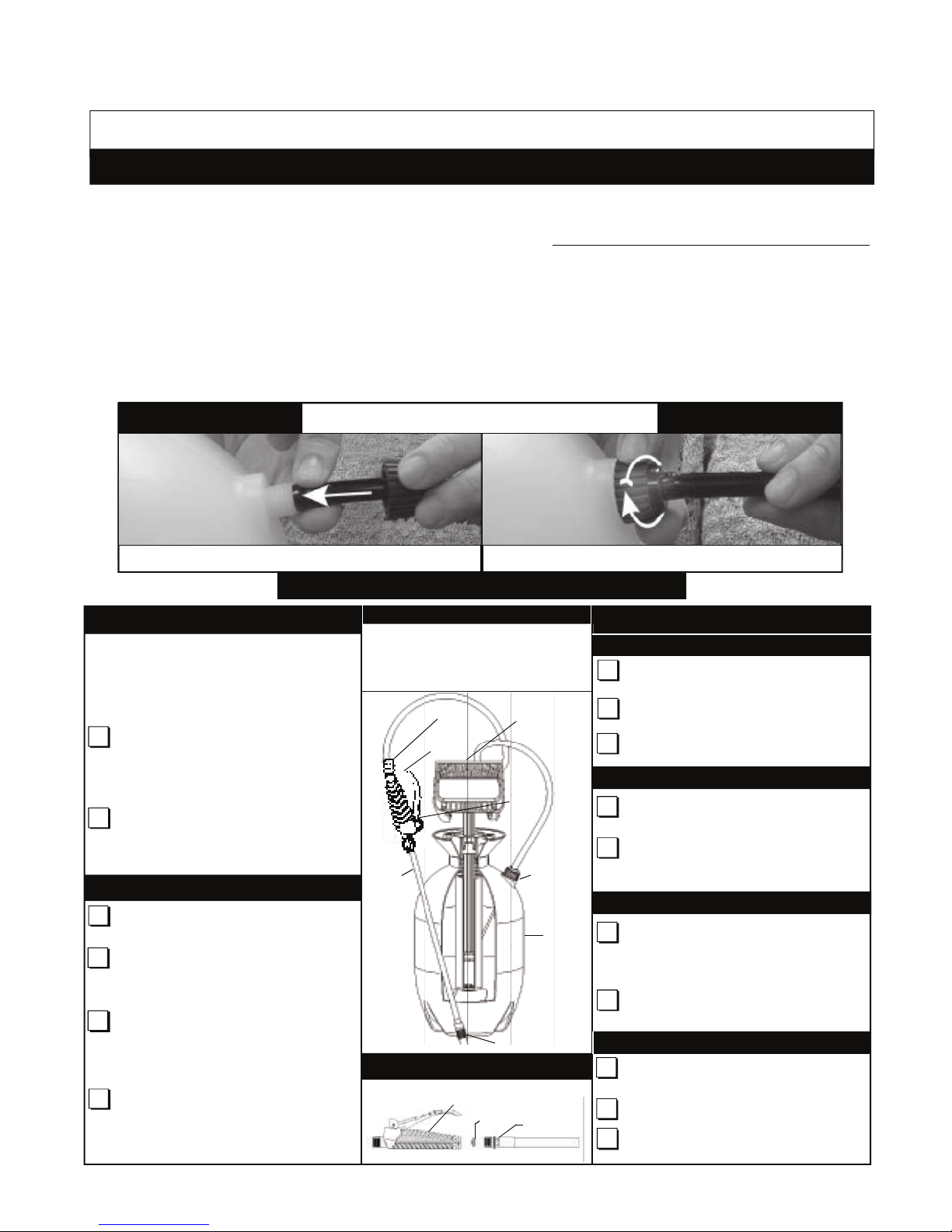

HOSE ASSEMB LY INSTRUCTIONS

11

22

11

1. PUSH HOSE COMPLETELY ON. 2. TIGHTEN NUT COMPLETEL Y.

! !

NEVER USE SPRAYER WITHOUT NU T.

1 .

2 .

1 .

2 .

3 .

HOS E A S S EMBL Y TO T A N K:

IM PORT A NT : A ho se nu t i s inc lud ed i n th e pa rts

ki t. The hose n ut i s re qu ired for pro per as se mbly

of t he spr aye r. Do n ot a tte mpt t o hea t, or a lte r

ho se , h ose nu t, or b arb prior t o a ssembly .

Sl ide h ose n ut ove r en d of ho se ( obs erv e

pr ope r ho se n ut o rie nta tio n in a bov e

di agr am) . P ush h ose c omp let ely o nto t ank

barb, as shown in step #1 of above dia gr am .

Sl ide hos e nu t al ong hos e an d ov er b arb

th rea ds. Turn ho se nu t c loc kwi se to

co mpl etel y t igh ten o ver hose , a s s how n i n

step #2 of ab ov e d ia gr am (d o not u se to ols) .

Re mov e pr ote cti ve c ap f rom end of s hut -of f

assem bl y.

Sc rew e xte nsio n on to e nd o f sh ut- off

as sem bly unt il f irm ly a tta che d.

Se lec t a noz zle , us ing NOZ ZLE SEL ECT ION

CH AR T. Scr ew se lec ted no zzl e ont o

ex ten sio n un til fir mly att ach ed, mak in g s ure

#1 710 92 ( o-r ing ) is in p la ce on end of

e x t en si on .

When using flat f an noz zl es, ma ke sure t abs

on nozz le ti ps ar e f it te d i nt o s lo ts on en d o f

extensi on . Tip can be in st al le d to produce a

ve rt ical o r h orizo nt al fla t f an.

4 .

EX T E NSION A S SEMBL Y TO SH U T - O F F

E- mail : Info@ TheF GI.co m • Web si te: w w w .TheF ounta inhea d Group .com • 1- 800-3 11-99 03

FI L T ER C LEAN I N G (

(S ee SPR AYE R

MA INT ENA NCE P AGE 2 )

OP E R ATI NG I NST R UCT IONS

F I LL I NG

1 .

2 .

Remove p ump by turni ng pump handle

counterclockwise.

Fill tank to desired level (always refer to

chemical manufacturer for proper mixture)

Place pump into tank opening and turn handle

clockwise to tighten.

3 .

Ma ke su re shu t- off lo ck is no t e nga ge d ( if

sh ut- off lo ck is eng age d w hile pr ess uri zing ,

th e un it w il l im med iat el y st art spr aying )

Pr ess uri ze spr aye r by pu mpi ng han dle i n a

sm oot h u p and d own m oti on. W hen d esi red

pres su re is a ch ieved, l oc k h andl e o nto pump .

P R ES S UR IZ I N G

Po int n ozz le aw ay fro m you. Pre ss shu t-o ff

bu tto n to be gin spr ayi ng. Re leas e b utt on to

st op s pra yi ng. Wh en u si ng a dju st able n ozzle ,

ad jus t sp ray p att ern b y tu rni ng n ozz le t ip.

(N ot e: Fla t fan no zzle i s not ad justabl e).

Fo r co nti nuo us spra yin g, s quee ze s hut -of f

handle and rot at e l oc k t ow ar d t he spra ye r t ip .

1 .

2 .

S P R A YI NG

1 .

2 .

Direc t nozzle away fro m you and press

han dle on shu t-off until unit stops spraying

(this will rel ease pr essure in tank).

Tu rn pum p ha ndl e cou nte rcl ock wis e to

re mov e p ump .

Empty any r em ai ni ng li qu id ac co rd ing to

produ ct dispo sal dire ctions. Clean sprayer as

dire ct ed und er CL EA NING SP RA YE R .

F I NI SH I N G

1 .

2 .

PN 180 568 20 03

3 .

ALWAY S ENSURE PRESSUR E IS RELEASE D

FROM TANK BEF ORE FIL LING OR SERV ICING .

Sq ue ez e sh ut-o ff h andl e and hold do wn u ntil

the unit stop s spr aying . Th en, a nd on ly th en, i t

is sa fe t o re move pump .

I M PO R TA N T!

Fi lt er

Hos e A ssem bly

Sh ut -O ff

As se mb ly

Lawn Insects

Insects on Roses

& Ornamental Plants

Insects on Fruit &

Vegetables

Insects and Diseases

on Roses & Ornamental

Plants

Insects and Disease

on Fruit Trees

Home-Invading Pests in

Lawn & Around

Perimeter of Home

Dormant Season

Spraying for Insect

Control on Fruit Trees &

Woody Ornamentals

14 178024 Extension-Curved-14”-Poly

180343 Extension-Straight-Brass 14”

180352 Extension-Curved-Brass 14”

15 178054 Nozzle Cap-Poly

180340 Nozzle Cap-Brass

16 178052 Nozzle Base

17 178055 Nozzle Assembly-Poly

180344 Nozzle Assembly-Brass

18 171092 O-Ring

19 180298 Pump Handle

20 180337 Parts Kit

21 180299 Pump Gasket

22 180320 Filter (If Equipped)

23 178083 Hose Adapter

1 180482 2 Gallon Tank-ML-2, Yellow

180507 2 Gallon Tank-ML-2, Natural

2 180292 Funnel

3 180294 Pump Barrel

4 180296 Pump Cap (2 required)

5 180449 Hose Assembly

6 180448 Shut-off Assembly

7 178085 Shut-off Body

8 178090 Shut-off Lever

9 178087 Plunger

10 178088 Shut-off Spring

11 178089 Retainer

12 178086 Diaphragm

13 180386 Hose 32”

KEY

NO.

PART #

DESRCRIPTION

KEY

NO.

PART # DESCRIPTION

KEY

NO.

PART #

DESCRIPTION

24 178084 O-Ring

25 180011 Lock

26 180007 Fan Tip Set

27 180097 High Volume Fan Tip (Red)

28 180168 Low Volume Fan Tip (Yellow)

29 178067 Cap Nut

30 180300 O-Ring, Pump

31 180305 Pump Assembly

32 180513 Outlet Tube

33 180364 Nut

34 171015 Check Valve

180568 Parts List / Instructions

35 180266 Foaming Nozzle

NOTE: MODELS OMLP-2 AND RMLP-2 ARE EQUIPPED WITH POLY EXTENSIONS AND NOZZLES.

MODELS OMLB-2 AND RMLB-2 ARE EQUIPPED WITH BRASS EXTENSIONS AND NOZZLES.

Remove pump as de scri bed in FINI SH

section.

Fill tank with tap water. Replace pump and

turn clockwise to tighten. Agitate tank to rinse

chemical off tank wall and pump.

Remove pump and empty contents into gravel

or bare soil.

Refill tank with tap water.

Check to be sure pump is free of debris and

place pump into tank. Turn handle clockwise

to tighten pump.

Pressurize tank. Follow all instructions in

PRESSURIZING section.

Point nozzle away from you and spray for

approximately 30 seconds to clean hose and

shut-off.

Release pressure as outlined in OPERA TING

and FINISH sections. Empty contents as in

step 3.

Repeat steps 4 thru 8 until thoroughly cleaned.

Note: It is best to keep 2 sprayers: One for

herbicides and one for other products, such

as fertilizers or insecticides.

CLEANING SPR AYER

SPRAYER MAINTENANCE

Pump should be periodically oiled by dropping 10 to 12 drops of light oil

down pump rod through opening in cover.

If nozzle clogs: remove nozzle assembl y, disassemble nozzle and clean

openings of any obstructions.

Never use any tool to remove pump if there is pressure in sprayer.

If filter clogs: remove and clean filter as shown on page 1 under FILTER

CLEANING .

Sprayer tank should be hung upside down, with pump removed,

in a warm, dry location.

Do not store or leave any solution in tank after use.

Store in a warm dry location out of direct sunlight.

KEEP SPRAYER OUT OF REACH OF CHILDREN.

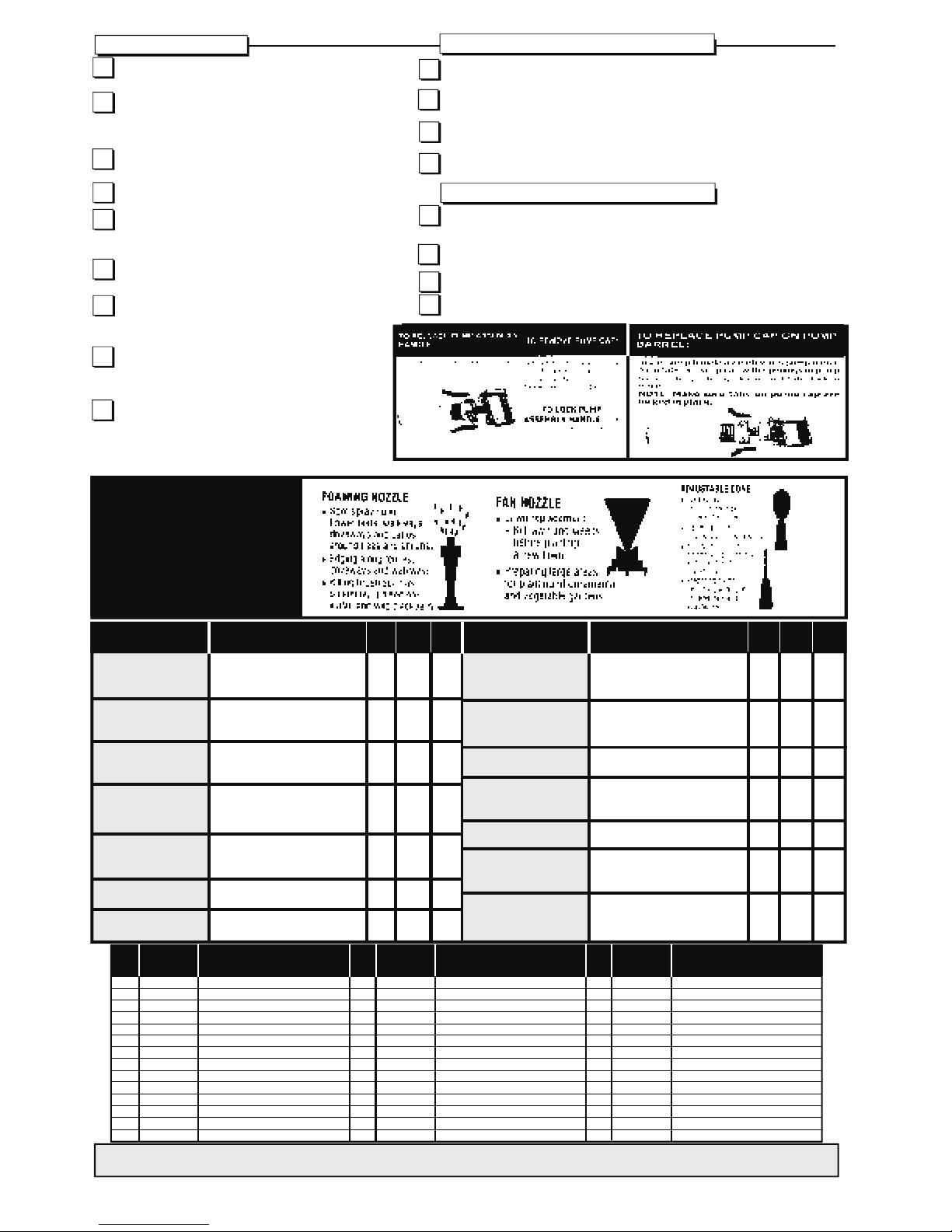

NOZZLE

SELECTION

CHART

1.

2.

3.

4.

5.

6.

7.

8.

9.

E-mail: Info@TheFGI.com • Web site: www.TheFountainheadGroup.com • 1-800-3 11-9903

1.

2.

3.

4.

SPRAYER STORAGE

1.

2.

3.

4.

Broadleaf Weeds in Lawn

Grassy Weeds in Lawn

Brushy Weeds (Such as

Poison Oak, Poison Ivy,

Kudzu, Wild Blackberry)

Weeds in Non-Planted

Areas

(Mulch, Gravel, etc.)

Spot Control of Weeds in

Flowerbeds, around Trees

& Shrubs

Disease Control on

Vegetables

Disease Control on Fruit

Trees

Ortho® Weed-B-Gon® Weed Killer For

Lawns, Ortho® Weed-B-Gon

®

Chickweed, Clover & Oxalis Weed

Killer For Lawns

Ortho® Weed-B-Gon® Crabgrass

Killer For Lawns

Ortho® Brush-B-Gon® Poison Ivy,

Poison Oak & Brush Killer

Roundup® Weed & Grass Killer

Roundup® Weed & Grass Killer

Ortho® Garden Disease Control

Ortho® Garden Disease Control

PROBLEM

Ortho® Termite & Carpenter Ant

Killer, Ortho® Bug-B-Gon® MultiPurpose Insect Killer

Ortho® Bug-B-Gon® MultiPurpose Insect Killer, Ortho

®

Systemic Insect Control

Ortho® Bug-B-Gon® MultiPurpose Insect Killer

Ortho®Orthenex® Garden Insect

& Disease Control

Ortho® Orthenex® Garden Insect

& Disease Control

Ortho® Termite & Carpenter Ant

Killer, Ortho® Bug-B-Gon® MultiPurpose Insect Killer

Ortho® Volck® Oil Spray

SOLUTION

PROBLEM

SOLUTION

HIGH

VOLUME

FAN

(RED)

ADJUSTABLE

CONE

LOW

VOLUME

FAN

(YELLOW)

HIGH

VOLUME

FAN

(RED)

ADJUSTABLE

CONE

LOW

VOLUME

FAN

(YELLOW)

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Loading...

Loading...