Page 1

When a loaded round no longer has a clearance of .002” to .003” between the neck and the chamber of the

gun, it becomes necessary to reduce the thickness of the neck wall to reestablish the original clearance. This

can be accomplished with the conventional inside neck reamer, which will establish the required clearance but

not necessarily produce neck walls of even thickness. This prompted the development of the Outside Neck

Turning accessory, which will produce neck walls of even thickness and desired outside diameter.

NOTE — Cases to be neck turned must have the neck resized and expanded first.

OUTSIDE NECK TURNING ACCESSORY INSTRUCTIONS

www.forsterproducts.com

A

SSEMBLY TO THE

FORSTER

CASE TRIMMER

Use four wood screws to fasten your Forster Case Trimmer securely to a bench or board to allow the free

use of both hands. (If the Case Trimmer is mounted on a board, it can be held in a vise so that the Trimmer

can easily be set up or put away.)

Remove the ring from its groove in the Cutter Shaft (9).

Slide the Cutter Shaft (9) out of the Trimmer Bearing (8).

Select the proper Outside Neck Turner Pilot (5) for the caliber you will turn. (Outside neck turning requires

a special, non-tapered pilot.) Insert the Pilot (5) into the Cutter Shaft (9). Lock the Pilot (5) in place by tightening the Pilot Set Screw (7) against the flat on the shank of the Pilot (5).

If necessary, for longer cases, remove the base screw that holds the Trimmer Bearing (8) to the aluminum

base. Move the Trimmer Bearing (8) out 1/4” so that it overhangs the base. Replace the base screw using

the other threaded hole in the Trimmer Bearing (8). Tighten. Then remove the base screw that holds the collet housing to the aluminum base. Move the collet housing out 1/4” so that it overhangs the base. Replace

the base screw using the other threaded hole in the collet housing. Tighten.

Slip the Cam Follower (10) (square-cut end first) into the slot between the Trimmer Bearing (8) and the Case

Trimmer base. (See the drawing above.)

Slip the Cam (4) onto the Cutter Shaft (9) and slide it into contact with the Stop Collar (11) as shown in the

drawing above.

Replace the Cutter Shaft (9) by sliding it through the Trimmer Bearing (8).

Slide the Cutter Head (carbide cutter end last) onto the Cutter Shaft (9) as shown in the drawing above.

Tighten the Cutter Head Screw Set (6).

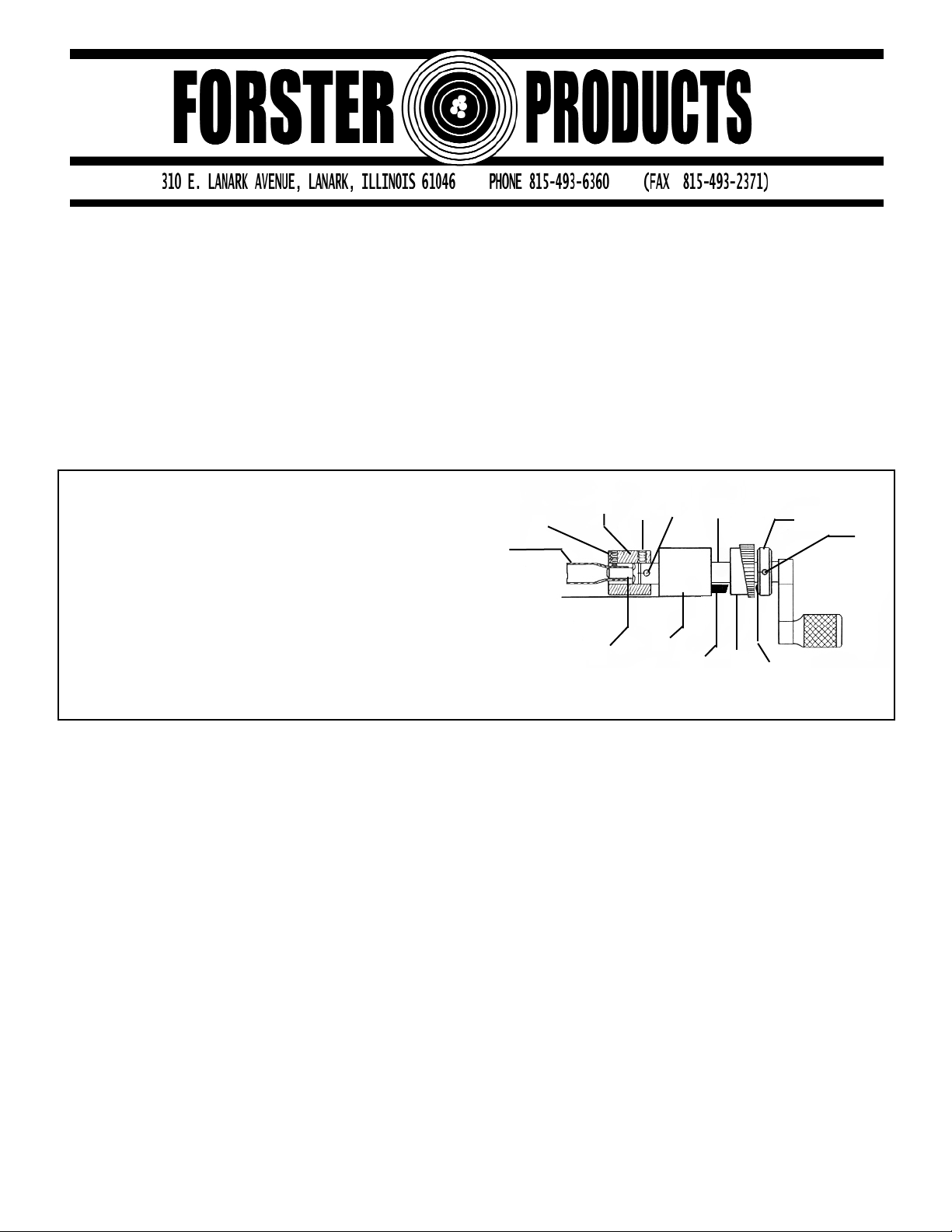

1)

2)

3)

4)

5)

6)

7)

8)

9)

Name Part Number

1) Cartridge Case n/a

2) Carbide Cutter Allen Screw OT1010-012

3) Body OT1010-011

4) Cam OT1010-013

5) Outside Turner Pilot Varies with size

6) Cutter Head Screw Set SCR1032 x 3/16”

7) Pilot Set Screw SCR1032 x 1/8”

8) Trimmer Bearing CT1010-020

9) Cutter Shaft CTC400

10) Cam Follower OT1010-014

11) Stop Collar CT1010-021

12) Stop Collar Fine Adjustment Screw CT1010-017

13) Stop Collar Coarse Adjustment Screw CT1010-016

3

6

7

9

11

13

2

1

5

8

10

4

12

Page 1

Page 2

NECK TURNING INSTRUCTIONS

Select the proper collet for the case you will turn. Remove the collet screw from the collet housing. Apply a small

amount of grease to the front face, tapered portion and base of the collet. Insert the collet into the collet screw. Replace

the collet and the collet screw.

With tension on the collet released, insert the base of the case to be trimmed into the collet. Move the pilot about 1/2”

into the neck of the case. Hold the case firmly against the shoulder of the collet with your right hand then lock the case

in place by tightening the collet screw.

Turn the Carbide Cutter Allen Screw (2) clockwise until the carbide cutter is close to, but not in contact with, the case neck.

Slide the Cam (4) into contact with the Cam Follower (10). Rotate the Cam (4) clockwise as far as possible.

Set the Stop Collar Coarse Adjustment Screw (13) so that the carbide cutter will stop cutting about 1/16” from the shoulder of the case.

Move the cutter head so that the carbide is not above the case neck. Turn the Carbide Cutter Allen Screw (2) 1/16 of

a turn clockwise. (One full turn will move the carbide cutter approximately .032”, therefore, 1/16 of a turn will move the

carbide cutter .002”. CAUTION — A .002” adjustment of the carbide cutter will alter the neck diameter by .004”.)

Tighten the carbide cutter lock screw.

To turn the case neck:

a) Hold the Cam (4) in place against the Cam Follower (10) with your left index finger and thumb.

b) Rotate the carbide cutter by smoothly turning the crank handle clockwise.

c) Feed the Cam (4) clockwise, slowly and evenly with the left hand while continuing to turn the crank handle with

the right hand.

d) When the stop is reached, reverse the cam feed, turning the Cam (4) counterclockwise with the left hand

while continuing to turn the crank handle with the right hand.

If the carbide cutter took a light cut in step #7, go to step #9. If the carbide cutter did not remove any brass, adjust the

cutter toward the case neck another 1/16 of a turn. (Be certain to tighten the carbide cutter lock screw after each adjustment.) Turn the case neck again. Continue to adjust the carbide cutter until it takes a light cut from the case neck.

Measure the case neck’s diameter with a micrometer or dial caliper. Refer to a reliable reloading manual for the proper outside neck diameter. Adjust the carbide cutter accordingly to obtain the proper neck diameter setting. (Case necks

frequently have high and low spots, so don’t be concerned if the proper outside neck diameter is achieved without

removing brass from the entire outside diameter of the neck.)

Once the proper outside neck diameter has been reached, you may set the length of the cut to blend the cut with the

shoulder angle of the case. (Some shooters neck turn only to the depth the bullet is seated.)

a) Begin turning the case neck again. Slow the cam feed when the cutter approaches the shoulder of the

case. When the cut almost blends with the shoulder angle, stop turning.

b) Set the case trimmer stop collar to stop the carbide cutter 1/16” from the shoulder of the case.

c) Adjust the Stop Collar Fine Adjustment Screw (13) as needed to blend the neck cut with the shoulder angle of

the case.

CAUTION — Do not cut into the shoulder of the case. The Outside Neck Turning accessory is now set up to turn

your entire lot of cases. Just repeat steps #2 and #7 of the Neck Turning Instructions for each case. Measure the turned

neck diameter occasionally to ensure accuracy. You are now on your way to greatly improved accuracy.

The Outside Neck Turner will turn 17 caliber cases to 375 caliber cases. A special, hardened and precision ground pilot for the

Outside Neck Turner must be used in place of the regular Case Trimmer Pilot. 375 Magnum or longer cases should be turned on an

extra long case trimmer base. (See catalog.) Outside Neck Turner Pilots are available in the following calibers: .170 (requires 17 caliber cutter shaft and 17 caliber carbide cutter, see catalog), .224, .243, .257, .263, .277, .284, .308, .311, .323, .333, .338, .358, .375.

CARTRIDGE MAXIMUM OUTSIDE NECK DIAMETERS

Compiled from SAAMI Drawings

Tolerance is +.000” - .008”

17 Remington .1990” 6.5 x 55 Swede .2970” 300 H&H .3380”

22 Hornet .2425” 25-06 .2900” 300 Win. Mag. .3397”

222 Remington .2530” 257 Roberts .2900” 30-06 .3397”

223 Remington .2530” 270 Weatherby .3050” 308 Winchester .3435”

22-250 Rem. .2540” 270 Winchester .3080” 8 x 57 Mauser .3493”

220 Swift .2600” 7mm-08 Rem. .3150” 8mm Rem. Mag. .3541”

243 Winchester .2760” 7mm. Rem. Mag. .3150” 338 Win. Mag. .3690”

244 Remington .2760” 280 Remington .3150” 375 Weatherby .4030”

257 Weatherby .2850” 7 x 57 Mauser .3207” 378 Weatherby .4030”

Thank you for purchasing a Forster Precision Product. Please wear safety glasses.

Forster Catalogs available upon request.

OT1010-002 Rev. 1

1)

2)

3)

4)

5)

6)

7)

8)

9)

10)

Page 2

Loading...

Loading...