The Fountainhead Group

Compressed Air Sprayer

1-800-311-9903

Owner’s Manual

Models OML-1, RML-1, GGS-1, SML-1, SML-2

WARNING!

The sprayer is operated with liquid under pressure. Failure to observe CAUTION and to follow instructions for operating and cl eaning

can cause tank, hose and other parts to be weakened and/or rupture under pressure. This can result in SERIOUS INJURY from high

pressure discharge of liquids

or forcible ejection of parts. DO NOT USE FLAMMABLE MATERIALS IN THIS SPRAYER. Material could ignite or explode, causing seri

ous injury. FOR SAFE USE

OF THIS PRODUCT - YOU MUST READ AND FOLLOW ALL INSTRUCTIONS BEFORE USE.

TEST SPRA

YER WITH W

ATER BEFORE USING ANY CHEMICALS.

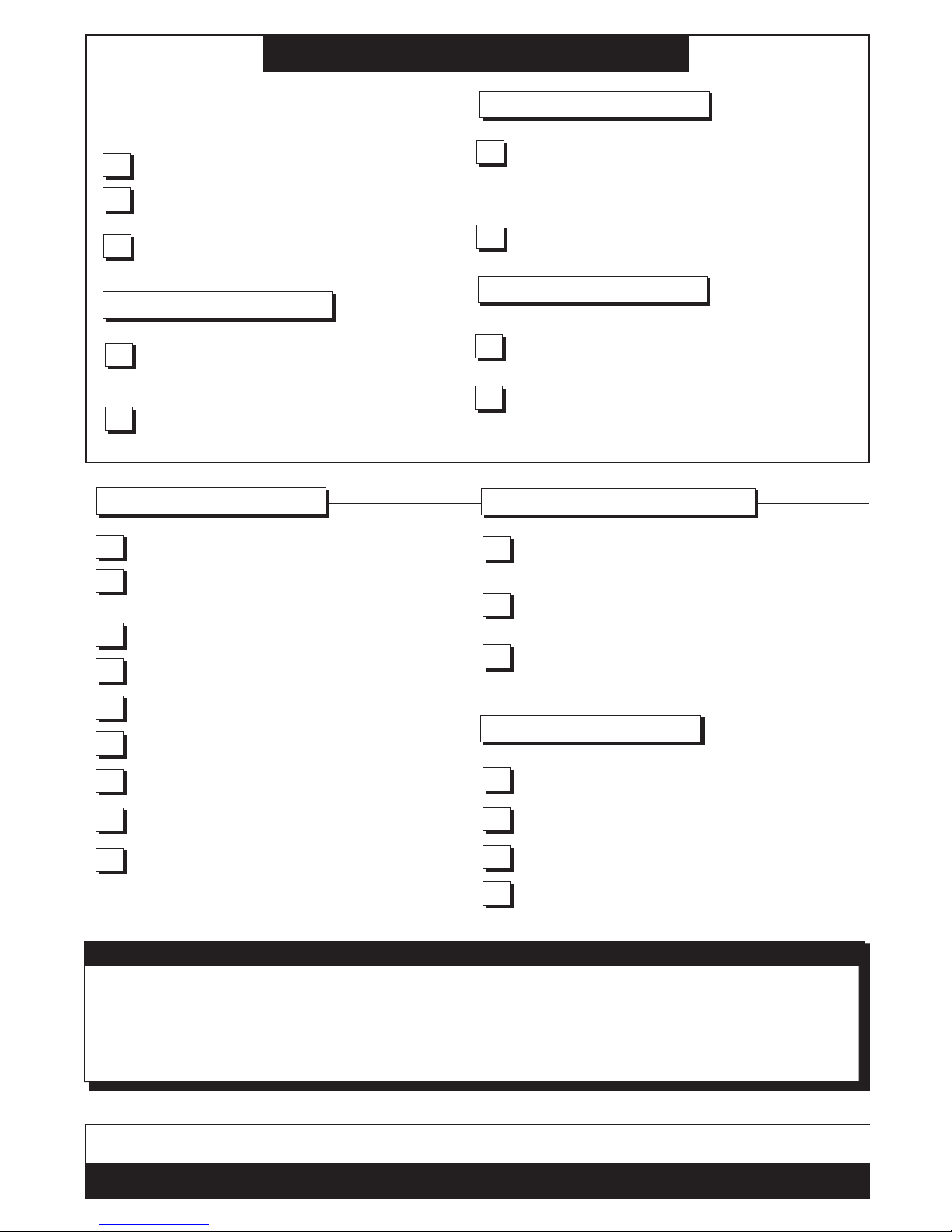

ASSEMBLY INSTRUCTIONS

1.

2.

BARB

CONNECTION

SHUT-OFF

PUMP HANDLE

SHUT-OFF

LOCK

EXTENSION

BARB

CONNECTION

TANK

NOZZLE

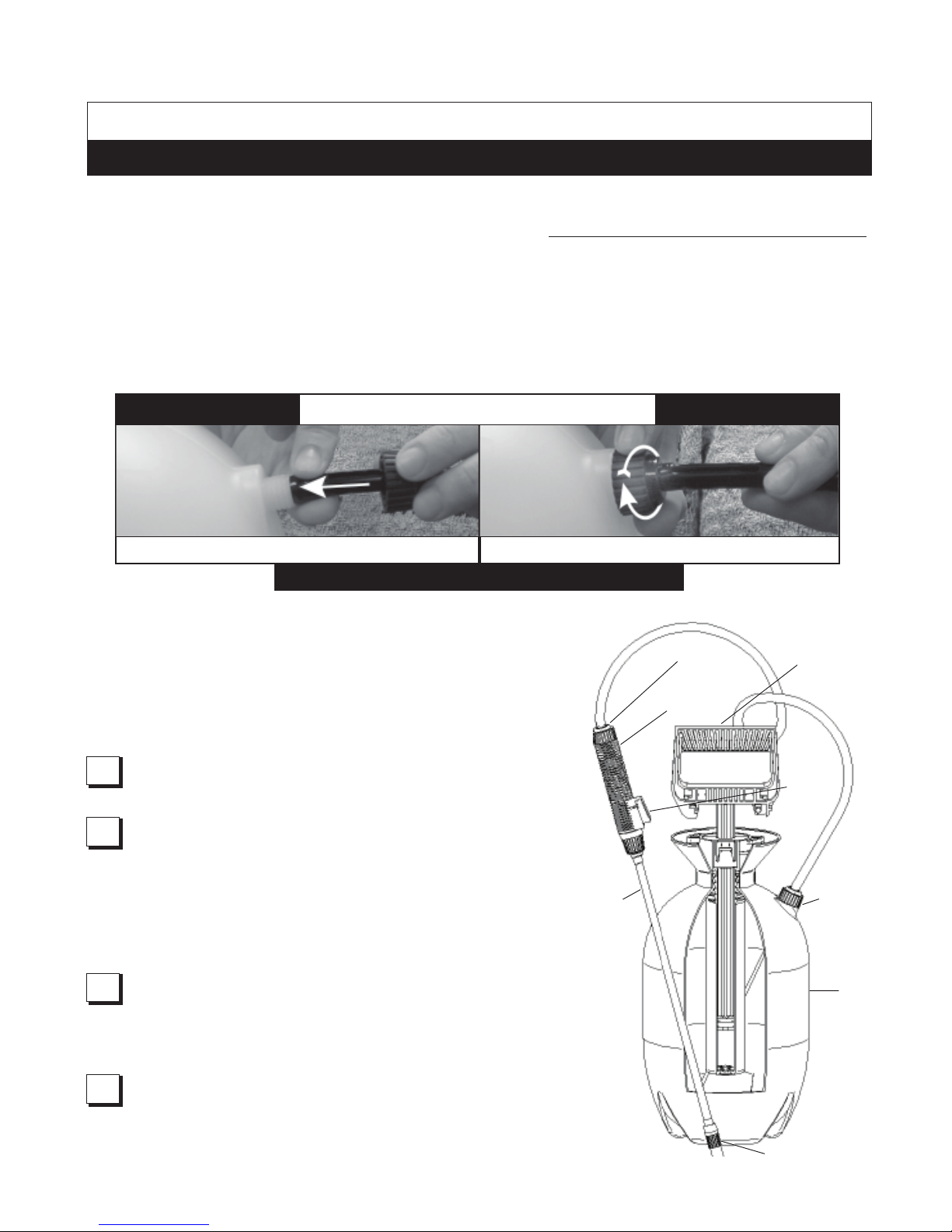

HOSE ASSEMBLY TO TANK:

IMPORTANT: Two

identical

hose nuts are included in the parts kit. Both

hose nuts are

required for proper assembly of the sprayer. Do not

attempt

to

heat,

or alter

hose, hose nut, or barb prior to assembly.

Slide hose nut over end of hose (observe proper hose nut

orientation in above diagram). Push hose completely onto tank

barb, as shown in step #1 of above diagram.

Slide hose nut along hose and over barb threads. Turn hose nut

clockwise to completely tighten over hose, as shown in step #2 of

above diagram (do not use tools).

HOSE ASSEMBLY TO SHUT-OFF:

Repeat steps #1 and #2 above, while connecting hose to barb of shut-off.

IMPORTANT:

1.

2.

It is recommended to test sprayer using plain tap water before

spraying chemicals. Test all connections for possible leaks. Use

proper eye protection while testing. If sprayer does not pass the

water test, call our customer service center before using sprayer

with chemicals.

Make sure hose is not cracked or frayed and does not show signs of

swelling. Make sure the hose is securely connected to sprayer.

OPERATING INSTRUCTIONS ARE CONTINUED ON NEXT PAGE

E-mail: Info@TheFGI.com • Web site: www.TheFountainheadGroup.com

SAFETY PRECAUTIONS:

1. R ead owne r’s m anu al co mp let ely befo re

operating this sprayer.

2. This sprayer is designed for light duty lawn and

garden use only.

3. A lways use goggles, glov es and pro tective

clothing when using sprayer.

4. Read and follow all instructions and cautions on

label of products used in this sprayer.

5. Spray when air is calm to prevent drift of

chemical.

6. Do not leave sprayer in the sun when not in

use.

7. Never use flammable liquids, caustics, acids

or hot water in this tank.

8. Never store chemicals in this tank.

9. Always release pressure when sprayer is not in

use and before removing pump from tank.

10. Never stand with face or body over sprayer when

pressurizing tank or releasing pressure.

11. Clean and rinse sprayer thoroughly after each use.

12. Never attempt to alter sprayer from original

condition.

13. Always use replaceme nt parts from original

manufacturer.

1-800-311-9903

If you have any problems with, or have any questions about your sprayer,

BEFORE YOU

RETURN IT TO THE STORE, CALL OUR TOLL FREE CUSTOMER SERVICE CENTER AT:

HOSE ASSEMBLY INSTRUCTIONS

IMPORTANT

1

1

1

1

1

2

2

2

2

2

IMPORTANT

1

1

1

1

1

1. PUSH HOSE COMPLETELY ON. 2. TIGHTEN NUT COMPLETELY.

! !

NEVER USE SPRAYER WITHOUT NUT.

Remove pump as described in

finish section.

Fill tank with tap water. Replace pump and turn

clockwise to tighten. Agitate tank to rinse chemical off

tank wall and pump.

Remove pump and empty contents into gravel or bare soil.

Refill tank with tap water.

Check to be sure pump is free of debris and place pump

into tank. Turn handle clockwise to tighten pump.

Pressurize tank. Follow all instructions in pressurize

section.

Point nozzle away from you and spray for

approximately 30 seconds to clean hose and shut-off.

Release pressure as outlined in operating and finish

sections.

Empty contents as in step 3.

Repeat steps 4 thru 8 until thoroughly cleaned. Note: It

is best to keep 2 sprayers: One for herbicides and one

for other products, such as fertilizers or insecticides.

CLEANING SPRAYER

SPRAYER STORAGE

SPRAYER MAINTENANCE

1.

2.

3.

4.

5.

6.

7.

8.

9.

1.

2.

3.

4.

Pump should be periodically oiled by dropping 10 to 12

drops of light oil down pump rod through opening in cover.

If nozzle clogs: remove nozzle assembly, disassemble nozzle

and clean openings of any obstructions.

Never use any tool to remove pump if there is pressure in

sprayer.

Sprayer tank should be hung upside down, with pump

removed, in a warm dry location.

Do not store or leave any solution in tank after use.

Store in a warm dry location out of direct sunlight.

KEEP SPRAYER OUT OF REACH OF CHILDREN.

1.

2.

3.

IMPORTANT! Always ensure pressure is released from

tank before filling or servicing.

To release pressure, press

button on shut-off until the unit stops spraying. Then, and

only then, it is safe to remove pump.

1.

2.

Remove pump by turning pump handle counterclockwise.

Fill tank to desired level (always refer to chemical

manufacturer for proper mixture)

Place pump into tank opening and turn handle

clockwise to tighten.

3.

PRESSURIZING:

1.

2.

Make sure shut-off lock is not engaged (if shut-off

lock is engaged while pressurizing, the unit will

immediately start spraying)

Pressurize sprayer by pumping handle in a smooth

up and down motion. When desired pressure is

achieved, lock handle onto pump.

SPRAYING:

1.

2.

Point nozzle away from you. Press shut-off button to

begin spraying. Release button to stop spraying. When

using adjustable nozzle, adjust spray pattern by turning

nozzle tip. (Note: Flat fan nozzle is not adjustable).

For continuous spraying, push lock onto shut-off button.

FINISH:

1.

2.

Direct nozzle away from you and press button on shut-off

until unit stops spraying (this will release pressure in tank).

Turn pump handle counterclockwise to remove pump.

OPERATING INSTRUCTIONS

1-800-311-9903

1-800-311-9903

If you have any problems with, or have any questions about your sprayer,

BEFORE YOU

RETURN IT TO THE STORE, CALL OUR TOLL FREE CUSTOMER SERVICE CENTER AT:

1 171015 Check

Valve

2 171653 Nozzle Cap

3 178354 Shut-off Assembly

4 180284 Fan Nozzle

5 180287 Parts / Instructions

6 180426 1 Gallon Tank-Yellow

6 180425 1 Gallon Tank-Natural

6 180477 2 Gallon Tank-Yellow

7 180299 Pump Gasket

8 180300 O-Ring, Pump

9 180305 Pump Assembly

10 180308 Hose 32”

KEY NO. PART # DESCRIPTION KEY NO. PART # DESCRIPTION

11 178363 Extension Curved

12 180332 Parts Kit

13 1783541 Hose /

Shut-off Nut

14 1785096

O-Ring, Nozzle End

15 1785097

O-Ring, Base End

KEY NO. PART # DESCRIPTION

CUT ON DOTTED LINE

ASSEMBLY & REPAIR PARTS

Please Refer To The Parts List On Bottom Of Previous Page

12

7

14

15

2

8

1

8

9

7

1

13

3

15

11

14

2

4

6

13

10

DESCRIPTION

PARTS & ACCESSORIES

171015 Check Valve $1.23

171653 Nozzle Cap $1.50

178354 Shut-off Assembly $2.50

180284 Fan Nozzle $1.75

180287 Parts / Instructions N/C

180426 1 Gallon Tank-Yellow $11.50

180425 1 Gallon T ank-Natural $1

1.50

180477 2 Gallon Tank-Yellow $12.50

180299 Pump Gasket $1.25

180300 O-Ring, Pump $1.01

180305 Pump Assembly $10.00

180308 Hose 32” $3.95

178363 Extension $3.40

180332 Parts Kit $6.09

1783541 Hose Nut $1.55

1785096

O-Ring, Nozzle End $1.01

1785097 O-Ring, Base End $1.01

COST

SUBTOTAL

8% TAX (NY ONLY)

SHIPPING & HANDLING $3.00

GRAND TOTAL

To order any parts below, simply state quantity in left hand column, fill in bottom portion, and send to address on reverse sid

e

QTY.

PART # DESCRIPTION

COST

TOTAL

PART #

COST

TOTAL

171015 Check V

alve 1

171653 Nozzle Cap 2

180299 Pump Gasket 7

PART # DESCRIPTION KEY NO.

180300 O-Ring, Pump 8

1785096 O-Ring, Nozzle End 14

1785097

O-Ring, Base End 15

PART # DESCRIPTION KEY NO.

180332 PARTS KIT CONTAINS

QTY.

1-800-311-9903

If you have any problems with, or have any questions about your sprayer, BEFORE YOU

RETURN IT TO THE STORE, CALL OUR TOLL FREE CUSTOMER SERVICE CENTER AT:

Expiration Date:_______________

CUT ON DOTTED LINE

Send Check payable to:

The Fountainhead Group, Inc.

23 Garden Street • New York Mills, NY 13417 • Telephone: (800) 311-9903 or (315) 736-0037 • FAX: (315) 768-4220

E-mail: Info@TheFGI.com • Web site: www.TheFountainheadGroup.com

E

N

O

H

P

EM

A

N

ADDRESS

P

I

Z

Y

TIC

STATE

Method of payment

VISA MASTERCARD

$10.00 minimum on all credit card orders.

Acct.

No.

TROUBLE SHOOTING

LIMITED WARRANTY

1-800-311-9903

If you have any problems with, or have any questions about your sprayer,

BEFORE YOU

RETURN IT TO THE STORE, CALL OUR TOLL FREE CUSTOMER SERVICE CENTER AT:

PN 180287

TROUBLETROUBLE

TROUBLETROUBLE

TROUBLE

LOOK FOR LOOK FOR

LOOK FOR LOOK FOR

LOOK FOR

REMEDYREMEDY

REMEDYREMEDY

REMEDY

Sprayer starts to spray Shut-off lock is engaged. Depress button on shut-off

.

k

c

o

l-l

a

t

e

m

esa

e

ler

d

n

a

r

e

yarps ro

g

n

i

pmu

p

n

e

h

w

will not stop spraying.

Sprayer leaks at closure.

Sprayer material overflows Sediment or foreign Depressurize tank.

through pump barrel or particles under check valve Remove pump assembly,

pump handle rises when or chipped, torn, or swollen clean check valve. Replace

handle is unlocked. pump check valve. if necessary.

Hose leaks at tank. 1. Loose hose nut. 1. Tighten hose nut

2. Cracked hose. 2. Replace hose assembly.

Hose leaks at shut-off. Swollen, slit or faulty hose. Replace hose assembly.

Poor spray pattern, partial Spray extension or nozzle

spray or complete clogged.

stoppage.

Sprayer is difficult to pump.

Outlet tube leaks. When shut-off valve is Replace removable plastic

opened, tank air pressure outlet tube.

is released through nozzle

before tank is empty.

Sprayer tank leaks. Evidence of spray material Replace tank.

escaping from tank.

1. Clean all foreign

particles from pump gasket and closure

2. Remove old gasket and

replace with new one.

1. Remove nozzle and

clean.

2. Remove extension and

clean.

1. Replace with new

plunger o-ring.

2. Oil plunger o-ring.

1. Sediment or foreign

particles on surface

gasket or closure.

2. Chipped, torn, swollen,

or defective pump gasket.

1. Damaged or worn

plunger o-ring.

2. Plunger o-ring is dry.

Loading...

Loading...