Page 1

Formax FD 262 Single-

Head Crash Tabber

Instruction Manual

Page 2

FD 262

Tabletop Single Head Tabber

Operator Manual

3/2016 First Edition

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

Page 3

Table of Contents

Section Page #

SECTION 1 – GETTING ACQUAINTED________________________________________________ 3

Safety Precautions _________________________________________________________________ 3

Packaging/Shipping ________________________________________________________________ 3

Contents __________________________________________________________________________ 4

Front View ________________________________________________________________________ 5

Rear View ________________________________________________________________________ 6

SECTION 2 – ASSEMBLY AND INSTALLATION _______________________________________ 7

Assembly _________________________________________________________________________ 7

Installation ________________________________________________________________________ 8

SECTION 3 – OPERATING THE TABBER _____________________________________________ 9

Loading Tabs: _____________________________________________________________________ 9

Tab Sensitivity Adjustment _________________________________________________________ 10

Metering Bracket/Separator Adjustment ______________________________________________ 11

Media Supports and Media Side Guide Adjustment _____________________________________ 12

Media Transport Test______________________________________________________________ 12

Horizontal Tab Positioning _________________________________________________________ 13

Tab Fold Position Adjustment _______________________________________________________ 13

Operating Sequence _______________________________________________________________ 13

SECTION 4 – TROUBLESHOOTING _________________________________________________ 14

Tabbing Problems: ________________________________________________________________ 14

Media Feeding Problems: __________________________________________________________ 15

SECTION 5 – MAINTENANCE _______________________________________________________ 16

Cleaning _________________________________________________________________________ 16

Feed Rollers and Forwarding Rollers ________________________________________________ 16

Cleaning the Sensors _____________________________________________________________ 17

APPENDIX - SPECIFICATIONS _____________________________________________________ 18

APPENDIX B – OBTAINING SUPPLIES, SERVICE AND SUPPORT ______________________ 19

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

Page 4

3

Section 1 – Getting Acquainted

Safety Precautions

OBSERVE THE FOLLOWING SAFETY RULES WHEN OPERATING THE FD 262

TABBER.

BEFORE USING THE FD 262, READ THIS MANUAL CAREFULLY AND FOLLOW THE

RECOMMENDED PROCEDURES, SAFETY WARNINGS, AND INSTRUCTIONS:

Keep hands, hair, and clothing clear of rollers and other moving parts.

Avoid touching moving parts or materials while the machine is in use. Before clearing a jam, be sure machine

mechanisms come to a stop.

Always turn off the machine before making adjustments, cleaning the machine, or performing any maintenance

covered in this manual.

Use the power cord supplied with the machine and plug it into a properly grounded wall outlet located near the

machine and easily accessible. Failure to properly ground the machine can result in severe personal injury

and/or fire.

The power cord and wall plug is the primary means of disconnecting the machine for the power supply.

DO NOT use an adapter plug on the line cord or wall outlet.

DO NOT remove the ground pin from the line cord.

DO NOT route the power cord over sharp edges or trapped between furniture.

Avoid using wall outlets controlled by wall switches, or shared with other equipment.

Make sure there is no strain on the power cord caused by jamming between the equipment, walls or furniture.

DO NOT remove covers. Covers enclose hazardous parts that should be accessed only by a qualified service

technician. Report any damage of covers to your service technician.

This machine requires periodic maintenance. Contact your authorized service technician for required service

schedules.

To prevent overheating, do not cover the vent openings.

Use this equipment only for its intended purpose.

In addition, follow any specific occupational safety and health standards for your workplace or area.

Packaging/Shipping

The Tabber is shipped in appropriate packaging so that, under normal shipping conditions, it reaches its

destination without damage.

NOTICE: Report damage to the carrier. The carrier is liable for any damage during transport. Transport

and storage should take place under normal conditions, i.e. at temperatures between +5°C and +70°C and

relative air humidity of up to 80%. Exposure to conditions that are not permissible may lead to damage

which is not externally visible.

IMPORTANT Please save the packaging materials for future use! It will be required if you ever need to

ship the Tabber.

Page 5

4

Contents

The following items are included with your tabber:

1 Operations Manual

1 Tab Roll Support Assembly

1 Tab Roll Side Guide

1 Power Cord

2 Media Support Guides

2 Media Side Guides

Note: Tabs can be purchased through your local Formax dealer.

General: The FD 262 Tabber is a desktop tabbing machine that is designed for the moderate

volume user. It can handle documents ranging from 3 5/8” x 5” card stock to 11” x 11” booklets

up to 5/32”.

The FD 262 Tabber will process a range of Tabs in most colors and either round or square from

5/8” to 1.5” in length and width.

Operation: The FD 262 is a stand-alone machine that can process media into a stacker or tray.

The FD 262 will process various sizes of media and place a single “tab” on the lead edge of the

media. The media can vary in length from 3.6” to 11” and vary in thickness from a C-folded

sheet of 20# bond paper to a booklet of 5/32” thick.

The FD 262 will process media at a speed up to 12,000 pieces per hour depending on the skill of

the operator, the length (depth) of the media and the type of material.

When the media is fed, a media sensor detects the lead edge of the media and feeds tab into

position. The media contacts the tab, then the exit roller presses the tab to the media and carries

the media out of the tabber. At the same time, the tab feed stops until another piece of media is

seen by the media sensor. The sensitivity of the tab sensor is adjusted by the tab sensor

adjustment on the rear of the tabber for different types of tabs.

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

Page 6

5

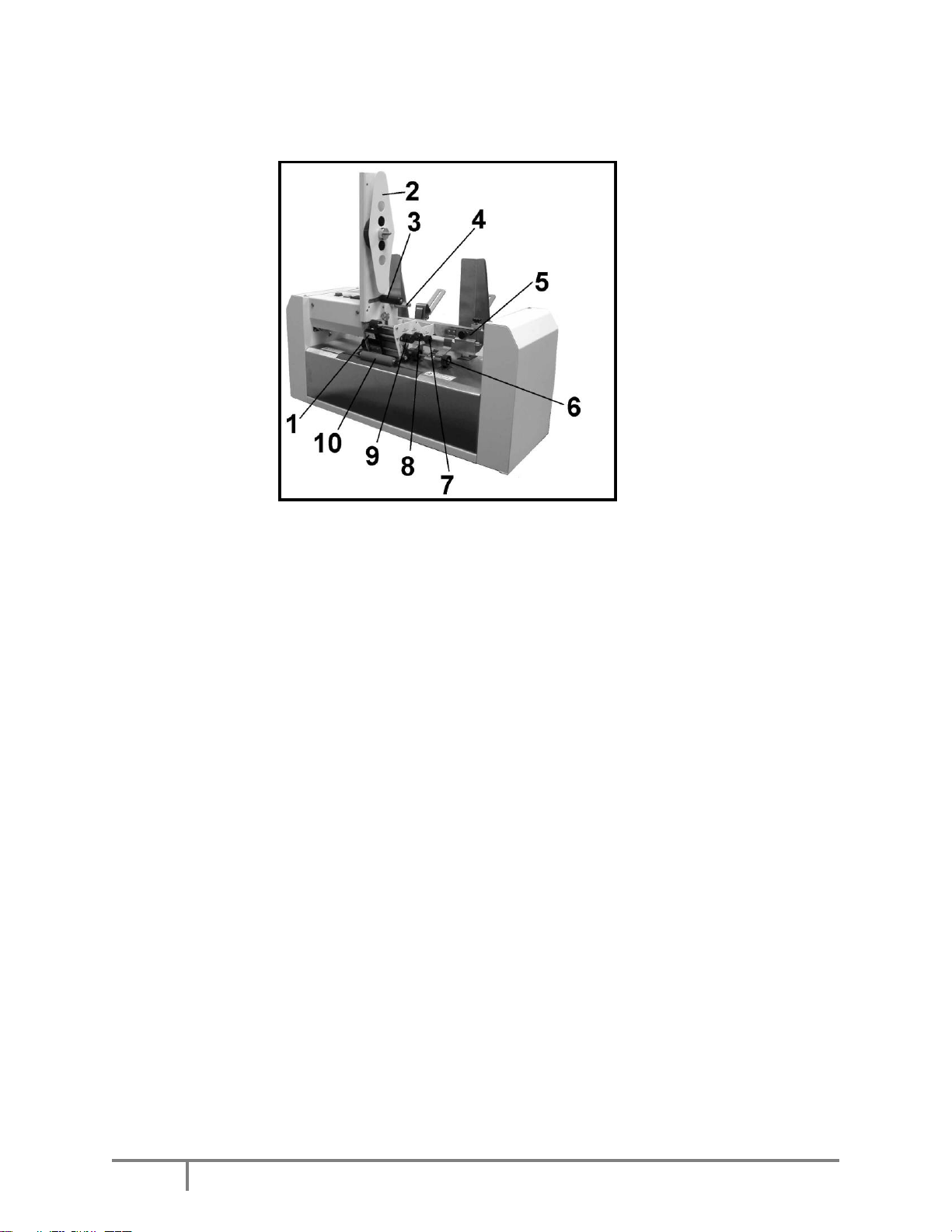

Front View

1.

Tab Sensor and Tab Guide Assembly – This assembly keeps the tab aligned so

that the sensor can sense the tab.

2.

Tab Roll Side Guide – Holds the tab roll in place on the Tab Roll Support.

3.

Reel Brake Assembly – Prevents the roll of tabs from unwinding when they are

not being fed.

4.

Tab Take-up Reel – Winds up the tab backing material.

You will need to clear the backing from this reel when it reaches a diameter of about 3”.

5.

Metering Bracket Assembly – Separates the media so that only one piece feeds

at a time

6.

Media Pressure Rollers – Drive the media through the tabber.

7.

Tab Position Adjustment Knob – Adjusts the fold position of the tab on the

media.

8.

Tab Drive Pressure Knob – Provides pressure on the tab stock to hold it against

the tab advance roller.

9.

Tab Advance Knob – Attached to the tab advance roller. Turn this roller to

manually advance the tab stock.

10.

Exit Roller – Applies pressure to the tab to help it stick to the media.

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

Page 7

6

Rear View

1.

Media Support – Supports media during feeding.

2.

Media Side Guides – Helps maintain position of media in relationship to tabs.

3.

Tab Roll Support – Tab roll is mounted here.

4.

Media Counter – Resettable counter to track number of pieces fed.

5.

Tab Feed Button – Press this button to feed tabs, when the media feed switch is

also pressed.

6.

Media Feed Button – Press this button to feed media.

7.

Tab Sensitivity Adjustment Knob – Different tabs have different densities.

This adjustment compensates for different types of tabs.

8.

Main Power Switch – Controls the power to the tabber.

9.

Fuse – The main power fuse is located here.

10

Power Inlet – The power cord is plugged in here.

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

Page 8

ASSEMBLY AND INSTALLATION

7

Section 2 – Assembly and Installation

Assembly

Follow the steps below to assemble the FD 262 Tabber prior to operation:

Step 1: Remove all the components from

the carton.

Step 2: Attach the two media support

guides using the two thumbscrews

provided. The pin on the guide fits into

the lower hole and the guide is secured

with the thumbscrew as shown.

Step 3: Install the two side guides over

the metering bracket support bar, then

tighten the thumbscrew.

Step 4: Loosen the thumbscrew. Place

the slot on the tab roll support over the

stud and slide it down until it reaches the

thumbscrew. Tighten the thumbscrew.

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

Page 9

8

Installation

CAUTION

DO NOT USE AN ADAPTER PLUG OR EXTENSION CORD TO CONNECT

THE TABBER TO THE WALL RECEPTACLE.

DO NOT USE OUTLETS CONTROLLED BY WALL SWITCHES.

DO NOT USE AN OUTLET THAT SHARES THE SAME CIRCUIT WITH

LARGE ELECTRICAL MACHINES OR APPLIANCES.

Place the tabber on a flat surface away

from windows or heat sources and near

an electrical outlet. Plug the power cord

into the receptacle at the side of the

tabber then plug it into the wall outlet.

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

Page 10

MAINTENANCE

9

Section 3 – Operating the Tabber

Follow these steps to set up the FD 262 Tabber to apply tabs to your media:

1: Load a roll of tabs on the tabber.

2: Set the sensitivity of the Tab Sensor.

3: Adjust the Metering Bracket Assembly to the media.

4: Adjust the Media Supports and Media Side guides to the media.

5: Test for proper media transport.

6: Test/Adjust for proper horizontal Tab position.

7: Adjust Tab Fold Position.

Loading Tabs:

1. Remove the Exit Roller

2. Remove the Tab Roll Side Guide

by pulling it away from the Tab

Roll Support.

3. Mount the roll of tabs with the tab

leader coming off the roll on the

exit side of the tabber.

4. Replace the Tab Roll Side Guide.

5. Unwind approximately 12 inches

of tabs and remove the first 12

tabs from the backing material.

6. Thread the tab roll leader behind

the Reel Brake Roller then in

front of the Idler Roller.

7. Set the Tab Pressure Knob to the

ON position (pressure engaged).

8. While turning the Tab Advance

Knob counter-clockwise; thread

the tab stock leader above the metal lip, up into and between the Abrasive Roller

and the Pressure Roller.

9. Continue turning the Tab Advance Knob counter-clockwise until you have

enough tab stock leader to feed 2” to 3” through the center of the Tab Take-up

Reel pins.

Operating Tip: You will need to clear the backing from the Take-up Reel when it

reaches a diameter of about 3”.

Page 11

MAINTENANCE

10

10. Slide the tabs stock into the open side of the black plastic Tab Guide and Sensor

Assembly.

Tip: Turning the Tab Pressure Knob to OFF helps with the alignment. Return

the pressure knob to the ON position after positioning.

11. Set the Tab Side Guide (post) to

confine, but not bind the tab

backing.

12. When using 1.25” wide or

narrower tab stock; adjust (slide)

the black plastic Tab Guide and

Sensor Assembly so that the red

centerline is in the approximate

center of the tab stock.

When running tabs larger than

1.25”, adjust (slide) the black

plastic Tab Guide and Sensor

Assembly so the inside of the

assembly just begins to touch the

left side of the tab stock; without

pushing the stock toward the

right. In this case, the red center line will not be centered on the tab stock.

13. Replace the Exit Roller by pushing it back into its holder.

Note: This roller is removed in the next step (Tab Sensitivity Adjustment), so you

can leave it off, if you plan to do this adjustment.

Tab Sensitivity Adjustment

There are two types of tabs designed for

use in the FD 262 Tabber. Type 1 is a

paper tab with a plain paper backing.

Type 2 is a clear plastic or translucent

paper tab with a black or brown backing

behind the tab and a white stripe between

the tabs. Do Not use clear tabs that have

a white backing behind the tab and a

black line between the tabs.

1. Remove the exit roller.

2. With the tab exposed under the sensor, turn the main power switch ON.

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

Page 12

MAINTENANCE

11

3. Turn the Tab Sensitivity Adjustment knob fully counter-clockwise. Then turn it

clockwise until the Red LED above the adjusting knob is illuminated. Make a

note of the number that the indicator, on the knob, is pointing at.

4. Turn the Tab Drive Pressure Knob OFF and roll the tabs backwards until the Red

LED goes OFF. Turn the Tab Sensitivity Knob clockwise until the Red LED

lights again. Make a note of the number that the indicator, on the knob, is

pointing at.

NOTE: If during this step the Tab Sensitivity Knob is maxed-out (fully

clockwise), but the LED still does not light; then proceed as if the second number

is 12. If at any time during the tabbing process double tabbing occurs, advance

the setting one more position clockwise.

5. Set the Tab Sensitivity Knob indicator halfway between the two points measured

in the two previous steps.

Example: If the LED illuminates at position 4 with the tab under the sensor and at

position 10 with the backing or white line under the sensor. The difference

between the two positions is six clicks (10 - 4 = 6).

Divide this number in half (6 ÷ 2 = 3).

In this case, you turn the Tab Sensitivity Knob counter-clockwise 3 clicks, to

position 7, which is halfway between 3 and 10.

6. Turn the Tab Pressure Roller ON and use the Tab Advance Knob to advance the

tab until it starts to peel away from the backing paper.

7. Reinstall the Exit Roller.

Metering Bracket/Separator Adjustment

This procedure is used to ensure that only one piece of media is fed at a time.

1. Loosen the two thumbscrews that attach the Metering Bracket to its mounting bar.

2. Raise the Metering Bracket and place a piece of media under the separator

fingers, then lower the Metering Bracket until it contacts the media. Make sure

the media is between all the fingers and rollers.

3. Tighten the two thumbscrews.

4. Remove the media and be sure the bar is level and that the separator fingers are

not rubbing against the feed rollers.

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

Page 13

MAINTENANCE

12

Feeding

Doubles

Reduce the distance between the separator fingers and the feed roller.

Not Feeding

Increase the distance between the media side guides and the media.

Increase the distance between the separator fingers and the feed

roller.

Heavy

Material

When setting the metering bracket, place 1-1/2 times the material

between the separator fingers and the feed roller.

Skewing

Place the media side guides closer to the edges of the media.

Check/adjust the metering bracket.

Media Supports and Media Side Guide Adjustment

1. Position the media on the Media

Supports approximately where

you wish to position the tab.

2. Place one sheet of media on the

Media Supports so that it is

resting against the Separator

Fingers.

3. Reposition the Media Supports

and Stack Rests as required to

support the media.

4. Position the Side Guides so that

they are approximately 1/16”

from each side of the media.

Media Transport Test

Take the time to verify proper media transport before trying to tab. If the media

doesn’t feed correctly, it will not be tabbed correctly.

Proper Media Transport:

One piece of media is fed at a time.

A small gap of at least 0.25” is generated between each piece of media.

Media is feeding straight.

1. Start by placing one piece of media into the hopper, so it is against or just feeding

under the separators.

2. Place a handful of media on top of the piece already in the hopper.

NOTE: When placing material on the Media Support ensure that it is shingled.

3. Be sure the Tab Switch is OFF (not illuminated), then press the Feed button to

start feeding.

If you have a problem feeding, check the following:

4. Once the media is feeding correctly, go to the next step.

Page 14

MAINTENANCE

13

Horizontal Tab Positioning

1. With media loaded, press the TAB switch (button will illuminate), followed by

the FEED switch (button will illuminate) and tabber will begin to feed.

2. Run at least two pieces, then press the Feed button to stop the tabber.

3. Check the horizontal position (leading edge, left/right position) of the tab.

4. Adjust if necessary by moving the Media Side Guides to the left or right.

5. Once the horizontal tab position is correct, perform the Tab Fold Position

Adjustment.

Tab Fold Position Adjustment

Tab a few pieces and check the position of the tab on the media. The tab should be

positioned so that approximately half of the tab folds on the top of the media and half of

the tab folds on the bottom of the media.

If placement is incorrect, follow this procedure:

1. Loosen the Tab Fold Position

Adjustment Knob.

2. Move the knob towards “TOP” to

allow more tab to be placed on the

top of the media.

Move the knob towards

“BOTTOM” to allow more of the

tab to be placed on the bottom of

the media. Tighten the knob.

3. Run at least two pieces through the machine then recheck the tab fold position,

top-to-bottom, on the second piece.

4. Repeat steps 1-3 until you are satisfied with the fold position of the tab.

Operating Sequence

1. Turn on the Main Power Switch.

2. If you want to zero out the Media Counter, press the reset button on the Media

Counter, which is located on the top of the Tabber.

3. Activate the Tab button (will illuminate)

4. Press the Feed button (will illuminate) to start the media feeding.

5. To Stop the Tabber press the Feed button again.

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

Page 15

14

Problem

Possible Cause

Tab fold placement inconsistent

Tabs not threaded correctly.

Tabs not centered on sensor guide’s center

line.

Tab Roll is loose on spindle.

Rollers dirty, glazed or worn.

Media is feeding skewed.

Horizontal placement of tab moves

side to side

Media is feeding skewed.

Media Side Guides are loose.

Tab stock moving. Tab Side Guide post/Tab

Guide not set properly.

Multiple tabs placed on media

Tabs not centered on sensor guide’s center

line.

Tab sensitivity adjustment incorrect.

Tab sensor may be dirty or damaged.

Media feeds without tabs

Tab Switch not turned ON.

Out of Tabs.

Tab sensitivity adjustment incorrect.

Tab Drive Pressure knob in OFF position.

Media Sensor dirty/damaged.

Tabs not peeling off backing.

Media positioned incorrectly; missing Media

Sensor.

Tab sensitivity LED does not

illuminate

Power not on.

Perform tab sensitivity adjustment.

Incompatible tabs being used.

Tab sensor may be dirty or damaged.

Power Switch not illuminated

Unit not plugged in.

Switch not turned on.

Fuse blown.

Tabs stream feed

Tab Drive Pressure knob in OFF position.

Tab Sensor Switch not set properly. (Sensor

not reading tabs.)

Tabs not threaded properly. Missing sensor.

Incompatible tabs being used.

Tab sensor may be dirty or damaged.

Section 4 – Troubleshooting

Tabbing Problems:

MAINTENANCE

Page 16

15

Media Feeding Problems:

Problem

Possible Cause

Feeding Doubles

Media not properly fanned before loading.

Nested Media.

Reduce the distance between the separator

fingers and the feed roller.

Separator Fingers worn.

Media Not Feeding

Media not properly fanned before loading.

Side Guides too tight

Increase the distance between the separator

fingers and the feed roller.

Glazed or dirty feed rollers.

Feed Rollers worn.

Media Opening as it Feeds

Too much friction at the separation point.

Increase the distance between the separator

fingers and the feed roller by using 1-1/2

times the material thickness to set the

Metering Bracket.

Skewing

Media Side Guides too loose.

Metering Bracket/Separators not set evenly.

Separator Fingers or Feed Rollers worn.

MAINTENANCE

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

Page 17

MAINTENANCE

16

WARNING

BEFORE PERFORMING ANY MAINTENANCE, DISCONNECT THE

TABBER FROM ITS POWER SOURCE!

CAUTION

NEVER SPRAY OR POUR CLEANERS DIRECTLY ON OR INTO

THE TABBER. EXCESS LIQUID COULD HARM ELECTRONIC

PARTS. ALWAYS DAMPEN A RAG WITH THE CLEANER AND

APPLY IT TO THE PARTS TO BE CLEANED.

WARNING

DO NOT USE SOLVENTS TO CLEAN THE RUBBER ROLLERS

Section 5 – Maintenance

This section describes maintenance that an experienced operator can perform. If service or

maintenance is needed, beyond what is described in this document, please contact your local

Formax dealer to obtain service and support for your tabber.

Service should only be performed by a qualified service technician.

Cleaning

The Tabber must be cleaned regularly of accumulated paper dust and ink. Unplug the tabber

from the wall outlet before cleaning.

The visible areas are best cleaned with a vacuum that has a soft brush attachment to help loosen

the dust particles.

The covers of the machine may be cleaned with any standard household cleaner, which is nonabrasive and does not contain plastic harming solvents.

Feed Rollers and Forwarding Rollers

The feed and forwarding rollers can become glazed with paper lint and ink from the media. They

should be regularly cleaned with a mild abrasive household cleaner on a damp cloth.

Avoid using solvents on the rubber rollers.

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

Page 18

MAINTENANCE

17

WARNING

DO NOT USE ABRASIVES OF ANY KIND TO CLEAN SENSORS.

DO NOT USE LIQUIDS OF ANY KIND, TO CLEAN SENSORS.

Cleaning the Sensors

Periodically check the tab sensor located in the Tab Sensor and Guide assembly. The sensor

should be clean and free of accumulated paper dust. Use a vacuum with a soft brush attachment

or dry compressed air to remove the dust.

To aid in cleaning, the Tab Guide Assembly can be removed from the shaft by pulling out on the

Tab Guide Assembly.

WARNING! Be careful not to damage the Tab Guide Assembly or sensor wiring when

removing/installing this assembly. If you don’t feel comfortable performing this procedure,

please contact a qualified Formax service technician to perform this procedure for you.

Also, clean the media sensor located in the plate attached to the Tab Fold Position Adjustment

Knob. Use a vacuum with a soft brush attachment or dry compressed air to remove the dust.

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

Page 19

18

Appendix - Specifications

Dimensions:

25" Wide x 15.5" Depth x 22" High

Speed:

12,000 pieces per hour (8.5" x 11" tri-folds)

Weight:

45 lbs. Shipping wt.; 40 lbs. installed

Media Size:

Length – 3 5/8" to 18"

Width – 5" to 17"

Media Thickness:

Up to 5/32"

Tab Size:

Length – 5/8" min to 1.5" max

Width – 5/8” min to 1.5” max

Tab Sensitivity Control:

Adjusts for density in tab/wafer seals

Reel Capacity:

10,000 tabs

Counter:

5 digit LCD (operator resettable)

Feeder:

Top load, bottom feed for continuous operation

Electrical:

120 VAC 50/60 Hz

Options:

CJ-10 Drop-Stacking Conveyor

FD 262 Tabber

INDEX

Specifications subject to change without notice.

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

Page 20

Appendix B – Obtaining Supplies, Service and

Part #

Description

Roll

Diameter

Tabs per

Roll

Rolls per

Case

262-10

1" Round White Paper Tabs

9”

10K

12

262-11

1" Round Translucent Tabs

9”

11K

12

262-13

1.5" Tabs White Paper, No Perforation

9”

7K

8

262-14

1.5" Tabs Translucent, No Perforation

9”

7K

8

Clear or Translucent tab stock with black

box below tab area

Tab Material: Clear or Translucent

Backing: Black block below tab area.

Tab Material: White Paper Circle

Backing: All White (plain)

Support

Please contact your local Formax dealer to obtain supplies, service and support for your tabber.

Service should only be performed by a qualified service technician.

FD 262 Tab Supplies:

The following supply items are available from Formax and your Formax dealer. Please check

with your Formax dealer for possible changes or additions to the following tab supplies.

All the tab rolls, shown above, are on a 3” core.

Examples of Compatible Tab Stocks:

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920

Loading...

Loading...