Foster MILANO ISLAND 36"" 2454 900, MILANO ISLAND 48"" 2455 900 Installation Instructions Manual

Models covered by this instructions:

Notice d’instruction pour les modèles:

2454 900 - 2455 900

*** BEFORE INSTALLATION ***

ENSURE THERE IS NO VISIBLE OR HIDDEN DAMAGE SUSTAINED DURING SHIPPING

*** AVANT L’INSTALLATION ***

S’ASSURER QUE LES PRODUITS N’ONT SUBI AUCUN DOMMAGE PENDANT LE TRANSPORT

*** SHIPPING DAMAGE ***

MUST BE REPORTED WITHIN 5 DAYS OF RECEIPT

*** DOMMAGES DE TRANSPORT ***

DOIVENT ÊTRE NOTIFIÉS DANS LES 5 JOURS SUIVANT LA RÉCEPTION

INSTALLATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS

CARE AND USE MANUAL FOR:

NOTICE D’UTILISATION ET D’ENTRETIEN POUR:

ISLAND RANGE HOODS

HOTTES ÎLOT

HOOD MILANO ISLAND 36” 2454 900

HOOD MILANO ISLAND 48” 2455 900

WARNING

Thank you for purchasing a Foster Range Hood.

Please read all the instructions in this manual before

installing the appliance.

Save these instructions for future reference.

Only use this appliance as an exhaust ventilation system for the removal of

cooking vapors. DO NOT use to expel ammable substances or any other

materials or vapors.

The installation procedures in this manual are intended for qualied installers, service technicians or persons with similar qualied background.

DO NOT attempt to install this appliance yourself.

Ensure that electrical power is turned o at source before commencing installation. All electrical wiring must be properly installed, insulated and

grounded and conform to all applicable codes and standards.

Make sure all existing duct work is clean of grease build up, or duct work

should be replaced, if necessary, to avoid the possibility of a grease re.

Check all joints on ductwork to ensure proper connection and all joints

should be properly taped. Be careful when cutting through ceilings or walls

not to damage any hidden pipes or electrical wiring. Ensure your kitchen has

sucient air return vents to replace the exhausted air.

Fan ducts should always be vented to the outside of your home and never

into spaces within walls, ceilings, lofts or attics. Only use rigid, smooth steel

for ducting. The exhaust point of the blower requires a 6” round connection.

2

TABLE OF CONTENTS

3

BEFORE YOU BEGIN 4

MINIMUM AND MAXIMUMS 4

DUCTING 4

Duct Run Calculation 5

ELECTRICAL 5

Electrical Supply 5

INSTALLATION 6

Structural preparation for the hood fan installation 6

Fixing the Main Support Bracket 6

Attaching the range hood to the ceiling 7

Connecting Electricity and Ducting 8

Re-Circulating Requirements 8

Schematic of Classical Island Components 9

OPERATING PROCEDURES 11

General Advice 11

Functions 11

MAINTENANCE 12

Cleaning the Filter 12

Cleaning the Hood 12

Light Bulb Replacement 13

WARRANTY 14

4

BEFORE YOU BEGIN: It is advisable to test

run the range hood before installation.

BEFORE STARTING – please read this entire document and ensure you are fully

conversant with the require-ments and

limitations. These units weigh approximately 125lbs and therefore require a

minimum of two people to install.

BEFORE YOU BEGIN

The manufacturer declines all responsibility in the event of failure to observe the

instructions given here for installation,

maintenance and suitable operation of

the product. The manufacturer further

declines all responsibility for injury due

to negligence and the warranty of the

unit automatically expires due to improper maintenance and/or installation.

MINIMUM AND MAXIMUMS

Min length of power unit structure with

deector connected = 36.6”

Min length of power unit without deector = 32”.

Max length of power unit structure = 48”.

Recommended height from cook top to

underside of hood = 30” for gas, 25” for

electric.

Use the shortest most direct ductwork

route possible. Only use metal ducting

- plastic ducting is generally not permitted by code. Do not use exible metal

ducting as the ridges of the ducting cause severe air turbulence and will signicantly reduce the eciency of any hood

-THIS TYPE OF DUCTING WILL REDUCE

EFFICIENCY BY 50%.

Vent hoods may interrupt the proper ow

of exhaust gases from re-places, gas

furnaces and gas water heaters. To minimize the risk of drawing these lethal gases back into the home please follow the

heating equipment manufacturers safety

standards and guidelines. Refer to NFPA

and ASHRAE for additional information.

DUCTING

If vented externally, 6” / 150mm round

ducting must be available for the hood

through the ceiling, in line with the central vertical axis of the range hood.

This unit must have it’s own ductwork.

Do not under any circumstances vent this

unit into any other ductwork or exhaust

ducting in the building.

PLEASE NOTE THAT THE DUCT OUTLET ON

THE TOP OF THE POWER UNIT IS OFF SET

FROM CENTRE AND THEREFORE AN ADJUSTABLE 6” ROUND BEND WILL BE REQUIRED

TO LINE THE EXHAUST OUTLET WITH THE

6” HOLE IN THE CEILING MOUNT BRACKET.

Duct Run Calculation.

The maximum duct run before eecting

the performance of the hood is 100’. Calculate your duct run by measuring linear

feet and adding the elbows, transitions

and caps based on the table below.

5

Maximum Run

6” or 3 1/4 x 10” duct 100 FT

Deduct

Each 90 elbow used 15FT

Each 45 elbow used 9FT

Each 6” or 3 1/4 x 10” duct

Transition used 1FT

Each 3’1/4 x 10” to 6”

Transition used 5FT

Side Wall with damper 30FT

Roof Cap 30FT

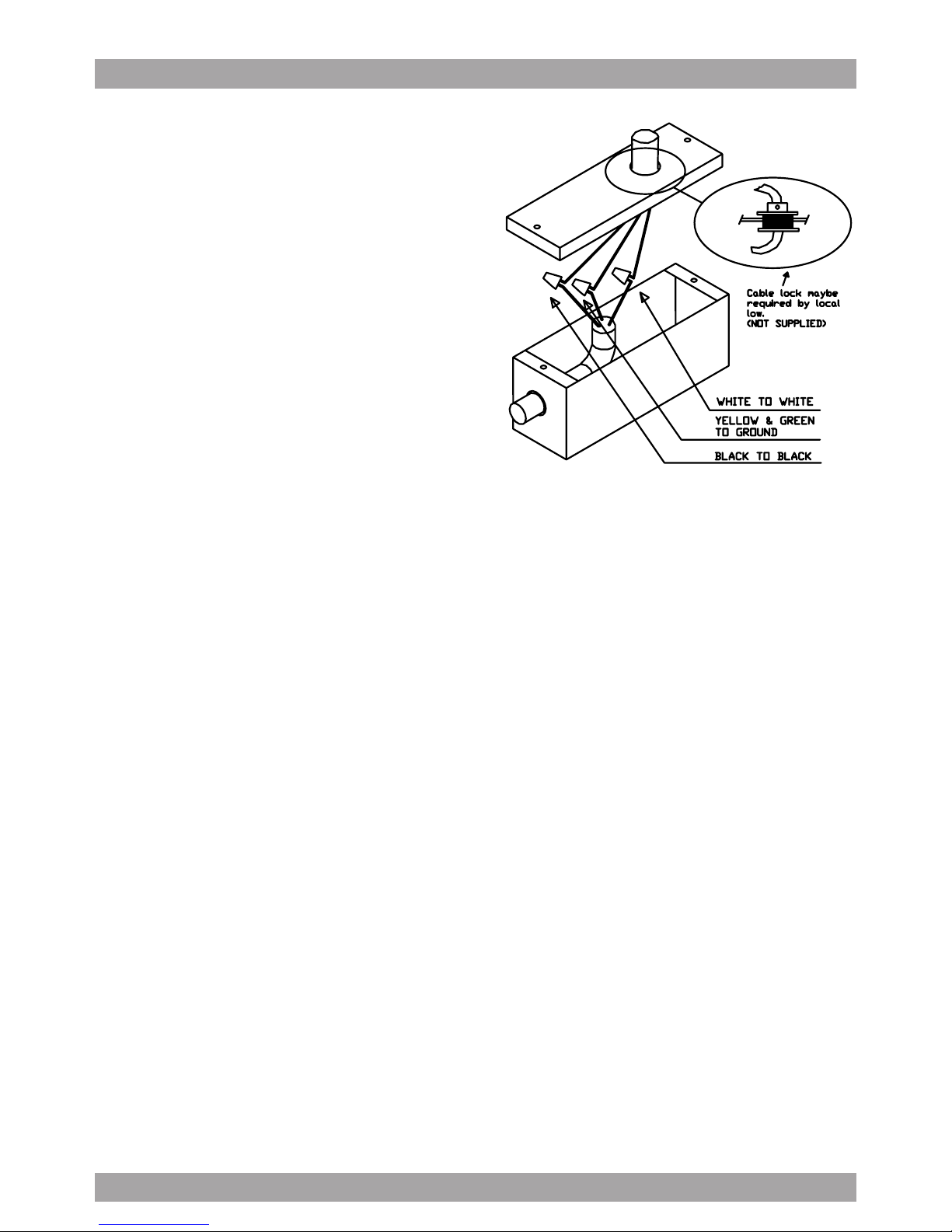

Electrical Supply.

This appliance requires 120V/60Hz,

3amp electrical supply – ensure an appropriately qualied person completes

the electrical hook-up. The connection

point for the electrical supply is at the top

of the unit, therefore the electrical supply

must be run down from the ceiling alongside the ductwork.

All electrical and venting hook-ups must

be in place before commencing installation of the hood-fan.

ELECTRICAL

WARNING: All electrical work must be

performed by a qualied electrician.

Please ensure that the appropriate electrical codes or prevailing local building codes and ordinances are adhered to.

Ensure that the electricity supply is disconnected at source. Do not use an extension cord or adapter plug with this

appliance.

This appliance must be grounded. Connect to a properly grounded branch

circuit, protected by a 15 amp circuit

breaker.

6

Do not switch on the lights with the hood

at on any surface as the in-tense heat will

burn the surface and destroy the lamps.

Connect a power supply to the unit and test

all functions.

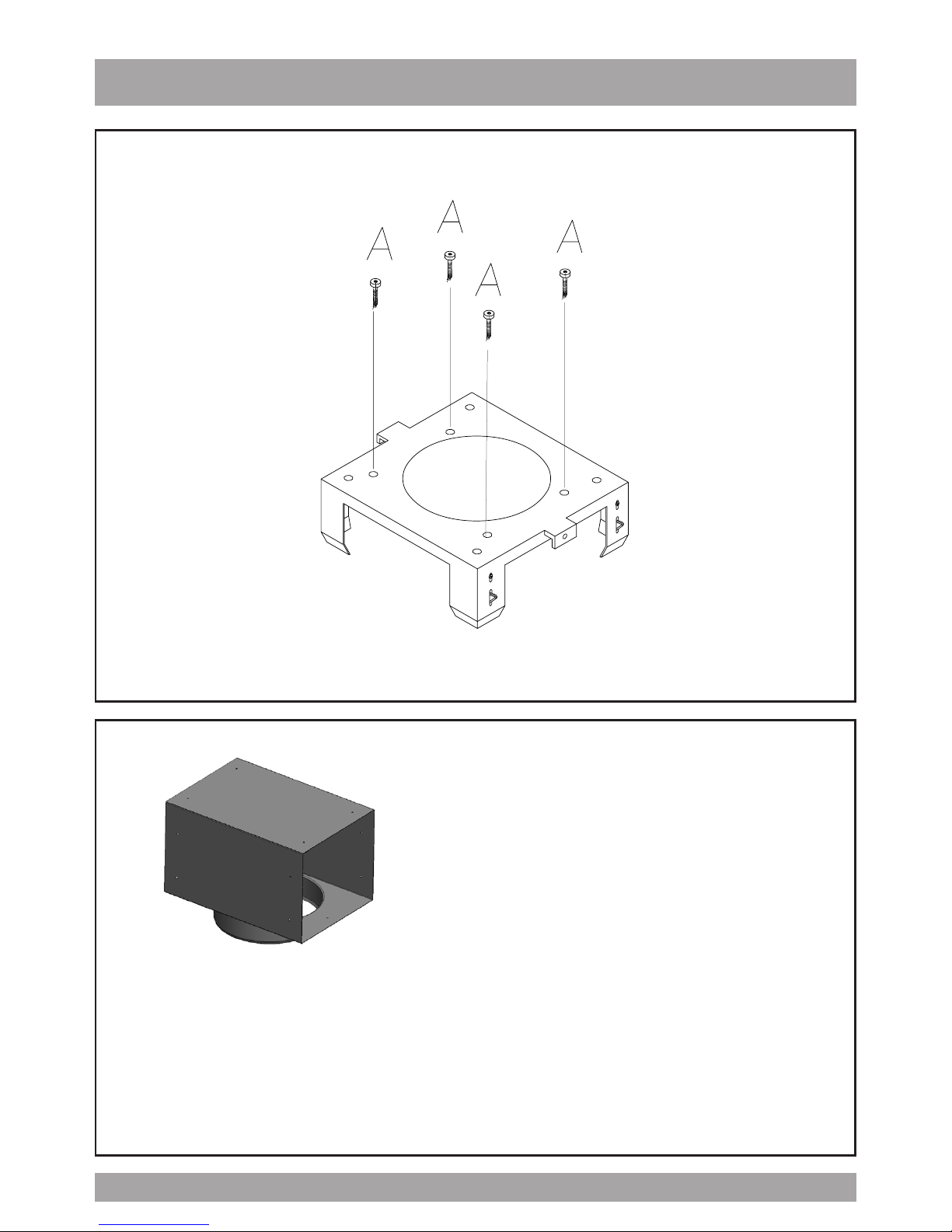

Installation of the island hood consists

of xing the ceiling Bracket A substantial

members in the ceiling. The bracket must

be xed to the frame by screwing through

the ceiling into the heavy members inside the ceiling. This is critically important

as the entire hood fan hangs from this

position, and ceiling board alone will

not support the weight of the hood fan.

Discard the plastic wall plugs supplied for

xing the bracket to the ceiling – these are

not appropriate for North American structures.

Fixing the Main Support Brackets

Using Bracket “A” as a template mark the

ceiling where the xing screws “A” will be

positioned – remember the correct orien-

tation from above. Attach bracket “A” to

the ceiling permanently. If re-circulating,

attach the deector to Bracket “A” before

xing it to the ceiling – refer schematic on

page 5.

The 2 brackets for the support of the chimney (Part A) is to be installed to Bracket A

with the screws. Fix the structure on the

ceiling by inserting the 2 dowels.

INSTALLATION

Structural Preparation for the Hood

Fan Installation.

The island hood weighs approximately 125

lbs. It is therefore imperative that a substantial structure is prepared in the ceiling

to attach the range hood to. Ideally block

o an area of at least 12”x12” between the

ceiling joists using 2x4’s. Allow for a hole

through the center of this blocking of at

least 6” in diameter through which to pass

the ductwork and electrical cable.

The underside of the hood must not be

closer than 30” from the cook-top and

ideally not higher than 32”above the

cook-top. It is strongly recommended, at

this point, that calculations and measurements be made and all planning and heights be nalized. You will need to t the

appropriate length of ducting to the hood

fan before installing it to the ceiling.

Planning should consist of a test assembly of the power unit and telescoping

structure before attempting to mount

everything to the ceiling. By following

this test assembly you will be able to nalize the correct length of the assembly

before mounting it to the ceiling.

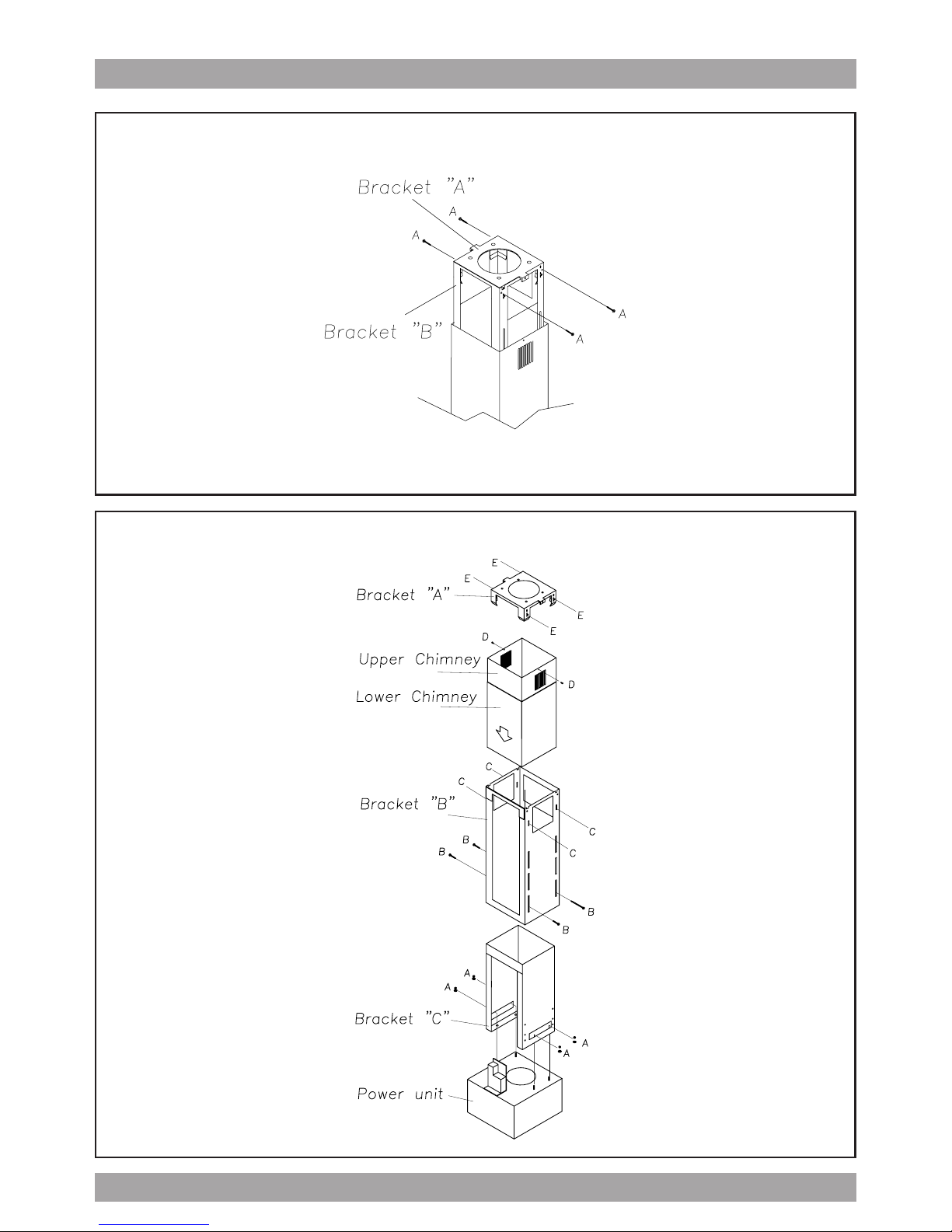

Test assembly should include actually

attaching the following items together

– refer schematic of components and

“Fixing the main support brackets”

below – Brackets A, B, C, power unit and

deector if re-circulating.

This is also a good time to test the electrical

functioning of the hood before it is installed. Before switching on the light or lights,

ensure the tape holding the globes in place

has been removed.

The globes gets extremely hot and will very

quickly burn the tape and discolor the globes irreparably.

Fix Bracket “C” to the power unit with the

nuts and washers supplied (Items “A” on

the schematic on page 5). Please ensure

that the bracket is installed as shown to

enable full ac-cess to the square plastic

black box and the metal electrical junction box. Slide Bracket “B” over Bracket

“C” (once again ensure full access to the

plastic and electrical boxes is main-tained) and x it in place, at the previously calculated length using the machine screws denoted by items “B” on the

schematic on page 5.

Check that the plastic aps at the exhaust

outlet for the fan move freely and have not

become jammed during shipping or whilst

working with the power unit. Connect an

appropriate length of ducting to the unit.

Do not x the ducting to the outlet with

screws - use DUCT TAPE.

Stand the assembled structure on a clean

soft surface. Ensure the underside of the

hood does not get scratched and slide

the chimneys of the assembled structure

from the top down as per the schematic

on page 5. Ensure that the holes for xing the decorative chimney are correctly orientated with the holes at the top of

bracket A.

Attaching the Range Hood to the Ceiling.

The entire structure that has been preassembled above, must now be hoisted

up to the ceiling. A few things have to

happen at once here: the slots (as discussed below) need to be engaged and

the ductwork must make connection with

the length of ductwork on the structure.

7

This will require two strong people –do

not attempt this step on your own. Bracket “B” has slots, position C per Diagram

“A” (refer to page 5), at the top that will

receive the spring clips located on Bracket

“A” –THIS IS A TEMPORARY HOLD ONLY

–DO NOT RELY SOLELY ON THESE CLIPS

TO HOLD THE HOOD UP – THEY WON’T.

Once “hooked” by the spring clips immediately secure the structure with the machine screws at point “E” on the schematic

on page 5 – this must be done imme-

diately and should not be skipped. Raise the upper chimney to the ceiling and

x it to the bracket “A” with the screws

supplied “D”.

Ensure the entire structure is sturdy - serious injury, death and MAJOR damage

could result should the unit not be well

connected to the frame structure within

the ceiling.

This is of utmost importance – do not go any

further until this has been tested and double

checked – the installer has sole responsibility for the safe installation of this product.

Attaching the Range Hood to the Ceiling.

The entire structure that has been preassembled above, must now be hoisted

up to the ceiling. A few things have to

happen at once here: the slots (as discussed below) need to be engaged and the

ductwork must make connection with the

length of ductwork on the structure.

This will require two strong people –do

not attempt this step on your own. Bracket “B” has slots, position C per Diagram

“A” (refer to page 5), at the top that will

receive the spring clips located on Bracket “A” –THIS IS A TEMPORARY HOLD

ONLY –DO NOT RELY SOLELY ON THESE

CLIPS TO HOLD THE HOOD UP – THEY

WON’T. Once “hooked” by the spring

clips immediately secure the structure

with the machine screws at point “E” on

the schematic on page 5 – this must be

done immediately and should not be

skipped.

Ensure the entire structure is sturdy- serious injury, death and MAJOR damage

could result should the unit not be well

connected to the frame structure within

the ceiling.

This is of utmost importance – do not go

any further until this has been tested and

double checked – the installer has sole

responsibility for the safe installation of

this product.

Once the entire structure has been xed

to the ceiling slide the chimneys on the

assembled structure from the bottom up

as per the schematic on page 5. And x

the chimneys with the screws supplied.

Raise the upper chimney to the ceiling

and x it to the bracket “A” with the

screws supplied “D”.

Connecting Electricity and Ducting.

Make sure power is turned o at the

source. Make the electrical connection.

Test the functioning of the hood. Slide

the upper chimney into place and attach

with the machine screws provided to

Bracket “A”.

Re-Circulating Requirements.

Fit the carbon lter after the installation is

complete – these t in behind the aluminum grease lter.

A short length of ductwork must be connected from the exhaust outlet up to the

deector (must be purchased with hood).

The deector, after attaching part B with

screws E connects to the top of Bracket

“A” and forces the air out through the

grills on the side of the chimney section

back into the room. (see diagram C).

8

SCHEMATIC OF MODULAR ISLAND COMPONENTS

9

Diagram c

Bracket

Deector

Part B

Deector attaches to ceiling mount bracket when island hood is installed in re-circulating mode and the air that has passed through the fat and carbon lters is returned

to the room via a short length of 6” round ductwork attached to the power unit and

deector.

10

Diagram b – Securing Bracket “A” to “B”

Please note – this is critically important – do not rely on the spring clips.

Diagram A – Main Assembly

Loading...

Loading...