Formsprag Long Life Holdbacks Series, LLH 700, LLH 1027 Service & Installation Instructions

P-222-14-FC

Bulletin 2224

Long Life Holdbacks

Model LLH™ 700 thru 1027

Service & Installation Instructions

Introduction

Formsprag LLH – Long Life Hold-backs are specifically

designed and built for head shaft mounting on

conveyors to prevent reverse rotation. They contain full

complements of load carrying Formchrome®‚ sprags, in

“Free-Action” Retainers, for maximum torque capacity.

Follow the step by step installation and maintenance

instructions in this bulletin for optimum performance and

life.

Prior to installation in a location outside the

primary drive line, shaft run-out should be

measured in at least two locations in the

Holdback mounting area. Measured values should

not exceed those in the following table:

Max Overrunning

Speed, RPM

Thru 100 0.010

Thru 150 0.006

Thru 250 0.004

Thru 400 0.002

Maximum TIR,

inches

Failure to follow these

instructions may result in product damage,

equipment damage, and serious or fatal injury

to personnel.

Pre-installation Check

1. Before installing, check Shaft to Bore fit:

Holdback Bore Recommended Fit*

inches inches

1.937 to 2.125 .001 to .0035 loose

2.250 to 2.500 .001 to .0040 loose

2.625 to 3.000 .001 to .0045 loose

3.250 to 4.000 .001 to .0055 loose

4.250 to 5.937 .001 to .007 loose

6.000 to 6.937 .002 to .008 loose

7.000 .002 to .005 loose

*If a press fit is necessary under special

circumstances. Do not exceed .001 inches tight.

In some cases, builders of equipment in which a

Holdback is used specify other shaft fit limits. In

this event, direct questions concerning fit limits to

the equipment builder.

Shaft Run-out Recommendations for LLH

Holdback Units

LLH Holdback units are designed for installation

on primary drive line shafting with typical

dimensional tolerances and run-outs. Some

applications dictate installation in locations not

in the primary drive line, i.e. in locations where

tolerances and run-outs exceed “typical” values.

In these situations, some basic measurements

are required to determine the suitability of the

proposed mounting location. Holdback lubrication

sealing and overall product life can be adversely

affected by excessive shaft run-out or lack of

straightness.

Across the Holdback mounting area, the shaft

should be straight within 0.003 inches per foot of

length.

These requirements are based on maintaining

acceptable axial and radial vibration levels on

the Holdback. Installations that exceed these

limits can result in leakage of lubricant from the

Holdback, excessive seal wear, and premature

failure of bearings and/or Sprags.

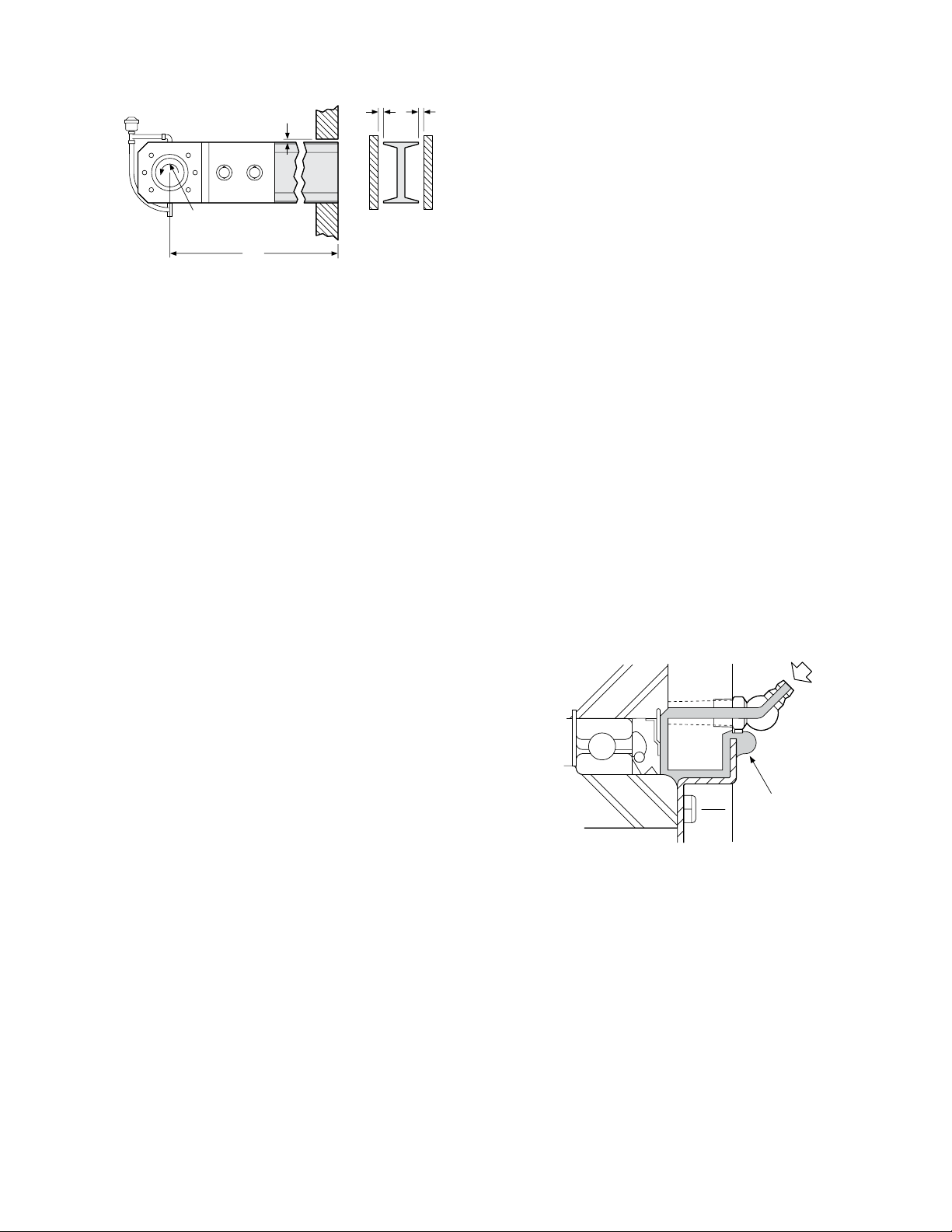

Set Collars (not furnished)

Figure 1

2. Key and Keyseat

A hardened key, (25-40 Rockwell “C” scale) is

furnished with the Holdback and is as long as

the inner race keyseat for proper support. Check

shaft keyseat. Key must fit with a “push” fit. Do

not use a driving or force fit.

3. Rotation

Turn the inner race to check the Holdback for

direction of rotation. The arrow on the clutch

name plate indicates the direction of inner race

overrunning.

2 Formsprag Clutch • 800-927-3262 P-222-14-FC • 5/19

Angular Clearance

Grease In

Shaft Rotation

Important: Angular and axial clearances must be

maintained at all times. Set collars (or other

retention devices) should be used on the shaft to

maintain axial clearance.

0.5

(12.7)

B

Axial Clearance

1.0

(25.4)

END VIEW

1.0

(25.4)

6. Position Holdback and torque arm. Coat torque

arm pins and pin holes with anti-seize compound

(furnished). Insert pins and cotter keys as shown

in (Figure 1).

7. Attach torque arm stops to conveyor frame or

supporting structure. The stops are required to

prevent rotation of torque arm when holdback

torque is applied. Allow clearance between

stops and torque arm as shown in Figure

2. The clearance is necessary to permit free

axial and angular movement of the torque arm

resulting from shaft runout and eccentricity.

We recommend set collars on shaft to prevent

Holdback from shifting which would eliminate

this clearance.

Figure 2

The torque arm reaction force is the force which the

torque arm stops must resist. Formsprag recommends

that the stops be at least 3/4 of the distance (B) away

from the center line of the clutch.

Installing

1. Place inboard set collar on shaft. Set collars

should be used to keep Holdback in position on

shaft. Otherwise, the Holdback might shift on

shaft causing torque arm to bind.

2. Coat Holdback bore, shaft and key with an

anti-seize compound to facilitate installation

and removal. A supply of this compound is

furnished with each new clutch assembly.

3. Place Holdback and key on shaft. Be sure that

shaft is free of nicks and burrs.

Note: Oil lubricated Holdbacks should be

mounted on horizontal shafts only. For

mounting on vertical shafts, contact

Formsprag.

4. Apply pressure to end face of inner race only.

Pressing against the outer race could preload the

bearings excessively. To simplify mounting, should

a bore-to-shaft fit of .001 inches tight be required

(this is tightest allowable) immerse Holdback in

hot, clean oil (not to exceed 200°F/93°C) for ten

to fifteen minutes before mounting.

5. Secure Holdback in position on shaft. Use flat

washer fastened to shaft end with screw, snap

rings or set collars to keep Holdback in position

on shaft. It is essential to hold unit in position on

the shaft.

Note: Torque arms may be installed at any angle,

however, vertical torque arms should be

installed at lease 10° from the true vertical

position. The Holdback should be mounted

in an orientation so that the weight of the

torque arm will keep the torque arm in

constant contact with the reacting surface

and structure.

8. Grease auxiliary seals. These labyrinths are built

into each Holdback to minimize the harmful

effects to the oil seals from dusty or abrasive

atmosphere. For instructions on regreasing these

seals, follow instructions in (Figure 3).

Purge

Grease

Out

Figure 3

9. Install oil sight gauge attachment. Follow

instructions in (Figure 4).

Install breather in highest position after Holdback

installation is complete. Follow instructions in

(Figure 4).

Formsprag Clutch • 800-927-3262 P-222-14-FC • 5/19 3

3/4 Full Min

7/8 Full Max

Center Line

Horizontal

Oil sight gauge must be installed so that “3/4

(19.05) full” level (shaft horizontal center line) is

clearly visable in the plastic tubing. Two sets of

opposing lubrication holes, at 90 intervals, are

provided in the outer race for the sight gauge.

Select highest and lowest opposed holes to install

gauge.

unless other lubricant was specified on order.

The use of lubricants in clutch

assemblies, other than those shown, can result in

improper sprag engagement. Improper sprag

engagement may cause personal injury or property

damage.

Oil sight gauge must be installed so that “3/4 full” level

(shaft horizontal centerline) is clearly visible in the plastic

tubing. Two sets of lubrication holes, at 90˚ intervals, are

provided in the outer race for the sight gauge. Select

highest and lowest opposed holes to install gauge.

Formsprag is not responsible for any changes

made by the manufacturers in their lubricants.

Figure 4

10. Check Holdback lubrication and replace any oil

lost while installing gauge.

Note: Oil lubricated Holdbacks which will not

be operated within three months after

installation should be filled completely

full of oil to prevent corrosion of interior

surfaces. Excess oil should be drained

prior to operation.

Auxiliary Seal Lubrication

1. Lubricate auxiliary seals every Three Months of

normal operation, more often if extremely dusty

conditions prevail. The auxiliary grease seals are

protective barriers for the oil seals. Lubricants with

EP additives must not be used. Use any of the

following greases, or equivalent:

Lubriplate Low Temp (Fiske Bros.)

Mobil SHC-32 (Mobil Oil)

Rykon #2 (Amoco)

Amolith #2 (Amoco)

2. With a low pressure grease gun, pump seals full,

through fittings on both sides, until old grease

is purged and fresh grease runs out around the

entire circumference of the seal.

The use of any lubricants, other than those

listed in this bulletin, will automatically void any

warranty.

Do not use lubricants containing

slippery additives, or those having extreme

pressure characteristics such as any EP type

lubricants.

Oil Lubrication Maintenance

1. Lubrication is the most important Holdback

maintenance factor. Keep oil clean.

2. Check oil level weekly. To add oil, remove

breather cover and pour oil into Holdback through

the breather housing.

3. Flush Holdback every Six Months with mineral

spirits.

Important: If Holdback operates under severe

dust conditions or twenty-four

hours per day, FLUSH EVERY

THREE MONTHS.

4. Flush with mineral spirits and relubricate before

operating if the Holdback has been in storage or

out of service for six months or more.

3. Holdbacks supplied for grease lubrication may

use Fiske Brothers Lubriplate Low-Temp grease

for all lubrication. See Grease Lubrication.

Oil Lubrication

Use oil selected from the table below according to

the temperature existing at the Holdback. Holdback

should be 3/4 full of oil. Holdbacks are shipped from

Formsprag 3/4 full of Mobil DTE Heavy Medium oil

4 Formsprag Clutch • 800-927-3262 P-222-14-FC • 5/19

Temperature Range Recommended Lubricant

+20°F to 150°F Mobil DTE Heavy Medium

(-7°C to 65°C) Shell Turbo Oil 68

(Max. permissible High grade Automatic Trans.

ambient temp.) Fluid (ATF)

Texaco Regal R&O 68

Chevron GST Oil 68

Exxon Terristic Oil 68

AMOCO Industrial Oil 68

Sunoco Sunvis Oil 931

Gulf Harmony

-10°F to +150°F Mobil Gargoyle Arctic C

(-23°C to +65°C) Heavy

High grade Automatic Trans.

Fluid (ATF)

Texaco Regal R&O 46

Chevron GST Oil 46

Sunoco Sunvis Oil 921

-40°F to +150°F Mobil Jet Oil 2

(-40°C to +65°C) Shell Turbo Oil 500

Exxon Turbo Oil 2389

Standard Esso Turbo Oil 2389

MIL-L-23699 or MIL-L-7808

Military Specification Oils

Ambient temperature below -40°F/-40°C consult Formsprag.

Storage

Formsprag LLH Holdbacks are shipped 3/4 full of oil

and ready for operation. If the Holdback is to be stored

for a long period of time (6 months to 2 years), it must

be completely filled with oil (Mobil Gargoyle Arctic C

Heavy) and stored under a roof at above freezing

temperatures. At the customer’s request, Formsprag

will prepare the Holdback for storage in accordance with

our Spec SP-194.

Flushing Procedure

1. Remove pipe plug from lower “Tee” in oil sight

gauge and drain oil.

Grease Lubrication – (No sight Gauge)

1. Grease lubricated Holdbacks, available by

special order, are packed at the factory with

Fiske Brothers Refining Company Lubriplate

Low-Temp grease. Use no other grease unless

specific recommendation has been obtained

from Formsprag to use an alternate.

Grease lubricated Holdbacks

must operate in ambient temperatures of

+20°F/-7°C or higher.

2. Do not attempt to substitute grease lubrication

in a standard oil lubricated Holdback. The use of

grease lubrication in Holdbacks intended for oil

lubrication may cause a malfunction. To convert

from oil to grease lubrication, a change of internal

construction may be required which can only be

accomplished by Formsprag Clutch. Consult the

Formsprag Clutch Service Department and give

clutch model number.

Grease Lubrication Maintenance

1. Lubricate Holdback every three months. If

Holdback operates under sever dust conditions

or twenty-four hours per day, grease monthly.

2. Use Fiske Brothers Refining Company Lubriplate

Low-temp Grease only. (Do not use alternate

greases without specific recommendation from

Formsprag Clutch.)

3. Clean grease fittings by wiping with clean cloth.

4. Pump grease in with grease gun until fresh

grease flows freely from around the entire seal

circumference on both sides of the Holdback.

Seals have been installed to provide automatic

venting and to allow purging of old grease and dirt

during regreasing. This will lubricate both clutch

mechanism and auxiliary seals.

2. Reinstall drain plug.

3. Fill Holdback completely with mineral spirits or

Kerosene.

4. Operate conveyor for one or two minutes to

cause Holdback to overrun. This will circulate

Sight Gauge Service (Ref. Figure 5)

• Sight gauge tubing (8) should be mounted on a

vertical plane.

• Breather (10) must be above tube (8) and elbow

(3) fitting.

solvent for better cleaning of internal parts.

• Apply a suitable pipe joint compound, such as

5. Remove drain plug and drain solvent.

6. Reinstall drain plug. Add oil to 3/4 full level as

shown on the oil sight gauge.

Permatex #2 or equivalent, to the threads making

sure sealant does not get into lube.

Replacement Oil Sight Gauges may be ordered from

Formsprag. Simply provide Holdback model Number.

Formsprag Clutch • 800-927-3262 P-222-14-FC • 5/19 5

(10)

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

Gasket

Adapter

Elbow

Nipple

Tee

Nipple

Clamp

Tubing

Drain Plug

Breather

10

4

Clutch Rebuilding Service

Disassembly and Repair of Formsprag Clutches in

the field is not Recommended.

3

Formsprag clutches are precision devises manufactured

2

1

5

under careful controls to meet exacting standards.

When reconditioning is required, clutches should be

6

7

returned to Formsprag directly, through the Distributor,

or through the Original Equipment Manufacturer.

Formsprag clutch and holdback are mechanical devices

8

designed to protect mechanical equipment from rotation

in the opposite direction and should generally not be

considered Safety Devices. Formsprag clutches and

1

2

5

9

7

6

holdbacks have surfaces which wear with use over time

and as a result will need to be replaced. The clutches

and holdbacks do not offer a feature for determining the

time of their replacement. As a result the decision for the

time of replacement must be made by the operator of

the equipment based upon the specific application and

performance of the clutch or holdback.

Figure 5

Oil Sight Gauge Assembly

CL-7362-5

Replacement Filter Elements

Keep adequate supply of filter elements on hand. They

can be purchased from Great Lakes Filter Media Co.,

5151 Lorraine, Detroit, Michigan 48208

To Clean Breather Filter Element

1. Loosen wing nut, lift off whole breather.

2. Remove cover and filter. Rinse filter in solvent.

3. Reinstall breather housing. Add clean oil to the

mark on housing.

4. Reinstall cover and filter. Tighten wing nut.

Breathers

Clutch Model Breather No.

Mfr. No. Formsprag No.

LLH-700 569022-01 CL-30703

Dry Filter

LLH-750 to

LLH-1027 FAOB-07 CL-30703-5

Oil Bath Filter

Packaging

Your Formsprag clutch, carefully wrapped in Vapor

Inhibitor type activated paper for corrosive protection

and packed in a shipping box conforming to the

requirements of Rule 41, Uniform Freight Classification,

may be stored for up to two (2) years and reshipped

without added packaging.

These instructions cannot cover all details or variations

in equipment and applications nor provide for every

possible contingency which may be met in installation,

operation or maintenance. Should further information be

needed, contact Formsprag Clutch.

For additional technical and dimensional information on

LLH Series clutches refer to Formsprag Overrunning

Clutch Catalog P-956 or call Formsprag Application

Assistance at 1-800-927-3262.

Rotating Equipment

Rotating equipment is potentially dangerous and should

be properly guarded. The user should check for all

applicable safety codes (in local area) and provide a

suitable guard.

6 Formsprag Clutch • 800-927-3262 P-222-14-FC • 5/19

NOTES

Formsprag Clutch • 800-927-3262 P-222-14-FC • 5/19 7

Warranty

Formsprag LLC warrants that it will repair or replace (whichever in its sole discretion it deems advisable) any

product it manufactured and sold which proves to be defective in material or workmanship within a period of one

(1) year from date of original purchase for consumer, commercial or industrial use. This warranty extends only to

the original purchaser and is not transferable or assignable without Formsprag LLC’s prior consent.

This warranty covers normal use and does not cover damage or defect which results from alterations, accident,

neglect, disassembly, or improper installation, operation, or maintenance.

Formsprag LLC’s obligation under this warranty is limited to the repair or replacement of the defective product. In

no event shall Formsprag LLC be liable for consequential, indirect or incidental damages of any kind incurred by

reason of manufacture, sale or use of any defective product. Formsprag LLC neither assumes nor authorizes any

other person to give any other warranty or to assume any other obligation or liability on its behalf.

www.formsprag.com

23601 Hoover Road

Warren, MI 48089

586-758-5000

P-222-14-FC 5/19

Loading...

Loading...