Foundry Networks NetIron MLX-4, NetIron MLX-8, NetIron MLX-16, NetIron MLX-32 Installation And Configuration Manual

Page 1

Foundry® NetIron MLX Series

Installation and Basic Configuration

Guide

NetIron MLX-4

NetIron MLX-8

NetIron MLX-16

NetIron MLX-32

Release 04.0.00

Release Date: December 17, 2008

Publish Date: December 31, 2008

Page 2

Copyright © 2008 Foundry Networks, Inc. All rights reserved.

No part of this work may be reproduced in any form or by any means – graphic, electronic or mechanical, including

photocopying, recording, taping or storage in an information retrieval system – without prior written permission of the

copyright owner.

The trademarks, logos and service marks ("Marks") displayed herein are the property of Foundry® or other third

parties. You are not permitted to use these Marks without the prior written consent of Foundry or such appropriate third

party.

Foundry Networks, BigIron, Terathon, FastIron, IronView, JetCore, NetIron, SecureIron, ServerIron, Tu r b o Ir o n ,

IronWare, EdgeIron, IronPoint, the Iron family of marks and the Foundry Logo are trademarks or registered trademarks

of Foundry Networks, Inc. in the United States and other countries.

F-Secure is a trademark of F-Secure Corporation. All other trademarks mentioned in this document are the property of

their respective owners.

Foundry Networks

4980 Great America Parkway

Santa Clara, CA 95054

Tel 408.207.1700

www.foundrynetworks.com

Page 3

Contents

CHAPTER 1

ETTING STARTED...................................................................................... 1-1

G

INTRODUCTION ...........................................................................................................................................1-1

A

UDIENCE ..................................................................................................................................................1-1

N

OMENCLATURE .........................................................................................................................................1-1

U

PDATES TO MANUALS ...............................................................................................................................1-1

H

OW TO GET HELP OR REPORT ERRORS ....................................................................................................1-2

W

EB ACCESS .......................................................................................................................................1-2

E

MAIL ACCESS .....................................................................................................................................1-2

T

ELEPHONE ACCESS ............................................................................................................................1-2

W

ARRANTY COVERAGE ...............................................................................................................................1-2

CHAPTER 2

RODUCT OVERVIEW .................................................................................. 2-1

P

PRODUCT OVERVIEW ..................................................................................................................................2-1

N

ETIRON MLX SERIES ROUTER APPLICATIONS ...........................................................................................2-2

H

ARDWARE FEATURES ...............................................................................................................................2-2

C

HASSIS ..............................................................................................................................................2-2

N

ETIRON MLX-4 ........................................................................................................................... 2-6

N

ETIRON MLX-8 ........................................................................................................................... 2-6

N

ETIRON MLX-16 ......................................................................................................................... 2-6

N

ETIRON MLX-32 ......................................................................................................................... 2-7

M

ANAGEMENT MODULES ......................................................................................................................2-7

PCMCIA S

C

ONSOLE PORT............................................................................................................................. 2-8

10/100/1000 E

LED

I

NTERFACE MODULES .........................................................................................................................2-10

10 G

FE/G

10/100/1000 E

1 G

IGABIT X 48-T MODULE .......................................................................................................... 2-14

December 2008 © 2008 Foundry Networks, Inc. -iii

LOTS............................................................................................................................ 2-8

THERNET PORT ...................................................................................................... 2-8

S............................................................................................................................................ 2-9

IGABIT ETHERNET INTERFACE MODULES (2-PORT AND 4-PORT) ............................................. 2-10

BE (100/1000) ETHERNET INTERFACE MODULE (SFP)......................................................... 2-12

THERNET INTERFACE MODULE (RJ-45) ................................................................. 2-14

Page 4

Foundry NetIron MLX Series Installation and Basic Configuration Guide

POS INTERFACE MODULES ................................................................................................................2-15

D

UAL SPEED OC-12C AND OC-48C............................................................................................. 2-15

S

INGLE-SPEED OC-192C ............................................................................................................ 2-16

LED O

OC-12

OC-192

C

S

WITCH FABRIC MODULE ...................................................................................................................2-20

P

OWER SUPPLIES ..............................................................................................................................2-22

B

UILT-IN MOUNTING BRACKETS ..........................................................................................................2-23

C

OOLING SYSTEM ..............................................................................................................................2-23

R

ACK MOUNT KIT ..............................................................................................................................2-27

S

UPPORTED SOFTWARE FEATURES ...........................................................................................................2-27

PERATION ......................................................................................................................... 2-17

C AND OC-48C PORTS...................................................................................................... 2-18

C PORTS......................................................................................................................... 2-19

LOCKING AND TIMING A POS INTERFACE MODULE...................................................................... 2-19

CHAPTER 3

INSTALLING A NETIRON MLX SERIES ROUTER ............................................ 3-1

INSTALLATION PRECAUTIONS ................................................................................................................3-1

G

ENERAL PRECAUTIONS ................................................................................................................ 3-1

P

OWER PRECAUTIONS .........................................................................................................................3-2

I

NSTALLING A NETIRON MLX-4 ROUTER ......................................................................................................3-4

P

REPARING THE INSTALLATION SITE .....................................................................................................3-4

C

ABLING INFRASTRUCTURE ............................................................................................................ 3-4

I

NSTALLATION LOCATION................................................................................................................ 3-4

U

NPACKING A NETIRON MLX-4 ROUTER ...............................................................................................3-4

C

HASSIS LIFTING GUIDELINES FOR NETIRON MLX-4 ROUTERS ..............................................................3-5

I

NSTALLING A NETIRON MLX-4 CHASSIS IN A RACK ..............................................................................3-5

P

REPARING TO MOUNT A NETIRON MLX-4 CHASSIS IN A RACK ...................................................... 3-5

R

EMOVING NETIRON MLX-4 EXTRA SHIPMENT SCREWS................................................................. 3-5

M

OUNTING A NETIRON MLX-4 CHASSIS IN A RACK......................................................................... 3-5

R

EMOVING THE SLOT BLANKS........................................................................................................ 3-7

I

NSTALLING NETIRON MLX-4 MODULES ................................................................................................3-7

I

NSTALLING POWER SUPPLIES IN A NETIRON MLX-4 CHASSIS ...............................................................3-9

C

ONNECTING AC POWER TO A NETIRON MLX-4 CHASSIS .....................................................................3-9

C

ONNECTING DC POWER TO A NETIRON MLX-4 CHASSIS ..................................................................3-10

F

INAL STEPS ......................................................................................................................................3-11

I

NSTALLING A NETIRON MLX-8 ROUTER ....................................................................................................3-12

P

REPARING THE INSTALLATION SITE ...................................................................................................3-12

C

ABLING INFRASTRUCTURE .......................................................................................................... 3-12

I

NSTALLATION LOCATION.............................................................................................................. 3-12

U

NPACKING A NETIRON MLX-8 ROUTER .............................................................................................3-12

C

HASSIS LIFTING GUIDELINES FOR NETIRON MLX-8 ROUTERS ............................................................3-13

I

NSTALLING THE NETIRON MLX-8 CHASSIS IN A RACK .........................................................................3-13

P

REPARING TO MOUNT A NETIRON MLX-8 CHASSIS IN A RACK .................................................... 3-13

R

EMOVING NETIRON MLX-8 EXTRA SHIPMENT SCREWS............................................................... 3-13

M

OUNTING A NETIRON MLX-8 CHASSIS IN A RACK....................................................................... 3-13

R

EMOVING THE SLOT BLANKS...................................................................................................... 3-15

I

NSTALLING NETIRON MLX-8 MODULES ..............................................................................................3-15

I

NSTALLING POWER SUPPLIES IN THE NETIRON MLX-8 CHASSIS .........................................................3-17

C

ONNECTING AC POWER TO A NETIRON MLX-8 CHASSIS ...................................................................3-17

-iv © 2008 Foundry Networks, Inc. December 2008

Page 5

Contents

CONNECTING DC POWER TO A NETIRON MLX-8 CHASSIS ..................................................................3-18

F

INAL STEPS ......................................................................................................................................3-19

I

NSTALLING A NETIRON MLX-16 ROUTER ..................................................................................................3-20

P

REPARING THE INSTALLATION SITE ...................................................................................................3-20

C

ABLING INFRASTRUCTURE .......................................................................................................... 3-20

I

NSTALLATION LOCATION.............................................................................................................. 3-20

U

NPACKING A NETIRON MLX-16 ROUTER ...........................................................................................3-20

C

HASSIS LIFTING GUIDELINES FOR NETIRON MLX-16 ROUTERS ..........................................................3-21

I

NSTALLING A CHASSIS IN A RACK .......................................................................................................3-21

P

REPARING TO MOUNT A NETIRON MLX-16 CHASSIS IN A RACK .................................................. 3-21

A

TTACHING MOUNTING BRACKETS TO A NETIRON MLX-16 CHASSIS ............................................. 3-21

M

OUNTING A NETIRON MLX-16 CHASSIS IN A RACK..................................................................... 3-22

R

EMOVING THE SLOT BLANKS...................................................................................................... 3-23

I

NSTALLING NETIRON MLX-16 MODULES ............................................................................................3-23

P

OPULATING A NETIRON MLX-16 CHASSIS .................................................................................. 3-25

R

ULES FOR POPULATING A NETIRON MLX-16 CHASSIS ................................................................ 3-25

I

NSTALLING POWER SUPPLIES IN A NETIRON MLX-16 CHASSIS ...........................................................3-25

C

ONNECTING AC POWER TO A NETIRON MLX-16 CHASSIS .................................................................3-26

C

ONNECTING DC POWER TO A NETIRON MLX-16 CHASSIS ................................................................3-27

F

INAL STEPS ......................................................................................................................................3-28

I

NSTALLING A NETIRON MLX-32 ROUTER ..................................................................................................3-29

P

REPARING THE INSTALLATION SITE ...................................................................................................3-29

C

ABLING INFRASTRUCTURE .......................................................................................................... 3-29

I

NSTALLATION LOCATION.............................................................................................................. 3-29

U

NPACKING A NETIRON MLX-32 ROUTER ...........................................................................................3-29

U

NCRATING THE NETIRON MLX-32 CHASSIS................................................................................ 3-30

I

NSTALLING A NETIRON MLX-32 CHASSIS IN A RACK ..........................................................................3-31

P

REPARING TO MOUNT A NETIRON MLX-32 CHASSIS IN A RACK .................................................. 3-31

A

TTACHING MOUNTING BRACKETS TO A NETIRON MLX-16 OR

N

ETIRON MLX-32 CHASSIS ............................................................................................ 3-31

M

OUNTING A NETIRON MLX-32 CHASSIS IN A RACK..................................................................... 3-31

I

NSTALLING NETIRON MLX-32 MODULES ............................................................................................3-33

N

ETIRON MLX-32 MODULE INSTALLATION DETAILS ...................................................................... 3-34

U

SING THE INSERTION/EXTRACTION TOOL .................................................................................... 3-35

N

ETIRON MLX-32 CABLE MANAGEMENT .............................................................................................3-36

C

ABLE ROUTING FOR THE UPPER-LEFT QUADRANT....................................................................... 3-38

C

ABLE ROUTING FOR THE UPPER-RIGHT QUADRANT..................................................................... 3-40

C

ABLE ROUTING FOR THE LOWER-LEFT QUADRANT. ..................................................................... 3-42

C

ABLE ROUTING FOR THE LOWER-RIGHT QUADRANT. ................................................................... 3-44

I

NSTALLING POWER SUPPLIES IN A NETIRON MLX-32 CHASSIS .................................................................3-45

C

ONNECTING AC POWER TO A NETIRON MLX-32 CHASSIS .................................................................3-46

C

ONNECTING DC POWER TO A NETIRON MLX-32 CHASSIS ................................................................3-47

F

INAL STEPS ......................................................................................................................................3-49

A

TTACHING A MANAGEMENT STATION .......................................................................................................3-49

A

TTACHING A PC OR TERMINAL TO THE CONSOLE PORT OR ETHERNET PORT .....................................3-50

A

TTACHING THE MANAGEMENT MODULE’S ETHERNET PORT TO A NETWORK ........................................3-50

P

OWERING-ON THE POWER SOURCE ........................................................................................................3-50

V

ERIFYING PROPER OPERATION ...............................................................................................................3-51

O

BSERVING THE LEDS .......................................................................................................................3-51

December 2008 © 2008 Foundry Networks, Inc. -v

Page 6

Foundry NetIron MLX Series Installation and Basic Configuration Guide

DISPLAYING THE MODULE STATUS ......................................................................................................3-57

CHAPTER 4

ONNECTING A NETIRON MLX SERIES ROUTER

C

TO A NETWORK DEVICE .............................................................................. 4-1

ASSIGNING PERMANENT PASSWORDS .........................................................................................................4-1

C

ONFIGURING IP ADDRESSES .....................................................................................................................4-2

S

UPPORT OF SUB-NET MASKS .............................................................................................................4-3

A

SSIGNING AN IP ADDRESS TO A MANAGEMENT INTERFACE ..................................................................4-3

A

SSIGNING AN IP ADDRESS TO AN INTERFACE, VIRTUAL INTERFACE, OR LOOPBACK ...............................4-4

E

NABLING AND DISABLING THE INTERFACES ..........................................................................................4-5

U

NDERSTANDING HOW THE MANAGEMENT PORT FUNCTIONS .......................................................................4-5

C

ONNECTING A NETIRON MLX SERIES ROUTER .........................................................................................4-5

I

NSTALLING A FIBER-OPTIC MODULE .....................................................................................................4-5

C

ABLING A FIBER-OPTIC MODULE .........................................................................................................4-6

C

LEANING FIBER-OPTIC MODULES ........................................................................................................4-6

T

ROUBLESHOOTING NETWORK CONNECTIONS .......................................................................................4-6

T

ESTING NETWORK CONNECTIVITY ..............................................................................................................4-8

P

INGING AN IP ADDRESS ......................................................................................................................4-8

T

RACING A ROUTE ...............................................................................................................................4-8

CHAPTER 5

ANAGING THE NETIRON MLX SERIES

M

HASSIS AND MODULES ............................................................................. 5-1

C

MANAGING THE NETIRON MLX SERIES CHASSIS .........................................................................................5-1

D

ISPLAYING CHASSIS STATUS AND TEMPERATURE READINGS ................................................................5-1

D

ISPLAYING THE SYSLOG CONFIGURATION AND STATIC AND DYNAMIC BUFFERS ....................................5-4

S

TATIC AND DYNAMIC BUFFERS ..................................................................................................... 5-5

M

ANAGING THE COOLING SYSTEM ..............................................................................................................5-6

C

ONFIGURING THE COOLING SYSTEM ...................................................................................................5-6

C

HANGING TEMPERATURE THRESHOLDS FOR MODULES AND FAN SPEEDS...................................... 5-6

C

HANGING THE TEMPERATURE POLLING INTERVAL ....................................................................... 5-11

M

ANUALLY SETTING THE FAN SPEED ..................................................................................................5-11

M

ONITORING THE COOLING SYSTEM ...................................................................................................5-12

D

ISPLAYING FAN TRAY STATUS AND SPEED ................................................................................. 5-12

D

ISPLAYING TEMPERATURE WARNINGS ....................................................................................... 5-12

T

EMPERATURE LOG REDUCTION .........................................................................................................5-13

C

ONFIGURING TEMPERATURE LOGGING........................................................................................ 5-13

M

ANAGING THE INTERFACE MODULES .......................................................................................................5-13

C

ONFIGURING INTERFACE MODULE BOOT PARAMETERS ......................................................................5-14

S

YNCHRONIZING THE INTERFACE MODULE’S MULTI-SERVICE IRONWARE IMAGES BETWEEN

M

ANAGEMENT AND INTERFACE MODULES ........................................................................ 5-14

C

HANGING THE BOOT SOURCE .................................................................................................... 5-15

C

HANGING PRIORITY OF CHASSIS SLOTS FOR INTERFACE MODULES ....................................................5-18

D

ISABLING AND REENABLING POWER TO THE INTERFACE MODULES .....................................................5-19

E

NABLING AND DISABLING MANAGEMENT MODULE CPU USAGE CALCULATIONS .........................................5-19

D

ISPLAYING CPU USAGE ...................................................................................................................5-20

-vi © 2008 Foundry Networks, Inc. December 2008

Page 7

Contents

DISPLAYING MANAGEMENT MODULE CPU USAGE .....................................................................................5-21

E

NABLING AND DISABLING PACKET LOGGING FOR MANAGEMENT AND INTERFACE MODULES .......................5-21

D

ISPLAYING A PACKET LOG ................................................................................................................5-22

R

EMOVING MAC ADDRESS ENTRIES .........................................................................................................5-24

CHAPTER 6

MAINTAINING A NETIRON MLX SERIES ROUTER ..........................................6-1

HARDWARE MAINTENANCE SCHEDULE .........................................................................................................6-1

C

LEANING THE FIBER-OPTIC CONNECTORS .................................................................................................6-2

R

EPLACING A MANAGEMENT MODULE .........................................................................................................6-2

R

EMOVING A MANAGEMENT MODULE ....................................................................................................6-2

I

NSTALLING A NEW MANAGEMENT MODULE ...........................................................................................6-3

R

EPLACING AN INTERFACE MODULE ............................................................................................................6-3

R

EMOVING AN INTERFACE MODULE .......................................................................................................6-4

I

NSTALLING A NEW INTERFACE MODULE ................................................................................................6-4

R

EPLACING A SWITCH FABRIC MODULE .......................................................................................................6-8

R

EMOVING A SWITCH FABRIC MODULE .................................................................................................6-8

I

NSTALLING A NEW SWITCH FABRIC MODULE ........................................................................................6-8

R

EPLACING A FIBER-OPTIC TRANSCEIVER ...................................................................................................6-9

R

EMOVING A FIBER-OPTIC TRANSCEIVER ..............................................................................................6-9

I

NSTALLING A NEW FIBER-OPTIC TRANSCEIVER .....................................................................................6-9

C

ABLING A FIBER-OPTIC TRANSCEIVER ...............................................................................................6-10

R

EPLACING A POWER SUPPLY ..................................................................................................................6-10

D

ETERMINING WHICH POWER SUPPLY FAILED ....................................................................................6-10

S

ETTING THE THRESHOLD FOR POWER SUPPLY MONITORING ..............................................................6-10

C

LEARING POWER SUPPLY FAILURE TIMESTAMPS ...............................................................................6-11

D

ISPLAYING POWER SUPPLY MONITORING TIMESTAMPS ......................................................................6-11

E

NABLING A POWER SUPPLY SHUTDOWN ............................................................................................6-11

P

OWERING ON THE POWER SUPPLY THROUGH THE CLI ......................................................................6-12

R

EPLACING A POWER SUPPLY ............................................................................................................6-12

R

EPLACING FAN ASSEMBLIES ....................................................................................................................6-14

R

EPLACING FAN ASSEMBLIES IN THE NETIRON MLX-32 ......................................................................6-14

R

EPLACING FAN ASSEMBLIES IN THE NETIRON MLX-16 ......................................................................6-15

R

EPLACING THE REAR FAN ASSEMBLIES IN THE NETIRON MLX-16 ............................................... 6-16

R

EPLACING THE FRONT FAN ASSEMBLY IN THE NETIRON MLX-16 ................................................ 6-17

R

EPLACING THE FAN TRAY ASSEMBLY IN THE NETIRON MLX-4 AND NETIRON MLX-8 ..........................6-17

R

EPLACING THE AIR FILTERS IN A NETIRON MLX SERIES ROUTER ......................................................6-19

R

EPLACING THE AIR FILTERS IN THE NETIRON MLX-32 ................................................................ 6-19

R

EPLACING THE AIR FILTER IN THE NETIRON MLX-16 .................................................................. 6-21

R

EPLACING THE AIR FILTER IN THE NETIRON MLX-4 OR NETIRON MLX-8..................................... 6-22

CHAPTER 7

PGRADING SOFTWARE IMAGES AND CONFIGURATION FILES....................... 7-1

U

SNMP ON SYSTEMS WITH NI-MLX-1GX48-T MODULES ..............................................................................7-2

S

OFTWARE IMAGES REQUIRED ....................................................................................................................7-2

I

MAGES AND PROCEDURES REQUIRED ..................................................................................................7-3

December 2008 © 2008 Foundry Networks, Inc. -vii

Page 8

Foundry NetIron MLX Series Installation and Basic Configuration Guide

DESCRIPTION OF THE SOFTWARE IMAGES REQUIRED ............................................................................7-3

U

PGRADING SOFTWARE IMAGES AS REQUIRED BY VERSION ..................................................................7-4

U

PGRADING TO VERSION 03.5.00 (OR LATER) FROM A PRE-03.5.00 VERSION................................. 7-4

D

OWNGRADING FROM VERSION 03.5.00 (OR LATER) TO A PRE-03.5.00 VERSION ............................ 7-5

U

PGRADING FROM VERSION 03.5.00 (OR LATER) TO A LATER VERSION........................................... 7-5

D

ISPLAYING FLASH MEMORY AND VERSION INFORMATION .....................................................................7-6

D

ISPLAYING FLASH INFORMATION ................................................................................................... 7-6

D

ISPLAYING VERSION INFORMATION ............................................................................................. 7-11

U

PGRADING THE MANAGEMENT MODULE’S MONITOR AND BOOT IMAGES .............................................7-14

U

PGRADING THE MANAGEMENT MODULE’S IRONWARE IMAGE .............................................................7-15

U

PGRADING THE INTERFACE MODULE’S MONITOR AND BOOT IMAGES ..................................................7-17

U

PGRADING THE INTERFACE MODULE’S IRONWARE IMAGE ..................................................................7-18

U

PGRADING THE MANAGEMENT AND INTERFACE MODULE IRONWARE IMAGES TOGETHER ....................7-18

U

PGRADING MBRIDGE FPGA ON THE MANAGEMENT MODULE ..........................................................7-19

O

VERVIEW OF TASKS IN THE FPGA IMAGE UPGRADE PROCESS ................................................... 7-19

D

ETERMINING THE MBRIDGE IMAGE VERSIONS........................................................................... 7-19

U

PGRADING THE MBRIDGE FPGA IMAGE................................................................................... 7-20

U

PGRADING AN FPGA FOR AN INTERFACE MODULE ............................................................................7-20

O

VERVIEW OF TASKS IN THE FPGA IMAGE UPGRADE PROCESS ................................................... 7-21

D

ETERMINING THE FPGA IMAGE VERSIONS.................................................................................. 7-21

U

PGRADING ALL FPGA IMAGES FOR ALL INTERFACE MODULES AT THE SAME TIME ..............................7-24

U

PGRADING ALL LP FPGA IMAGES AT THE SAME TIME ................................................................ 7-24

U

PGRADING THE FPGA IMAGES ONE IMAGE AT A TIME................................................................. 7-24

R

EBOOTING THE MANAGEMENT MODULE ............................................................................................7-26

H

ITLESS OS UPGRADE .......................................................................................................................7-27

C

ONSIDERATIONS WHEN USING THE FEATURE .............................................................................. 7-28

T

HE HITLESS OS SOFTWARE PROCESS ....................................................................................... 7-29

P

ERFORMING A HITLESS OS SOFTWARE UPGRADE, ..................................................................... 7-31

L

OADING THE MULTI-SERVICE IRONWARE SOFTWARE ONTO THE ROUTER..................................... 7-31

S

ETTING UP CONSOLES ............................................................................................................... 7-31

E

XECUTING THE HITLESS UPGRADE COMMAND............................................................................. 7-31

L

OADING AND SAVING CONFIGURATION FILES ............................................................................................7-31

C

ONFIGURING FILE SIZE FOR STARTUP AND RUNNING CONFIGURATION ...............................................7-32

R

EPLACING THE STARTUP CONFIGURATION WITH THE RUNNING CONFIGURATION .................................7-32

R

EPLACING THE RUNNING CONFIGURATION WITH THE STARTUP CONFIGURATION .................................7-32

C

OPYING A CONFIGURATION FILE TO OR FROM A TFTP SERVER ........................................................7-33

M

AKING LOCAL COPIES OF THE STARTUP CONFIGURATION FILE ..........................................................7-33

D

YNAMIC CONFIGURATION LOADING ..........................................................................................................7-33

U

SAGE CONSIDERATIONS............................................................................................................. 7-33

P

REPARING THE CONFIGURATION FILE ......................................................................................... 7-34

L

OADING THE CONFIGURATION INFORMATION INTO THE RUNNING-CONFIG ...........................................7-35

U

SING SNMP TO SAVE AND LOAD CONFIGURATION INFORMATION .............................................................7-35

E

RASING IMAGE AND CONFIGURATION FILES ..............................................................................................7-36

F

ILE SYNCHRONIZATION ............................................................................................................................7-36

F

ILE SYNCHRONIZATION BETWEEN THE ACTIVE AND STANDBY MANAGEMENT MODULES .......................7-36

C

OMPARING AND SYNCHRONIZING FILES ...................................................................................... 7-37

S

YNCHRONIZING FILES WITHOUT COMPARISON ............................................................................ 7-37

F

ILE SYNCHRONIZATION BETWEEN THE MANAGEMENT AND INTERFACE MODULES ................................7-37

S

YNCHRONIZING THE INTERFACE MODULES IRONWARE IMAGES DURING BOOTUP ......................... 7-38

-viii © 2008 Foundry Networks, Inc. December 2008

Page 9

Contents

SPECIFYING AN IMMEDIATE SYNCHRONIZATION ............................................................................. 7-38

S

CHEDULING A SYSTEM RELOAD ...............................................................................................................7-38

R

ELOADING AT A SPECIFIC TIME .........................................................................................................7-38

R

ELOADING AFTER A SPECIFIC AMOUNT OF TIME ................................................................................7-38

D

ISPLAYING THE AMOUNT OF TIME REMAINING BEFORE A SCHEDULED RELOAD ...................................7-39

C

ANCELING A SCHEDULED RELOAD ....................................................................................................7-39

D

IAGNOSTIC ERROR CODES AND REMEDIES FOR TFTP TRANSFERS ..........................................................7-39

CHAPTER 8

ARDWARE SPECIFICATIONS....................................................................... 8-1

H

HARDWARE SPECIFICATIONS .......................................................................................................................8-1

P

OWER SPECIFICATIONS ......................................................................................................................8-1

P

HYSICAL DIMENSIONS .........................................................................................................................8-3

O

PERATING ENVIRONMENT ........................................................................................................................8-4

S

TORAGE ENVIRONMENT .....................................................................................................................8-4

S

AFETY AGENCY APPROVALS ...............................................................................................................8-4

E

LECTROMAGNETIC APPROVALS ...........................................................................................................8-4

P

ORT SPECIFICATIONS ................................................................................................................................8-5

C

ONSOLE PORT PIN ASSIGNMENTS ......................................................................................................8-5

M

ANAGEMENT PORT PIN ASSIGNMENTS ................................................................................................8-6

APPENDIX A

EGULATORY STATEMENTS ........................................................................A-1

R

U.S.A. ...................................................................................................................................................... A-1

I

NDUSTRY CANADA STATEMENT ................................................................................................................. A-1

E

UROPE AND AUSTRALIA ........................................................................................................................... A-1

G

ERMANY ................................................................................................................................................. A-1

J

APAN ....................................................................................................................................................... A-2

K

OREA ...................................................................................................................................................... A-2

APPENDIX B

AUTIONS AND WARNINGS..........................................................................B-1

C

CAUTIONS ................................................................................................................................................. B-1

W

ARNINGS .............................................................................................................................................. B-11

December 2008 © 2008 Foundry Networks, Inc. -ix

Page 10

Foundry NetIron MLX Series Installation and Basic Configuration Guide

-x © 2008 Foundry Networks, Inc. December 2008

Page 11

Chapter 1

Getting Started

Introduction

This guide describes the NetIron MLX router from Foundry Networks. It provides procedures for installing modules

into the NetIron MLX Series chassis, cabling the Ethernet interface ports, and performing a basic configuration of

the software. This guide also explains how to perform tasks using the command line interface (CLI).

Audience

This guide is designed for network installers, system administrators, and resellers who will install and perform a

basic software configuration for the NetIron MLX Series router. This guide assumes a working knowledge of Layer

2 and Layer 3 switching and routing concepts.

Nomenclature

This guide uses the following typographical conventions to show information:

Italic highlights the title of another publication and occasionally emphasizes a word or phrase.

Bold highlights a CLI command.

Bold Italic highlights a term that is being defined.

NOTE: A note emphasizes an important fact or calls your attention to a dependency.

WARNING: A warning calls your attention to a possible hazard that can cause injury or death.

CAUTION: A caution calls your attention to a possible hazard that can damage equipment.

Updates to Manuals

Manuals for this product may be updated between releases. For the latest edition of manuals, check the Foundry

Knowledge Portal at kp.foundrynet.com.

December 2008 © 2008 Foundry Networks, Inc. 1-1

Page 12

Foundry NetIron MLX Series Installation and Basic Configuration Guide

How to Get Help or Report Errors

Foundry Networks is committed to ensuring that your investment in our products remains cost-effective. If you

need assistance, or find errors in the manuals, contact Foundry Networks using one of the following options:

Web Access

If you find errors in this document, please report the error by going to kp.foundrynet.com. After you login in, click

Cases > Create a New Ticket. Make sure you specify the document title in the ticket description.

Email Access

Send an e-mail to support@foundrynet.com.

Telephone Access

1.877.TURBOCALL (887.2622) United States

1.408.207.1600Outside the United States

Warranty Coverage

Contact Foundry Networks using any of the methods listed above for information about the standard and extended

warranties.

1-2 © 2008 Foundry Networks, Inc. December 2008

Page 13

Chapter 2

Product Overview

The NetIron MLX Series router provides high-performance routing for service providers, metro topologies, and

Internet Exchange Points. This chapter provides an overview of Foundry’s NetIron MLX Series routers. It provides

the following information:

• Overview of the benefits the NetIron MLX Series router offers

• Network topologies in which a NetIron MLX Series router will be commonly deployed

• The NetIron MLX Series router hardware and how each major hardware component functions

• Software features that the NetIron MLX Series router supports

• The NetIron MLX Series router’s architecture, how it differs from other Layer 3 router architectures, and how

you will benefit from the differences

Product Overview

The NetIron MLX Series router provides the following benefits:

• The ability of the 10 Gigabit Ethernet ports to process both inbound and outbound user packets at a full

10Gbps, thereby delivering true wire-speed performance

• IPv4 routing with very large hardware-based forwarding table and powerful hardware-based ACL and rate

limiting functions

• IPv6 routing with a rich feature set including hardware-based forwarding, and dual-stack support

• High availability (redundancy) of the following NetIron MLX Series router critical components:

• Management modules

• Fans

• Power supplies

• Switch fabric module

Each of these components, along with the interface modules, is hot swappable, which means you can remove

and replace them while the NetIron MLX Series chassis is powered on and running.

• Completely separate data and control planes, which results in uncompromised switching performance,

increased reliability of both planes, and increased security of the control plane in the event of a Denial of

Service attack (DoS) on the data plane

• Distributed data and control planes, which results in uncompromised wire-speed performance for the data

plane and faster and more efficient performance of management functions for the control plane

December 2008 © 2008 Foundry Networks, Inc. 2-1

Page 14

Foundry NetIron MLX Series Installation and Basic Configuration Guide

• A management (10BaseT/100BaseTX/1000BaseTX Ethernet) port that can provide connectivity to your

existing management network

• Increased amount of TCAM on the interface modules, which accommodates the processing of more software

functions such as those related to routing protocols

• Increased amounts of processor RAM on the management and interface modules, which allows larger default

table sizes for the MAC address table, the IP route table, and so on

• Airflow that circulates from the front to the back of the NetIron MLX Series router chassis, which directs hot air

from the chassis away from other racks of equipment rather than toward them

NetIron MLX Series Router Applications

The NetIron MLX Series router is commonly deployed in the following situations:

• Layer 2 metro networks

• MPLS Layer-3 VPN service provider networks supporting multi-VRFs and RFC 2547bis

• MPLS Layer-2 VPN service provider networks supporting both VPLS and VLL

Hardware Features

This chapter covers the following major hardware components of NetIron MLX Series routers:

• “Chassis”

• “Management Modules”

• “Interface Modules”

• “Switch Fabric Module”

• “Power Supplies”

• “Cooling System”, which is composed of temperature sensors, fans, fan control modules, and an air filter

• “Rack Mount Kit”

The following sections provide more information about these components.

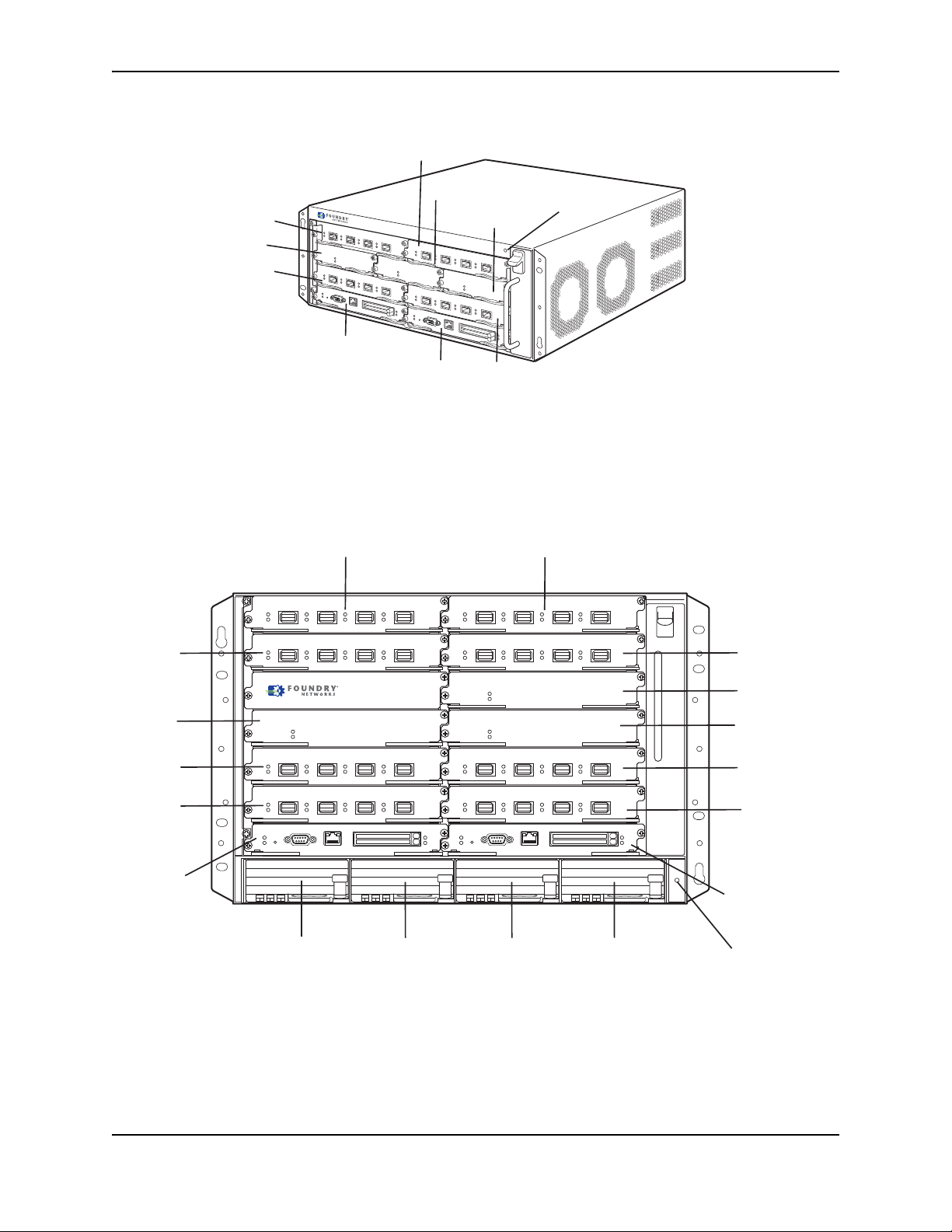

Chassis

The NetIron MLX Series chassis consists of the following four chassis:

• NetIron MLX-4: Provides 4 interface slots

• NetIron MLX-8: Provides 8 interface slots

• NetIron MLX-16: Provides 16 interface slots

• NetIron MLX-32: Provides 32 interface slots

The following figures illustrate the NetIron MLX Series chassis.

2-2 © 2008 Foundry Networks, Inc. December 2008

Page 15

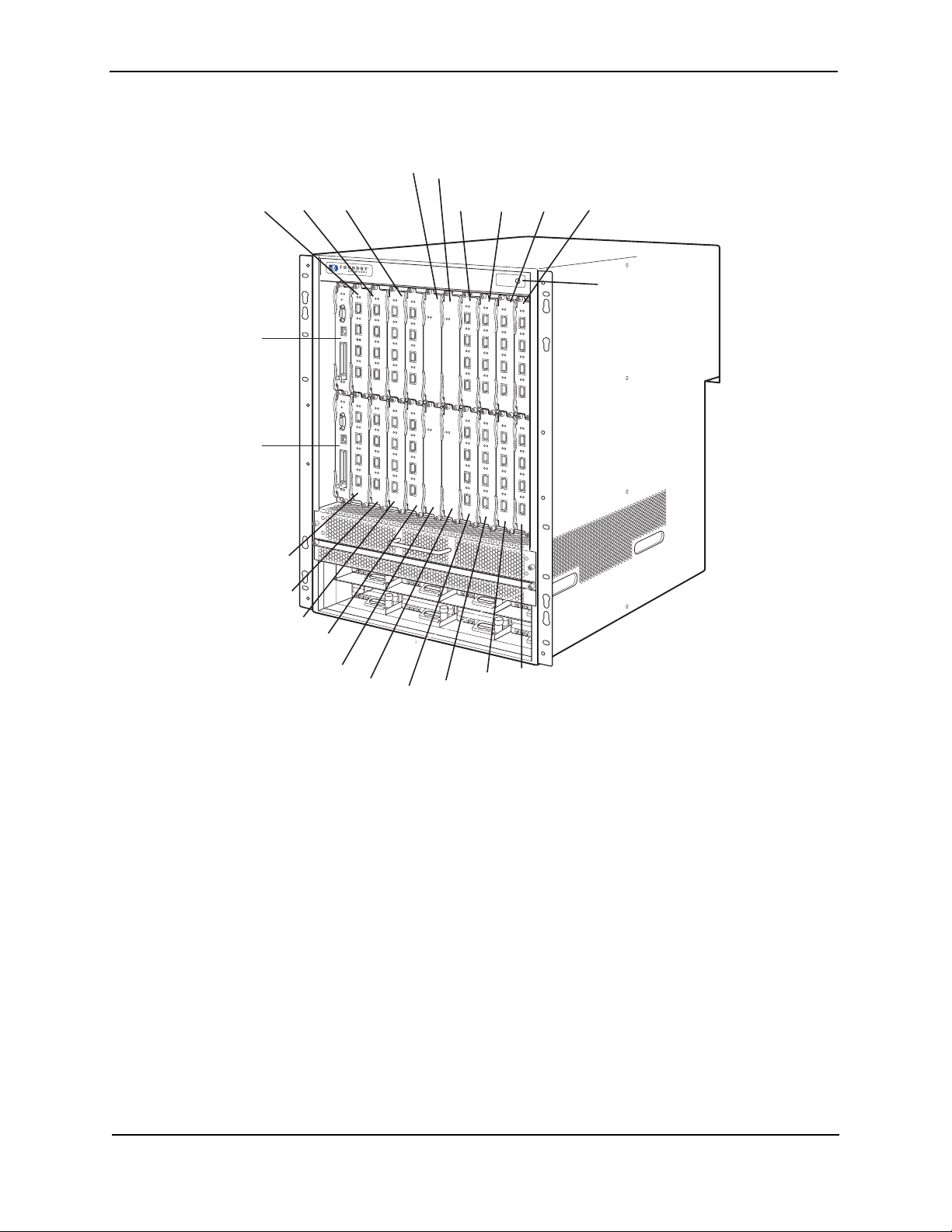

Figure 2.1 NetIron MLX-4 Chassis

Switch Fabric

Slot 3

Interface

Slot 1

Interface

Slot 2

Interface

Slot 3

Interface

Slot 4

Switch Fabric

Slot 1

Switch Fabric

Slot 2

Management

Slot 1

Management

Slot 2

ESD Connector

NetIron MLX 8

Interface

Slot 1

Interface

Slot 2

Interface

Slot 4

Switch

Fabric

Slot 1

Switch

Fabric

Slot 3

Interface

Slot 6

Interface

Slot 8

Management

Slot 2

Interface

Slot 3

Switch

Fabric

Slot 2

Interface

Slot 5

Interface

Slot 7

Management

Slot 1

Power Supply

Slot 1

Power Supply

Slot 2

Power Supply

Slot 3

Power Supply

Slot 4

ESD

Connector

Figure 2.2 NetIron MLX-8 Chassis

Product Overview

December 2008 © 2008 Foundry Networks, Inc. 2-3

Page 16

Foundry NetIron MLX Series Installation and Basic Configuration Guide

Management

Slot 1

Management

Slot 2

NetIron MLX 16

Interface

Slot 1

Interface

Slot 3

Interface

Slot 5

Interface

Slot 7

Switch

Fabric

Slot 1

Switch

Fabric

Slot 3

Interface

Slot 9

Interface

Slot 11

Interface

Slot 13

Interface

Slot 15

Interface

Slot 2

Interface

Slot 4

Interface

Slot 6

Interface

Slot 8

Switch

Fabric

Slot 2

Switch

Fabric

Slot 4

Interface

Slot 10

Interface

Slot 12

Interface

Slot 14

Interface

Slot 16

ESD Connector

Figure 2.3 NetIron MLX-16 Chassis

2-4 © 2008 Foundry Networks, Inc. December 2008

Page 17

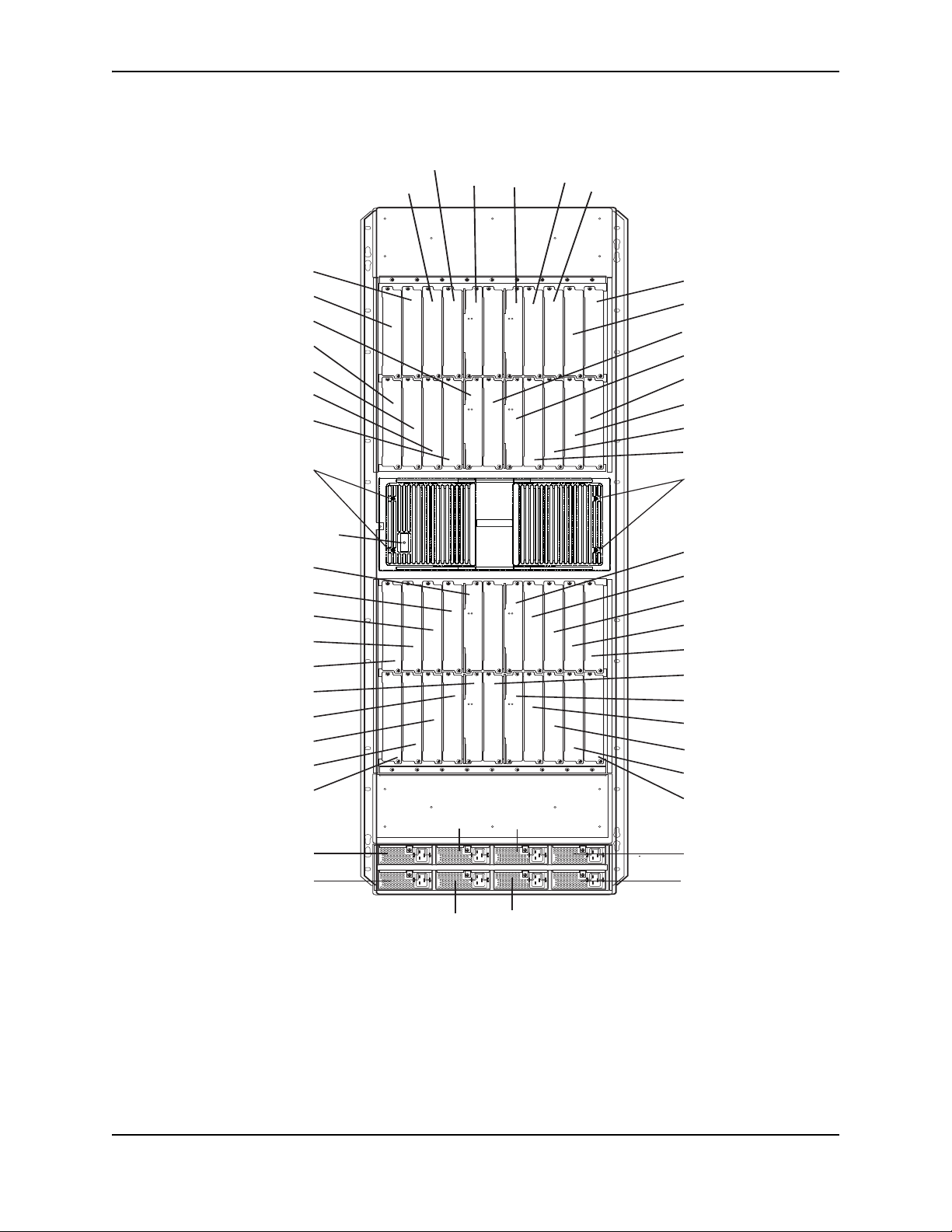

Figure 2.4 NetIron MLX-32 Chassis

Pwr

Active

Pwr

Active

Pwr

Active

Pwr

Active

Pwr

Active

Pwr

Active

Pwr

Active

Pwr

Active

AC OK

DC OK

ALM

AC OK

DC OK

ALM

AC OK

DC OK

ALM

AC OK

DC OK

ALM

AC OK

DC OK

ALM

AC OK

DC OK

ALM

AC OK

DC OK

ALM

AC OK

DC OK

ALM

Switch

Fabric

Slot 1

Switch

Fabric

Slot 3

Interface

Slot 7

Interface

Slot 5

Interface

Slot 9

Interface

Slot 11

Power Supply 2

Power Supply 3

Power Supply 6

Power Supply 7

Interface Slot 3

Interface Slot 1

Switch Fabric Slot 2

Interface Slot 2

Interface Slot 4

Interface Slot 6

Interface Slot 8

ESD St

r

ap Connector

Switch Fabric Slot 5

Interface Slot 23

Interface Slot 21

Interface Slot 19

Interface Slot 17

Switch Fabric Slot 6

Interface Slot 24

Interface Slot 22

Interface Slot 20

Interface Slot 18

Power Supply 1

Power Supply 5

Power Supply 4

Power Supply 8

Interface Slot 15

Interface Slot 13

Management Slot 1

Switch Fabric Slot 4

Interface Slot 16

Interface Slot 14

Interface Slot 12

Interface Slot 10

Switch Fabric Slot 7

Interface Slot 25

Interface Slot 27

Interface Slot 29

Interface Slot 31

Management Slot 2

Switch Fabric Slot 8

Interface Slot 26

Interface Slot 28

Interface Slot 30

Interface Slot 32

Captive Screws

Captive Screws

Product Overview

December 2008 © 2008 Foundry Networks, Inc. 2-5

Page 18

Foundry NetIron MLX Series Installation and Basic Configuration Guide

Upon shipment from the factory, the following components are installed in the four versions of the NetIron MLX

Series chassis as described:

NetIron MLX-4

• Two switch fabric modules.

• A slot blank in each interface module slot. The slot blank covers a slot that does not currently have a module

installed in it, ensuring proper airflow within the chassis.

• A fan tray assembly, which is located in the front right side of the chassis. For more information about the fans,

see “Cooling System” on page 2-23.

• One power supply (AC or DC).

In the slots of the chassis, you can install the following:

• Up to two management modules (one active and one redundant).

• Up to three switch fabric modules.

• Up to four interface modules.

• Up to three power supplies (AC or DC).

Before installing any modules or power supplies, you must remove the slot blank or blank power supply faceplate,

respectively.

NetIron MLX-8

• Two switch fabric modules.

• A slot blank in each interface module slot. The slot blank covers a slot that does not currently have a module

installed in it, ensuring proper airflow within the chassis.

• A fan tray assembly, which is located in the front right side of the chassis. For more information about the fans,

see “Cooling System” on page 2-23.

• Two power supplies (AC or DC).

In the slots of the chassis, you can install the following:

• Up to two management modules (one active and one redundant).

• Up to three switch fabric modules.

• Up to eight interface modules.

• Up to four power supplies (AC or DC).

Before installing any modules or power supplies, you must remove the slot blank or blank power supply faceplate,

respectively.

NetIron MLX-16

• Three switch fabric modules.

• A slot blank in each interface module slot. The slot blank covers a slot that does not currently have a module

installed in it, ensuring proper airflow within the chassis.

• A fan tray assembly located in the front right side of the chassis, and two fan assemblies located at the rear of

the chassis. For more information about the fans, see “Cooling System” on page 2-23.

• Four power supplies (AC or DC).

In the slots of the chassis, you can install the following:

• Up to two management modules (one active and one redundant).

• Up to four switch fabric modules.

• Up to sixteen interface modules.

2-6 © 2008 Foundry Networks, Inc. December 2008

Page 19

Product Overview

• Up to eight power supplies (AC or DC).

NetIron MLX-32

• Empty chassis with backplane and card cage shipping panels, and ten fan assemblies located at the rear of

the chassis, four for the upper card cage, four for the lower card cage, and two for the power supplies.

• Eight switch fabric modules (shipped separately).

• One management module (shipped separately).

• A slot blank for each module slot (shipped separately). The slot blank covers a slot that does not currently

have a module installed in it, ensuring proper airflow within the chassis.

• Four AC power supplies.

In the slots of the chassis, you can install the following:

• Two management modules.

• Eight switch fabric modules.

• Up to 32 interface modules.

• Up to eight AC power supplies.

Before installing any modules or power supplies, you must remove the slot blank or blank power supply faceplate,

respectively (NetIron MLX-4, -8, and 16). On the NetIron MLX-32, before installing any modules, you must remove

the shipping panels covering the upper and lower card cages.

CAUTION: If you do not install a module in a slot, you must keep the slot blank in place. If you run the chassis

with an uncovered slot, the system may overheat.

Figure 2.1, Figure 2.2, Figure 2.3, and Figure 2.4 show the NetIron MLX Series chassis and the slots into which

you install the various modules. You must install the primary power supplies and the redundant power supplies as

described in the figures.

Figure 2.1, Figure 2.2, and Figure 2.3 and Figure 2.4 also show an electrostatic discharge (ESD) connector, into

which you can plug an ESD wrist strap to ground yourself while handling and installing modules.

WARNING: For safety reasons, the ESD wrist strap should contain a 1 meg ohm series resistor.

The NetIron MLX-16 and NetIron MLX-32 chassis versions also include a grounding lug connector, located on the

rear panel (left side).

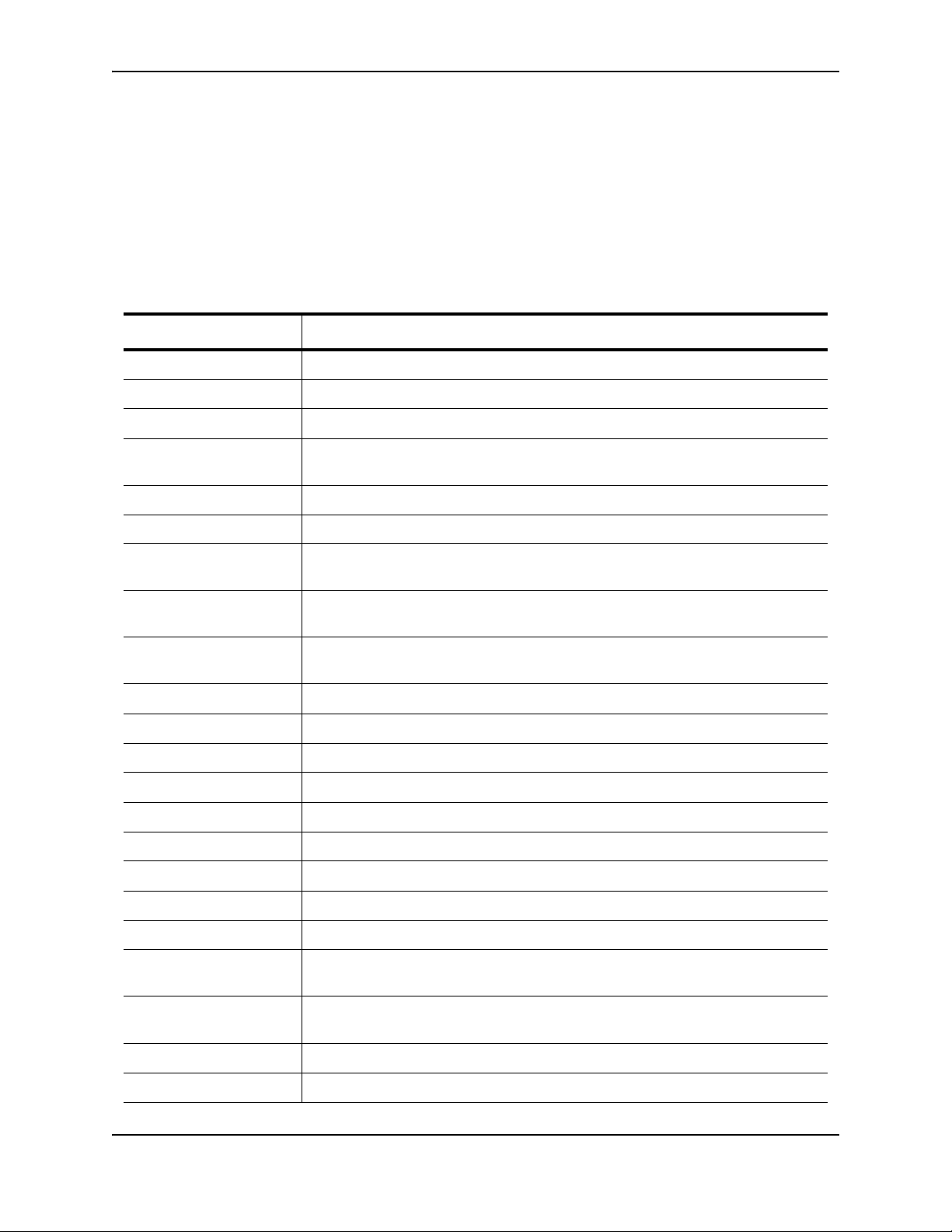

Management Modules

The following management modules are available for NetIron MLX Series routers:

Part Number Description

NI-MLX-MR NetIron MLX Series management module, 1 GB SDRAM, dual PCMCIA slots,

EIA/TIA-232 and 10/100/1000 Ethernet ports for out-of-band management.

NI-MLX-32-MR NetIron MLX-32 management module, 1 GB SDRAM, dual PCMCIA slots,

EIA/TIA-232 and 10/100/1000 Ethernet ports for out-of-band management

The management module controls the NetIron MLX Series hardware components, runs the networking protocols,

and provides the Real Time Operating System (RTOS).

Each NetIron MLX Series chassis requires one management module and can accept a second one for

redundancy. A redundant management module works along with the active management module. If the active

December 2008 © 2008 Foundry Networks, Inc. 2-7

Page 20

Foundry NetIron MLX Series Installation and Basic Configuration Guide

Pwr

Active

10/100/1000

Port 1

Port 2

Console

module becomes unavailable, the redundant management module automatically takes over the system operation,

minimizing system downtime. For information about the redundancy feature, see the chapter titled "Using a

Redundant Management Module" in the "Foundry NetIron XMR/MLX Configuration Guide".

The NetIron MLX-32 chassis uses a different management module than any of the other Foundry Networks

products. You cannot use management modules designed for the NetIron MLX-32 in any of the other NetIron MLX

Series chassis or management modules in the NetIron MLX-32 chassis designed for the NetIron MLX-4, NetIron

MLX-8, or NetIron MLX-16.

You can install management modules in dedicated slots marked M1 and M2. By default, the system considers the

module installed in the slot marked M1 to be the active management module.

NOTE: The NetIron MLX Series management module is dedicated, which means that you must install it in the

NetIron MLX Series chassis only. If you attempt to install the NetIron MLX Series management module in another

Foundry chassis or a management module intended for another Foundry chassis in the NetIron MLX Series

chassis, the module will not boot up to become active.

Additionally, the NetIron MLX-32 chassis uses a different management module than any of the other NetIron MLX

Series chassis. You cannot use management modules designed for the NetIron MLX-32 in any other Foundry

device, because it will not function properly.

A management module is hot swappable, which allows you to remove and replace it without powering down the

system.

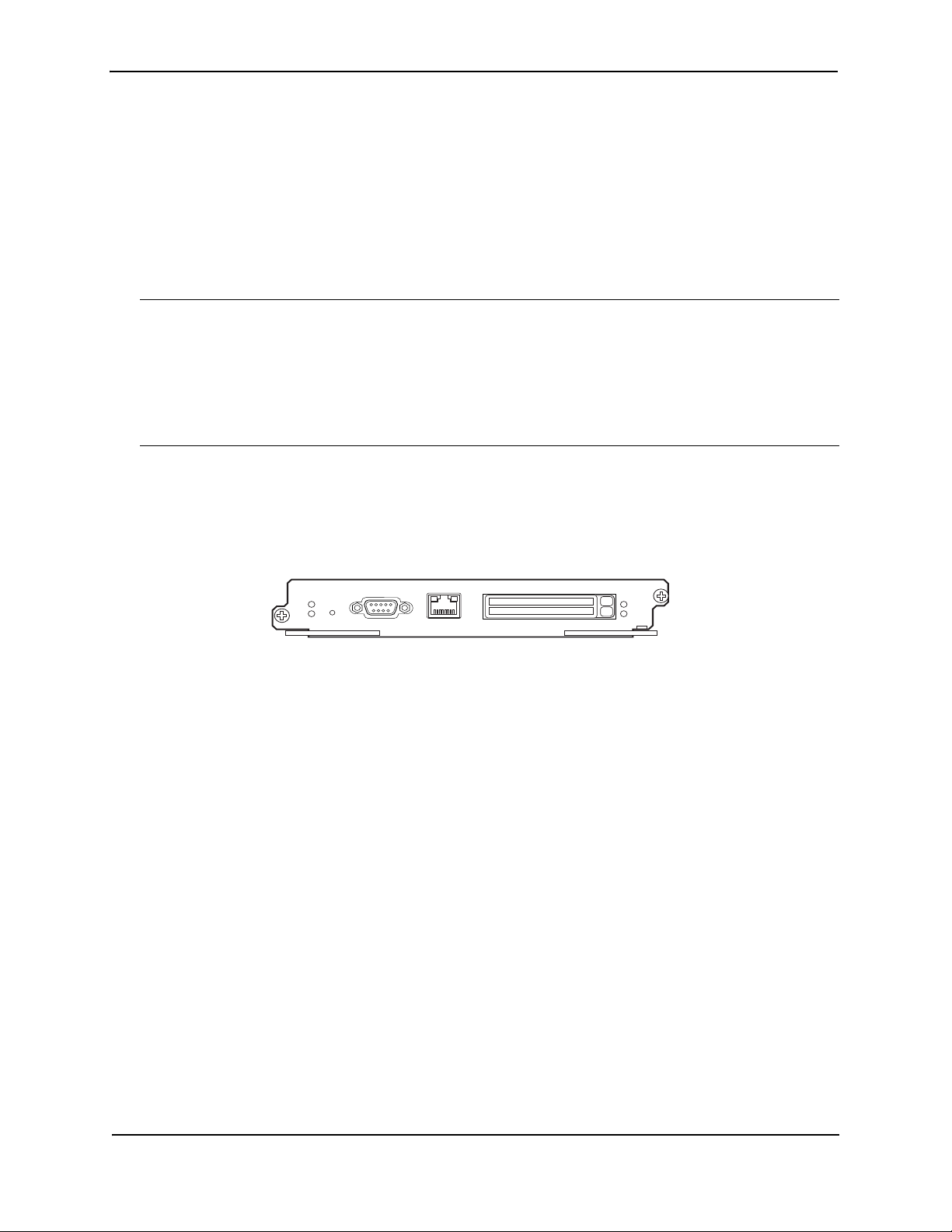

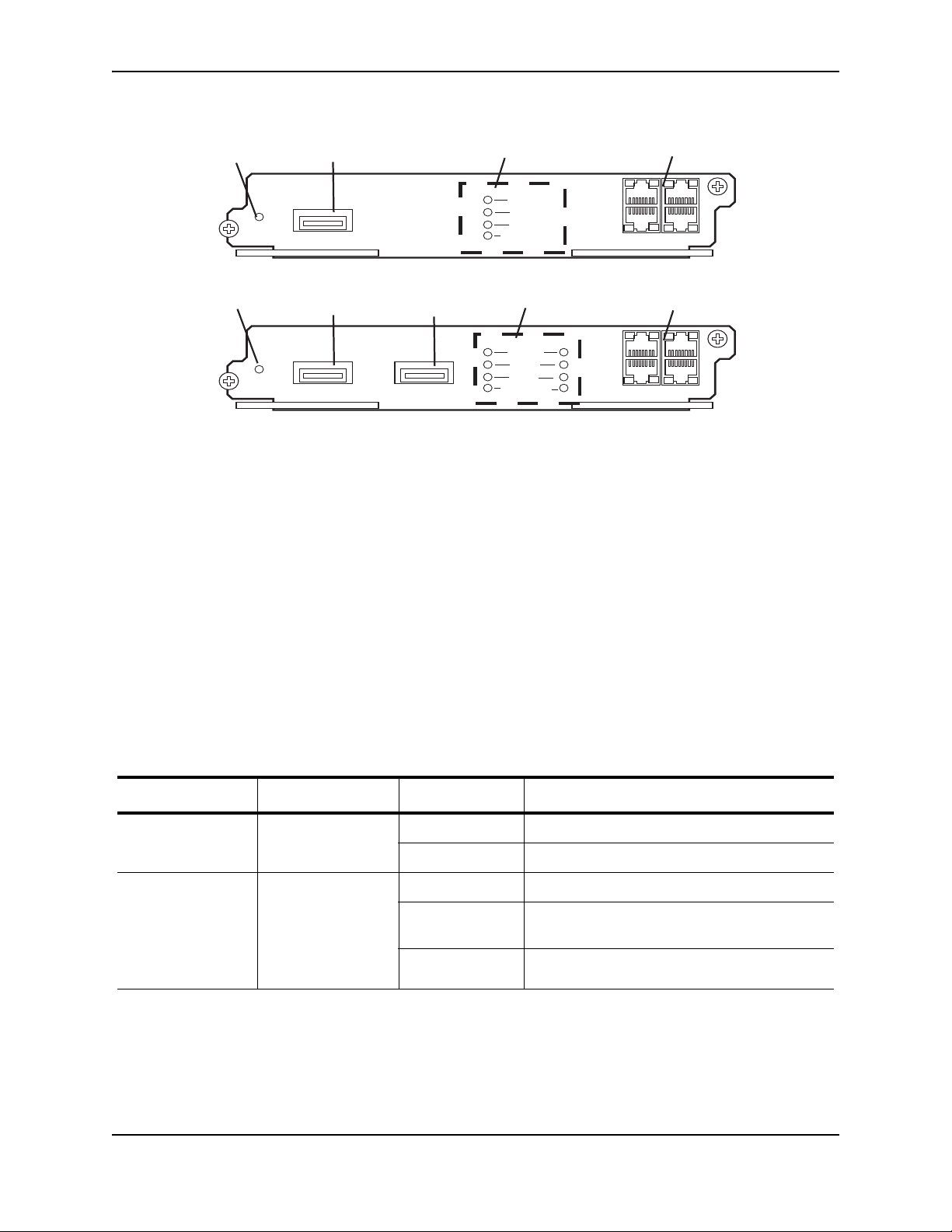

Figure 2.5 shows the management module’s front panel.

Figure 2.5 Management Module Front Panel

The front panel includes the following control features:

• Two PCMCIA slots

• A Console port

• A 10/100/1000 Ethernet port

• Six LEDs

PCMCIA Slots

The PCMCIA slots support a flash PC card. The flash PC card provides storage space in addition to the system’s

flash memory. A flash PC card can store system files, including Boot images, startup configuration files, running

configuration files, and so on. As a result, you can perform system management tasks, such as copying files

between flash PC cards, copying files between a flash PC card and flash memory, and so on.

Console Port

The Console port is a standard DB-9 serial connector through which you can attach a PC or terminal to configure

the NetIron MLX Series system using the CLI.

This port interfaces the control plane only and not the data plane.

10/100/1000 Ethernet Port

The front panel includes a 10BaseT/100BaseTX/1000BaseTX auto-sensing, auto-negotiating Ethernet port. This

port has an RJ-45 unshielded twisted pair (UTP) connector.

Typical uses of this port include but are not limited to the following:

• Connecting a PC through which you can access the system through a Telnet or SSHv2 connection and

2-8 © 2008 Foundry Networks, Inc. December 2008

Page 21

Product Overview

configure, monitor, and manage the NetIron MLX Series system.

• Connecting to the 10BaseT/100BaseTX/1000BaseTX port of a switch or router for connectivity to your

existing management network. You can then access the NetIron MLX Series system and configure, monitor,

and manage the system from a management station.

NOTE: The existing management network into which you can connect the 10/100/1000 Ethernet port must be

separate and isolated from the network over which user packets are switched and routed. For information about

the management port’s functionality, see “Understanding How the Management Port Functions” on page 4-5.

For information about connecting a PC and a switch to the 10/100/1000 Ethernet port, see “Attaching a

Management Station” on page 3-49.

This port interfaces the control plane only and not the data plane.

LEDs

Table 2.1 describes the LEDs on the management module’s front panel.

Table 2.1: Management Module LEDs

LED Position State Meaning

Por t 1

and

Por t 2

Active Lower Left On The module is functioning as the active management

Pwr Upper Left On The module is receiving power.

10/100/1000

Ethernet Port

10/100/1000

Ethernet Port

Each adjacent

to the PCMCIA

slot that it

represents

Above and right

of RJ-45

connector

Above and left

of RJ-45

connector

On or blinking The software is currently accessing the PCMCIA flash card.

Off The software is not currently accessing a PCMCIA flash

card inserted in a slot.

module.

Off The module is functioning as the redundant management

module.

Off The module is not receiving power.

On (Green) A link is established with the remote port.

Off A link is not established with the remote port.

On or blinking

(Yellow)

Off for an

extended period

The port is transmitting and receiving packets.

The port is not transmitting or receiving packets.

December 2008 © 2008 Foundry Networks, Inc. 2-9

Page 22

Foundry NetIron MLX Series Installation and Basic Configuration Guide

Interface Modules

The following interface modules are available for NetIron MLX Series routers:

Part Number Description

NI-MLX-10Gx4 4-port 10 GbE module with IPv4/IPv6/MPLS hardware support--requires XFP

optics

NI-MLX-10Gx2 2-port 10 GbE module with IPv4/IPv6/MPLS hardware support--requires XFP

optics

NI-MLX-1Gx20-SFP 20-port FE/GE (100/1000) module with IPv4/IPv6/MPLS hardware support--

requires SFP optics

NI-MLX-1Gx20-GC 20-port 10/100/1000 copper modules with IPv4/IPv6/MPLS hardware support

NI-X-OC192x2 2-port Packet over SONET (SDH) OC-192 (STM-64) interface module

NI-X-OC192x1 1-port Packet over SONET (SDH) OC-192 (STM-64) interface module

NI-X-OC48x8 8-port Packet over SONET (SDH) OC12/48 (STM-4/16) interface module

NI-X-OC48x4 4-port Packet over SONET (SDH) OC-12/48 (STM-4/16) interface module

NI-X-OC 48x2 2-port Packet over SONET (SDH) OC-12/48 (STM-4/16) interface module

Depending on the size of you NetIron MLX Series chassis, you can install up to 32 NetIron MLX Series interface

modules as described:

• NetIron MLX-4: Supports up to 4 interface modules

• NetIron MLX-8: Supports up to 8 interface modules

• NetIron MLX-16: Supports up to 16 interface modules

• NetIron MLX-32: Supports up to 32 interface modules

NOTE: A NetIron MLX Series interface module is dedicated, which means that you must install it in the NetIron

MLX Series chassis only. If you attempt to install a NetIron MLX Series interface module in another Foundry

chassis or an interface module intended for another Foundry chassis in the NetIron MLX Series chassis, the

module will not boot up to become active. Interface modules can be shared between NetIron MLX-4, NetIron MLX8, NetIron MLX-16, and NetIron MLX-32.

The interface modules are hot swappable, which means you can remove and replace them without powering down

the system.

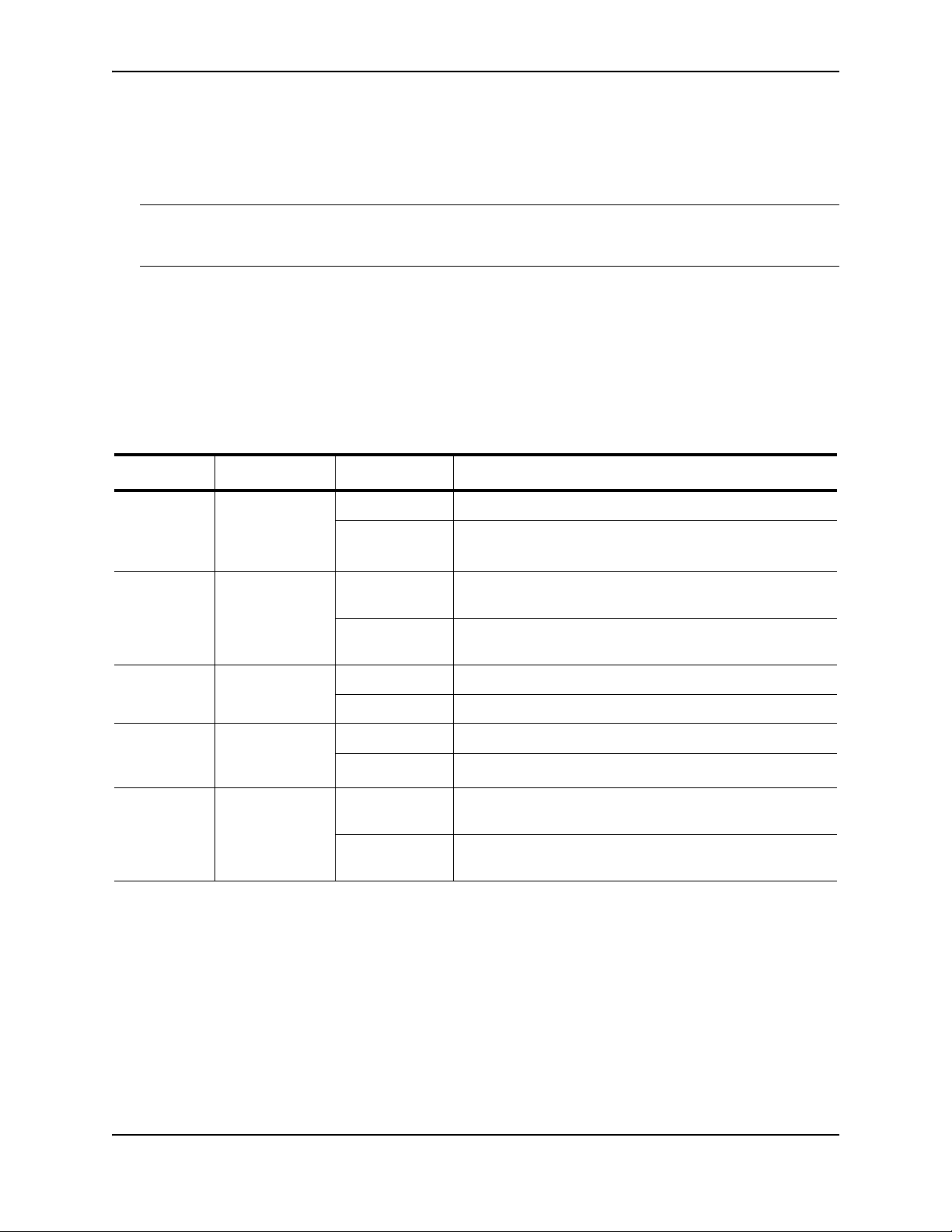

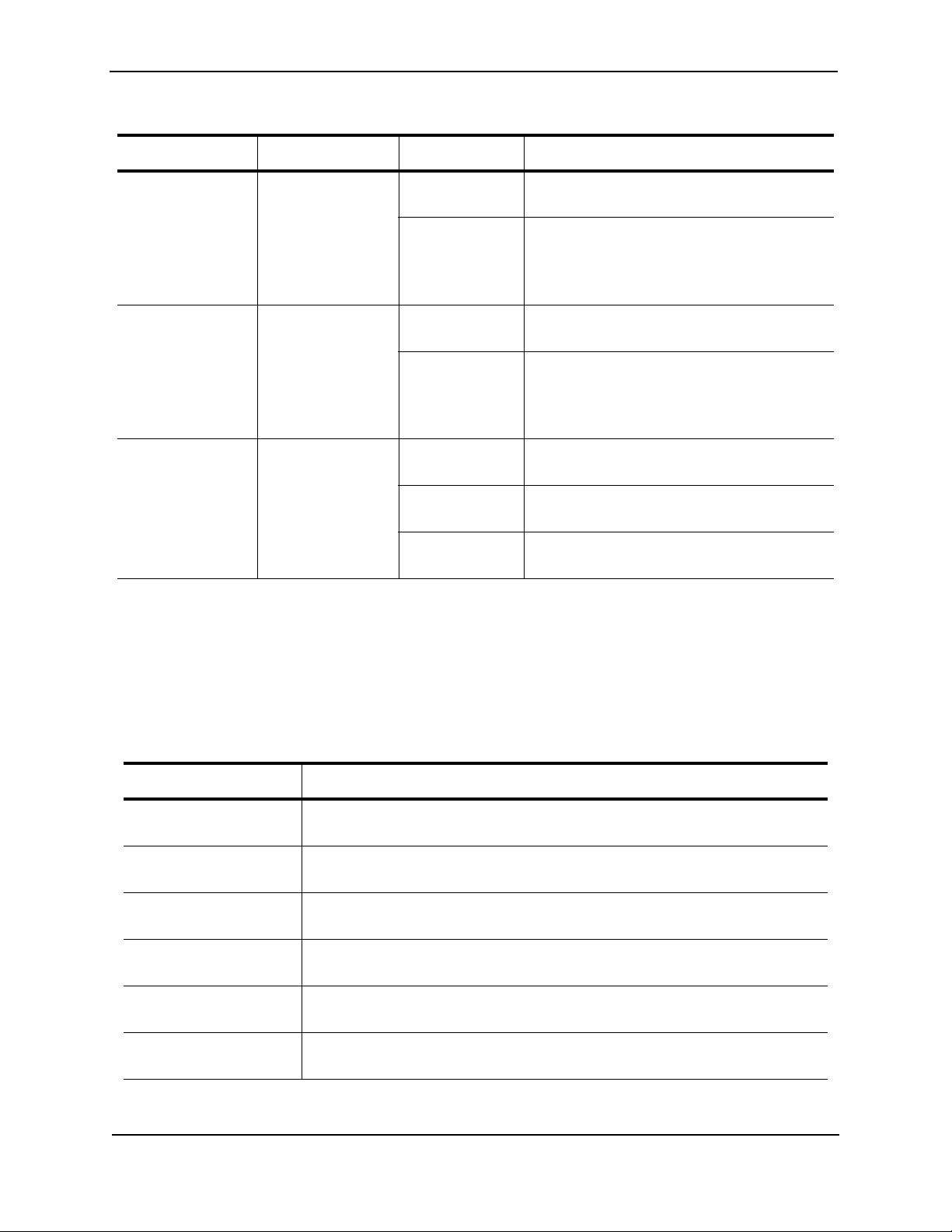

10 Gigabit Ethernet Interface Modules (2-port and 4-port)

Figure 2.6 shows the 2-port and 4-port 10 Gigabit Ethernet module’s front panels with XFP optics installed.

2-10 © 2008 Foundry Networks, Inc. December 2008

Page 23

Figure 2.6 2- port and 4-port 10 Gigabit Ethernet Modules Front Panel

Lnk

Act

Lnk

Act

Lnk

Act

Lnk

Act

1

2

34

Lnk

Act

Lnk

Act

1

2

The front panel of the 4-port module includes the following control features:

• Eight LEDs

• Four 10 Gigabit Ethernet XFP optics slots

The front panel of the 2-port module includes the following control features:

• Four LEDs

• Two 10 Gigabit Ethernet XFP optics slots

LEDs

The module’s front panel includes two LEDs that indicate the status of each port.

Product Overview

Table 2.2 describes the LEDs on the 10 Gigabit Ethernet module’s front panel.

Table 2.2: 10 Gigabit Ethernet Module LEDs

LED Position State Meaning

Link Left of each

Ethernet port

On A link is established with the remote port.

Off A link is not established with the remote

port.

Active Left of each

Ethernet port

On The port is transmitting and receiving

packets.

Off The port is not transmitting or receiving

packets.

10 Gigabit Ethernet Ports

A 10 Gigabit Ethernet module contains two or four physical ports, through which you can connect your NetIron

MLX Series router to other network devices at a speed of 10 Gigabits.

Into a physical port, you must insert a fiber-optic transceiver provided by Foundry. The XFP-compliant fiber-optic

modules provide an optical transceiver or physical medium-dependent (PMD) interface for single or multi-mode

fiber that can be used with the LAN physical layer (PHY).

December 2008 © 2008 Foundry Networks, Inc. 2-11

Page 24

Foundry NetIron MLX Series Installation and Basic Configuration Guide

Port Status LEDs

(In each pair, the left most LED supports the port in the top row directly above it

and the right-most LED supports the port in the bottom directly above it )

The following 10 Gigabit optics are available from Foundry:

Table 2.3: XFP-Compliant Optics for the 10 GbE Ethernet Interface Module

Part Number Description

10G-XFP-SR 850nm serial pluggable XFP optic (LC), target range 300m over multi-mode fiber

10G-XFP-LR 1310nm serial pluggable XFP optic (LC) for up to 10km over single-mode fiber

10G-XFP-ER 1550nm serial pluggable XFP optic (LC) for up to 40km over single-mode fiber

10G-XFP-ZR 1550nm serial pluggable XFP optic (LC) for up to 80km over single-mode fiber

10G-XFP-ZRD-XXXX-AA 10GBase-ZR DWDM, XFP optic, 80km, 1530.33 to 1561.42

10G-XFP-CX4 10-Base-CX4, XFP transceiver, 15km, CX connector (supported only on integrated

XFP slot on FGS624XGP and FGS624XGP-POE)

For more information about the fiber-optic transceivers and the cabling associated with them, see “Installing a

Fiber-Optic Module” on page 4-5.

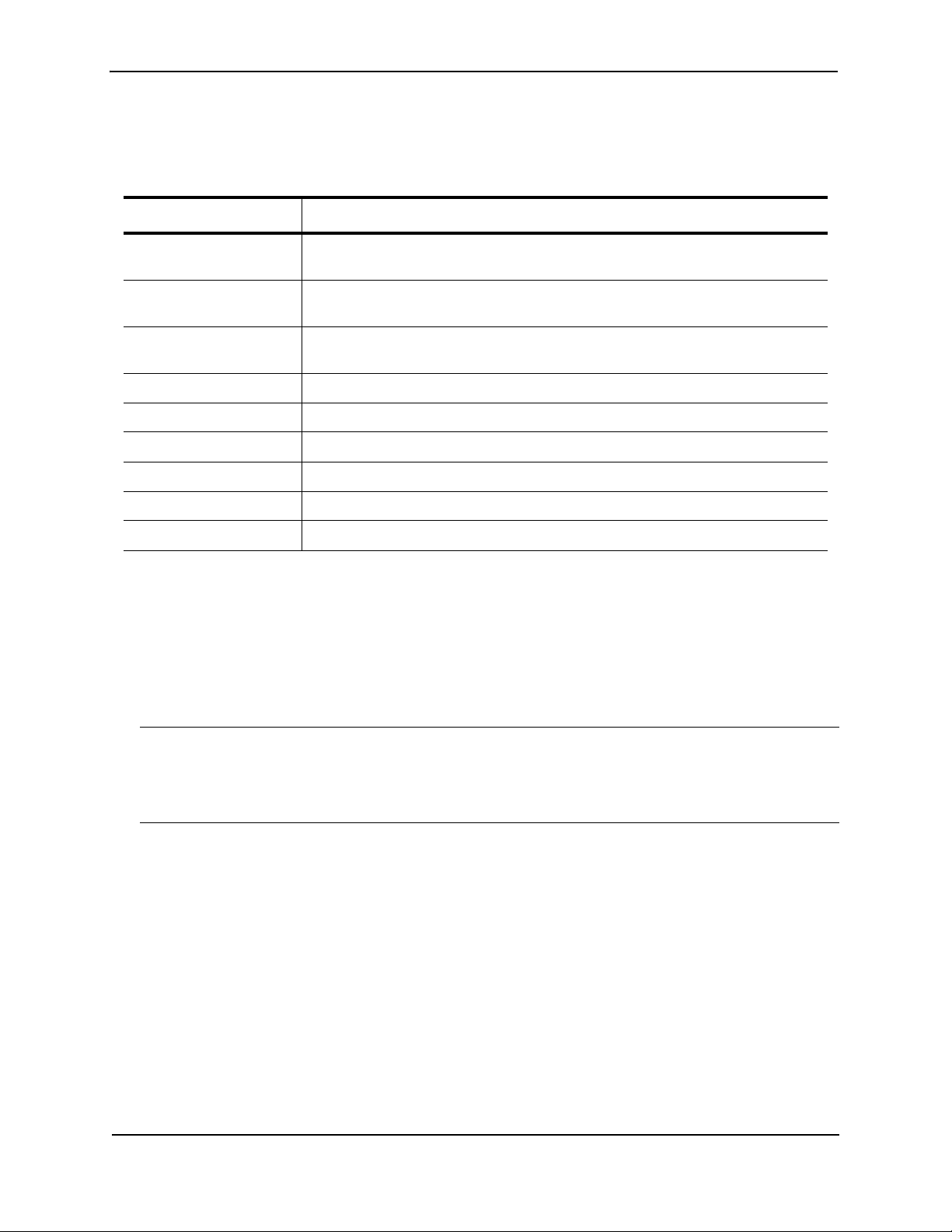

FE/GbE (100/1000) Ethernet Interface Module (SFP)

Figure 2.8 shows the 20-port 100/1000 Ethernet mini-GBIC (or SFP) module’s front panel.

Figure 2.7 20-port 100/1000 Ethernet SFP Module Front Panel

The front panel includes the following control features:

• LEDs - The LEDs to the left support the top

• 20 100/1000 Ethernet mini-GBIC (SFP) ports

Table 2.4: Gigabit Ethernet Module LEDs

Position State Meaning

Below each

On or blinking The port is transmitting and receiving

Ethernet port

(Left-side LED

supports port in

Off for an extended

period

top row while

right-side LED

supports port in

bottom row)

2-12 © 2008 Foundry Networks, Inc. December 2008

packets.

The port is not transmitting or receiving

packets.

Page 25

Product Overview

100/1000 Ethernet Ports

This Ethernet interface module contains 20 physical ports, through which you can connect your NetIron MLX

Series router to other network devices at a speed of 100 Mbps or 1 GbE.

Into a physical port, you must insert a fiber-optic transceiver provided by Foundry. The SFP-compliant fiber-optic

modules provide an optical transceiver or physical medium-dependent (PMD) interface for fiber that can be used

with the LAN physical layer (PHY)

The following 100 Mbps and 1 GbE optical transceivers are available from Foundry:

Table 2.5: SFP-Compliant Transceivers for the 100/1000 Ethernet Interface Module

Part Number Description

E1MG-TX SFP Copper, RJ-45 connector

E1MG-SX 1000Base-SX SFP optic, multi-mode fiber, LC connector

E1MTG-SX 1000Base-SX SFP optic, multi-mode fiber, MTRJ connector

E1MG-SX2-1310 1310 1000Base-SX SFP optic multi-mode fiber, LC connector and support for

distances up to 2km

E1MG-LX 1000Base-LX SFP optic, single-mode fiber, LC connector

E1MG-LHA 1000Base-LHA SFP optic, single-mode fiber, LC connector

E1MG-LHB 1000Base-LHB SFP optic, single-mode fiber, LC connector, 150km Maximum

Reach

E1MG-BXU 1000Base-BXU SFP optic single-mode fiber, 1310nm, LC connector.

This optic can only be connected to an E1MG-BXD

E1MG-BXD 1000Base-BXD SFP optic single-mode fiber, 1490nm, LC connector.

This optic can only be connected to an E1MG-BXU

E1MG-CWDM80-1470 CWDM SFP optic, 80km, 1470nm, LC connector

E1MG-CWDM80-1490 CWDM SFP optic, 80Km, 1490nm, LC connector

E1MG-CWDM80-1510 CWDM SFP optic, 80Km, 1510nm, LC connector

E1MG-CWDM80-1530 CWDM SFP optic, 80Km, 1530nm, LC connector

E1MG-CWDM80-1550 CWDM SFP optic, 80Km, 1550nm, LC connector

E1MG-CWDM80-1570 CWDM SFP optic, 80Km, 1570nm, LC connector

E1MG-CWDM80-1590 CWDM SFP optic, 80Km, 1590nm, LC connector

E1MG-CWDM80-1610 CWDM SFP optic, 80Km, 1610nm, LC connector

E1MG-100FX 100Base-FX SFP optic multi-mode fiber, LC connector

E1MG-100BXU 100Base-BXU SFP optic single-mode fiber, 1310nm, LC connector.

This optic can only be connected to an E1MG-100BXD.

E1MG-100BXD 100Base-BXD SFP optic single-mode fiber, 1490nm, LC connector.

This optic can only be connected to an E1MG-100BXU.

E1MG-100FX-IR 100BaseFX-IR optic for SMF with LC connector. For distances up to 15nm.

E1MG-100FX-LR 100BaseFX-LR SFP optic for SMF with LC connector. For distances up to 40km.

December 2008 © 2008 Foundry Networks, Inc. 2-13

Page 26

Foundry NetIron MLX Series Installation and Basic Configuration Guide

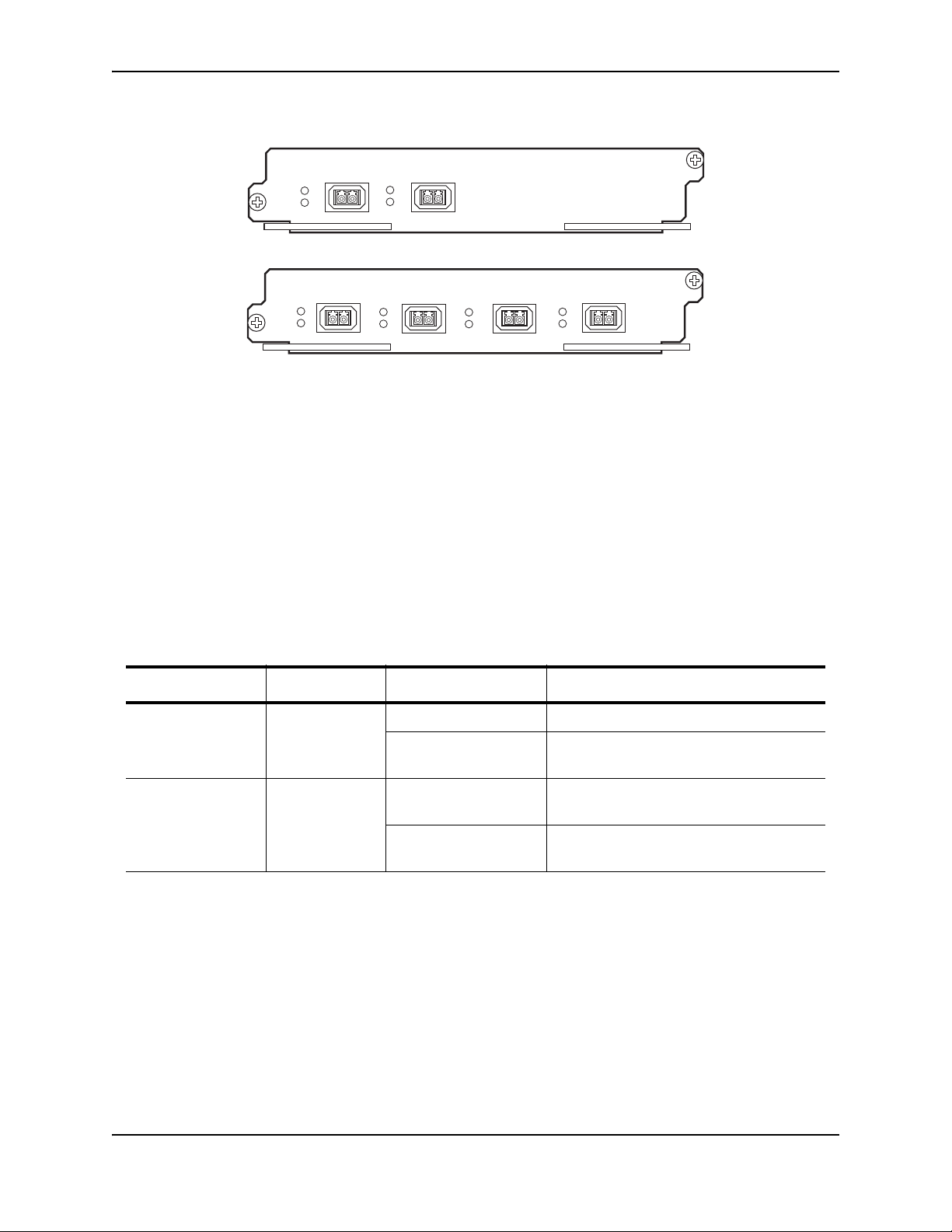

10/100/1000 Ethernet Interface Module (RJ-45)

Figure 2.8 shows the 20-port 10/100/1000 Ethernet module’s front panel.

Figure 2.8 20-port 10/100/1000 Copper Ethernet Module Front Panel

The front panel includes the following control features:

•LEDs

• Twenty 10/100/1000 Copper Ethernet ports

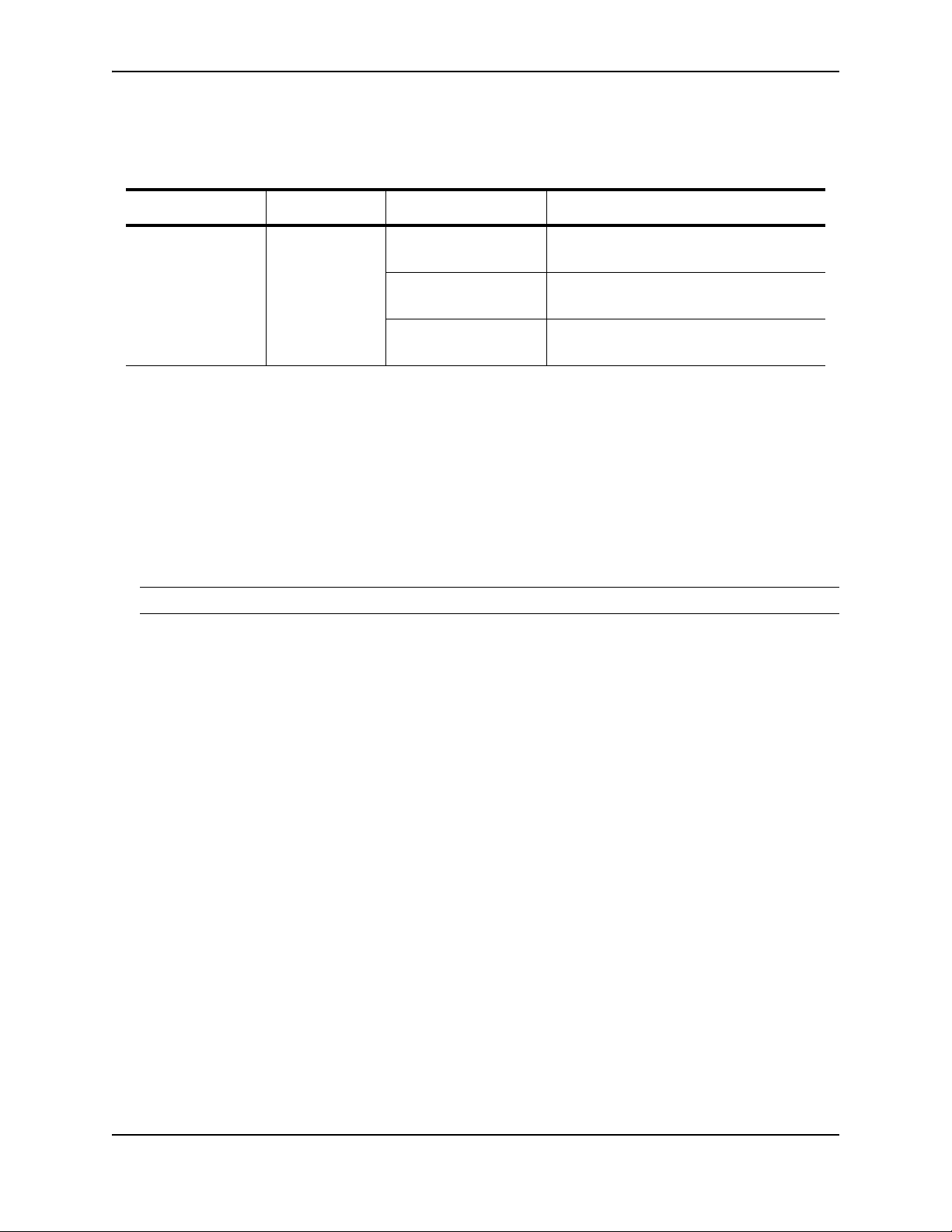

Table 2.6: Gigabit Ethernet Module LEDs

LED Position State Meaning

Link/Active As shown in

Figure 2.8 on

page 2-14.

On (solid) A link is established with the remote port

(with no traffic).

Blinking The port is transmitting and receiving

packets.

Off A link is not established with the remote

port and no traffic is being passed.

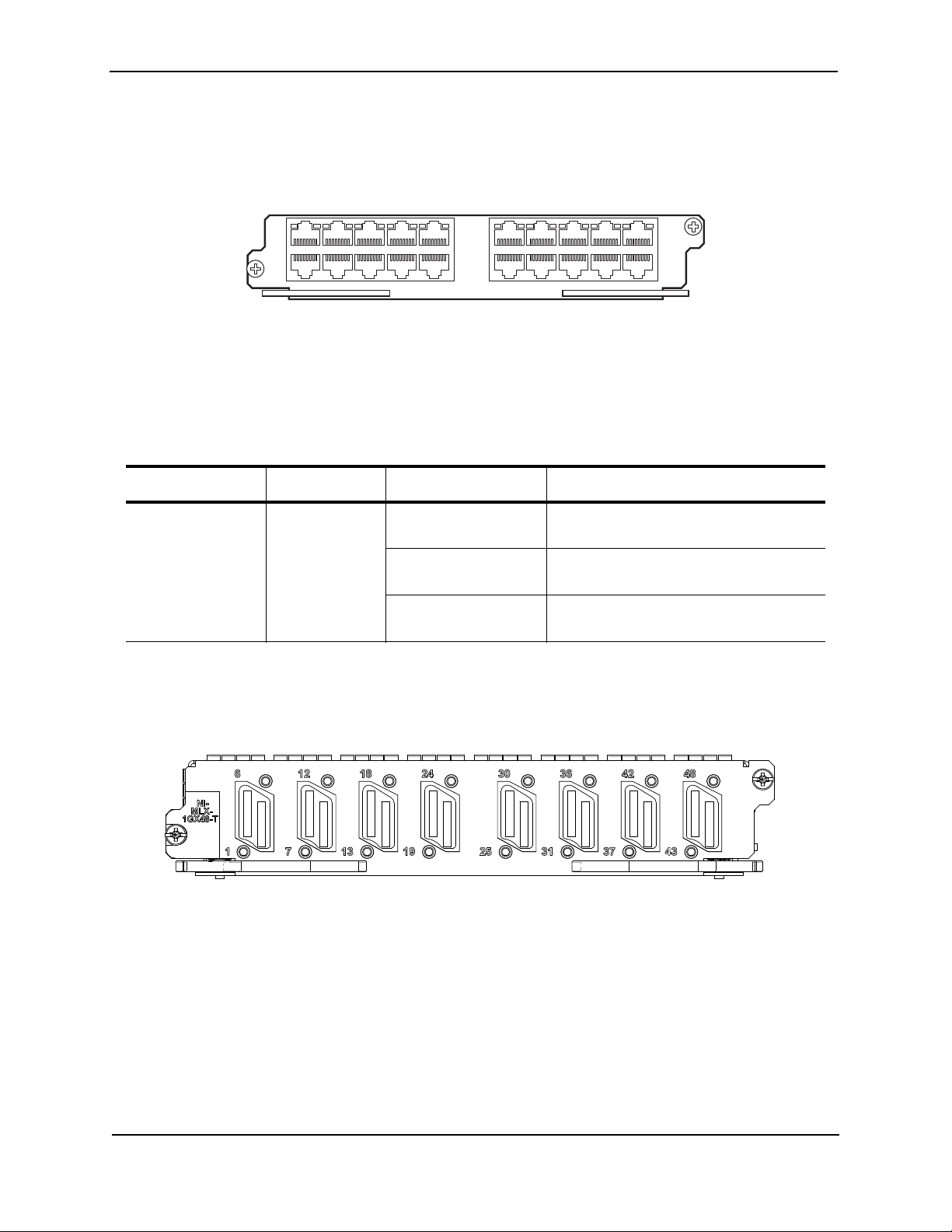

1 Gigabit x 48-T Module

Figure shows the 1 Gigabit x 48-T module’s front panel.

Figure 2.91 Gigabit x 48-T Module Front Panel

The front panel includes the following control features:

•LEDs

• 8 ports of Mini-RJ21 connectors with each connector supporting 6 ports of 1GbE

The front panel includes eight Mini RJ-21 connectors that support six 1 Gigabit Ethernet ports each. A cable

connects from the RJ-21 connector on the interface module to a Mini RJ-21 connector on a patch panel. At the

patch panel, the ports are broken out into individual RJ-45 connectors for each port.

Cables and patch panels that support this module are available through any Tyco International distribution partner.

Information about these products is available at the following URL:

www.ampnetconnect.com/foundrynetworks

2-14 © 2008 Foundry Networks, Inc. December 2008

Page 27

Table 2.7: Mini RJ-45 Module LEDs

LED Position State Meaning

Product Overview

Link/Active As shown in

Figure on

page 2-14.

On (solid) A link is established with the remote port

(with no traffic).

Blinking The port is transmitting and receiving

packets.

Off A link is not established with the remote

port and no traffic is being passed.

POS Interface Modules

The NetIron MLX routers support the following Packet Over SONET/SDH (POS) interface modules beginning with

release 03.4.00 of Multi-Service IronWare software:

• Dual speed (OC-48c/STM-16)/(OC-12c/STM-4) – Available with 2, 4, or 8 ports

• Single speed OC-192C/STM-64 – – Available with 1 or 2 ports

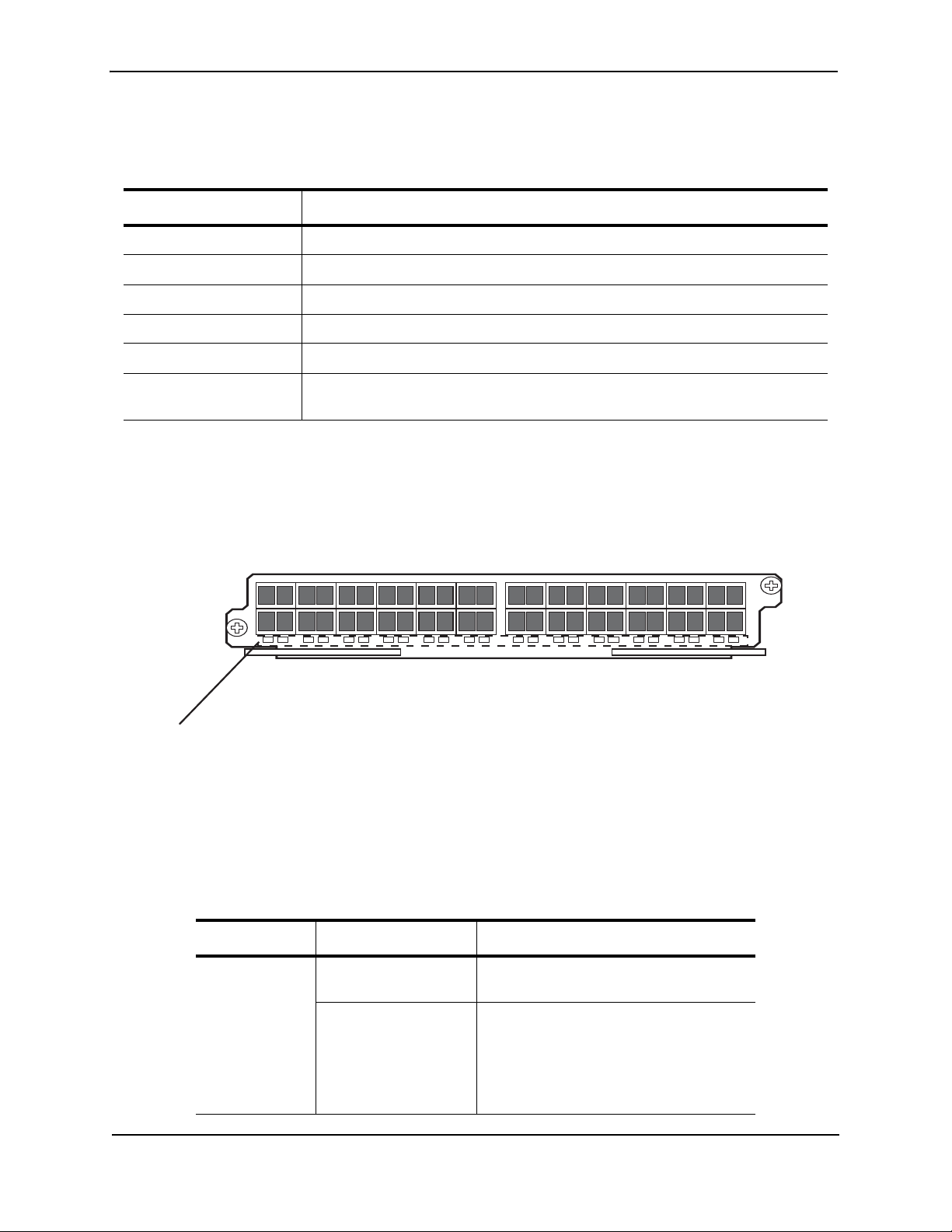

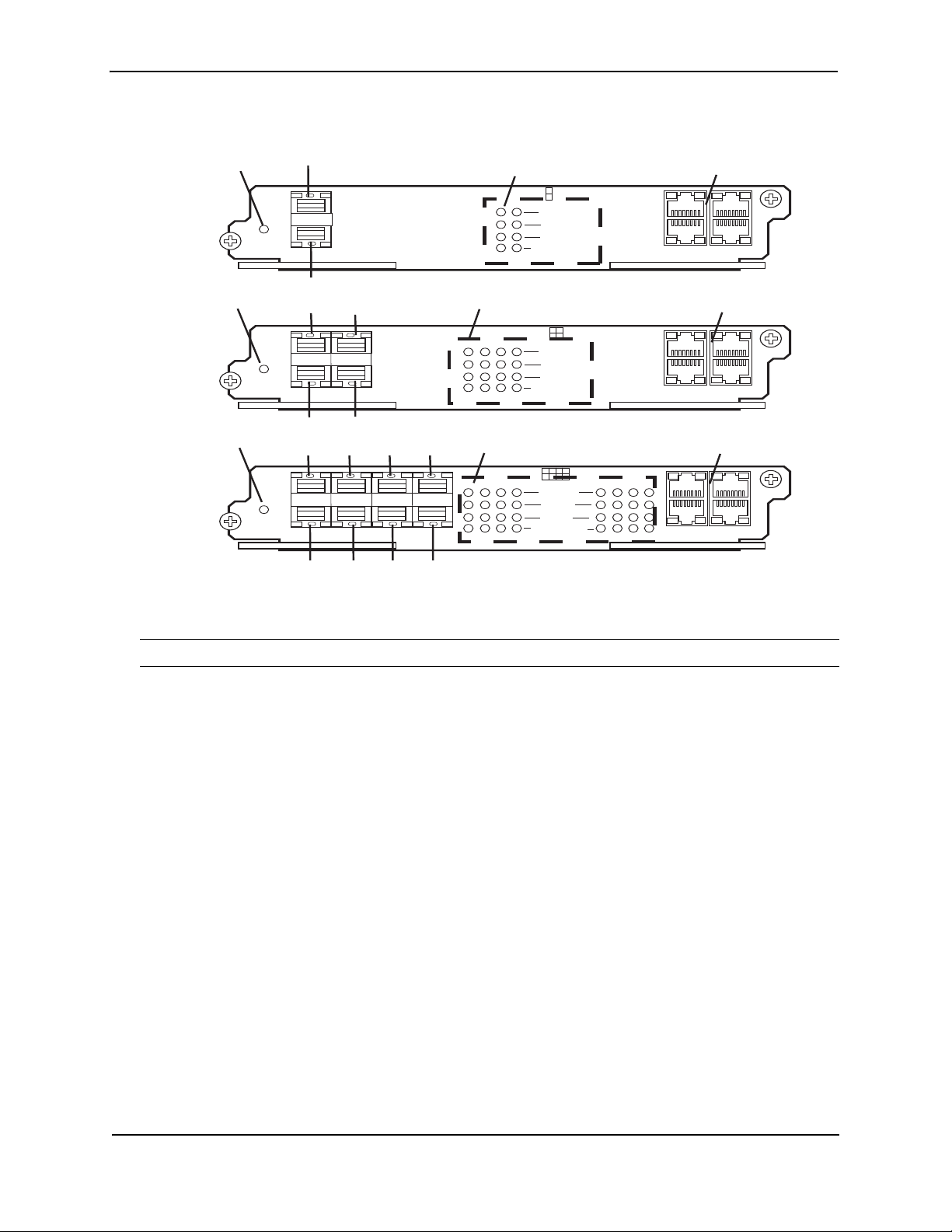

Dual Speed OC-12c and OC-48c

The dual-speed OC-48c/OC-12c POS module is reconfigurable and can be reconfigured through CLI to support

OC-48 or OC-12 speeds.

NOTE: All POS modules for the NetIron MLX Series support both Packet over Socket and Packet over SDH

Figure 2.10 highlights the following features of the OC-12c/OC-48c POS interface module front panels:

• 2, 4, or 8 ports that can accommodate SFP optics for the OC-12c/OC-48c modules

• A single LED to indicate if power is being received by the module

• 4 LEDs per port that indicate the following port status: Active/Local Rail, TX Pkt, RX Pkt, and Carrier Rcvd /

Remote Fail

• 2 IN and 2 OUT RJ-48 connectors to provide an BITS external clock source and to propagate a common

clock source (Line or BITS) among POS modules

December 2008 © 2008 Foundry Networks, Inc. 2-15

Page 28

Foundry NetIron MLX Series Installation and Basic Configuration Guide

Power

Active /

Local Fail

Tx Pk

t

BITS1

BITS2

Rx Pkt

Carrier Rcvd /

Remote Fail

I

N

O

U

T

1234 5678

1234567

8

I

N

O

U

T

Power

Active /

Local Fail

Tx Pk

t

BITS1

BITS2

Rx Pkt

Carrier Rcvd /

Remote Fail

I

N

O

U

T

1234

123

4

I

N

O

U

T

Power

Active /

Local Fail

Tx Pk

t

BITS1

BITS2

Rx Pkt

Carrier Rcvd /

Remote Fail

I

N

O

U

T

1

2

1

2

I

N

O

U

T

Port 1

Port 2

Port 1

Port 3

Port 2 Port 4

Port 1 Port 3 Port 5 Port 7

Port 2 Port 4 Port 6 Port 8

Port Status LEDs

Port Status LEDs

Port Status LEDs BITS Clocking Ports

BITS Clocking Ports

BITS Clocking Ports

Power

Power

Power

Figure 2.10 OC-12c/OC-48c POS Interface Modules

Single-Speed OC-192c

NOTE: All POS modules for the NetIron MLX Series support both Packet over Socket and Packet over SDH

Figure 2.11 highlights the following features of the OC-192c POS interface module front panel:

• 1 or 2 ports that accommodate XFP optics

• A single LED to indicate if power is being received by the module

• 4 LEDs per port that indicate the following port status: Active/Local Rail, TX Pkt, RX Pkt, and Carrier Rcvd /

Remote Fail

• 2 IN and 2 OUT RJ-48C connectors to provide an BITS external clock source and to propagate a common

clock source (Line or BITS) among POS modules

2-16 © 2008 Foundry Networks, Inc. December 2008

Page 29

Figure 2.11 OC-192c POS Interface Modules

Power

Active /

Local Fail

Tx Pk

t

BITS1

BITS2

Rx Pkt

Carrier Rcvd /

Remote Fail

I

N

O

U

T

12

I

N

O

U

T

1

2

Power

Active /

Local Fail

Tx Pk

t

BITS1

BITS2

Rx Pkt

Carrier Rcvd /

Remote Fail

I

N

O

U

T

1

I

N

O

U

T

1

Power

Power

Port 1

Port 2

Port 1

Port Status LEDs

Port Status LEDs

BITS Clocking Ports

BITS Clocking Ports

The front panels of the POS interface modules contain the following:

• a power LED