Page 1

QC 11 & QC 600

Blast Chiller

&

BQCF 40 Chill / Freeze

Bakery Cabinet

Page 2

Contents

Page

Introduction 2

Model Details 2

QC 11 & QC 600 BQCF 40 Blast Chill Operating Instructions 3

Controller operating instructions 4

LED’s and there meanings

4

Program function and operation. 5

Cycle Parameter Definitions. 5

Cycle Parameter Access

QC 11 Cycle Parameters.

QC 600 Cycle Parameters.

BQCF 40 Cycle Parameters.

5

5 to 6

6

6 to 7

Function Menu 7 to 8

Parameter Access and modification 8

Parameter Settings

Parameter Definitions

8 to 9

9 to 11

Printer Management 11

Alarm Signals 11

Controller Electrical Connections 11

Technical Data 12

Wiring Diagram Numbers 12

1

Page 3

Introduction.

Cook Chill Operation.

Blast chilling is a process to reduce the temperature of cooked food by swiftly arresting the cooking process,

locking in its colour, flavour, texture and nutritional value. Department of health guidelines state that to safely blast

chill food the temperature must be reduced from +70°c to +3°c within 90 minutes.

Pre Chill ensures the correct cabinet temperature in the unit before chilling commences therefore improving the

chilling performance.

Program 1

Soft Chilling.

Soft chilling is the process of rapid but gentle chilling of food.

This cycle brings down the food temperature to +3°c in no more than 90 minutes without the air or food

temperature going below +2°c.

This prevents large ice crystals forming therefore maintaining the texture, consistency and appearance of food

such as vegetables, rice, pasta, custard and fruit with no dehydration or cell damage.

Program 2

Hard Chilling Time.

Hard chilling is the process of general purpose chilling using time.

This cycle brings down the food temperature to +3°c in no more than 90 minutes and is ideal for chilling meat pies,

lasagne, pasta and individually portioned meals. The air temperature for this process goes down to -15°c for the

first 70 minutes of the cycle, to extract the maximum amount of heat from the product quickly. The air temperature

then increases to +2°c for the final 30 minutes of the time to reduce surface damage and ensure quality.

Program 3

Hard Chill +

This program is for specialist chilling only and not recommended for normal use.

Program 4

Hard Chilling Temperature.

Hard chilling is the process of general purpose chilling using the food probe.

This cycle brings down the food temperature to +3°c in no more than 90 minutes and is ideal for chilling meat pies,

lasagne, pasta and individually portioned meals. The air temperature for this process goes down to -15°c for the

first 70% of the cycle, to extract the maximum amount of heat from the product quickly. The air temperature then

increases to +2°c for the final 30% of the time to reduce surface damage and ensure quality.

Longer Term Storage – ‘Hold’ Mode (Conservation)

Upon the completion of the blast chilling cycle the controller will automatically enter the ‘Hold’ mode. This will either

be because the selection set time has elapsed or the product core temperature has been achieved. When the hold

period commences an alarm will sound for a period denoted in the service operating parameters.

The controller will determine the temperature to be maintained during the hold phase based on the chilling or

freezing cycle that has been completed. If a soft or hard chill has taken place the controller will maintain an air

temperature of 2°c, if a freeze program is completed the air temperature of -21°c will be maintained.

The hold mode is principally intended as a temporary storage facility offering the operator flexibility until the product

can be unloaded into a longer term storage units at the correct storage temperature. On occasion this hold period

may become extended to operate overnight or to provide emergency refrigeration backup. In such instances

defrosting would automatically occur as necessary.

Model Details.

Cabinet Blast Chiller & Freezers.

Controls located in the unit cover.

All of the cabinet range incorporate a bottom mounted refrigeration systems with the evaporator located on the

back wall. The refrigerant used is R404a.

Door operated fan switches stop the fans when the door is opened.

QC11, QC 600 all 230/1/50Hz 13amp.

QC11: Economy Blast Chiller, 11kg capacity with three GN1/1 shelves.

QC 600: Economy Blast Chiller, 40kg capacity

BQF 40: Bakery Quick Freeze,

2

Page 4

QC 11, QC 600 & BQCF 40 Blast Chill Operating Instructions.

Operation

When mains electrical power is first applied to the controller it will carry out a self-test function - - - for

approximately 3 seconds, after this the cabinet air temperature will be displayed.

To start, select the program required by pressing the program mode button (1, 2, 3,4), the LED for that mode will

illuminate, press and hold start key

time.

The compressor may pause before starting at the start of a cycle to prevent short cycling of the condensing system

and is normal.

When the time or temperature is achieved the machine will go in to the Hold mode with the sounding of an alarm.

To stop the cycle press and hold the start key for 2 seconds, the cycle will be terminated.

Manual Defrost.

When the blast chiller is in hold press the defrost key and hold for 2 seconds to start the defrost.

When defrost is complete the machine will revert to the hold temperature.

for three seconds to start the program. The display will show the program

Program Mode Program Type

SOFT 90 90 minutes @ +2°c N/A +3°c

HARD 90

HARD + 240 240 minutes @ -15°c N/A +3°c

HARD

Program

Time

Air Temperature Chill Temperature

70 minutes @ -15°c

20 minutes @ +2°c

75% @ -15°c 75% @ -6°c

25% @ +3°c 25% @ +2°c

N/A +3°c

Hold

Temperature

+3°c

IMPORTANT. Please note: Program 3 is for specialist markets only and not for normal

use.

Introduction

There are four main programmes that you will need to use your Blast Chiller.

Soft Chill- for the safe chilling of delicate products.

Hard Chill Time - For general purpose chilling based on time.

Hard Chill +-. This program is for specialist chilling only and is not recommended for normal use.

Hard Chill Temperature - For general purpose chilling using the food probe.

Guide for Blast Chilling

Blast Chill

Food Type Includes

Meat Beef, pork, lamb, poultry & mince 2 or 4

Fish

Prepared dishes Stews & casseroles, lasagne, risotto, shepherds pie 2 or 4

Vegetables & Pulses Steamed or roasted veg, rice and potatoes etc. 1

Fruit Stewed and cooked fruits. 1

Bakery Cakes 2 or 4

Bakery Pastries 2 or 4

Desserts Fruit Based desserts & egg based flans. 1

Desserts Sponge puddings and dense desserts such as cheesecake. 2 or 4

Fried, poached or baked – haddock, plaice, salmon, cod

fillets etc

3

Programme

required

1

Page 5

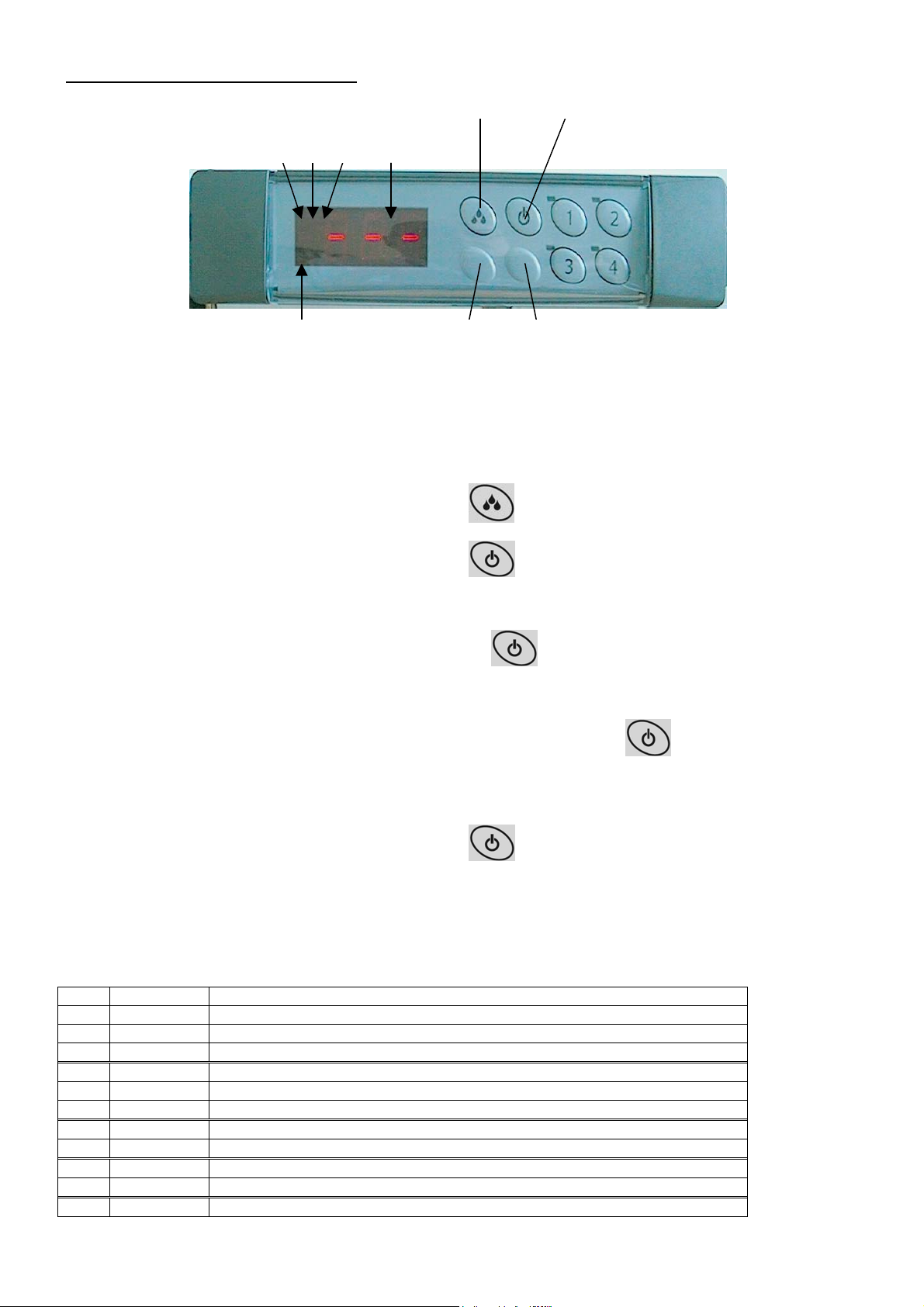

Controller operating instructions

4 3 2 1

DEFROST/ UP START/ STOP

5

Display Set Point: Press the SET key whilst in the HOLD Mode will display the set point for 5 seconds.

Modify Set Point: Press and hold the SET key for 2 seconds. The SET point will be displayed and the LED’s

of the first and third digits will blink. To change the value, press the UP key to increase the

value or the DOWN key to decrease. To store the new value either press the SET key or

wait for the controller to return to displaying air temperature.

Manual Defrost: Press and hold the DEFROST/UP key for 2 seconds to initiate a manual defrost.

Starting the cycle: Press and hold the START/STOP key for 3 seconds.

Temporarily Stopping the Cycle:

Press and release the START/STOP key.

The condensing system will stop and the message “Stb” will be displayed.

To restart the cycle press and release the START/STOP key for the cycle to

continue from the point it was interrupted.

Alternatively the cycle will restart automatically after the time set in parameter PAU (see

parameter list on page ).

DOWN

SET

Stopping the Cycle: Press and hold the START/STOP until the display shows “End”, the buzzer will

sound and the unit will enter the stand by mode.

LED’s and there meanings

A series of LED’s, number 1 to 4, on the front panel are used to indicate certain functions controlled by the

controller. There functions are listed below.

LED Mode Function

1 Illuminated Compressor Enabled

1 Flashing Programming Phase (flashing with LED 2).

1 Flashing Anti Short Cycle Enabled

2 Illuminated Fan/s Enabled

2 Flashing Programming Phase (flashing with LED 1).

2 Flashing Activation Delay Active

3 Illuminated Defrost Active

3 Flashing Drip Time Active

4 Illuminated Freezing Cycle or Hold Mode Active

4 Flashing Instrument Temporarily Stopped

5 Illuminated Alarm Signalling

4

Page 6

5 Illuminated When in program Pr2 indicates the parameter is also present in

Program function and operation.

Each of the programs is divided into 3 phases of operation.

Phase 1: Hard Chill.

Phase 2: Soft Chill.

Phase 3: Freezing Cycle.

For each phase there are 3 parameters.

IS1 (iS2, iS3): operation controlled by the Food Probe.

RS1 (rS2, rS3): set point for the room Temperature Probe for each phase.

Pd1 (Pd2, Pd3): The maximum time duration for each phase.

Hds: hold phase set point at the end of the whole cycle.

There are also 2 parameters relating to defrost.

These are dbC = Defrost Before cycle, dbH = defrost before hold (at the end of the cycle).

Cycle Parameter Definitions.

Parameter Range Minimum Description

dbc:

First Phase

iS1

rS1

Pd1

Second Phase

iS2

rS2

Pd2

Third Phase

iS3

rS2

Pd3

yes/ no

50 to + 50°C 1°C or 1°F Food Probe Set Point (when the temperature

50 to + 50°C 1°C or 1°F Air Temperature Set Point (prevents the air

OFF to 4.0 hours 10 minutes Maximum Time For The First Phase

50 to + 50°C 1°C or 1°F Food Probe Set Point (when the temperature

50 to + 50°C 1°C or 1°F Air Temperature Set Point (prevents the air

OFF to 4.0 hours 10 minutes Maximum Time For The Second Phase

50 to + 50°C 1°C or 1°F Food Probe Set Point (when the temperature

50 to + 50°C 1°C or 1°F Air Temperature Set Point (prevents the air

OFF to 4.0 hours 10 minutes Maximum Time For The Third Phase.

------------

Defrost before cycle

measured by the food probe reaches this value

the first phase is ended).

temperature going to low during the first phase).

measured by the food probe reaches this value

the second phase is ended).

temperature going to low during the first phase).

measured by the food probe reaches this value

the whole cycle is ended).

temperature going to low during the third

phase).

dbH

HdS

Important Note: If the duration time phase is set to OFF the corresponding phase is disabled.

E.G. If Pd3 = OFF the third phase of the cycle is not active.

Cycle Parameter Access

To access the cycle parameters Press and Hold the Set and Down buttons for 2 seconds.

The display will show “Prb” press the down button and scroll through until you get to “FCY” cycle management.

Press Set “Cy1” will be displayed, press the down button to scroll through the submenu to select the required

cycle parameters. Once selected press the set key to access the cycle parameters.

yes/ no

50 to + 50°C or OFF 1°C or 1°F Set Point OF The Hold Phase. If set to OFF the

------------

Defrost before the hold phase

hold Phase is disabled.

QC 11 Cycle Parameters.

Soft Chill- for the safe chilling of delicate products. (Cy1)

dbC = no iS1 = -10°C iS2 = 5°C iS3 = 3°C dbH = no

rS1 = 2°C rS2 = -2°C rS3 = -2°C HdS = 3°C

Pd1 = 1.3 hours Pd2 = OFF Pd3 = OFF

5

Page 7

6

Page 8

Hard Chill Time - For general purpose chilling based on time. (Cy2)

dbC = no iS1 = -15°C iS2 = 2°C iS3 = -18°C dbH = no

rS1 = -15°C rS2 = 2°C rS3 = -30°C HdS = 3°C

Pd1 = 1.1hours Pd2 = 0.2 hours Pd3= OFF

Hard Chill +-. This program is for specialist chilling only and is not recommended for normal use. (Cy3)

dbC = no iS1 = -15°C iS2 = -18C iS3 = -18°C dbH = no

rS1 = -15°C rS2 = -30°C rS3 = -15°C HdS = 3°C

Pd1 = 4 hours Pd2 = OFF Pd3 = OFF

Hard Chill Temperature - For general purpose chilling using the food probe. (Cy4)

dbC = no iS1 = -6°C iS2 = 3°C iS3 = -18°C dbH = no

rS1 = -15°C rS2 = 2°C RS3 = -30°C HdS = 3°C

Pd1 = 1.1 hours Pd2 = 0.2 Pd3 = OFF

QC 60 Cycle Parameters.

Soft Chill- for the safe chilling of delicate products. (Cy1)

dbC = no iS1 = -10°C iS2 = 5°C iS3 = 3°C dbH = no

rS1 = 2°C rS2 = -2°C rS3 = -2°C HdS = 3°C

Pd1 = 1.3 hours Pd2 = OFF Pd3 = OFF

Hard Chill Time - For general purpose chilling based on time. (Cy2)

dbC = no iS1 = -15°C iS2 = 2°C iS3 = -18°C dbH = no

rS1 = -15°C rS2 = 2°C rS3 = -30°C HdS = 3°C

Pd1 = 1.1hours Pd2 = 0.2 hours Pd3= OFF

Hard Chill +-. This program is for specialist chilling only and is not recommended for normal use. (Cy3)

dbC = no iS1 = -15°C iS2 = -18C iS3 = -18°C dbH = no

rS1 = -15°C rS2 = -30°C rS3 = -15°C HdS = 3°C

Pd1 = 4 hours Pd2 = OFF Pd3 = OFF

Hard Chill Temperature - For general purpose chilling using the food probe. (Cy4)

dbC = no iS1 = -6°C iS2 = 3°C iS3 = -18°C dbH = no

rS1 = -15°C rS2 = 2°C RS3 = -30°C HdS = 3°C

Pd1 = 1.1 hours Pd2 = 0.2 Pd3 = OFF

BQCF 40 Cycle Parameters.

Soft Chill- for the safe chilling of delicate products. (Cy1)

dbC = no iS1 = -10°C iS2 = 5°C iS3 = 3°C dbH = no

rS1 = 2°C rS2 = -2°C rS3 = -2°C HdS = 3°C

Pd1 = 1.3 hours Pd2 = OFF Pd3 = OFF

Hard Chill Time - For general purpose chilling based on time. (Cy2)

dbC = no iS1 = -15°C iS2 = 2°C iS3 = -18°C dbH = no

rS1 = -15°C rS2 = 2°C rS3 = -30°C HdS = 3°C

Pd1 = 1.1hours Pd2 = 0.2 hours Pd3= OFF

7

Page 9

Hard Chill +-. This program is for specialist chilling only and is not recommended for normal use. (Cy3)

dbC = no iS1 = -6°C iS2 = 3°C iS3 = -18°C dbH = no

rS1 = -15°C rS2 = 2°C rS3 = -30°C HdS = 3°C

Pd1 = 1.1 hours Pd2 = 0.2 Pd3 = OFF

Hard Chill Temperature - For general purpose chilling using the food probe. (Cy4)

dbC = no iS1 = -6°C iS2 = 3°C iS3 = -18°C dbH = no

rS1 = -15°C rS2 = 2°C RS3 = -30°C HdS = 3°C

Pd1 = 1.1 hours Pd2 = 0.2 Pd3 = OFF

Function Menu

To access the cycle parameters Press and Hold the Set and Down buttons for 2 seconds.

The display will show “Prb”.

Prb: Probe Display.

Allows the probe temperatures to be displayed for ten seconds.

• rPr: Displays temperature measured by the AIR probe.

• Epr: Displays temperature measured by the EVAPORATOR probe.

• IPr: Displays temperature measured by the FOOD probe.

Press SET to display the reading of the selected probe, press SET with the reading displayed returns to the probe

labels.

Probe Fault Identification.

rPF = AIR probe fault.

EPF = EVAPORATOR probe fault.

iPF = Food probe fault.

Pr1: User Parameters.

Includes all user accessible parameters. If no parameters are present in the menu “Pr2” will be displayed.

Pr2: Installer Parameters.

Includes all the instrument parameters (at installer level). It can only be accessed using the security code. On

entering the parameters it is possible to modify all parameters and add or remove parameters from “Pr1” (user

level) by pressing “SET” + “UP”. When a parameter is enabled at user level, LED 5 (Alarm LED) is on.

Fcy: Cycle Managent.

The Fcy menu contains the Cy1, Cy2, Cy3 and Cy4 sub menus. Each of the sub menus should be set to the

Standard Cycle Parameters as detailed on pages 6 and 7.

Sto: Cycle Length.

The “Sto” menu records the real length of a cycle and the real length of each single phase. It contains the

following sub menu:

tCy: Cycle Duration. tP1: First Phase Duration. tP2: Second Phase Duration. tP3: Third Phase Duration.

rtC: Clock Managent.

Real time clock parameters.

SEC: Seconds (00 to 59).

Min: Minutes (00 to 59).

Hou: Hours (1 to 24).

7dY: Day of the week (Mon = Monday. tue = Tuesday. Wed = Wednesday. Thu = Thursday. Fri = Friday. Sat =

Saturday. Sun: Sunday)

dAY: Day of the Month (1 to 31).

Mon: Number of the month (1 to 12).

YEA: Year (0 to 99).

Alr: Alarms Display.

This function displays any alarm messages.

Prt: Printer Management.

Contains the parameters for the management of the printer.

8

Page 10

PrP: Printer presence. (Yes or no) Enables or disables the printer.

ItP: Printing interval. (0.0 to 30.0). Sets the print interval.

PbP: Print probe selection. (iP: only the food probe selected. rP: only the air probe selected. irP: Food and Air

probe selected. irE: All probes selected).

PtH: (yes or no) Enables or disables the printing during the holding phase.

tSt: Starts the controller self test function.

Out: Exit from the menu.

Parameter Access and modification

To access the parameters firstly enter the function menu by pressing the “SET” and “DOWN” keys for 3 seconds.

Scroll through the labels and select “PR2”, press the “SET” key. “PAS” label flashes for a few second followed by

“0 _ _” with the zero flashing. The access code is ‘ 321’.

Use the “UP” or “DOWN” key to input the first number of the security code in the flashing section, confirm by

pressing “SET”.

Repeat the operation for the second and third digits.

If the security code is correct “Hy” will be displayed.

NOTE: if no key is pressed for 15 seconds the controller reverts to displaying the room temperature.

Parameter Settings

Lab Description Default QC 11 QC 600 BQCF 40

Regulation

Hy

AC

1c2

rPO

EPP

EPO

iPP

iPO

CF

rES

PAU

PFt

iPd

iPt

Con

COF

diC

diP

did

OAC

OAP

OAt

OAS

OAH

OAi

tdF

dPO

IdF

dtE

MdF

dFd

Fdt

FnC

FSt

AFH

Fnd

differential

Anti-short cycle delay

Second compressor configuration

Thermostat probe calibration

Evaporator probe presence

Evaporator probe calibration

Insert probe presence

Insert probe calibration

Temperature measurement unit

Resolution (for °C):

Time of stand by

Maximum acceptable duration of power failure

Temperature difference for the automatic recognition of the insert probe

Time delay for the automatic recognition of the insert probe

Compressor ON time with faulty probe

Compressor OFF time with faulty probe

Digital input operating mode

Digital input polarity

Digital input delay

Auxiliary output configuration

Auxiliary output polarity

AUX output timer

Set point for AUX output

Differential for AUX output

Probe selection for the AUX output

Defrost

Defrost type

Defrost before holding cycle

Interval between defrost cycles

Defrost termination temperature

Maximum length for defrost

Temperature displayed during defrost

Drip time

Fans

Fan operating mode

Fan stop temperature

Differential for the stop temperature and for the alarm

Fan delay after defrost

3 3 3 3

2 2 2 2

0 0 0 0

0 0 0 0

YES NO YES YES

0 0 0 0

YES YES YES YES

0 0 0 0

°C °C °C °C

IN IN IN IN

1 1 1 1

2 2 2 2

3 3 3 3

60 60 60 60

15 15 15 15

10 10 10 10

dor dor dor Dor

OP OP OP OP

5 5 5 5

AL AL AL AL

OP CL CL CL

60 60 60 60

0 0 0 0

2 2 2 2

rP rP rP rP

in in in In

YES YES YES YES

6.0 6.0 6.0 6.0

20 20 20 20

20 20 20 20

rt rt rt Rt

1 1 1 1

c_n O_Y O_Y O_Y

30 30 30 30

2 2 2 2

2 2 2 2

9

Page 11

Alarm

ALU

ALL

ALd

EdA

tbA

MAXIMUM temperature alarm

Minimum temperature alarm

Temperature alarm delay

Alarm delay after defrost

Silencing alarm relay

30 30 30 30

30 30 30 30

60 60 60 60

30 30 30 30

YES YES YES YES

Others

Ad1

Ad2

Lod

rEd

LOC

PAS

tPb

rEL

Ptb

Address 1 for RS485:

Address 2 for RS485

Local display

Remote display

Keypad LOCK

Security code set up

Type of probe

Release code (readable only)

Parameter code (readable only)

0 0 0 0

1 1 1 1

nr nr nr nr

iP iP iP IP

no no no No

321 321 321 321

ntc ntc ntc Ntc

1,0 1.0 1.0 1.0

-- -- -- --

Parameter Definitions

REGULATION

Hy Intervention differential for set point: (0,1 ÷ 12,0 /0,1°C/1°F), always positive. Compressor cut IN is Set Point

Plus Differential (Hy). Compressor cut OUT is when the temperature reaches the set point.

AC Anti-short cycle delay: (0÷30 min) minimum interval between the compressor stop and the following

restart.

1c2 Second compressor setting: (enabled only if OAC=C2)

The fourth relay work as second compressor if OAC=Co2.

Second compressor operates on set + OAS. (whit set= set loaded during the current phase). It starts oAt min.

after the first compressor

The following table shows how it works:

1c2=0

1c2=1

1c2=2

1c2=3

Cycle

Holding

C1 ON; C2 On C1 on; C2 On

C1 on; C2 On C1 on C2 off

C1 on; C2 off C1 on; C2 On

C1 on; C2 off C1 off; C2 On

rPO Thermostat probe calibration (-12,0 ÷ 12,0; res. 0,1 °C /1°F)

EPP Evaporator probe presence (not present in the XB350C): (no / YES) no: not present (timed defrost); YES:

present (end defrost )

EPO Evaporator probe calibration (not present in the XB350C): (-12,0 ÷ 12,0; res. 0,1 °C /1°F)

iPP Insert probe presence (no / YES) no: not present; YES: present.

iPO Insert probe calibration (-12,0 ÷ 12,0; res. 0,1 °C /1°F)

CFTemperature measurement unit: °C =Celsius; °F =Fahrenheit

rES Resolution (for °C): in: integer; de: with decimal point

PAU Time of stand by: (0 ÷ 60min) after this time the controller restart the cycle

PFt Maximum acceptable duration of power failure: (0 ÷ 250 min) if power failure duration is less than PFt,

the cycle restarts from the same point at which it was stopped otherwise the cycle restarts from the beginning of

the current phase.

iPd Temperature difference for the automatic recognition of the insert probe: (0 ÷ 30; ris.1 °C/1°F) if the

difference of temperature between the insert probe and the thermostat probe is less than iPd, the selected cycle

is made by time.

iPt Time delay for the automatic recognition of the insert probe: (0÷255sec, with 0 only timed cycles are done)

time between the start of a cycle and the comparison of the temperature of the thermostat probe and the insert

probe to recognising if the insert probe is used.

Con Compressor ON time with faulty probe: (0÷ 255 min) time during which the compressor is active in case of

faulty thermostat probe. With COn=0 compressor is always OFF

COF Compressor OFF time with faulty probe: (0÷255 min) time during which the compressor is off in case of

faulty thermostat probe. With COF=0 compressor is always active

diC Digital input operating mode (EAL, bAL, dor)

EAL: external alarm; bAL: serious alarm; dor: door open function

diP: digital input polarity: (OP÷CL)select if the digital input is activated by opening or closing the contact. OP=

opening; CL=closing

did: digital input delay (0÷255 min) delay between digital input activation and his signalling for configurable or

door opened alarm.

NOTE: with diC=EAL did has to be different from zero.

10

Page 12

OAC: AUX output configuration: (AL, Li, UL, Ip, AA, rE, dF, C2)

AL: alarm output; Li: light of the cabinet; UL: for the ultra-violet light (It is actionable only when the controller is

in OFF position); Ip: to extract the insert probe (It is actionable only when the controller is in OFF position); AA:

anti - condensation; rE: the IV relay works as a thermostat, with direct action (cooling) (OAH>0), and inverse

actions (heating) (OAH<0); dF: the IV relay is activated during the defrost, at the end of the defrost it remains

ON for the OAt time; C2: second compressor. See 1c2 parameter for different settings.

OAP AUX output polarity (OP ÷ CL) OP= normally open; if it is ON the terminals 6-8 are closed. CL= normally

closed; if it is ON the terminals 6-7 are closed.

OAt AUX output timer: (0÷255 min) time in which the AUX output stays ON. It is enabled when OAC = Li or

UL or Ip or AA or dF.

OAS Set point for AUX output (-50÷50; ris.1 °C/ 1°F)

OAH Differential for AUX output: (-12.0÷12,0; ris.0,1°C/1°F, always ≠0) Intervention differential for the set point

of the auxiliary, with OAH<0 the action is for heating, with OAH>0 it is for cooling. COOLING: AUX cut IN is

OAS Plus Differential (OAH>0). AUX cut OUT is when the temperature reaches the set point OAS.

HEATING: AUX cut IN is OAS Plus Differential (OAH<0). AUX cut OUT is when the temperature reaches the set

point OAS.

OAi Probe selection for the AUX output (rP, EP, iP) rP = thermostat probe, EP = evaporator probe; iP =

insert probe

DEFROST

tdF Defrost type (not present in the XB350C): (rE= electrical heater; in = hot gas).

dPO Defrost before the holding: no= no defrost; YES= defrost at the start of a holding cycle.

IdF Interval between defrost cycles: (0.1÷ 24.0; res. 10 min) Determines the time interval between the

beginning of two defrost cycles. (with 0.0 the defrost is disabled)

dtE Defrost termination temperature (not present in the XB350C): (-50÷50 °C/°F) Sets the temperature

measured by the evaporator probe, which terminates the defrost.

MdF Maximum length for defrost: (0÷255 min) When EPP = no (timed defrost) it sets the defrost duration, when

EPP = YES (defrost termination based on temperature) it sets the maximum length for defrost.

dFd Temperature displayed during defrost: (rt , it, SEt, dEF) rt: real temperature; it: temperature at the start

of defrost; SEt: set point; dEF: “dEF” message

Fdt Drip time (not present in the XB350C): (0 ÷ 60 min) Time interval between reaching defrost termination

temperature and the restoring of the controllers' normal operation. This time allows the evaporator to eliminate

water drops that might have formed during defrost.

FANS

FnC Fans operating mode during the holding phase:

C-n= runs with the compressor, OFF during defrost; o-n = continuous mode, OFF during defrost; C-Y = runs

with the compressor, ON during defrost; o-Y = continuous mode, ON during defrost;

FSt Fan stop temperature: (-50÷50°C/°F; res. 1°C/1°F) if the temperature, detected by the evaporator probe is

above FSt fans are stopped. It serves to avoid blowing warm air around the room.

AFH Differential for the stop temperature and for the alarm (0.1 ÷ 25.0 °C; ris.0.1°C/1°F) Fans carry on working

when the temperature reaches the FSt-AFH value, the temperature alarm recovers when the temperature is

AFH degrees below the alarm set.

Fnd Fan delay after defrost: (0 ÷ 255 min) The time interval between end of defrost and evaporator fans start.

ALARM

ALU MAXIMUM temperature alarm: (1 ÷ 50 °C/°F) When the “SET+ALU” temperature is reached the alarm is

enabled, (possibly after the “Ald” delay time).

ALL Minimum temperature alarm: (1÷50°C/1°F) When the “SET-ALL” temperature is reached the alarm is

enabled, (possibly after the “Ald” delay time).

ALd Temperature alarm delay: (0÷255 min) time interval between the detection of an alarm condition and alarm

signalling.

EdA Temperature alarm delay at the end of defrost: (0 ÷ 255 min) Time interval between the detection of the

temperature alarm condition at the end of defrost and alarm signalling.

tbA Silencing alarm relay: (Yes= silencing buzzer and alarm relay, no= only buzzer silencing).

OTHER

Ad1 Address 1 for RS485: (0 ÷ 94)

Ad2 Address 2 for RS485 (0 ÷ 94)

Lod: Local display: (rP, EP, iP, nr) Select which probe is displayed by the instrument. rP: Thermostat probe.

EP: Evaporator probe. iP: Insert probe, nr: During a temperature cycle the insert probe is displayed, during the

holding phase the room probe is displayed. If the cycle is made by time the time remaining is displayed (in

minutes).

rEd Remote display: (rP, EP, Ip) select which probe is displayed by the XR REP. rP: thermostat probe; EP:

evaporator probe; iP: insert probe.

Loc Set point of the holding phase lock (no - YES) It locks the set point of the holding phase.

11

Page 13

PAS Security code set up: (0 ÷ 999)

tPb Type of probe: it displays the probe used (NTC or PTC) (readable only)

rEL Release code (readable only)

Ptb Parameter code (readable only)

Printer Management

The instrument XB570L can drive the serial printer XB05PR by means of the RS232 output. So temperatures

measured during a freezing cycle can be printed.

The internal Real Time clock of the instrument provides time reference.

The “Prt” functions manages the printer by means of the following parameters:

Prt: printer presence: (Yes/no) it enables or disables the printer.

itP: printing interval: (0.0÷30.0 min).

PbP: which probe has to be printed: (iP: Only the insert probe; rP: Only the thermostat probe; irP: Insert and

thermostat probes; irE: All the probes.

PtH: Printing during the holding phase (yES, no) yES = Printing enabled during the holding phase; no = Printing

disabled during the holding phase.

NOTE: Although the controller is capable of several features ie. HACCP recording and output, it is intentional by

Foster that these have not been developed to maintain the simplicity of operation for the end user. Therefore these

features are not offered or supported.

Alarm Signals

Mess. Cause Outputs

“EE”

“rPF”

“EPF”

“iPF”

“rtC”

“rtF”

“HA”

“LA”

“FF”

“PFA”

“OCF”

“EA”

“CA”

“dA”

Data or memory failure Alarm output ON; Other outputs unchanged

Thermostat Probe failure

Evaporator Probe failure

Insert probe failure

Real Time Clock data lost Alarm output ON; Other outputs unchanged;

Real Time Clock failure

Maximum temperature alarm Alarm output ON; Other outputs unchanged.

Minimum temperature alarm Alarm output ON; Other outputs unchanged.

Fast freezing interrupted by short power failure

Fast freezing interrupted by long power failure Alarm output ON; The freezing cycle restart from the current phase.

Max duration of the cycle is expired

External alarm Alarm output ON; Other outputs unchanged.

Serious external alarm Alarm output ON; Other outputs OFF.

Door open alarm Alarm output ON; Other outputs unchanged.

Alarm output ON; Compressor output according to parameters

“COn” and “COF”

Alarm output ON; Defrost termination is timed; No temperature

control on fans.

Alarm output ON; Other outputs unchanged; The cycle is made by

time

Alarm output ON; Other outputs unchanged; The date and the

duration of the cycle are not available.

Alarm output ON; The freezing cycle restart from the same point at

which was interrupted.

Alarm output ON; Other outputs unchanged. In any case the cycle

ends when the final temperature is reached

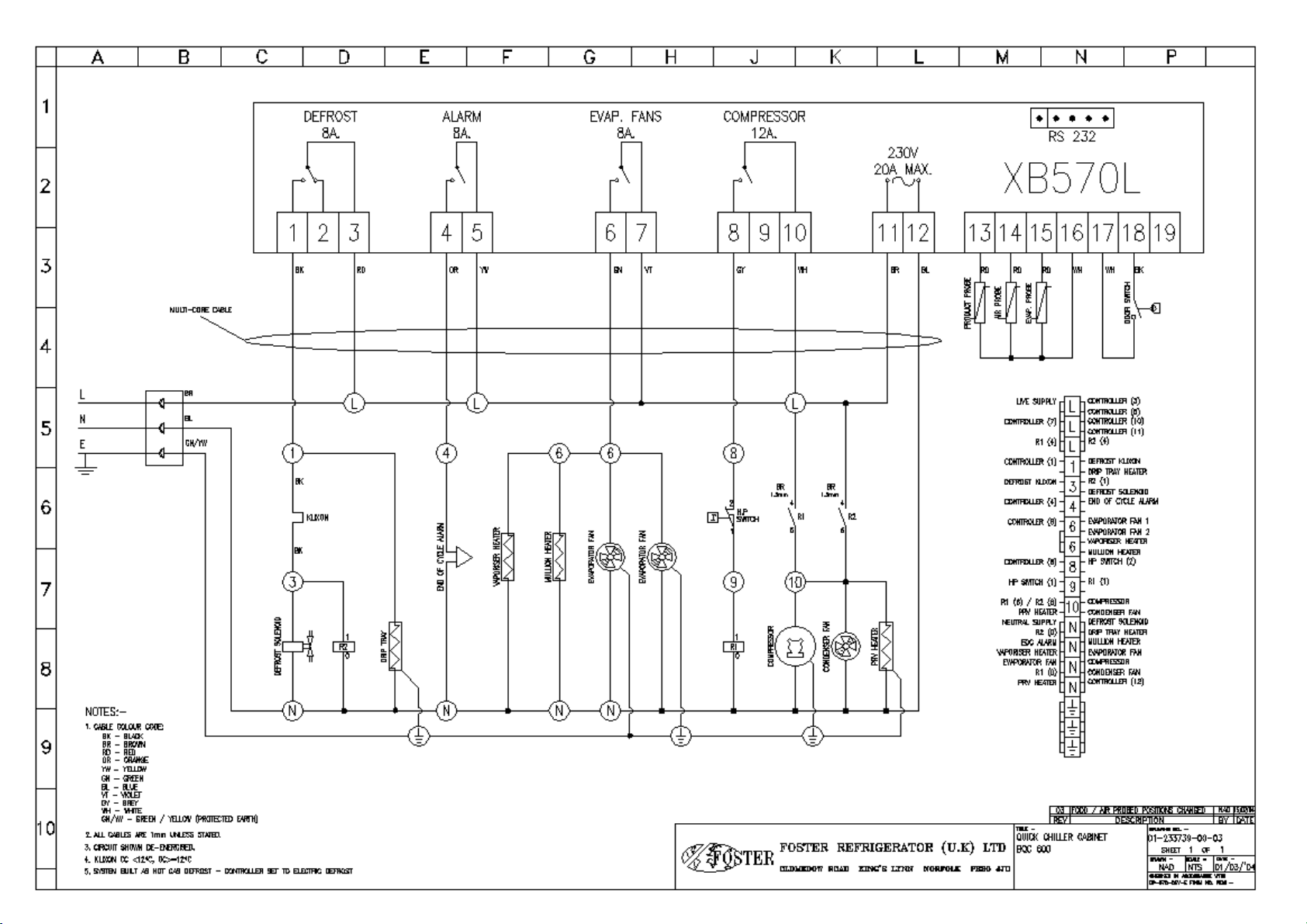

Controller Electrical Connections

12

Page 14

Technical Data

QC11 QC600 BQF 40

Nominal Chilling Capacity 11Kg 40Kg

Duty @ -15°C 830w 1031w

Fans 1 2

Defrost Load N/A N/A

Evaporating Temperature -15°C -15°C

Refrigerant Control TEV TEV

Refrigerant R404a R404a

Refrigerant Quantity 1000g TBA

Electrical Supply 230/1/50 – 13amp 230/1/50 – 13amp

Total Heat Rejection 1500w 2080w

Wiring Diagram Numbers

Model Wiring Diagram Number Fuse Rating

QC 11 01-233728 13 Amp

QC 600 01-233729 13 Amp

BQCsF 40 13 Amp

13

Page 15

QC 11 Wiring Diagram

Page 16

QC 600 Wiring Diagram

2

Page 17

BQCF 40 Wiring Diagram. Sheet 1 of 2

3

Page 18

BQCF 40 Wiring Diagram. Sheet2 of 2

4

Page 19

Foster European Operations

France

Foster Refrigerator France SA

Tel: (33) 01 34 30 22 22. Fax: (33) 01 30 37 68 74.

Email: commercial@fosterfrance.com

Germany

Foster Refrigerator Gmbh,

Tel: (49) 2333 839375. Fax (49) 2333 839377.

Email: info@foster-gmbh.de

Foster Refrigerator

Oldmedow Road

Kings Lynn

Norfolk

PE30 4JU

Tel: 01553 691122

Fax: 01553 691447

Website: www.fosterrefrigerator.co.uk

Email: sales@foster-uk.com

a Division of ‘ITW (UK) Ltd’

BC11 BC600/SM/08/04

Loading...

Loading...