Page 1

Formax FD 90 Rotary

Perforating and

Creasing Machine

Instruction Manual

Page 2

FD 90

Rotary Perforator

8/2015

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

OPERATOR MANUAL

FIRST EDITION

Page 3

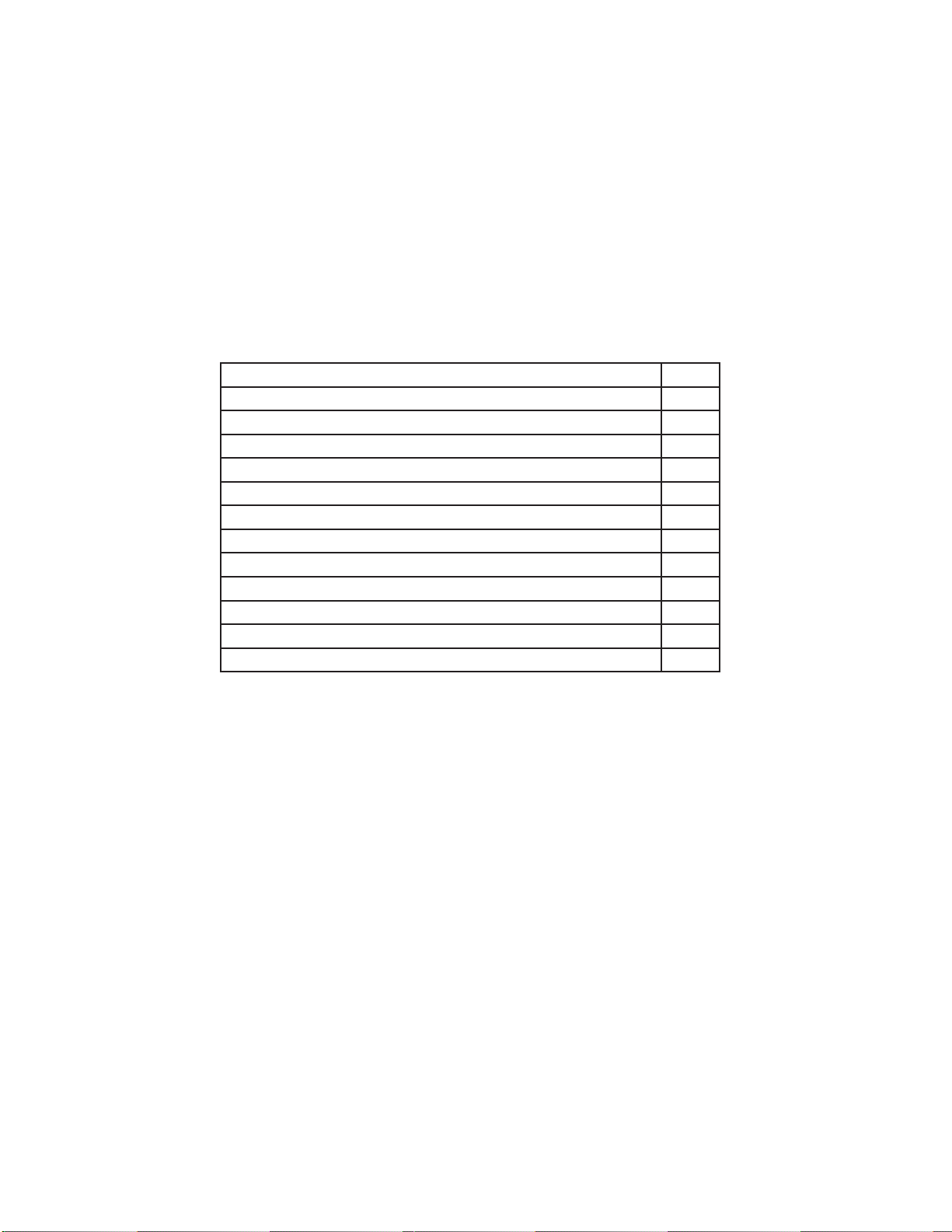

TABLE OF CONTENTS

SPECIFICATIONS 1

SAFETY PRECAUTIONS 1

DESCRIPTION 2

INSTALLATION AND OPERATION 3

INFEED TABLE ADJUSTMENT 3

OUTFEED TABLE ADJUSTMENT 4

OPERATION 4

REPLACING AND ADJUSTING PERFORATING TOOLS 4 - 5

REMOVING PERFORATING AND/OR CREASING WHEELS 6

REMOVING COVERS 6

SEPARATOR PRESSURE ADJUSTMENT 6

TROUBLESHOOTING 7

MAINTENANCE 7

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

Page 4

SPECIFICATIONS

Paper size: Letter, Half Sheet, Ledger

Recommended paper weight: 55 – 180

Note: 55-60 gsm paper can be processed using special guide strips (optional)

Speed: Up to 113 sheets/min (up to 6,800/hr)

Max. feed table width: 13.8” (350mm)

Feed table capacity: Max. sheet stacking height: 1.18” (30mm)

Dimensions: Closed: 19.5” L x 14” W x 15” H

Fully extended: 43” L x 14” W x 15” H

Shipping dimensions: 21.5” L x 15.7” W x 16” H (545 x 400 x 405mm)

Perforating blade capacity: Up to 5 (includes 2 perforating tools and 1 creasing wheel)

Power: 110V / 60Hz (30W)

Weight: Net weight 41 lbs (18.5 kg)

Optional equipment: Microperforation knife (17tpi), guide strips to accommodate 55-60 gsm paper

gsm

SAFETY PRECAUTIONS

• Read all instructions carefully before operating.

• The FD 90 is designed to perforate paper only with specications noted above.

• DO NOT use the FD 90 to perforate metal foil, tin sheets or similar material.

• Be sure all covers are in place and secure before operation.

• The FD 90 should only be used indoors.

• If paper jams, the machine makes an unusual noise or is damaged, discontinue use immediately, switch off the power,

unplug and check the troubleshooting procedures.

• Only trained operators should use the machine.

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

1

Page 5

DESCRIPTION

The FD 90 Electric Rotary Perforator is designed to perforate sheets allowing for easy separation. The friction feeding

system can perforate up to 113 sheets per minute, and can create up to 5 parallel perforations in a single pass (two perforating tools included). The telescoping outfeed and extendable infeed table allow for processing sheets up to 11” x 17”.

Adjustable side guides and ne-tuning knobs allow for precise positioning of sheets prior to perforating.

1 Infeed table

2 Outfeed table

3 Front cover

4 Back cover

5 Upper cover

6 Lower cover

7 Power switch

8 Side guides

9 Infeed table extension

10 Outfeed guides

11 Outfeed bridge

12 Red LED power indicator

13 Paper pressure adjustment wheel

14 Outfeed guide strap

8

9

1

11

14

5

4

13

12

7

3

10

2

6

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

2

Toll Free: 1-800-944-4573

Local: 503-640-5920

Page 6

INSTALLATION AND OPERATION

After unpacking the FD 90, place it on a solid surface and slide the infeed table into the machine and secure with enclosed

screws. Connect the male part of the cable into the female part of the connector that is located on the inside of the left

side cover of the machine. Connect the power cord into the FD 90 and plug into an appropriate electrical outlet. Do not

turn on power until adjustments have been made.

Infeed table

Connector inputElectrical input

Infeed table adjustment

Push the feed tray down until the lever (13) locks to secure the table in the open position. Set the side guides (8) to the width

of the paper being used and secure the position of of the side guides using the thumb screws (14). When feeding small-size

sheets, remember to align the paper to the center of the table. The center of the sheet should always make contact with the

center of the rubber singulator pad (15). To make ne adjustments to the side guides (± 5mm), use the screw adjustment

knob (16).

The squareness of the feed table to the infeed can be adjusted using the skew adjustment knob (17). Check the ideal center

position by aligning the cross position mark (18). The feed table extension can be used to support large paper sheets (9).

Note: Sheets weighing 180 g/m² and more must be inserted one at a time.

8

13

15

17

9

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

14

16

18

3

Page 7

Outfeed table adjustment

Adjust the output table (2) by sliding the table outward, depending on the size of the sheet being processed.

For easier stacking of larger sheets attach the bridge (11) and magnetic side guides (10). These facilitate sheet stacking and

substantially reduce paper jamming.

Note: If the table is not extended above the pad, do not overload it, as the table might become damaged or bent.

11

10

Operation

Start the machine by pressing the power switch (7). Be sure the upper cover (5) is closed. When the upper cover is closed

and paper is loaded correctly on the infeed table, the machine will automatically begin to feed paper and the red LED (12)

will list. When the paper runs out or the upper cover is opened, the LED will blink.

Replacing & Adjusting Perforating Tools or Creasing Wheels

To adjust the perforating tools (21, 27) or the creasing wheels (26), rst unplug the machine. Open the cover (5) and use

an Allen wrench to loosen the screws on the hubs of the blade guides (22) and remove the shaft with the bled guides from

the machine.

Loosen the screws on the hubs of all tools you want to adjust or remove. Loose tools can be moved freely along the shafts.

When the tools are positioned, the screws must be tightened and the tools secured in the required position. Return the shaft

with the blade guides into the machine to its working position near the perforating wheels.

It is possible to install a maximum of 5 perforating tool sets including the blade guide (28). (Two sets of perforating tools are

include.)

19

20

21

22

2726252423

4

Page 8

Replacing & Adjusting Perforating Tools or Creasing Wheels (cont.)

NOTE: Always put indented cutting tools on the upper shaft (20). Place the tools (21, 27) on the shaft in a mirroring way

starting from the center of the shaft. An odd pair of tools must always be oriented according to the half of the adjusted

sheet on which that pair of tools is placed. The guide pulleys (19, 24) must always be on the outer edge of the document

in a mirrored position. If the tools are oriented only on one side of the document, the mirroring plane equals one half of the

distance between the tools located in the farthest positions.

28 = 21, 22, 27

21

27

26

Figure A

To process 60 g/m2 paper, an optional set of guide strips must be used and positioned as shown above. Magnets will hold

them in place on the upper and lower covers.

22

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

5

Toll Free: 1-800-944-4573

Local: 503-640-5920

Page 9

Removing Perforating and/or Creasing Wheels

To remove the perforating wheels or the creasing wheel, rst remove the shaft with the blade guides then remove the shaft

with the perforating wheels.

Remove the shaft by holding the bearing (29) and pulling it over the spring into the terminal position. Then push the whole

shaft back including the bearing, and remove the shaft from the machine as shown below.

Reverse the process to replace the shaft.

29

Removing Covers

Covers can be removed after paper processing has been nished and fully disconnected from the power supply. Before

resuming work, the covers must be reattached and secured. The covers should be removed only by a trained technician.

NOTE: The covers should be removed only when service interference, belt replacement or feed roller pressure is required.

Separator Pressure Adjustment

The pressure of the separator on the feed tire (30) of the

feeding shaft must be adjusted to accurately feed the paper

from the feeding table (1).

Turn the separator adjustment wheel (31) clockwise to

increase the pressure on the separator. If a thicker sheet

is fed into the feeding table, the pressure of the separator

should be decreased by turning the wheel counterclockwise.

30

31

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

6

Page 10

TROUBLESHOOTING

The machine won’t start but the red LED

is on:

Paper gets crumpled inside the machine: Open the upper cover (5) and remove the paper from the machine.

Several sheets are fed simultaneously: Adjust the pressure of the separator (30) using the adjustment wheel (31).

The perforated cut is wide and frayed: Be sure the blades are sharp and set the clearance between both tools. Both

The machine gets jammed: Check all mobile parts under the cover (5).

Be sure the upper cover (5) is closed properly and that the optical sensor on

the input feeding table operates properly (1).

Be sure the feed roller turns freely and that it remains in the proper position,

(Figure A, pg 5).

tools must touch each other on the external, i.e. not beveled side (see Figure

A, pg 5).

Be sure the blades are sharp and have not been crossed or misaligned.

MAINTENANCE

Clean the machine once a month to remove dust and other impurities, concentrating on the inside of the machine, especially

in the area near the electric motor.

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

7

Loading...

Loading...