Page 1

V-STACK36

Vertical Stacker

11/2013

OPERATOR MANUAL

FIRST EDITION

Page 2

TABLE OF CONTENTS

TOPIC PAGE

Description 1

Specications 1

Unpacking 1

Congurations 2

Setup and Operation 3

Page 3

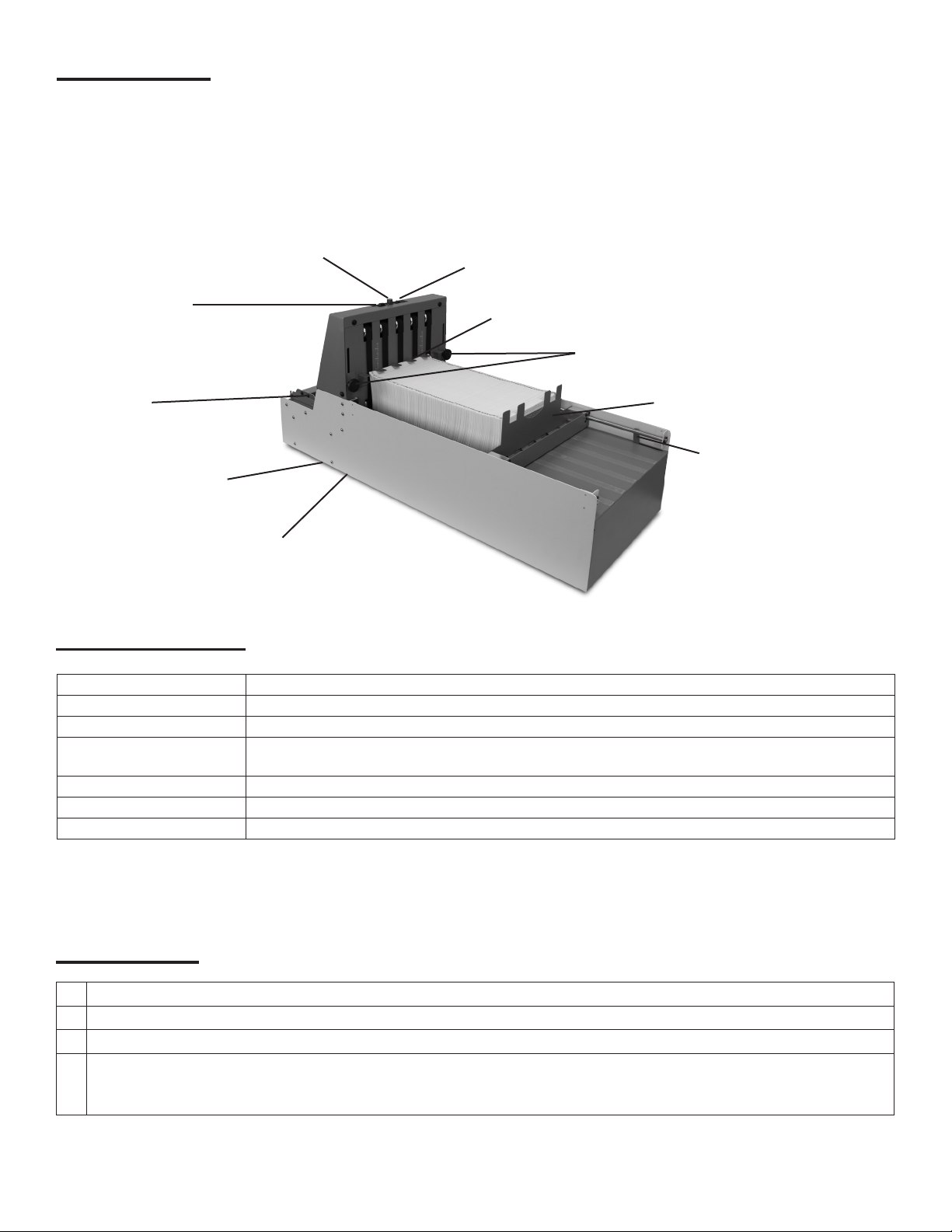

Description

The V-Stack36 vertical stacker is designed to work with a variety of Formax pressure sealers and tabletop

folders. Unlike a traditional outfeed conveyor, it stacks forms vertically, providing a neat stack which is easier to

unload for further processing. A height-adjustable stand with locking casters is available to align with a variety

of inputs. The stand is optional for use with tabletop folders and pressure sealers, and required for use with

production pressure sealers.

LED lamp

Run-out switch

Power switch

Vertical paper stop

Vertical paper stop adjustment knobs

Infeed deck

Power cord inlet

(not shown)

Interlock cable inlet

(not shown)

Specications

Speed: Variable, depending on source machine

Capacity: Up to 22” of folded documents, approx 1,500 sheets

Dimensions: 16” H x 37.25” W x 14.5” D

Height w/Optional Stand: 41.5 to 45.5” (oor to top of stacker)

30” to 34” (oor to infeed deck)

Weight: 73 lbs (122 lbs with stand)

Power: 110V, 50/60Hz

Made in USA

Horizontal paper stop

Horizontal paper stop

sensor lever

Unpacking

1. Check the outside of the carton for visible damage. Make note of any damage on the carrier’s receiving report.

2. Open the carton.

3. Carefully remove the carton contents and inspect the unit for paint and structural damage.

4. Carefully check for missing parts. If damage or missing parts are noted, contact your Sales Representative immediately. Save cartons and packing materials. They may be required to substantiate a damage claim or to return a

damaged unit.

1

Page 4

Congurations

The V-Stack36 is designed for a variety of congurations, including those shown below:

In-line with an FD 382 or FD 38X Document Folder

When placed on a level surface with the folder, the

V-Stack36 infeed deck aligns easily with the folder’s

outfeed and can be used without a stand.

It can also be used with the optional V-Stack36-10 stand,

which adjusts for various heights.

FD 38X and V-Stack36, with optional cabinet and stand

In-line with an FD 2054 Tabletop Pressure Sealer

When placed on a level surface with the pressure sealer,

the V-Stack36 infeed deck aligns easily with the outfeed

and can be used without a stand.

It can also be used with the optional V-Stack36-10 stand,

which adjusts for various heights.

In-line with an FD 2094/2084 or 2200 Series

Production Pressure Sealer

To properly align the V-Stack36 infeed with the outfeed

of these production models, the height-adjustable

V-Stack36-10 stand is required, and can easily be

moved into place thanks to its locking casters.

FD 2054 and V-Stack36, with optional cabinet and stand

FD 2094 and V-Stack36, with required V-Stack36-10

height-adjustable stand

2

Page 5

Set-up and operation

Without V-Stack36-10 Stand

1. Determine location of folder or pressure sealer

and where the stacker will sit.

2. Remove the extended outfeed tray from the folder

or pressure sealer.

3. Align the outfeed of the folder or pressure sealer

with the infeed of the stacker.

4. Place the 6-roller-ball deck onto the pins (A) on

either side of the stacker infeed and slide into

place.

5. Place the crossbar (B) of the guide wheels into the

grooves of the stacker infeed.

6. Plug power cord into stacker and appropriate electrical outlet. Swtich on power. (C)

7. Adjust the vertical paper stop (see pg. 4).

8. Load documents or forms into the input machine

and operate as usual. The forms will feed from the

folder/pressure sealer into the stacker.

9. When the stacker is nearing full capacity, the red

LED (E) will light. At this time, stop the folder/pressure sealer, press the run-out button (F) to clear

the infeed, and remove the nished documents.

NOTE: the horizontal paper stop is spring-loaded.

Guide Wheels

C

Crossbar

B A

E

F

6-ball-roller deck

Vertical paper stop

With V-Stack36-10 Stand

1. Attach stacker to mounting plate on stand see assembly instructions on pg. 5.

2. Adjust the height of the stand/stacker using the

lock handle.

3. Continue setup following the procedure above.

D

Mounting plate

Lock handle

3

Page 6

SETTING THE VERTICAL PAPER STOP

1. Place a folded piece against the backstop so that

the fom sits between the backstop and the feed

belts. (Fig 1)

2. Holding the folded piece in positon, loosen the

black knobs on either side of the paper stop. (Fig

2)

Fig1

Fig 2

Feed belts

3. Lower the paper stop down so that it is resting on

the top edge of the folded piece, then tighten the

blck knobs to hold the paper stop in position. For

quicker setup in the future note the position of the

backstop on the ruler guides. (Fig 3)

Fig 3

4

Page 7

Assembling V-STACK36-10

#2

REMOVE 10 EACH

ALLEN SCREWS FROM

BOTTOM OF STACKER

POSITION RAILS ONTO

BOTTOM OF STACKER

AND REINSTALL SCREWS

(SECURELY TIGHTEN SCREWS)

#3

PLACE STACKER WITH RAILS

ATTACHED ONTO STAND AND

SECURE WITH 4 EACH HEX NUTS

AND FLAT WASHERS

(SECURELY TIGHTEN HEX NUTS)

#1

INSTALL 4 EACH HEX BOLTS

THRU LOCK WASHERS

THEN THRU BASE ASSEMBLY

(SECURELY TIGHTEN HEX BOLTS)

5

Loading...

Loading...