This picture shows

CT 6,5–10 D

INSTRUCTION BOOK

FARMA T 10

SERVICE AND SPARE PARTS

TABLE OF CONTENTS

1 INTRODUCTION.................................................................................................. 1

2 TECHNICAL SPECIFICATION............................................................................. 2

2.1. CONSTRUCTION OF THE TRAILER........................................................... 2

2.2. SPAREPART LIST FOR TRAILER T 10 ....................................................... 4

2.3. HYDRAULIC CYLINDERS ........................................................................... 5

2.4. TECHNICAL DATA....................................................................................... 6

3 OPERATING INSTRUCTIONS............................................................................. 7

3.1. SAFETY ....................................................................................................... 7

3.2. INSTRUCTIONS FOR SAFE OPERATION .................................................. 8

3.3. WORKING AT EXTREME CONDITIONS ..................................................... 9

4 MAINTENANCE INSTRUCTIONS........................................................................ 9

TRAILER T 10

4.1. SAFETY ....................................................................................................... 9

4.2. LUBRICATION ........................................................................................... 10

© 2005 FORS MW Ltd www.forsmw.com Page i

1 INTRODUCTION

This manual deals with the T 10 forest trailer and

contains all the operating and maintenance

instructions you need for using the trailer safely

and correctly.

Even if you are experienced user of this kind of

equipment, read this manual carefully.

It contains information that enables the trailer to

be used efficiently and safely. Make sure that

this trailer corresponds to your demands.

Regular maintenance is essential for troublefree,

efficient and economical utilization.

It is the operator duty to familiarize and obey all

TRAILER T 10

safety precautions and instructions carefully

.

© 2005 FORS MW Ltd www.forsmw.com Page 1

2 TECHNICAL SPECIFICATION

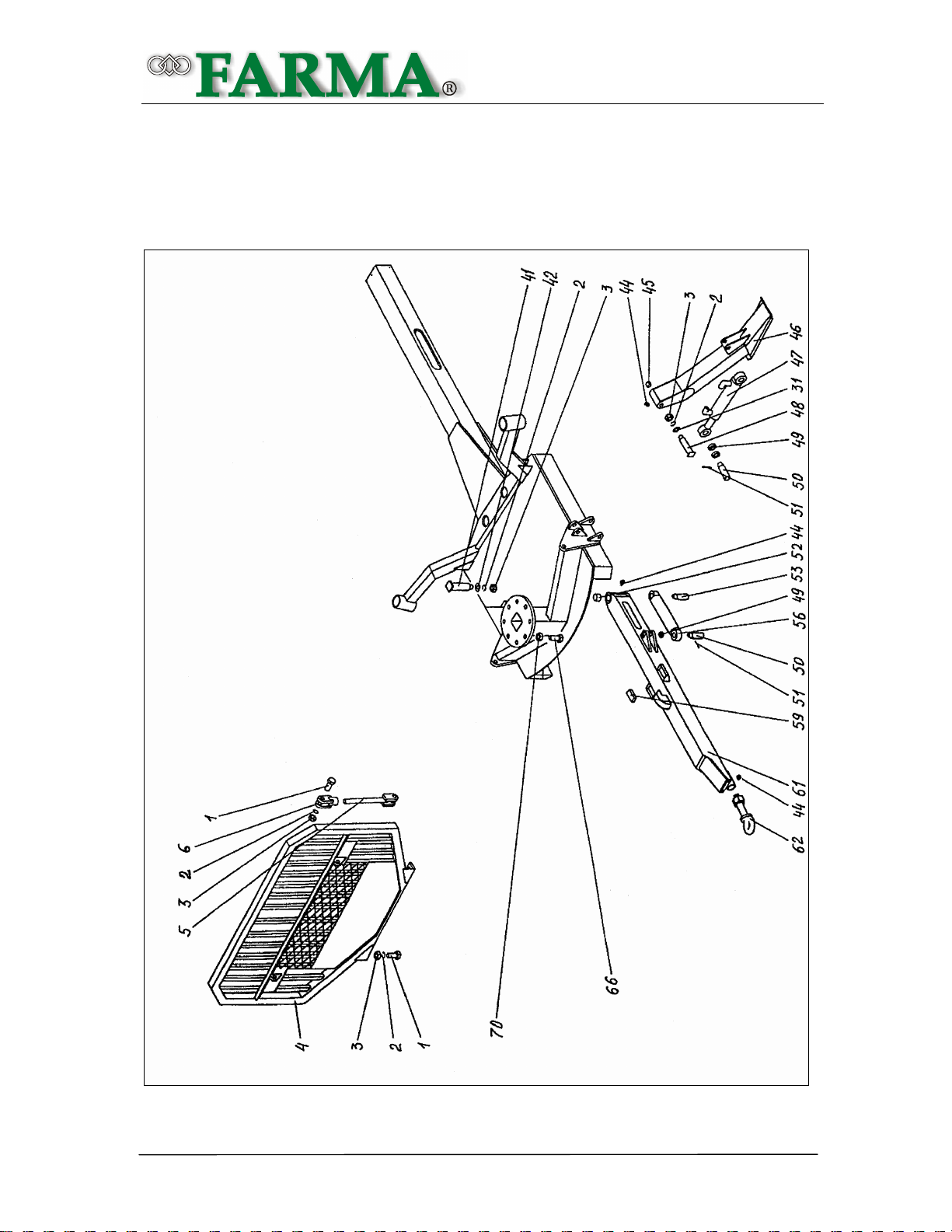

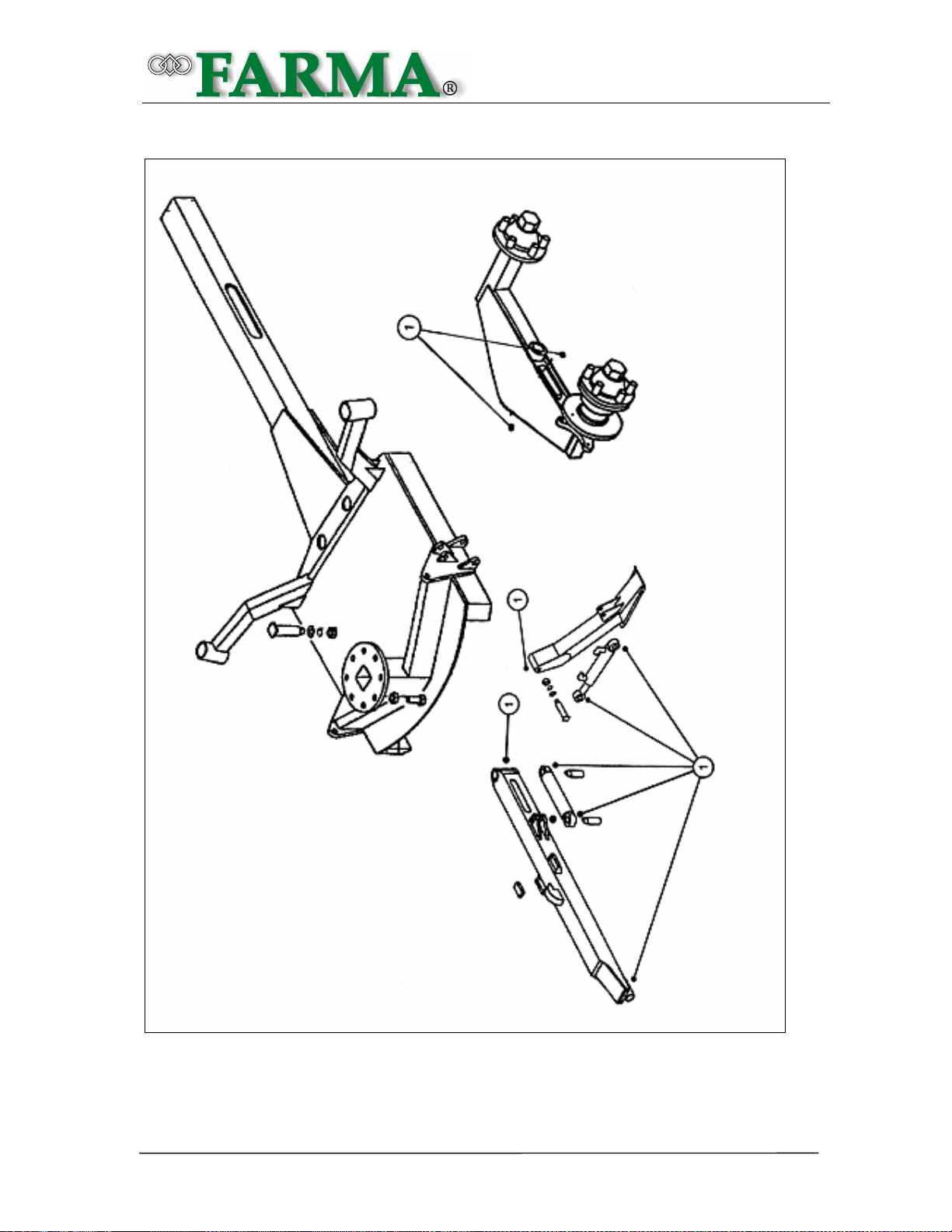

2.1. CONSTRUCTION OF THE TRAILER

TRAILER T 10

© 2005 FORS MW Ltd www.forsmw.com Page 2

TRAILER T 10

© 2005 FORS MW Ltd www.forsmw.com Page 3

TRAILER T 10

2.2. SPAREPART LIST FOR TRAILER T 10

Pos no Art no Number Sparepart Dimension Pcs

1 10001 Bolt M24×80 M6S 8.8 Zn ISO 4017 6

2 10002 Spring washer 24,5x40,0x5 DIN 127B 13

3 10003 Nut M24 M6M-8 Zn ISO 4032 16

4 10004 FMW10-080000.000 Railing 1

5 10005 FMW10-070003.000 Tie rod 2

6 10006 FMW10-070004.000 Lug nut 2

23 10007 Bolt M10x25 M6S8,8 Zn ISO 4017 26

24 10008 Spring washer 10,2x18,1x2,2 Zn DIN 127B 34

25 10009 Plane washer 10,5x20x2 Zn DIN 125A 15

41 10010 FMW10-100004.000-040 Pin 1

42 10011 MAP13-000000.001 Washer 3

44 10012 Grease nipple 1/8 inch BSP 10

45 10013 Bush Ø35x30 8

46 10014 FMW10-140000.000 Stabilizator left 1

- 10015 FMW10-140000.000-010 Stabilizator right 1

47 10016 FMW10-100200.000 Hydraulic cylinder 2

90x40x300

48 10017 MAP13-010050.000-050 Pin 2

49 10018 MAP13-000000.017 Distance ring 12

50 10019 MAP13-000000.002 Pin 5

51 10020 Split pin 4x50 Zn DIN 94 10

52 10021 Bush Ø50x40 6

53 10022 MAP13-000000.002-020 Pin 1

56 10023 MAP13-100100.000 Hydraulic cylinder 1

90x40x200

59 10024 FMW 10-070000.002 Glide plastic 2

61 10025 FMW 10-050000.000 Tow 1

62 10026 FMW13-000010.000 Pull-loop 1

66 10027 Bolt M20x80 M6S 8.8 Zn ISO4017 8

70 10028 Lock nut M20 Zn DIN 985 8

72 10029 FMW 10-071007.005 Cover 2

73 10030 ESH 3635.03 Electric control 1

79 10031 FMW 10-060000.000 Wheel support 1

80 10032 Bolt M24x60M6S 8.8 Zn ISO 4017 1

81 10033 FMW13-150000.000 Column 8

82 10034 FMW 10-070005.000 Plug 1

83 10035 FMW 10-070000.001 Plate 1

87 10036 MAP13-000030.000-030 Pin 2

89 10037 Wheel nut 24

90 10038 Wheel left 400/60-15,5/14PR Trac 2

- 10039 Wheel right 400/60-15,5/14PR Trac 2

91 10040 MAP 13-090000.000-030 Boggie side, left 1

- 10041 MAP 13-090000.000-031 Boggie side, right 1

92 10042 Positive hydr caliper 2 60 INPI 2

93 10043 FMW 13-190000.001-010 Casing left 1

- 10044 FMW 13-190000.001 Casing right 1

95 10045 Nut M16 M6M Zn ISO 4080 4

96 10046 Spring washer 16,2x27,6x3,5 DIN 127B 4

97 10047 Bolt M16x70 M6S 8.8 Zn ISO 4017 4

© 2005 FORS MW Ltd www.forsmw.com Page 4

TRAILER T 10

2.3. HYDRAULIC CYLINDERS

Sparepartlist for Hydraulic-cylinder 90/40-200

Frame steering cyl for 9; 10 trailer

Production no M13-100200.000.

Pos Art no Number Sparepart Dimension Pcs

1 56201 M13-100120.000 Piston road 1

2 56202 M13-100110.000 Tube 1

4 56203 F13-100100.001 Front bush 1

5 56204 F13-100100.002 Piston 1

8 56205 Scrape-ring AS40-50-7-10 1

9 56206 Sealing NI 300 40-55-10 1

10 56207 Buch DFI 40-45-5,5 1

11 56208 Sealing Simco 5×2 90-70-33,8 1

13 56209 0-ring 79,2×5,7 1

14 56210 0-ring 40,2×3,0 1

15 56211 Sealing SRA 90-5,1-2 1

16 56212 Sealing SRI 40-2,6-1,5 2

19 56213 Lock-ring SGH 55 2

20 56214 Lock-ring SGA 87 1

21 56215 Lock-ring N° 72310 1

23 56216 Grease-nipple 1/8" 2

24 56217 Joint bearing GE35ES 2

© 2005 FORS MW Ltd www.forsmw.com Page 5

TRAILER T 10

Sparepartlist for Hydraulic-cylinder 90/40-300

Stabilizer cyl for Trailer T 10

Production no F10-100400.000

Pos Art no Number Sparepart Dimension Pcs

1 56401 F13-100410.000 Piston road 1

2 56402 F10-100220.000 Tube 1

4 56403 M13-100100.001 Front bush 1

5 56404 M13-100100.002 Piston 1

8 56405 Scrape-ring AS40-50-7-10 1

9 56406 Sealing NI 300 40-55-10 1

10 56407 Buch DFI 40-45-5,5 1

11 56408 Sealing

13 56409 0-ring 79,2×5,7 1

14 56410 0-ring 40,2×3,0 1

15 56411 Sealing SRA 90-5,1-1,5 1

16 56412 Sealing SRI 40-2,6-1,5 2

19 56413 Lock-ring SGH 55 2

20 56414 Lock-ring SGA 87 1

21 56415 Lock-ring N° 72290 1

23 56416 Grease-nipple 1/8" 2

24 56417 Joint bearing GE35ES 2

Simco 5×2 90-7033,8 1

2.4. TECHNICAL DATA

Loading capacity, t 10

Loading area, m2 2,6

Ground clearance, mm 530

Center beam, mm 160x160x16

Axle, mm 70x70

Length, m 5,8

Width, m 2,2

Tyres 400/60-15,5

Tyre pressure, bar 3,3 — 4,8

Max operation pressure for brakes, bar 145

Weight, kg 2 000

© 2005 FORS MW Ltd www.forsmw.com Page 6

3 OPERATING INSTRUCTIONS

3.1. SAFETY

Read the manual before operating the

trailer. Neglecting the instructions can

cause danger to operator and machine.

Operator must have sufficient training for

using this machine.

DON’T FORGET TO LIFT THE SUPPORT LEGS UP BEFORE

MOVING TO ANOTHER PLACE.

Operator must have full visibility all over

working area.

The vehicle must be on stable ground

and positioned securely. Support legs

Do not use the trailer until you are familiar

with the controls.

Before loading works, ensure there is no

one in danger zone (20 m).

must be used while loading to prevent

the trailer tipping over.

Use vehicles parking brakes during the

loading.

Do not exceed maximum loading values.

TRAILER T 10

© 2005 FORS MW Ltd www.forsmw.com Page 7

3.2. INSTRUCTIONS FOR SAFE OPERATION

SUPPORTING THE TRAILER

Always engage the base machines parking

brakes before loading. If necessary put

some obstacles in front of wheels.

DO NOT USE SUPPORT LEGS FOR LIFTING THE LOAD.

USE SUPPORT LEGS ONLY FOR SUPPORTING THE

TRAILER.

TRAILER T 10

Always use support legs. Make sure the

trailer is situated at firm terrain.

MANIPULATING THE HYDRAULIC FUNCTIONS

NEVER CONTROL THE HYDRAULIC FUNCTIONS FROM

ONE EXTREME POSITION TO ANOTHER WITH SPEED! THIS

MAY CAUSE OVERTURNING THE TRAILER.

Avoid loading on a slanted ground or at

least work with extreme cautiousness.

When working on a slanted surface load

less than usual.

ALWAYS ENGAGE THE BASE MACHINES PARKING BRAKES

BEFORE LOADING WORKS. IF NECESSARY PUT SOME

OBSTACLES IN FRONT OF WHEELS.

© 2005 FORS MW Ltd www.forsmw.com Page 8

3.3. WORKING AT EXTREME CONDITIONS

Recommended working temperature range for

trailer is –30°C up to +40°C.

Note that working at low temperatures

accelerates hydraulic gaskets wearing and

increases hydraulic hoses exposure to damages

and steel constructions exposure to brittle

fracture. Before start working at cold conditions

let the oil circulate freely through system a few

minutes.

4 MAINTENANCE INSTRUCTIONS

4.1. SAFETY

TRAILER T 10

Slowly drive every action through several times

so that gaskets come pliable before they

receive full pressure.

At exceptionally warm conditions beware of

hydraulic oils excessive heating. Too high oil

temperature (higher +80°C) degrades oil and

damages gaskets.

READ THE MAINTENANCE INSTRUCTIONS BEFORE

SERVICE OR MAINTENANCE WORKS. DO NOT ATTEMPT

TO PERFORM SUCH MAINTENANCE WORKS WHICH YOU

DO NOT FULLY UNDERSTAND

Repair all safety endangering defects

immediately.

Check that the trailer is on a level and

stable ground.

Use vehicles parking brake during

maintaining the trailer. Make sure that

nobody can unnecessarily have access

to trailers or vehicles controls.

Never attempt to do maintenance works

on the hydraulic system before you are

sure there is no pressure.

Do not tighten or repair a leaking

hydraulic couplings while the system is

pressurized.

Never attempt to localize a leakage from

hoses or connections by feeling with

hand. The high pressure oil jet can

penetrate skin and cause serious burns

and damages. High pressure oil is also

highly flammable.

Do not work under such device that is

sustained only by hydraulics. During

maintenance use supports.

Avoid getting oil into eyes. Use safety

goggles and gloves.

© 2005 FORS MW Ltd www.forsmw.com Page 9

4.2. LUBRICATION

TRAILER T 10

© 2005 FORS MW Ltd www.forsmw.com Page 10

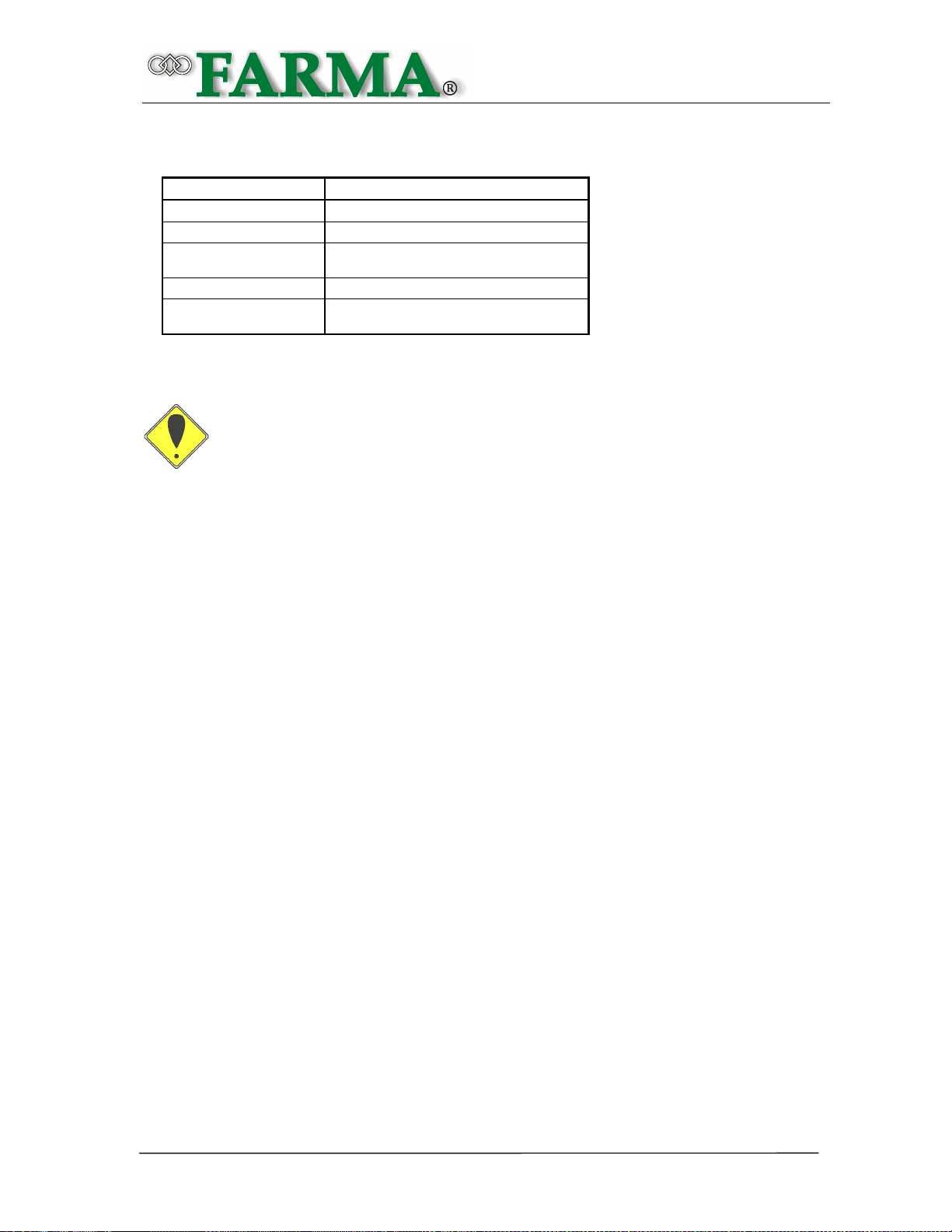

RECOMMENDED GREASES

BRAND TYPE

BP

ESSO

MOBIL

SHELL

UNION/TEXACO

Energrease LS-EP2, L2M

Beacon EP2, Multipurpose GR Moly

Mobilux EP2, Mobil Grease MP

Special

Alvania EP Grease 2

Marfak Multi-Purpose 2, Molytex

Grease 2

PAY SPECIAL ATTENTION TO THE TOWBAR CYLINDER.

GREASE IT AFTER EVERY 50 WORKING HOURS

SAFETY

Before any lubrication or service works

read these instructions and follow

recommended procedures.

When lubrication or servicing the trailer,

turn off the vehicle engine.

Ensure regularity of lubrication by

following the lubricating schedule.

Keep your hands, feet and loose clothing

away from power driven parts.

Inspect equipment daily for signs of failure

or beginning of failure.

Use proper tools for service.

Keep flammable material away from heat,

sparks and open fire.

Do not let oil get into nature. Oil spilled

into ground pollutes environment. It is

recommended to use vegetable-based oil

instead of mineral oil.

Pressurized oil can penetrate skin and

cause serious injures.

Hot oil and oil spray can be hazardous.

Small amounts swallowed or inhaled do

not usually cause intoxication. Old oil is

more dangerous than new.

Use safety goggles. If oil has got into eyes

flush them with cool water, after which go

to the doctor.

Although the occasional skin exposure

with oil is not dangerous it is

recommended to use protective gloves

and clothing.

TRAILER T 10

© 2005 FORS MW Ltd www.forsmw.com Page 11

Loading...

Loading...