Page 1

RBC20-60

Blast Chiller

Page 2

Contents Page

Introduction 1 to 2

Model Details 2

Controller Technical Detail 2

Parts List 2

Operating Instructions 3 to 6

Electrical Connections 7

Service Information 7 to 19

Diagnostics 8

Function Test 8

Passcode 8

Profiles 9

Parameter Access 9

Parameters 9 to 11

Parameter Definitions 11 to 18

Alarms and Warnings 18

Foot Print Test Operation 19

Probes 19

Technical Data 20 to 22

Wiring Diagrams 23 to

Introduction.

Cook Chill Operation.

Blast chilling is a process to reduce the temperature of cooked food by swiftly arresting the cooking process, locking in its

colour, flavour, texture and nutritional value. Department of health guidelines state that to safely blast chill food the

temperature must be reduced from +70°c to +3°c within 90 minutes.

Pre Chill

Pre chilling ensures the correct cabinet temperature in the unit before chilling commences therefore improving the chilling

performance.

Soft Chilling.

Soft chilling is the process of rapid but gentle chilling of food.

This cycle brings down the food temperature to +3°c in no more than 90 minutes without the air or food temperature going

below 0°c.

This prevents large ice crystals forming therefore maintaining the texture, consistency and appearance of food such as

vegetables, rice, pasta, custard and fruit with no dehydration or cell damage.

Hard Chilling.

Hard chilling is the process of general purpose chilling.

This cycle brings down the food temperature to +3°c in no more than 90 minutes and is ideal for chilling meat pies,

lasagne, pasta and individually portioned meals. The air temperature for this process goes down to -15°c for the first 70%

of the cycle, to extract the maximum amount of heat from the product quickly. The air temperature then increases to +3°c

for the final 30% of the time to reduce surface damage and ensure quality.

Hard Chill Max.

Hard chill max brings down the food temperature to +3°c in no more than 90 minutes and is used for chilling high density

or high fat content food such as meat joints, stews or packaged products.

The air temperature during the cycle is allowed to go down to -20°c.

After either a pre-designated time has elapsed or product temperature has been achieved, the air temperature is allowed

to rise to the ‘hold’ value with the temperature being maintained at this level indefinitely.

Surface Protection.

Removing the heat energy from food product as rapidly as possible by the combination of powerful refrigeration and

evaporator fans moving large volumes of cooled air can cause damage to the food product. The food product could have

a form of ‘Frost Burn’ caused by the fast moving air feeling cooler than the actual air temperature ‘Wind Chill Effect’. This

may lead to product discoloration, dehydration, localised freezing and spoilage of the food product.

Surface protection overcomes this by reducing the evaporation operation, and hence the air speed at pre-determined

stages in the cycle to ensure that this does not happen. This is a discreet function and happens automatically without any

intervention from the operator. To enable the surface protection; and determine at what stage it would be activated values

are set in the service operating parameters.

Longer Term Storage – ‘Hold’ Mode (Conservation)

Upon the completion of the blast chilling cycle the controller will automatically enter the ‘Hold’ mode. This will either be

because the selection set time has elapsed or the product core temperature has been achieved. When the hold period

commences an alarm will sound for a period denoted in the service operating parameters.

1

Page 3

The controller will determine the temperature to be maintained during the hold phase based on the chilling cycle that has

been completed. If a soft or hard chill has taken place the controller will maintain an air temperature of 2°c.

The hold mode is principally intended as a temporary storage facility offering the operator flexibility until the product can

be unloaded into a longer term storage units at the correct storage temperature. On occasion this hold period may

become extended to operate overnight or to provide emergency refrigeration backup. In such instances defrosting would

automatically occur as necessary.

Model Details.

The RBC 20-60 is capable of blast chilling 60kg of product from +70°c to +3°c in 90 minutes with entry temperature up to

90°c

The cabinet is compatible with the Rational 20 rack GN 1/1 201 trolley.

Refrigerant used is R404A.

The RBC20-60 has two separate refrigeration systems co mprising, two condensing units, a twin circuit condenser and a

twin circuit evaporator. (See pages 20 and 21 for assembly details and page 22 for schematic dual circuit re frigeration

layout).

The RBC20-60R has the same refrigeration systems but the con densing units are remotely sited.

Refrigerant control is by expansion valve to control the correct amount of refrigerant required to meet the demand of the

evaporator. (See page 21 for assembly detail).

The parameter ‘Capacity Enable’ is set to ‘ON’ to allow for both condensing units to be running during the chill cycle

therefore maximising the heat extraction from the product. During the ‘HOLD’ mode with the ‘Capacity Enable’ set to ‘ON’

one compressor will control the temperature throughout unless the temperature exceeds the capacity control limit.

A 1½” BSP drain outlet is fitted in to the base of the cabinet for connection to external drain.

The cabinet is delivered with the legs secured to the base of the cabinet.

Controller Technical Detail

The FCC controller is a three-piece unit made up of the Front Display and Dial Shaft Encoder, Mother Board plus

Evaporator, Food and Air temperature probes. The front display PCB and the CPU/ Switching PCB unit are

interconnected by a ribbon cable. The membrane attached to the front provides an IP rating of IP54 providing a scratch

free wipe clean finish.

The control dial is the method by which the controller is accessed for all requirements. It has three planes of movement,

clockwise, anticlockwise and inwards.

The control dial allows the operator/ engineer to move forward and backwards through various menu selections shown on

the display, and enter a desired programme. The control system will then respond appropriately either commencing the

operating cycle or allowing further configuration.

Part numbers

Item Description Part Number

Controller Mother Board 00-555395

Controller Shaft Encoder 00-555396

Controller LCD Display 00-555394

Air Probe P1 NTC type. 2.5m 00-555397

Evaporator Probe P2 NTC type. 2.5m 00-555397

Food Probe 5M Length 00-555663

Compressor x 2 TAJ4519ZH T 400/50 00-555885

Condenser Coil BC6013/122 01-257300-01

Condenser Fan Assembly S4E300-BP26-30 00-555886

Sight Glass 3/8" 15483015

Drier 00-555388

Solenoid Valve EVR6 32F5219+0 15451215

Liquid Receiver 00-555579

LP Switch 2.5 Bar 0.5 Bar Diff 00-555387

HP Switch 28 Bar – 3 Bar Diff 00-555386

High Pressure Thermostat KP5 Auto Re-set (set at 18 BAR with a 3 BAR diff.) 15452109

Evaporator Coil BC6013/121 01-256400-01

Expansion Valve Valve Body TES2-NL68Z34300/68 15450386

Orifice NO 02 68-2092/68-2072 15451104

Expansion Valve Solder Adaptor 68-2 15450910

Evaporator Fan Motor W4E420-CP02-66788-4-7320 00-555375

hinge Edgemount 00-555880

Door Gasket 1406x546MM 01-256387-01

Door Switch Circular (Reed Type) 00-555829

Door Switch Magnet Circular 00-555828

Door Handle Edgemount Latch Kit 00-555881

2

Page 4

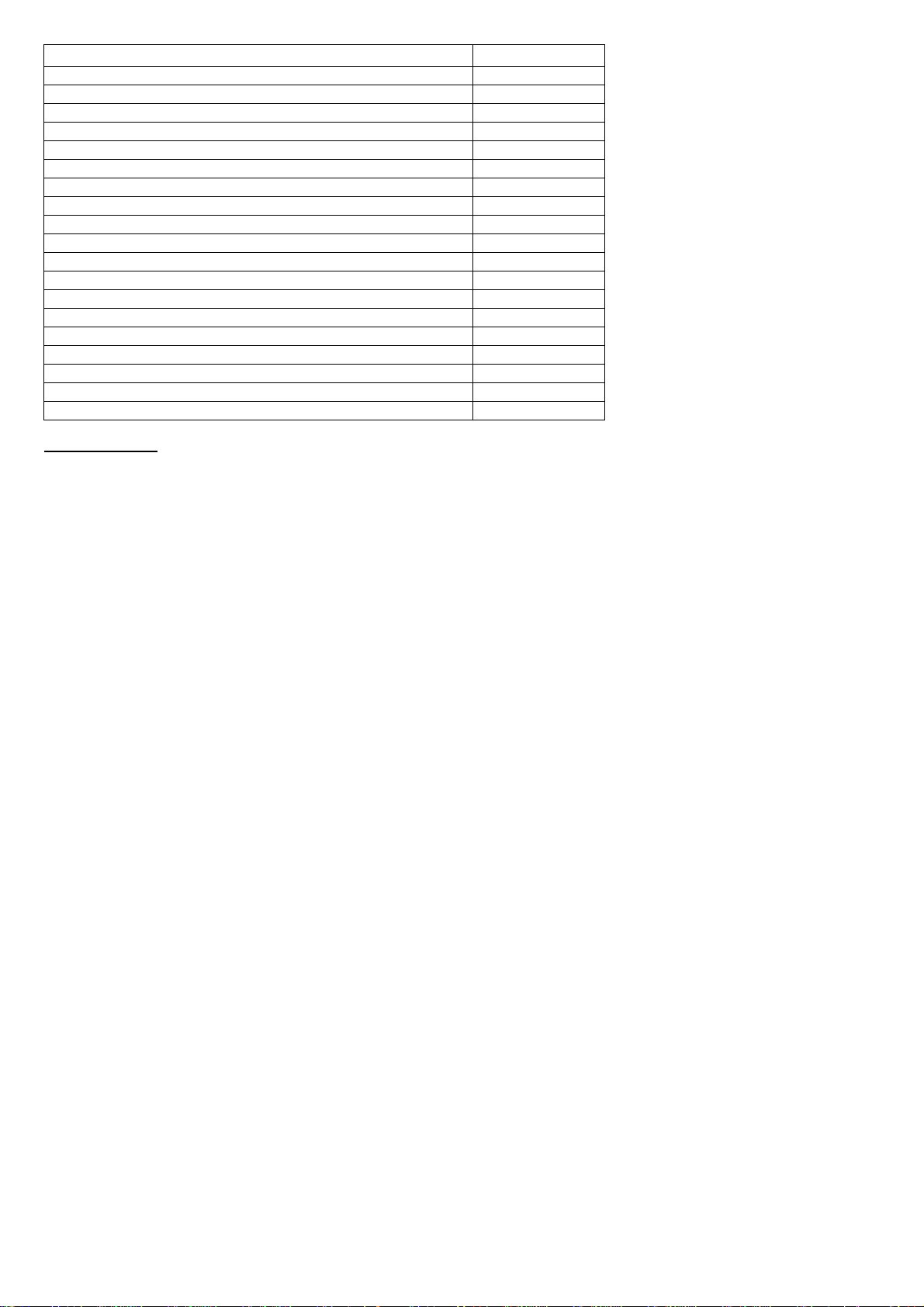

Standard Operation

When mains electrical power is first applied to the controller it will carry out a self-test function,

for approximately 3 seconds. During this period the display will show.

On completion of the self test, the controller will revert to the last chill program that was run

(Pre-chill, Soft Chill, Hard Chill, Hard Chill Max, Shock Freeze, Professional 1, Professional 2,

or Professional 3). The availability of these is dependent on how the controller has been

configured.

The example shows the controller in Hard Chill mode with the previous and next programs

indicated at the top of the display. To change the program rotate the dial, either clockwise or

anticlockwise to select the type of program you require.(for guidelines refer to page 7)

Blast Chill & Shock Freeze Operating Instructions.

To initiate the program just press and release the dial for the program to start.

The program starts with the screen on the left being displayed for 2 minutes. After which the

intelligent probe determines if the cycle is controlled by time, displayed by the screen in the

middle, or by temperature as displayed by the screen on the right.

On completion of the program the controller will cause the blast chiller to enter the Hold Mode,

as displayed on the left. An alarm will sound, press and release the dial to cancel the alarm, if

the alarm is not cancelled the blast chiller will still enter the Hold Mode with the periodical

sounding of the alarm. To cancel press and release the dial.

To stop the blast chiller during operation, press and hold the dial for 2 seconds, the display returns to the program

selection screen.

At any time when the blast chiller is operational the dial can be rotated to give information on

the status of the particular mode of operation.

The display will remain for 10 seconds and then revert to the normal operating screen

automatically.

3

Page 5

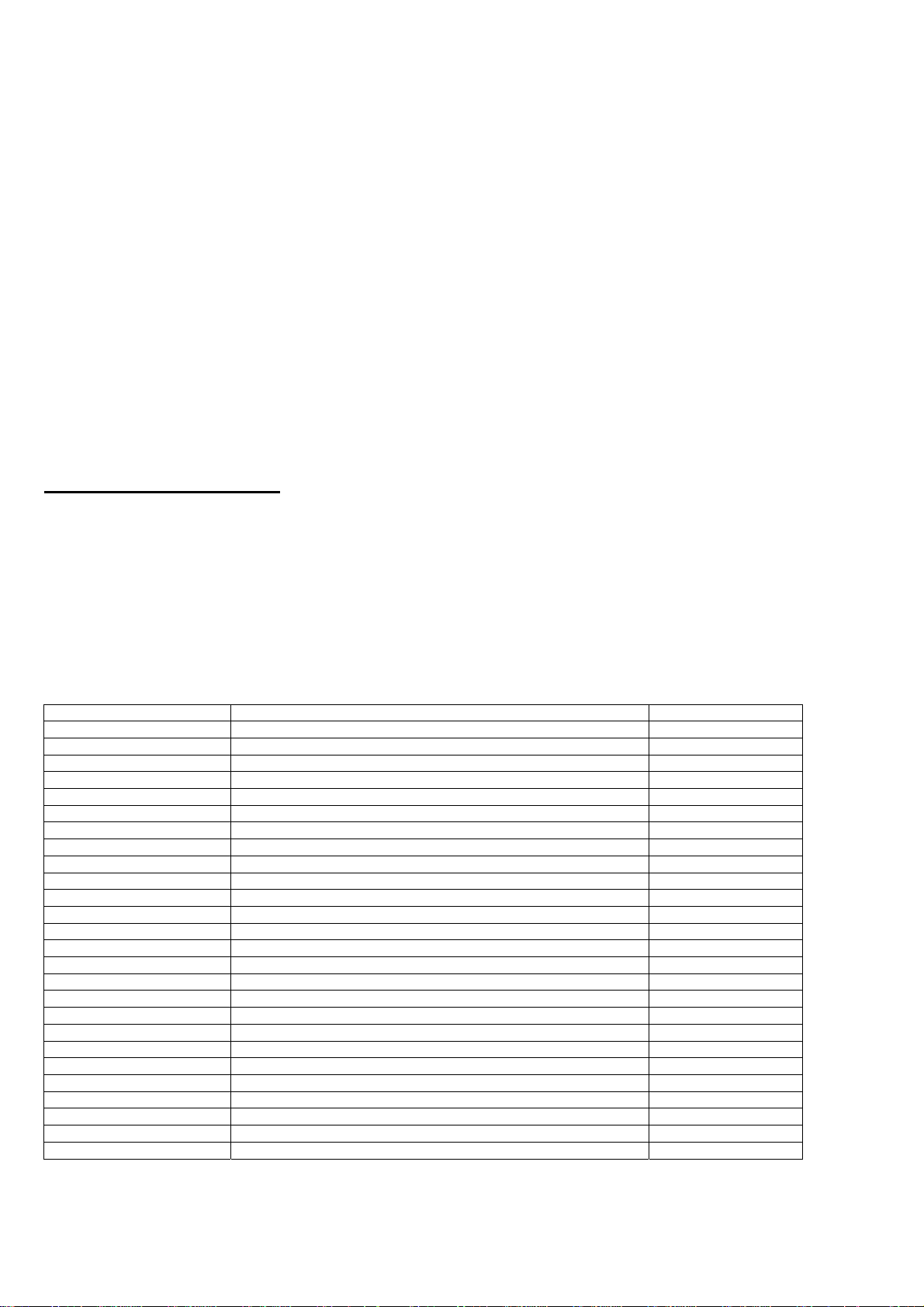

Pre Chill

This program is used to Pre Chill the cabinet prior to the first cycle.

Blast Chiller empty and is a short time based program of about 20 minutes.

It is generally recognised as the correct method of preparing for a blast chill cycle.

The program is selected by rotating the dial until the display shows, press and release the dial

to start the program.

Defrost.

Defrosting is not normally required but if there is an ice build up on the coil inside the cabinet a manual defrost can be

selected. Rotate the dial until the Defrost screen, below left, is displayed.

Press and release the dial to start the defrost.

During defrost the screens will alternate between the middle and ri ght hand screens.

Defrost will last 20 minutes and when completed the alarm will sound. Press the dial to acknowledged or if not wait until it

comes to the end of the alarm period, the alarm will stop and the display will revert to the previous screen.

Further Operational Features.

Chill time adjustment. (All programs excluding Professional 1, 2 or 3)

Whilst in the pre-programmed selection screen press and hold the dial for 2 seconds, the information screen will be

displayed, below left. Press and release the dial to move to the time set, see below right. Rotate the dial clockwise to

increase the time, anticlockwise to decrease. Once the time has been selected, press and release the dial and ‘CHILL

TEMP’ will be highlighted.

On completion press and hold the dial for 2 seconds to return to the program selection screen, to continue press and

release the dial for the program to start.

On completion of the program the time changes will revert to the default settings.

Chill / Hold temperature adjustments. (Professional 1, 2 or 3 only)

Professional 1, 2 and 3, if configured, are programs that can be used to tailor the chill time and temperature to suit

specific product requirements.

Adjust the ‘CHILL TIME’ as above. With the ‘CHILL TEMP’ highlighted, below second from the left, press and release the

dial to move to the temp set, below second from the right. Rotate the dial clockwise to increase the time, anticlockwise to

decrease. Once the time has been selected, press and release the dial and ‘HOLD TEMP’ will be highlighted. Follow the

procedure for changing chill temp to change the hold temp.

On completion press and hold the dial for 2 seconds to return to the program selection screen, to continue press and

release the dial for the program to start.

The chill time and chill / hold temperature adjusted settings are retained for professional 1, 2 and 3 programs and will not

revert to the default.

This is done with the

4

Page 6

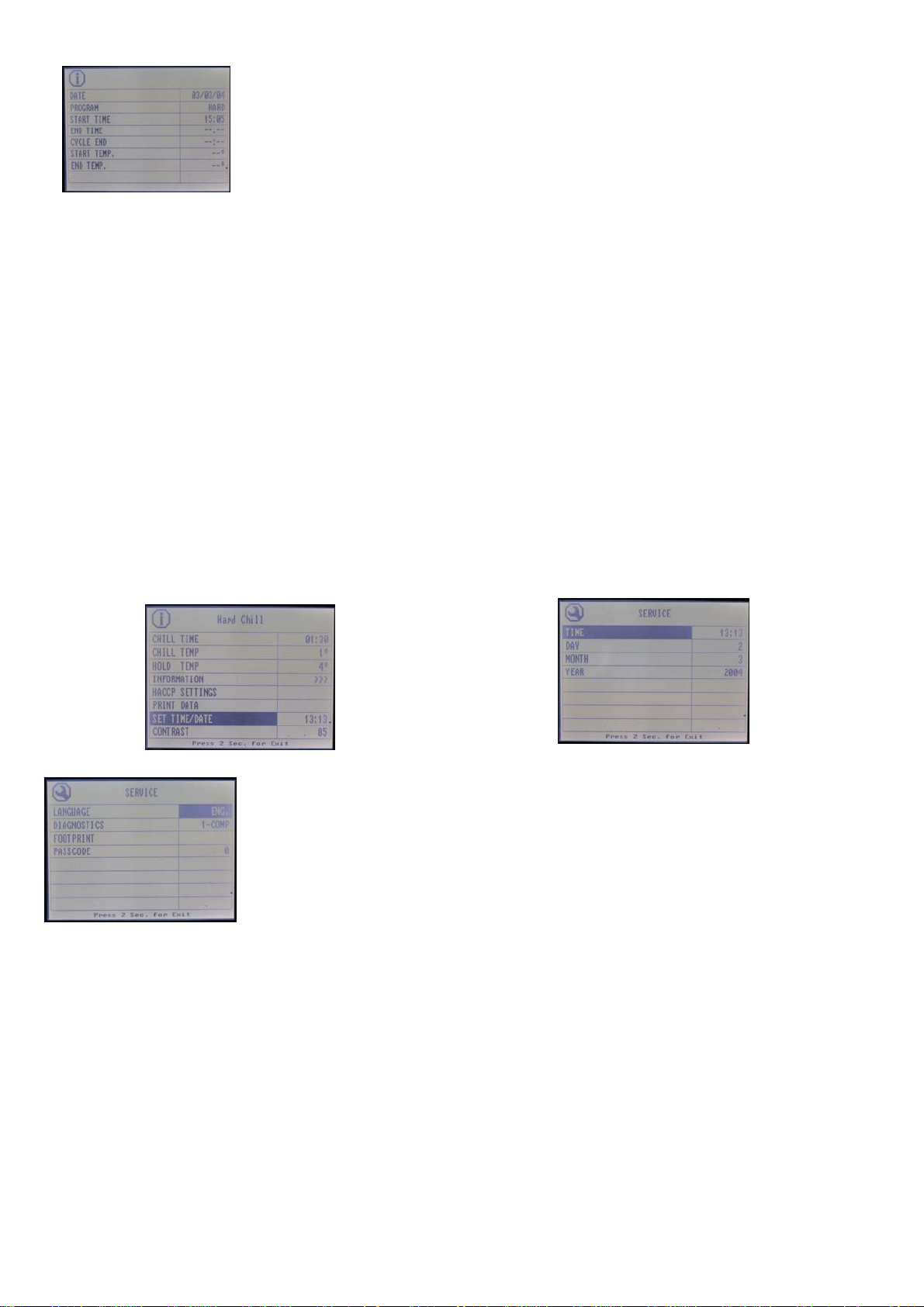

Information

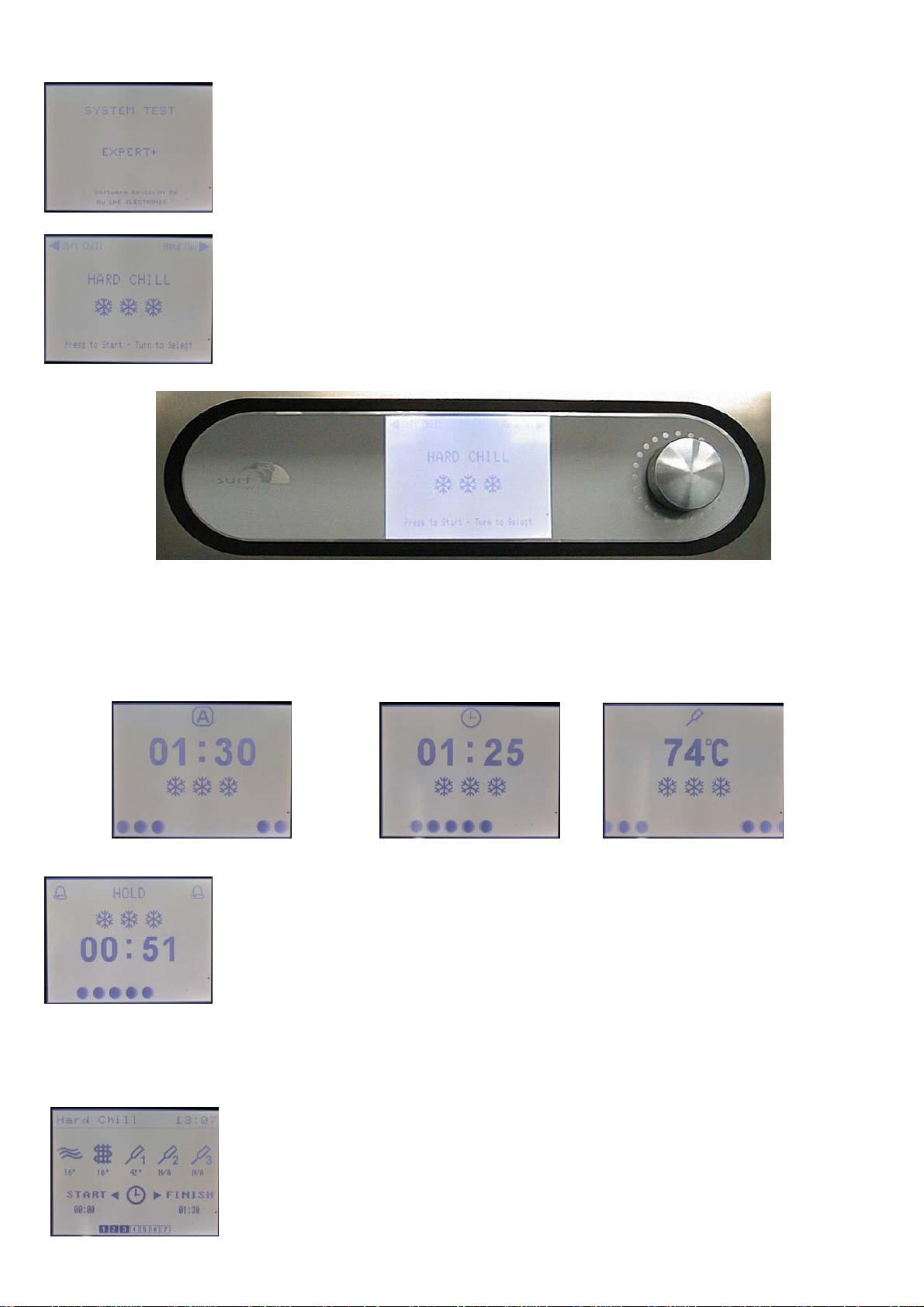

Whilst in the program selection screen press and hold the dial for 2 seconds, the information

screen will be displayed. Rotate the dial until ‘INFORMATION’ is highlighted. Press and

release the dial to display the screen showing the last run cycle. The information relates to

date, program run, start time, start temperature and end temperature.

HACCP settings.

Whilst in the program selection screen press and hold the dial for 2 seconds, the information screen will be displayed.

Rotate the dial until ‘HACCP SETTINGS’ is highlighted. Press and release the dial to access the HACCP option screen.

Press and release the dial to move to the selection screen for long or short reports, rotate the dial to select which option,

once selected press and release the dial to confirm.

Press and release the dial to move to the selection screen for the print sample, select 3 or 5 minute selection rate.

On completion press and hold the dial for 2 seconds to return to the program selection screen.

Print Data.

Whilst in the program selection screen press and hold the dial for 2 seconds, the information screen will be displayed.

Rotate the dial until ‘PRINT DATA’ is highlighted. If using a hand held printer switch the printer on now. Point the printer at

the infra red download sensor (optional), located in display area, press and release the dial to download the print data.

On completion press and hold the dial for 2 seconds to return to the program selection screen.

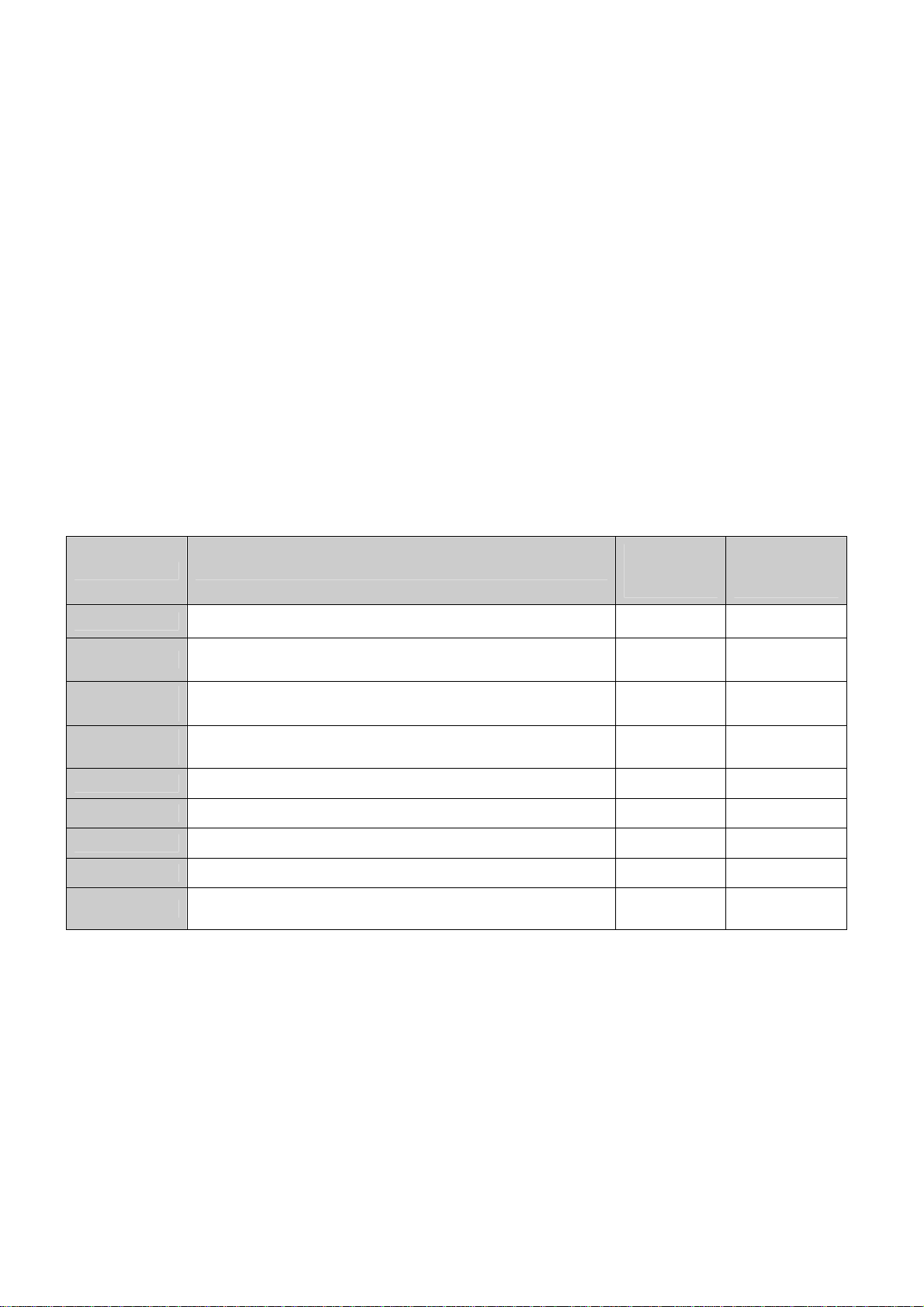

Set time and date.

Whilst in the program selection screen press and hold the dial for 2 seconds, the information screen will be displayed,

below left. Rotate the dial until ‘SET TIME/DATE’ is highlighted. Press and release the dial to access the service screen,

below right. Press and release the dial to move to the displayed time in hours and minutes, rotate the dial to alter the time,

once the correct time has been achieved press and release the dial to move to ‘DAY’. If it is necessary to change the day,

month and year change the settings using the same procedure for setting the time.

On completion press and hold the dial for 2 seconds to return to the program selection screen.

Changing Text Language.

Whilst in the program selection screen press and hold the dial for 2 seconds, the

information screen will be displayed continue pressing the dial for a further 2 seconds to

display the ‘SERVICE MENU’. LANGUAGE will be highlighted, press and release the dial,

‘ENG’ (English) will be highlighted. Rotate the dial to change the language. Select the

preferred language, press and release the dial to confirm.

Screen Saver

The screen saver screen is displayed if the machine is not used for 20 minutes, providing power is connected to it. It

shows a series of ‘Z’ indicating sleep mode. Pressing and releasing the dial or opening the door will awaken the unit, the

program selection screen will be displayed.

Alarms and Warnings

Air Probe: If this alarm occurs it will remain in the program selected until it is completed, however no further

operation will be possible. Call your Foster Authorised Service Company.

Evap Probe: If this alarm occurs it will remain in the program selected until it is completed, however no further

operation will be possible. Call your Foster Authorised Service Company.

Food Probe: If this alarm occurs it will automatically change to a timed program until it is completed, however no

further operation will be possible. Call your Foster Authorised Service Company.

Door Open: The display will continue to show the alarm message until the door is closed. If this does not cancel the

alarm call your Foster Authorised Service Company.

5

Page 7

High Temperature: This alarm will only occur in the hold mode only. Probe the product to determine it is at the correct

HP Switch: Causes for this alarm could be:

Power Fail: If the power fails for up to five minutes the unit will re-start on the resumption of the power supply without

There are Three main programmes RBC 20-60 Blast Chiller.

Soft Chill- for the safe chilling of delicate products such as gateaux and patisserie items, and high water content items

such as vegetables, rice and pasta.

Hard Chill- For general purpose chilling. The Hard Chill cycle is ideal for chilling ‘standard products’ such as meat pies,

lasagne, individually portioned meals etc. Providing surface protection for the later part of the program.

Hard Chill Max- For high density and high fat content products such as meat joints, stews and sous vide.

Guide for Blast Chilling.

Food Type Includes

temperature. If it is at the correct temperature place in a storage refrigerator or freezer and call your

Foster Authorised Service Company. If the product temperature is above the guidelines check the chill

time selected or the weight of product being chilled does not exceed the specification for the Cabinet.

Does the product temperature exceed 90°c. Has too much product been placed in the cabinet. Is the

airflow restricted. Does the condenser filter require cleaning. If the problem persists call your Foster

Authorised Service Company.

affecting the selected cycle. Longer than five minutes and the controller will enter the hold mode. To

check the cycle operation look in the information screen to check the cycle time.

To re-start press and release the dial, the screen will return to the hold screen. Press and hold the

dial for two seconds the display returns to the program selection.

Blast Chill

Programme

required

Time required

to Blast Chill

(Minutes)

Meat Beef, pork, lamb, poultry & mince Hard 40 - 90

Fish

Prepared

dishes

Vegetables &

Pulses

Fruit Stewed and cooked fruits. Soft 60 – 90

Bakery Cakes Hard 30 – 90

Bakery Pastries Hard 60 – 90

Desserts Fruit Based desserts & egg based flans. Soft 30 – 90

Desserts Sponge puddings and dense desserts such as cheesecake. Hard 30 – 90

Fried, poached or baked – haddock, plaice, salmon, cod

fillets etc

Stews & casseroles, lasagne, risotto, shepherds pie Hard 50 - 90

Steamed or roasted veg, rice and potatoes etc. Soft 30 - 90

Soft 30 - 90

NOTE: All times listed should be used as a guide only, and will depend on type, size and quantity.

6

Page 8

Electrical Connections.

Inputs.

L - Mains ‘Live’ supply (115V 230V, 50Hz / 60Hz). 4 terminals.

N - Mains ‘ Neutral’ supply – 16 terminals.

E - Protective Earth – 16 terminals.

DOOR - Door Switching connection (not voltage carrying).

DOOR2 - Safety door switch connection (not voltage carrying).

HP - High Pressure switch connection (not voltage carrying).

TA - Air probe connection.

TE - Evaporator probe connection.

FP1 - Food/ product temperature connection.

FP2 - Additional second food / product temperature probe connection.

FP3 - Additional third food / product temperature probe connection.

Outputs.

C1 - Condensing system switched relay (30A/ 8A) – normally open (NO) output – 3 terminals.

F1 - Evaporator fan 1 switch relay (8A/ 4A) – normally open (NO) output – 3 terminals.

F2 - Evaporator fan 2 switch relay (8A/ 4A) – normally open (NO) output – 3 terminals.

D1 - Defrost system switched relay (8A/ 4A) – normally open (NO) output – 3 terminals.

S1 - UV light system switched relay (8A/ 4A) – normally open (NO) output 2 terminals.

A1 - Alarm relay (8A/ 4A) normally closed (NC) – 1 terminal, normally open (NO) 2 terminals.

P1 - Capacity relay (8A/ 4A) normally closed (NC) – 1 terminal, normally open (NO) 2 terminals.

Display Power - Man Machine socket 2 – way connection.

Display Data - Man Machine RJ54 Type 4 – way connection.

Logger - 4 – way RS 485 connections.

Service Information

Refer to the operating instructions on page 4 for operating instructions.

When mains electrical power is first applied to the controller it will carry out a self test function, for approximately 3

seconds, to ensure that there are good connections between the component parts. During this period the display will

show.

The information displayed in the centre of the screen refers to which of the profiles the controller is set for.

The software version relates to the software release. The number relates to the major operating changes or model

variants. The letter relates to the minor operating changes that may have been made from the original, such as parameter

settings.

On completion of the self test the controller will revert to the last chill program that was run (Pre-chill, Soft Chill, Hard Chill,

Hard Chill Max, Shock Freeze, Professional 1, Professional 2, or Professional 3). The availability of these is dependent on

how the controller has been configured. The example below shows the controller in Hard Chill.

Press and hold the dial for 5 seconds.

Firstly the display will display the information page, below left, continue pressing until the ‘SERVICE’ screen is displayed,

below right. For changes to language see page 5.

7

Page 9

Diagnostics

Rotate the dial until you reach ‘Diagnostics’, below left, press and release the dial to highlight the component. In this

program you can test each of the major components on the machine in sequence, 1- COMPRESSOR, 2-FAN1, 3-FAN2,

4- DEFROST, 5- ALARM, 6- CCAP (Capacity Control), 7- UV-L (UV light if fitted), ESC (escape). Rotate the dial until the

relay output is highlighted, once selected press and the dial to test the relay, the relay will remain energised for as long as

it is pressed. On completion of the test you must rotate the dial until you highlight ‘ESC’ press and release the dial to

move to the next program.

Function Test

Rotate the dial until you reach ‘FOOTPRINT’, see below, press and release the dial to initiate the controller function self

test.

This allows for the engineer to test the operation of the machine without having to wait for a full program to run. The test

lasts for ten minutes and should be carried out with the cabinet / room empty. Each of the relays will be energised to

simulate the chill process. Relay 1-COMPRESSOR, Relay 2-FAN1, Relay 3-FAN2, Relay 4-DEFROST, Relay 5-ALARM,

Relay 6-CCAP (Capacity Control), and Relay 7- UV-L will all be switched on and of automatically in a pre determined

manner to simulate program operation (whether they are connected or not).

The test is based around an algorithm built into the software. Prior to starting the program it is advisable to place a probe,

in the centre of the cabinet/room, attached to an independent measuring device to check the air temperature as the air,

coil and food probes are not active during this program. The temperature achieved will depend on the model. The air

temperature should be checked 5 to 6 minutes into the program. The temperature achieved should be the minimum

temperature and can be checked against the model type found in the parameter table on page 9. (For further information

go to page 19).

Once the test is completed the display reverts to the last chill program and not to the service parameters.

Passcode.

Rotate the dial until you reach ‘PASSCODE’, below left, press and release the dial to highlight the code, below right.

Rotate the dial until you reach the code ‘131’. Once achieved press and release the dial to acknowledge.

8

Page 10

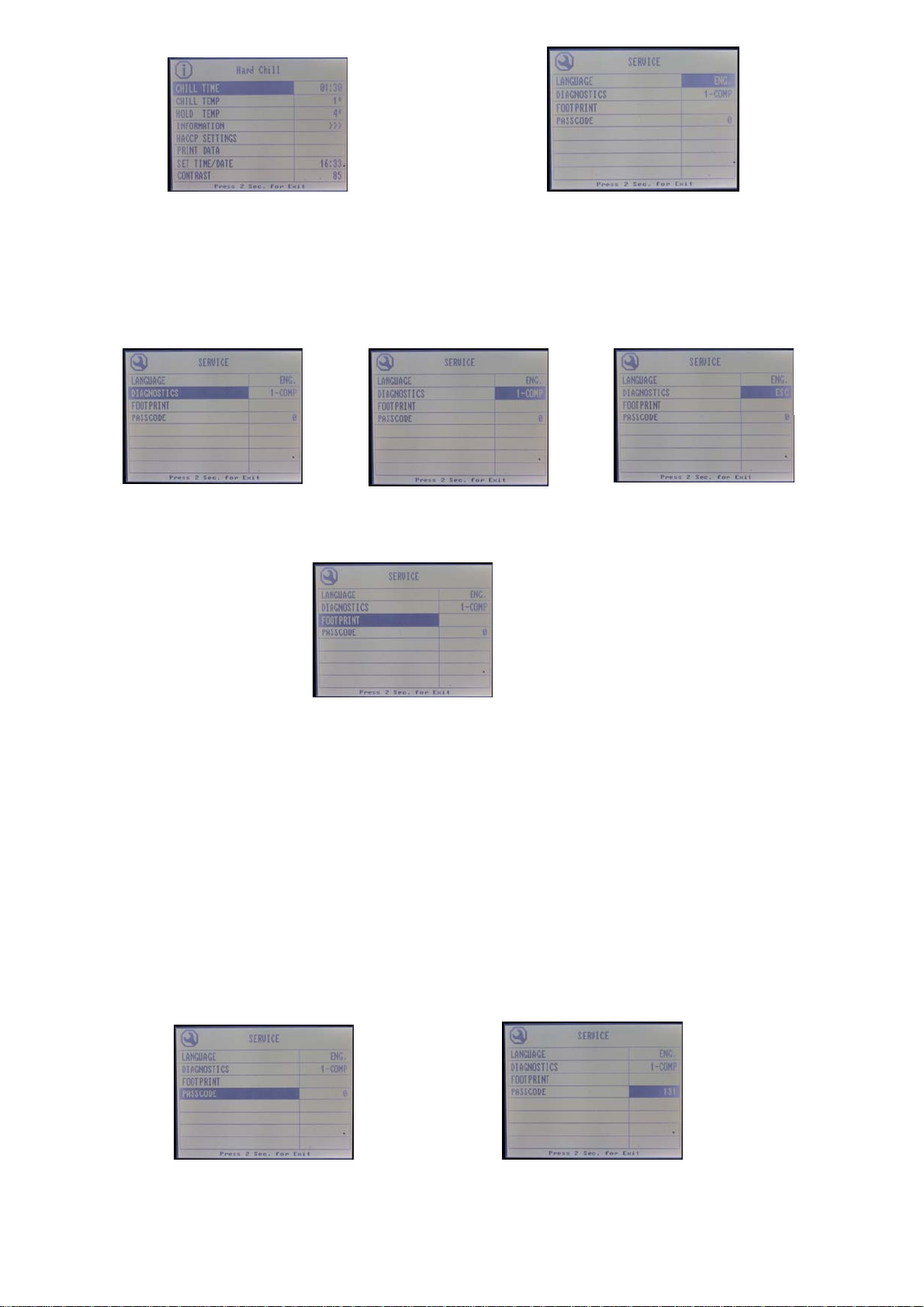

Profiles.

You are now in the program profiles. The controller has 9 operating programs – Pre Chill, Soft Chill, Hard Chill, Hard Chill

Max, Shock Freeze, Professional 1, Professional 2, Professional 3, Defrost and 2 optional programs – UV Sanitisation

and Information. These programs are all available depending upon which of the profiles are selected, see below.

To change the profile rotate the dial to select program, press and release the dial to accept the change. The 3 chevrons in

the box opposite the selected program confirm the change.

The default operating profile for the RBC20-60 and RBC20-60R is ‘LE CHEF’.

The table identifies which programs are available from the profile with ‘LE CHEF’ highlighted.

PROGRAMS

PRE CHILL

SOFT CHILL

HARD CHILL

HARD CHILL MAX

SHOCK FREEZE

PROFESSIONAL 1

PROFESSIONAL 2

PROFESSIONAL 3

DEFROST

UV SANITISATION OPTIONAL OPTIONAL OPTIONAL OPTIONAL OPTIONAL OPTIONAL OPTIONAL

INFORMATION OPTIONAL OPTIONAL OPTIONAL OPTIONAL OPTIONAL OPTIONAL OPTIONAL

SIMPLE SIMPLE + CHEF CHEF+ LE CHEF EXPERT EXPERT+

U U U U

U U

9 9 9 9 9

9 9 9 9 9 9 9

U U

U

9

U U U U U

U U U U U

U U U U U

9 9 9 9 9

U

9 9 9 9 9 9 9

PROFILES

9

9 9 9

U U

9

9 9

9 9

9 9

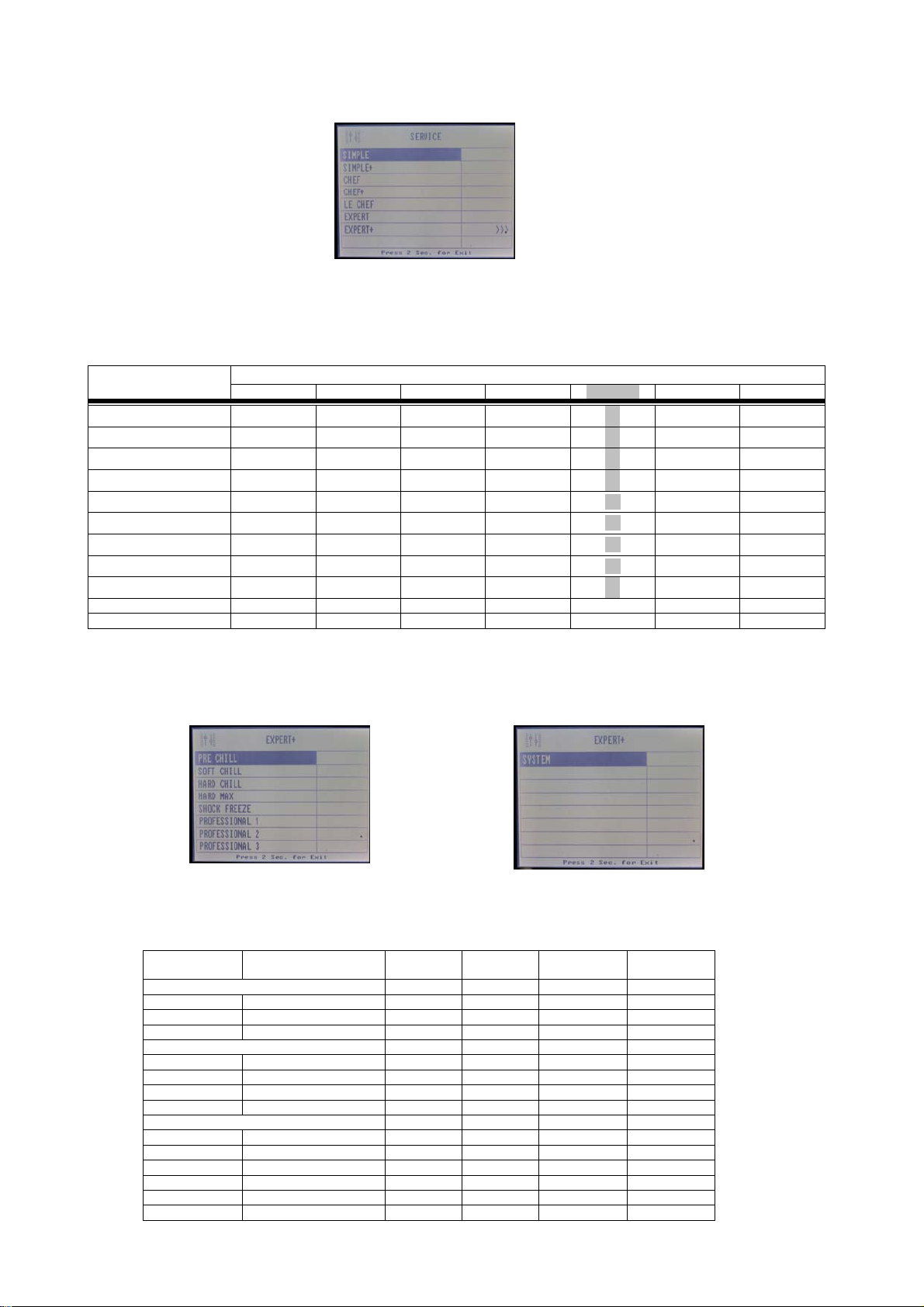

Parameter Access.

From the profile screen once the selection has been made press and release the dial to access the parameter list. The

screen will display the parameters as shown in the screen below left. To access the system parameters rotate the dial

anticlockwise see below right.

Selection is made by pressing and releasing the dial.

The table below contains the complete parameter list and includes the selectable range and default values.

Parameters

PARAMETER

PO1 AIR TEMP °C -15 15 -10

PO2 CHILL TIME MINUTES 5 60 15

PO3 HOLD TEMP °C -10 15 3

PO4 AIR TEMP °C -10 15 1

PO5 CHILL TIME MINUTES 5 480 90

PO6 CHILL TEMP °C -5 15 3

PO7 HOLD TEMP °C -5 15 3

PO8 AIR TEMP °C -20 15 -15

PO9 CHILL TIME MINUTES 5 480 90

P10 CHILL TEMP °C -15 15 3

P11 HOLD TEMP °C -15 15 3

P12 CHANGE TIME % 5 95 80

P13 CHANGE TEMP % 5 95 80

DESCRIPTION VALUE MINIMUM MAXIMUM DEFAULT

PRE-CHILL

SOFT-CHILL

HARD CHILL

9

Page 11

P14 AIR TEMP °C -20 15 -15

P15 Chill Time MINUTES 5 480 90

P16 CHILL TEMP °C -15 15 3

P17 HOLD TEMP °C -15 15 3

P18 AIR TEMP °C -35 15 -30

P19 CHILL TIME MINUTES 5 480 240

P20 CHILL TEMP °C -35 15 -21

P21 HOLD TEMP °C -35 15 -21

P22 Air Temp. Std. °C -20 15 -15

P23 Chill Time Std. Minutes P24 P25 90

P24 Chill Time Minimum Minutes 5 60 5

P25 Chill Time Maximum Minutes 60 480 240

P26 Chill Temp. Std. °C P27 P28 3

P27 Chill Temp. Minimum °C -20 -5 -10

P28 Chill Temp. Maximum °C -5 15 5

P29 Hold Temp. Std. °C P30 P31 3

P30 Hold Temp. Minimum °C -10 0 0

P31 Hold Temp. Maximum °C 0 10 10

P32 Change Time % 5 95 80

P33 Change Temp. % 5 95 80

P34 Air Temp. Std. °C -20 15 -15

P35 Chill Time Std. Minutes P36 P37 90

P36 Chill Time Minimum Minutes 5 60 5

P37 Chill Time Maximum Minutes 60 480 240

P38 Chill Temp. Std °C P39 P40 3

P39 Chill Temp. Minimum °C -20 -5 -10

P40 Chill temp. Maximum °C -5 15 5

P41 Hold Temp. Std. °C P42 P43 3

P42 Hold Temp. Minimum °C -10 0 0

P43 Hold Temp. Maximum °C 0 10 10

P44 Change Time % 5 95 80

P45 Change Temp. % 5 95 80

P46 Air Temp. Std. °C -20 15 -15

P47 Chill Time Std. Minutes P48 P49 90

P48 Chill Time Minimum Minutes 5 60 5

P49 Chill Time Maximum Minutes 60 480 240

P50 Chill Temp. Std. °C P51 P52 3

P51 Chill Temp. Minimum °C -20 -5 -10

P52 Chill Temp. Maximum °C -5 15 5

P53 Hold Temp. Std. °C P54 P55 3

P54 Hold Temp. Minimum °C -10 0 0

P55 Hold Temp. Maximum °C 0 10 10

P56 Change Time % 5 95 80

P57 Change Temp. % 5 95 80

P58 UV Light Enable Minutes 0 120 0

P59 HACCP Enable Function NO YES NO

P60 Shock Chill Temp. Function NO YES NO

P61 Chill Hysteresis °K 2 20 4

P62 Hold Hysteresis °K 2 20 4

P63 APM Time Minutes 0 30 2

P64 APM Differential °K 0 20 10

P65 FAN 1 Hold Operation Function OFF/ CYCLE/ AUTO/ ON AUTO

P66 FAN 2 Hold Operation Function OFF/ CYCLE/ AUTO/ ON AUTO

P67 Capacity Enable Function OFF/ AUTO/ ON ON

P68 Capacity Hysteresis °K 2 20 5

P69 Defrost Type Function OFF/ ELE/ GAS OFF

P70 Smart Defrost Inc Integer 0 240 30

P71 Defrost End Time Minutes 1 60 20

P72 Defrost End Temp. °C 0 50 20

P73 Drain Time. Minutes 0 30 1

P74 Fan Delay Temp. °C -15 15 5

P75 Duty Cycle % 0 100 60

P76 Comp. Rest Time Minutes 0 30 3

P77 HP Switch Function NO YES YES

P78 Door Switch 2 Function NO YES NO

P79 Door Switch 1 Function NO YES YES

P80 Door Stop Minutes 0 30 1

P81 Door Alarm Delay Minutes 0 30 5

P82 High Alarm Temp. °K 0 50 10

P83 High Alarm Delay Minutes 0 120 30

P84 Alarm Time Minutes 0 120 1

P85 Alarm Repeat Interval Minutes 0 480 0

HARD MAX

SHOCK FREEZE

PROFFESSIONAL 1

PROFFESSIONAL 2

PROFESSIONAL 3

SYSTEM

10

Page 12

P86 Alarm Buzzer Function NO YES NO

P87 Air Probe Offset °K -15 15 0

P88 Coil Probe Offset °K -15 15 0

P89 Food 1 Offset °K -15 15 0

P90 Food 2 Enable Function NO YES NO

P91 Food 2 Offset °K -15 15 0

P92 Food 3 Enable Function NO YES NO

P93 Food 3 Offset °K -15 15 0

P94 Address Integer 1 255 255

Parameter Definitions

Pre-Chill

P01 Pre-Chill Enable

The air temperature, which the air probe must read before the condensing system is de-energised in the chill

mode of the Pre-Chill Program.

Range -15°C to 15°C.

P02 Chill Time

The period Pre-Chill is in the chill mode prior entering the Hold Mode.

Range 5 minutes to 60 minutes.

P03 Hold Temp

The temperature, which the air probe must read before the condensing system is de-energised in the Hold mode

of the Pre-Chill program.

Range -15°C to 15°C.

Soft-Chill

P04 Air Temp

The temperature, which the air probe must read before the condensing system is de-energised in the chill mode

of the Soft-Chill Program.

Range -10°C to 15°C.

P05 Chill Time

The period Soft Chill program is in chill mode prior to entering Hold mode in a time based chill cycle.

Range 5 minutes to 480 minutes.

P06 Chill Temp

The temperature, whic h the Food Probe 1 must read before the condensing system is de-energis ed in the chill

mode of the Soft Chill program prior to entering the Hold mode of a temperature based cycle.

Range -5°C to 15°C.

P07 Hold Temp

The temperature, which the air probe must read before the condensing system is de-energised in the Hold mode

of the Soft Chill program.

Range -5°C to 15°C.

Hard Chill

P08 Air Temp

The temperature, which the air probe must read before the condensing system is de-energised in the chill mode

of the Hard Chill Program.

Range -20°C to 15°C.

P09 Chill Time

The period Hard Chill program is in chill mode prior to entering Hold mode in a time based chill cycle.

Range 5 minutes to 480 minutes.

P10 Chill Temp

The temperature, whic h the Food Probe 1 must read before the condensing system is de-energis ed in the chill

mode of the Hard Chill program prior to entering the Hold mode of a temperature based cycle.

Range -15°C to 15°C.

P11 Hold Temp

The temperature, which the air probe must read before the condensing system is de-energised in the Hold mode

of the Hard Chill program.

Range -15°C to 15°C.

P12 Change Time

The percentage period of a time based chill cycle, which is to have passed before automatically adjusting the air

temperature set point to 1°C.The range is adjustable in 5% increments.

Range 05% to 95%.

11

Page 13

P13 Change Temp

The percentage of a temperature based chill cycle, which is passed before automatically adjusting the air

temperature set point to 1°C.The range is adjustable in 5% increments.

Range 5% to 95%.

Hard Max

P14 Air Temp

The temperature, which the air probe must read before the condensing system is de-energised in the chill mode

of the Hard Chill Max Program.

Range -20°C to 15°C.

P15 Chill Time

The period Hard Chill Max program is in chill mode prior to entering Hold mode in a time based chill cycle.

Range 5 minutes to 480 minutes.

P16 Chill Temp

The temperature, whic h the Food Probe 1 must read before the condensing system is de-energis ed in the chill

mode of the Hard Chill Max program prior to entering the Hold mode of a temperature based cycle.

Range -15°C to 15°C.

P17 Hold Temp

The temperature, which the air probe must read before the condensing system is de-energised in the Hold mode

of the Hard Chill Max program.

Range -15°C to 15°C.

Shock Freeze

P18 Air Temp

The temperature, which the air probe must read before the condensing system is de-energised in the chill mode

of the Shock Freeze Program.

Range -35°C to 15°C.

P19 Chill Time

The period Shock Freeze program is in chill mode prior to entering Hold mode in a time based chill cycle.

Range 5 minutes to 480 minutes.

P20 Chill Temp

The temperature, whic h the Food Probe 1 must read before the condensing system is de-energis ed in the chill

mode of the Shock Freeze program prior to entering the Hold mode of a temperature based cycle.

Range -15°C to 15°C.

P21 Hold Temp

The temperature, which the air probe must read before the condensing system is de-energised in the Hold mode

of the Shock Freeze program.

Range -35°C to 15°C.

Professional 1

P22 Air Temp Std

The standard temperature, which the air probe must read before the condensing system is de-energised in the

chill mode of the Professional 1 Program.

Range -20°C to 15°C.

P23 Chill Time Std

The standard period Professional 1 program is in chill mode prior to entering Hold mode in a time based chill

cycle.

Range 5 minutes to 480 minutes.

P24 Chill Time Minimum

The minimum period Professional 1 program is in chill mode prior to entering Hold mode in a time based chill

cycle that it can be adjusted to by the operator.

Range 5 minute to 60 minutes.

P25 Chill Time Maximum

The maximum period Professional 1 program is in chill mode prior to entering Hold mode in a time based chill

cycle that it can be adjusted to by the operator.

Range 60 minute to 480 minutes.

P26 Chill Temp Std

The standard temperature, which the Food Probe 1 must read before the condensing system is de-energised in

the chill mode of the Professional 1 program prior to entering the Hold mode of a temperature based cycle.

Range -15°C to 15°C.

12

Page 14

P27 Chill Temp Minimum

The minimum value that the temperature, which Food Probe 1 must read before the condensing system is de-

energised in the chill mode of the Professional 1 program, prior to entering the Hold mode of a temperature based

cycle, which it can be adjusted to by the operator.

Range -20°C to -5°C.

P28 Chill Temp Maximum

The maximum value that the temperature, which Food Probe 1 must read before the condensing system is de-

energised in the chill mode of the Professional 1 program, prior to entering the Hold mode of a temperature based

cycle, which it can be adjusted to by the operator.

Range -5°C to -15°C.

P29 Hold Temp Std

The standard temperature, which the air probe must read before the condensing system is de-energised in the

Hold mode of the Professional 1 Program.

P30 Hold Temp Minimum

P31 Hold Temp Maximum

P32 Change Time

The percentage period of a time based chill cycle, which is to have passed before automatically adjusting the air

Range 05% to 95%.

P3

Range -15°C to 15°C.

The minimum value that the Hold temperature set point can be adjusted to by the operator in the Professional 1

program.

Range -10°C to 0°C.

The maximum value that the Hold temperature set point can be adjusted to by the operator in the Professional 1

program.

Range 0°C to 10°C.

temperature set point to 1°C.The range is adjustable in 5% increments.

3 Change Temp

The percentage of a temperature based chill cycle, which is passed before automatically adjusting the air

temperature set point to 1°C.The range is adjustable in 5% increments.

Range 5% to 95%.

Pr

ofessional 2

4 Air Temp Std

P3

The standard temperature, which the air probe must read before the condensing system is de-energised in the

chill mode of the Professional 2 Program.

Range -20°C to 15°C.

P35 Chill Time Std

The standard period Professional 2 program is in chill mode prior to entering Hold mode in a time based chill

cycle.

Range 5 minutes to 480 minutes.

P36 Chill Time Minimum

The minimum period Professional 2 program is in chill mode prior to entering Hold mode in a time based chill

cycle that it can be adjusted to by the operator.

Range 5 minute to 60 minutes.

P37 Chill Time Maximum

The maximum period Professional 2 program is in chill mode prior to entering Hold mode in a time based chill

cycle that it can be adjusted to by the operator.

Range 60 minute to 480 minutes.

P38 Chill Temp Std

The standard temperature, which the Food Probe 1 must read before the condensing system is de-energised in

the chill mode of the Professional 2 program prior to entering the Hold mode of a temperature based cycle.

P39 Chill Temp Minimum

The minimum value that the temperature, which Food Probe 1 must read before the condensing system is de-

Range -20°C to -5°C.

Range -15°C to 15°C.

energised in the chill mode of the Professional 2 program, prior to entering the Hold mode of a temperature based

cycle, which it can be adjusted to by the operator.

13

Page 15

P40 Chill Temp Maximum

The maximum value that the temperature, which Food Probe 1 must read before the condensing system is de-

energised in the chill mode of the Professional 2 program, prior to entering the Hold mode of a temperature based

cycle, which it can be adjusted to by the operator.

Range -5°C to -15°C.

P41 Hold Temp Std

The standard temperature, which the air probe must read before the condensing system is de-energised in the

Hold mode of the Professional 2 Program.

P42 Hold Temp Minimum

P43 Hold Temp Maximum

P44 Change Time

The percentage period of a time based chill cycle, which is to have passed before automatically adjusting the air

Range 05% to 95%.

P4

Range -15°C to 15°C.

The minimum value that the Hold temperature set point can be adjusted to by the operator in the Professional 2

program.

Range -10°C to 0°C.

The maximum value that the Hold temperature set point can be adjusted to by the operator in the Professional 2

program.

Range 0°C to 10°C.

temperature set point to 1°C.The range is adjustable in 5% increments.

5 Change Temp

The percentage of a temperature based chill cycle, which is passed before automatically adjusting the air

temperature set point to 1°C.The range is adjustable in 5% increments.

Range 5% to 95%.

Pr

ofessional 3

6 Air Temp Std

P4

The standard temperature, which the air probe must read before the condensing system is de-energised in the

chill mode of the Professional 3 Program.

Range -20°C to 15°C.

P47 Chill Time Std

The standard period Professional 3 program is in chill mode prior to entering Hold mode in a time based chill

cycle.

Range 5 minutes to 480 minutes.

P48 Chill Time Minimum

The minimum period Professional 3 program is in chill mode prior to entering Hold mode in a time based chill

cycle that it can be adjusted to by the operator.

Range 5 minute to 60 minutes.

P49 Chill Time Maximum

The maximum period Professional 3 program is in chill mode prior to entering Hold mode in a time based chill

cycle that it can be adjusted to by the operator.

Range 60 minute to 480 minutes.

P50 Chill Temp Std

The standard temperature, which the Food Probe 1 must read before the condensing system is de-energised in

the chill mode of the Professional 3 program prior to entering the Hold mode of a temperature based cycle.

P51 Chill Temp Minimum

The minimum value that the temperature, which Food Probe 1 must read before the condensing system is de-

Range -20°C to -5°C.

P52 Chill Temp Maximum

The maximum value that the temperature, which Food Probe 1 must read before the condensing system is de-

Range -5°C to -15°C.

Range -15°C to 15°C.

energised in the chill mode of the Professional 3 program, prior to entering the Hold mode of a temperature based

cycle, which it can be adjusted to by the operator.

energised in the chill mode of the Professional 3 program, prior to entering the Hold mode of a temperature based

cycle, which it can be adjusted to by the operator.

14

Page 16

P53 Hold Temp Std

The standard temperature, which the air probe must read before the condensing system is de-energised in the

Hold mode of the Professional 3 Program.

Range -15°C to 15°C.

P54 Hold Temp Minimum

The minimum value that the Hold temperature set point can be adjusted to by the operator in the Professional 3

program.

Range -10°C to 0°C.

P55 Hold Temp Maximum

The maximum value that the Hold temperature set point can be adjusted to by the operator in the Professional 3

program.

Range 0°C to 10°C.

P56 Change Time

The percentage period of a time based chill cycle, which is to have passed before automatically adjusting the air

temperature set point to 1°C.The range is adjustable in 5% increments.

Range 05% to 95%.

P5

7 Change Temp

The percentage of a temperature based chill cycle, which is passed before automatically adjusting the air

temperature set point to 1°C.The range is adjustable in 5% increments.

Range 5% to 95%.

System

P58 UV Light Enable

Determines whether the user can select the UV sanitisation.

Minutes 0 = disabled, 1 to 120 = enabled (set the time between 1 and 120 to determine the length of the

P59 HACCP Enable

Determines whether the logging system is available to the user.

Function, YES = enabled. NO = disabled.

P60 Shock Freeze Temp

Allows for the probe to be used in the Shock Freeze mode.

P61 Chill Hysteresis

Allowable temperature increase from chill cycle air temperature Set Point before switching on the refrigeration

Range 02°K to 20°K.

P62 Hold Hysteresis

Allowable temperature increase from hold cycle air temperature Set Point before switching on the refrigeration

Range 02°K to 20°K.

P63 APM Time

Automatic Program Mode Time. The time period that must pass before the air temperature and Food Probe 1

00 = Instantaneous decision. 01 to 30 = the time selected determines the start time decision.

P64 APM Differential

Automatic Program Mode Differential. The difference in temperature between the air temperature and food probe

P65 FAN 1 Hold Operation

Determines the evaporator fan relay energisation during ‘Hold’ mode.

‘OFF’ = Evaporator fan 1 relay is not energised in ‘Hold’.

‘CYCLE’ = Evaporator fan 1 relay cycles with condensing system relay in ‘Hold’.

‘AUTO’ = Evaporator fan 1 relay cycles with condensing system and fan hysteresis in ‘Hold’.

‘ON’ = Evaporator fan 1 relay is always energised in ‘Hold’.

program).

Function, YES = enables. NO = disables.

system.

system.

temperature are compared to determine whether the cycle is time or temperature based.

1 temperature after APM time to determine whether the cycle is time or temperature based. If air probe

temperature + the APM differential is greater than or equal to food temperature the chill cycle will be time based.

If air probe temperature + APM differential is less than the food probe temperature the chill cycle will be

temperature based.

Range 0°K to 20°K.

15

Page 17

Note: The fan 1 hold operation does not effect routine defrost operation.

P66 FAN 2 Hold Operation

Determines the evaporator fan relay energisation during ‘Hold’ mode.

‘OFF’ = Evaporator fan 2 relay is not energised in ‘Hold’.

‘CYCLE’ = Evaporator fan 2 relay cycles with condensing system relay in ‘Hold’.

‘AUTO’ = Evaporator fan 2 relay cycles with condensing system and fan hysteresis in ‘Hold’.

‘ON’ = Evaporator fan 2 relay is always energised in ‘Hold’.

Note: The fan 2 hold operation does not effect routine defrost operation.

P67 Capacity Enable

Determines if Capacity Control is enabled.

‘OFF’ = Capacity is disabled.

‘AUTO’ = Capacity is enabled in chill and hold modes in conjunction with Capacity Hysteresis.

‘ON’ = Capacity is enabled (in hold mode only).

P68 Capacity Hysteresis

The differential value at which capacity control is de-energised.

Capacity control is disabled during the chill hold cycle (Capacity Enable set to ‘Auto’) if the temperature =

program air set point + chill hysteresis + capacity hysteresis (rising from chill set point). During hold (Capacity

Enable set to ‘Auto’ or ‘On’) if the temperature = hold air set point + hold hysteresis + capacity hysteresis (rising

from hold air set point).

Range 2°C to 20°C.

P69 Defrost Type

Identifies the type of defrost cycle to be initiated either standard or manually.

OFF = Off cycle defrost. ELE = Electric defrost. GAS = Hot gas defrost.

P70 Smart Defrost Inc

DO NOT ADJUST.

P71 Defrost End Time

The length of time that the Defrost period will last before reverting to the chill or hold cycle.

Range 01minute to 60 minutes.

P72 Defrost End Temp

The coil temperature as detected by the evaporator probe at which the Defrost function will terminate before

reverting back to chill or hold mode.

Range 0°C to 10°C.

P73 Drain Time

The time period following the defrost routine (terminated by time or temperature) that is allowed for ‘melt water’ to

drain from the evaporator coil prior to the condensing system restarting.

00 = No drain down time. 01 to 30 = Drain down period in minutes.

P74 Fan delay Temp

The temperature the evaporator coil must reach following a defrost before the evaporator fan/s are allowed to re-

start.

Range -15°C to 15°C.

P75 Duty Cycle

The percentage time that the condensing system will operate in order to maintain Hold temperature in the event

of an air probe failure.

Range 0% to 100%.

P76 Comp. Rest Time

The forced rest period before the condensing system can be energised from when it was de-energised.

00 = Excludes compressor rest period. 01 to 30 = Compressor rest period in minutes.

Note: This is not a compressor start delay.

P77 HP Switch

Terminates the condensing system in the event of a high pressure developing in the refrigeration system as a

result of, to high food temperature, condenser fan failure, blocked condenser, air flow restriction etc.

Automatically re – sets when the normal working pressure is achieved.

YES = enabled. NO = disabled.

P78 Door Switch 2

Determines if a safety door switch is fitted. If enabled this will not allow any chill, defrost or UV Sanitisation

programs to be run if the door is open.

16

Page 18

NO = No safety door switch fitted. YES = Safety door switch fitted.

Note: Usually fitted to the evaporator fan door on Modular Blast Chillers.

P79 Door Switch 1

Determines if a door switch is fitted or not, and consequently dictates Evaporator Fan operation, UV Sanitisation

operation and door alarm activation’s. Also used to initiate the controller from the energy saving mode.

NO = No door switch fitted. YES = Door switch fitted.

P80 Door Stop

The delay period between the door being opened and the condensing unit stopping (only active if the ‘Door

Switch’ is set to ‘YES’).

00 minutes = Condensing unit stops instantaneously. 01 to 30 minutes = Delay before unit stops.

P81 Door Alarm Delay

The delay following the ‘Door Stop’ period before the door open alarm sounds. Therefore if the ‘Door Stop’ is set

for 1 minute, and the ‘Door Alarm’ is set to 5 minutes, the door alarm will sound 6 minutes after the door was

opened. (Only active if ‘Door Switch’ = YES).

00 minutes = //instantaneous door alarm. 01 to 30 minutes = Delay before alarm sounds.

P82 High Alarm Temp

The temperature at which the alarm will sound to warn that the measured air temperature value is too high. The

alarm sounding is dependent upon the selected program and the stage of the cycle. I.e. during a chill cycle if the

measured temperature is greater than or equal to program air set point temperature + chill hysteresis + high

alarm temperature value (after the appropriate alarm delay period) the alarm will sound. Similarly if the measured

hold temperature is greater than or equal to program hold set point + hold hysteresis + high alarm temperature

value the alarm will sound.

Range 1°C to 50°C.

P83 High Alarm Delay

The delay period between a temperature alarm condition occurring.

00 minutes = Instantaneous audible alarm. 01 to 120 minutes = period of delay.

P84 Alarm Time

The length of time, which the alarm will sound for an end of program cycle alarm or any other alarm warning prior

to automatically muting.

00 minutes No alarm. 01 to 120 minutes = Alarm energised period.

P85 Alarm Repeat Interval

The length of time between an acknowledged alarm being automatically muted and the alarm sounder being re-

energised.

00 minutes = No alarm reminder. 01 to 480 minutes = Alarm reminder period.

P86 Alarm Buzzer

Enables or disables the board alarm buzzer.

NO = Alarm disabled. YES = Alarm enabled.

P87 Air Probe Offset

Allows the value of the Air Probes to be offset allowing the product temperature to be accurately measured.

Range -15°C to +15°C

P88 Coil Probe Offset

Allows the value of the Evaporator Coil Probe to be offset allowing the coil temperature to be accurately

measured.

Range -15°C to +15°C.

P89 Food 1 Offset

Allows the value of Food Probe 1 to be offset allowing for the product temperature to be accurately measured.

Range -15°C to +15°C.

P90 Food 2 Enable

Determines whether a second Food Probe is fitted.

NO = No second food probe fitted. YES = Second food probe fitted.

P91 Food 2 Offset

Allows the value of Food Probe 2 to be offset allowing for the product temperature to be accurately measured.

Range -15°C to +15°C.

P92 Food 3 Enable

Determines whether a third Food Probe is fitted.

17

Page 19

NO = No third food probe fitted. YES = Third food probe fitted.

P93

Food 3 Offset

Allows the value of Food Probe 3 to be offset allowing for the product temperature to be accurately measured.

Range -15°C to +15°C.

P94 Address

The controller peripheral number. This is only necessary when controller are linked via a network to a computer

management and data recording system (such as with the Foster TAB or ARGO systems).

Range 00 to 255.

Alarm and Warnings

In general if an alarm occurs the appropriate alarm symbol will be displayed and the alarm will sound to attract attention.

The cabinet will attempt to continue running or to finish the cycle (if safe to do so).

The distinction between an alarm and a warning is that a warning may be a non-critical occurrence such as door open or

temporary power failure. An alarm would be for a system failure such as a probe fault or high-pressure fault, which would

require positive intervention.

High pressure developing in the refrigeration system as a result of, to high food temperature,

condenser fan failure, blocked condenser, air flow restriction etc. Automatically re – sets

when the normal working pressure is achieved.

Air Probe Fault

Evaporator Probe Fault

Food Probe Fault. If more than 1 probe are enabled the probe fault would be displayed

accordingly

Door 2 open. Will not allow any chill, defrost or UV Sanitisation programs to be run if the door

is open.

Ribbon cable between the power switching PCB and the display disconnected.

18

Page 20

Foot Print Test operation

The foot print test is a method of checking the operation of the process in a reduced time period

The foot print test takes ten minutes.

The first ten seconds are used for the display test, after that the relays are energised in a simple operating pattern to

ensure each are energised. During the final ten seconds the alarm is sounded to indicate the end of the test.

The graph below shows how the relays are energised relating to time.

The air, coil and food temperature probes are disregarded (the only exception is an over temperature alarm).

All relays commence Footprint test in the de-energised state.

• Relay 1 is energised after 10 seconds from start of test for 470 seconds (de-energises 480 seconds from start).

• Relay 2 is energised after 60 seconds from start of test for 30 seconds (de-energises 90 seconds from start).

• Relay 2 is energised again after 120 seconds from start of test for 300 seconds (de-energises 420 seconds from start).

• Relay 3 is energised after 90 seconds from start of test for 330 seconds (de-energises 420 seconds from start).

• Relay 3 is energised after 540 seconds from start of test for 30 seconds (de-energises 570 seconds from start).

• Relay 4 is energised after 450 seconds from start of test for 90 seconds (de-energises 540 seconds from start).

• Relay 5 is energised after 590 seconds from start of test for 10 seconds (de-energises 600 seconds from start).

• Relay 6 is energised after 360 seconds from start of test for 90 seconds (de-energises 450 seconds from start).

• Relay 7 is energised after 570 seconds from start of test for 20 seconds (de-energises 590 seconds from start).

All relays are de-energised on completion of the test.

Operation Summary

At any point during the test pressing and holding the dial for 2 seconds can stop it. The test will be terminated and the

display will revert to the last run cycle. Upon normal completion of the test the display will revert to the last run cycle (not

the service parameters).

Probes

Air and Evaporator Probes

The air and evaporator probes are the same and are identified as T1 Air Probe and T2 Evaporator Probe. These are the

thermistor type and are fully enclosed to make it completely waterproof and resilient to temperature variation within the

limits of rapid cycling. The probe is capable of measuring temperature in excess of -30°C and 50°C with 1°K accuracy at

1°C and no more than 2°K at the upper and lower temperature ranges.

Food Probe

The food probe is inserted directly into the product that is being chilled to measure the core temperature. The resistance

values are the same as for the air and evaporator probes.

Probe temperature resistance values

°C K ohm °C K ohm °C K ohm °C K ohm °C K ohm

-40 44.657 -5 7.198 30 1.651 65 0.497 100 0.189

-35 33.505 0 5.716 35 1.371 70 0.426 105 0.166

-30 25.388 5 4.571 40 1.143 75 0.367 110 0.142

-25 19.402 10 3.682 45 0.958 80 0.318 115 0.125

-20 14.961 15 2.987 50 0.807 85 0.276 120 0.111

-15 11.644 20 2.437 55 0.683 90 0.24 125 0.099

-10 8.133 25 2 60 0.582 95 0.21

19

Page 21

Technical Data

RBC20-60

Nominal Chilling Capacity 60Kg

Duty @ -15°C 3800w

Fans 3

Evaporating Temperature -15°C

HP Switch Setting

Refrigerant Control TEV

Refrigerant R404a

Refrigerant Quantity

System 1 1900grms

System 2 1900grms

Electrical Supply 400/3/50 – 16amp

Total Heat Rejection 1500w

230/1/50 13 amp (Fans & Defrost)

RBC20-60R

60Kg

3800w

3

-15°C

TEV

R404a

Important Note

There are two refrigeration systems on this model

Refrigerant used is R404A.

The RBC20-60 has two separate refrigeration systems co mprising, two condensing units, a twin circuit condenser (see

below) and a twin circuit evaporator. (See page 21for assembly details and page 22 for schematic dual circuit refrigeration

layout).

The condenser fan on system 2 is controlled by the HP switch, which is set at 18 BAR with a 3 BAR diff.

The RBC20-60R has the same refrigeration systems but the con densing units are remotely sited.

System 2

HP Switch

System 1

CONDENSING UNIT ASSEMBLY RBC20-60

The parameter ‘Capacity Enable’ is set to ‘AUTO’ to allow for both condensing units to be running at the start of the chill

cycle therefore maximising the heat extraction from the product. On reaching ‘HOLD’ one of the condensing units will shut

down. During the ‘HOLD’ mode one compressor will control the temperature throughout unless the temperature exceeds

the capacity control limit.

Refrigerant control is by expansion valve to control the correct amount of refrigerant required to meet the demand of the

evaporator. (See page 21 for assembly detail).

Expansion Valve Setting (Superheat)

Adjust the superheat by turning the expansion valve setting spindle anti clockwise until back seated then turn the setting

spindle clockwise THREE FULL TURNS IN.

20

Page 22

SERVICE PLATE

SYSTEM 1 & SYSTEM 2

PHIALS MUST BE FITTED

IN THE HORIZONTAL

POSITION AND CORK

TAPED

FAN PLATE

EVAPORATOR ASSEMBLY RBC20-60

21

Page 23

PHIAL

PHIAL

EVAPORATOR – DUAL CIRCUIT

LP SW.

COMPRESSOR

LP SW.

COMPRESSOR

STAT

CONDENSER - DUAL CIRCUIT

HP SW.

EQUALISING LINE

EQUALISING LINE

EXP. VALVE

EXP. VALVE

SIGHT

GLASS

SIGHT

GLASS

SOL.

VALVE

SOL.

VALVE

DRIER

DRIER

LIQUID RECEIVER

HP SW.

LIQUID RECEIVER

Schematic Dual Circuit Refrigeration Layout

22

Page 24

COMPRESSOR WIRING RBC20-60

23

Page 25

RBC20-60 1 of 2 Wiring Diagram

24

Page 26

RBC20-60 2 of 2 Wiring Diagram

25

Page 27

RBC20-60R 1 of 2 Wiring Diagram

26

Page 28

RBC20-60R 2 of 2 Wiring Diagram

27

Page 29

Page 30

2

Page 31

3

Page 32

Foster European Operations

rance

F

oster Refrigerator France SA

F

T

el: (33) 01 34 30 22 22 Fax: (33) 01 30 37 68 74 Email: info@fosterfrance.com

Germany

F

oster Refrigerator Germany

T

el: (0781) 96 93 00 Fax: (0781) 96 93 019 Email: info@fosterrefrigerator.de

F

oster Refrigerator

O

ldmedow Road, King’s Lynn,

N

orfolk Pe30 4JU

E

ngland

T

el: 01553 691122

F

ax: 01553 691447

W

ebsite: www.fosterrifrigerator.co.uk

Email: sales@foster-uk.com

a Division of ITW (UK) Ltd.

BC20/SM/0107

R

4

Loading...

Loading...