Page 1

Saba 50

USER GUIDE

Page 2

CONTENTS

TECHNICAL INFORMATION

A) Identity file .......................................................................................................................... 4

B) Characteristics ..................................................................................................................... 5

C) Rigging and fitting ropes ................................................................................................... 6

SAILING

A) Leaving harbour ................................................................................................................. 8

Starting the engines ................................................................................................................... 11

Manoeuvres common to the different engine types .................................................................. 12

B) Sailing .................................................................................................................................. 14

B1) Sail reduction table according to apparent wind ............................................................... 14

B2) Main sail............................................................................................................................. 15

B3) Helm system ...................................................................................................................... 16

C) Anchoring ........................................................................................................................... 17

C1) Setting the anchor .............................................................................................................. 17

C2) Lifting the anchor ............................................................................................................... 18

D) Arrival at harbour ............................................................................................................ 20

Volvo engines: EVC system ..................................................................................................... 20

Page 3

COMFORT

A) Electricity............................................................................................................................ 22

A1) Electrical installations ...................................................................................................... 22

A2) 220V circuit (optional ........................................................................................................ 23

A3) Power generator (optional) ............................................................................................... 24

A4) Sockets on inverter (optional) ............................................................................................ 24

B) Cold ..................................................................................................................................... 25

B1) 2-drawer galley fridge ....................................................................................................... 25

B2) Additional galley freezer or fridge (optional) ................................................................... 26

B3) Additional cockpit fridge (optional) ............................................................................... 26

C) Gas ....................................................................................................................................... 27

D) Water .................................................................................................................................. 28

D1) Fresh water circuit ............................................................................................................. 28

Deck shower (mixer tap optional)............................................................................................. 29

D2) Sea water circuit (optional) .............................................................................................. 29

D3) Using the toilets ................................................................................................................. 30

D4) Using the holding tanks ..................................................................................................... 32

D5) Shower evacuation ......................................................................................................... 33

D6) Sink evacuation ................................................................................................................. 33

D7) Bilge pumping .................................................................................................................. 34

MAN OVER BOARD AND RECOVERY .......................................................................... 35

FIRE PROTECTION ............................................................................................................ 36

A) Recommandations ............................................................................................................... 37

B) Installation .......................................................................................................................... 37

MAINTENANCE .................................................................................................................... 38

Drainage .................................................................................................................................. 38

Page 4

A) IDENTITY FILE

Catégory A : « Ocean-going »

The ship is designed for long journeys during which the wind may exceed force 8 (on the Beaufort scale) and the waves of

significant height of 4 metres, for which these ships are broadly self-sufficient.

HIN NUMBER :

055

BUILDER :

FOUNTAINE PAJOT

Zone industrielle - 17290 AIGREFEUILLE

TYPE OF CRAFT:

CATAMARAN

SERIE :

SABA 50

TECHNICAL INFORMATION

4

DAD_MDP_055_001 — 15/05/16

Page 5

B) Characteristics

Length (LMAX):

14.98 m / 49.15 ft Draft: 1.25 m / 4.1 ft

Width of hull (BH) : 7.99 m / 26.21 ft

Light displacement:

15474 kg

Air draft (excluding antenna):

22.21 m / 72.87 ft

Maximum recommended load:

3995 kg

Maximum load displacement

:

19069 kg

Sails:

Main sail:

Genoa:

Asymmetric spinnaker (optional): Gennaker (optional):

83.5 m2 / 898.79 ft²

57.5 m2 / 618.92 ft²

135 m² approx / 1453.13 ft² 115 m² approx / 1237.85 ft²

Number of people / Maximum load per category:

A: 14 / 5190 Kg B: 14 / 4910 Kg

C: 24 / 5530 Kg D: 30 / 5890 Kg

Inboard engines:

Brand

Reference

Power

Cruising rate Max rate

VOLVO

D2-55 2x55 hp / 2x40.5 kw 2300 3000

YANMAR

4JH5-CE

2x55 hp / 2x39.6 kw 2200

3000

VOLVO

D2-75

2x75 hp / 2x55.9 kw 2300 3000

YANMAR

4JH4TCE 2x75 hp / 2x55.2 kw 2000

3200

Tank capacity:

fresh water: 700 l gas (Option): 2x13 kg

Port diesel tank: 470 l Starboard diesel tank: 470 l

Hot water tank:

60 l

Holding tank for each WC (option):

45 l

Electricity:

Starboard engine battery park 12V 1 x 50 Ah

Service / port battery park

12V

5 x 150 Ah

Dinghy:

Max dinghy length

3.80 m

Max load per davit 100 kg

Max raft dimensions

920x400x580 mm 12 seats

DAD_MDP_055_001 — 15/05/2016

5

Page 6

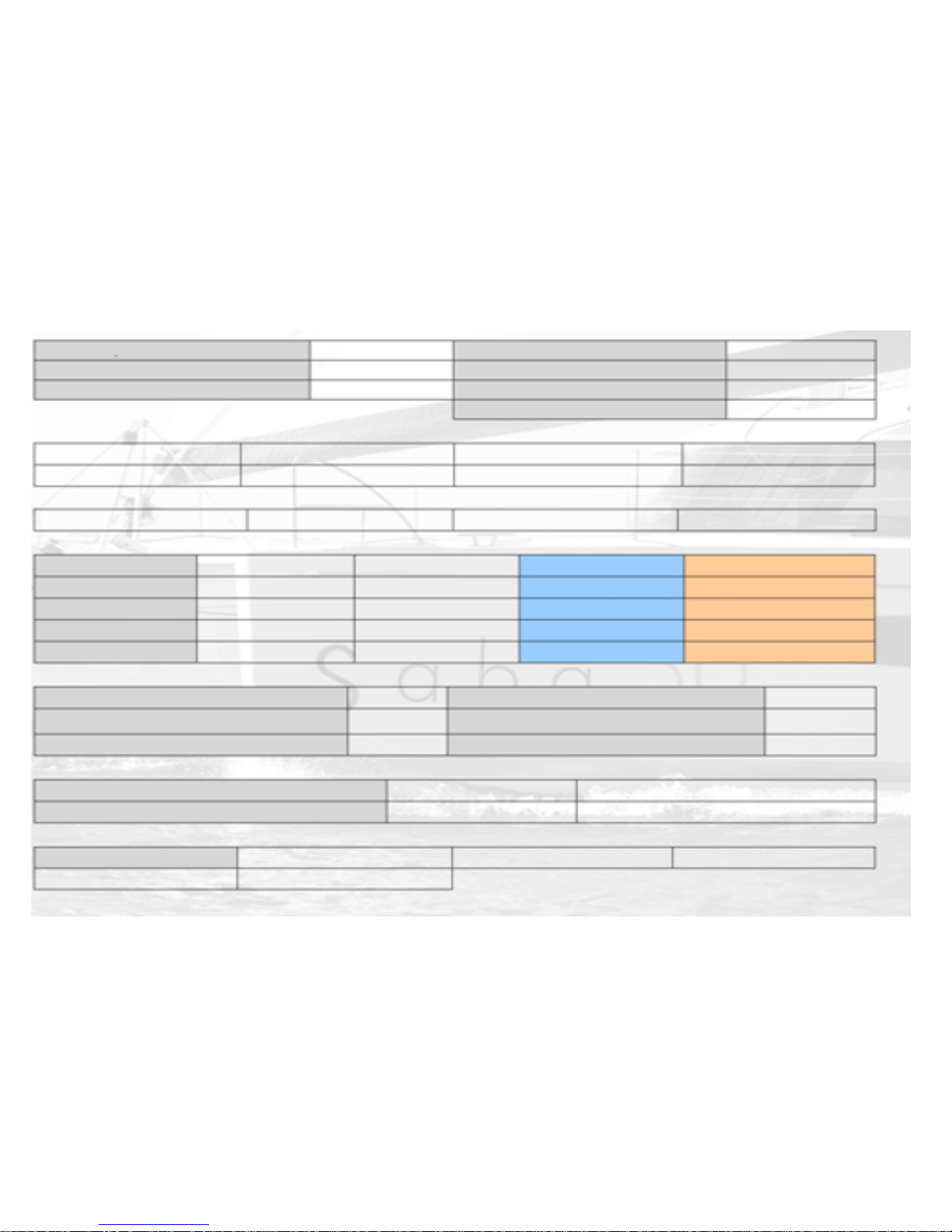

C) Rigging and fitting ropes

DAD_MDP_055_001 — 24/07/2014 6

SABA 50

Description Quality Quantity Ø en mm

Finished

length

Mainsail

sheet

Polyester 24fx, core

polyester braided 12/16fx

1 12 mm 45

Mainsheet

traveller Port side

(Splice

larks head)

Double braid polyester

sheath 16fx, core 12/16fx

1 10 mm 36

Genoa

sheet Port Side

Polyester 24fx, core

polyester braided12/16fx

1 14 mm 18

Genoa

sheet Starboard

Polyester 24fx, core

polyester braided 12/16fx

1 14 mm 15

Roller

reefing

Double braid polyester

sheath 16fx, core 12/16fx

1 10 mm 30

Lashing

border

Dyneema® SK75 16fx,

extended braiding, oiled

1 6 mm 2

RUNNING

RIGGING

Page 7

SABA 50

Description Quality Quantity Ø en mm

Finished

length

Mainsail

halyard

Double

braid polyester

24fx,

core Dyneema

® SK78 12fx

1 14 mm 64

Genoa

halyard

Dyneema® SK78 12fx

preextended et oiled

1 10 mm 20

Gennaker

Halyard

Polyester 24fx, core

polyester braided 12/16fx

1 14 mm 44

Reef

1 (auto)

Polyester 24fx, core

polyester braided 12/16fx

1 14 mm 35

Reef

2

Polyester 24fx, core

polyester braided 12/16fx

1 14 mm 32

Reef

3

Polyester 24fx, core

polyester braided 12/16fx

1 14 mm 35

Lazy

Jack 23ml

Polyester 16fx, core

polyester //

2 8 mm 23

Lazy Jack 6,5ml

Polyester 16fx, core

polyester //

6 8 mm 6,5

Topping

lift

Double braided polyester

sheath 16fx, core 12/16fx

1 12 mm 44

Messenger

Double braid polyester

sheath 16fx, core 12/16fx

1 6 mm 40

RIGGING

MAST

7

DAD_MDP_055_001 — 15/05/2016

Page 8

A) Leaving terminal

Close all the hull portholes, the covers, and the deck and

windscreen panels.

Unlock all the doors and chests then check that the water

has been emptied from the bilges.

Open the diesel valves and the "sea water" inlets

Fill:

• The fresh water tanks from the front port deck

plug.

• The diesel tanks from the plugs on the flats

Interior rear port and starboard cockpit descents.

DAD_MDP_055_001 — 15/05/2016

SAILING

,

8

Page 9

Caution - Battery coupling principle:

• The coupling between the service battery pack and the engine battery

is triggered when the voltage on one of the parks exceeds 13.2 V.

• The coupling is maintained until the park voltage falls below 12.8 V.

• When the voltage is below 12.8 V, the coupling is interrupted and the

engine battery is then isolated from the service park

• The BACKUP/START-UP circuit breaker enables the

battery parks to be coupled IF ONE PARK IS INSUFFICIENT.

It must always be disconnected as soon as the engine is running.

Fuse panels:

The 3 fuse panels are positioned as follows:

1 under the chart table in the saloon,

1 in the rear port engine compartment

1 in the starboard passage hanging closet.

The content of each box is detailed on the lid

.

DAD_MDP_055_001 — 15/05/2016

9

In contact

Connect the circuit breakers (port and port engine compartments) and check that

the windlass circuit breaker is triggered.

Page 10

Check the water and diesel levels on the dashboard

("Navigation instruments" switch on the electrical panel).

Place the safety equipment outside (life belts, life rafts, etc.).

Check that there is no fuel and gas vapour inside the compartments.

DAD_MDP_055_001 — 15/05/2015

10

Page 11

Starting the engines

Check the engine and base levels every month.

Check the opening of the water intake valve on the base in the

engine compartment.

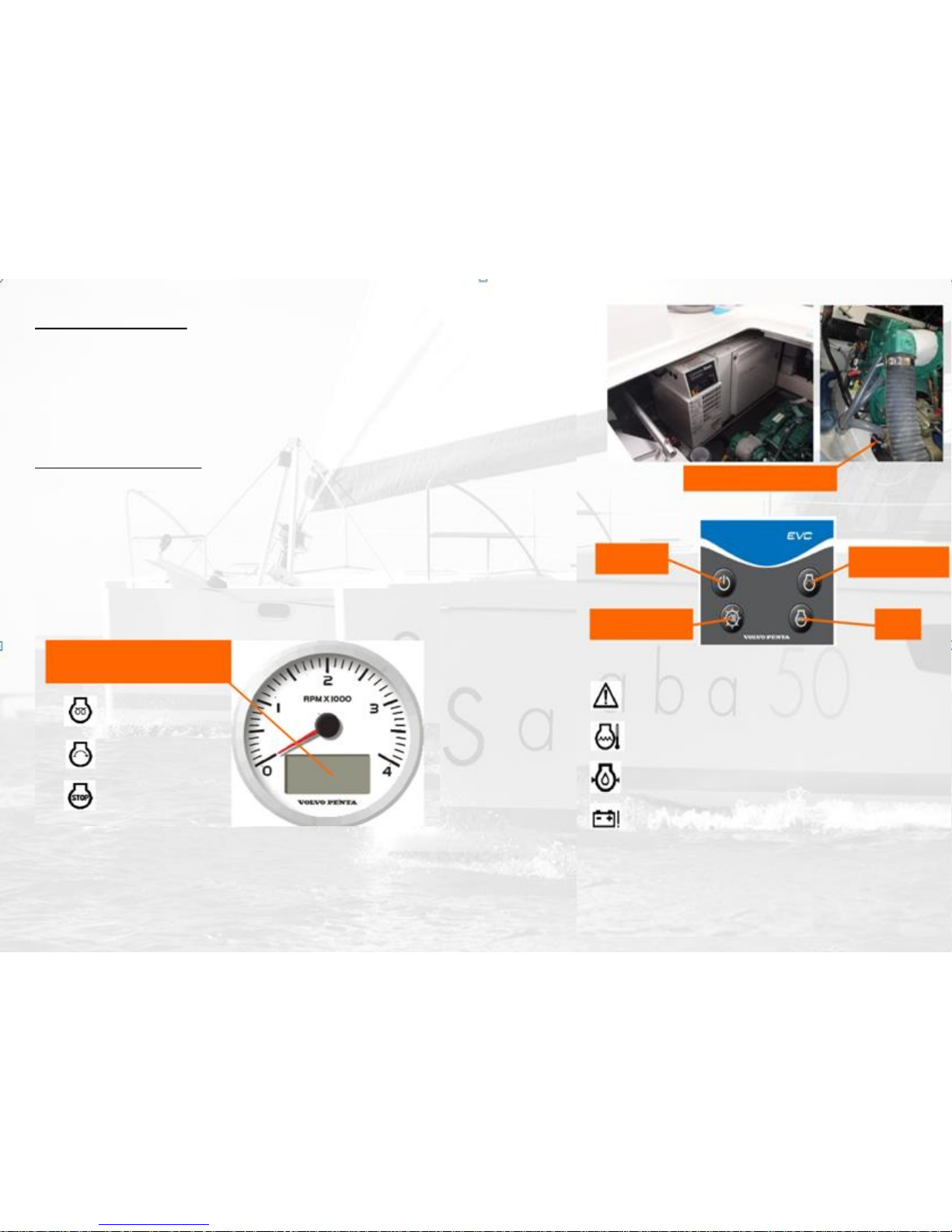

Volvo engines: EVC system

Activate the EVC system by pressing the ON/OFF button.

NB: The EVC control panel cannot be deactivated if an engine is

running.

DAD_MDP_055_001 — 15/05/2016

9

Alarm/Dimmer

ON /OFF

Seawater intake valve

Start (Pre-heat)

Stop

System fault

Cooling fluid temperature

Oil pressure

Batteries

VOLVO REV COUNTER

LCD display

Pre-heating

Starter

engine launch

Off

11

Page 12

Manoeuvres common to the different engine types:

(1) Clutch, position the lever ½ forward,

(2) Start by pressing the START button and let the engines run for 5

min at 1000 rpm (reduced speed to warm up the engine .

Check that the cooling water leaves the exhaust and the

anti-siphon through-hull fitting.

N: Neutral

F: Forward

R: Reverse

T: Acceleration

1: Lever

2: Clutching

Caution - engine supplier's recommendation:

Before starting a navigation under sails, consult the engine

supplier's instruction manual.

CAUTION :

Never activate the starter motor more than ten seconds to start

up the engine as water may get into the exhaust and damage

the engine

12

DAD_MDP_055_001 — 15/05/16

Anti-siphon through-hull fitting

Exhaust outlet

Page 13

Commission the electronic appliances: speedo, log, GPS,

VHF, etc. according to the options installed.

In strong winds, carefully secure anything which could move.

Check operation of navigation lights before night sailings.

DAD_MDP_055_001 — 15/05/2016

13

Page 14

B) Sailing

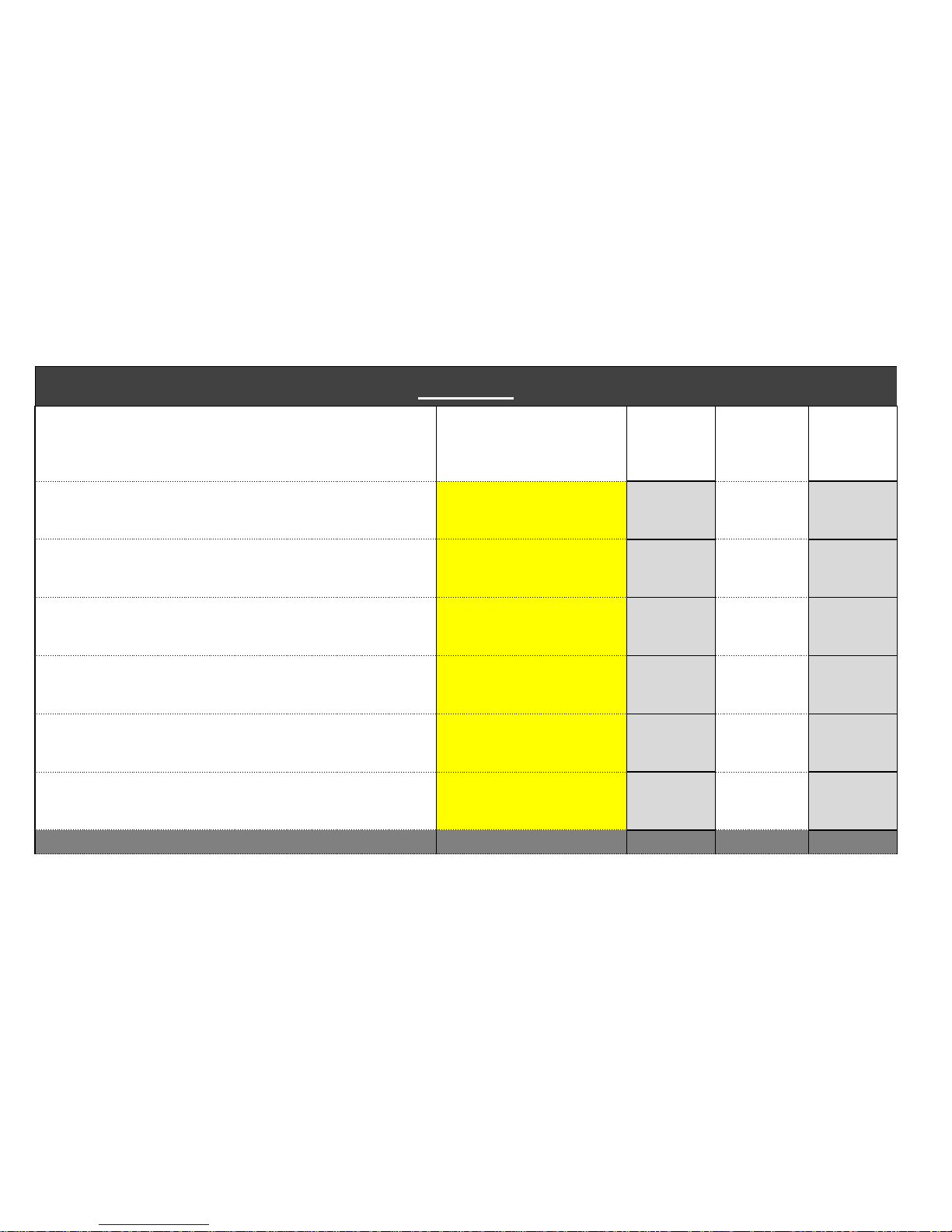

B1) Sail reduction table according to apparent wind

Beat and close reaching Downwind and broad reaching

Maximum

sail area

0-18 knots

0-15 knots

Main

sail 1 reef

Genoa

2/3

18-25 knots

15-20 knots

Main

sail 2 reef

Genoa

½

25-30 knots

20-25 knots

Main

sail 3 reef

Genoa

1/3

30-35 knots

25-30 knots

Main

sail 3 reef

Genoa

1/5

35-40 knots

30-35 knots

Main

sail down

Genoa

1/10

> 40 knots

> 35 knots

Using the asymmetric spinnaker or gennaker (optional)

The asymmetric spinnaker and the gennaker are sails that are

designed to be used in high speeds and relative wind below 15

knots.

-They must be stored:

-In winds over 15 knots

- When anchored

-In dock

- When not used in sailing

02010523222120

19

DWL

1817162408100913121114150607090403

0712 0506 010203

DWL

20212324 22 1718 14151619 08 0413 091011

07081213 1011 03040506091718 141920212223 151624

DWL

0102 09

0110 0913 09021112 08 07 0605 0421 20 19 1423 22 0318 17 1615

DWL

24

13 091011 02 090112 07192021 040508 0314 06222324 15161718

DWL

02 0111 10 0913 12 0907 0423 08 0521 20 0618 17 1622 19 1415

DWL

24 03

14

DAD_MDP_055_001 — 15/05/16

Page 15

B2) Main sail

1

Hoisting the mainsail

1) Hoist the mainsail almost to the 1st spreaders’ level.

The mainsail head comes close to the mast

2) Using the green handle, bring the stainless steel hookinto contact with the

headboard car

Pull sharply the handle in order to hook the mainsail head onto the headboard

car

3) Store properly the 2 handles ( red and green) into the pocket , that avoids the

hook lines getting trapped into the standing rigging or the lazy jacks.

4) Hoist the main sail

2

4

DAD_MDP_055_001 — 15/05/2016 15

Headboard car

Hook

Lowering the mainsail

1) Bring the mainsail down to until you can reach the hook handle pocket

and bring out the red handle

2) Pull sharply onto the red handle to unhook the mainsail

3) Lower the rest of the mainsail, the head batten will stack properly along

the mainsail

4

3

3

Page 16

B3) Helm system

LINK TILLER

The steering wheel pilots a hydraulic system which

uses the starboard cylinder to drive a transverse link

tiller that connects the 2 stock arms on the rudder

blade.

HYDRAULIC CYLINDER

To use the emergency tiller, you must first release the

hydraulic

circuit cylinder using the "BY-PASS" in "ON" position.

The emergency tiller is secured to the top of the PORT

or STARBOARD rudder blade. It is only designed for

sailing at reduced speed in the event of damage to the

helm.

BY-PASS OFF BY-PASS ON

DAD_MDP_055_001 — 15/05/2016 16

Page 17

C) Anchoring:

Check that the port engine is running (1500 rpm).

The windlass is controlled using the remote control in the anchor tub.

C1 Setting up the anchor

Unhook the safety hoist and drop the anchor and chain to a few

metres from the final length desired.

Hook the chain to the bridle snap hook availlable in the

anchor locker

DAD_MDP_055_001 — 15/05/2016

17

Page 18

Drop the end of the length of chain desired until the

anchoring tension is picked up by the bridle.

C2) Lifting the anchor

Raise the anchor to the bridle snap hook and undo the snap hook from the

bridle.

Raise the anchoring slowly, checking that the anchor is placed

correctly in its davit.

When the anchor is close to the davit, check that the tip moves into the

davit entry roller in the right direction.

DAD_MDP_055_001 — 15/05/2016

18

Page 19

Lock the chain with the hoist provided.

The circuit breaker is triggered if there is too much effort applied to the

windlass;

reset it to restart the windlass.

Attention

During operation, keep away from the windlass and

the chain.

In particular, make sure that you protect your hands

and feet.

DAD_MDP_055_001 — 15/05/2016

19

Page 20

D) Arrival at terminal:

Volvo engines: EVC system

Stop the engines by pressing the STOP button (1), then press the ON/OFF

button to deactivate the system. (2)

NB: Always let the engines run idle for a few minutes before shutting them

down completely.

Disconnect all the functions on the electrical panel.

Close all the gas supply valves (bottle, appliances).

Check that the water has been drained from the bilges.

Disconnect the battery circuit breakers when stopped for a long period.

DAD_MDP_055_001 — 15/05/2016

20

2

1

Page 21

Close the diesel tank valves when there is a long stoppage period.

These are located under the bed frame in the port and starboard aft cabins.

DAD_MDP_055_001 — 15/05/2016

21

Page 22

A) Electricity:

A1) Electrical installations

Engine 12 V DC network

The onboard power is produced by the engine alternators

(130 Ah) and stored by 12V DC batteries.

The batteries are separated into 2 separate parks:

Engine battery / port service park = 5 x150 Ah

Starboard engine battery park = 1 x 50 Ah

The starboard engine battery park powers:

the starboard engine only

The port engine battery powers

the port engine

All the 12v functions on the electrical distribution panel.

Caution - Battery coupling principle:

The coupling between the service battery park and the engine battery is triggered when the voltage on one of the parks exceeds 13.2 V.

The coupling is maintained until the park voltage falls below 12.8 V.

When the voltage is below 12.8 V, the coupling is interrupted and the engine battery is then isolated from the service park.

The BACKUP/START-UP circuit breaker enables the battery parks to be coupled IF ONE PARK IS INSUFFICIENT.

It must always be disconnected as soon as the engine is running.

DAD_MDP_055_001 — 15/05/2016

220 V AC alternating network: (optional)

The 220 V AC alternating network is powered:

- Either by a dock extension

- Or by a power generator (optional)

The whole network is protected by a 30 mA differential

circuit breaker.

- Each function is protected by a circuit breaker

.

22

COMFORT

Page 23

A2) 220 V AC circuit: (optional)

Connect the dock extension by rolling it out fully or start the power generator.

Check the cable's condition,

If the cable is damaged, replace it with an identical cable.

.

Attention

Never connect an extension whose plug is damp.

Check that the current is flowing using the light indicator on the 220V unit.

Push in the differential circuit breaker and the circuit breakers for the function

required (starboard engine compartment).

Light indicator

DAD_MDP_055_001 — 15/05/2016 23

Page 24

A3) Power generator (optional):

To use the generator, refer to the supplier's documents.

Push in the generator's circuit breaker before you start it up.

The generator may be started locally in the starboard

compartment, or by remote from the chart table in the saloon.

The dock / generator switch is selected automatically.

A4) Sockets on inverter (optional):

Push in the differential circuit breaker and the circuit breakers

(starboard engine compartment)

A remote control panel is located on the back of the chart table.

DAD_MDP_055_001 — 15/05/206

24

Page 25

B) Cold:

Check the service battery park charge status (aft port

compartment) on the battery controller on the chart table.

Attention

If the service battery park charge level is ≤ 11.7V,

the refrigeration unit switches to safety.

B1) 2-drawer galley fridge

This is started up using the "Refrigerator" switch on the

electrical panel.

Set the cooling thermostat to the temperature required.

(For maintenance, see the manufacturer's manual)

DAD_MDP_055_001 — 15/05/2015

25

Attention

Respect the following instructions to limit the 12V energy consumption:

• Set the refrigerator thermostat to the minimum necessary

Limit door opening.

• Keep the refrigerator well filled,

• Defrost the refrigerator regularly.

Page 26

B2) Additional galley 12V 90L freezer/

or 130L refrigerator (OPTIONAL)

This is started up using the "Refrigerator" switch

on the electrical panel.

Set the freezer thermostat to the temperature required.

(For maintenance, see the manufacturer's manual)

B3) Additional 12V cockpit freezer

(OPTIONAL)

This is started up via the thermostat.

Set the freezer thermostat to the temperature required.

(For maintenance, see the manufacturer's manual)

DAD_MDP_055_001 — 15/05/2016

26

Page 27

C) Gas:

Open the general shut-off valve and the shut-off valve for the

appliance to be used (kitchen cupboard).

(valves open in the direction of the pipe)

Each gas appliance has a safety system.

To switch it on, hold the button down.

Attention

Ventilate fully when using the cooking surface.

DAD_MDP_055_001 — 15/05/2016

27

Open the regulator shut-off valve attached directly to the bottle

(gas unit in the cockpit).

Page 28

D) Water:

D1) Fresh water circuit

Open the main valve on the circuit to power the circuit from

the tanks (accessible under the chart table).

Check that the hot water tank supply valve (aft port cabin)

is in open position at all times.

Trigger the fresh water pump function on the electrical panel

DAD_MDP_055_001 — 15/05/2016

28

Page 29

Deck shower (mixer tap optional)

The deck shower is located on the aft starboard skirt.

It is commissioned by two taps (aft starboard

compartment) and activated by a mixer just beside it

(optional).

D2) Sea water circuit (OPTION)

Open the sea water supply valve at the bottom of the

port passage staircase.

Trigger the sea water pump function on the electrical

panel

DAD_MDP_055_001 — 15/05/2016

Future option

29

Page 30

D3) Using the toilets

Check that the sea water intake valves and the W.C.

evacuation valves are open.

The floor hatches open using suckers (stored in the

chart table).

Supply:

2 valves in each hull located under the forward

port/starboard and aft port/starboard cabins.

Evacuation:

1 evacuation valve per bathroom, accessible via the hatch

located in each shower.

DAD_MDP_055_001 — 15/05/2016 30

Page 31

Use the toilets in open sea only unless the craft is equipped

with a Holding tank.

Set the W.C. lever to "Water intake" position and pump

at least 10 times to evacuate and dilute the black water.

Set the W.C. lever to "Evacuation" position and pump

a few times to empty the bowl completely.

Repeat the operation at least twice.

DAD_MDP_055_001 — 15/05/2016

31

Page 32

D4) Using the holding tanks

To store the black water in the holding tanks:

• Close the evacuation valve (accessible via the hatch in

each shower)

Attention :

Never force the pump.

Storage capacity: 45 litres.

Drain the holding tank regularly :

• By evacuating the black water directly into the sea

(Open the evacuation valve when out at sea only)

• At the dock by pumping in the "Waste" deck plug.

DAD_MDP_055_001 — 15/05/2016

32

Page 33

D5) Shower evacuation

The shower drain is automatic. The grey water is stored

in a tank under the passage floors that evacuates directly into

the sea.

These tanks may be cleaned via a screwed-down access hatch.

D6) Sink evacuation

1 port sink evacuation valve and 1 starboard sink evacuation valve,

accessible via the hatches in the after port and starboard showers.

DAD_MDP_055_001 — 15/05/2016

33

Page 34

D7) Bilge pumping

:

Manual bilge pump ( in cockpit locker)

Open and unfold the manual pump on the aft port front panel

in the aft bench. A pipe stored inside the locker must unrolled

to drain the desired zones.

Electric bilge pumping

The craft is fitted with 6 electric bilge pumps :

1 per engine compartment,

2 per hull.

Push in the switch on the electrical panel: 2 positions possible

1) AUTO position (optional):

The bilge pump is triggered automatically if any water gets

in and its operation is indicated by an alarm.

1) MANUAL position:

The bilge pump is triggered manually by activating

the switch on the electrical panel.

Set the switch back to OFF position when drainage is

complete.

DAD_MDP_055_001 — 15/05/2016

34

Page 35

IV- MANOVERBOARD AND RECOVERY

During a passage at sea, it is recommended to remains in the areas of the deck that are designed for it.

These areas (sidewalks, cockpit, coachroof, mast step etc..…) are covered with an antiskid surface or teak covering that allow the crew

to move on the boat in a secure way.

It is also recommended, according to sea or wind conditions, to wear safety harnesses and use the various securing points on the deck

that are mentionned in the deck plan.

SABA is equipped with sternladder (starboard transom) that is designed to allow a crew to climb back on board in a manoverboard

situation

35

DAD_MDP_055_001 — 15/05/16

Page 36

V – FIRE PROTECTION

A) Installation

Fire extinguishers are subject to national rules, thus they are not supplied with the boat.

However, while being used, the boat must be equipped with portable extinguishers with the following fire fighting capacities and

these must be stored in specific areas of the boat.

• 1 kg powder extinguisher : entrance of saloon (galley cabinet)

• 1 kg powder extinguisher : port fore cabin

• 4 kg powder extinguisher + flexible : port aft cabin

• 4 kg powder extinguisher + flexible : starboard aft cabin

If you choose to install a carbon dioxyde extinguisher, it can not be installed in any living space holding any electrical equipments

under tension (for example electrical motors, battery compartment, powered hatches..) or inflammable liquids ( in galley for

example).

A fire blanket should also be stored near the galley, that is useful in case of gas stove fire (cause by oil for example)

36

DAD_MDP_055_001 — 15/05/16

Page 37

Engine room fire

extinguisher orifice

Engine

room fire

extinguish

er orifice

In order to access to this orifice, it is required to move

the mattress. Then punch through the orifice with the

fire extinguisher’s flexible and trigger the extinguisher

according to manufacturer’s instruction

Orifice view from

engine room

Engine room fire extinguisher orifice are located behind

the matttress below the bed headboard

DAD_MDP_055_001 — 15/05/16

37

A) Recommandations

B) Installation

Page 38

Drainage

DATE SAILING TIMES

FILTER CHANGE

DAD_MDP_055_001 — 15/05/2016

38

MAINTENANCE

Page 39

DATE SAILING TIMES FILTER CHANGE

DAD_MDP_055_001 — 15/05/2016

39

Loading...

Loading...