Redwood Global Ltd,

Unit 86, Livingstone Road, Walworth Business Park, Andover,

Hampshire. SP10 5NS. United Kingdom

PT6

Woodchipper

USER MANUAL

ENGLISH

3/12/2015 Revision 0

P a g e | 1

Table of Contents

Introduction ........................................................................................................................... 3

Purpose of machine .............................................................................................................. 4

Exterior component identification .......................................................................................... 5

Safe working ..................................................................................................................................... 6

Machine lifting ................................................................................................................................... 7

DOs and DON’Ts ............................................................................................................................. 8

Noise test information ........................................................................................................... 9

Machine operation .............................................................................................................. 10

Machine control panel, start/stop & operating settings ............................................................ 11

Feed speed adjustment ................................................................................................................. 13

Feed jam & blockages ......................................................................................................... 13

Attaching to the Tractor ................................................................................................................. 15

Transportation ..................................................................................................................... 15

Stopping the Chipper ..................................................................................................................... 15

Disconnecting from the Tractor ........................................................................................... 16

Routine maintenance .......................................................................................................... 16

Fastener tightening torques .......................................................................................................... 17

Blade sharpening ........................................................................................................................... 19

Hydraulic oil filter ............................................................................................................................ 20

Drive belt tension ............................................................................................................................ 22

Hopper tray touch sensor .......................................................................................................... 23

Chipping chamber assembly ........................................................................................................ 24

Chipping chamber assembly - Bottom feed. ............................................................................. 24

Chipping chamber assembly - Bottom feed & anvil. ................................................................ 26

Chipping chamber assembly - Drive .......................................................................................... 27

Chipping chamber assembly - Flywheel drive. ......................................................................... 28

Chipping chamber assembly - Bottom feed roller cover. ........................................................ 29

Chute assembly ............................................................................................................................ 30

Top feed roller assembly ............................................................................................................... 31

Flywheel assembly ......................................................................................................................... 32

Flywheel belt tensioner assembly ........................................................................................... 33

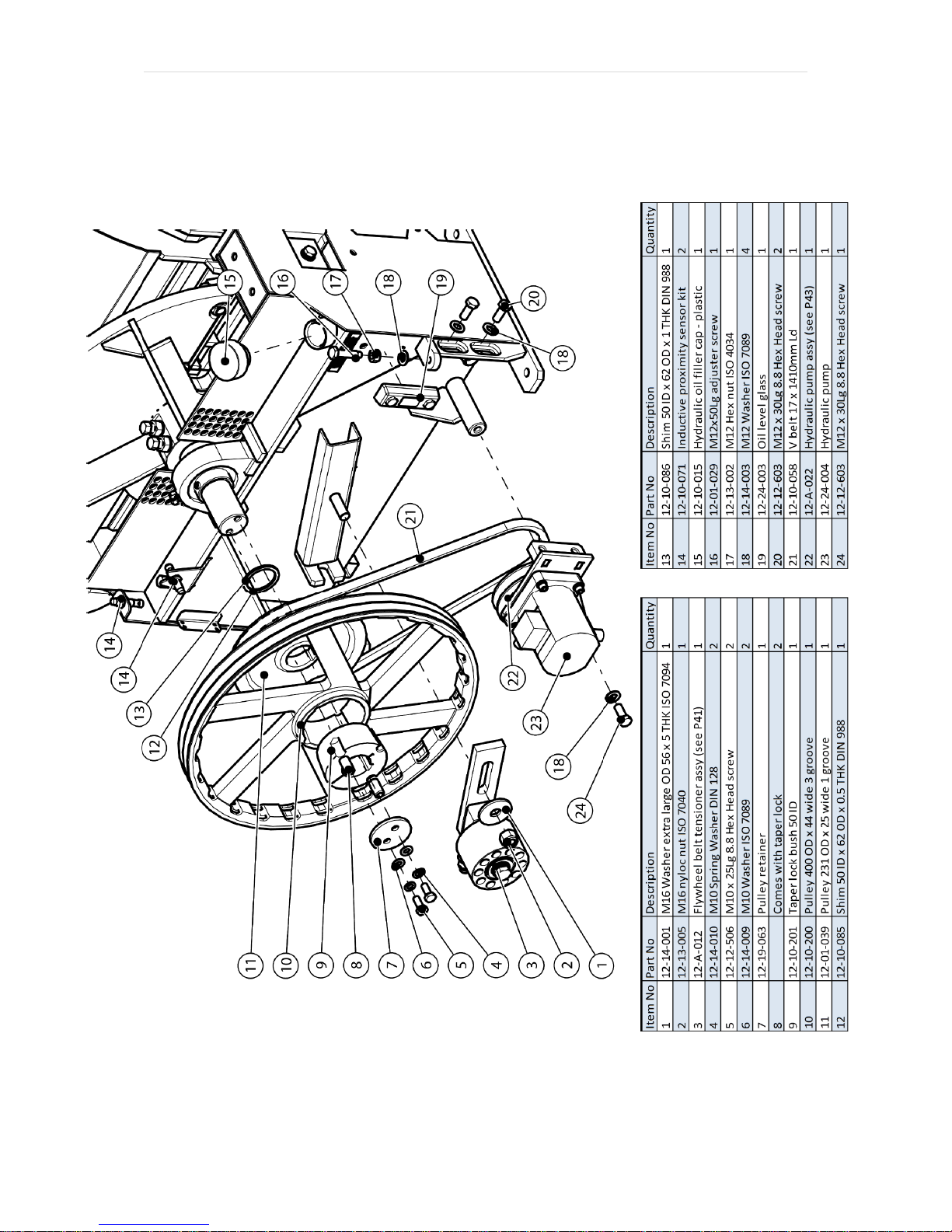

Hydraulic pump assembly ......................................................................................................... 34

PTO Assembly Parts………………………………………………………………..………………35

Hydraulics circuit diagram ................................ ................................................................ ... 36

Electrical circuit diagram – PTO touch sensor hopper ......................................................... 37

P a g e | 2

Decals ................................................................................................................................. 38

Manufacturer’s Statutory Plate ............................................................................................ 39

Warranty ............................................................................................................................. 40

CE Certificate ...................................................................................................................... 41

P a g e | 3

Introduction

Thank you for becoming the owner of this Redwood Global Ltd, Forst PT6

woodchipping machine. By observing the contents of this manual, we hope the

machine gives safe and productive service. This user manual is intended for the

owner/operator to safely and effectively operate this machine and carry out routine

maintenance between services. This is not a comprehensive service manual. See

Service Schedule for routine maintenance and when to take the machine to a service

specialist. For engine maintenance, please refer to the engine manual supplied with

this machine.

This machine has been through a pre-delivery inspection before leaving the factory

and is ready to use.

Before use and as a minimum, the safety and machine operation

sections covered on pages 4 to 13 must be read and understood.

Failure to do so could result in serious injury or loss of life to the

operator and others nearby. Also, damage to property and this machine may

occur. Please observe and obey all warning signs (decals) located on the machine.

Their meaning is covered in this manual under decals.

All personnel working with this machine must be adequately trained in its use and

most importantly, follow the advice on safe working practices.

Redwood Global Ltd endeavour to continuously develop and improve its products.

They reserve the right to make changes at any time, without notice or incurring any

obligation.

Continuous improvement will affect machine design and production so there may be

minor discrepancies between the actual product and this manual.

This manual must remain with the machine for reference by operators and includes

hiring or if the machine is resold.

P a g e | 4

Purpose of machine

The Forst PT6 is designed to reduce wood material up to 150mm diameter to

woodchip. This machine is capable of processing up to 5 tonnes of wood per hour.

Power source

Tractor PTO Roller feed

Twin series hydraulic motors

PTO speed

540rpm

Maximum material diameter

150mm

Required engine hp

25-50hp

Hydraulic oil capacity

20 litres

Overall weight

630kg

Material processing capacity

5 Tonnes/Hr

3 Point Mounting

CAT. 1 / 2

P a g e | 5

Exterior component identification

Figure 1

ITEM NO.

PART DESCRIPTION

1

Trip Bar

2

Control Valve Feed Speed Adjustment

3

Hopper Tray latch

4

Hopper

5

Chipping Chamber Cover

6

Chute Hood

7

Chute Chamber Cover

8

Machine Lifting Eye

9

Chipping Chamber

10

Grease Point

11

Control Panel

12

Feed Start/Stop Touch Sensors

13

Hopper Tray

P a g e | 6

Safety

Safe working

Before using this machine, make sure that you are trained and fluent in its operation.

Know the location of and how to use all the safety features. Know how to control the

feed and stop the machine in an emergency. Be familiar with the hazards and safe

working practices to prevent injury and damage to property and machine. Also be

aware of the legal restrictions for personnel and towing with vehicles.

1. The minimum age for service personnel is 18 years. Personnel aged 16 can

use the machine for training under supervision by a suitably trained person of

18 years or over.

2. Operators and personnel working with this machine must not be under the

influence of alcohol, drugs or medication that would impair judgement,

concentration or reaction times. Excessive tiredness is also a risk.

3. In use, woodchip and debris are ejected with considerable force from the

chute and can travel up to 10m. Make sure the chute directs woodchip to a

safe location so that no one can be harmed or property damaged. Do not

allow discharge to be directed onto roads or public rights of way.

4. Maintain a 10m exclusion zone around the machine and clearly mark if in a

public area. Keep this area free of material build up.

5. Make sure the machine is on even, level and stable ground and cannot move

or topple when in use. Use wheel chocks if necessary.

6. Keep children and animals well away from the working area.

7. The machine operator must wear protective equipment:

a. Chainsaw safety helmet with mesh visor.

b. Correctly rated ear defenders.

c. Work gloves with elasticated wrist bands.

d. Steel toe cap boots.

e. Close fitting heavy duty non-snag clothing.

f. Protect breathing with a face mask if appropriate. Some plant material

can give off harmful dust and poisonous vapours. This may cause

respiratory problems or serious poisoning. Check the material to be

processed before starting.

g. DO NOT wear rings, bracelets, watches, jewellery or anything that

could be caught on the material being fed and draw you into the

machine.

8. All personnel operating or feeding material into the machine must wear heavy

duty non-snag clothing to help prevent being caught on material and drawn

into the machine. The feed mechanism of this machine uses high powered

hydraulic motors to drive sharp toothed rollers that feed material into the

cutting blades. DO NOT take risks with it. NEVER ASSIST ANY MATERIAL

INTO THE FEED ROLLERS WITH HANDS OR FEET. Use a push stick or

further long material if necessary.

P a g e | 7

9. Never climb onto the hopper area while the machine is in operation.

10. Material can be forcibly ejected from the hopper towards the operator. Ensure

full head and face protection is worn.

11. Very twisted material should be trimmed into manageable pieces. Failure to

do this can result in material extending outside the hopper, moving

aggressively side-to-side creating a hazard to the operator.

12. Do not try to force material over 150mm in diameter into the machine.

13. Carefully site the machine so operators can work furthest from any local

danger. For example, on a road side, place machine so operators work on

the verge and not in the road exposed to traffic.

Machine lifting

The lifting eye is designed for securely holding the machine’s weight only. Do not

use hoist hook directly on the lifting eye. Use a correctly rated safety shackle.

Inspect lifting eye before each use and do not use if damaged.

Figure 2

P a g e | 8

DOs and DON’Ts

DO stop the machine before making

any adjustments, refuelling or

cleaning.

DO make sure the machine has

stopped rotating and remove the

ignition key before any maintenance or

the machine is left unattended.

DO ensure that the machine is level,

well supported and cannot move

during use.

DO run the machine at full throttle.

DO conduct regular machine checks

for visual fluid leaks.

DO take regular breaks. Wearing

protective equipment can be hot and

tiring leading to a lack of

concentration, increasing the risk of

having an accident.

DO keep hands, feet and clothing out

of feed area, chute and moving parts.

DO NOT use machine in poor visibility

or insufficient light to see clearly.

DO NOT use or attempt to start the

machine without the discharge chute

or guards correctly and securely fitted.

DO NOT stand in front of the chute.

DO NOT allow the following to enter

the machine as damage is likely:

BRICKS

METAL

STRING

GLASS

CLOTH

RUBBER

PLASTIC

ROOTS

STONES

BEDDING

PLANTS

DO NOT smoke when refuelling.

Diesel fuel is highly flammable and

explosive in certain conditions.

DO NOT let anyone who has not

received instruction, operate the

machine.

DO NOT climb on the machine at any

time except for a tracked machine

ride-on plate where fitted.

DO NOT handle material partially

engaged in the machine while in

operation.

DO NOT touch any exposed wiring

while the machine is running.

P a g e | 9

Noise test information

Machine

Forst PT6

Notes

Tested chipping 50 x 50mm sawn pine 4.2m in length.

Noise levels above 85dB (A) will be experienced at the working position and within a

4 metre radius. Operators and personnel within a 4 metre radius must wear

appropriate ear protection at all times while machine is in operation to prevent the

risk of hearing damage.

A-weighted emission sound pressure (beside operator’s ear) LpA = 111.7dB(A).

Peak C-weighted instantaneous sound pressure (beside operator’s ear) LCpeak =

136.7dB(C). Results at 10 metre radius are calculated.

Guaranteed sound power: 122dB(A)

As required by Machinery Directive 2006/42/EC “Noise Emission in the environment

by equipment for use outdoors.”

P a g e | 10

Machine operation

MACHINE USE

TOUCH SENSOR HOPPER

STAGE

1

Fold down hopper tray

Ensure Tactor and Chipper

are on leval ground

2

Ensure tractor horsepower and lift arm

capacity match that of the chipper

Start Tractor

3

Allow engine to run for 30 seconds then

open throttle to 540rpm

4

For forward feed, touch green button

twice 5Feed material

6

To stop, touch red button or push trip bar

7

To reverse feed, touch green button

once8To stop machine

9

Touch red button or push trip bar

10

Close throttle to minimum on the Tractor

11

Switch off ignition and remove key

12

Before transporting machine

14

Sweep out debris from hopper

15

Close hopper tray by lifting fully up

against stops and engage latch

P a g e | 11

Machine control panel, start/stop & operating settings

This machine is fitted with an engine PLC (Programmable Logic Controller) system

that manages the engine, feed and all safety features. The control panel is located

on the right side panel (see Figure 1). Feed and engine speed are controlled with a

“No Stress” function ensuring that cutting conditions are kept within optimum limits.

This maximises throughput while minimising jams and blockages. There will be

times when material is being cut and the feed will momentarily stop until engine

speed increases. At this point, the feed will start without warning. Service warnings

shown below will be displayed at certain intervals. The engine will not start until OK

is pressed.

First 20 Hour Warning: "Change Hydraulic Oil Filter"

Every 20 Hour Warning: "Blade and Machine check required see manual"

50 Hour Service Warning: "1st Full Service recommended"

Every 200 Hour Service Warning: "Full Service recommended"

Using the control panel:

Figure 3

ITEM NO.

PART NO.

1

Display Panel

P a g e | 12

When cable connected to Tractor Display will automatically go to P1

P1 shows Working Hours and charging indicator text at the screen bottom centre.

P2 shows I/O tests. Tests all functions and safety controls.

Pin screen

P3 shows No-Stress Settings

Actual RPM

Upper Band - 1400 RPM

Mid Band – 1125 RPM

Lower Band – 925 RPM

Pin screen automatically displays if any setting changes are attempted.

P a g e | 13

Feed speed adjustment

Figure 4

The feed speed can be adjusted to suit the material being chipped see Figure . Turn

dial to align number with pip. Set feed speed so that the No-Stress operates as little

as possible, this will give the highest throughput. When feeding Leylandii or leafy

material, set feed roller speed to 4.5.

Feed jam & blockages

Be aware that whatever is fed into the machine has to come out of the chute.

Always monitor the state of chip flow out of the chute. If this stops, STOP FEEDING

MATERIAL IMMEDIATELY. Continuing to feed material will further compact a

blockage and make it more difficult to clear.

If the chipping chamber or chute become blocked:

1. Stop the engine and remove ignition key.

2. Remove chute and check that it is clear.

3. If the chipping chamber is blocked, open the engine cover, then chipping

chamber cover. DO NOT REACH INTO THE CHIPPING CHAMBER WITH

HANDS. Beware that the flywheel within the chipping chamber has two sharp

blades mounted on it and can move causing a serious injury risk. Wearing

protective gloves and using a piece of wood, carefully clean out the chipping

chamber.

1

CONTROL VALVE FEED SPEED

ADJUSTMENT.

POSITION INDICATED BY PIP.

0 = MINIMUM

10 = MAXIMUM

P a g e | 14

If feed becomes jammed:

1. Stop the engine and remove ignition key.

2. Open engine and chipping chamber covers.

3. Release feed roller spring tension on both sides by slackening off the eye bolt

nuts and remove if necessary.

4. Insert feed lift tool and lift top feed roller to fully open.

5. Insert M12 screw into side of feed chamber and screw completely in. Lower

top feed roller onto the screw to secure in the open position.

6. There should now be access to the feed chamber. Beware that this is the

machines cutting zone. The top and bottom feed rollers have sharp teeth and

the flywheel cutting blades are not far from them. DO NOT PUT HANDS

INTO THIS AREA. Wearing protective gloves and using a piece of wood,

carefully clear jammed material inside feed chamber.

7. When clear, lift top feed roller via lifting tool, remove top feed M12 securing

screw, lower top feed roller and remove lifting tool.

8. Re-assemble feed tensioner springs and replace covers.

Figure 5

1

REMOVE EYE BOLT NUT BOTH

SIDES BEFORE LIFTING FEED

ROLLER

2

INSERT TOP FEED ROLLER

LIFTING TOOL INTO SLOT AND

LIFT

3

INSERT M12 SCREW TO HOLD

FEED IN OPEN POSITION

P a g e | 15

Attaching to the Tractor

Ensure tractor horsepower and lift arm capacity are matched to the chipper

and has a PTO speed of 540rpm

Ensure both tractor and chipper are on level ground

Attach chipper to 3 point linkage, making sure lower arms are the same

length

Attach and adjust top arm on the tractor making sure the chipper is level

Ensure tractor is turned off, ignition key removed and handbrake applied

Connect PTO shaft to Tractor and chipper

Connect power cable from the chipper to the tractor socket

Ensure all PTO guards on tractor, chipper and PTO shaft are all in place with

guard chains attached to prevent rotation.

Engage the PTO shaft on the Tractor and slowly increase the speed to 540

RPM.

Connecting the PTO Shaft

Check the angle of the PTO shaft, never goes beyond 16° when PTO shaft is

rotating and when lifted never goes beyond 40°

Ensure that the two halves of the PTO shaft have at least 150mm overlap

and when lifted, be of a suitable length so as not to butt up against each other

Caution The PTO shaft is protected with a shear bolt, this end of the shaft

must be attached to the tractor PTO.

Transportation

Do Not move the chipper with the PTO engaged

Clear machine of loose woodchip material before departing.

Ensure the chute is securely fixed at the inboard position before departing.

Ensure that the hopper tray is closed in the up position and the locking latch

is fully engaged before departing.

Stopping the Chipper

Push rear stop bar or touch red stop button

Set tractor throttle to idle

Turn off Tractor engine and remove ignition key

When engine stationary disengage PTO shaft

Warning Never disengage PTO shaft when tractor running as chipper flywheel

will continue to run after engine has stopped

P a g e | 16

Disconnecting from the Tractor

Ensure both tractor and chipper are on level ground

Ensure The tractor PTO is disengaged and handbrake applied

Lower the chipper to the ground, making sure the chipper is stable on the

ground

Turn off Tractor engine and remove ignition key

Disconnect the PTO shaft and unplug the power cable from the tractor

Uncouple the chipper from the 3 point linkage on the tractor

Routine maintenance

The following must be checked at least on a daily basis during use (also see Service

schedule):

Check hydraulic oil level. When the machine is new, the oil level may drop

during initial use. Regularly check and top-up until level settles. If a top up is

required, thoroughly clean around filler cap before removing to help prevent

debris falling into oil tank, top up as required and replace filler cap.

Grease machine. Every 8 hours, one pump of grease to each of the four

nipples at the central grease point manifold located near the control panel.

See Figure 1.

Check all fasteners are present and assembled to the correct torque.

Check proximity sensors on engine cover, removable hopper and trip bar are

not damaged and working correctly. The trip bar sensor is the most

vulnerable and if severely damaged could result in the trip bar not working.

Check drive belt tension and adjust as necessary.

Check pulleys and taper lock on flywheel shaft.

Check flywheel blades for damage and sharpness. Machine performance is

adversely affected if blades are blunt or damaged. Replace and sharpen

blades as required. Make sure that the blade seat is clean and free of

damage before reassembly. Shims are available to adjust for blade size

reduction after sharpening. Please refer to blade sharpening for size limits,

adjustment shims and setting. Ensure blade fasteners are correctly installed

and tightened to the appropriate torque. Check after 1 hours’ work then

weekly.

Anvil and side anvil are replaceable and double sided. Make sure that the

anvil seat is clean and free of damage before reassembly.

Exercise extreme care to avoid injury when removing and replacing blades

and anvils. The flywheel can turn creating crush and cutting points in and

around the chipping chamber.

P a g e | 17

Check all hydraulic hoses and fittings after 5 hours’ work. Beware of hydraulic

oil leaks, they can cause serious injury while the engine is running and the

system is under pressure. A leak can easily inject high pressure oil deep into

flesh and blood stream requiring immediate medical attention. DO NOT

CHECK FOR LEAKS WHILE THE PTO IS ENGAGED. Hoses to the feed

roller hydraulic motors are the most likely to become damaged as they are

constantly moving during use. If hoses are replaced, all seals must be

replaced at the same time.

Check top and bottom feed motor bracket bolts weekly.

Fastener tightening torques

Nominal

torque

Nm

Max/Min

torque

Nominal

torque

Nm

Max/Min

torque

Size

M6 10 9.5/10.4 14.5 14/15.3

M8 25 23.1/25.3 35 34/37.2

M10 49 46/51 72 68/75

M12 86 80/87 125 117/128

M12x1.5 wheel screws 95 90/100

M16 210 194/214 310 285/314

M20 410 392/431 610 558/615

M24 710 675/743 1050 961/1059

Class 8.8

Class 10.9

Tightening torques for class 8.8 and 10.9 fasteners

All machine fastener torques should be regularly checked to the above table. In

particular, those for the flywheel blades, flywheel bearings, axle assembly, hitch,

road wheels and engine mounts.

P a g e | 18

Service schedule

Wood chipper

After first

5 Hrs

Every 8

Hrs

(Daily)

After first

10 Hrs

After first

20 Hrs

Every 20

Hrs

After first

50 Hrs

Every 50

Hrs

(weekly)

Every

100 Hrs

(2 weeks)

Every

200 Hrs

(monthly)

Every

250 Hrs

(monthly)

Check the 3 point

linkage points

●

Tighten hydraulic fittings

●

Check fasteners

●

Visual check for fluid

leaks

●

Check drive belts

●

Grease via central point

on control panel

●

Grease PTO shaft

couplings

●

Change hydraulic filter

cartridge

●

Check flywheel shaft

bearings

●

Check cutting blade &

anvil condition, change if

required

●

Check feed roller

tension springs &

replace if required

●

Service Schedule

Service schedule

Wood chipper

Every

400 Hrs

Every

500 Hrs

Every

800 Hrs

Every

1000 Hrs

Every

1500 Hrs

Every

2000 Hrs

Every

3000 Hrs

Every 12

months

Every 2

years

Every 5

years

Change feed roller

bearings on motor side

●

Change hydraulic filter

cartridge

●

Change hydraulic oil

●

Get the machine

overhauled by a service

specialist

●

Check wiring for

damage & loose

connections

●

Change hydraulic hoses

●

Service Schedule

P a g e | 19

Blade sharpening

For optimum performance, blades need to be kept sharp. Minimum safe blade size

after sharpening as shown. After sharpening, the blade gap must be re-set by using

a blade shim as shown. Shims are available in thicknesses of 0.5, 1, 1.5, 2 & 2.5mm

as part number 12-03-093. On no occasion must more than one shim be fitted under

each blade at any time. A gap of 1mm must be set from the inner blade tip to anvil

after sharpening by placing an appropriate shim under the blade (also see flywheel

assembly). The outer blade tip is automatically set due to the anvil being set at an

angle to the blade. With 1mm at the inner blade tip, the outer blade tip should be

3mm from the anvil as shown.

The complete blade fastener set must be replaced every time blades are changed.

DO NOT Lubricate the Bolts when fitting.

Figure 6 Figure 7

Blade sharpening limit

80mm to 60mm

1

Flywheel

2

Flywheel blade

3

Blade shim

4

M16 10.9 hex nut

5

M16 x 45Lg 10.9 CSK

hex socket screw

6

M16 serrated lock

washer

P a g e | 20

Figure 8

Hydraulic oil filter

1

SIDE ANVIL

2

ANVIL

3

OUTSIDE BLADE GAP

4

FLYWHEEL BLADE

5

INSIDE BLADE GAP

Item Description Quantity

1 Complete filter 1

2 Filter element 1

3 Seal kits 1

3a O-ring for filter element 1

3b O-ring for housing 1

3c Anti-extrusion ring 1

3d Gasket 1

3e O-ring 1

3f Protection seal 1

4 Indicator plug 1

P a g e | 21

Use protective plastic gloves to keep oil off skin, dispose of oil and filter in an

environmentally responsible manner.

1. The filter housing is accessed via the left side panel. Thoroughly clean around

filler housing before removing to help prevent debris getting into oil.

2. Unscrew filter housing body, remove filter element and allow to drain for 15

minutes before disposal.

3. Screw on and tighten filter body with new filter into filter housing.

Oils, Fluids and Lubricants.

Hydraulic Oil: ISO VG 46.

It is advised that the oil is checked and topped up to the RED LINE on the sight

glass, when the machine is cold and on a flat surface.

Gearbox Oil: SAE90 – 0.75 Litre

Grease: Lithium EP2 General Purpose.

1

UNSCREW FILTER

BODY TO REPLACE

FILTER ELEMENT

P a g e | 22

Drive belt tension

Both Hydraulic pump and flywheel V belts must be checked for tension and

condition. If any belt shows signs of wear, surface damage, shredding, excessive

glazing, or have been stretched to their limit, they must be replaced. Multiple belt

drives must have all belts replaced at the same time. Belts that are too slack will

cause poor cutting performance, excessive belt and pulley wear.

All drive belts are located under the engine cover as shown in and tension checked

at arrows as shown. Check and set tension as follows:

1. Slacken clamp screw(s) or nut.

2. Hydraulic pump adjuster screw requires its lock nut to be slackened.

3. Turn adjuster nut or screw to tension belt until 4.5Kg force at the belt longest

centre span deflects by 6mm. Can be approximated by firmly gripping belt

between finger and thumb and twisting. The belt should not be able to be

rotated more than 90°.

4. Tighten all lock nuts, nuts and clamp screws.

5. Run machine and test.

6. Check belt tension.

Figure 9

1

FLYWHEEL DRIVE BELTS. CHECK TENSION HERE

2

HYDRAULIC PUMP DRIVE BELT. CHECK TENSION HERE

3

HYDRAULIC OIL LEVEL IN SIGHT GLASS

P a g e | 23

Parts lists

Hopper tray touch sensor

P a g e | 24

Chipping chamber assembly

P a g e | 25

Chipping chamber assembly - Bottom feed.

P a g e | 26

Chipping chamber assembly - Bottom feed & anvil.

P a g e | 27

Chipping chamber assembly - Drive

P a g e | 28

Chipping chamber assembly - Flywheel drive.

Item No Part No Description Quantity

1 12-10-056 V belt 17 x 1975mm Ld 3

P a g e | 29

Chipping chamber assembly - Bottom feed roller cover.

TOP

Item No Part No Description Quantity

1 12-12-504 M10 x 20Lg 8.8 Hex Head screw 2

2 12-14-010 M10 Spring Washer DIN 128 2

3 12-14-009 M10 Washer ISO 7089 2

4 12-03-045 Feed roller cover 1

P a g e | 30

Chute assembly

Item No Part No Description Quantity

1 12-19-056 Chute clamp fab assy 2

2 12-20-001 Spring Pin Slotted 10 DIA x 30Lg ISO 8752 2

3 12-10-005 M16 T bar screw 2

4 12-19-051 Chute fab assy 1

5 12-11-007 Plain bearing 12 ID, 16 OD, 22 flange x 10 Lg 4

6 12-14-003 M12 Washer ISO 7089 6

7 12-13-003 M12 nyloc nut ISO 7040 3

8 12-01-043 Hood hinge stud 1

9 12-19-151 Chute hood fab assy 1

10 12-30-024 Forst small orange decal 2

11 12-15-020 M12 Elastomer washer OD 25-ID 12 x 5 THK 2

12 12-19-055 Chute handle - standard 1

13 12-10-004 M12 female steel handle 1

14 12-14-004 M12 Washer extra large OD 44 x 4 THK ISO 7094 2

P a g e | 31

Top feed roller assembly

P a g e | 32

Flywheel assembly

BLADE SHIM THICKNESS AVAILABLE

Part No

Thickness

12-03-093.05

0.5mm

12-03-093.10

1mm

12-03-093.15

1.5mm

12-03-093.20

2mm

12-03-093.25

2.5mm

Note: Blade Bolt Set (Bolt, Washer & Nut) Part No

99-99-099

P a g e | 33

Flywheel belt tensioner assembly

Item No Part No Description Quantity

1 12-12-1104 M16 x 110Lg 8.8 Hex Head bolt 1

2 12-14-019 M16 Spring washer DIN 128 1

3 12-14-005 M16 Washer ISO 7089 3

3a 10mm Spacer between 3 and 8 1

4 12-11-011 6304 2RS Deep groove ball bearing 52 OD, 20 ID, 15 wide 2

5 12-01-036 Flat idler pulley-2x 17 V belt 1

6 12-01-024 Flat idler pulley shaft-2x 17 V belt 1

7 12-13-005 M16 nyloc nut ISO 7040 1

8 12-19-062 Tensioner slide fab assy 1

P a g e | 34

Hydraulic pump assembly

P a g e | 35

PTO Assembly parts drawing

ITEM

NO.

PART NO.

PART DESCRIPTION

QTY

1

20-19-006

Structural Top Subassembly

1

2

16-10-010

Gearbox

1

3

20-A-000

Chipper Assembly

1

4

20-19-004

Base Subassembly

1

5

12-14-003

M12 Washer

16

6

12-12-303

M6 x 16 Socket Button Head

Screw

9

7

20-19-005

Feed Brace Subassembly

1

8

12-13-003

M12 nyloc nut

6

9

12-12-306

M6x30 Cap Head

4

10

12-12-601

M12 x 50 8.8 Hex Head screw

10

11

12-14-017

M6 Washer

13

12

12-12-506

M10x30 Hex Head

4

13

12-13-010

M10 Nyloc Nut

6

14

12-14-009

M10 Washer

10

15

16-10-011

PTO Shaft

1

P a g e | 36

Hydraulics circuit diagram

1

Motor

2

Control valve

3

Test point

4

Filter

5

Pump

6

Oil tank

P a g e | 37

Electrical circuit diagram – PTO touch sensor hopper

P a g e | 38

Decals

Decal meaning:

1. Throttle movement relation to engine speed.

2. CE (Conformite Europeene or European Conformity) mark. Manufacturer’s

declaration that the product complies with the essential requirements of the

relevant European health, safety and environment protection legislation.

3. Ignition switch stop.

4. Hearing and eye protection of an appropriate specification to be worn.

5. Finger and toe amputation hazard.

6. Refer to user manual.

7. Allow machine to stop before touching.

8. Danger from flying objects.

9. Do not open or remove covers while engine is running.

10. Keep away from rotating machine parts.

11. Push to stop, trip bar operation.

These decals are placed on the machine where the hazard or information applies.

P a g e | 39

Manufacturer’s Statutory Plate

Information on the Manufacturer’s Statutory Plate in line order from top to bottom is

as follows:

1. Manufacturing company.

2. Vehicle type approval number and construction date.

3. 17 digit Vehicle Identification Number (VIN) construction.

4. Gross Vehicle Weight (GVW).

P a g e | 40

Warranty

Warranty statement

1. Redwood Global Ltd guarantee all Forst equipment supplied by them

against any defect in manufacture and assembly – this guarantee is for a

period of 12 months commencing on the date of sale to the first end user.

2. The guarantee will not apply to a failure where normal use has exhausted

the life of a component.

3. Engine units are covered independently by their respective manufacturer’s

warranties.

4. Redwood Global Ltd’s liability under this guarantee is limited to repair at

Redwood Global Ltd’s premises or at a selected Forst dealer.

5. No liability will be accepted for consequential lost or damage of any kind.

6. The Redwood Global Ltd guarantee is restricted to the first Redwood

Global Ltd user only and is not transferable except when authorized by

Redwood Global Ltd.

7. The owner is responsible to make sure the machine is operated at all

times in accordance with the user manual.

8. The Redwood Global Ltd guarantee will be invalidated if any of the

following points apply:

Failure to use genuine Forst parts

Failure to perform routine servicing and maintenance

Failed parts or assembly have been interfered with

Machine has been modified without written approval from Redwood

Global Ltd

Machine has been used to performed tasks contrary to those stated

in the Redwood Global Ltd User Manual

Exclusions to the above warranty terms are – fair wear and tear on

fuses and bulbs, tyres and brakes, lubrications and filters, blades

and anvils, feed rollers and paintwork.

Where an extended warranty has been given this will be stated on

the original machine invoice and will be subject to further conditions

as stated in our supplementary warranty terms

Warranty claims

To obtain warranty service please contact Redwood Global Ltd for the nearest

approved Forst Dealer. Your nearest dealer can be obtained from Redwood Global

Ltd at the address on the front of the User Manual. In the event of a failure Redwood

Global Ltd must be notified within 7 working days.

P a g e | 41

CE Certificate

CERTIFICATE & DECLARATION OF CONFORMITY

FOR CE MARKING

Company contact details:

Redwood Global Ltd,

Unit 86, Livingstone Road, Walworth Business Park, Andover,

Hampshire. SP10 5NS. United Kingdom

Redwood Global Ltd declares that their:

Wood Chippers listed as the following models

ST6 Towed & TR6 on Tracks

ST8 Towed & TR8 on Tracks

PT6 PTO & PT8 PTO

are classified within the following EU Directives:

Machinery Directive 2006/42/EC

Electromagnetic Compatibility Directive 2004/108/EC

and further conform with the following EU Harmonized Standards:

EN13525:2005 + A2:2009

EN 982:1996+A1:2008

EN ISO 12100:2010

EN ISO 14982:2009

Dated: …………………………

Position of signatory: Managing Partner

Name of Signatory: Raymond Gardner

Signed below:

…….……………………………….

on behalf of Redwood Global Ltd

Loading...

Loading...