Fortuna ES 50 Operating Manual

Skiving Machine ES 50

Operating Manual

English, Version 03

Copyright

FORTUNA Spezialmaschinen GmbH, Weil der Stadt, Germany

The German Operating Manual is the original and form the basis for all

translations.

Without our prior written consent, these instructions may neither be

translated, passed on to third parties nor be reproduced or distributed in

any way. Contravention will result in prosecution under existing laws.

All rights reserved, in particular in the case of patents issued.

©2010 FORTUNA Spezialmaschinen GmbH

Operating Manual part number: ES 50-BA-UK-V3

Version: 03

Date of issue: 24.01.2012

FORTUNA

Spezialmaschinen GmbH

Eisenbahnstraße 15

D-71263 Weil der Stadt

Germany

Phone: +49 (07033) 709-0

Fax: +49 (07033) 709-140

E-mail address: service.leder@fortuna-gmbh.de

Managing Director: Narith Meksavanh

———————————————————————————–––––––––––––––––––––––––

Operating Manual Skiving Machine ES 50-UK-V3/24.01.2012 2 von 45

Customer information

The Operating Manual has specially been compiled for the FORTUNA

Skiving Machine ES 50.

It consists of:

Machine description

User manual

The instructions must be read carefully and the reader must thoroughly

familiarise themselves with all details. Failure to comply with the

instructions in the documentation may result in a loss of warranty in case of

damage.

In addition to the Operating Manual, the generally applicable regulations as

well as the domestic and local regulations on accident prevention and

environmental protection must be made available and observed.

To help you understand your FORTUNA Skiving Machine ES 50, design

details are given, some of which are confidential. This information is

intended only for the operator of the machine and may be neither

reproduced nor made accessible to third parties.

We are certain that your new FORTUNA Skiving Machine ES 50 will

completely meet your expectations.

If you have any further questions, the FORTUNA advisory service

engineers are always available to provide additional information.

———————————————————————————–––––––––––––––––––––––––

Operating Manual Skiving Machine ES 50-UK-V3/24.01.2012 3 von 45

Summary of customer documentation

Machine description

Among other things the machine description comprises:

Machine data

Safety information

Important safety devices

Personnel (demands and duties)

Machine installation

User manual

The machine's user manual contain all the information necessary to

operate your FORTUNA Skiving Machine ES 50. They must be given to the

operator of the machine. These user manual must always be available at

the machine.

All safety information, regulations and demands stipulated in the “ Machine

description “ section also apply to operations with the machine.

Repair Manual

The Repair Manual contains all information necessary to replace wearing

and spare parts on your Skiving Machine ES 50.

This document must be handed to the member of staff who repairs the

machine. Staff entrusted with this task must be trained by FORTUNA

Spezialmaschinen GmbH.

All safety information, regulations and demands stipulated in the “ Machine

description “ section also apply to the repair and replacement of parts.

Spare parts list

The spare parts list contains all the information on the machine's individual

components and assemblies.

Circuit diagram

———————————————————————————–––––––––––––––––––––––––

Operating Manual Skiving Machine ES 50-UK-V3/24.01.2012 4 von 45

A

B

C

D

Table of content

E

Table of contents

1 Machine description ................................................................................... 7

1.1

Machine data ......................................................................................... 7

1.1.1 Range of application of the machine ............................................... 8

1.1.2 Technical data ................................................................................. 9

1.1.3 Electrical data .................................................................................. 9

1.1.4 Ambient conditions .......................................................................... 9

1.1.5 Tools and accessories ................................................................... 10

Applicable rules and regulations .......................................................... 11

1.2

Guarantees and liabilities .................................................................... 12

1.3

Copyrights ........................................................................................... 13

1.4

Training offers ...................................................................................... 14

1.5

CE declaration of conformity ............................................................... 15

1.6

Safety information ................................................................................ 16

1.7

1.7.1 Personal safety .............................................................................. 17

1.7.2 Safety in the operation area .......................................................... 17

1.7.3 Safety rules for the use of tools ..................................................... 17

1.7.4 Safety rules for the transport ......................................................... 18

1.7.5 Safety rules for the installation and operation of the machine ....... 18

1.7.6 Safety rules for repair and maintenance work ............................... 19

1.7.7 Inspection requirements ................................................................ 20

1.7.8 Further safety rules ........................................................................ 20

1.7.9 Symbols and reference marks ....................................................... 21

Important safety devices ...................................................................... 22

1.8

1.8.1 Main switch .................................................................................... 22

1.8.2 Motor protection switch .................................................................. 22

1.8.3 Protection switch against non-intended restart of the machine ..... 22

1.9

Personnel (requirements and tasks) .................................................... 23

1.9.1 Operators ....................................................................................... 24

1.9.2 Repair and maintenance personnel ............................................... 24

1.10

Installation of the machine ................................................................... 25

1.10.1 Transport ....................................................................................... 25

1.10.2 Unpacking the machine ................................................................. 25

1.10.3 Installation of the machine ............................................................. 26

1.10.4 Preliminary work for start-up .......................................................... 26

1.10.5 Electrical connection ...................................................................... 27

Start-up ................................................................................................ 28

1.11

1.11.1 Installation of the regulator pedal .................................................. 28

2 User manual .............................................................................................. 29

Main switch .......................................................................................... 29

2.1

Explanation of the control elements .................................................... 30

2.2

2.2.1 Adjusting screw for adjusting the skiving thickness ....................... 30

2.2.2 Knurled screw for adjusting the skiving angle ............................... 30

———————————————————————————–––––––––––––––––––––––––

Operating Manual Skiving Machine ES 50-UK-V3/24.01.2012 5 von 45

Table of content

2.2.3 Stop for adjusting the skiving width ............................................... 31

2.2.4 Adjusting spindle for adjusting the grinding intensity ..................... 31

2.2.5 Adjusting screw for dressing the grinding wheel ........................... 31

2.2.6 Opening for blunting and deburring the bell knife .......................... 32

2.2.7 Adjusting screw for adjusting the contact pressure of the feed roll 32

2.2.8 Adjusting screw for adjusting the feed roll distance ....................... 32

2.2.9 Adjusting spindle for the knife infeed ............................................. 33

2.2.10 Setpoint potentiometer .................................................................. 33

2.2.11 Regulator pedal ............................................................................. 33

2.2.12 Handle ........................................................................................... 33

Adjustment of the knife position indicator ............................................ 34

2.3

Adjustment of the feed regulator ......................................................... 36

2.4

Cleaning .............................................................................................. 38

2.5

2.5.1 Daily cleaning ................................................................................ 38

2.5.2 Weekly cleaning ............................................................................ 39

2.6

Maintenance work ............................................................................... 40

2.6.1 Troubleshooting ............................................................................. 41

2.6.1.1 Bad skiving results ................................................................. 41

2.6.1.2 Insufficient feeding ................................................................. 41

2.6.1.3 Bevels are too thick ............................................................... 41

2.6.1.4 Insufficient scrap removal ...................................................... 42

2.6.1.5 Noisy operation ...................................................................... 42

2.6.1.6 Electrical troubles .................................................................. 42

2.6.2 Cleaning and maintenance schedule ............................................ 43

Views and detailed drawings ............................................................... 44

2.7

A

B

C

D

E

List of figures

Figure 1: View of the machine ...................................................................... 7

Figure 2: CE declaration of conformity ....................................................... 15

Figure 3: Safety informations and nameplate on the machine ................... 16

Figure 4: Installation plan of the machine ................................................... 26

Figure 5: Mains connection cables of the machine .................................... 27

Figure 6: Knife guidance ............................................................................. 30

Figure 7: Knife position indicator ................................................................ 35

Figure 8: Regulator ..................................................................................... 37

Figure 9: Details of the machine – front view ............................................. 44

Figure 10: Details of the machine – lateral view ......................................... 29

———————————————————————————–––––––––––––––––––––––––

Operating Manual Skiving Machine ES 50-UK-V3/24.01.2012 6 von 45

Machine data

—————————————————————————————————————–———

1 Machine description

Machine data

1.1

This description of the machine helps you to operate the machine safely

and prevents damage. Please familiarize yourself with the safety

instructions before you transport, connect or start up the machine, see

chapter 1.7 Safety information (page 16).

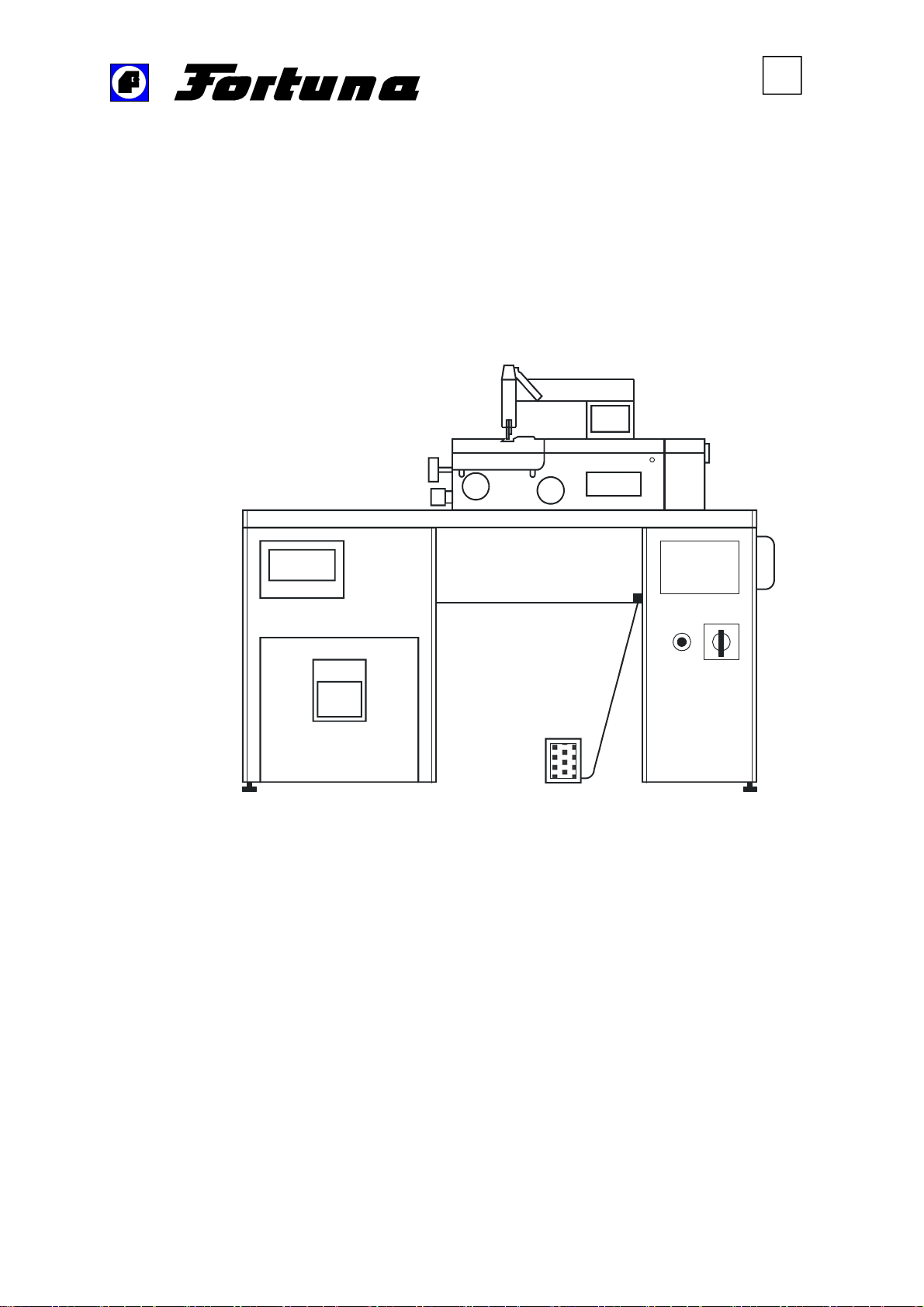

Figure 1: View of the machine

———————————————————————————–––––––––––––––––––––––––

Operating Manual Skiving Machine ES 50-UK-V3/24.01.2012 7 von 45

Machine data

—————————————————————————————————————–———

The guarantee for function and safe operation can only be given in the case

of appropriate operation and the utilization of the original FORTUNA spare

parts.

Check the functioning of all safety devices at regular intervals.

Contact the FORTUNA after sales service immediately if you find out

deficiencies in the safety area.

The operation of the machine must be carried out by skilled personnel only.

The operation of the machine by persons who are younger than 14 years is

not allowed.

The machine is designed to be operated by one person only and must be

used accordingly.

Make sure that the safety devices and control elements are accessible

without restriction during the operation.

1.1.1 Range of application of the machine

This machine is not permitted to be operated in an explosion-proof

area.

Only use this machine for cutting and skiving of leather or material that is

similar to leather (also artificial leather). If you intend to use any other

materials you must contact one of the FORTUNA-representations or the

FORTUNA Company and ask for written approval.

Any other use of the machine may not correspond with the application

range of the machine. The FORTUNA Company is not responsible for any

damages resulting from the non-observance of these rules.

Other considerations for the correct application of the machine are:

the observance of all recommendations in the Operating Manual and

the execution of all prescribed inspection and maintenance tasks.

The use of the following materials is not allowed:

Metals

Wood

Rubber with metallic insert

Hard PVC

Textiles

Glass

Ceramics

Please do not exceed or fall short of the values listed in Chapter 1.1.3

Electrical data (page 9).

———————————————————————————–––––––––––––––––––––––––

Operating Manual Skiving Machine ES 50-UK-V3/24.01.2012 8 von 45

Machine data

—————————————————————————————————————–———

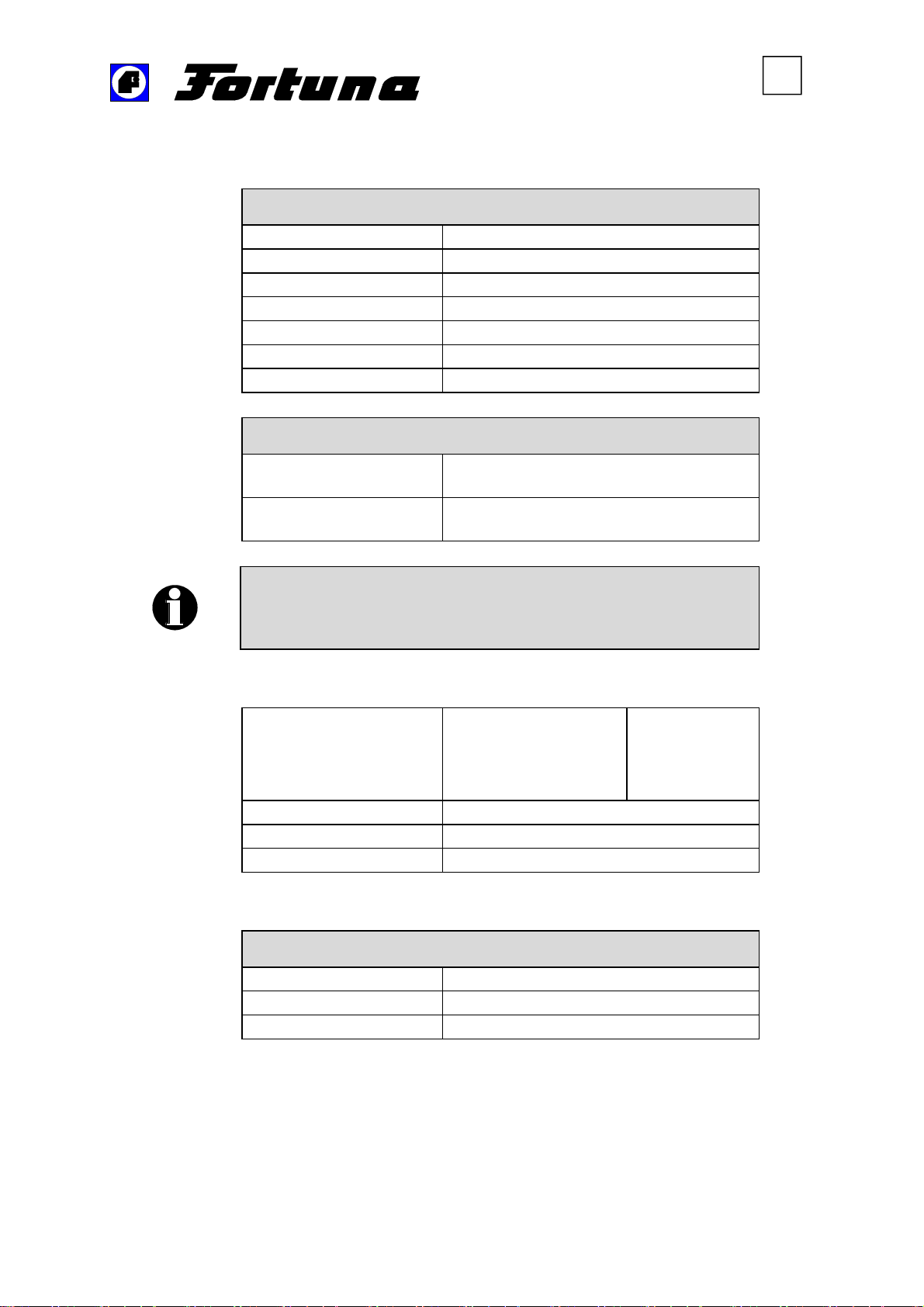

1.1.2 Technical data

Overall Dimensions of the Machine

Width

Required space width

Depth

Required space depth

Height

Weight of the machine

Utilized measuring

device

Value measured at the

operating place

A higher sound pressure level that causes defective hearing can

be generated depending on the local conditions. In this case, the

operating personnel must take protective measures with the

appropriate safety equipment.

1270 mm

1690 mm

565 mm

1115 mm

1200 mm

approx. 170 kg

Noise Emissions

Type ELT 3-215.8510.02

73 dB(A)

1.1.3 Electrical data

Operating voltages and

frequencies

Control voltage 12/220 VAC

Power input 1.0 KVA

Safety fuses max.: 16 A

380 – 420 V 5%

220 – 240 V 5%

380 – 420 V 5%

220 – 240 V 5%

1.1.4 Ambient conditions

Conditions during operation and storage

Humidity < 80 % (non-condensing)

Temperature, stored 0 ... 50 C°

Temperature, operating 10 ... 40 C°

50 cycles

50 cycles

60 cycles

60 cycles

———————————————————————————–––––––––––––––––––––––––

Operating Manual Skiving Machine ES 50-UK-V3/24.01.2012 9 von 45

Machine data

—————————————————————————————————————–———

1.1.5 Tools and accessories

Various accessory parts are delivered in the scrap material bin at the front

of the machine.

The following tools are packed in a box

Fork wrench

13 mm x 17 mm

Hexagonal socket-head wrench

2.5 mm / 3 mm / 5 mm

1 Oil stone with sleeve

1 Hex driver with T-handle

1 Set collar A8

Skiving accessories

Presser foot 361 V

Presser foot 361 HP

2 Work plates

Further accessory parts

Key for the switch cabinet

Operating Manual

———————————————————————————–––––––––––––––––––––––––

Operating Manual Skiving Machine ES 50-UK-V3/24.01.2012 10 von 45

Applicable rules and regulations

—————————————————————————————————————–———

Applicable rules and regulations

1.2

DIN EN ISO 12100–1 and 12100–2

DIN EN ISO 13857

EC Machinery Directive 2006/42/EG

DIN 60204

DIN EN ISO 13849-1

———————————————————————————–––––––––––––––––––––––––

Operating Manual Skiving Machine ES 50-UK-V3/24.01.2012 11 von 45

Guarantees and liabilities

—————————————————————————————————————–———

Guarantees and liabilities

1.3

Our "General sales and delivery conditions" are principally valid for the

guarantee and liability of our products. Personal and material liabilities are

excluded in the following cases:

The machine has been used for purposes other than originally intended.

Improper assembly, start-up, operation and maintenance of the machine.

Operation of the machine with defective safety devices and safety guards

that are not functional or have not been installed in accordance with the

instructions.

Non-observance of the rules that are listed in the Operating Manual with

regard to transport, storage, assembly, start-up, operation, maintenance

and setting-up of the machine.

Unauthorized constructional modifications to the machine.

Unauthorized alterations of the given parameter limits of the machine

(i.e. power, speed and fuses).

Insufficient maintenance of machine parts that are subject to wear.

Non-observance of the prescribed maintenance schedules.

Repair work carried out incorrectly.

Catastrophes caused by external influences or acts of God.

———————————————————————————–––––––––––––––––––––––––

Operating Manual Skiving Machine ES 50-UK-V3/24.01.2012 12 von 45

Copyrights

—————————————————————————————————————–———

Copyrights

1.4

The copyrights of this Operating Manual remain in the property of

FORTUNA. They are only intended to be used by the operator of the

machine and his personnel.

Requirements and rules included in these instructions may not be entirely

or partially

copied

distributed or

given to third persons.

Infringements may be prosecuted.

———————————————————————————–––––––––––––––––––––––––

Operating Manual Skiving Machine ES 50-UK-V3/24.01.2012 13 von 45

Training offers

—————————————————————————————————————–———

Training offers

1.5

Training possibilities for the Skiving Machine ES 50 are offered at our

Company in Weil der Stadt as well as at our subsidiary companies. Please

inquire about times, subjects and duration of training.

———————————————————————————–––––––––––––––––––––––––

Operating Manual Skiving Machine ES 50-UK-V3/24.01.2012 14 von 45

Loading...

Loading...