Page 1

MANUALE MANUTENZIONE

Installation instructions

Notice d’installation

Montageanweisungen

Instrucciones de instalación

Page 2

SUMMARY

DESCRIPTION OF THE APPLIANCE ...........................................................................................

MULTIZONES INSTALLATION .................................................................................................. 4

I

NSTALLATION

V

ENTILATION

I

NSTALLATION INSTRUCTIONS

CONNEXION OF THE DIFFERENT ELEMENTS ....................................................................... 6

C

ONNECTION OF THE COOKING ZONES

C

OMBINATION OF THE COOKING ZONES

INITIAL CONFIGURATION PROCEDURE ................................................................................. 8

WHAT TO DO IN CASE OF A PROBLEM .................................................................................. 8

ELECTRICAL CONNECTION ..................................................................................................... 9

............................................................................................................................. 4

.............................................................................................................................. 5

....................................................................................................... 6

.......................................................................................... 6

........................................................................................ 6

Page 3

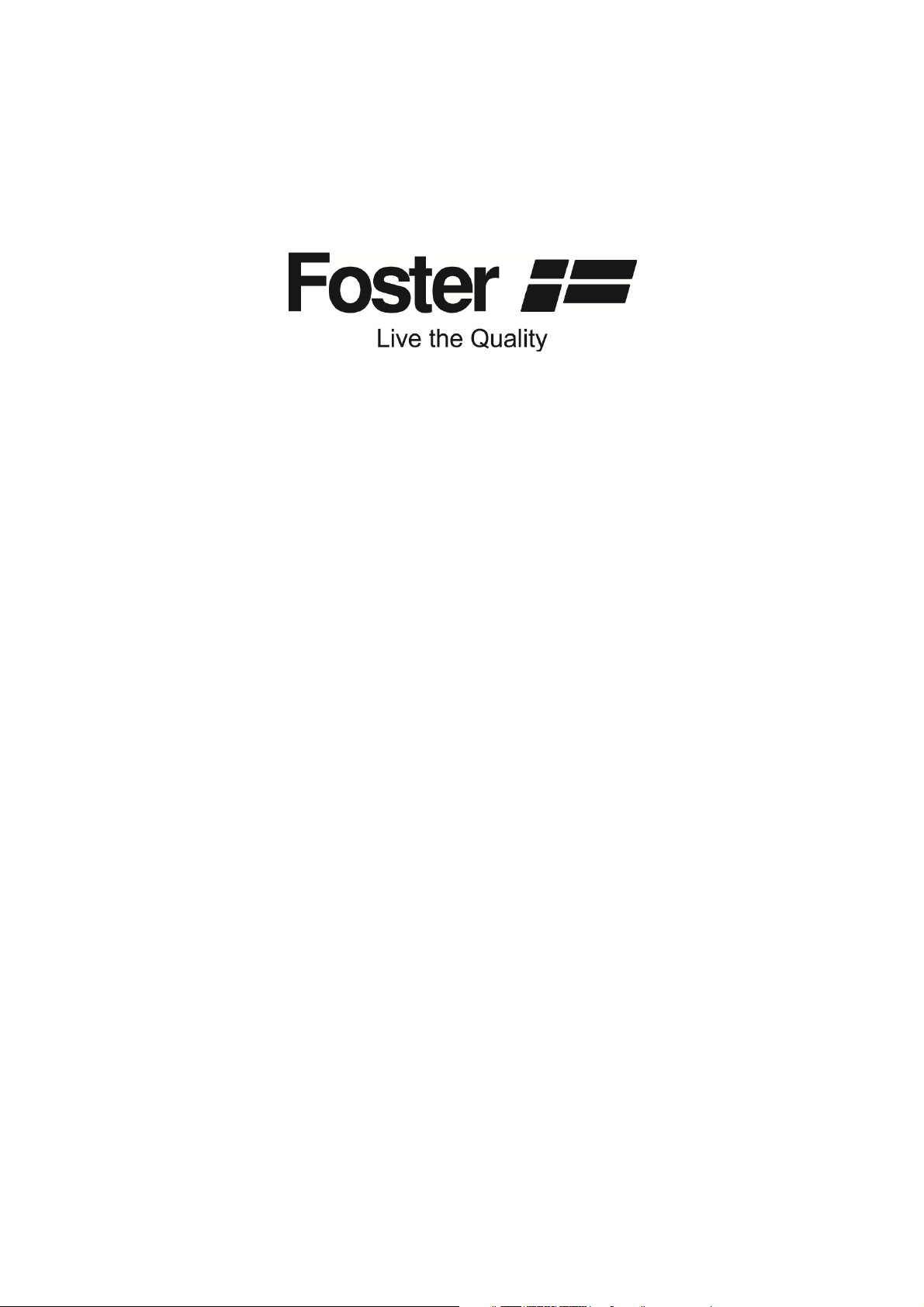

DESCRIPTION OF THE APPLIANCE

Cut out

Q4 border

Touch Control Panel

Dimensions of the control panel and cut out:

Cut out for

Flushmount

Border (mm)

B

279 x 154

R77

Product code

73 68 030

73 68 040

73 68 035

73 68 045

Color

Black

White

N°

Zones

3

4

3

4

Length

(mm)

A

275 150 75

Width

(mm)

Radius

(mm)

Depth

(mm)

D

5 4

Thickness

glass (mm)

EXAMPLE OF FLUSHMOUNT

Cut out for

Flushmount

Border (mm)

C

265 x 140

R70

Cut out for

(mm)

190 x 120

Tot.

Thickness

(mm)

37

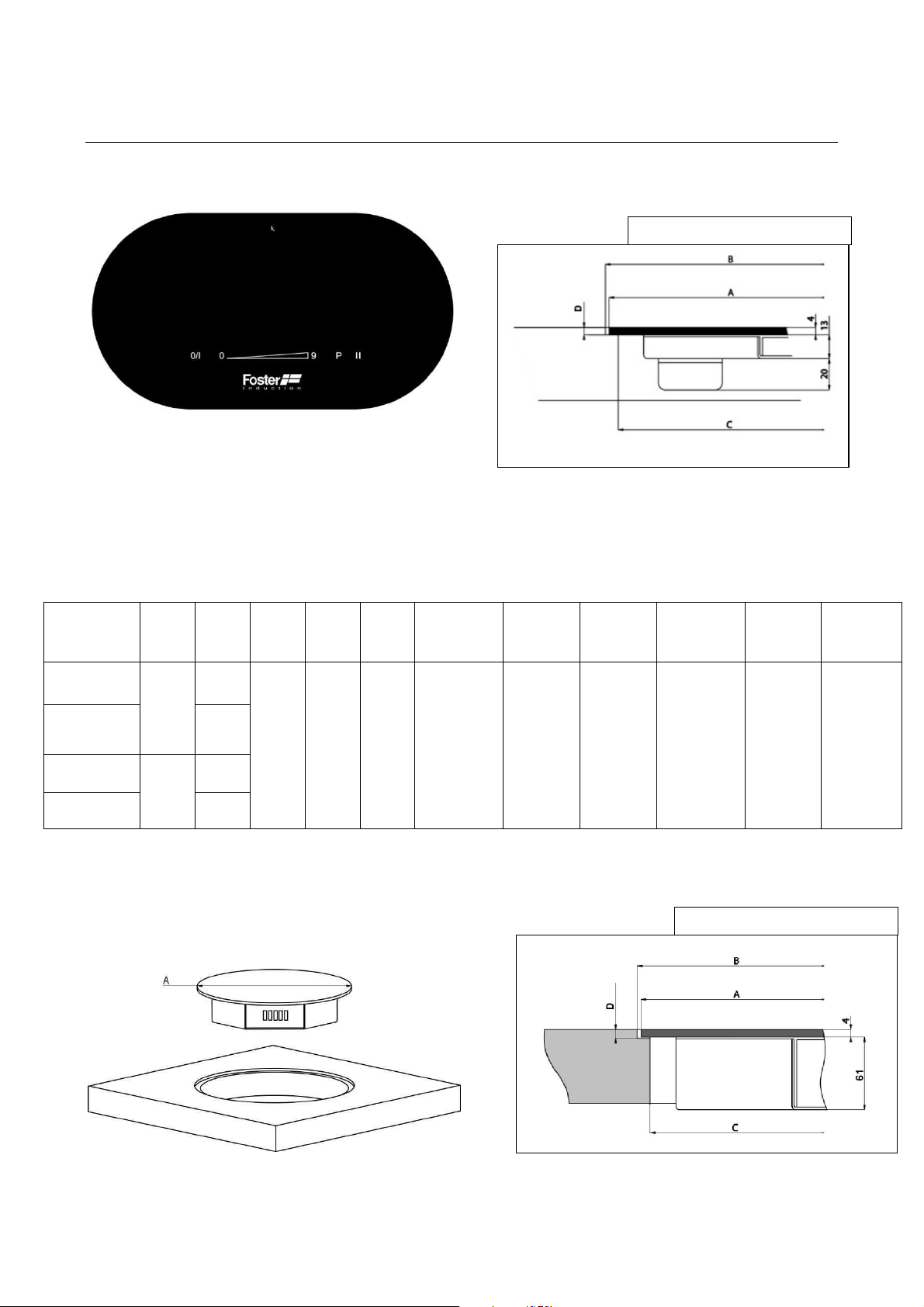

Induction Plates:

Dimensions of the Induction Plates and cut out:

EXAMPLE OF FLUSHMOUNT

Page 4

Product code

Diameter

Thickness

Cut out

Cut out

Cut out

Tot.

73 61

270 / 73 61 275

73 62

300 / 73 62 305

73 63

350 / 73 63 355

Product code

Dimensions (

excluding t

he

N° Zones

Power (W)

73 69 030

73 69 040

Example of connection

box 4 zone

s

(mm)

A

270

300 304 284

350 354 334

Connection box:

Dimensions of the box

connectors)

(mm)

270 x 210 x 48 mm 3 5800

270 x 210 x 48 mm 4 7400

glass

(mm)

4

Flushmount

Border (mm)

B

274

Depth

(mm)

D

5

Flushmount

Border (mm)

C

Thickness

(mm)

254

65

MULTIZONES INSTALLATION

Installation

• Unpack all the materials.

• The installation and connection of the appliance have to be carried out by an

approved specialists. The manufacturer cannot be held responsible for damages

caused by errors during installation or connection.

• In order to work properly this appliance must be installed properly on an approved

and appropriate worktop.

• This appliance is for domestic use and exclusively for the cooking of food, any other

domestic, commercial or industrial use is not appropriate.

Page 5

• Before proceeding remove all labels and adhesives from the ceramic glass.

• Do not alter or modify the appliance.

• It is very important that the cooking zones and the control panel are not used as

support or worktop.

•

The appliance must be installed and connected in accordance with local safety

standards and no extension cables should be used

• The appliance cannot be installed above a dishwasher or dryer. The steam may

damage the electronic appliances.

• If the appliance is installed above an oven this must have a cooling fan.

Furthermore there must be an insulation panel between the apparatus and oven to

avoid the heating of the electrical components of the cooker.

Ventilation

Important: the cooling system needs constant airflow. Please maintain a space of at least

50mm under the induction plates to guarantee a constant airflow: See the below drawing

as an example.

Page 6

Installation instructions

The installation must be carried out by a specialized technician.

The installer must respect the local norms and standards in use.

Installation:

• The worktop or support on which the hob is installed, along with all the materials

installed must be able to resist to temperatures of up to 100 °C.

• The nearby walls and edges must also be able to resist to high temperatures.

• The hobs are classified as “Y” class for heat protection. Ideally the hob should be

installed with plenty of side space on either side to allow air circulation. In the case

of a rear and side wall make sure the opposite sides are clear from any wall,

unit or divider, mobile or immobile, with a height superior to the installation

surface of the cooker hob.

• Ensure that there is a distance of 50 mm between the hob and the wall or edges.

• Some materials which are often used to make worktops tend to expand when in

contact with water. Attention must be used for the installation of the gasket

supplied with the apparatus. The main function of these gasket is to prevent that

spilled liquids flow to the below cabinets. This gaskets guarantees the maximum

protection in combination with a smooth work tops.

• The safety gap between the hob and the cooker hood placed above the apparatus

must respect the indications of the hood manufacturer. In case of absence of

instructions please maintain a minimum distance of 650 mm.

• The connection cords should be not be tense or subject to solicitation or friction, for

example near a drawer.

CONNEXION OF THE DIFFERENT ELEMENTS

The installation of this appliance and the connections of the electrical network should be

carried out by a specialised technician in respect with the local norms and standards in

use.

Connection of cooking zones

Each connector of each cooking zone, is identified by a sticker with a number from

5 to 8 which corresponds to the following:

• 5: Heating zone 1100 W / Glass diameter 270mm (code 736127*)

• 7: Heating zone 2300 W / Glass diameter 300mm (code 736230*)

• 8: Heating zone 2300 W / Glass diameter 350mm (codice 736335*)

• The control panel is identified with the letter “C” on the connector

On the junction box, you can find the female connectors with the corresponding units: 5-67-8-C.

Page 7

The cords of the connector c

induction plates

(see the belo

corresponding number of the ju

Connect the cable of the contro

Combinations of cook

(product

1 zone 5 (mandatory) (in

2 remaining zones (indu

(codice

2 zone 5 (mandatory) (in

indu

Nota:

-

It is

strictly forbid

We do not take

manual and/or safe

Connect the hea

the wire

s

of the cooking zones.

the

Touch control 3 zone:

-

-

Touch control 4 zone:

-

-

2 remaining zones (

Example:

ction plate code 736127*)

40)

5, 7, 8)

-

Page 8

INITIAL CONFIGURATION

The apparatus must be configured before the first use following the below instructions:

I) Important

II) Disconnect the appliance from the grid by removing the fuse or turning the circuit

breaker off

III) Reconnect the table to the grid

IV) Procedure:

* Take a pot with a ferromagnetic bottom with a minimum diameter of 16 cm

* start the procedure within 2 minutes after reconnecting the hob to the grid

* don’t use the [ 0/I ] button

V) First step: cancel the existing configuration

1) Press and hold the n°2 button

2) The symbol [ . ] will appear on each display

3) With your other hand, press in succession and

quickly (less than 2s) each [ . ] display.

Begin from the front right side and turn counter

clockwise, as described in the picture (a -> b -> c -> d)).

A double "beep" means an error occurred. If so, start again from point 1).

4) Remove your fingers from the touch control, then push and hold button 1

few seconds, until the blinking [ E ] symbols appear.

5) Wait until [ E ] symbols stop blinking.

6) After few seconds, [ E ] will automatically become [ C ] confirming that the

previous configuration was cancelled.

Note: For induction hobs with 3 cooking zones, because the right front zone doesn’t

exist, begin the procedure with the right rear zone (b).

VI) Second step: new configuration

1) Take a pot with a ferromagnetic bottom with a minimum diameter of 16 cm.

2) Select a cooking zone by pushing on the corresponding [ C ] display

3) Place the pot on the area that needs to be configured

4) Wait until the [ C ] display becomes a [ - ]. The selected cooking zone is now

configured.

5) Follow the same procedure for each cooking zone with a [ C ] display.

6) All the cooking zones are configured once all the displays are turned off.

Note: Please use the same pot for the whole procedure.

Never put several pots together on the zones during the setup-process.

! Before you start, make sure there is no pot on the hob

for

WHAT TO DO IN CASE OF A PROBLEM

The symbol [ E4] appears :

• Reconfigure the table as above from step one

• If the symbol remains, please contact our After sales service

Page 9

ELECTRICAL CONNECTION

• The installation of this appliance and the connections of the electrical network

should be carried out by a specialised and qualified technician in respect with the

local norms and standards in use.

• After installation an adequate protection of the tense pieces must be guaranteed

• The necessary connection details can be found on the label near the connection

box.

• The connection to the main plug must be made using a grounded plug or via an

omnipolar circuit with a fuse block with an opening of at least 3 mm.

• The electrical circuit must be separated from the network through appropriate

devices, such as fuses, or circuit breakers.

• If the appliance is not fitted with an accessible plug, a disconnection apparatus

must be used during installation

• The power cable must be positioned so that it does not come in contact with any of

the hot parts of the hob or oven.

Caution!

This appliance must only be connected to an electric network of 230 V~ 50/60 Hz.

Always ground the plug.

Respect the connection diagram.

The terminal is located at the back of the apparatus (box). To open the cover use a

medium screwdriver. Unscrew and open the cover.

Mains Connection Cable diameter Cable Protection fuse

230V~ 50/60Hz 1 Phase + N 3 x 2,5 mm²

400V~ 50/60Hz 2 Phases + N

* calculated with the simultaneous factor following the standard EN 60 335-2-6/1990

Important

It is strictly forbidden to lengthen or shorten the wires of the cooking zones ( 5,6,7,8;)

Only the wire of the control panel (C) may be extended (Using our prolonged wire ref.

A10506/0).

Connection of the hob

Setting up the configurations:

For the various connections, use the brass jumpers which are in the box near the terminal

4 x 1.5 mm²

H 05 VV - F

H 05 RR - F

H 05 VV - F

H 05 RR - F

25 A *

16 A *

Monophase 230V~1P+N

Insert the 1st jumper between terminals 1 and 2 and the 2nd between 3 and 4.

Attach the ground plug to the terminal “earth”, the neutral N to terminal 3 or 4, and L to

either terminal 1 or 2.

Biphase 400V~2P+N

Page 10

Insert the jumper between terminals 3 and 4.

We cannot be held responsible for any incident resulting from

the

incorrect connection

of

Attach the ground plug to the terminal “earth”, the neutral N to terminal 3 or 4, the Phase

L1 to the terminal 1 and the Phase L2 to the terminal 2.

Caution! Make sure to have carefully secured the cables and jumpers and tightened

the screws

the apparatus, including the use of an apparatus that has not been grounded properly or

one that has a defected grounding system.

Loading...

Loading...